Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Bad luck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

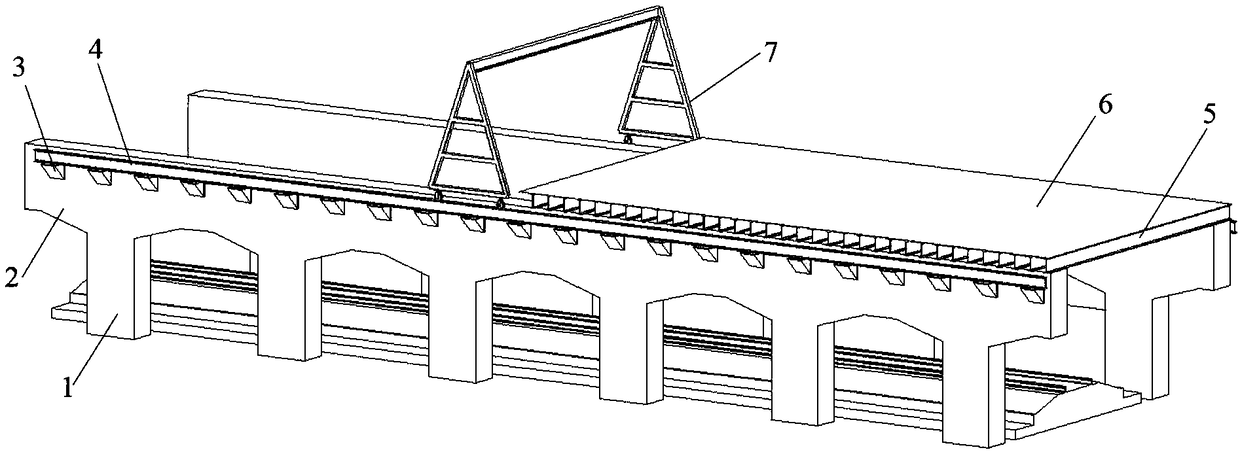

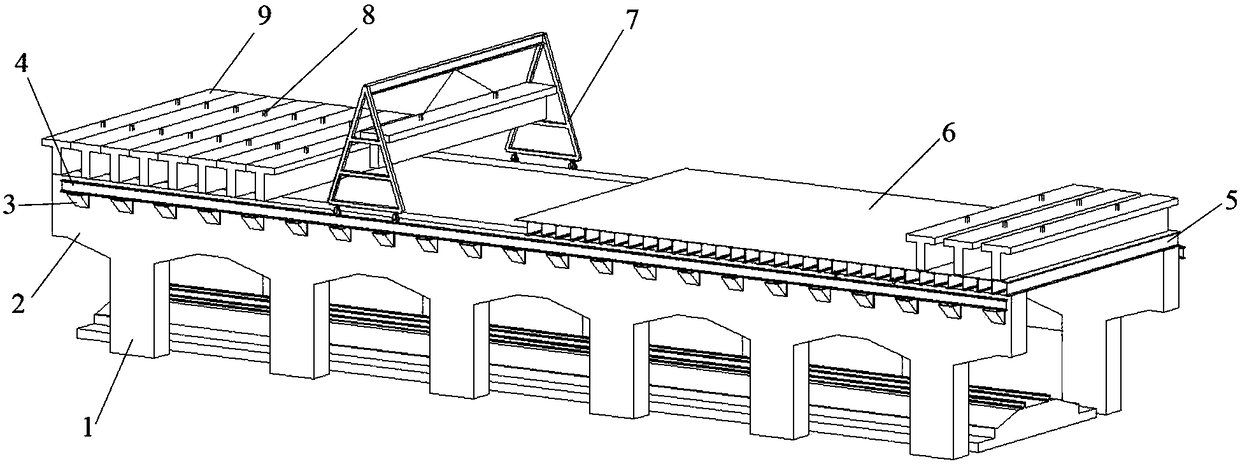

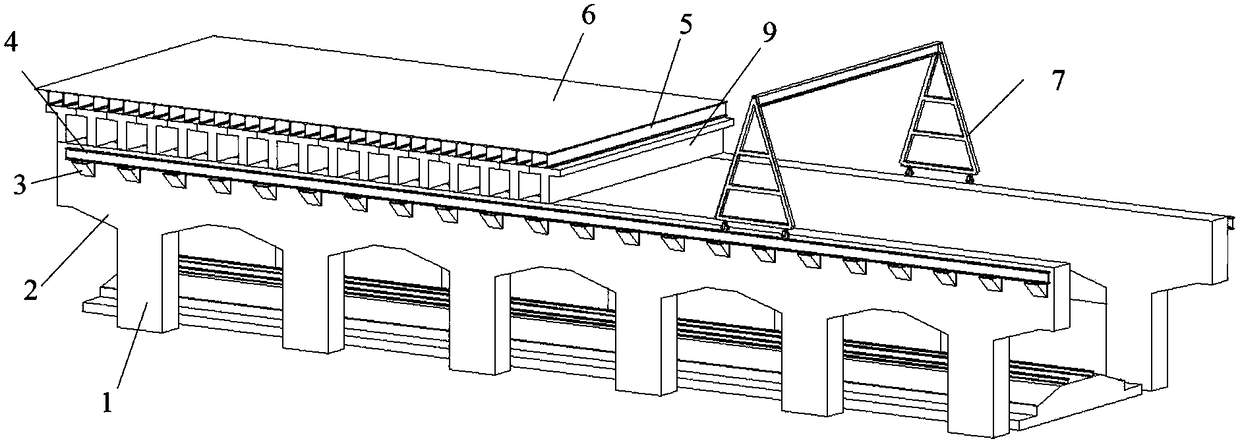

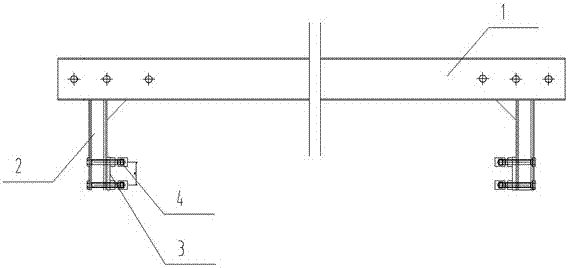

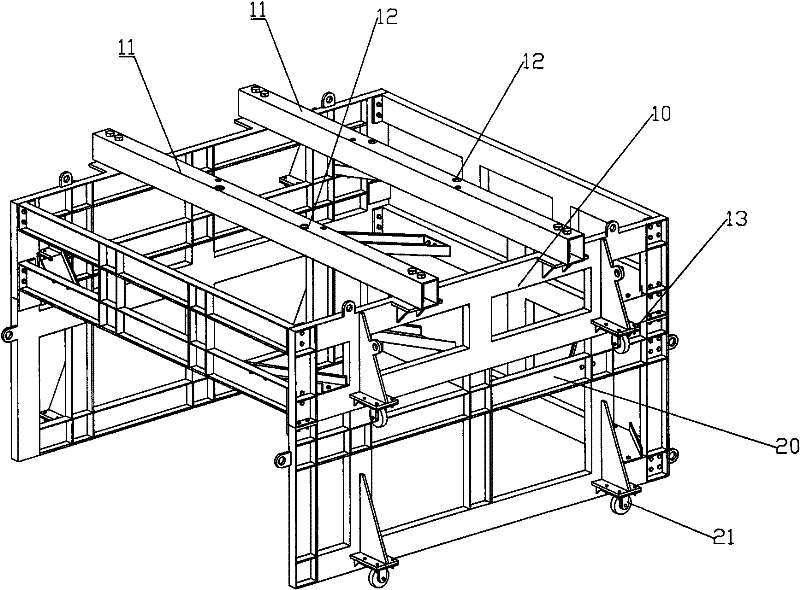

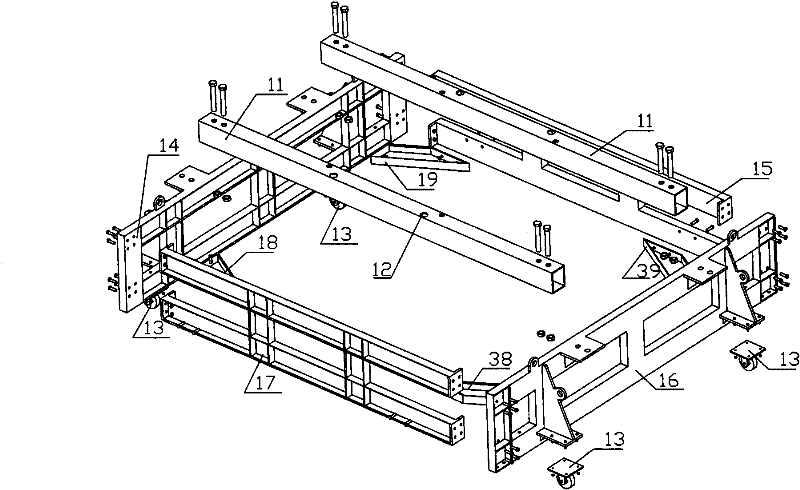

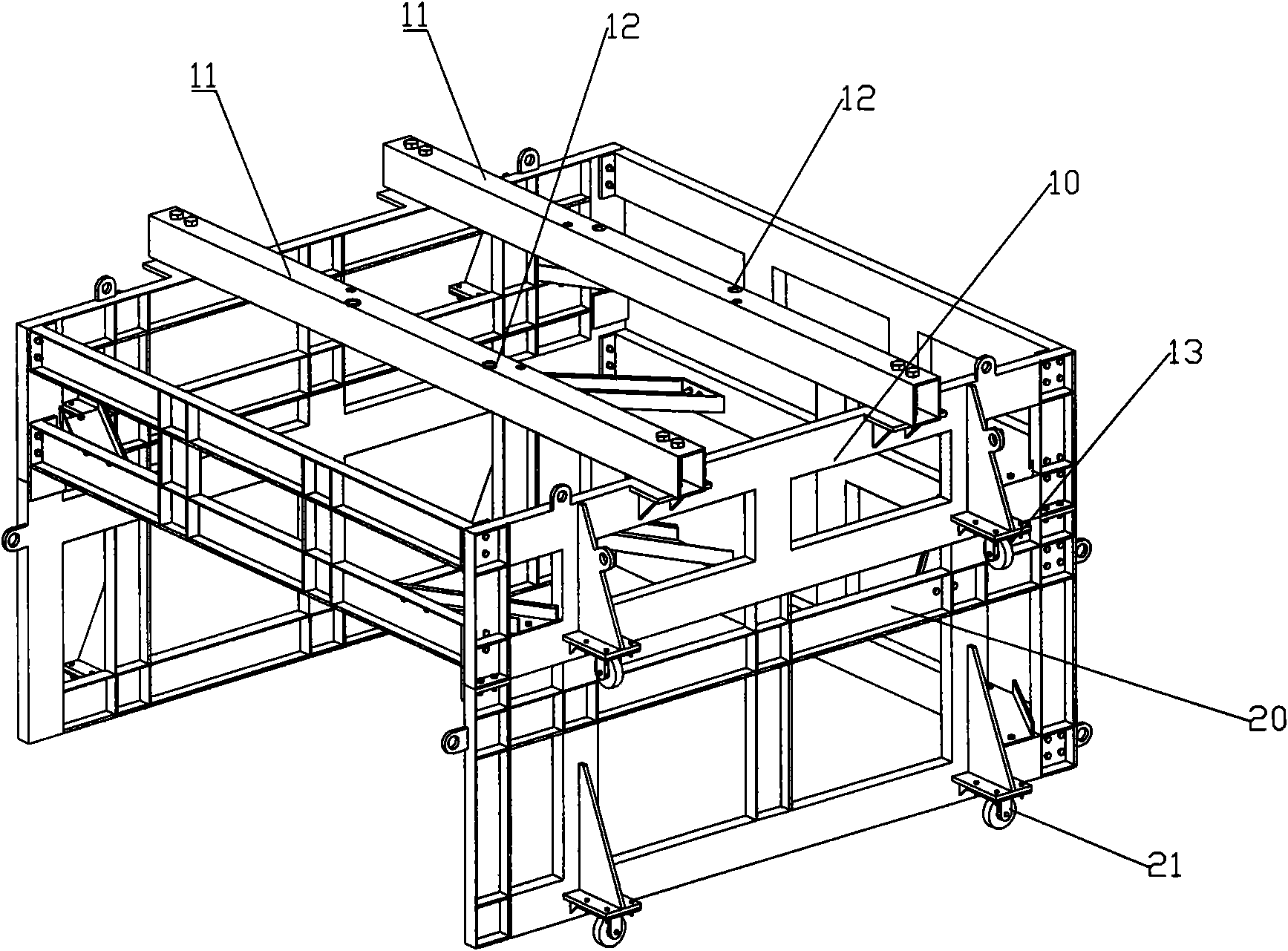

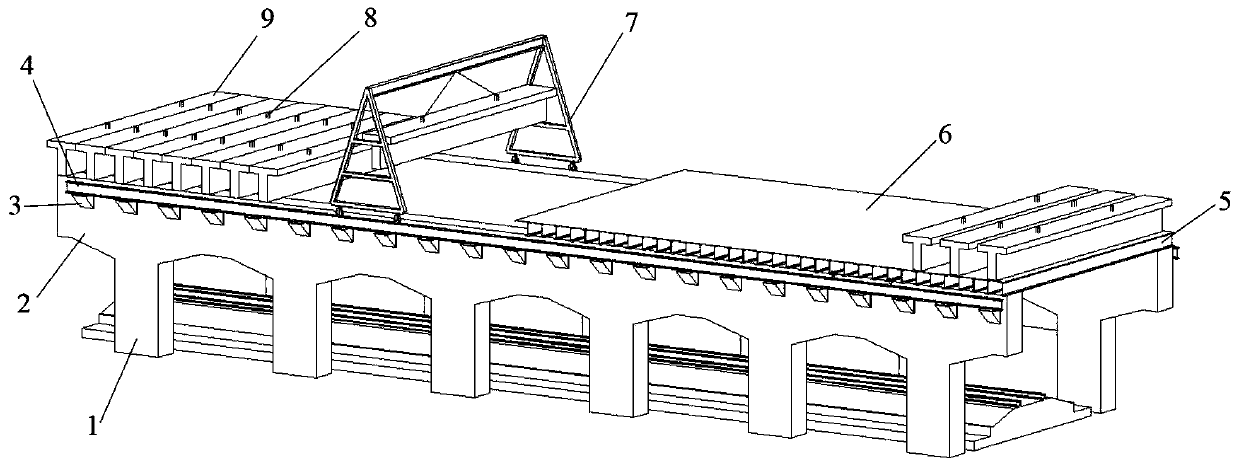

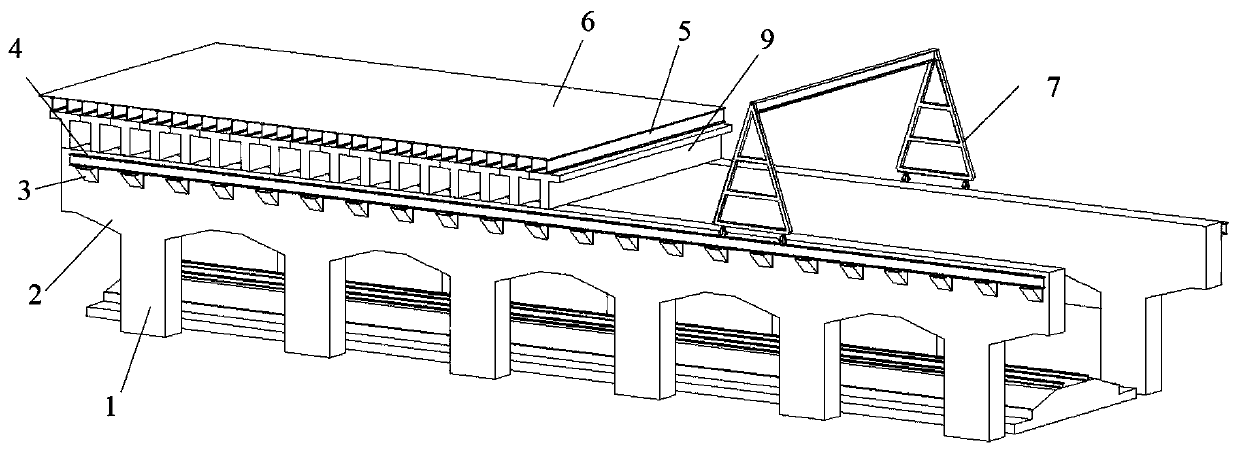

Segment-assembling simply supported box girder movable falsework construction method

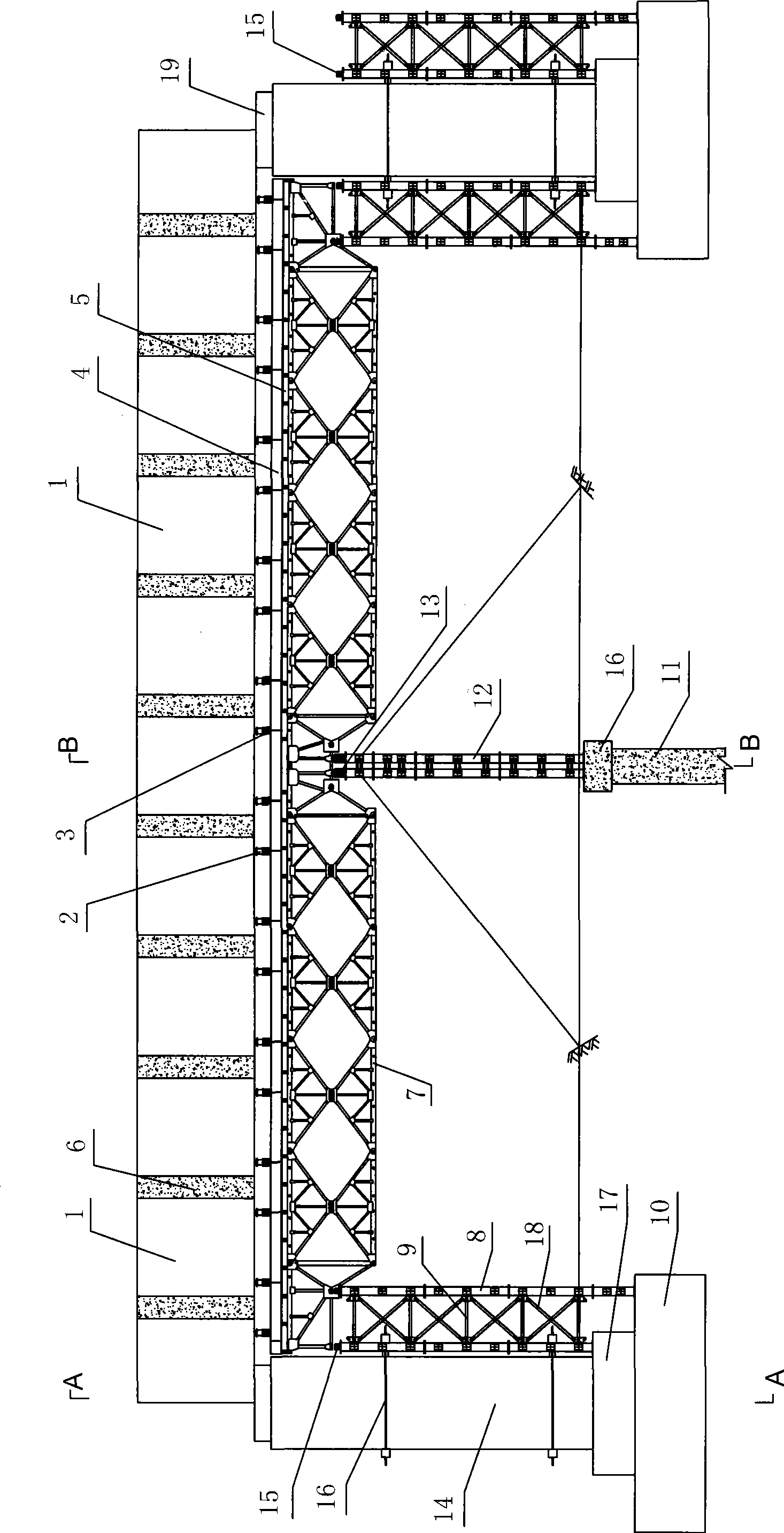

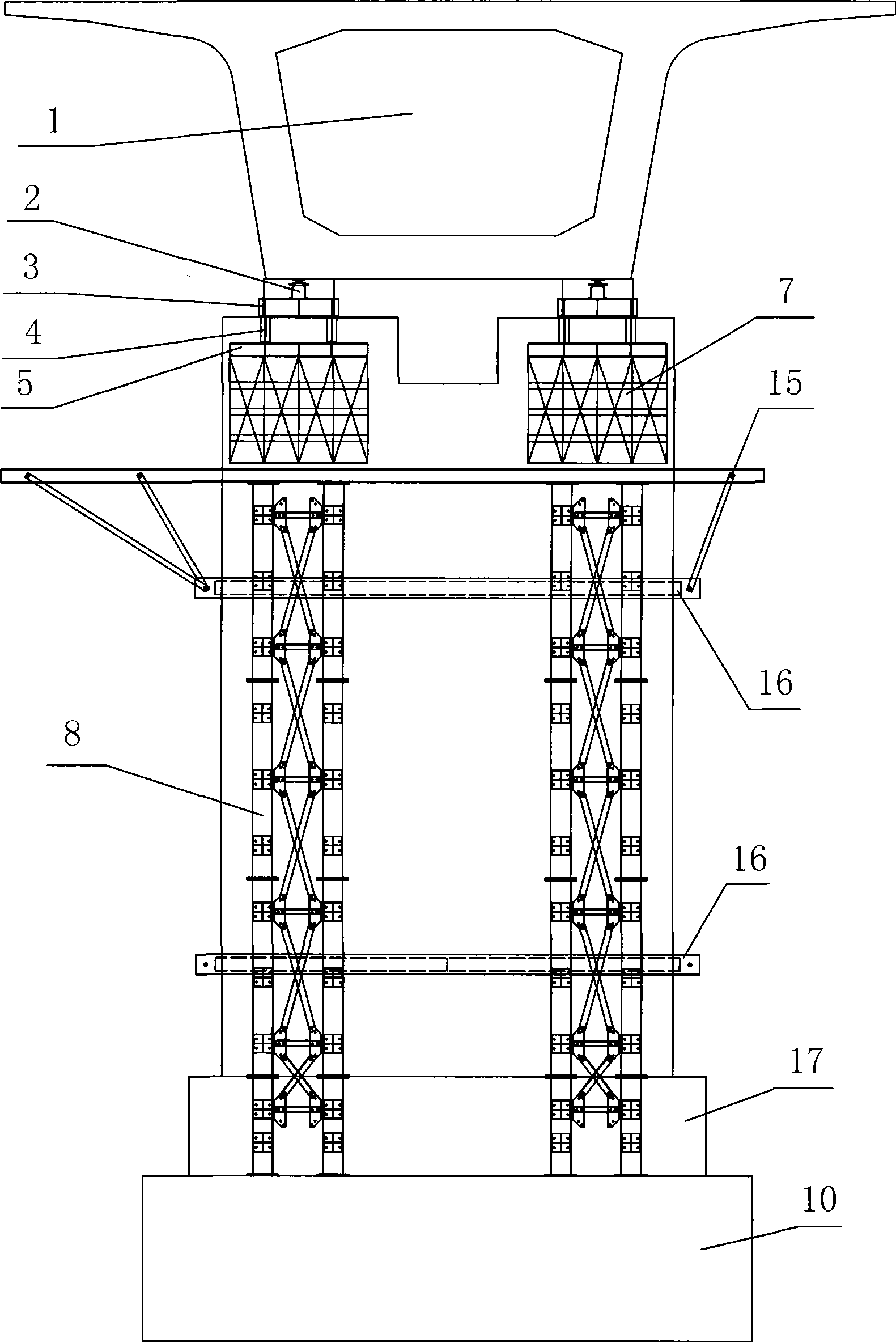

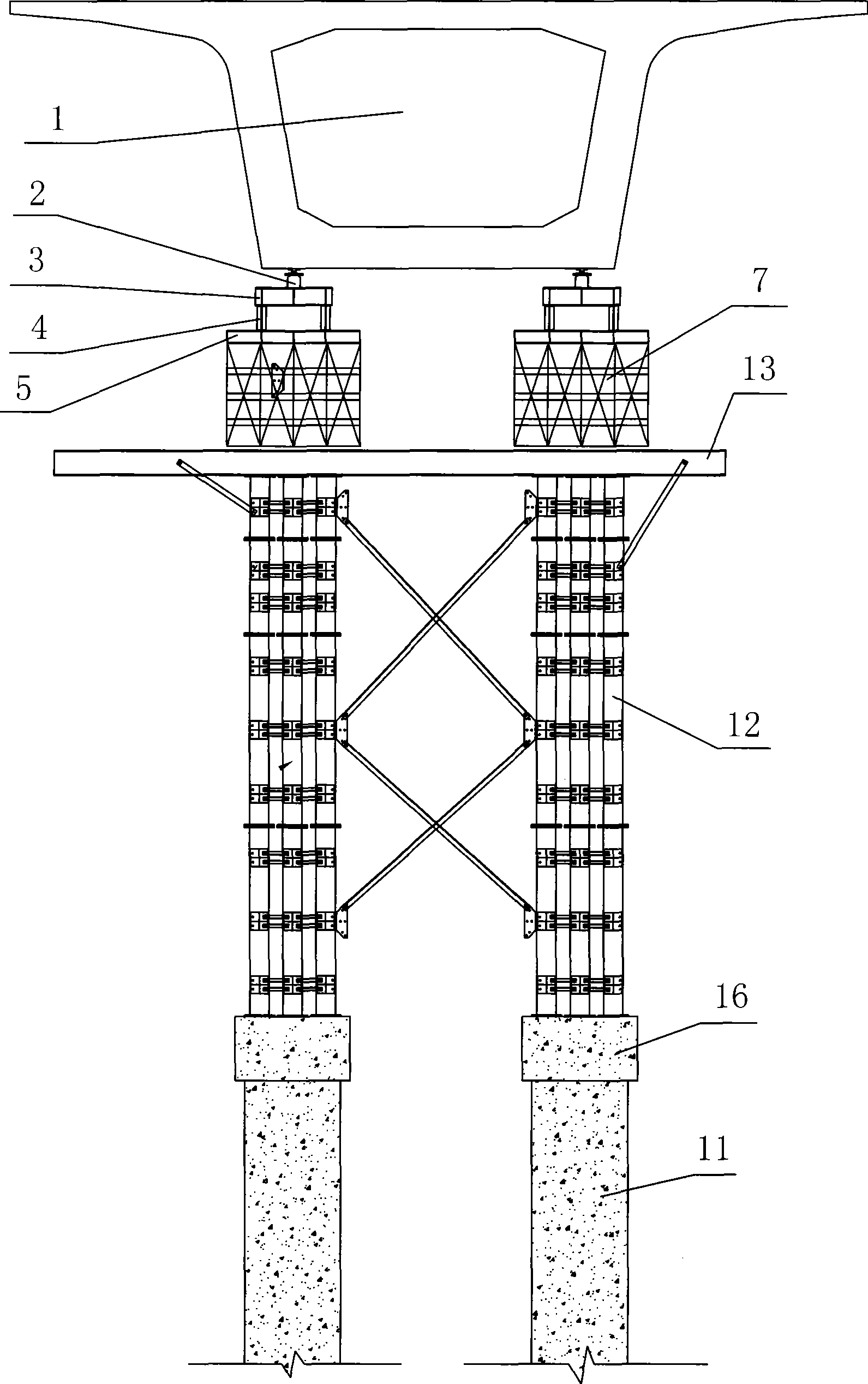

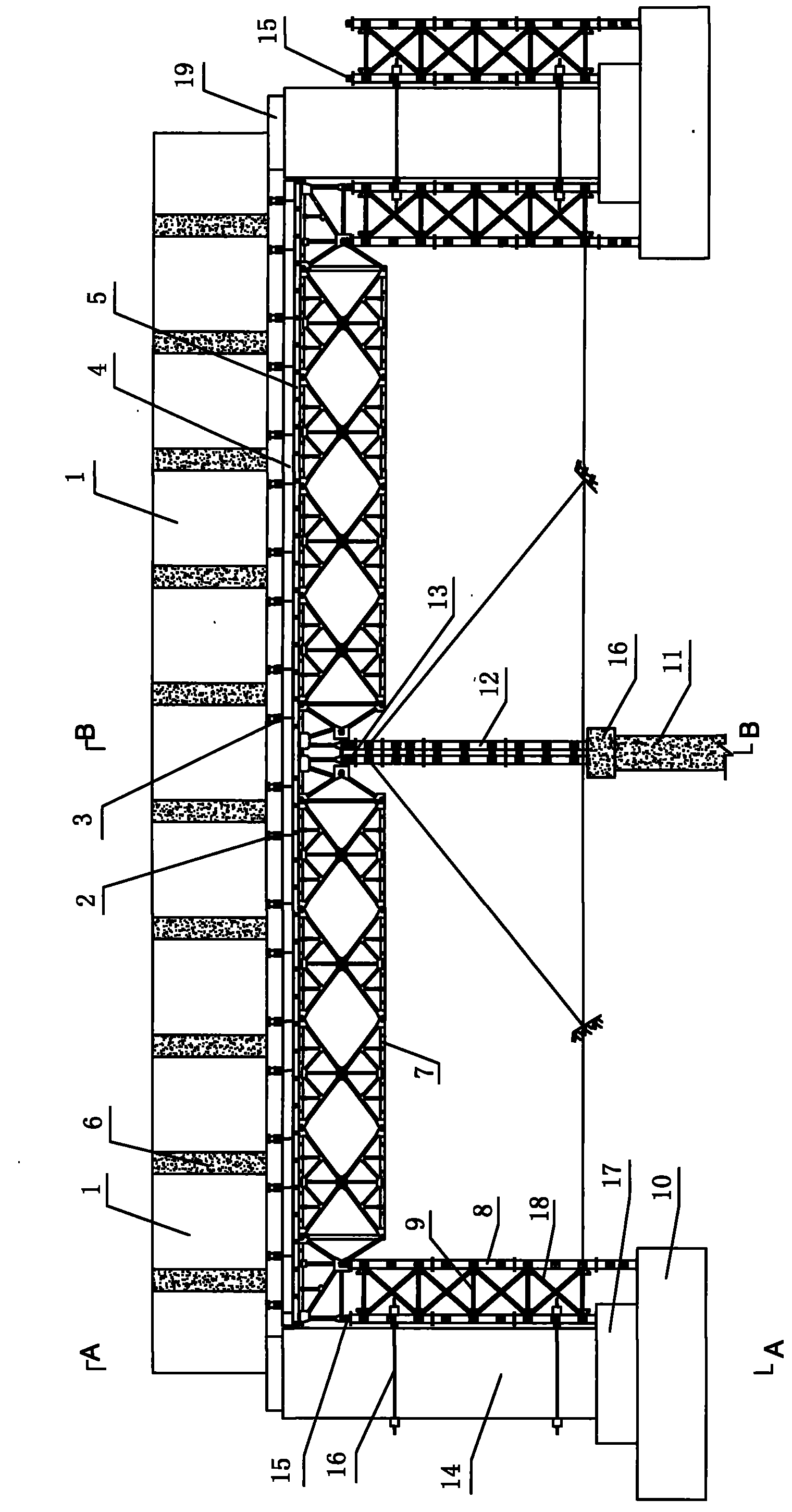

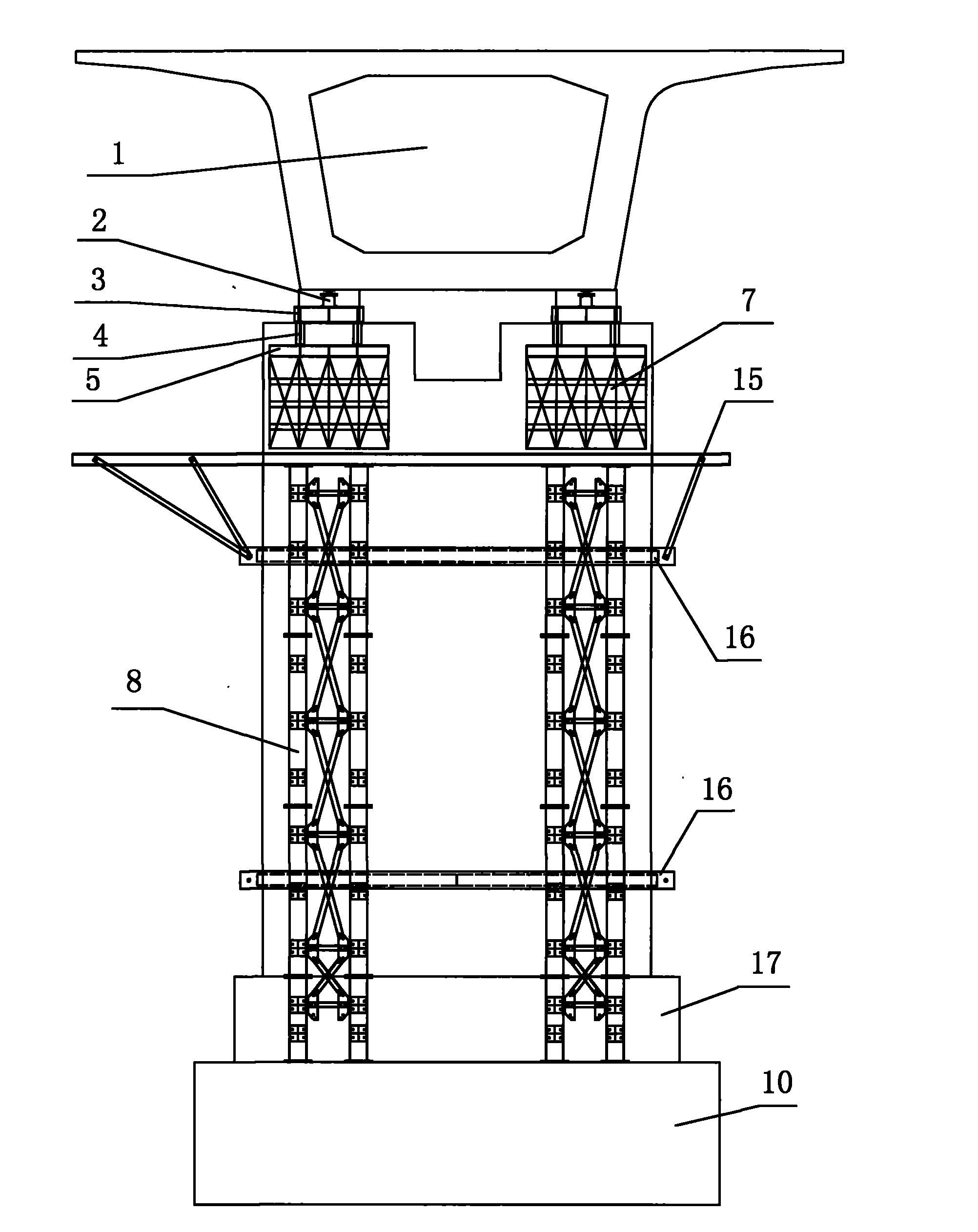

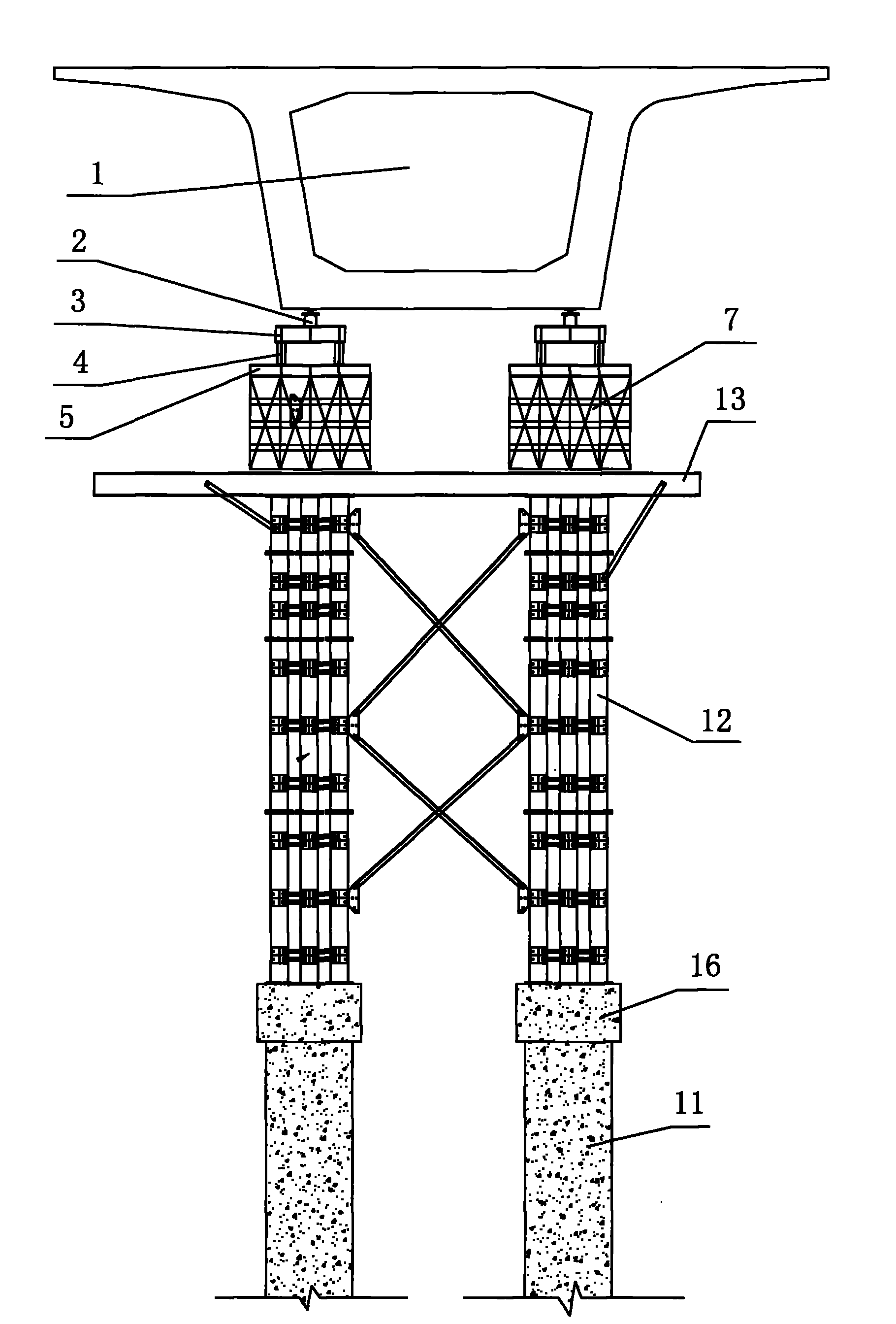

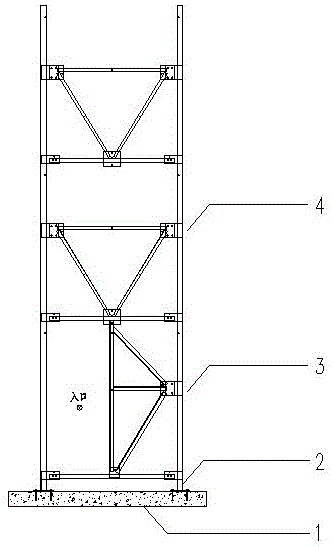

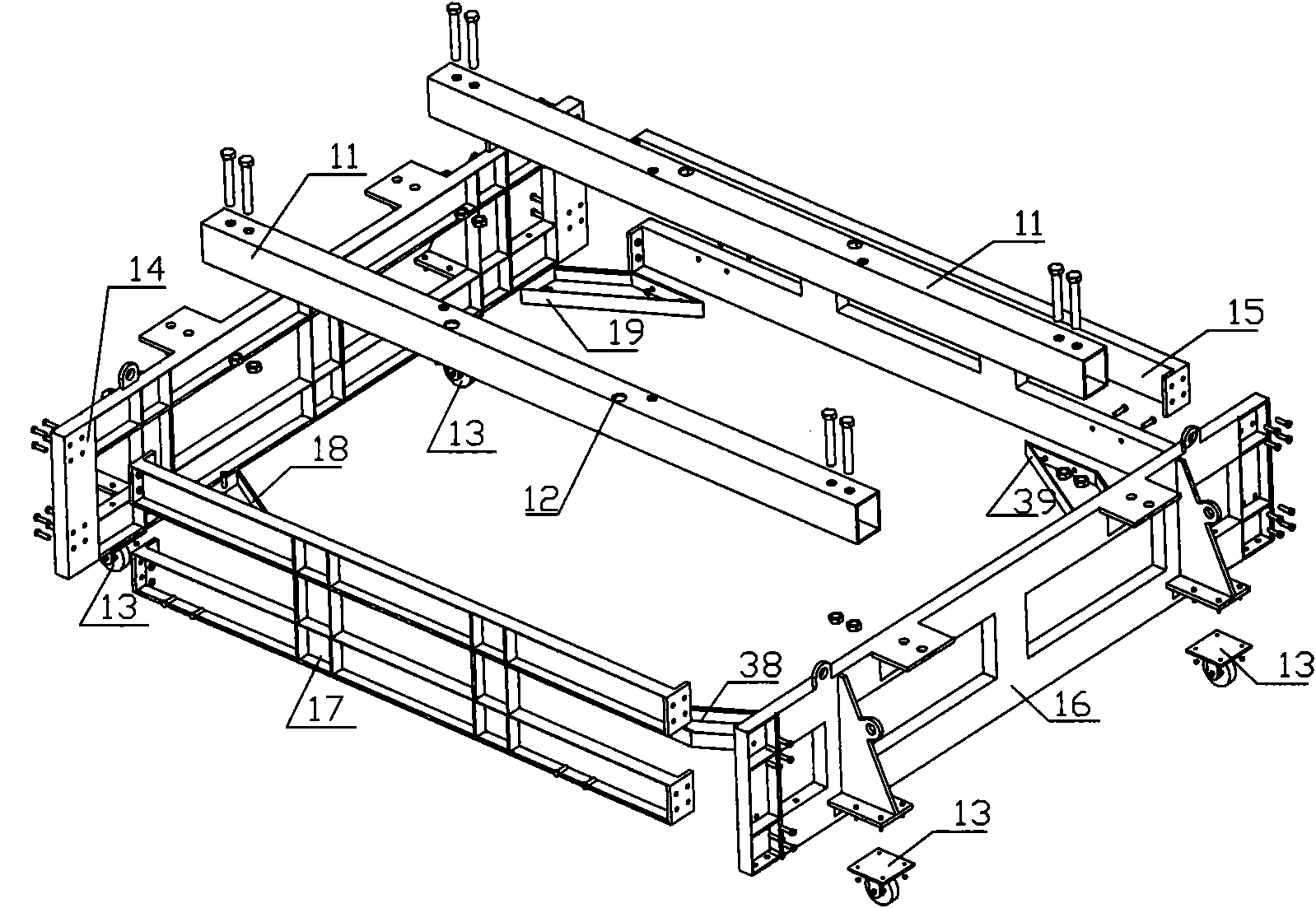

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

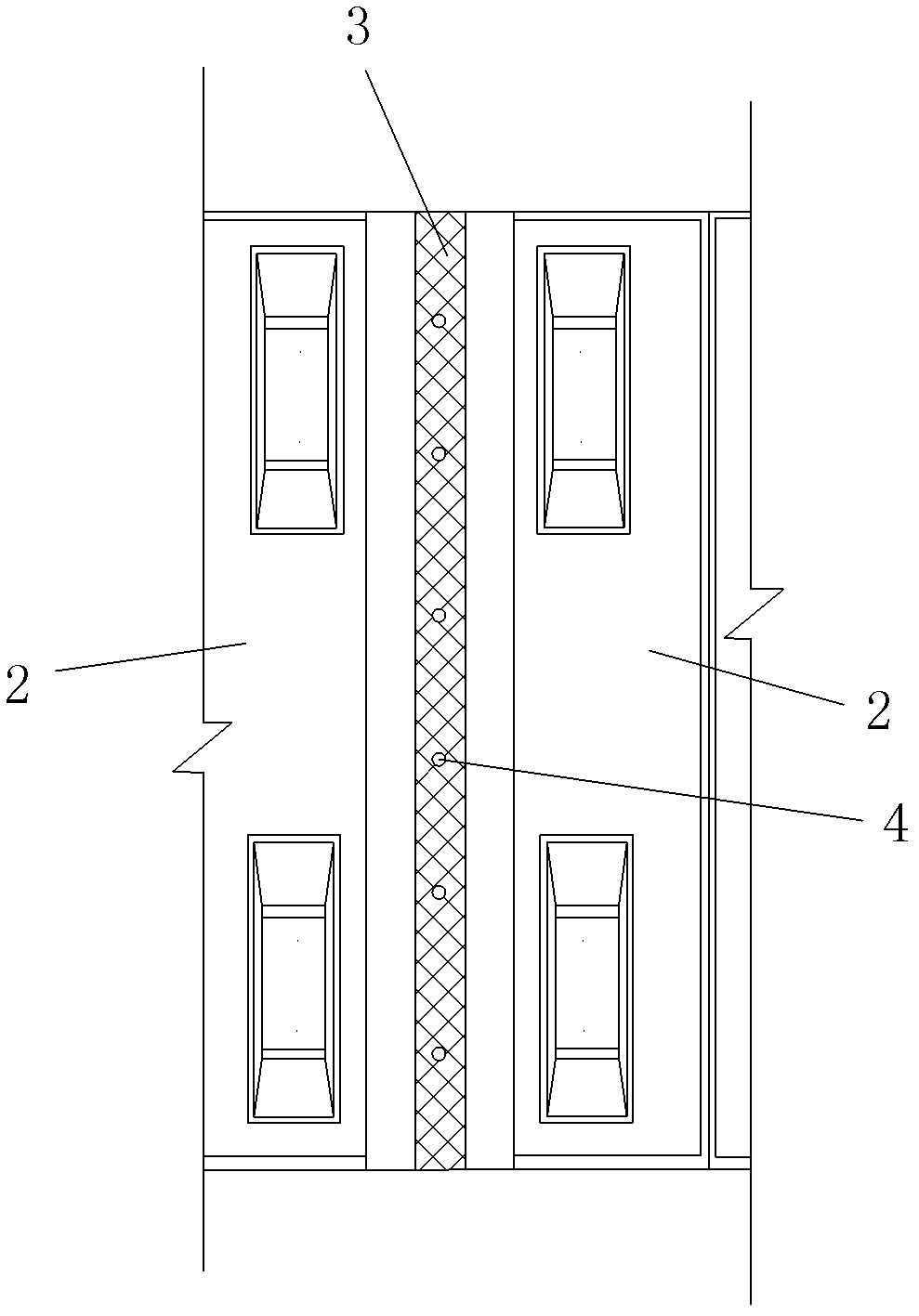

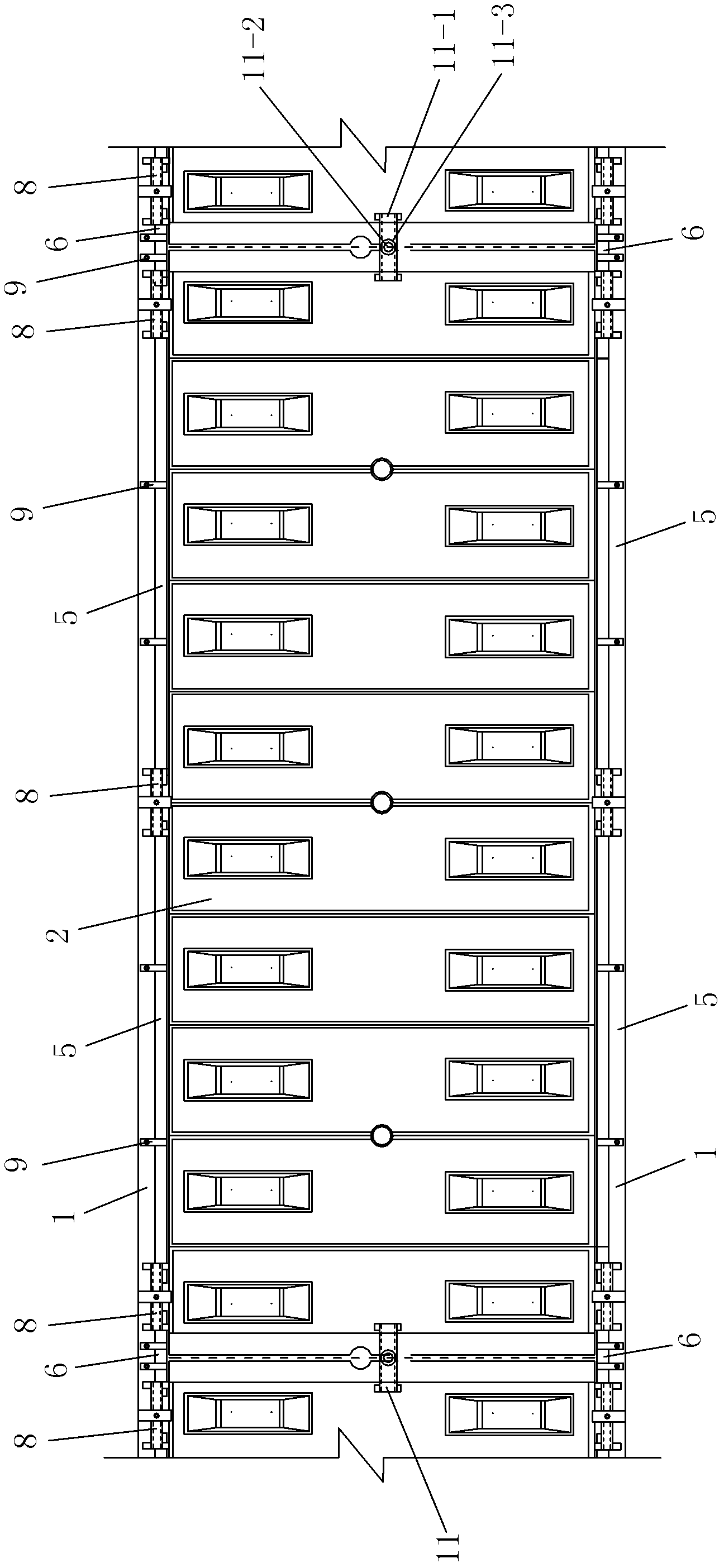

Fabricated aluminum alloy formwork system construction method

InactiveCN103206089ABad luckQuality improvementBuilding material handlingSystem constructionAluminium alloy

The invention discloses a fabricated aluminum alloy formwork system construction method. The method includes steps of formwork system designing, formwork mounting, concrete pouring and maintaining, formwork demounting and the like. The fabricated aluminum alloy formwork system construction method is convenient to construct and good in effective.

Owner:成军

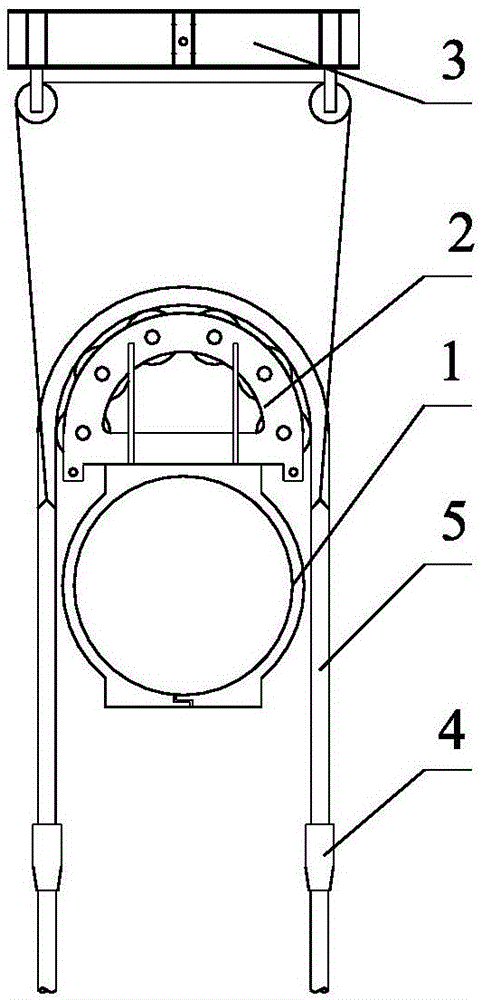

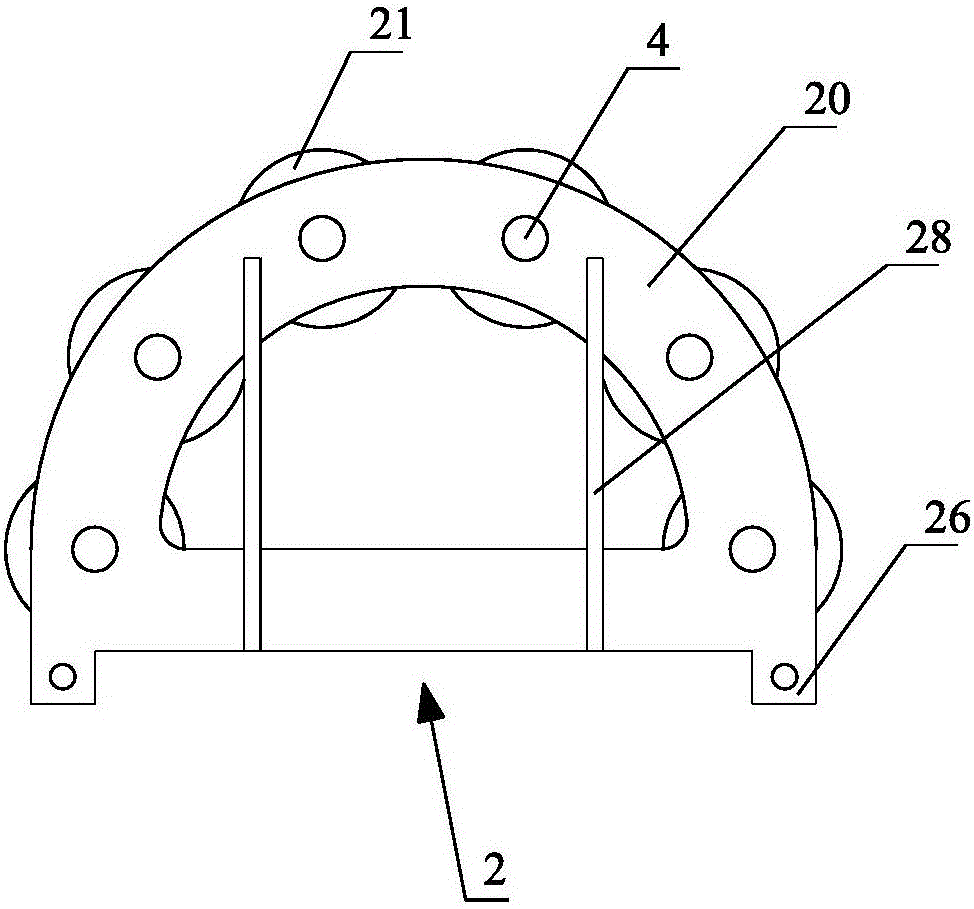

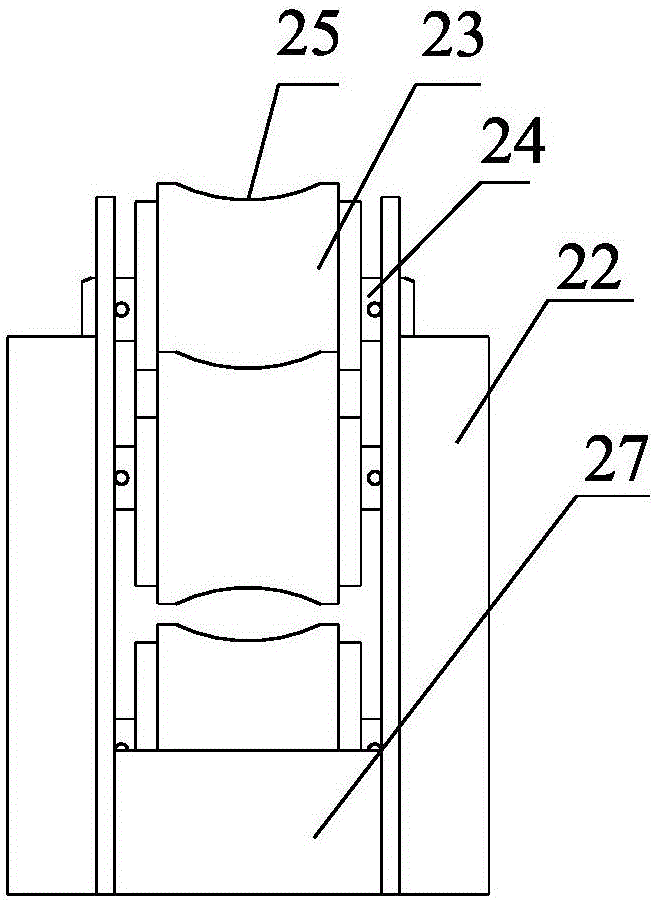

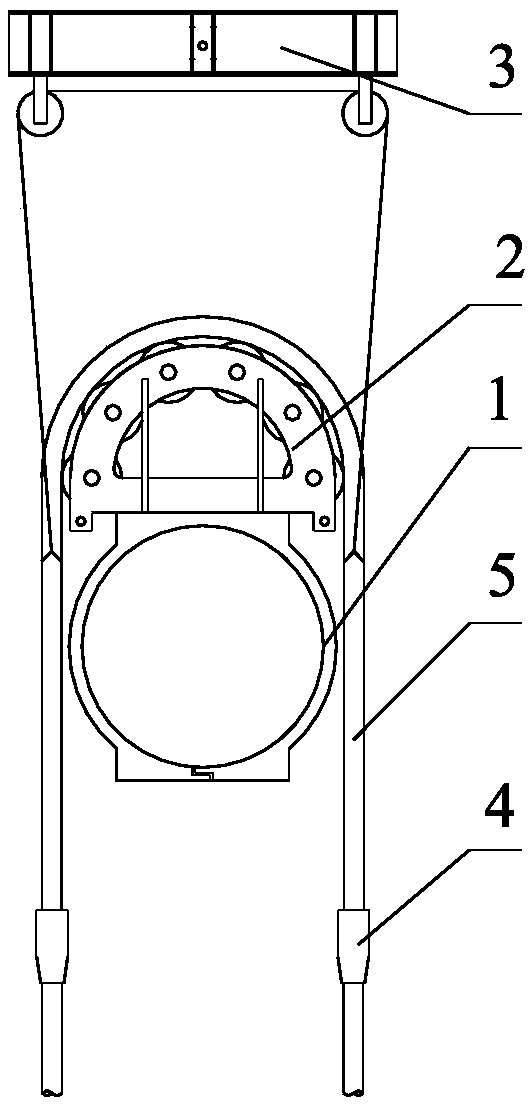

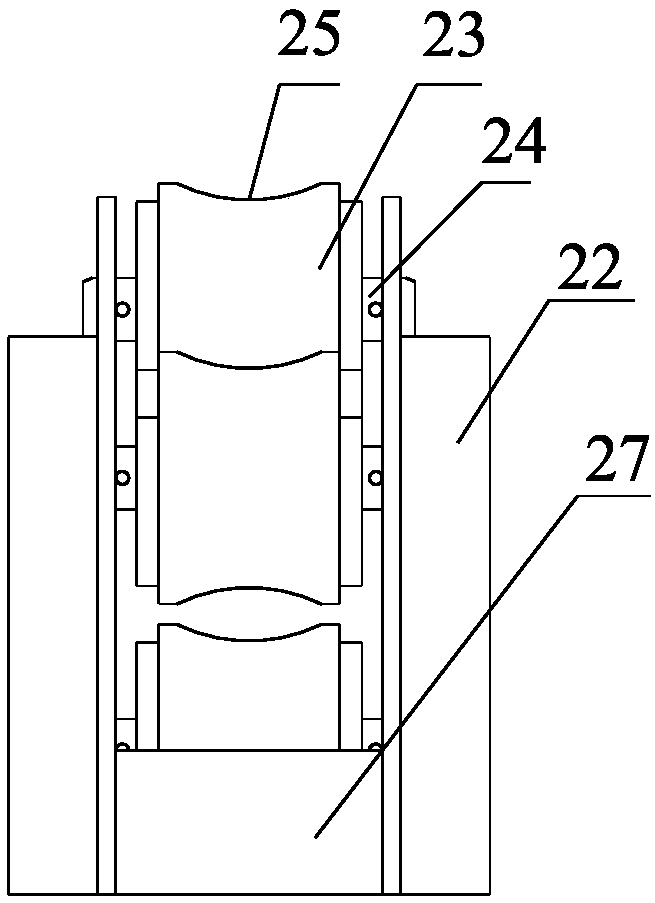

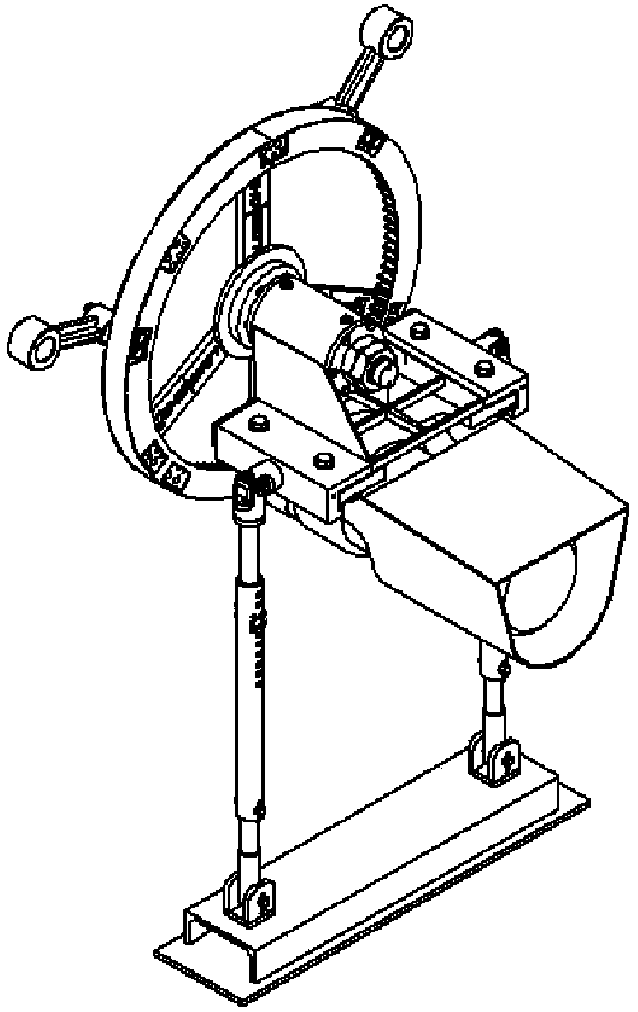

System for changing sling of suspension bridge and method for changing sling of suspension bridge

ActiveCN106480822AEasy to installEasy to removeBridge structural detailsBridge erection/assemblyEngineeringWinch

The invention discloses a system for changing a sling of a suspension bridge and a method for changing the sling of the suspension bridge, and relates to the technical field of change of the sling of the suspension bridge. The system comprises a sling clip, a towing wheel, a lifting appliance and two winches, wherein the towing wheel is arranged on the sling clip and comprises a pedestal and a plurality of rolling wheels; the rolling wheels are arranged on the pedestal; the plurality of rolling wheels are arranged along the arc-shaped path side by side to form an arc-shaped traction path; the lifting appliance is arranged above the sling clip and is used for lifting the sling to switch between the sling clip and the traction path; and the winches are connected with anchor heads arranged on two end parts of the sling correspondingly through steel wire ropes. According to the system and the method, the sling can be changed quickly and conveniently under the condition of low lifting height.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

Retractable unit horizontal hard protection

A retractable unit horizontal hard protection comprises a protective underframe and a protective railing. The outer side edge of the protective underframe is connected with the protective railing perpendicularly. The protective underframe is formed by connecting two main beams and a secondary beam. The protective underframe is paved with a bottom plate. The bottom plate is provided with a transverse rib. The inner end of the main beam is hinged with the outer side of the bottom of an inter-layer steel supporting bracket connected between two layers of structural floor slabs by a rotating shaft. The outer side of the gravity center for the two main beams is fixed with two hanging rings respectively. A wire cable is connected between the hanging ring and the inner side at the top of the inter-layer steel supporting bracket. The invention can resolve the safety demand and the construction demand of simultaneous construction at upper and lower different working areas in a same vertical direction, thereby reducing the limb working time for workers, lowering the risk of falling matters from high altitude, and simultaneously providing convenience for the inverse transportation of the material tool at the lower section by retracting the protective unit. The horizontal protective system is convenient to process and is convenient and fast to mount and demount; and the horizontal protective system is convenient to open and can be used in recycle manner with low cost.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV +2

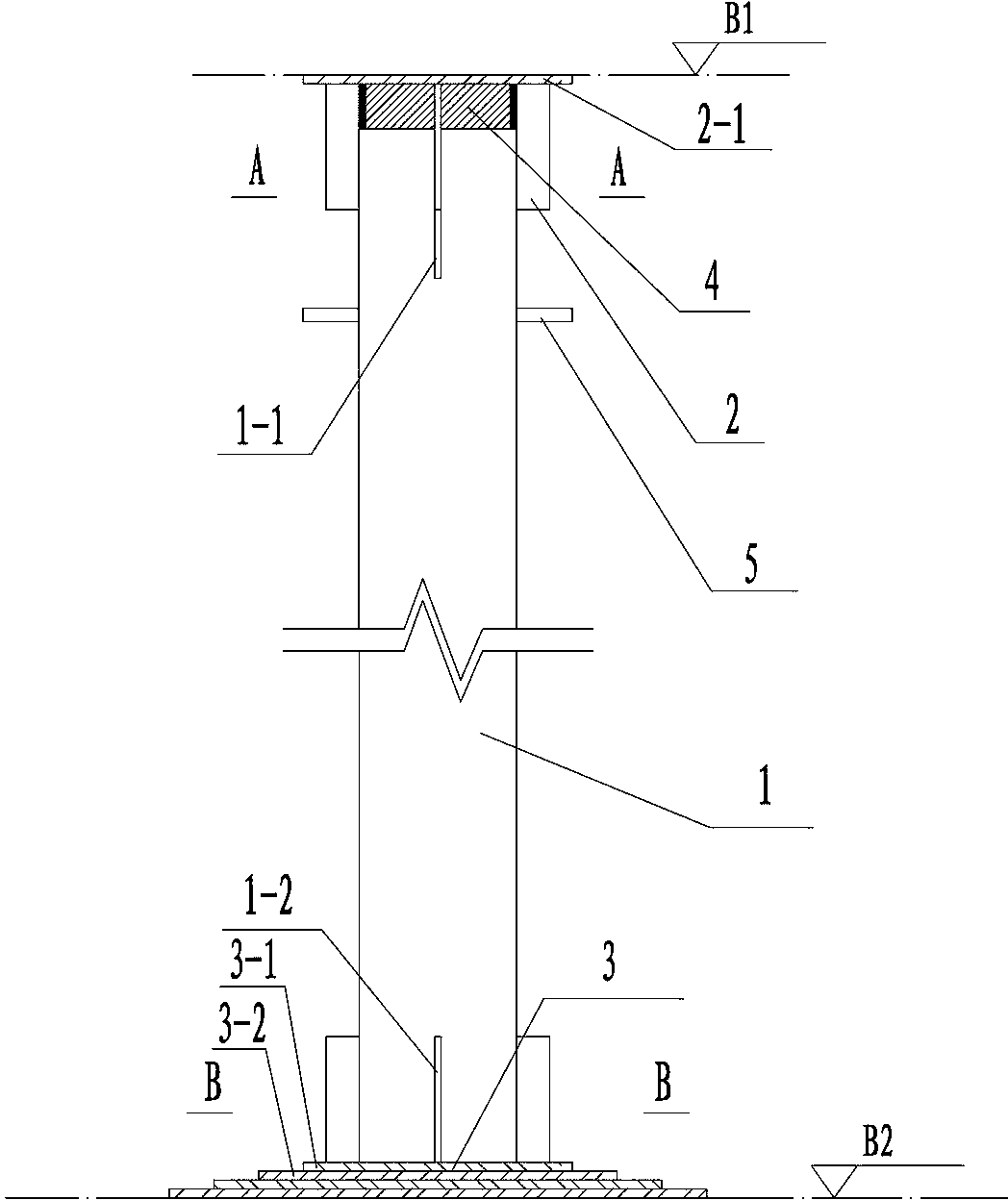

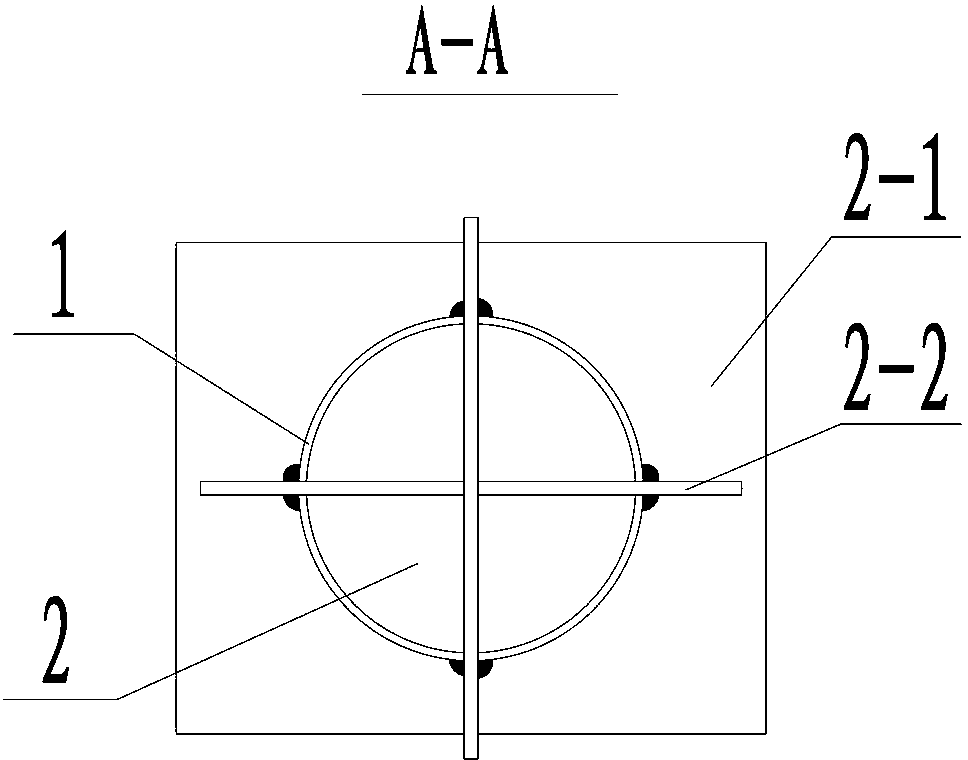

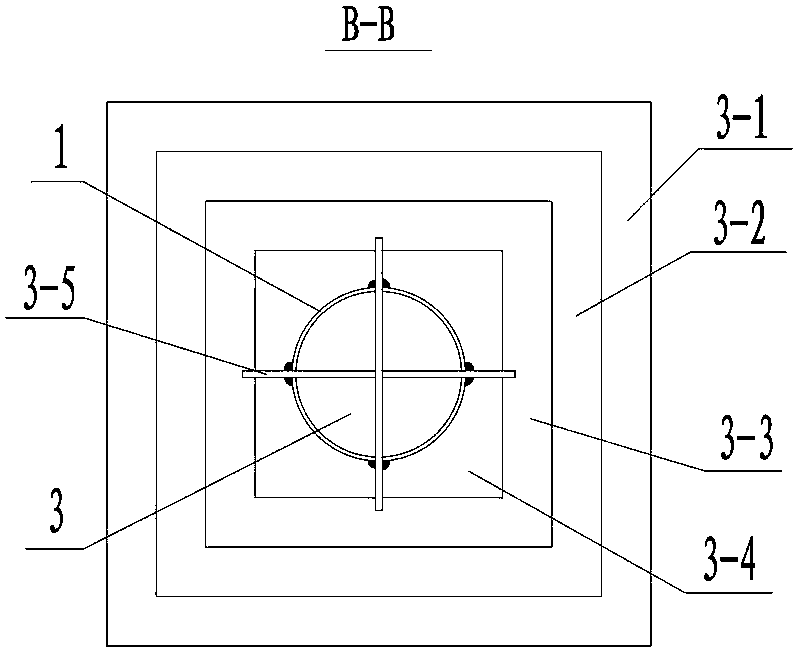

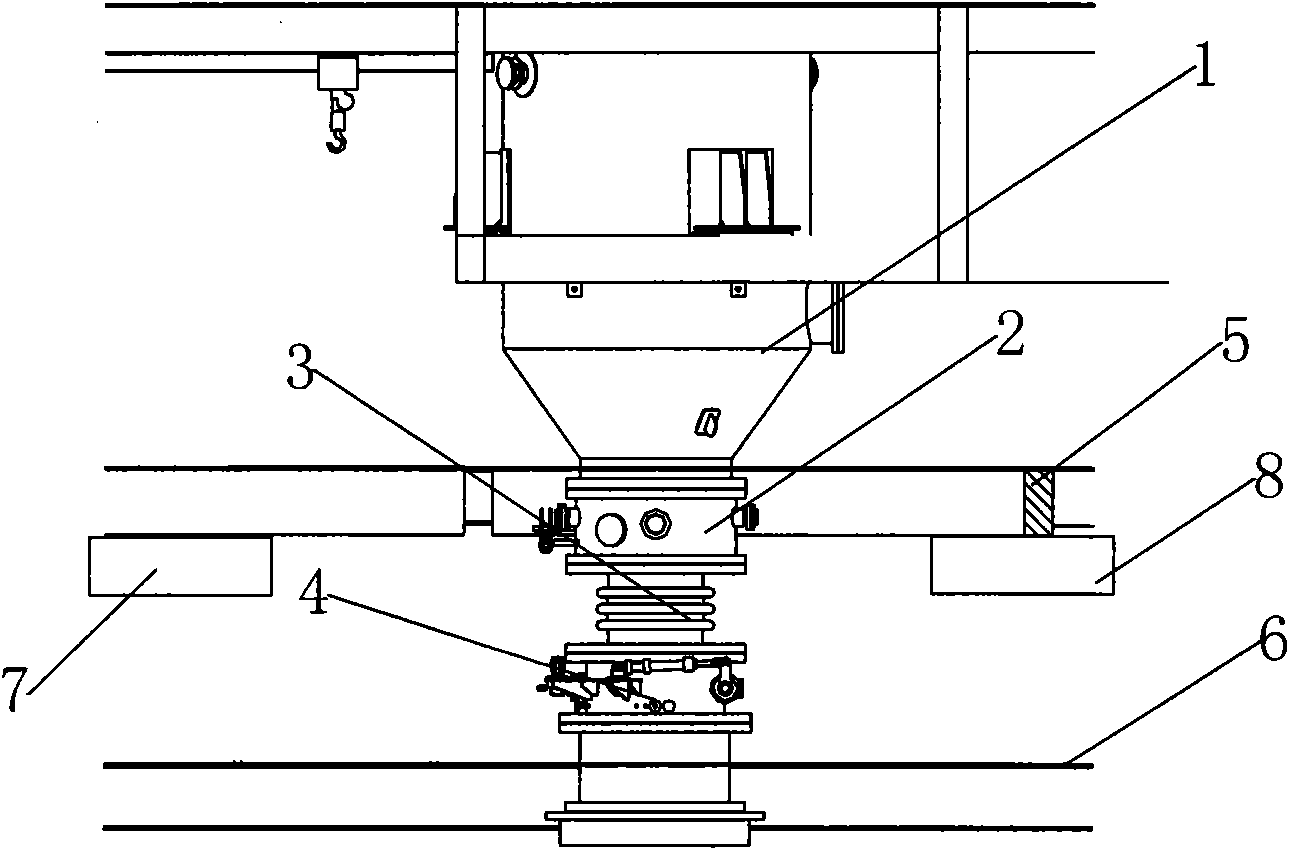

Adjustable support and construction method thereof

The invention provides an adjustable support and a construction method thereof. The adjustable support is arranged between a basement ceiling and the ground and is formed by a main force transfer component, the upper part of the main force transfer component is connected with an adjustable head component, the lower end of the main force transfer component is connected with a load dispersing component, the main force transfer component comprises a vacancy filling part, a jack ejector rod on a jack ejector base of the main force transfer component is in contact connection with the adjustable head component which has a linear upward movement trail on the main force transfer component, the vacancy filling part consists of four valve ring vacancy blocks, the inner diameter and the outer diameter of the vacancy filling part are equal to those of the main force transfer component, the vacancy filling part is inlaid between the main force transfer component with the adjusted supporting height and the adjustable head component. All parts are prefabricated in a factory, and are assembled, adjusted, fixed and erected in site. The adjustable support assists large-scale overhang steel structures or large-span steel structure in constructing, so that the tedious condition of overlapping a scaffold is avoided; the height of the head component of the adjusted support is adjustable, so that the problem that supporting stand columns cannot be erected due to the fact that the absolute length of the supporting stand columns is greater than the interlayer spacing of a basement is solved; the adjustable support can be conveniently detached, transferred and reused.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG

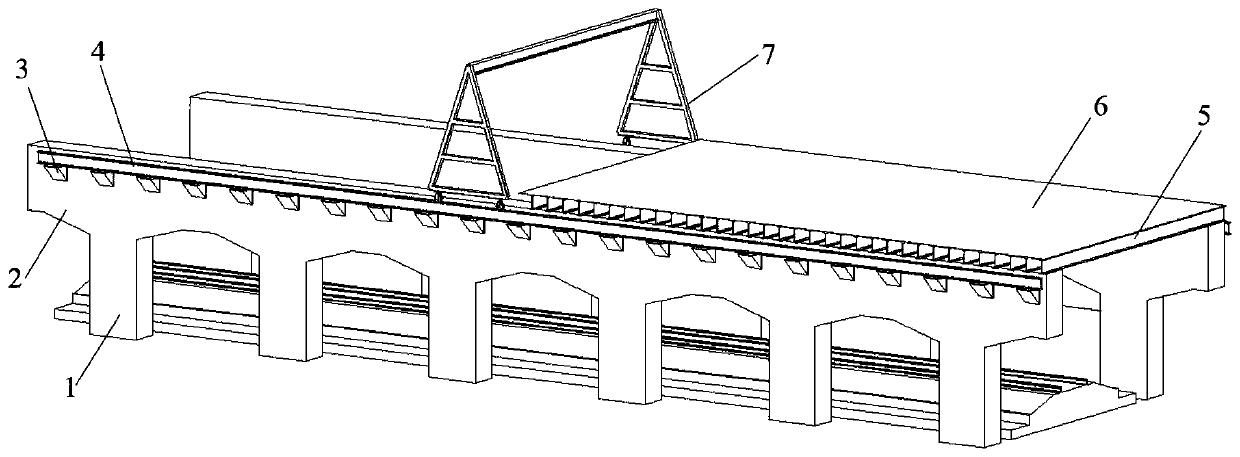

Quick construction method for over-crossing business line hangar tunnel T-shaped girder in narrow space

The invention discloses a quick construction method for an over-crossing business line hangar tunnel T-shaped girder in narrow space. The quick construction method includes the following steps that ahangar tunnel foundation pit is dug according to a designed location and a hangar tunnel stand column is constructed; a hangar tunnel vertical girder is constructed, a bracket support is pre-buried and a gantry crane walking railway is set up on the bracket support; a distributive girder and a form board are laid on the top of the hangar tunnel vertical girder to be used as a T-shaped girder primary prefabricating platform, and a gantry crane is arranged on the gantry crane walking railway; a T-shaped girder is poured on the T-shaped girder primary prefabricating platform and hoisted to a vacant zone; if the vacant zone can not be laid fully, then the step is conducted repeatedly; the T-shaped girder primary prefabricating platform is demolished, and the form board is laid on the T-shapedgirder to be used as a T-shaped girder secondary prefabricating platform; a T-shaped girder is poured on the T-shaped girder secondary prefabricating platform and hoisted to a vacant zone and erectingof the T-shaped girder is completed; the T-shaped girder secondary prefabricating platform is demolished and auxiliary facilities are exerted; and other unnecessary facilities are demolished. The problem of insufficient prefabricating places can be solved and the risk of the hoisting operation near the business line is avoided.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

High-speed railway aluminium alloy track plate pressing device

InactiveCN106988170AGuaranteed perfusion qualityGuaranteed fixed effectRailway track constructionEngineeringRebar

The invention relates to a high-speed railway aluminium alloy track plate pressing device. The device comprises a tie down block, landing legs, side fixing plates, pressing pull rods and pushing screws; the device is characterized in that the tie down block and the landing legs are welded perpendicularly to form a shape of a door; the side fixing plates are arranged at the lower ends of the landing legs in parallel and connected with the landing legs through bolts; the pressing pull rods are connected with a track base plate and the tie down block and connected with reserved openings of the track base plate in a suspended mode through rebar; the pushing screws push an edge sealing formwork through the side fixing plates; the landing legs and the side fixing plates are made from aluminum alloy materials. Accordingly, it is guaranteed that ballastless track construction is conducted smoothly, the self-compacting concrete pouring quality is guaranteed, and the working efficiency is improved; construction installation and transportation are convenient, operation is easy, learning is fast, and the self-compacting concrete pouring quality and the fixed track plate space position are guaranteed; turnover is conducted many times, and the phenomena of track plate floating, the self-compacting concrete layer open joint and the like are avoided.

Owner:湖南天象建筑科技有限公司

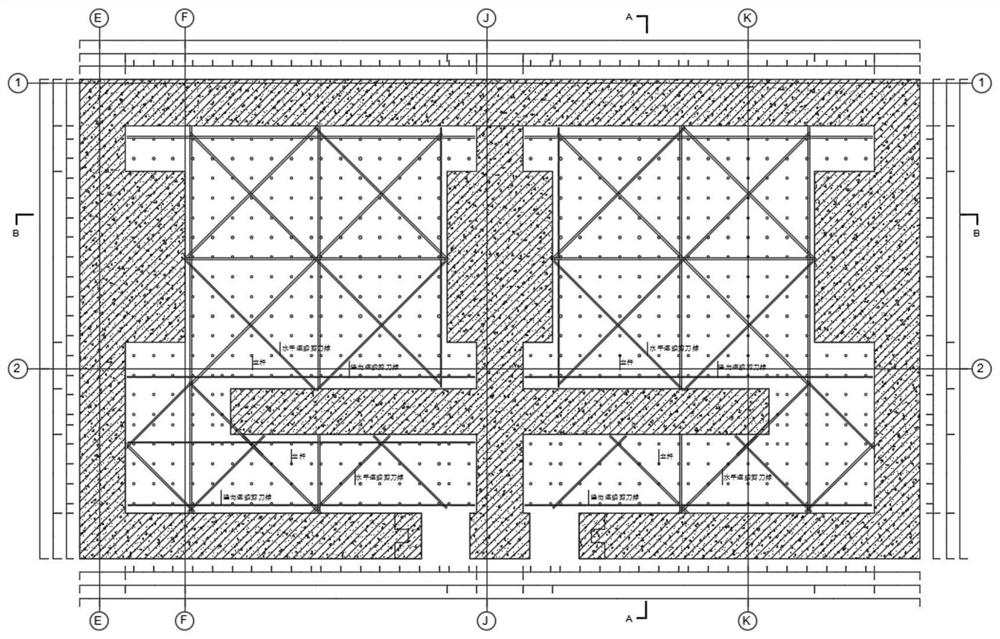

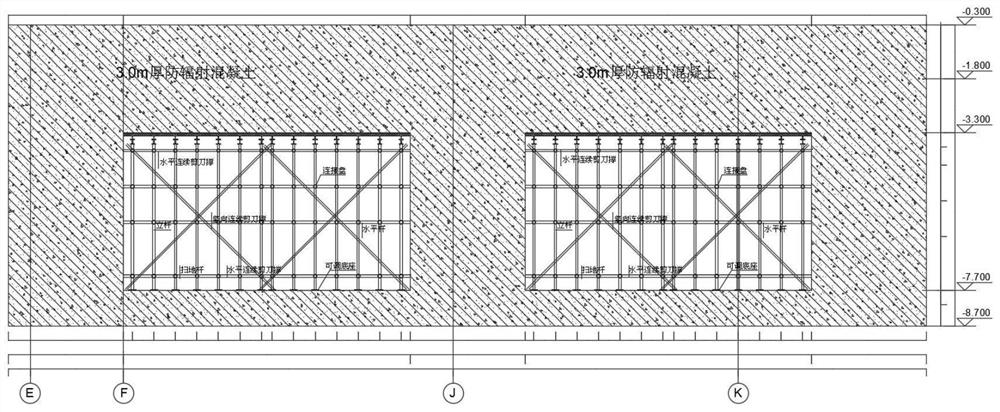

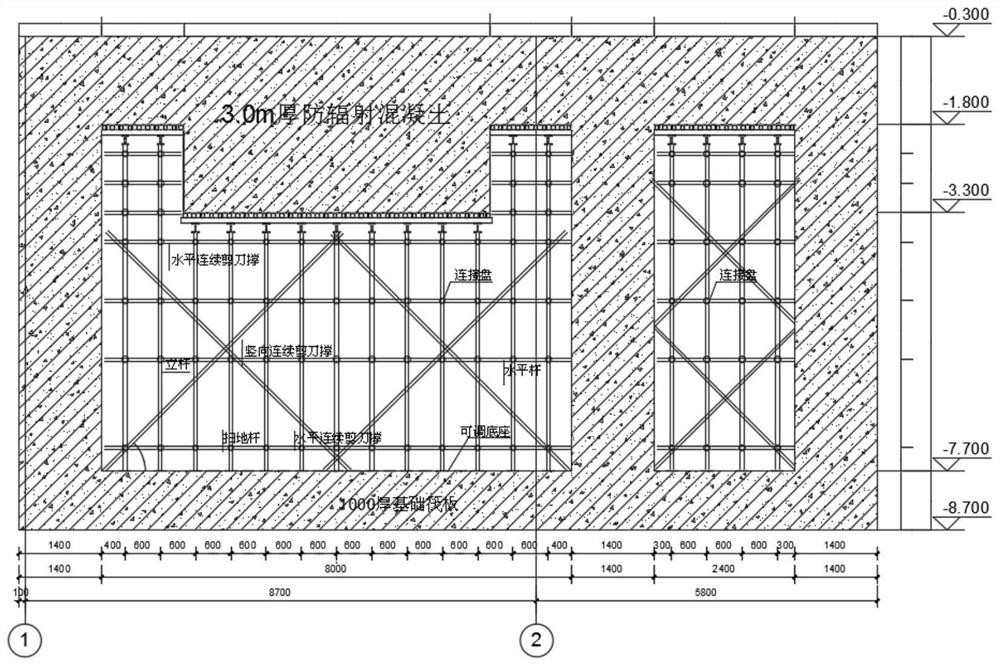

Construction method of super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system

InactiveCN113090018AImprove bearing capacityReasonable mechanical designForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention discloses a construction method of a super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system. The construction method comprises a beam plate bottom formwork, primary ridges, secondary ridges, vertical rods, horizontal rods, bottom horizontal rods, vertical inclined rods and horizontal inclined rods; the beam plate bottom formwork adopts 18 mm thick wood plywood; the secondary ridges are 70*70*5 mm square steel pipes; a distance between the adjacent square steel pipes is 150 mm; the primary ridges are 10# I-shaped steel; and a distance between every two adjacent I-shaped steel is 600 mm. The construction method of the super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system has the advantages that the bearing capacity is high by creatively adopting the novel plate buckle type formwork supporting system, the construction of anti-radiation concrete with the thickness of 3.0 m can be well met, the risk of harmful cracks caused by insufficient rigidity of a traditional support system is avoided, the distance between the vertical rods and the step pitch of the horizontal rods can provide larger operation space compared with a traditional supporting system, and shuttling construction and material reshipment of workers are facilitated. In addition, assembly is fast, use is convenient, cost is saved, and popularization is worthy.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

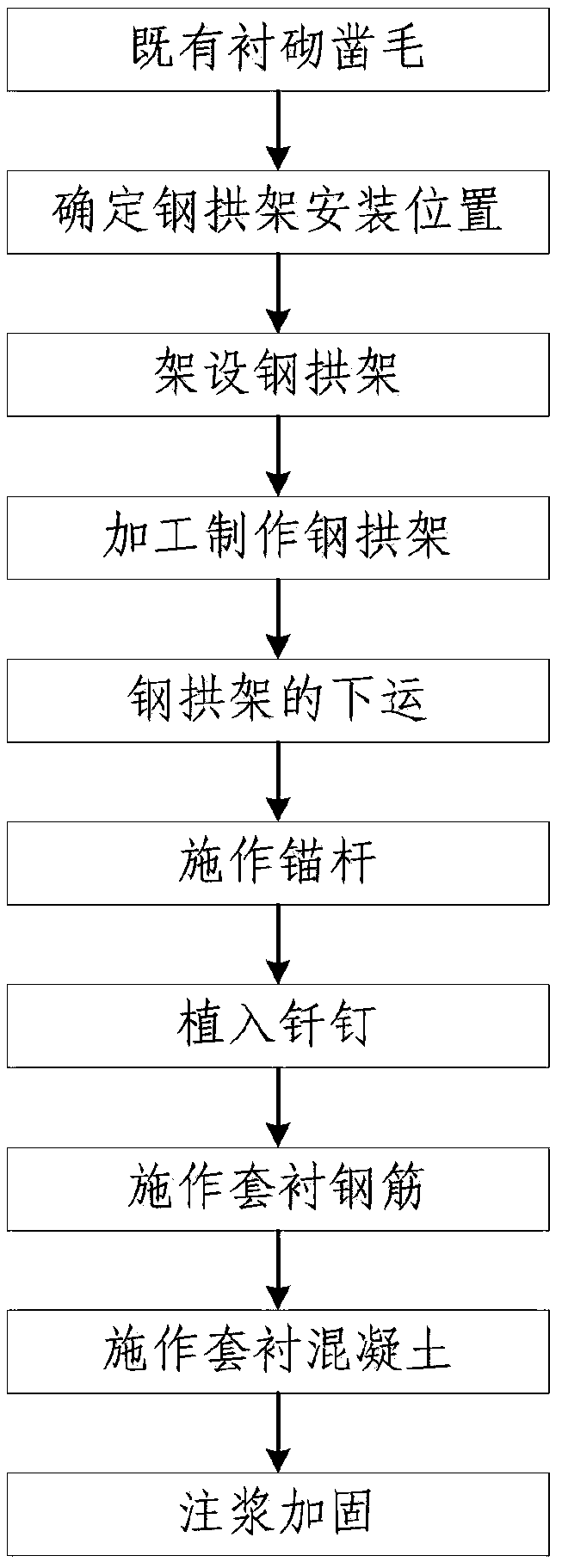

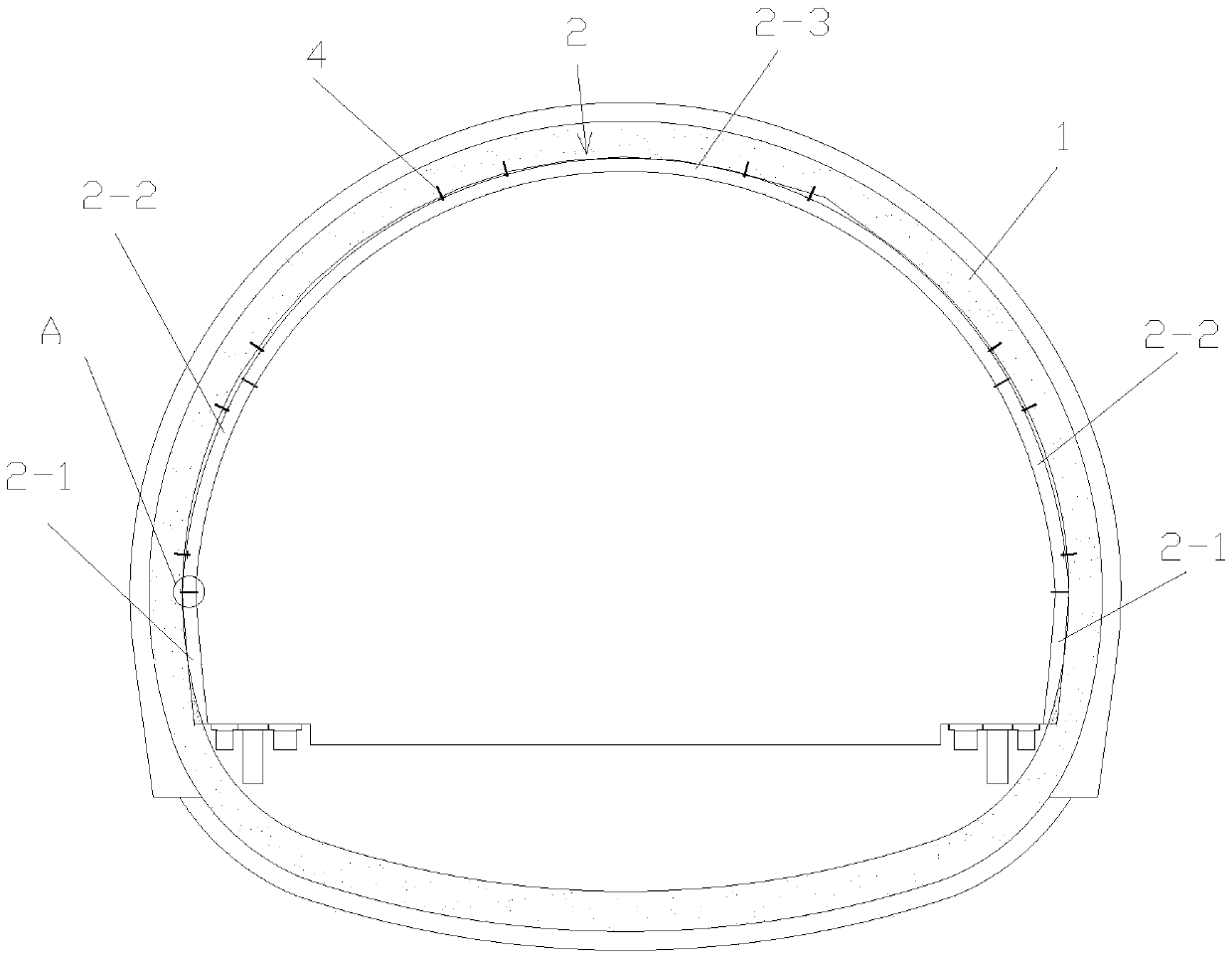

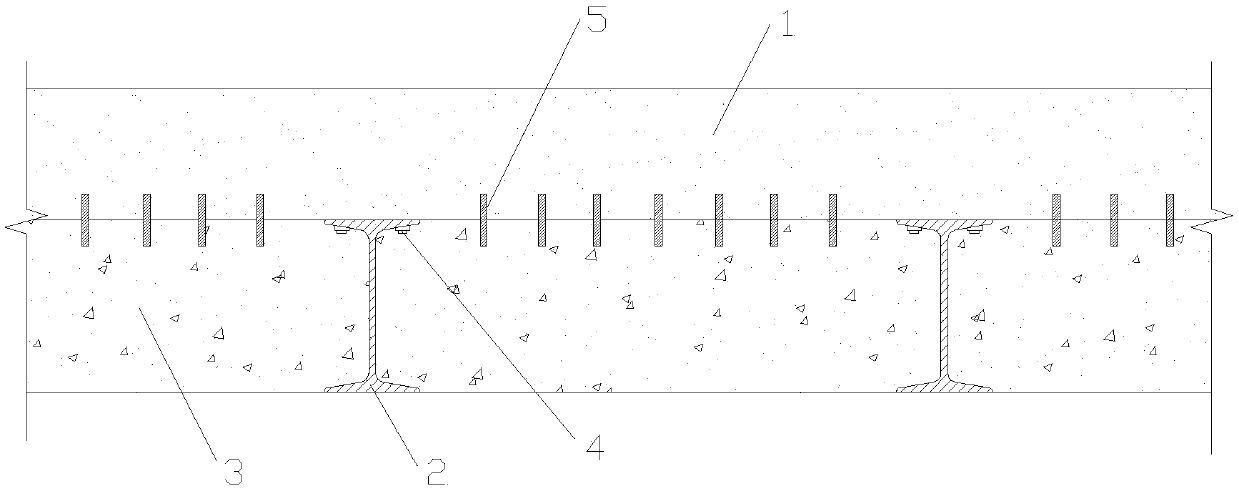

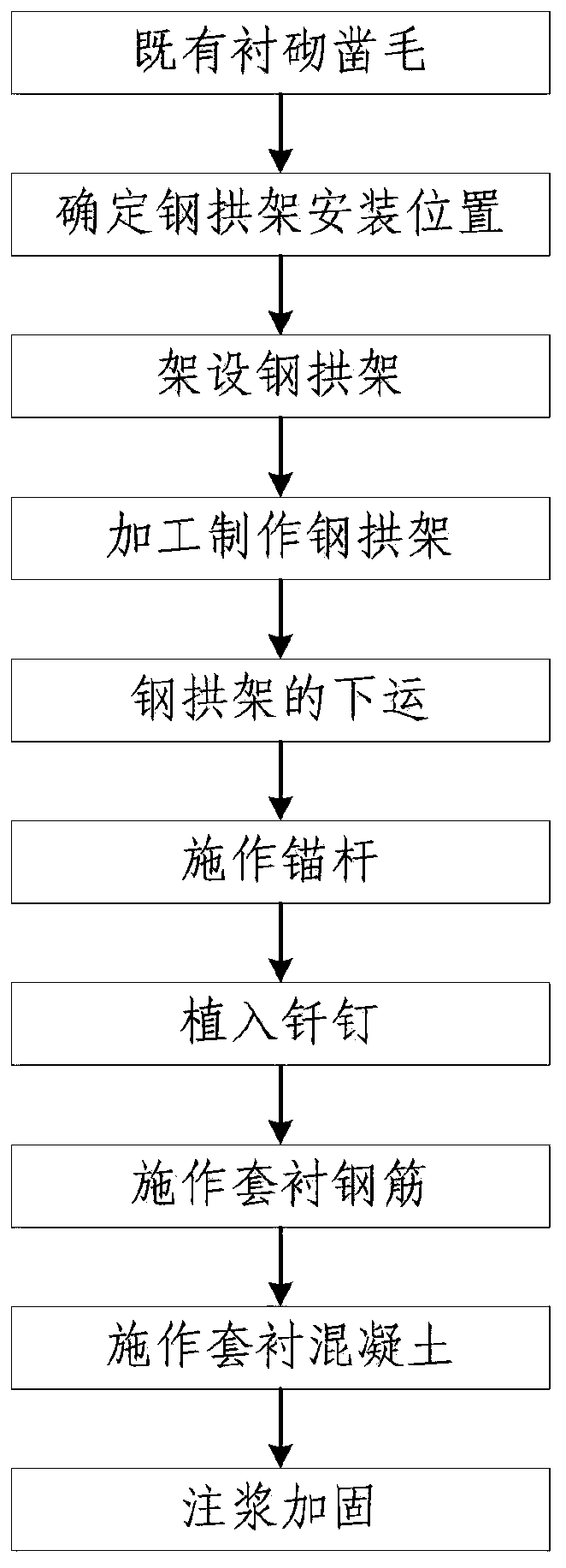

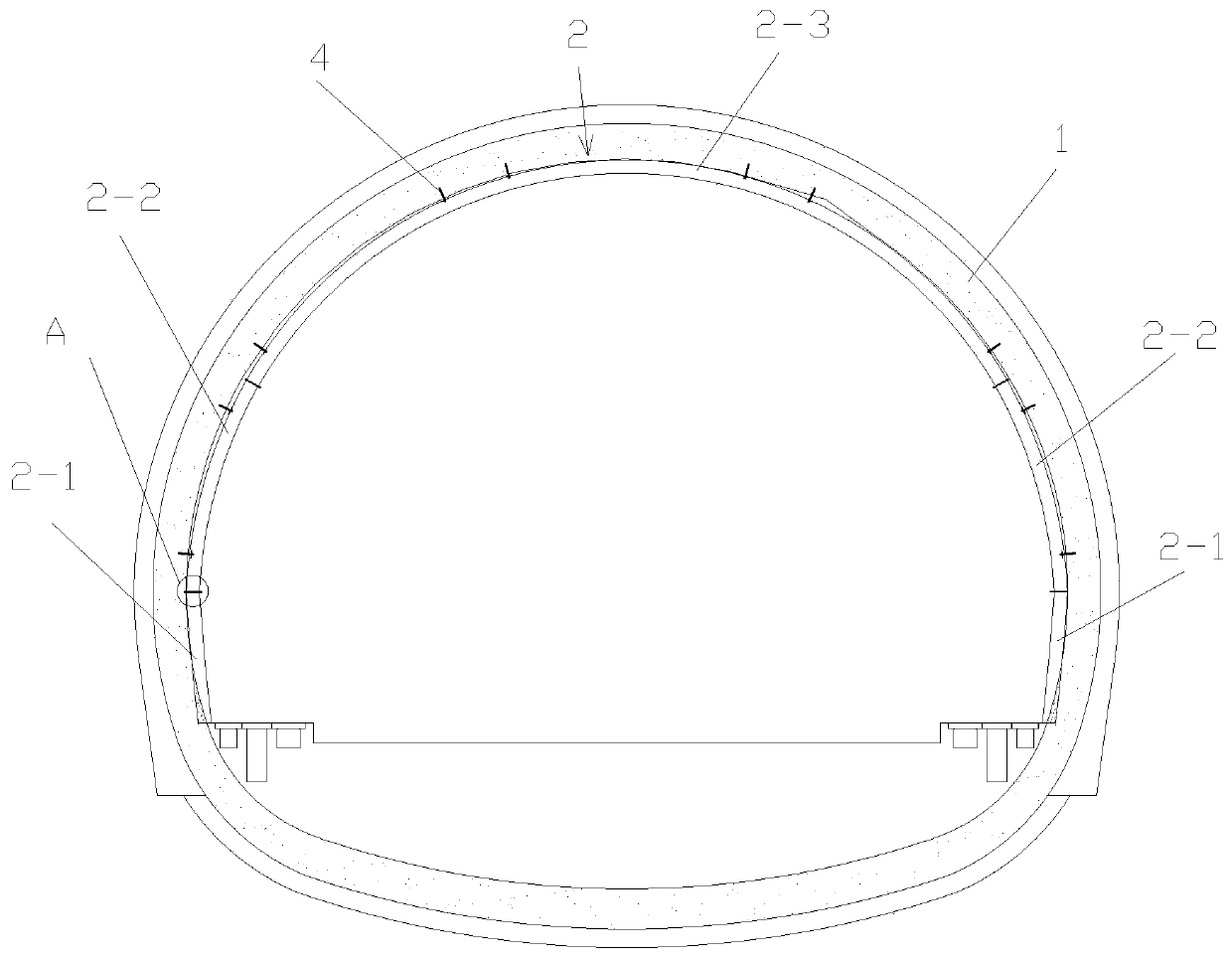

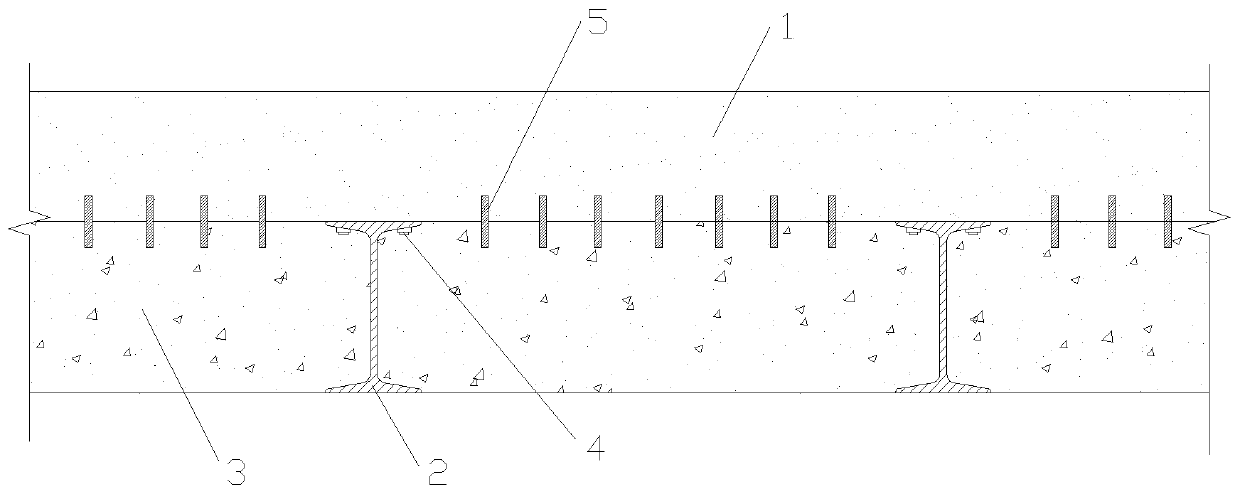

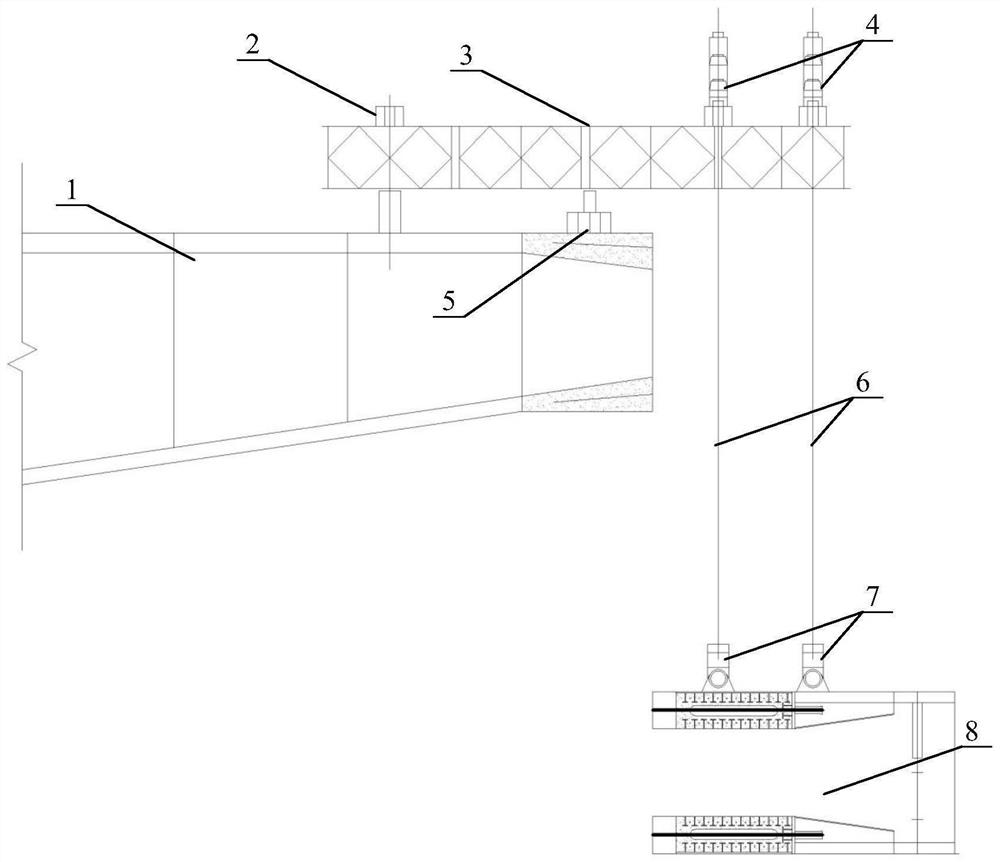

Existing line tunnel lining structure of railway and construction method thereof

ActiveCN109519193AExtended service lifeReduce security risksUnderground chambersTunnel liningRebarReinforced concrete

The invention discloses an existing line tunnel lining structure of a railway and a construction method thereof. The tunnel lining structure comprises multiple steel arch frames and a cast-in-place reinforced concrete lining. The construction method comprises the steps of 1 existing lining chiseling, 2 determining the installation positions of the steel arch frames, 3 processing and manufacturingthe steel arch frames, 4 transporting the steel arch frames, 5 erecting the steel arch frames, 6 applying anchors, 7 implanting drill nails, 8 laying lining steel bars, 9 applying lining concrete and10 grouting reinforcement. The structure is reasonable, the cast-in-place reinforced concrete lining is closely connected with the existing lining, the existing lining can be effectively reinforced without the influence on an existing lining structure, external formworks can be reused during the concrete pouring process, the construction cost is effectively reduced, and the steel arch frames are used as side formworks, do not need to be dismantled after being used and can be stressed together with the existing lining and work together to greatly improve the safety of the cast-in-place reinforced concrete lining structure.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

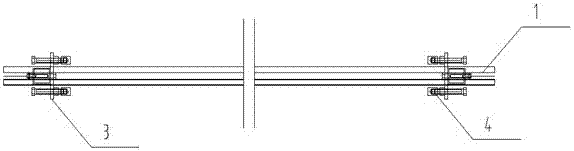

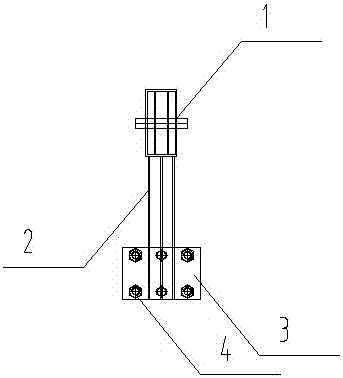

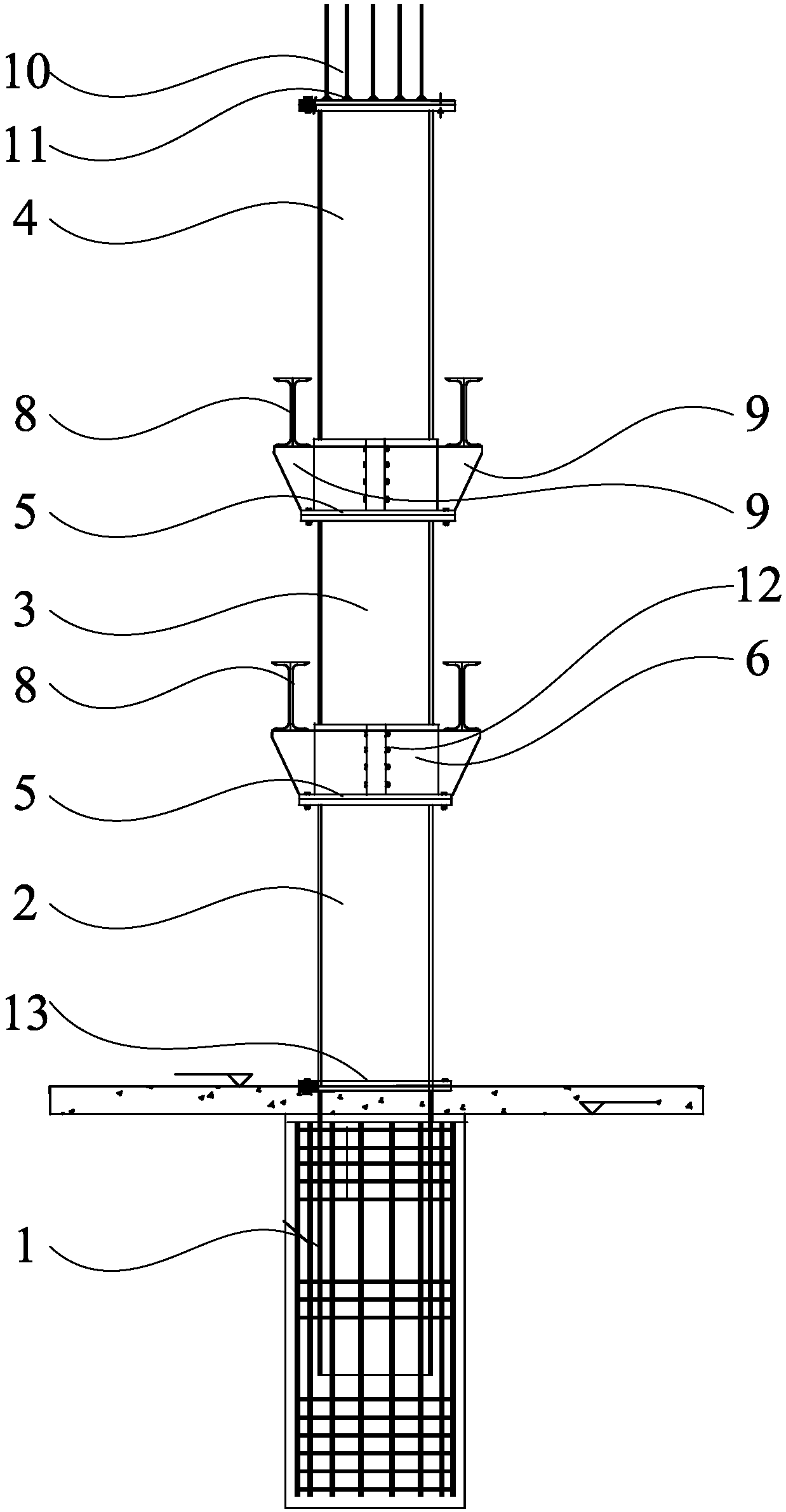

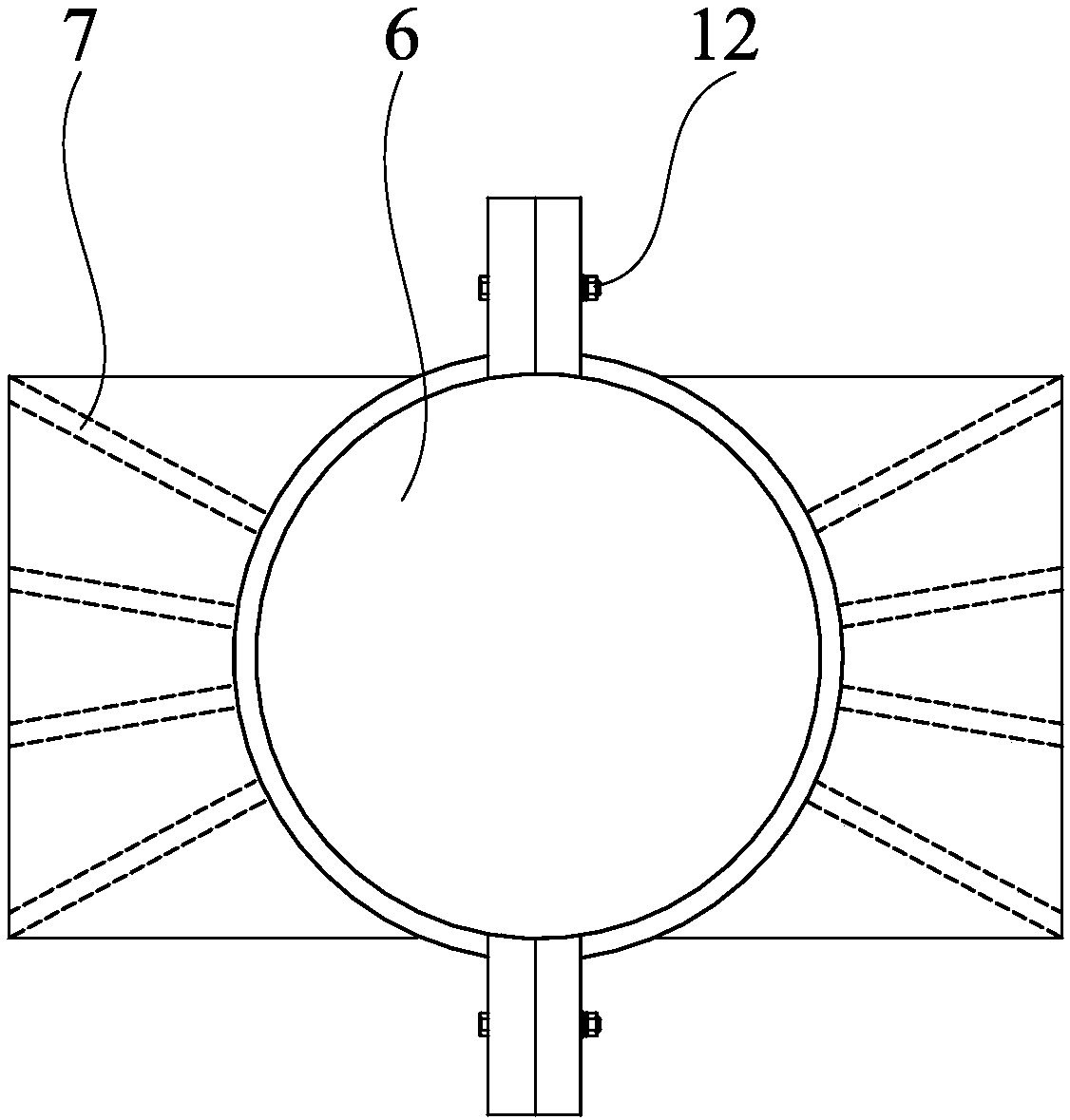

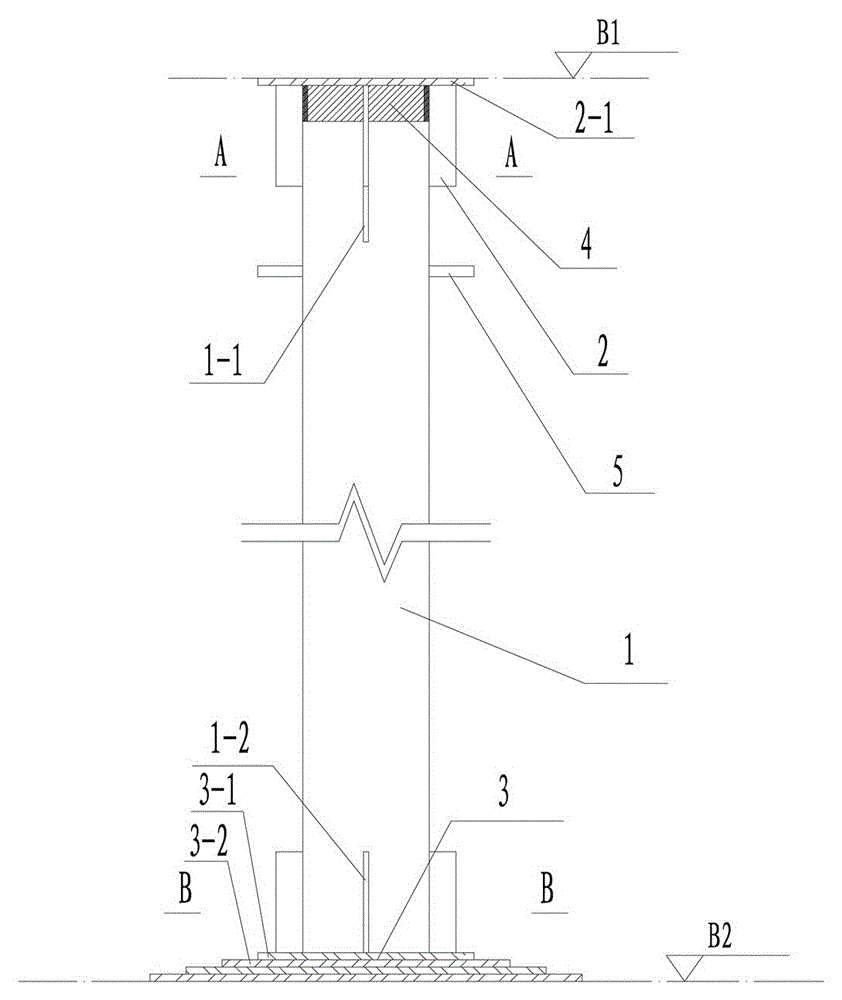

Combined recoverable steel pipe post and deep foundation pit support method thereof

PendingCN108560566AConvenient on-site hoistingFirmly connectedExcavationsBulkheads/pilesMaterials scienceFlange

The invention discloses a combined recoverable steel pipe post, which comprises a lower part section steel pipe, a middle part section steel pipe and an upper part section steel pipe, wherein the lower part section steel pipe is permanently inserted into a structure of a fender post and a bottom plate; the middle part section steel pipe is connected with the lower part section steel pipe; the upper part section steel pipe is connected with the middle part section steel pipe; the upper part section steel pipe and the middle part section steel pipe are connected through a steel pipe post flange;the middle part section steel pipe and the lower part section steel pipe are connected through a steel pipe post flange; the upper part of the steel pipe post flange is provided with a clamp hoop; asupport plate is arranged at the upper part of the clamp hoop; a connecting beam used for supporting a foundation pit horizontal supporter is arranged on the support plate; a rib plate is arranged atthe outer side of the clamp hoop; the top end of the upper part section steel pipe is connected with the concrete connecting beam through a flange. The combined recoverable steel pipe post of the structure is used; the field hanging, combination connection and dismounting, transferring and storage are convenient; meanwhile, the cyclic use is convenient; the construction cost is reduced; the construction risk is reduced.

Owner:THE 3RD ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP +2

Rotary lifting device for repairing coke oven door

ActiveCN104388102AImprove maintenance efficiencySave operating timeCoke oven doors/closuresEngineeringMechanical engineering

The invention discloses a rotary lifting device for repairing a coke oven door. The rotary lifting device comprises a main frame, a docking mechanism, a rotating mechanism, a lifting mechanism, a traveling mechanism and a control system, wherein the docking mechanism and the rotating mechanism are arranged on the main frame; the main frame is connected with the traveling mechanism by virtue of the lifting mechanism; the traveling mechanism can move along a ground guide rail; and the control system controls each mechanism to finish the actions such as docking and clamping, rotating, lifting, elevating and traveling of a traveling trolley on the coke oven door. Compared with the prior art, the rotary lifting device disclosed by the invention has the beneficial effects that 1) the device is suitable for two different bolt structures of a pressing mode and a rotating mode; 2) a main frame of a single-side frame structure is adopted, each part of the oven door is convenient to maintain, and the maintenance efficiency is high; 3) the operation is stable and reliable; 4) the lifting action is realized by virtue of retraction and rotation of a folding arm, and the operation is stable and reliable; 5) the left and right folding arms synchronously retract, so that the oven door is lifted to a proper height, and the working conditions are improved; and 6) a set of device can be shared on the machine and coke side, and the cost is saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

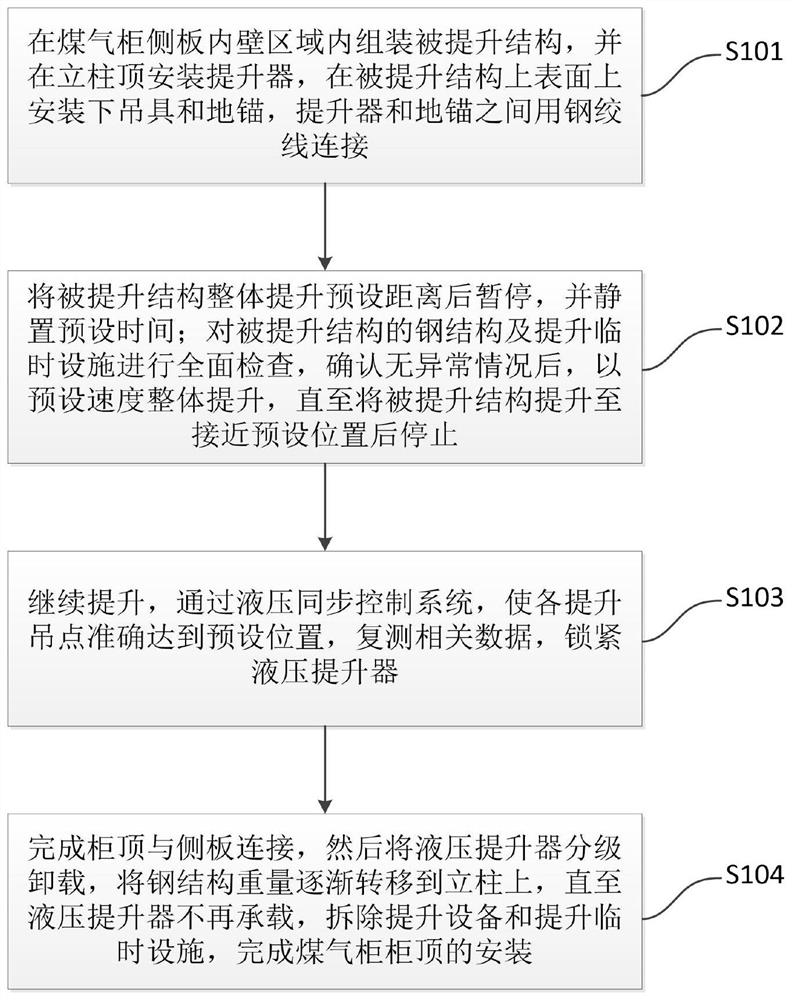

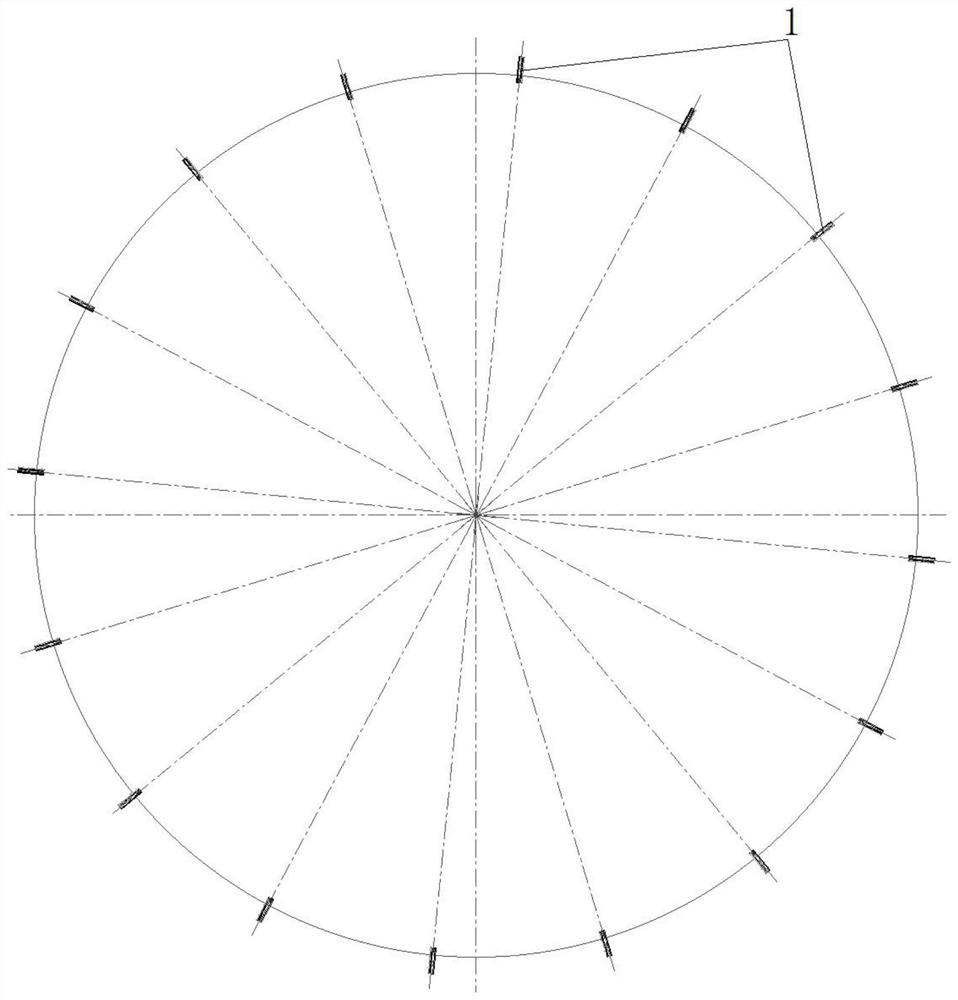

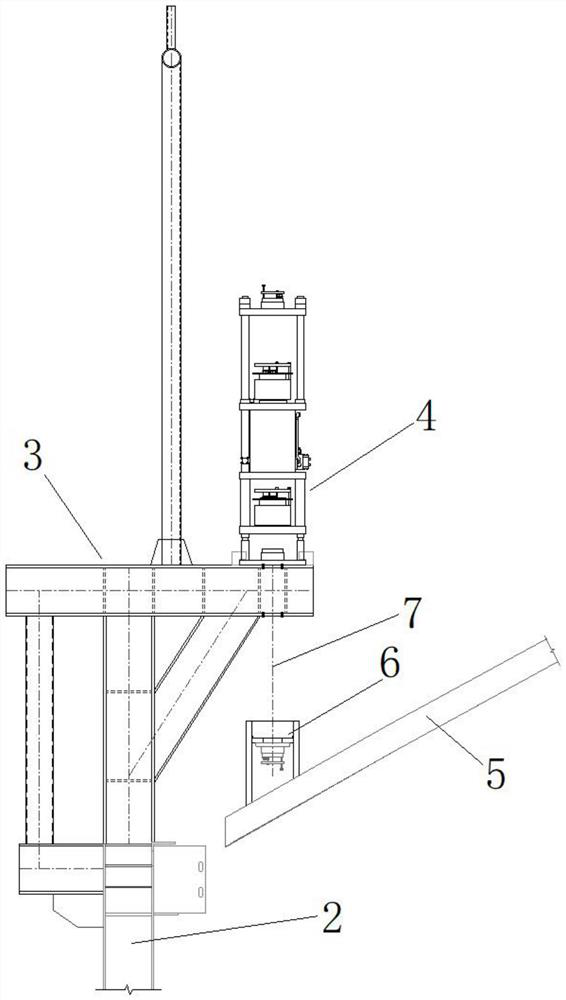

Mounting method for top of large gas holder of steel mill

InactiveCN112374344AReduce workloadShort installation and construction periodLoad-engaging elementsControl systemSynchronous control

The invention provides a mounting method for the top of a large gas holder of a steel mill. The method comprises the following steps that Step 1, a lifted structure is assembled in an inner wall areaof a gas holder side plate, and a lifter is mounted at the top of a stand column; Step 2, the lifted structure is integrally lifted by a preset distance, then is suspended and stands for a preset time; the steel structure of the lifted structure and temporary lifting facilities are comprehensively inspected; Step 3, lifting is continued, each lifting point accurately reaches a preset position through a hydraulic synchronous control system, related data are measured again, and a hydraulic lifter is locked; and Step 4, connection of the cabinet top and the side plate is completed, and then graded unloading is performed on the hydraulic lifter. According to the method, an integral hoisting mode is adopted, the steel structure at the top of the gas holder is firstly assembled on the ground, and then integral hoisting is carried out through hydraulic synchronous lifting of ultra-large components, so that the high-altitude hoisting workload is reduced to the greatest extent, the mounting andconstruction period is shortened, the construction efficiency is improved, and the construction quality and safety are ensured.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

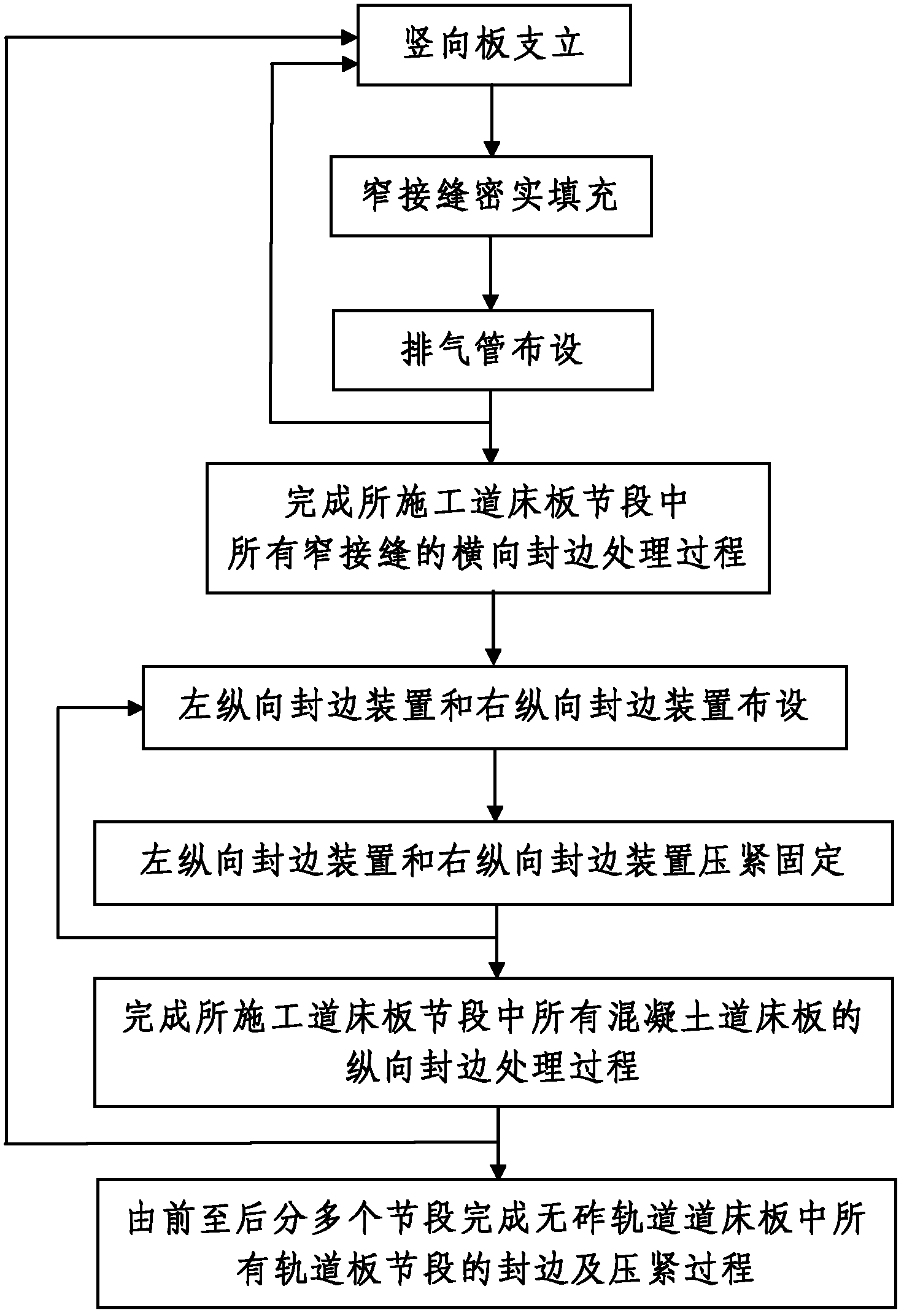

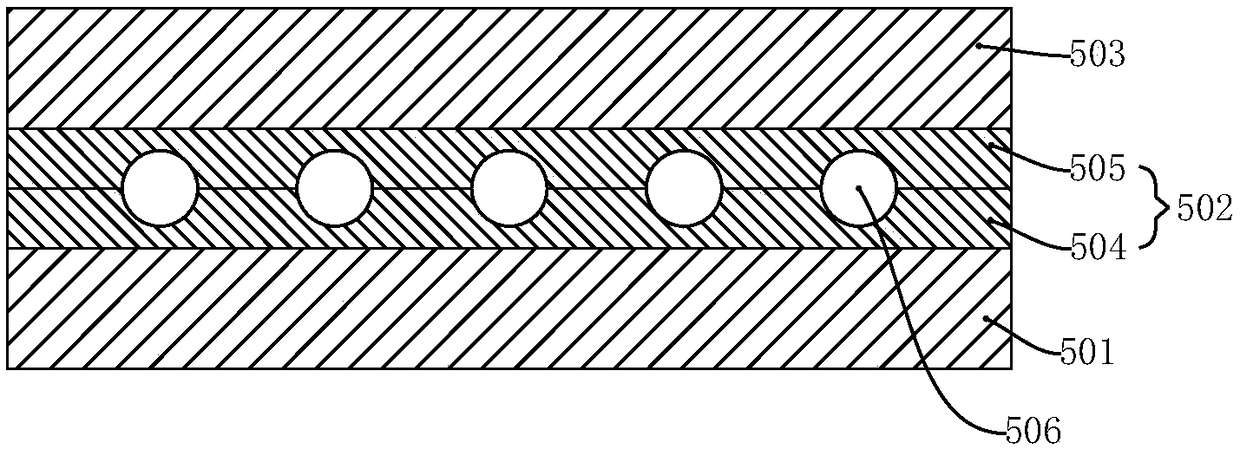

Track slab banding and pressing process for plate-type ballastless tracks

ActiveCN102392396BReasonable designThe process steps are simpleRailway track constructionExhaust pipeBallast

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

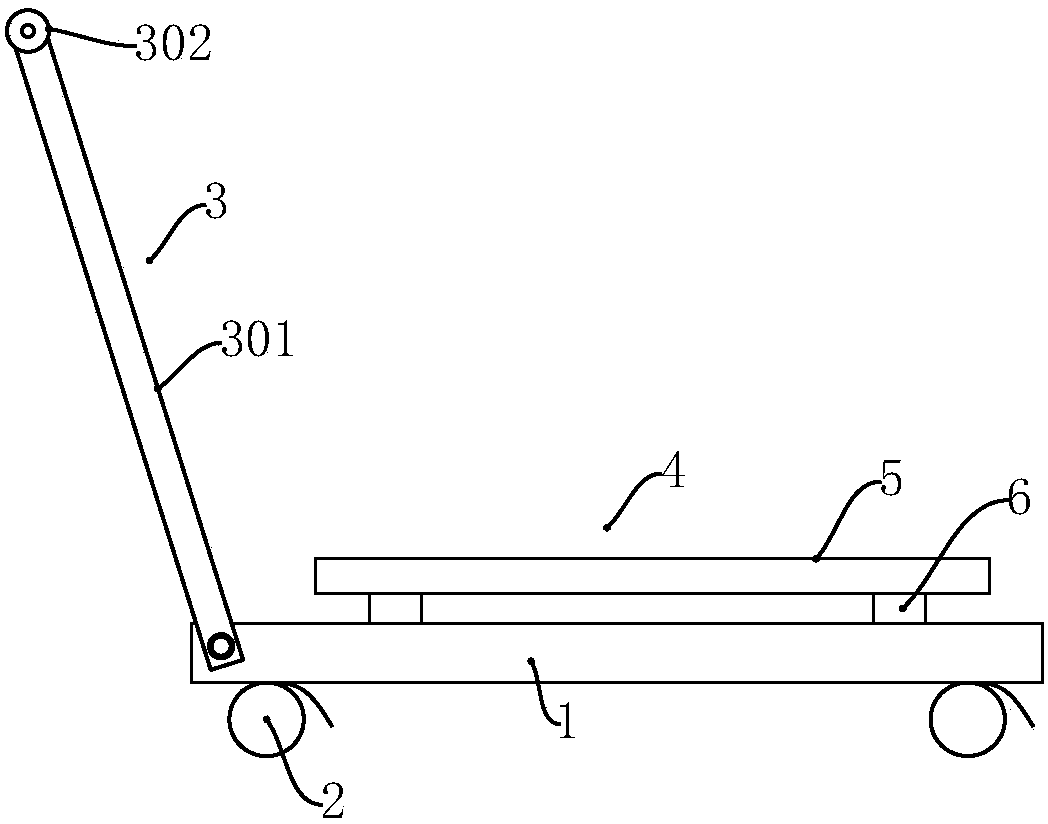

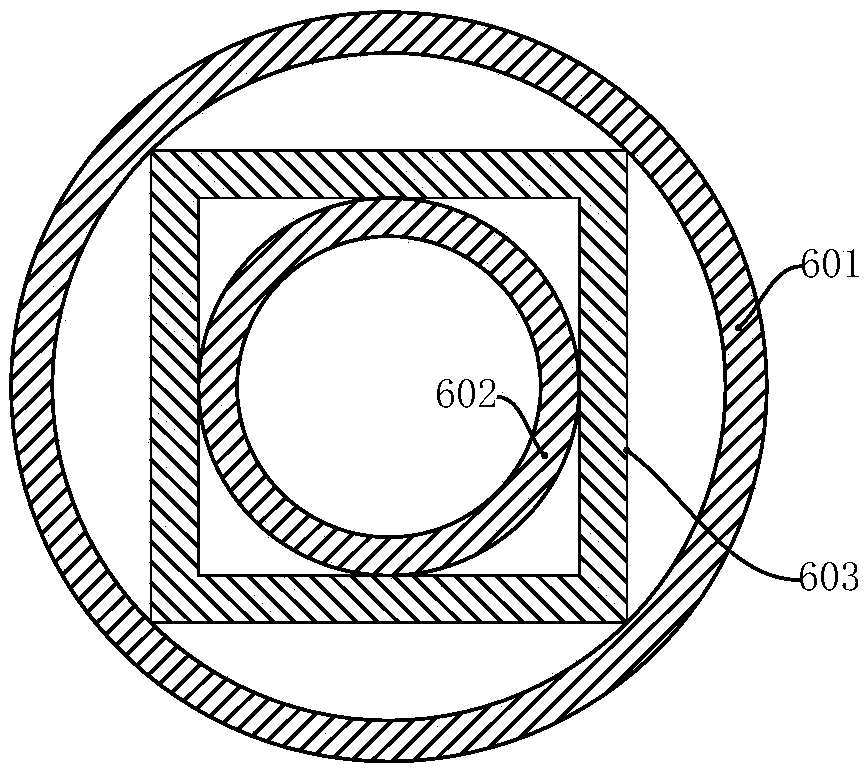

Handling cart for cardboards

InactiveCN109278820ASimple structureWith shock absorbing functionHand carts with multiple axesHand cart accessoriesCardboardDamping function

The invention relates to the technical field of paper product handling equipment, and specifically relates to a handling cart for cardboards. The handling cart includes a base plate, moving mechanismsarranged under the base plate, and a push rod support connected to the base plate; the base plate is provided with a forklift cushion; the forklift cushion includes a supporting plate and cushion blocks each of which is arranged on each of the four corners under the supporting plate; the base plate is provided with grooves matching the cushion blocks; the cushion blocks are inserted in the grooves; the heights of the cushion blocks are greater than the depths of the grooves; the cushion blocks include first cylinders, second cylinders and square-shaped tubes which are in hollow structures; the square-shaped tubes are connected to the inner sides of the first cylinders; and the second cylinders are connected to the inner sides of the square-shaped tubes. Through the arrangement of the forklift cushion, a forklift can conveniently and reversely carry cardboards, so that working efficiency can be enhanced; the forklift cushion is simple in structure, stable and firm, and has a certain buffering and vibration damping function; and the push rod support can be further adjusted, so that operators can perform voluntary adjustment according to situations, and more convenient and faster operation can be achieved.

Owner:德阳市永胜纸制品有限公司

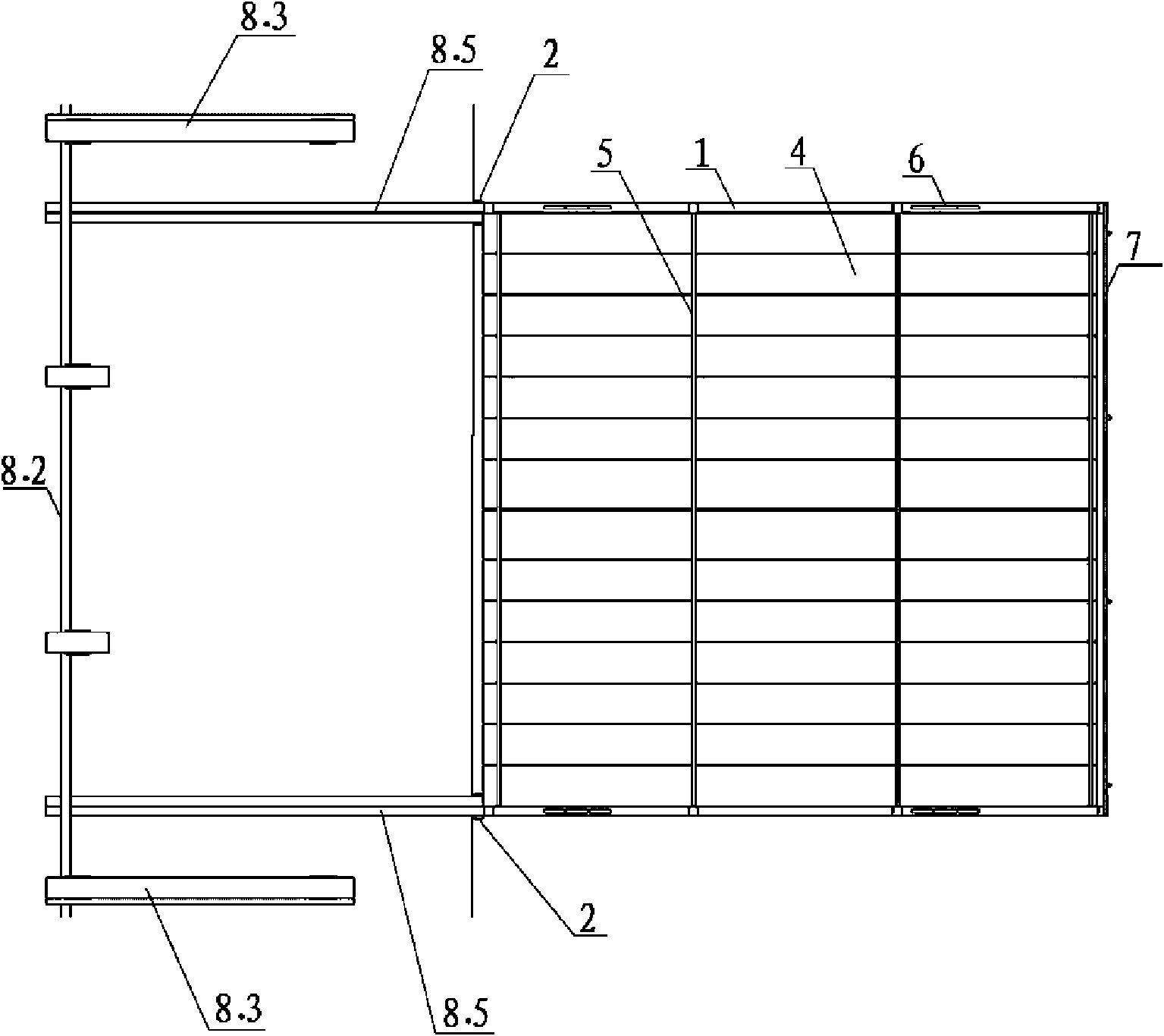

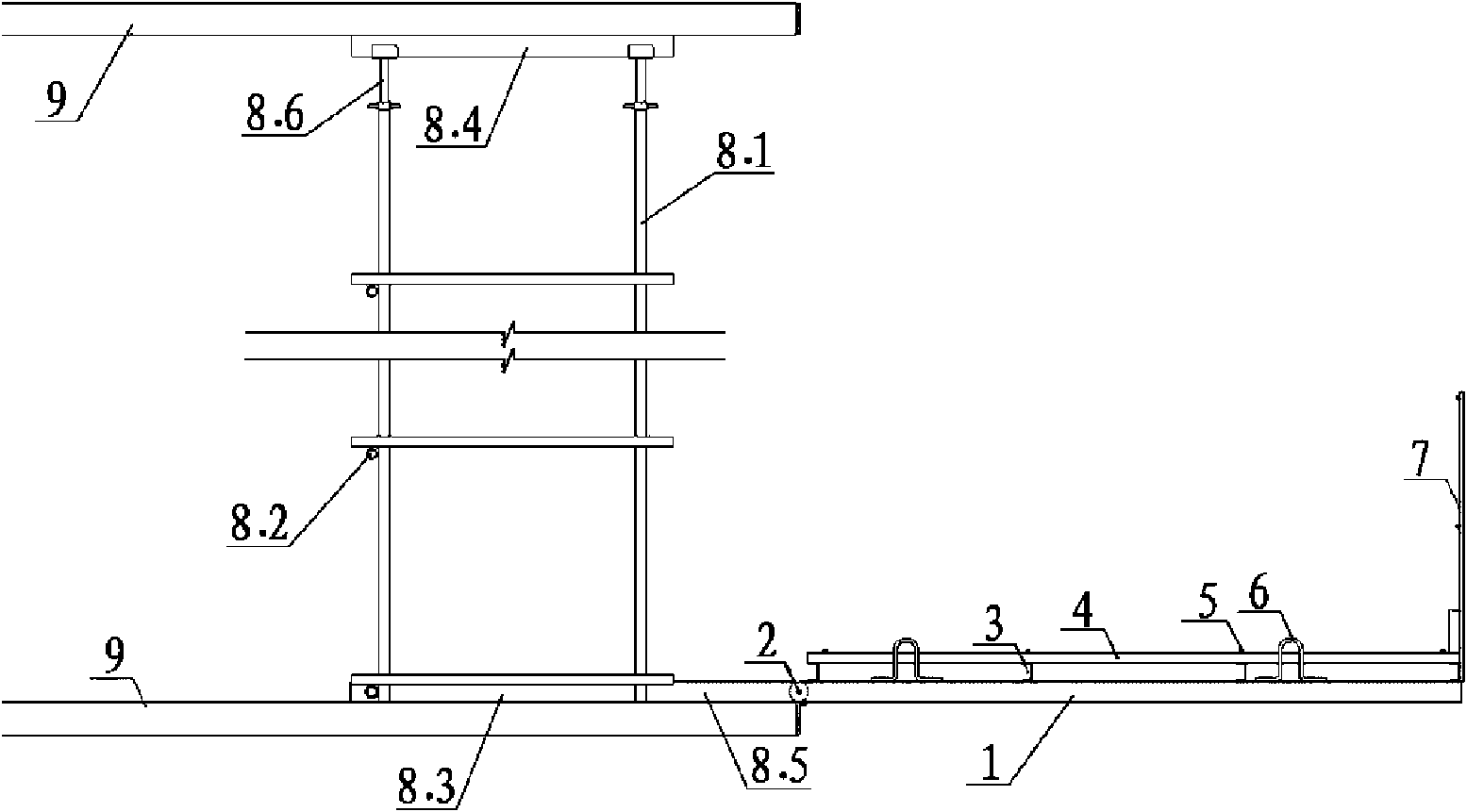

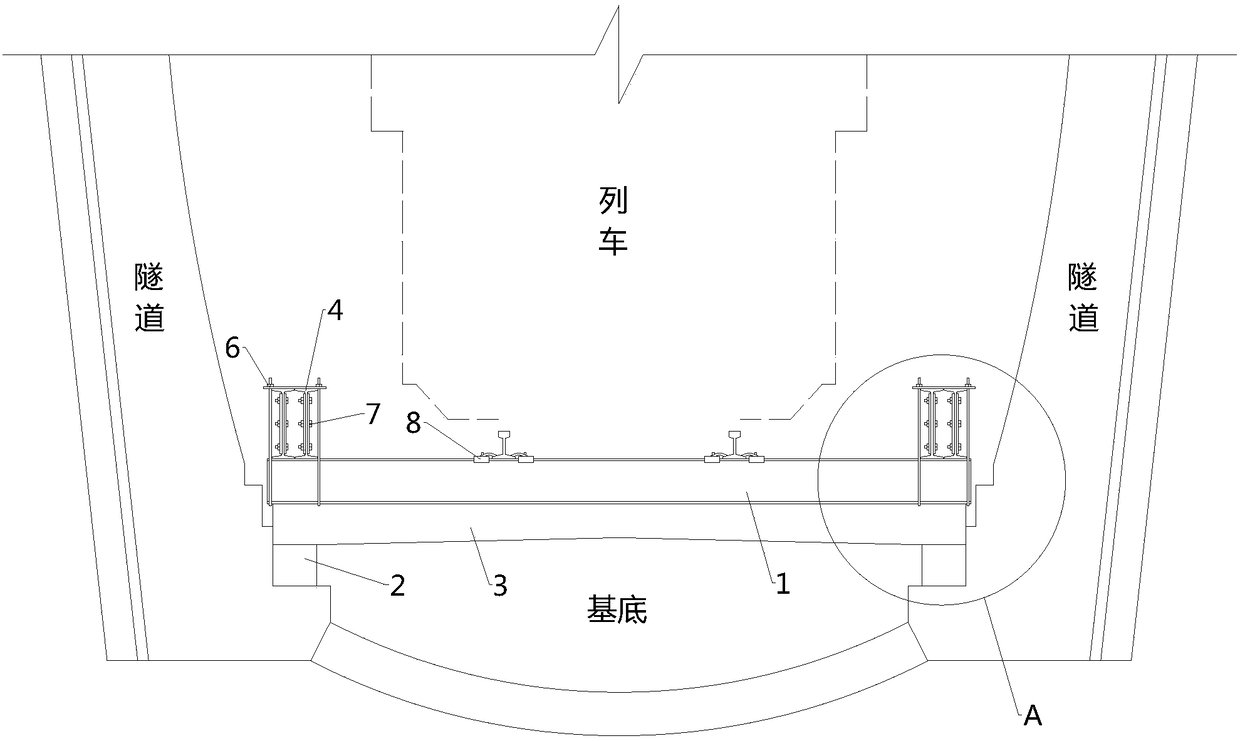

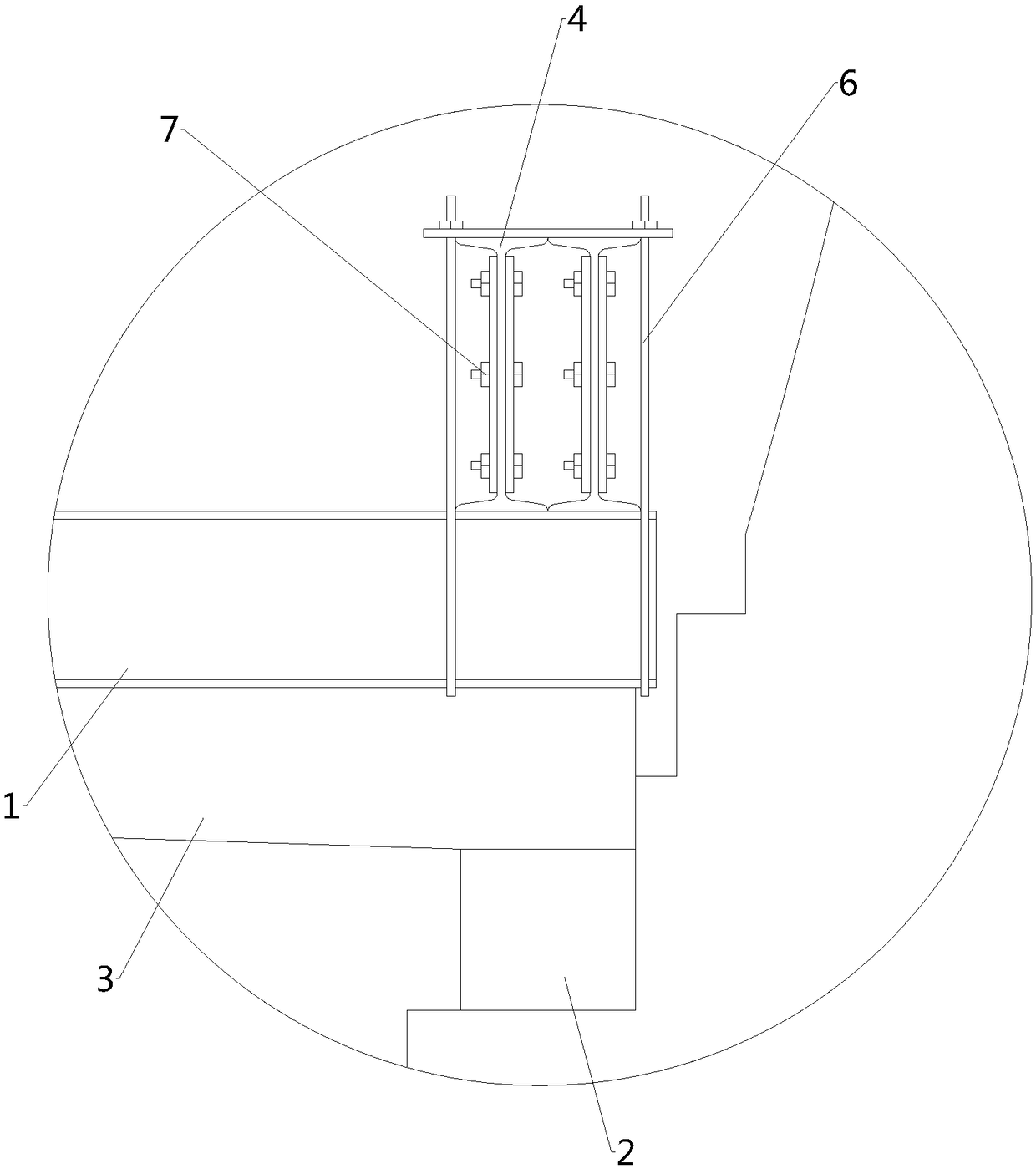

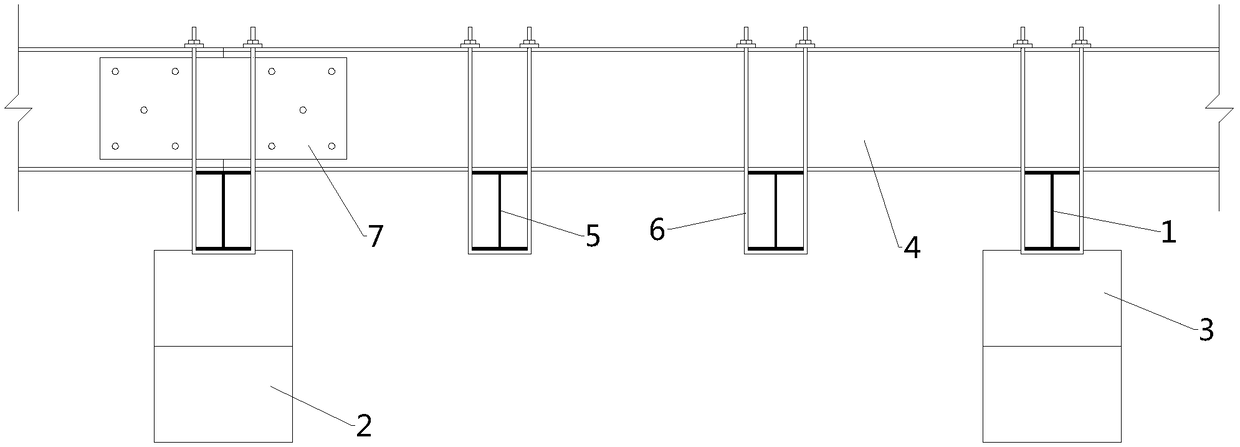

Construction structure enabling line to be overhead during existing railway foundation base disease treatment and construction method

PendingCN108239896AProspects for widespread applicationSolving limited headroom issuesRailway tracksStructure of the EarthDisease treatment

The invention discloses a construction structure enabling a line to be overhead during existing railway foundation base disease treatment. The construction structure comprises a main cross beam used for supporting a steel rail, wherein the two ends of the main cross beam are fixed. The invention also discloses a construction method based on the construction structure. The construction method comprises the following steps: firstly, removing a steel rail; secondly, mounting a main cross beam and a secondary cross beam; thirdly, erecting a longitudinal beam; fourthly, mounting the steel rail; andfifthly, carrying out base changing construction. The invention aims at solving the problem that an existing railway foundation base disease treatment construction technology can not carry out construction without interrupting a running train and provides the construction structure enabling the line to be overhead during the existing railway foundation base disease treatment and the constructionmethod. The construction structure and the construction method have the advantages that a railway line is overhead, and thorough foundation base disease treatment can be carried out while normal running of a business line can be guaranteed.

Owner:中铁二十三局集团第四工程有限公司

A kind of tunnel lining structure and construction method of existing railway line

ActiveCN109519193BExtended service lifeAvoid destructionUnderground chambersTunnel liningRailway tunnelReinforced concrete

The invention discloses a tunnel lining structure of an existing railway line and a construction method thereof. The tunnel lining structure comprises multiple steel arch frames and a cast-in-place reinforced concrete lining; the construction method comprises steps: 1. Existing lining is chiseled ; 2. Determine the installation position of the steel arch; 3. Process and manufacture the steel arch; 4. Lower the steel arch; 5. Erection of the steel arch; Applied as lining steel bars; 9. Applied as lining concrete; 10. Grouting reinforcement. The structure of the invention is reasonably arranged, the cast-in-place reinforced concrete lining is closely connected with the existing lining, and the existing lining can be effectively reinforced without affecting the existing lining structure, and the outer formwork can be reused during the concrete pouring process. The construction cost is effectively reduced. At the same time, the steel arch frame is used as a side formwork. It does not need to be dismantled after use. It can be stressed and work together with the existing lining, which greatly improves the safety of the cast-in-place reinforced concrete lining structure.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

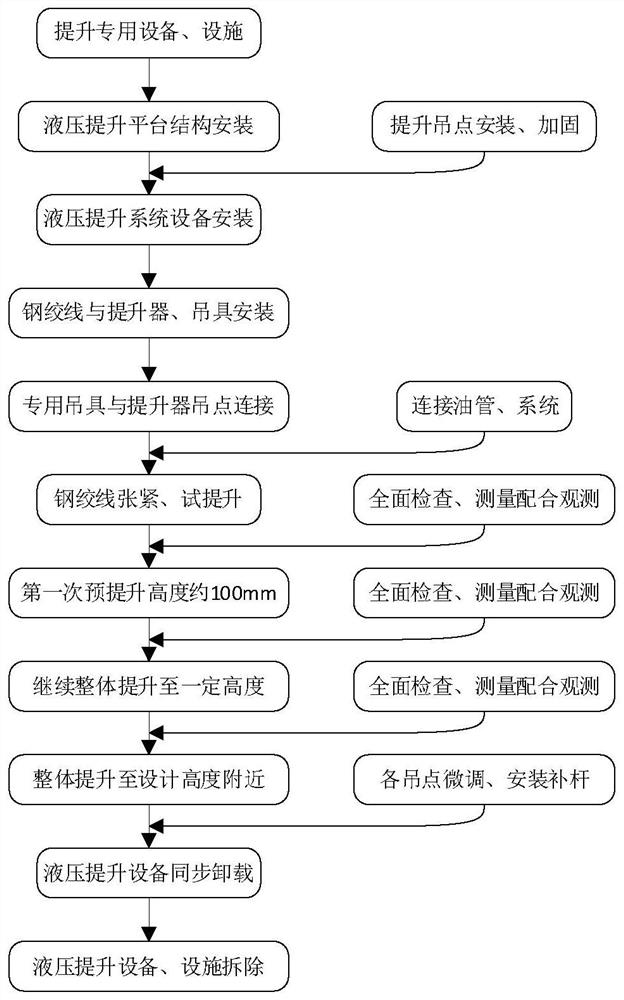

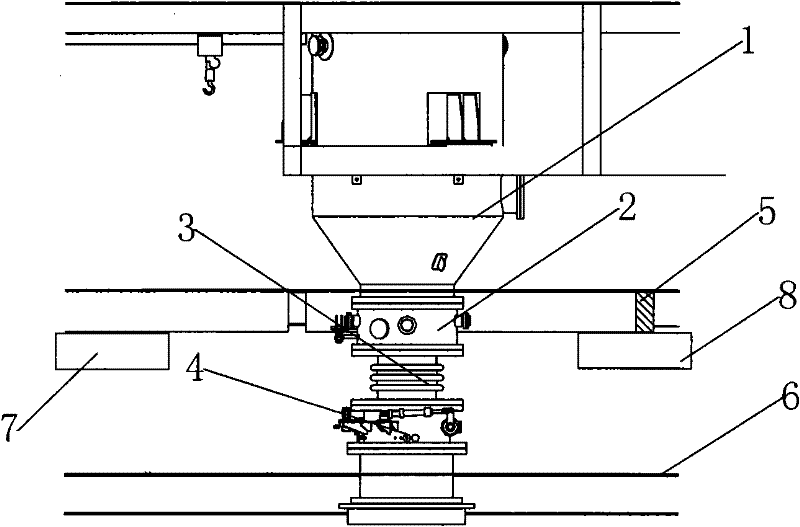

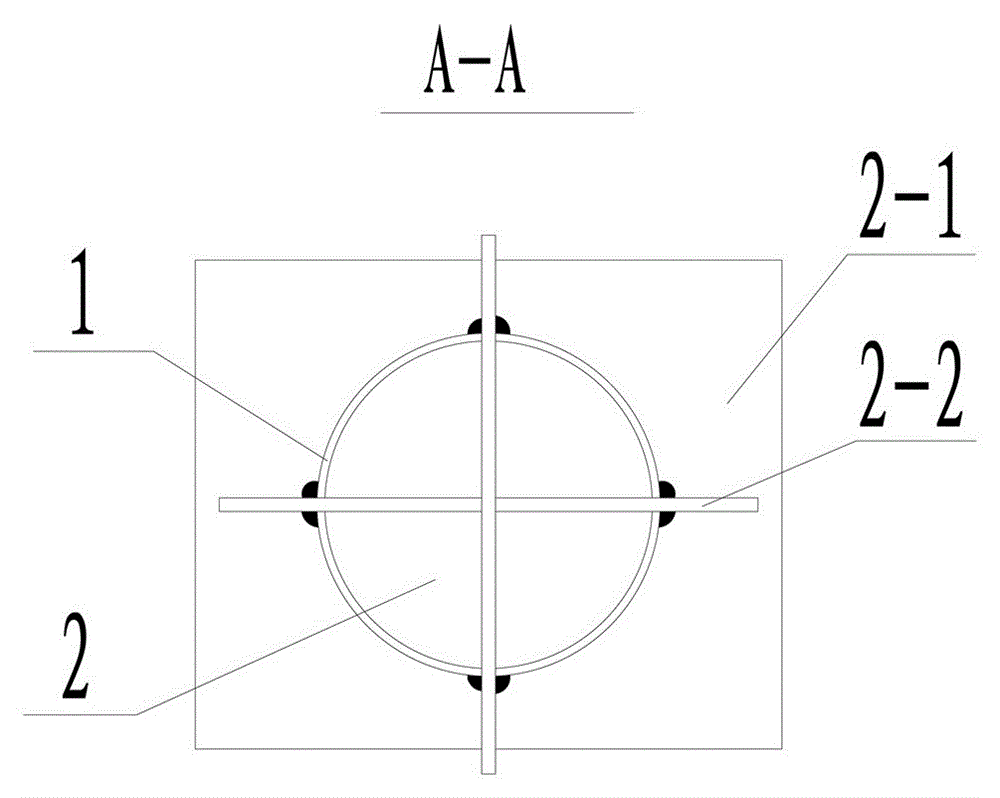

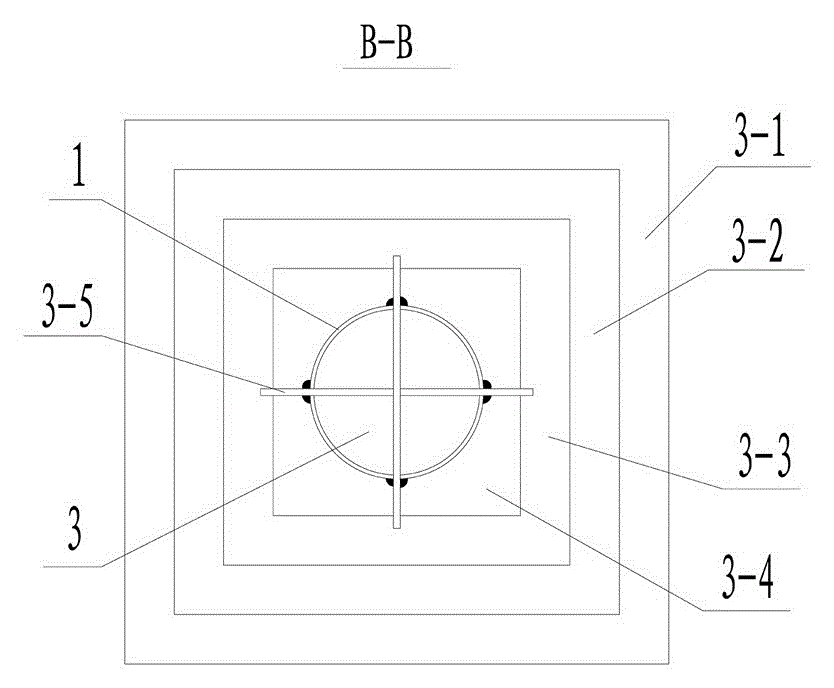

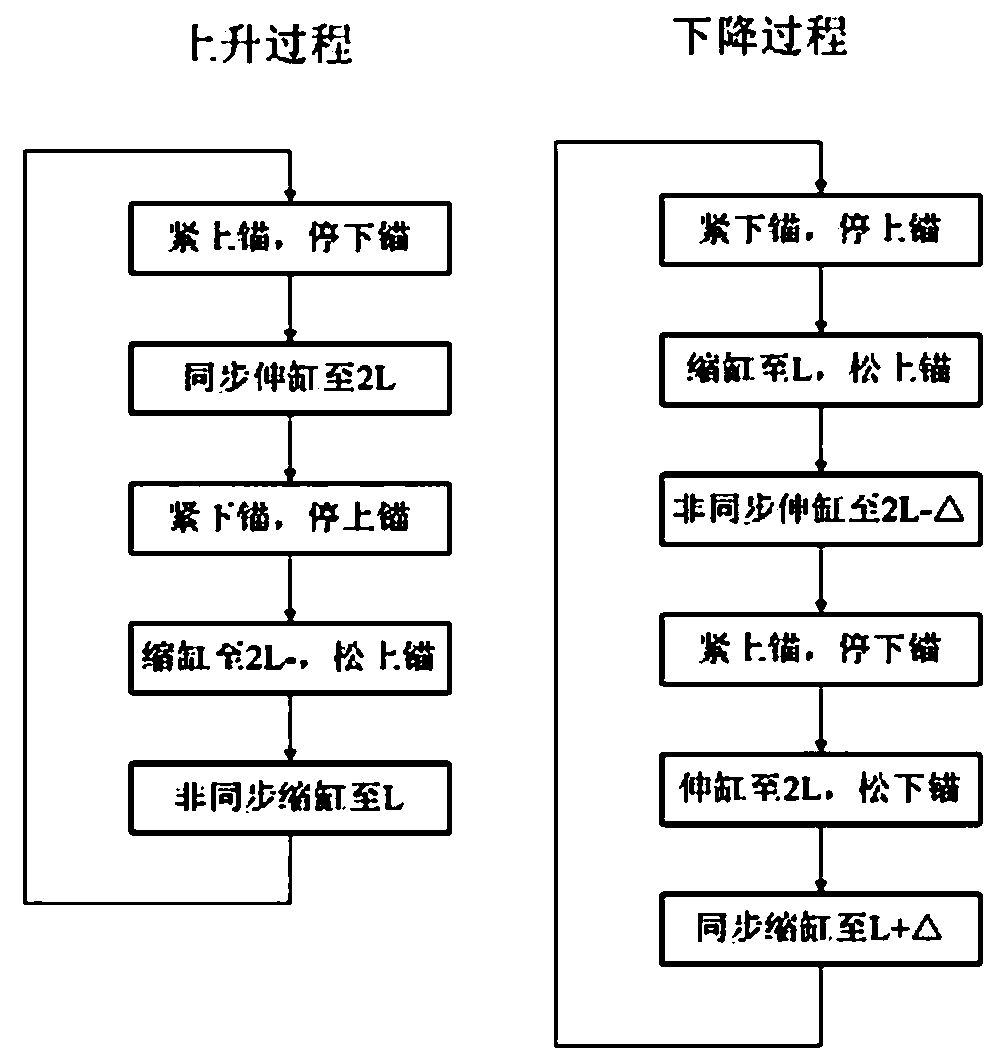

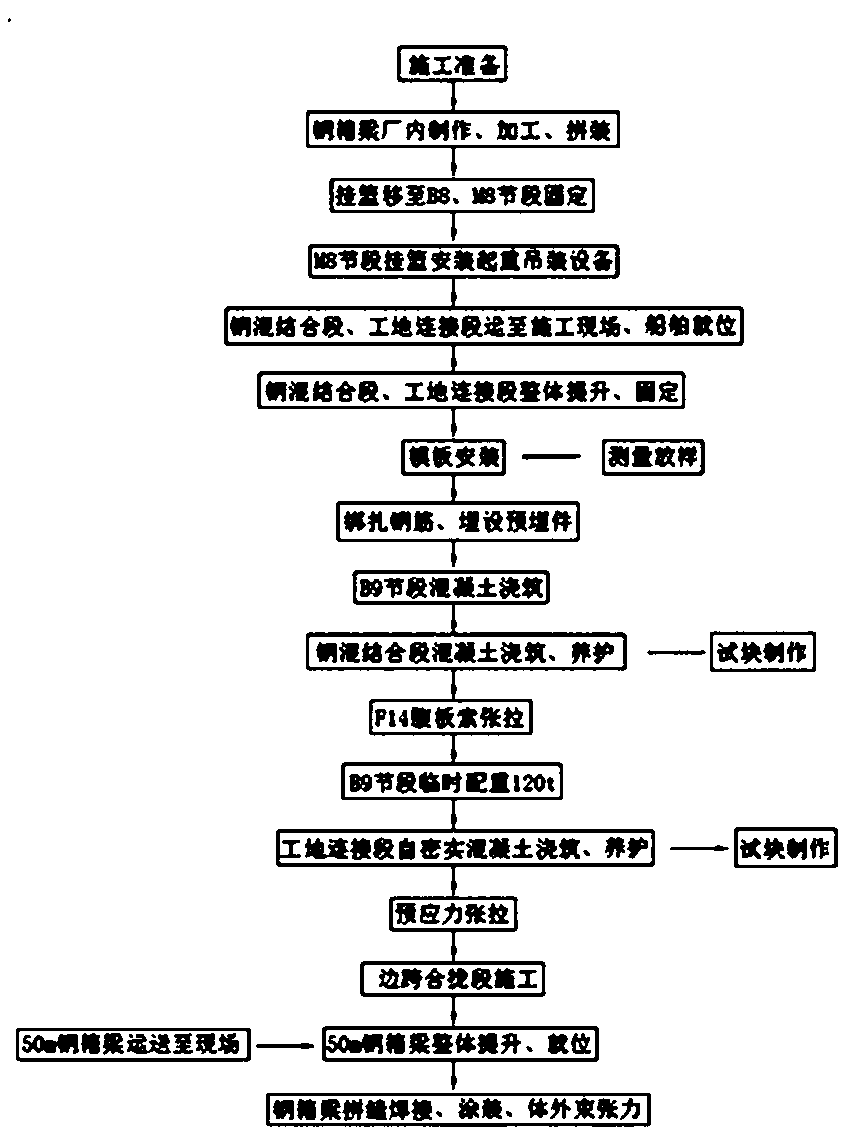

Hydraulic lifting and hoisting method for steel-concrete combined section

PendingCN114319108ASmall construction impactImprove construction efficiencyBridge erection/assemblyConcrete beamsControl system

The invention discloses a method for hydraulic lifting and hoisting of a steel-concrete combined section, which comprises the following steps: S1, preparation before hoisting: assembling the steel-concrete combined section on the ground, and mounting a lifting lug and a lower lifting appliance at the top of the steel-concrete combined section; meanwhile, a bailey truss and an ultra-large component hydraulic lifter are installed on the concrete beam, and a special lifting appliance is connected with a lifting point of the lifter; s2, trying to lift: lifting the reinforced concrete section to be 100mm away from the ground, leveling the reinforced concrete section, and standing for 12 hours; s3, formal lifting is conducted, specifically, after the steel-concrete combined section is lifted to the position close to the design position, lifting is suspended, and all lifting points enable the lifted steel-concrete combined section to be accurately in place through the fine adjustment and inching functions of a computer synchronous control system; and S4, graded unloading is conducted, specifically, all loads of the steel-concrete combined section are transferred to a concrete beam, and then hydraulic lifting equipment and temporary lifting measures are dismantled. The construction quality can be effectively guaranteed, the construction efficiency is improved, the construction period is shortened, the construction risk is reduced, and the construction cost is controlled.

Owner:HANGZHOU LOCAL RAILWAY DEV +1

Dismounting and transporting trolley

The invention discloses a dismounting and transporting trolley comprising an upper trolley and a lower trolley. The upper trolley is located above the lower trolley and comprises a closed upper frame, roller wheels are arranged at the bottom of the upper frame, and the upper frame is also provided with two support bars arranged in parallel; the lower trolley comprises a lower frame with an opening at one end, the roller wheels are arranged at the bottom of the lower frame, and the lower frame is detachably connected to the upper frame. The dismounting and transporting trolley has simple structure and convenient operation, the dismounting and the transporting of a material flow valve and a corrugated pipe in a COREX (Iron Making By Smelting Reduction)-C3000 shaft furnace can be quickly realized, the labor intensity of an operator is reduced, the construction time is shortened, the replacing speed of an ore charge distributor is quickened and the working efficiency is improved.

Owner:MCC BAOSTEEL TECH SERVICE

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girderin concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solvesthe practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

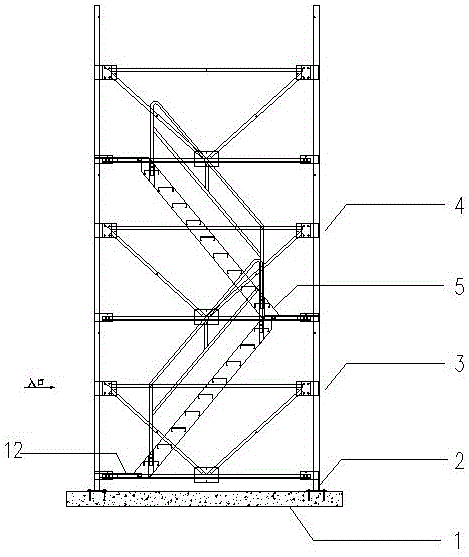

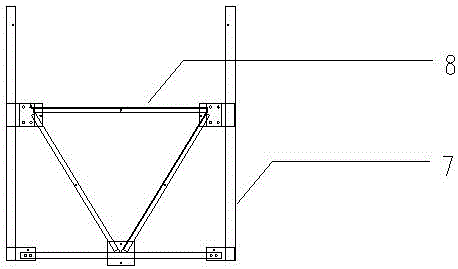

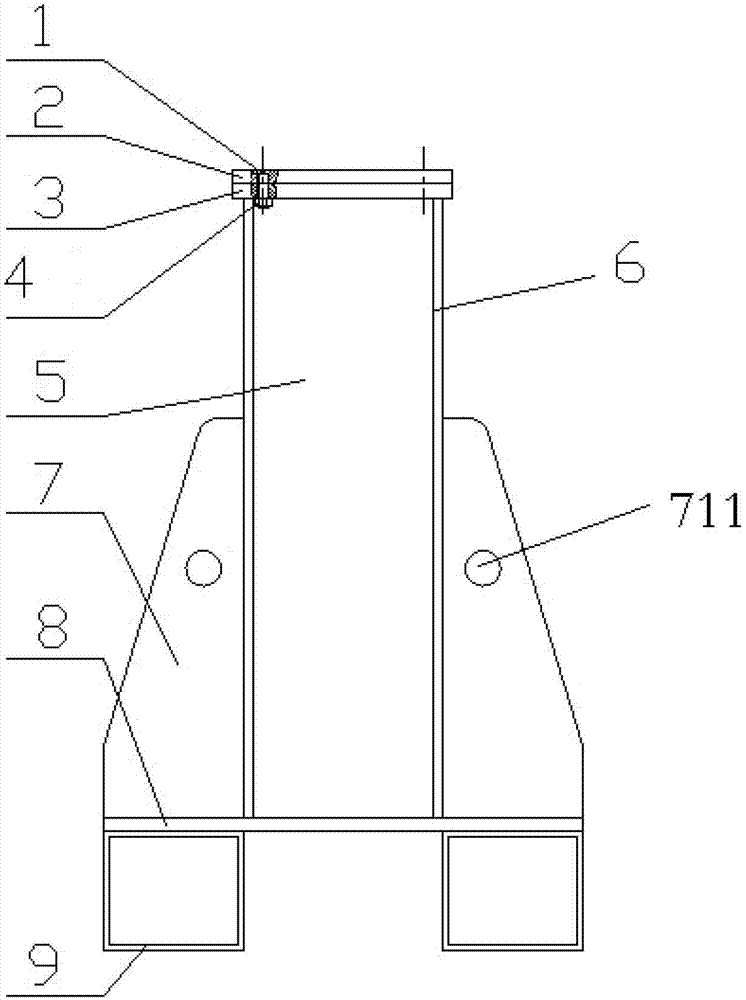

Safety climbing ladder and its installation method

The invention discloses a safety ladder and an installation method thereof. The safety ladder includes a ladder foundation, the ladder foundation is connected to the main body of the ladder through a base, and the main body of the ladder includes a standard section, an entrance section, and a staircase arranged inside the standard section and the entrance section; The entrance section includes four entrance poles placed in a rectangle, the entrance poles on the left and right sides are connected by long cross-links, the entrance poles on the rear side are connected by short cross-links, and the entrance poles on the front side are provided with entrance cross-links; The standard section includes four vertical poles placed in a rectangle, the vertical poles on the left and right sides are connected by long horizontal links, and the vertical poles on the front and rear sides are connected by short horizontal links. When installing, first install the base on the ladder foundation, then install the entrance section on the base, then install the standard section on the entrance section, install the stairs inside the entrance section and the standard section, install the anti-throwing net inside the entrance section and the standard section, and finally Install the attachment on the standard section. The invention is detachable, can be pre-assembled, is convenient to transport, and can extend the height of the ladder.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Suspension bridge suspension cable replacement system and method for replacing suspension bridge suspension cables

ActiveCN106480822BEasy to installEasy to removeBridge structural detailsBridge erection/assemblyEngineeringWinch

The invention discloses a system for changing a sling of a suspension bridge and a method for changing the sling of the suspension bridge, and relates to the technical field of change of the sling of the suspension bridge. The system comprises a sling clip, a towing wheel, a lifting appliance and two winches, wherein the towing wheel is arranged on the sling clip and comprises a pedestal and a plurality of rolling wheels; the rolling wheels are arranged on the pedestal; the plurality of rolling wheels are arranged along the arc-shaped path side by side to form an arc-shaped traction path; the lifting appliance is arranged above the sling clip and is used for lifting the sling to switch between the sling clip and the traction path; and the winches are connected with anchor heads arranged on two end parts of the sling correspondingly through steel wire ropes. According to the system and the method, the sling can be changed quickly and conveniently under the condition of low lifting height.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU +1

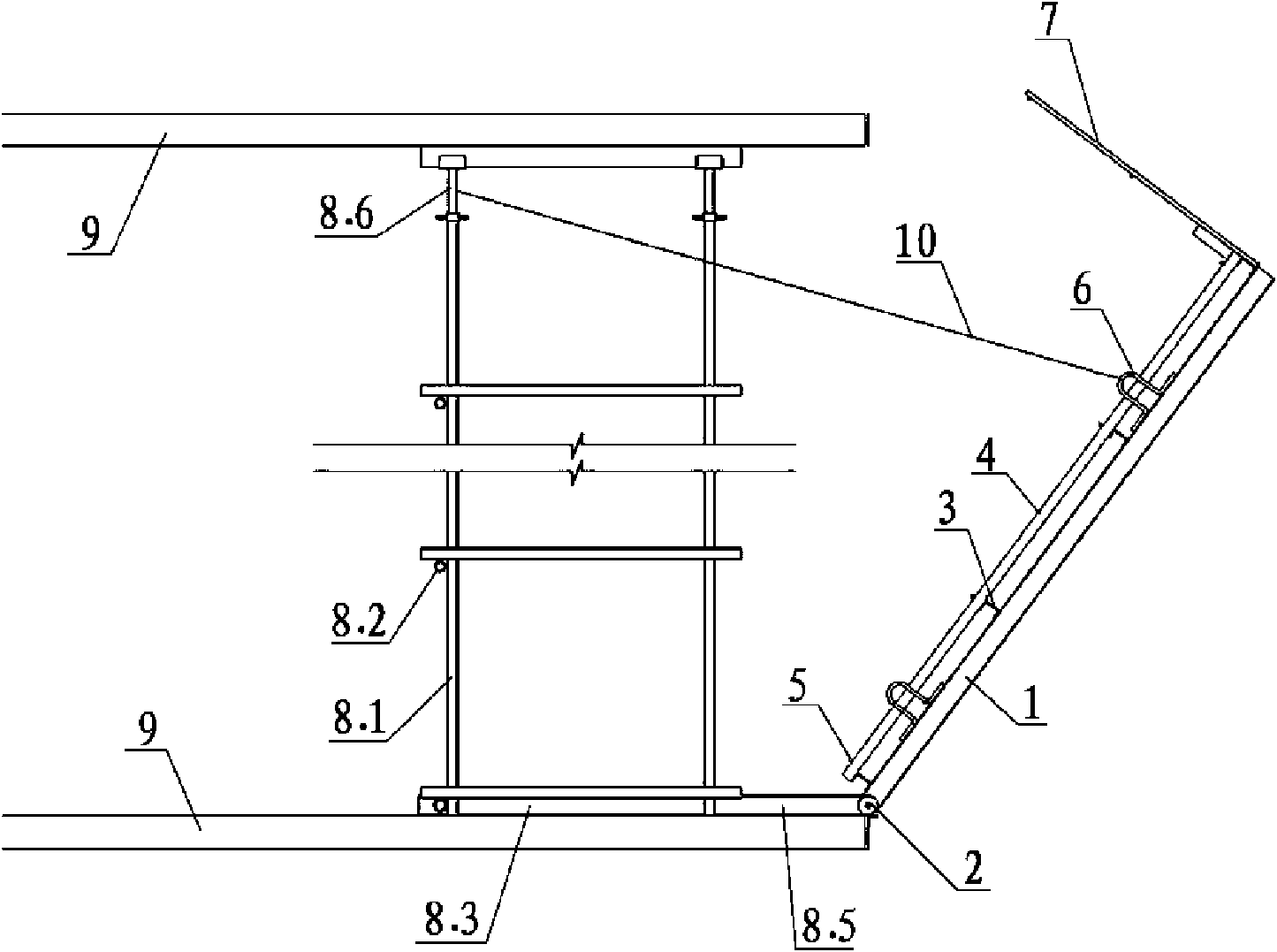

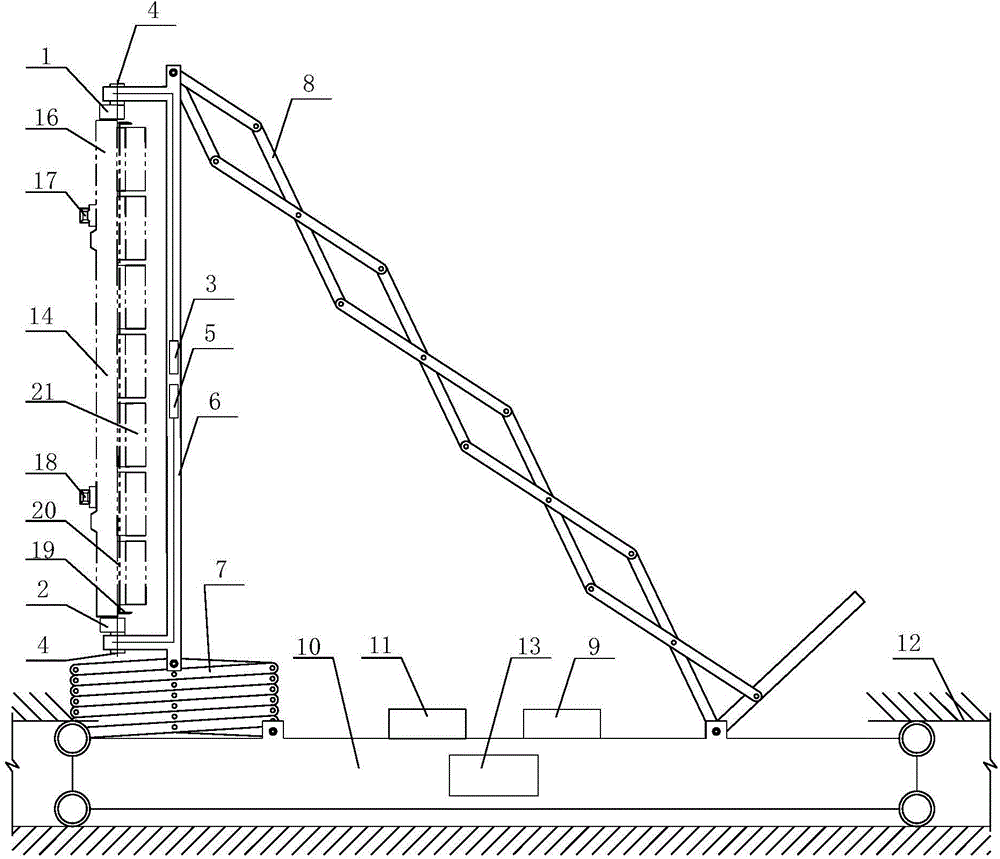

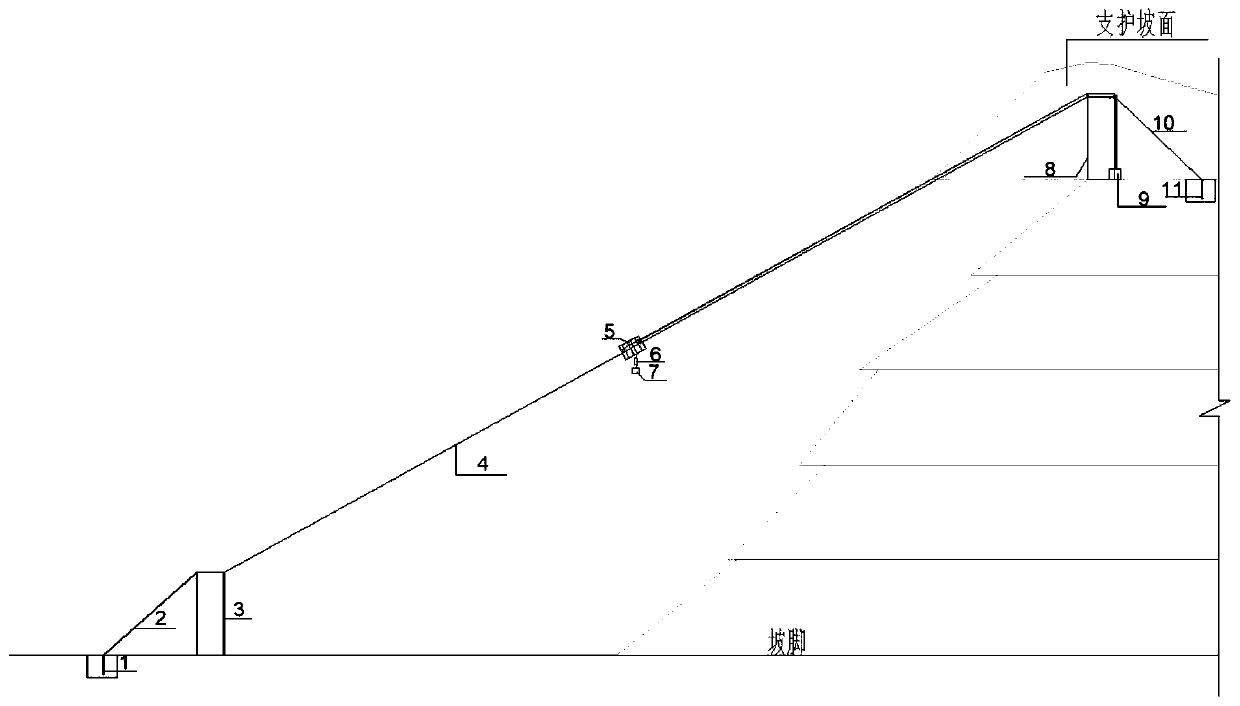

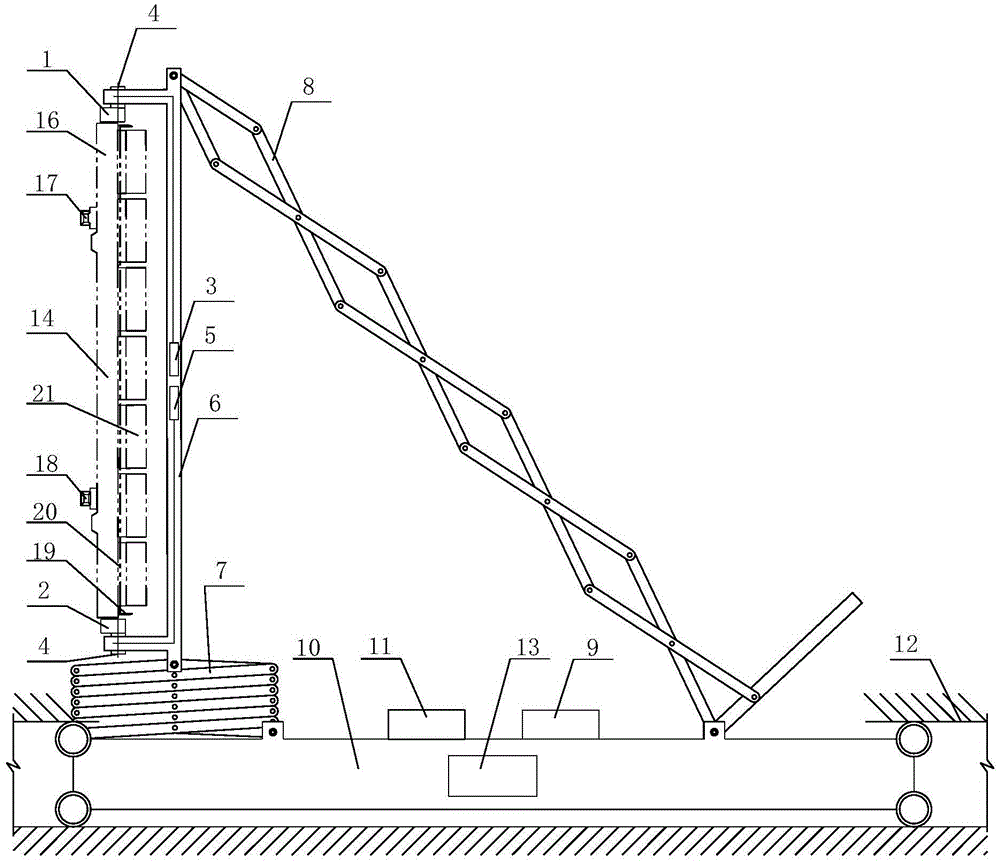

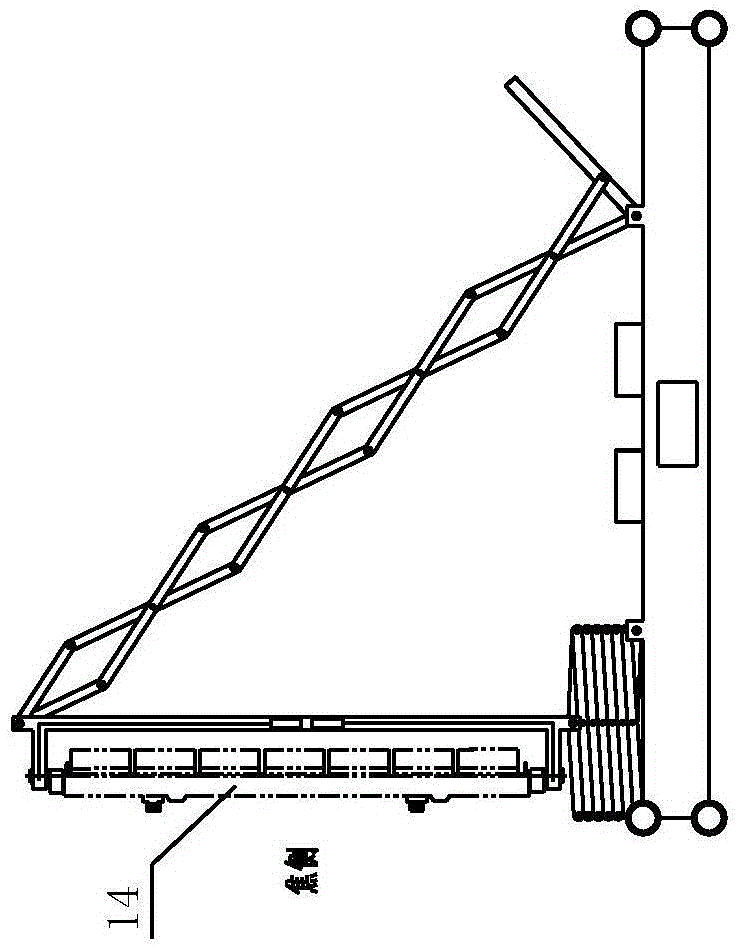

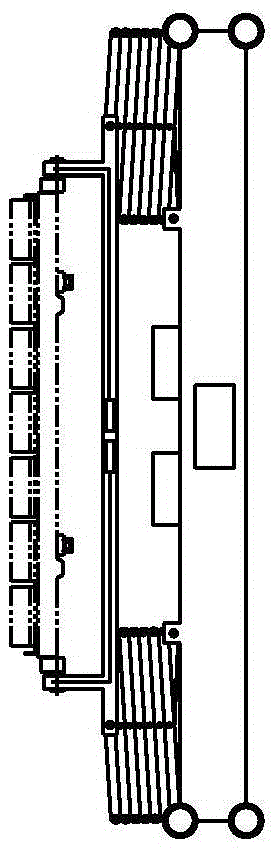

High slope supporting material conveying device

PendingCN111003430AEasy to assemble and disassembleBad luckMechanical conveyorsArchitectural engineeringTower

The invention provides a high slope supporting material conveying device. The high slope supporting material conveying device comprises a slope bottom fixing ground anchor and concrete anchor block, aslope bottom anchoring steel wire rope, a slope bottom tower, a trolley walking track, a walking trolley, an electric hoist, a slope top tower, a winch, a slope top anchoring steel wire rope, and a slope top fixing ground anchor and concrete anchor block, wherein the slope bottom fixing ground anchor and concrete anchor block, the slope bottom anchoring steel wire rope, the slope bottom tower, the trolley walking track, the slope top tower, the slope top anchoring steel wire rope, the slope top fixing ground anchor and concrete anchor block are sequentially arranged in the slope direction, the walking trolley is arranged on the trolley walking track in a sliding mode, the winch is installed on the slope top tower, and the winch steel wire rope is connected with the walking trolley throughthe slope top tower. The device is simple in structure, convenient to manufacture, capable of ensuring that materials can move up and down while being transported along the slope surface, capable ofimproving the slope construction efficiency, convenient to disassemble and capable of being repeatedly used.

Owner:MCC TIANGONG GROUP

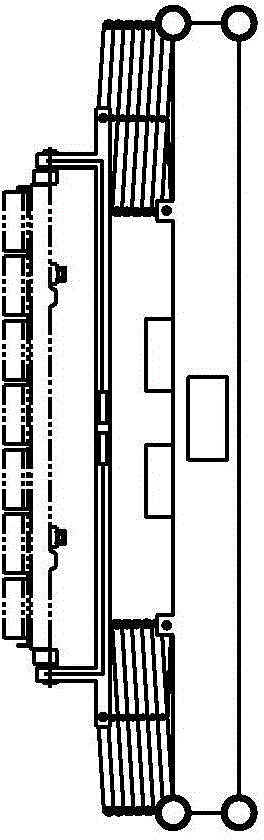

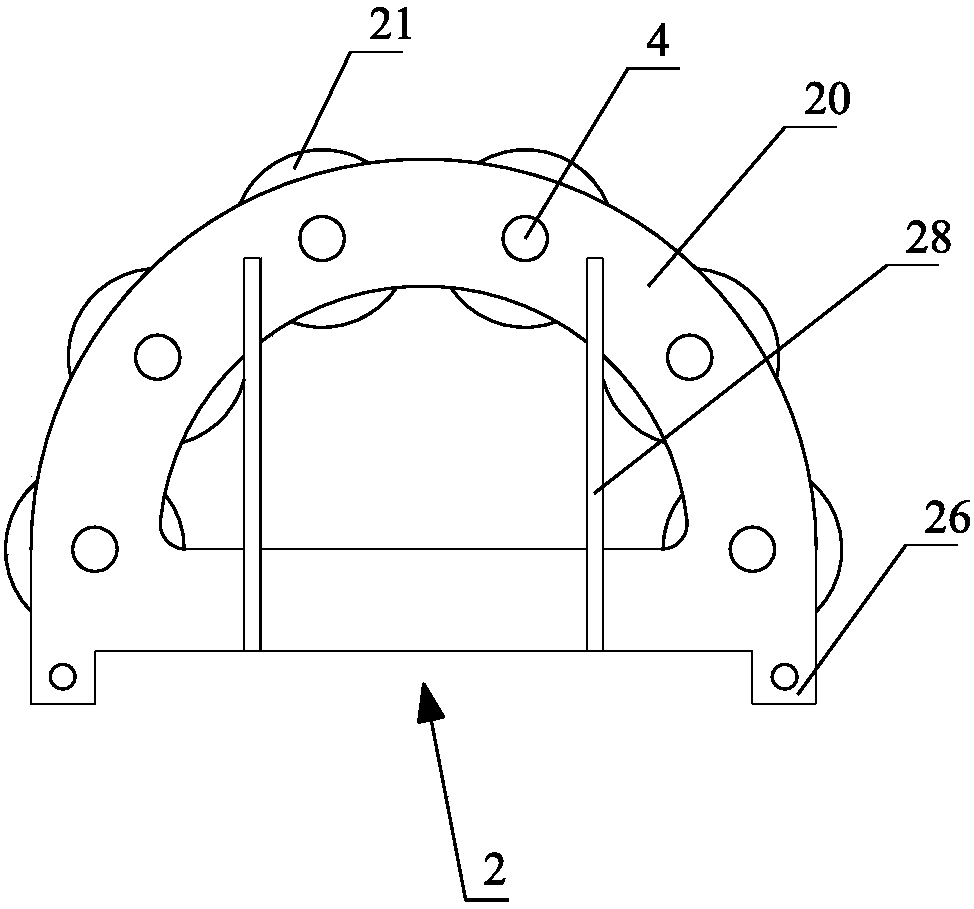

Clearing support tool of rotor of MW (megawatt)-level permanent magnetic direct drive wind driven generator

ActiveCN103187841BBad luckQuality improvementManufacturing stator/rotor bodiesWind drivenArchitectural engineering

Owner:JIANGSU CRRC ELECTRIC CO LTD

Adjustable support and its construction method

The invention provides an adjustable support and a construction method thereof. The adjustable support is arranged between a basement ceiling and the ground and is formed by a main force transfer component, the upper part of the main force transfer component is connected with an adjustable head component, the lower end of the main force transfer component is connected with a load dispersing component, the main force transfer component comprises a vacancy filling part, a jack ejector rod on a jack ejector base of the main force transfer component is in contact connection with the adjustable head component which has a linear upward movement trail on the main force transfer component, the vacancy filling part consists of four valve ring vacancy blocks, the inner diameter and the outer diameter of the vacancy filling part are equal to those of the main force transfer component, the vacancy filling part is inlaid between the main force transfer component with the adjusted supporting height and the adjustable head component. All parts are prefabricated in a factory, and are assembled, adjusted, fixed and erected in site. The adjustable support assists large-scale overhang steel structures or large-span steel structure in constructing, so that the tedious condition of overlapping a scaffold is avoided; the height of the head component of the adjusted support is adjustable, so that the problem that supporting stand columns cannot be erected due to the fact that the absolute length of the supporting stand columns is greater than the interlayer spacing of a basement is solved; the adjustable support can be conveniently detached, transferred and reused.

Owner:CHINA CONSTR FIRST DIV STEEL STRUCTUREENG

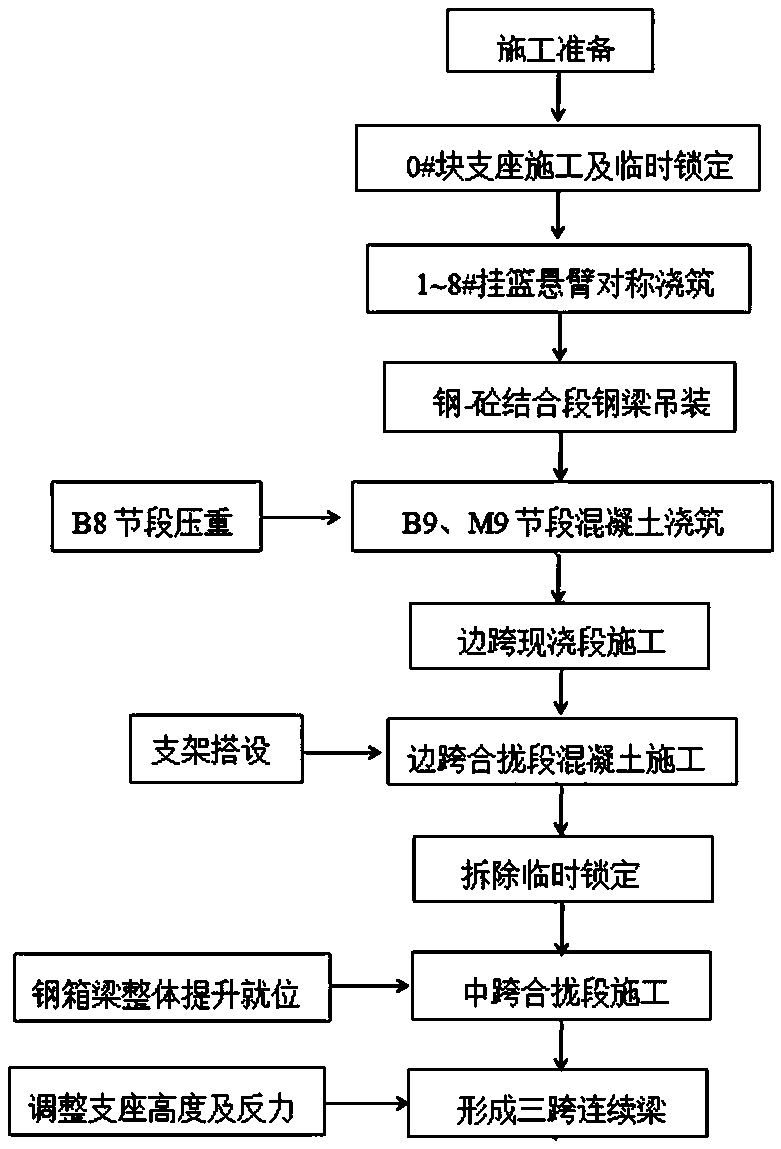

Three-span variable-height steel-concrete mixed continuous beam construction method

PendingCN111501558AShort lifting timeReduce temporary occupancy timeBridge erection/assemblyContinuous beamRebar

The invention relates to the technical field of bridge construction, in particular to a three-span variable-height steel-concrete mixed continuous beam construction method which comprises the following steps: firstly, constructing a NO. 0 block of a steel-concrete mixed continuous beam; after completion, symmetrically pouring first to eighth hanging basket cantilevers; after completion, hoisting asteel-concrete combined section; during hoisting, arranging a rhombus hanging basket at the position of an eighth poured beam body section, arranging a hoisting platform on the rhombus hanging basket, wherein the hoisting platform is provided with four hydraulic lifters, and the four hydraulic lifters are used for hoisting the steel box girder of the steel-concrete combined section to a mountingposition of the steel box girder from a river middle girder transporting ship; after the steel box girder is hoisted in place, creating a steel-concrete combined section reinforced concrete structureof the girder section, so that a steel-concrete combined section is formed; removing the temporary lock of the NO. 0 block; constructing a mid-span closure section and forming the three-span variable-height steel-concrete mixed continuous beam. The invention has the advantages that hoisting time is short, the traffic can be opened after the vehicle is in place, the temporary occupation time of roads and navigation channels is shortened, and the adverse effect on social traffic is reduced.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

Container type movable surfacing equipment

PendingCN109693114ACompact designReliable designOther manufacturing equipments/toolsReliability engineeringBuilding construction

Owner:LOESCHE (SHANGHAI) CO LTD +1

Dismounting and transporting trolley

The invention discloses a dismounting and transporting trolley comprising an upper trolley and a lower trolley. The upper trolley is located above the lower trolley and comprises a closed upper frame, roller wheels are arranged at the bottom of the upper frame, and the upper frame is also provided with two support bars arranged in parallel; the lower trolley comprises a lower frame with an opening at one end, the roller wheels are arranged at the bottom of the lower frame, and the lower frame is detachably connected to the upper frame. The dismounting and transporting trolley has simple structure and convenient operation, the dismounting and the transporting of a material flow valve and a corrugated pipe in a COREX (Iron Making By Smelting Reduction)-C3000 shaft furnace can be quickly realized, the labor intensity of an operator is reduced, the construction time is shortened, the replacing speed of an ore charge distributor is quickened and the working efficiency is improved.

Owner:MCC BAOSTEEL TECH SERVICE

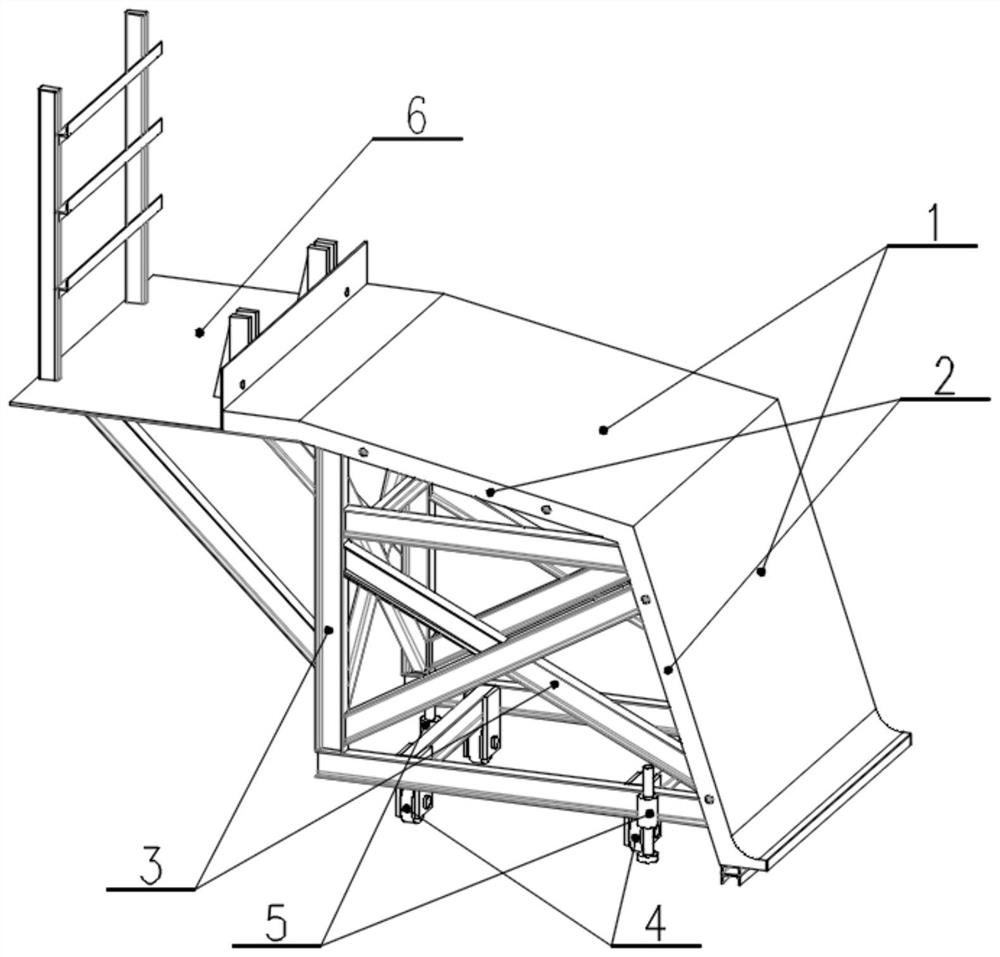

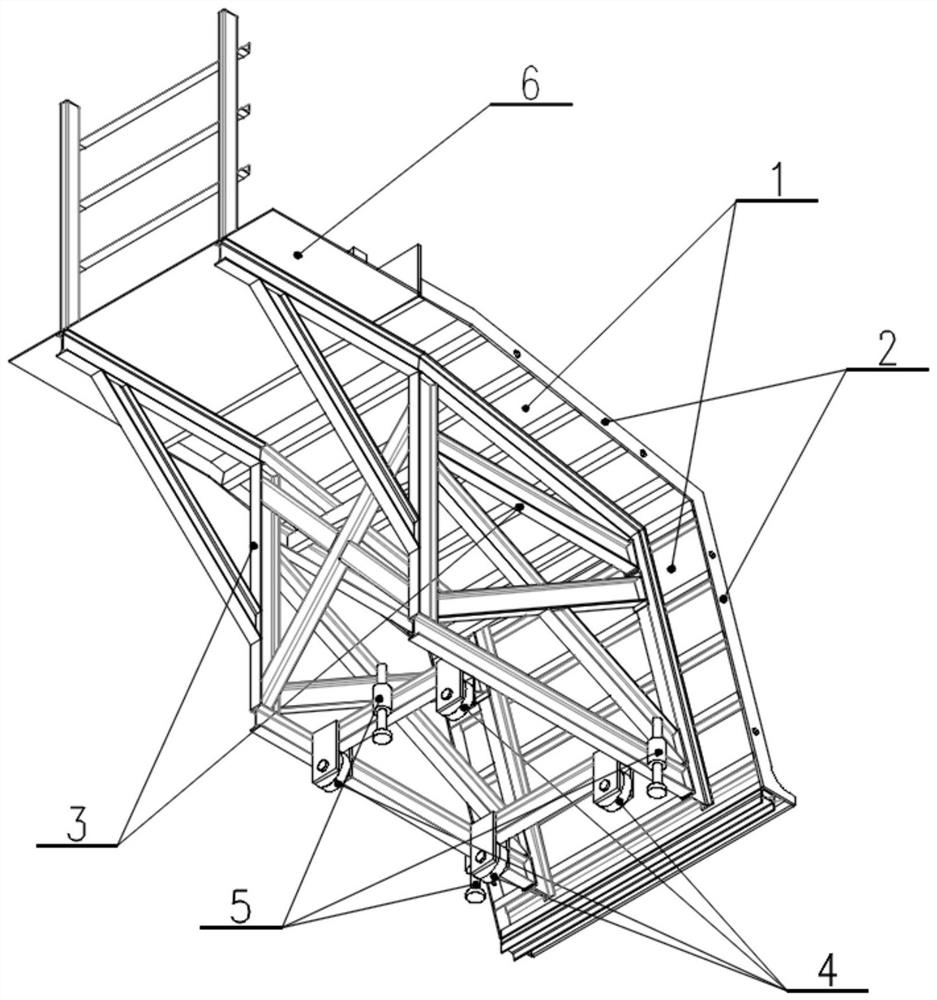

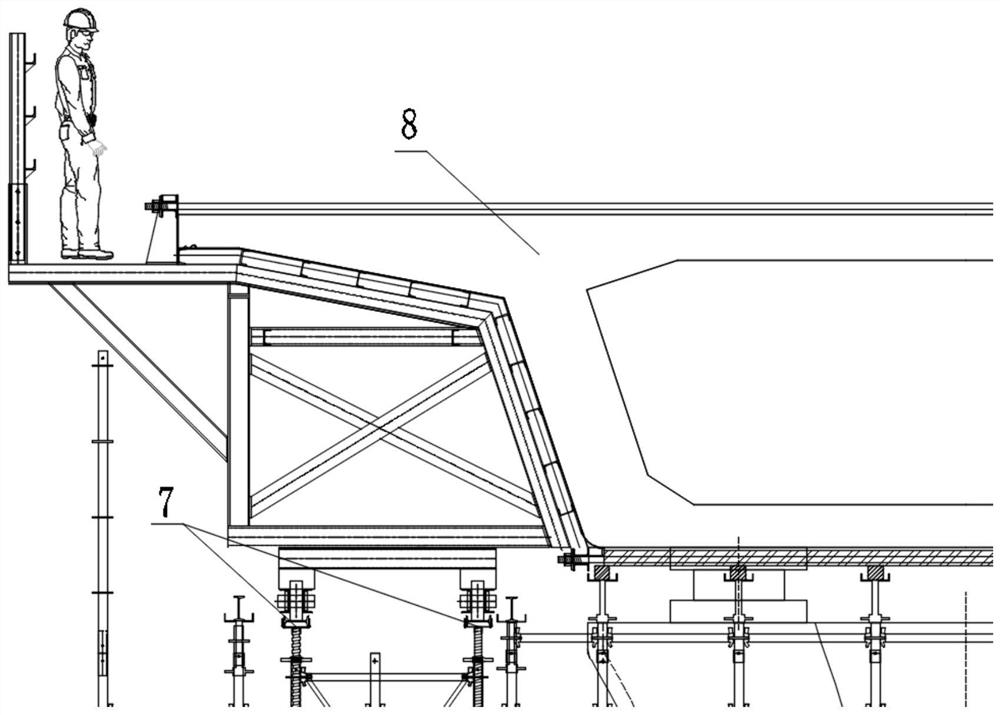

Movable cast-in-place beam side formwork device and using method thereof

PendingCN111749144AHeight adjustableEasy turnoverBridge erection/assemblyModular unitIndustrial engineering

The invention relates to the technical field of cast-in-place beams, and particularly relates to a movable cast-in-place beam side formwork device and a using method thereof. The surface of a workingplate is similar to the side face of a cast-in-place beam, the end, away from the cast-in-place beam, of the working plate extends upwards, and a matching hole is formed in the position, higher than the beam face of the cast-in-place beam, of the working plate in the direction close to the cast-in-place beam; a supporting truss is arranged at the bottom of the working plate and used for supportingthe working plate, and walking wheels and an adjusting jacking are arranged at the bottom of the supporting truss. Compared with the prior art, the device provided by the invention has the advantagesthat the working plate matches the two sides of the cast-in-place beam and is connected with the cast-in-place beam through split bolts, so that the pouring quality is guaranteed, and hoisting is facilitated; the adopted modular unit design is suitable for cast-in-place beam construction of various spans, and the applicability is high; the adjusting jacking is arranged, so that the height of a formwork is convenient to adjust; and by adopting a roller sliding design and matching the walking wheels with a channel steel rail, the formwork is very convenient to turn over and transfer.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

A rotary lifting device for repairing coke oven door

ActiveCN104388102BEasy maintenanceImprove maintenance efficiencyCoke oven doors/closuresControl systemCoke oven

The invention discloses a rotary lifting device for repairing a coke oven door. The rotary lifting device comprises a main frame, a docking mechanism, a rotating mechanism, a lifting mechanism, a traveling mechanism and a control system, wherein the docking mechanism and the rotating mechanism are arranged on the main frame; the main frame is connected with the traveling mechanism by virtue of the lifting mechanism; the traveling mechanism can move along a ground guide rail; and the control system controls each mechanism to finish the actions such as docking and clamping, rotating, lifting, elevating and traveling of a traveling trolley on the coke oven door. Compared with the prior art, the rotary lifting device disclosed by the invention has the beneficial effects that 1) the device is suitable for two different bolt structures of a pressing mode and a rotating mode; 2) a main frame of a single-side frame structure is adopted, each part of the oven door is convenient to maintain, and the maintenance efficiency is high; 3) the operation is stable and reliable; 4) the lifting action is realized by virtue of retraction and rotation of a folding arm, and the operation is stable and reliable; 5) the left and right folding arms synchronously retract, so that the oven door is lifted to a proper height, and the working conditions are improved; and 6) a set of device can be shared on the machine and coke side, and the cost is saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

A rapid construction method of T-beams in the shed opening of the upper-span business line in a narrow space

ActiveCN108589568BQuick erectionSolve problemsProtective constructionArchitectural engineeringStringer

The invention discloses a quick construction method for an over-crossing business line hangar tunnel T-shaped girder in narrow space. The quick construction method includes the following steps that ahangar tunnel foundation pit is dug according to a designed location and a hangar tunnel stand column is constructed; a hangar tunnel vertical girder is constructed, a bracket support is pre-buried and a gantry crane walking railway is set up on the bracket support; a distributive girder and a form board are laid on the top of the hangar tunnel vertical girder to be used as a T-shaped girder primary prefabricating platform, and a gantry crane is arranged on the gantry crane walking railway; a T-shaped girder is poured on the T-shaped girder primary prefabricating platform and hoisted to a vacant zone; if the vacant zone can not be laid fully, then the step is conducted repeatedly; the T-shaped girder primary prefabricating platform is demolished, and the form board is laid on the T-shapedgirder to be used as a T-shaped girder secondary prefabricating platform; a T-shaped girder is poured on the T-shaped girder secondary prefabricating platform and hoisted to a vacant zone and erectingof the T-shaped girder is completed; the T-shaped girder secondary prefabricating platform is demolished and auxiliary facilities are exerted; and other unnecessary facilities are demolished. The problem of insufficient prefabricating places can be solved and the risk of the hoisting operation near the business line is avoided.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com