Three-span variable-height steel-concrete mixed continuous beam construction method

A technology of mixed continuous and construction methods, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unfavorable waterway use, large site impact, complex construction technology, etc., and shorten the temporary occupation time and hoisting time Short, the effect of improving the construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

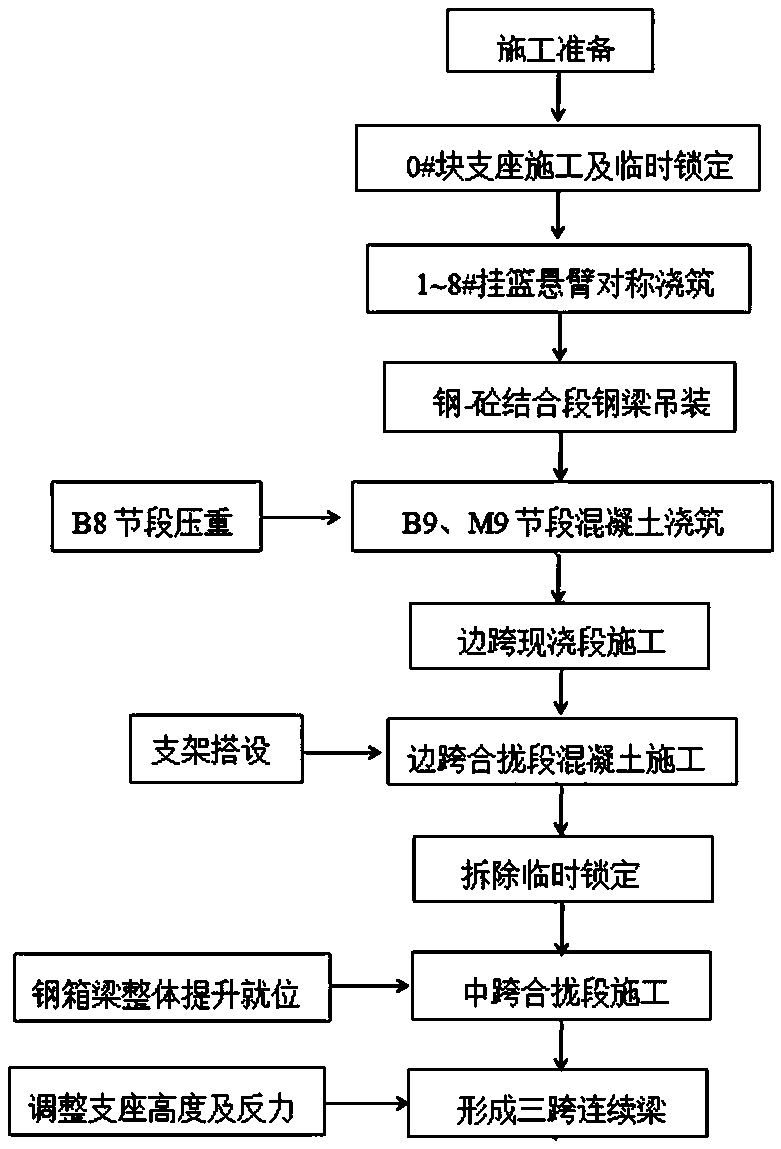

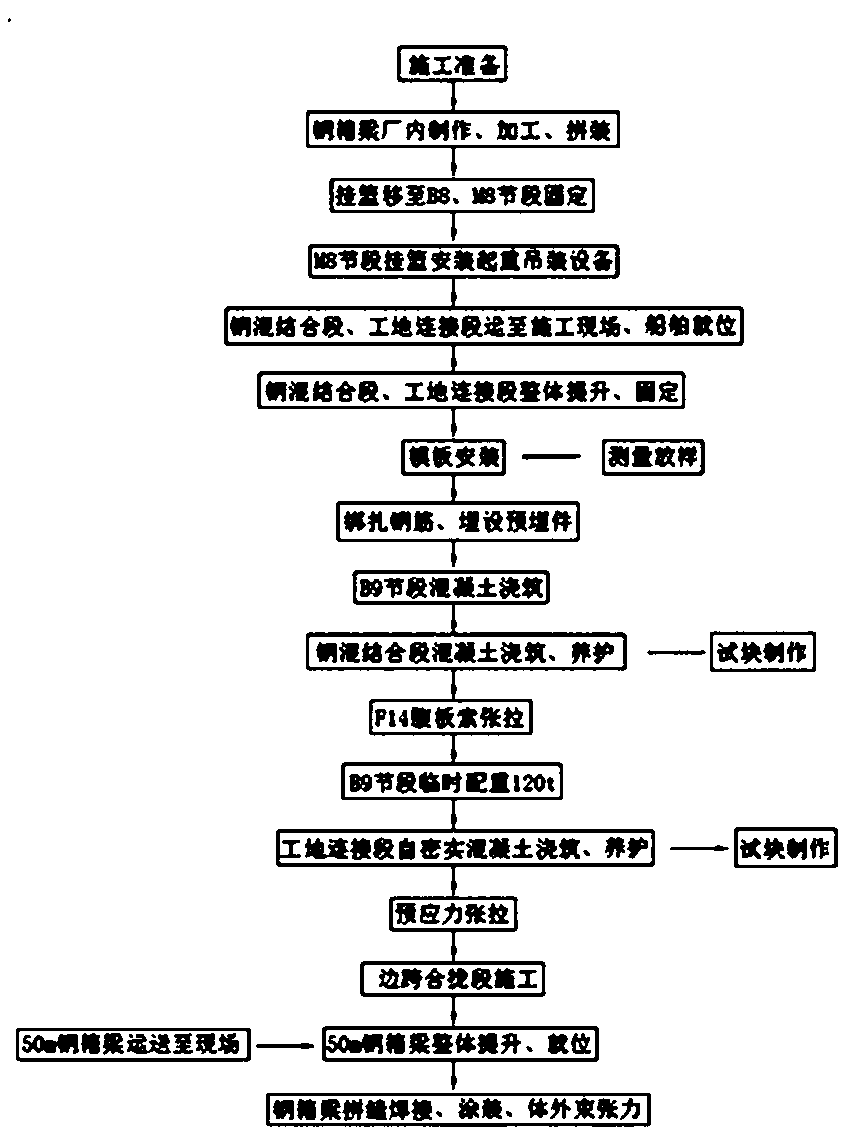

[0018] Example: as Figure 1 to Figure 3 As shown, the construction method of the three-span variable-height steel-concrete hybrid continuous beam in this embodiment is realized by the following steps, taking a certain actual project as an example:

[0019] 1) The segmental box girder of block 0# is cast-in-situ with cantilever brackets, and temporary locking and caps are set in block 0# for consolidation.

[0020] The construction of block 0# includes the following key points: Pier top treatment: In order to fill the gap on the side of the pier top support, a half brick wall can be built on the four peripheral lines of the pier top, and the height of the brick wall is 3- 5cm, then fill sand in the gap on the top of the pier and sprinkle water to vibrate it, then pour 3-5cm fine-graded concrete, the top surface of the concrete is 2-3mm higher than the support, and finally coat a layer of butter as the bottom mold of the 0# block . When the system conversion is completed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com