Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

702results about How to "Easy to transport and install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

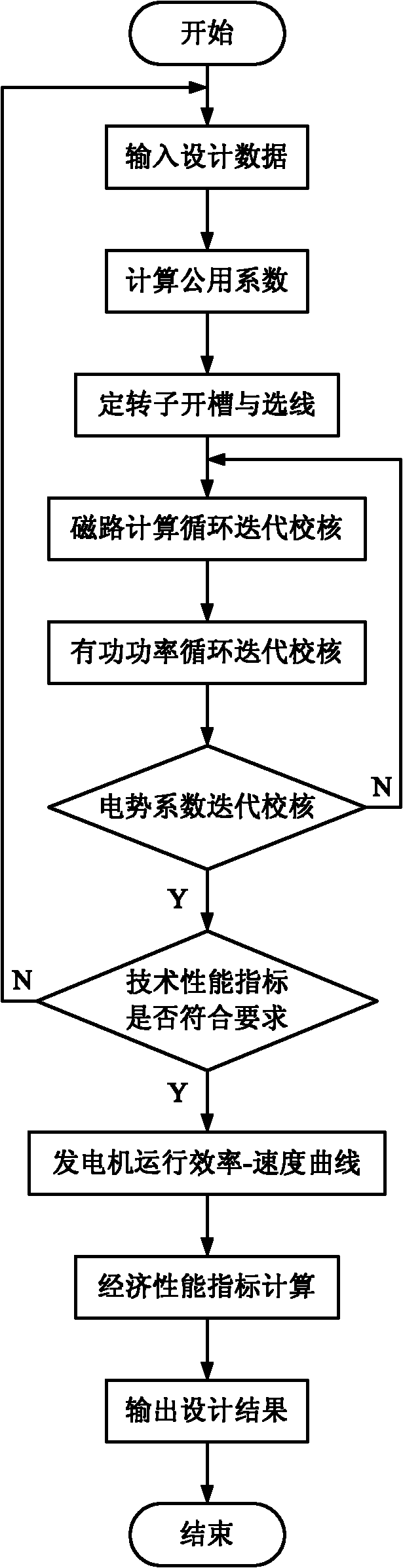

Multi-objective hybrid particle swam optimization design method for double-fed wind power generator

InactiveCN101833607AMeet performance requirementsIncrease cost benefitAC motor controlSpecial data processing applicationsSimulationWind power generation

The invention belongs to the field of motor optimization designs, and relates to a multi-objective hybrid particle swam optimization design method for a double-fed wind power generator. The method comprises the following steps of: (1) determining a constraint condition and a to-be-optimized design variable of the double-fed wind power generator, and establishing sub-objective function equations to form a multi-objective function; (2) constructing variable space by using the to-be-optimized design variable, and constructing non-dominated solution sets of population according to the quality of an objective value; (3) ordering the non-dominated solution sets according a Pareto domination mechanism, determining a population niche by taking a non-dominated solution as a core, establishing a particle speed updating mechanism and finally obtaining an optimal design scheme; manufacturing a mode machine according to the optimal design scheme, inspecting an actual operation index of a motor, and comparing the actual operation index with an index given by the design scheme; and if the actual operation index exceeds a requirement range of operation indexes, adjusting a performance design scheme. Due to the adoption of the motor optimization design method provided by the invention, overall economic benefit and wind energy utilization rate of a wind power generating system can be improved.

Owner:TIANJIN UNIV

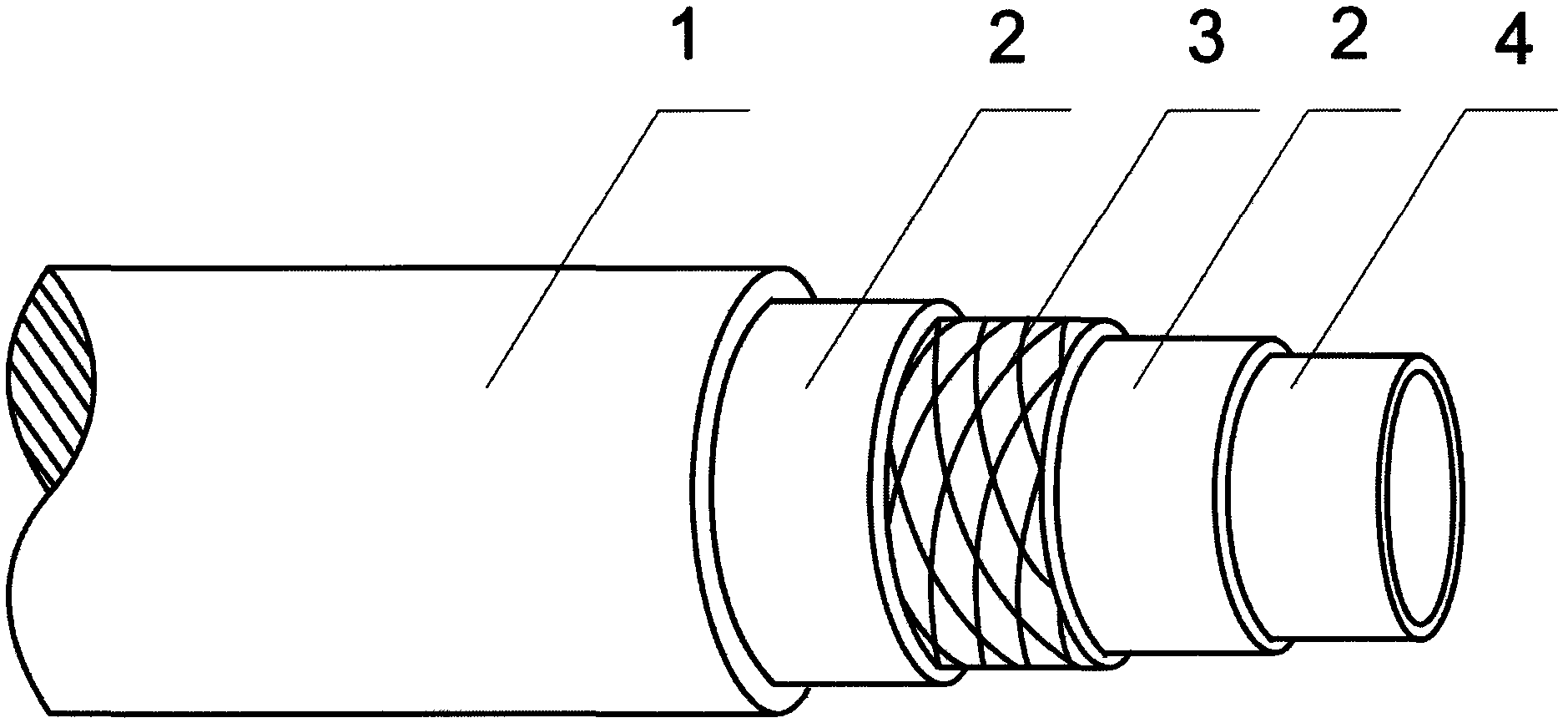

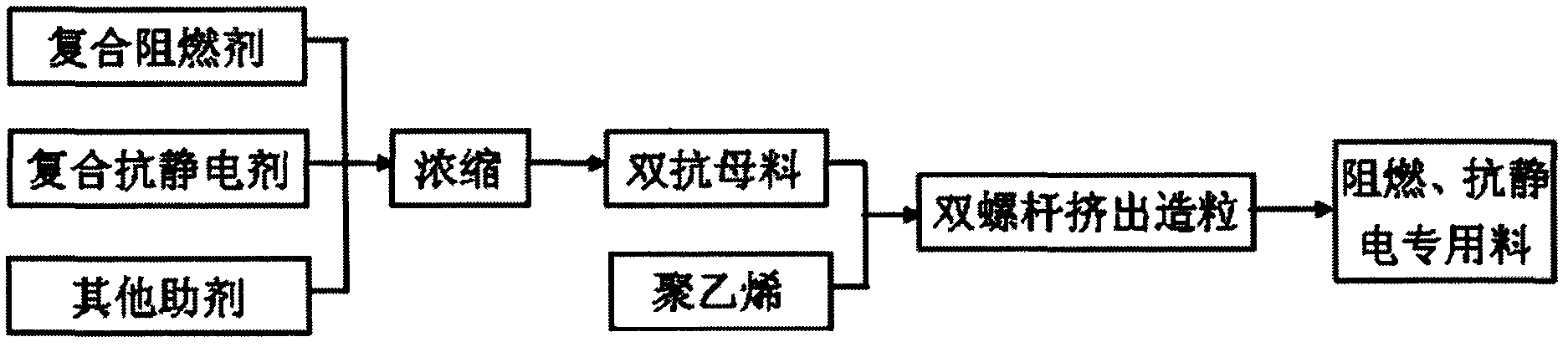

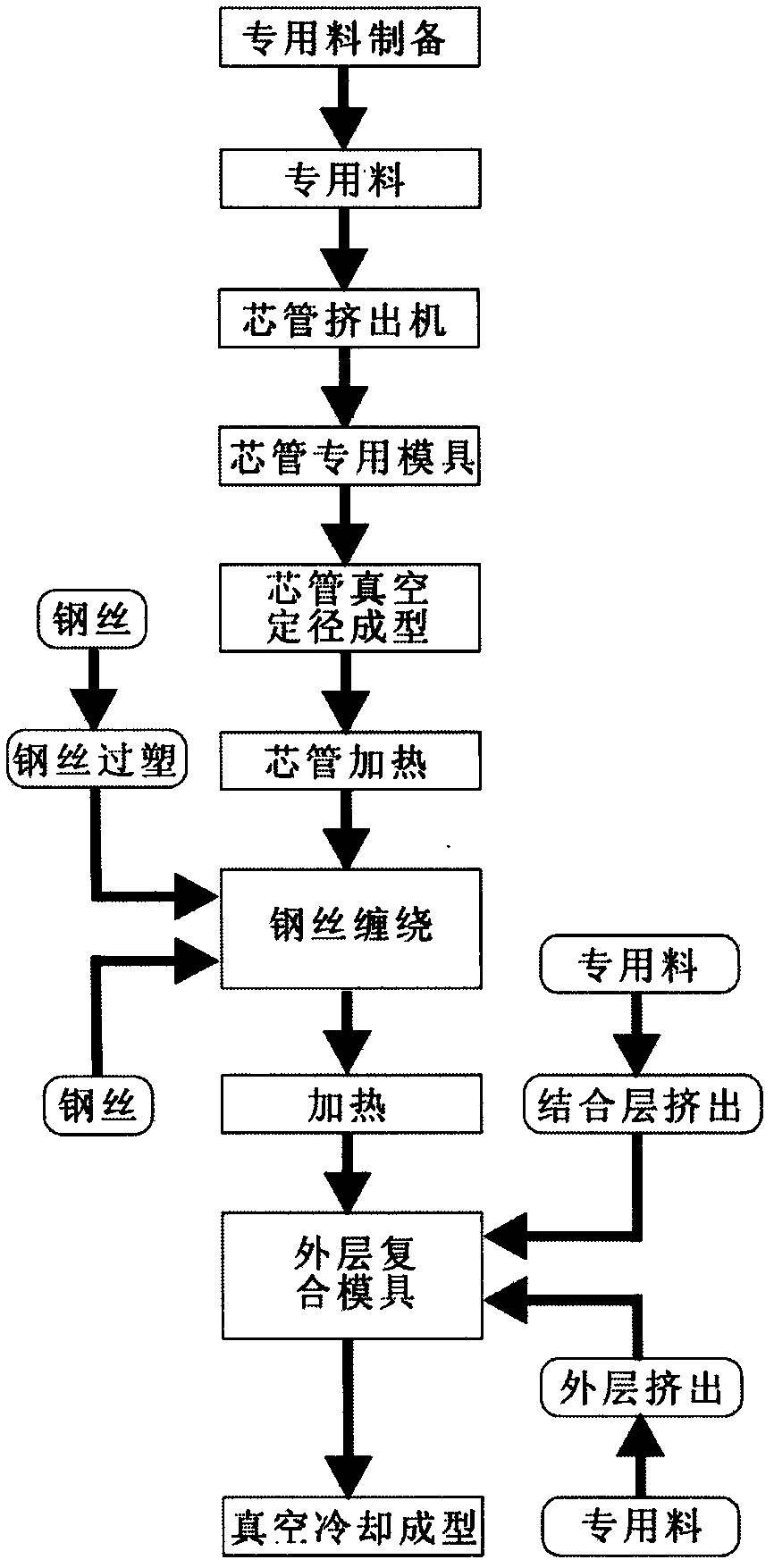

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

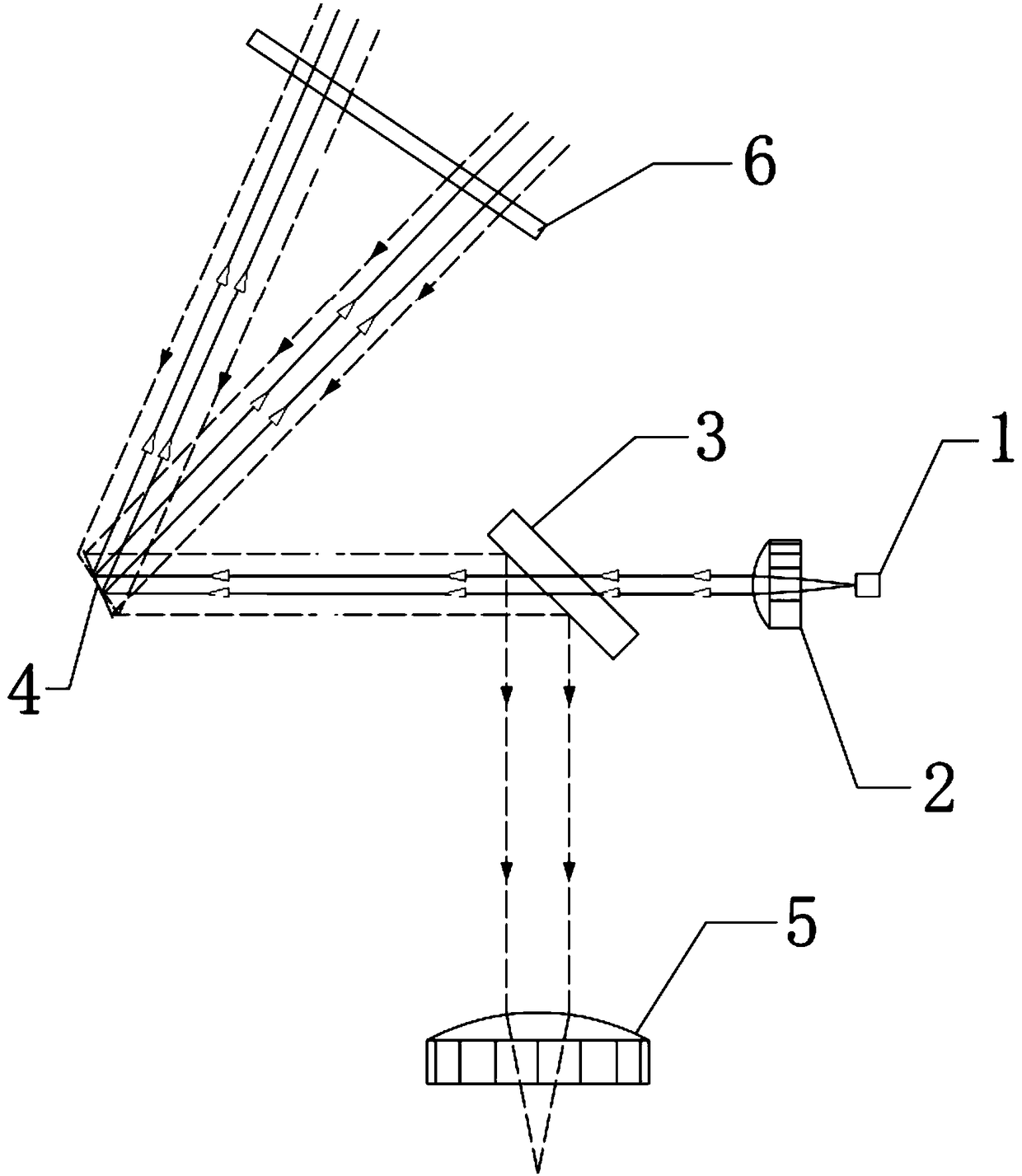

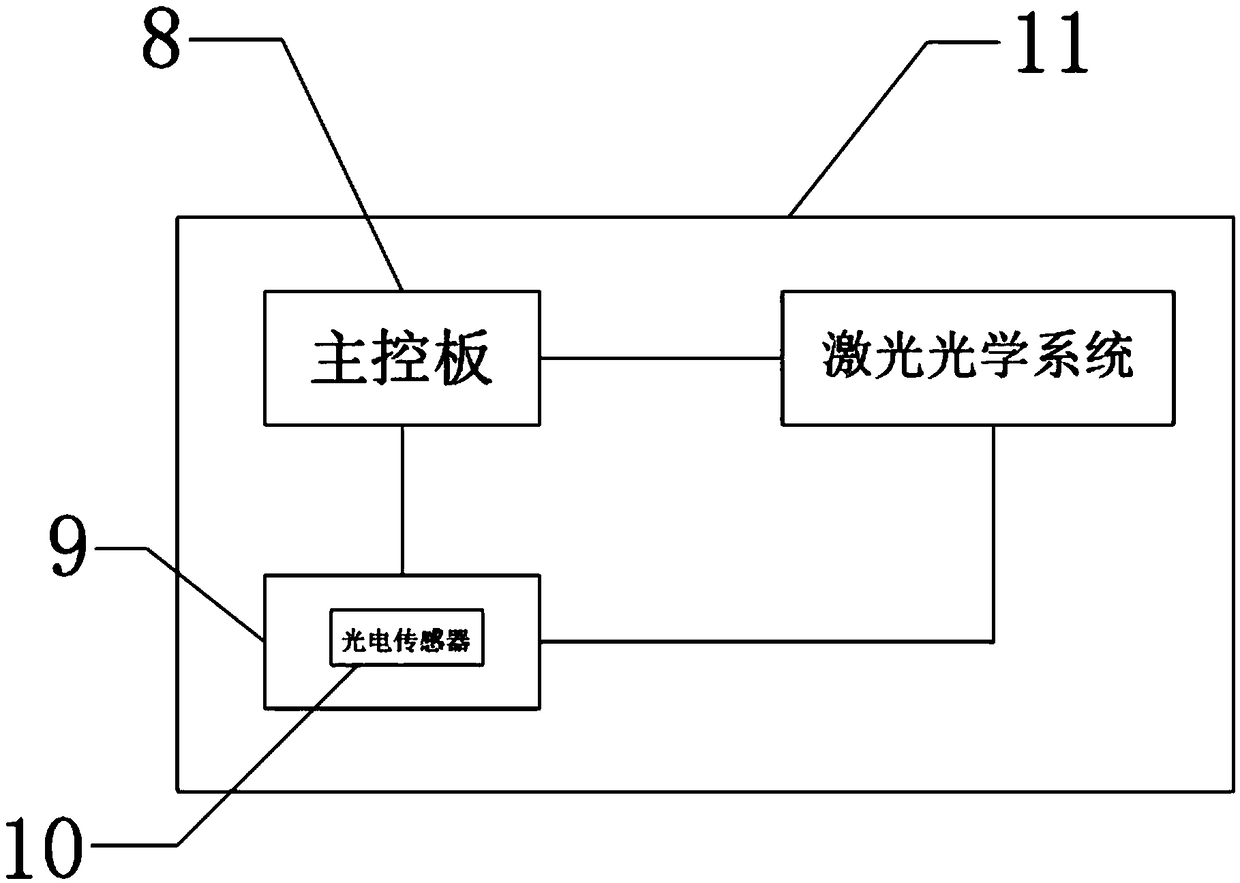

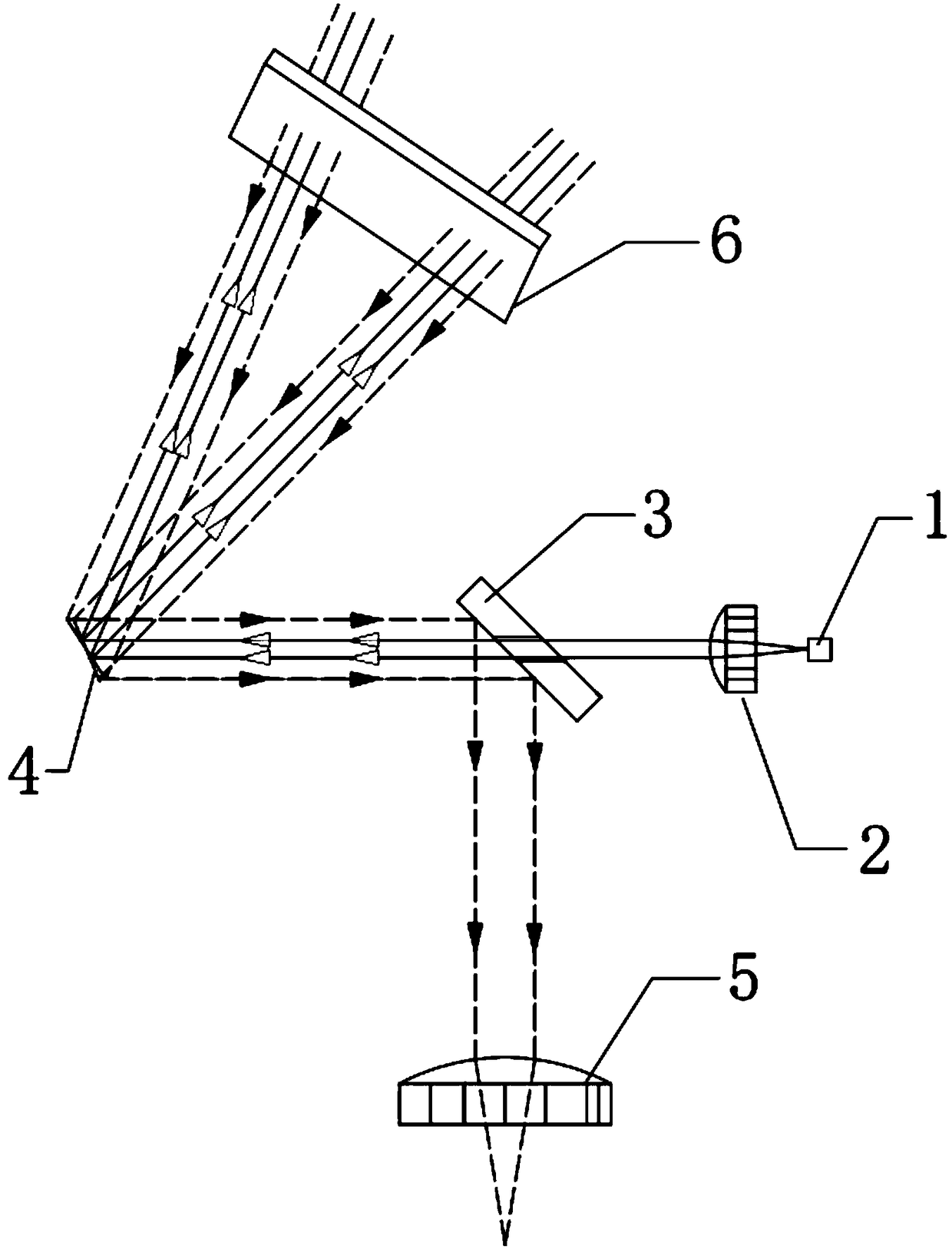

Laser radar coaxial optical system and laser radar

The invention relates to the technical field of artificial intelligence, and in particular relates to a laser radar coaxial optical system. The laser radar optical system comprises a transmitting optical unit and a receiving optical unit; the transmitting optical unit comprises a laser, a collimating lens and an MEMS galvanometer; the receiving optical unit comprises a receiving lens and an aperture reflector, wherein the collimating lens, the aperture reflector and the MEMS galvanometer are sequentially arranged on the subsequent optical path of the light beam transmitted by the laser; afterbeing collimated through the collimating lens, the light beam transmitted by the laser passes through the small hole of the aperture reflector, and enters the MEMS galvanometer; the MEMS galvanometerdeflects and reflects incidence laser onto a target object; and reflected light of the target object is reflected through the MEMS galvanometer, and enters the receiving optical unit. According to thelaser radar coaxial optical system and the laser radar in the invention, coaxial optical path design is adopted; transmitting and receiving optical paths are combined through the aperture reflector;exit laser is scanned from the combined laser through the MEMS galvanometer; the laser radar optical system is convenient to debug; furthermore, due to beam combination, optical signal loss is low; and the detection distance is greatly increased.

Owner:BENEWAKE BEIJING TECH CO LTD

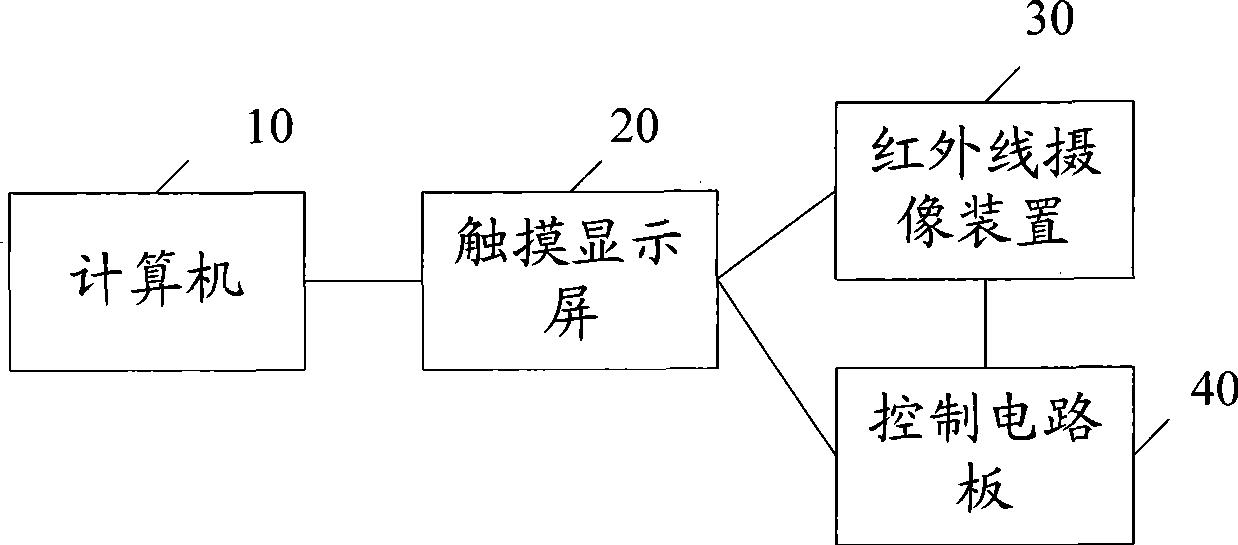

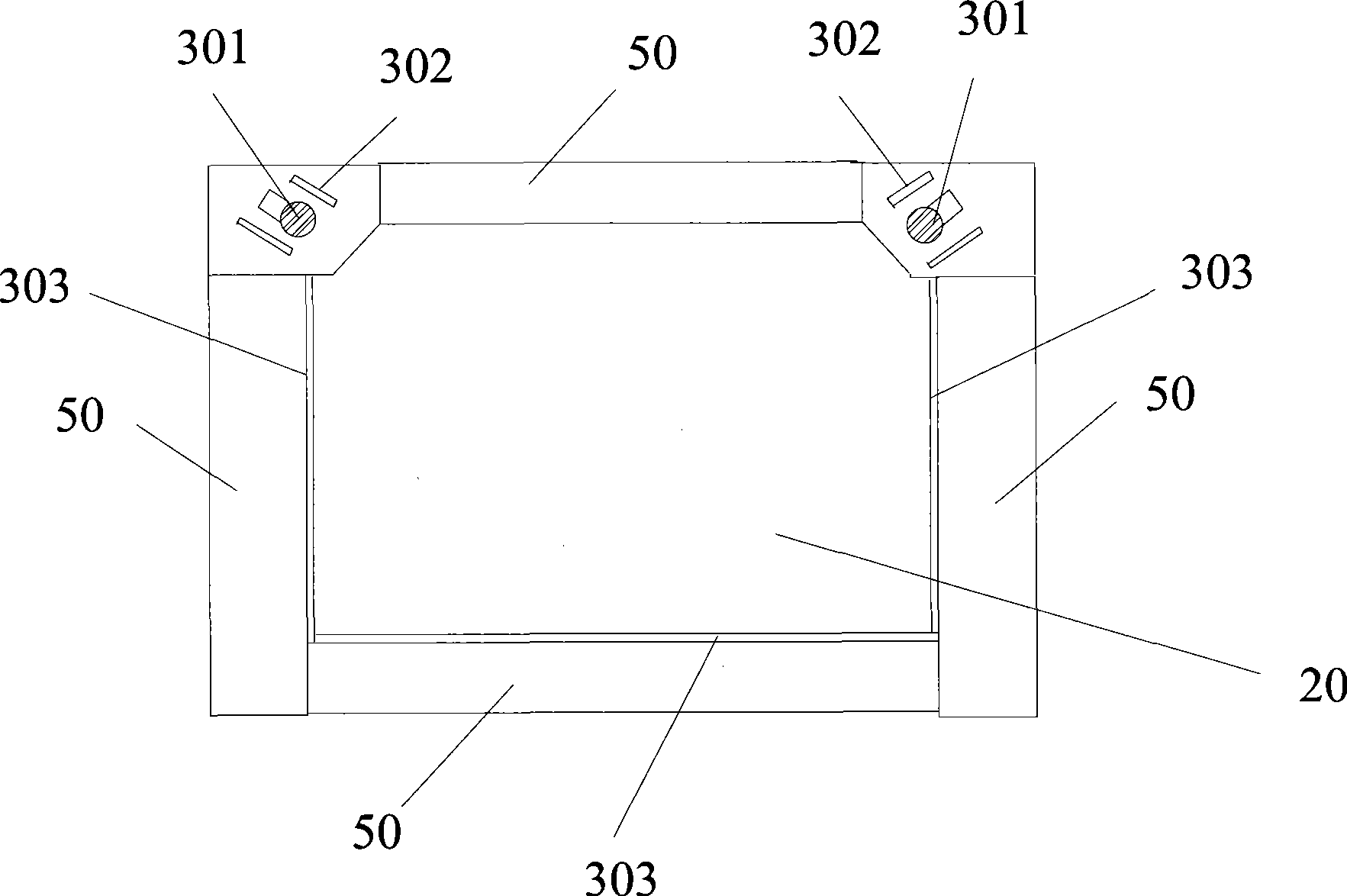

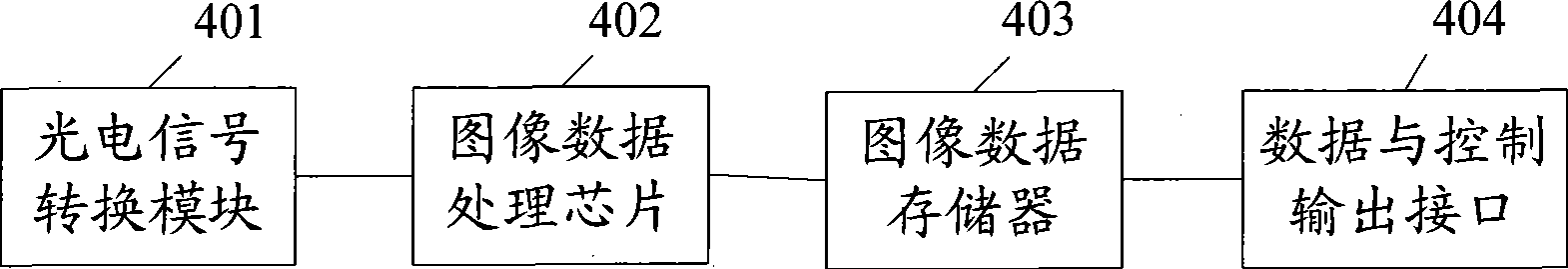

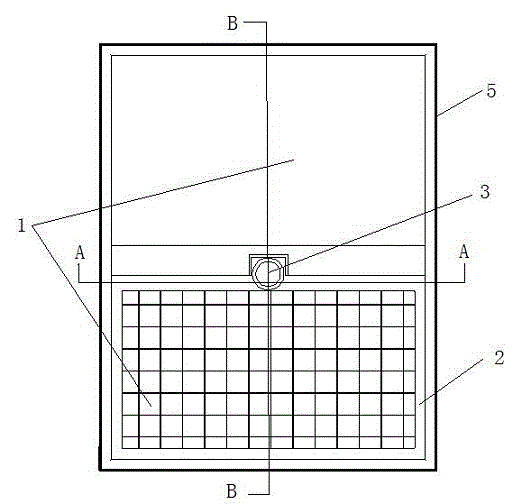

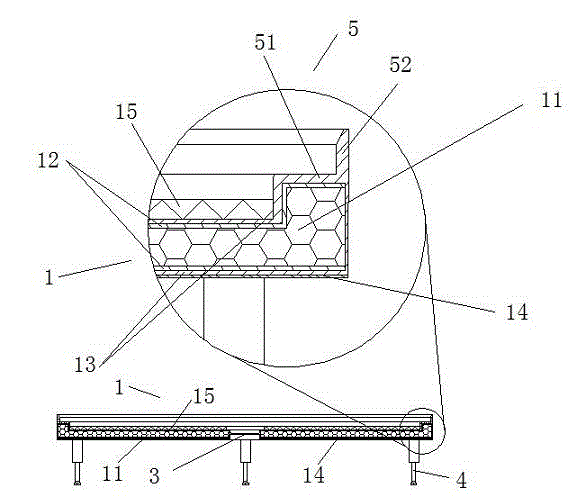

Touch display screen frame and system based on infrared videography, and its computing method

ActiveCN101498980AReduce volumeControl movementInput/output processes for data processingImage resolutionHuman–computer interaction

An embodiment of the invention discloses a touch display screen frame, system and calculating method based on infrared image pick-up; the system comprises a computer, a touch display screen, and an infrared image pick-up device and a control circuit board installed on the touch display screen frame, wherein the infrared image pick-up device comprises two high-resolution infrared cameras respectively at two ipsilateral angles of one rim of the touch display screen, infrared transmitting tubes installed at the tops or sides of the infrared cameras, and infrared refractive strips installed at the inner sides of the other three rims of the touch display screen; the four rims of the touch display screen are movably connected, and can be disassembled or folded from the touch display screen; the touch display screen frame can be independently and flexible configured, and the touch system can improve system resolution factor and computational accuracy of touch recognition point coordinates.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

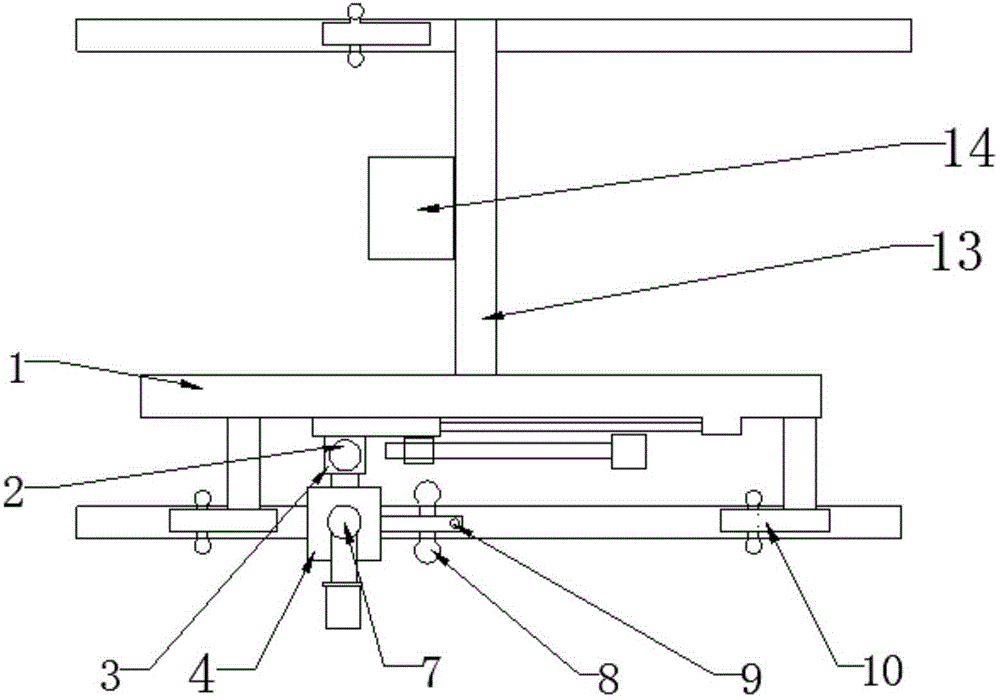

Portable device for accurately repairing wavy abrasion of steel rail of subway curve

ActiveCN104153262APrecise Repair GrindingPrecise consideration of radial misalignment compensationRailway track constructionLaser rangingEngineering

The invention relates to a portable device for accurately repairing the wavy abrasion of a steel rail of a subway curve. The portable device comprises a laser distance measuring sensor (9), a grinding assembly (7), a driving assembly, a control assembly and a detachable machine frame, wherein the laser distance measuring sensor (9) detects the wavy abrasion of the steel rail of the subway curve, the grinding assembly is used for repair, the driving assembly and the control assembly drive the grinding assembly (7) to move in the X-axis direction, the Y-axis direction and the Z-axis direction, and all the components of the device are installed on the detachable machine frame. Compared with the prior art, the portable device can be installed on site and is manually pushed to move, for a designated spot, the portable device can actively and accurately repair the wavy abrasion of the steel rail of the subway curve, when the radius of curvature of the steel rail of the curve is small, radial deviation compensation can be accurately considered, re-forming can be easily and repeatedly conducted, the grinding assembly can move in the direction of the rail and in the radial direction of the rail and can accurately ascend and descend, the included angle between a grinding wheel and the steel rail can be adjusted, and the portable device has the advantages of being convenient to use, high in efficiency, low in cost, high in precision and the like.

Owner:HUAHAI ENG CO LTD OF CREC SHANGHAI

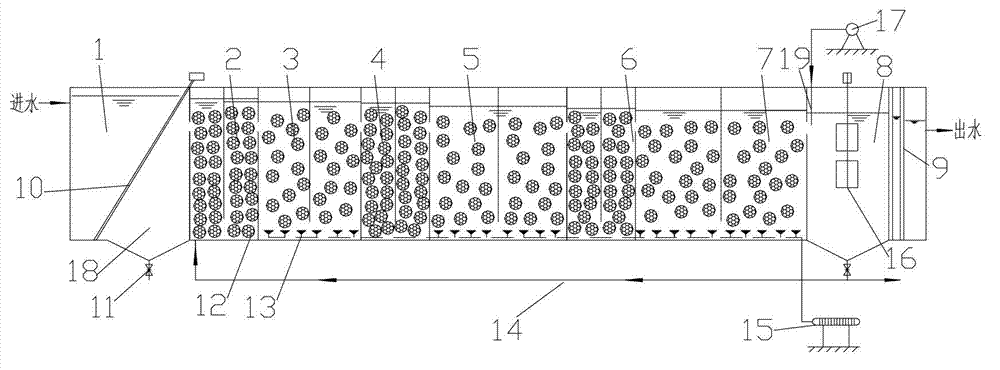

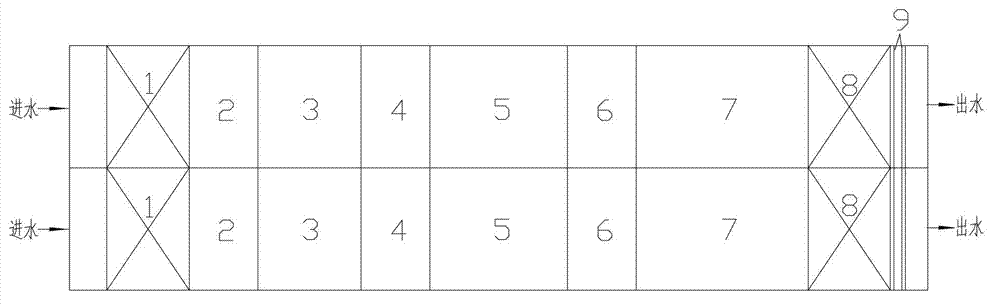

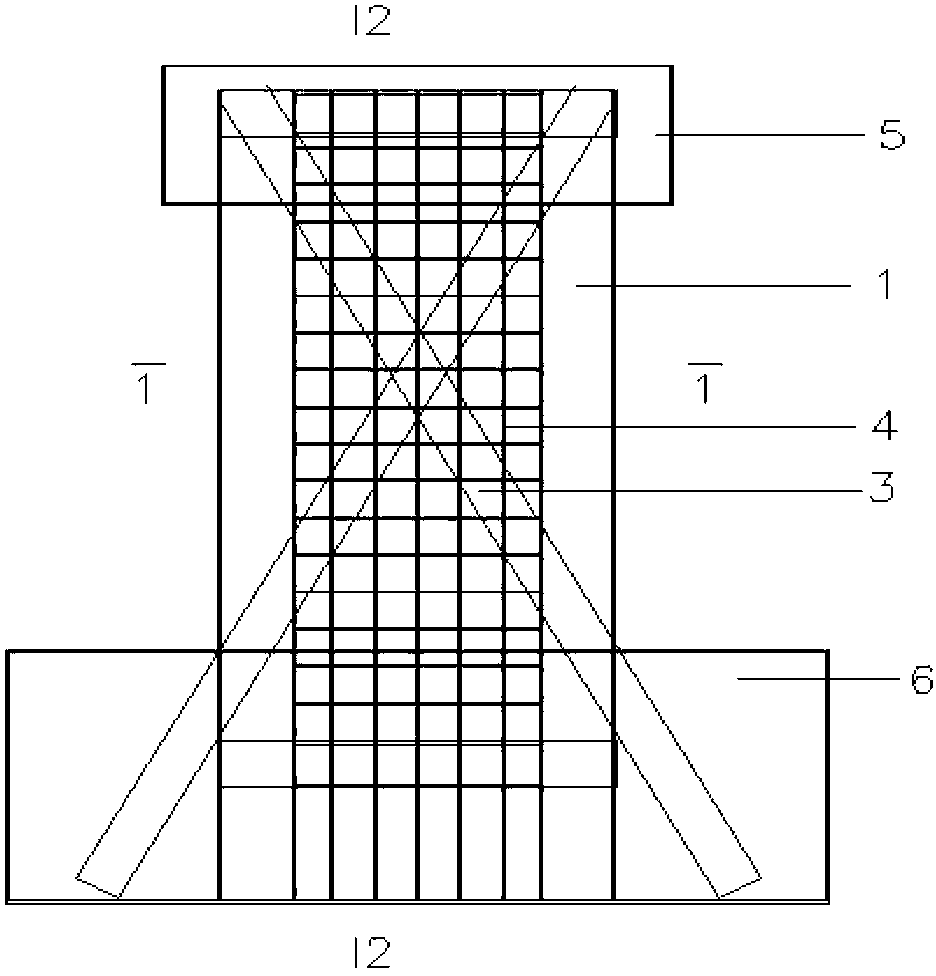

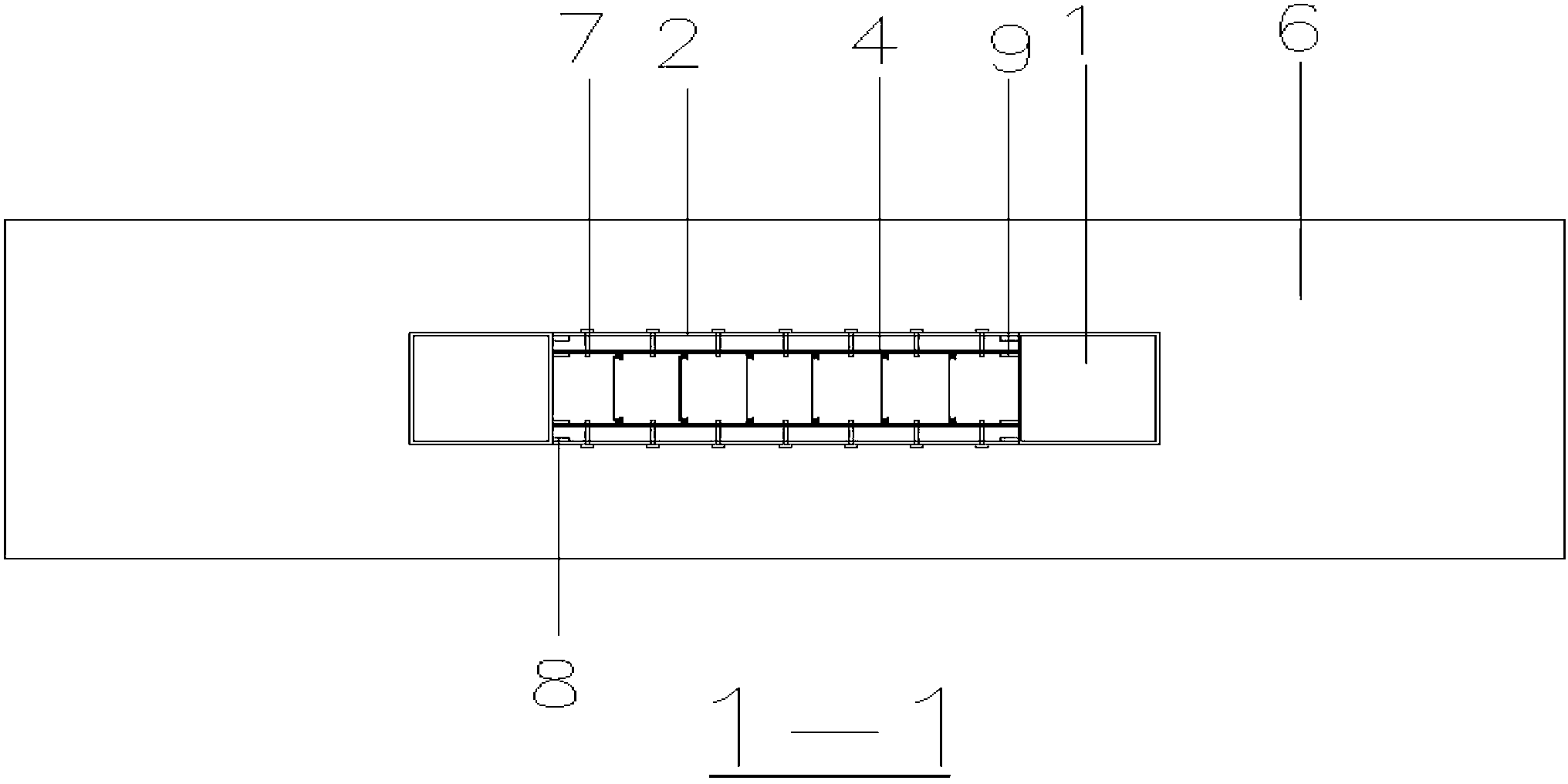

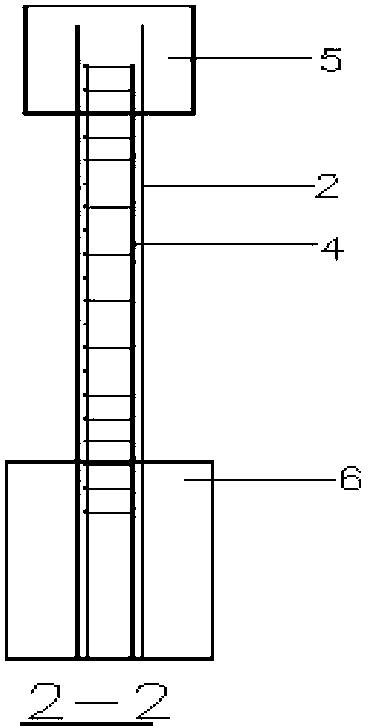

Integrated sewage treatment device with high efficiency and low consumption and treatment method

The invention relates to an integrated sewage treatment device with high efficiency and low consumption and a treatment method, and belongs to the field of sewage treatment. The integrated sewage treatment device comprises a pretreatment unit, a multi-oxidation-deoxidation environment coupling biological reaction pond unit and a deep treatment unit sequentially connected. The multi-oxidation-deoxidation environment coupling biological reaction pond unit adopts a three-stage anoxia-aerobiotic alternating reaction pond filled with a circular composite glass ball porous microbial carrier. The deep treatment unit comprises a filter cloth dynamic film biological reaction pond and first and second dynamic films. Sewage is treated through the devices sequentially. The device provided by the invention cannot only remove carbon containing organic matters, but also has good nitrogen and phosphorus removal capacity.

Owner:BEIJING UNIV OF TECH

Composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and construction method thereof

InactiveCN102704598AAct as a constraintImprove binding abilityWallsBuilding material handlingSteel frameSteel bar

A composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and a construction method thereof relate to the field of construction. According to the invention, the composite shear wall is formed by combining reinforced concrete frames, a double steel plate shear wall and steel plates with concealed bracings. The reinforced concrete frames are formed by pouring concrete into steel tubes; then, the double steel plates are placed, the double steel plates are welded to the reinforced concrete frames, and the steel plates are perforated and are connected through studs; oblique crossing concealed bracings are placed between the double steel plates, and the oblique angle of the concealed bracings is between 45 degrees and 60 degrees; tie bars are threaded through the interspace between the concealed bracings; a reinforcing mesh composed of transverse steel bars in horizontal arrangement and longitudinal steel bars in vertical arrangement is arranged between the concealed bracings and the steel plates; and concrete is poured between the double steel plates. The composite shear wall has the advantages that the bearing capability is enhanced, the bearing capacity and the rigidity attenuate slowly, the ductility and the energy dissipation of the shear wall are enhanced due to multi-defenses, and the earthquake resistant capability is more excellent. The composite shear wall also has the advantage of convenience in steel structure construction, and can be used in high-rise or large complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

Integrated bathroom base plate and manufacturing method thereof

ActiveCN104018700AHigh strengthImprove rigiditySewerage structuresLaminationManufacturing cost reductionSurface layer

Owner:GUANGZHOU HONLLEY COMPOSITE MATERIAL

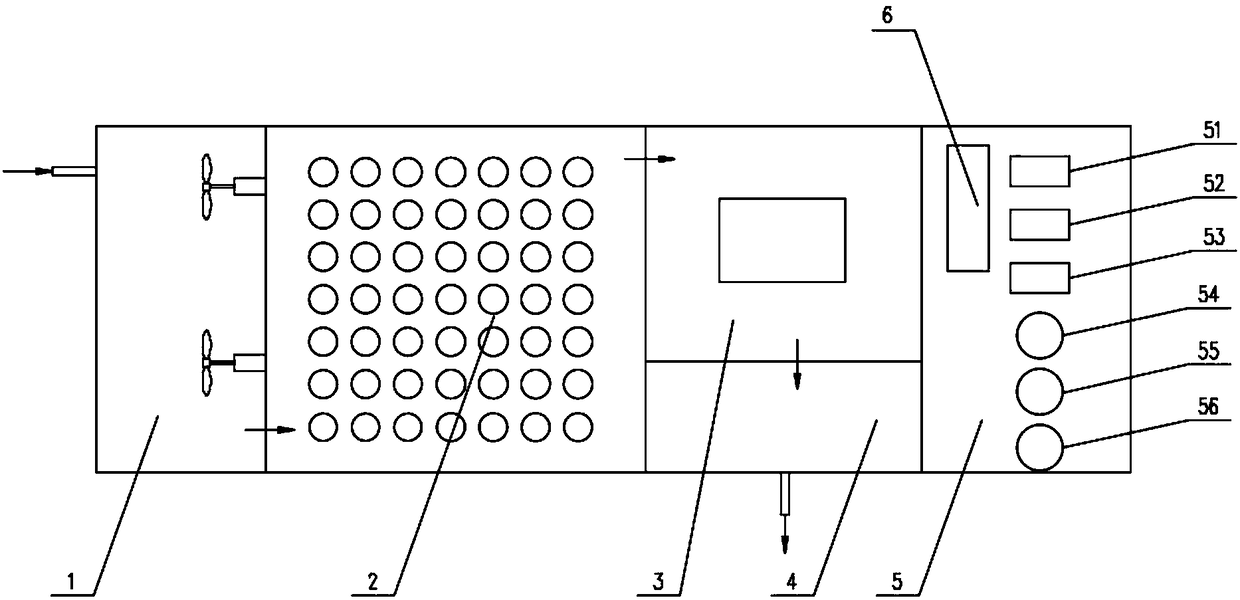

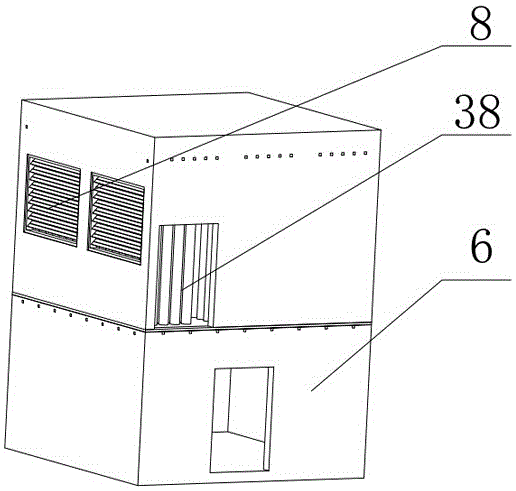

Smart integrated MBR sewage purifying device

InactiveCN108892331AControllable production cycleCompact structureSpecific water treatment objectivesWater contaminantsNitrationSewage

The embodiment of invention provides a smart integrated MBR sewage purifying device. The device comprises an oxygen deficit pool, an aerobic pool, a membrane pool, a clear water pool and an equipmentroom. The oxygen deficit pool is communicated with the bottom of the aerobic pool, the aerobic pool is communicated with the top of the membrane pool, the clear water pool and the membrane pool are not communicated in the same pool, and the equipment room is next to the clear water pool and comprises a phosphorous removal system, a back flush system, a sterilizing system and an electric control cabinet; the oxygen deficit pool primarily filters sewage, a denitrification reaction occurs, the sewage has the denitrification reaction through the aerobic pool to generate nitration liquid, the membrane pool performs deep-layer filtering through an MBR membrane device and is connected with the phosphorous removal system to remote phosphorous in the sewage, and the clear water pool is connected with the sterilizing system to sterilize produced water by the membrane pool, so that clear water is obtained. By the adoption of the modularized design, the production period is controllable, quality is good, the structure is compact, the size is small, transportation and installation are simple, full-automatic operation can be realized, remote monitoring can be realized, and the demand for treating the sewage in villages and small towns can be met.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

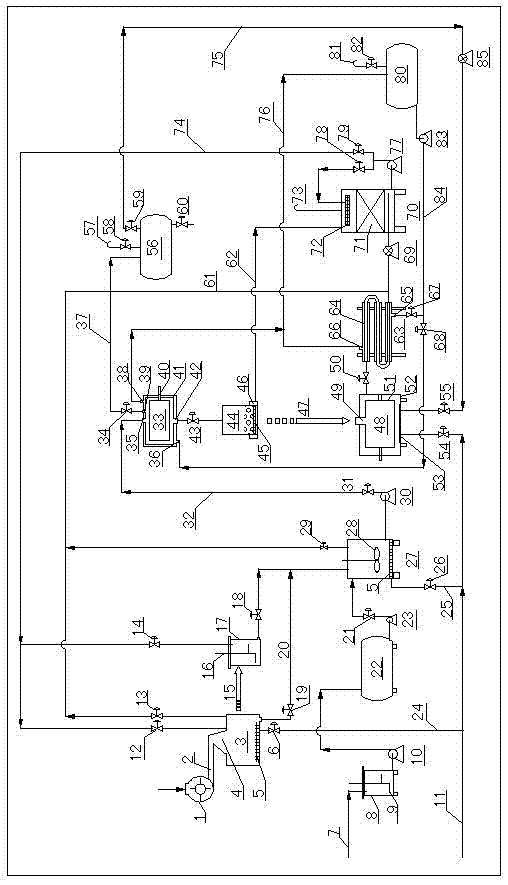

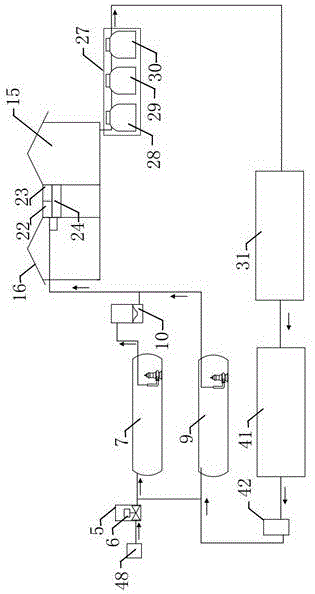

Low-emission solid organic waste treatment system realizing methane and active carbon production

ActiveCN103240264AEasy to handleReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsTreatments waterClean energy

The invention discloses a low-emission solid organic waste treatment system realizing methane and active carbon production. The technical method of the low-emission solid organic waste treatment system realizing methane and active carbon production uses a waste crushing treatment system, an anaerobic digestion raw material pre-treatment and blending system, an anaerobic digestion reactor system, an anaerobic digestion residuum dehydrating system, an anaerobic digestion residuum carbonizing system, a carbonized gas collecting, heat-exchanging and purifying system, and a treatment water recycling system. The technical integration of the low-emission solid organic waste treatment system realizing methane and active carbon production is capable of finishing the optimal treatment of the biomass solid organic waste, and the final product is the clean energy methane and environment-friendly material active carbon. The partial required energy can be produced by the technical method, the energy recycling rate is high, and the treatment on the exhaust gas and effluent can be finished in the production link, the system is energy-saving and environment-friendly. By sufficiently considering the influence of various factors and the coherence among various links, the period of anaerobically treating the biomass organic solid waste can be obviously shortened, and the treatment efficiency of the organic solid waste can be sufficiently improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Novel plastic thermal-insulation wallboard

ActiveCN103603459AQuick installationLight weightSynthetic resin layered productsBuilding componentsThermal insulationResource utilization

The invention discloses a novel plastic thermal-insulation wallboard. The novel plastic thermal-insulation wallboard is prepared by spraying and trowelling mortar on the outer surface of a plastic plate as a core. The novel plastic thermal-insulation wallboard comprises the plastic plate as the core, a metal wire mesh and a mortar layer. The outer surface of the plastic plate as the core is provided with a raised part. The metal wire mesh is fixed to the raised part. Mortar is sprayed on the metal wire mesh so that the mortar layer is formed. The novel plastic thermal-insulation wallboard realizes waste plastic building materializing, improves a resource utilization rate, has a simple structure, is convenient for operation, realizes wallboard fast-installation, saves labor and a construction period, has light weight, reduces building structure self-weight and saves energy.

Owner:嘉兴笼列电子商务有限公司

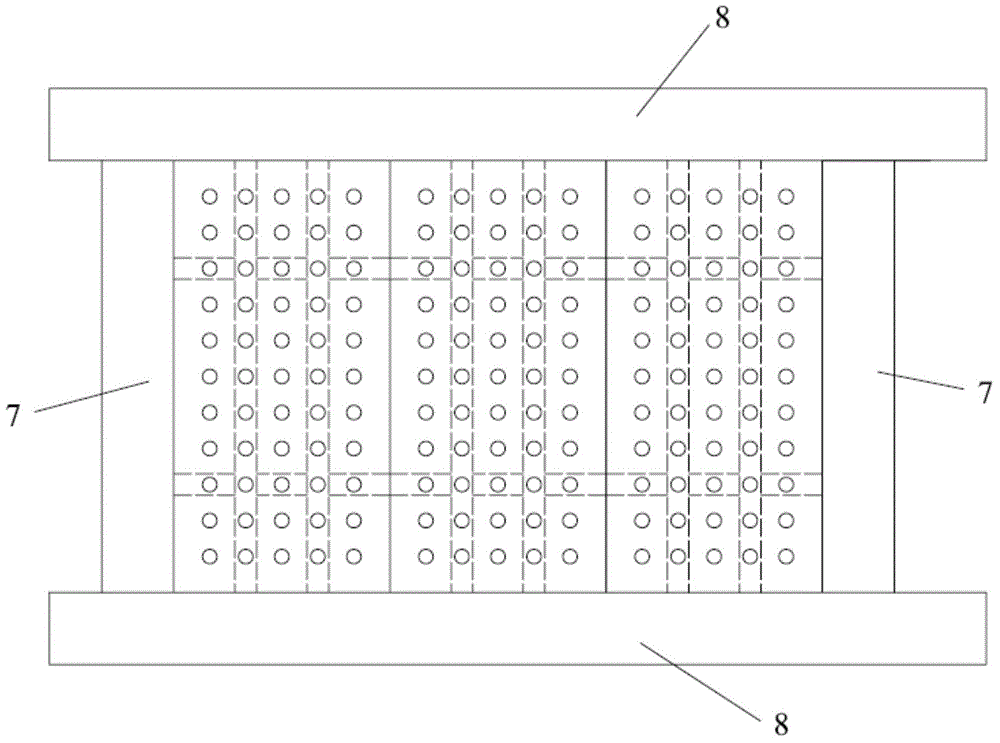

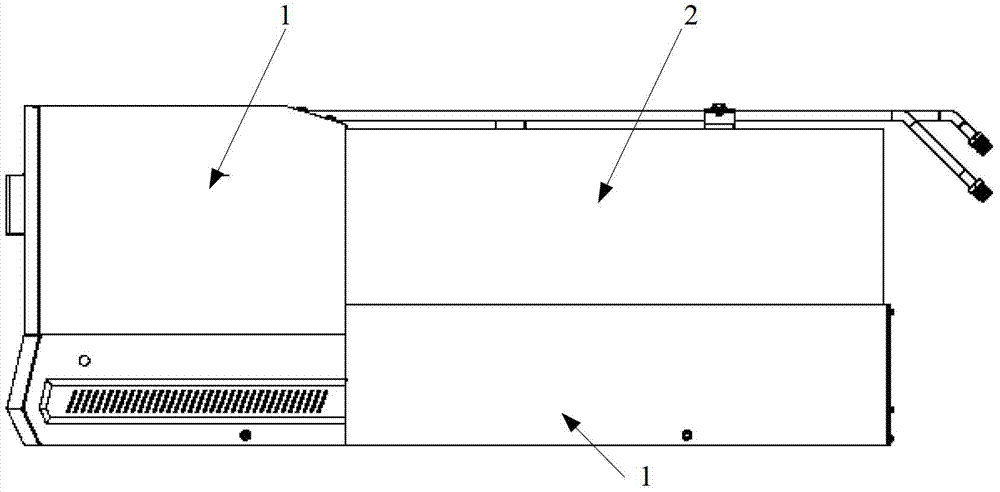

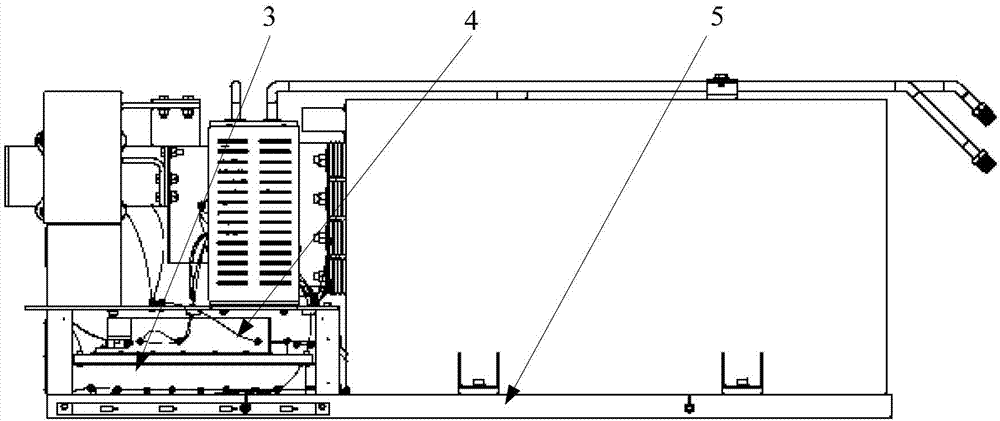

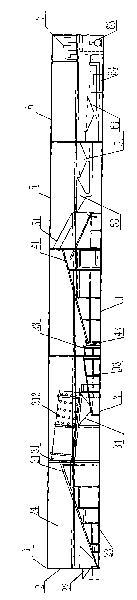

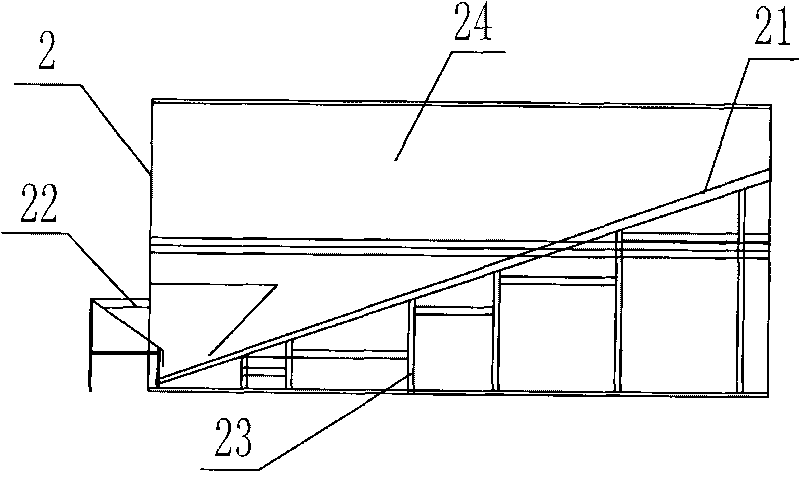

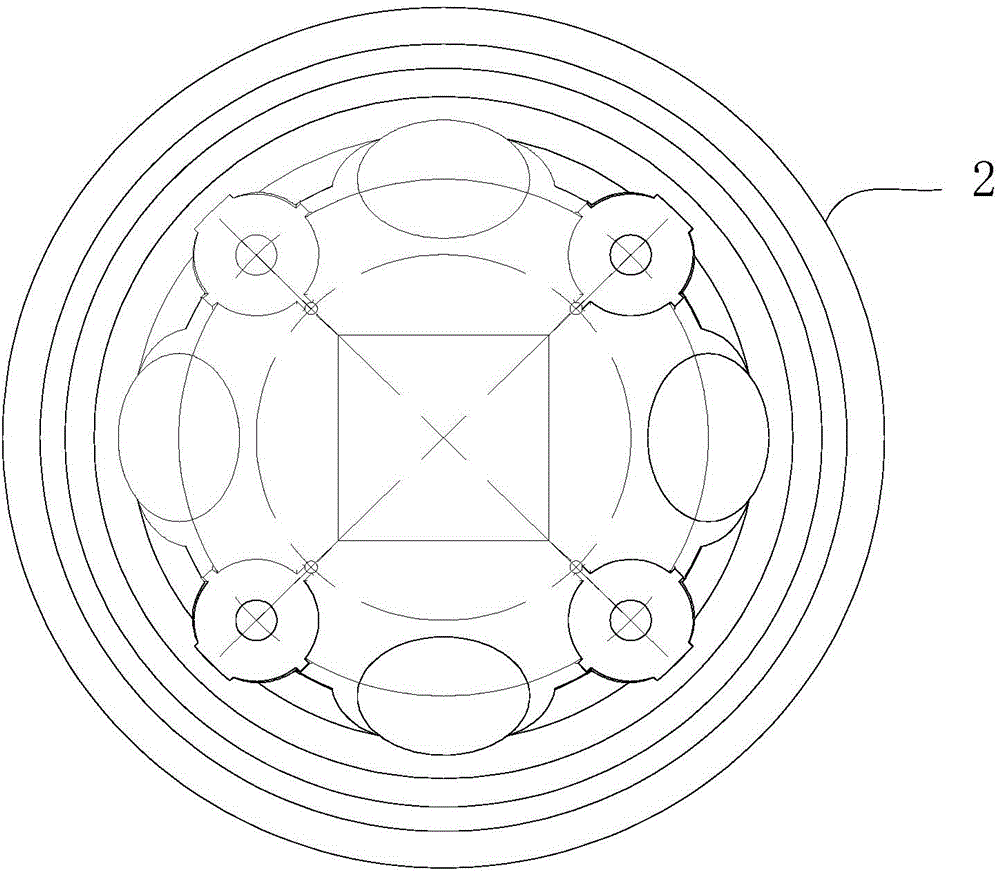

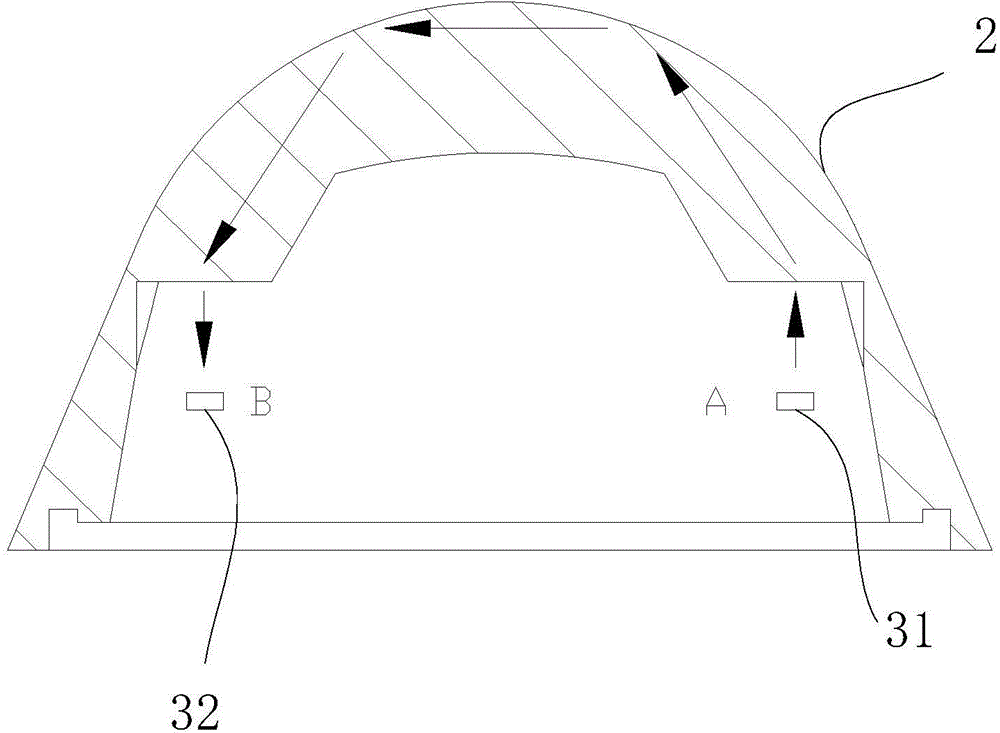

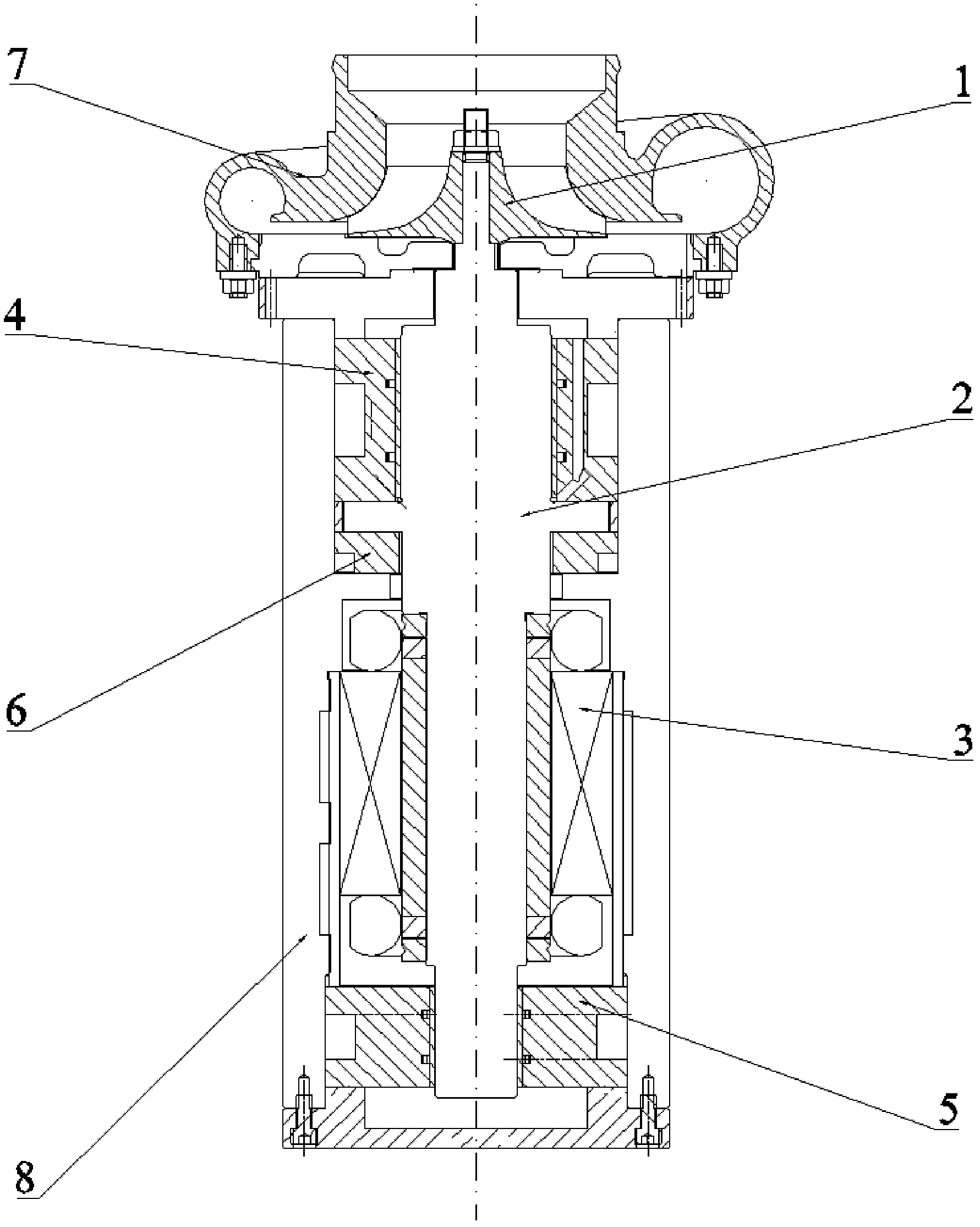

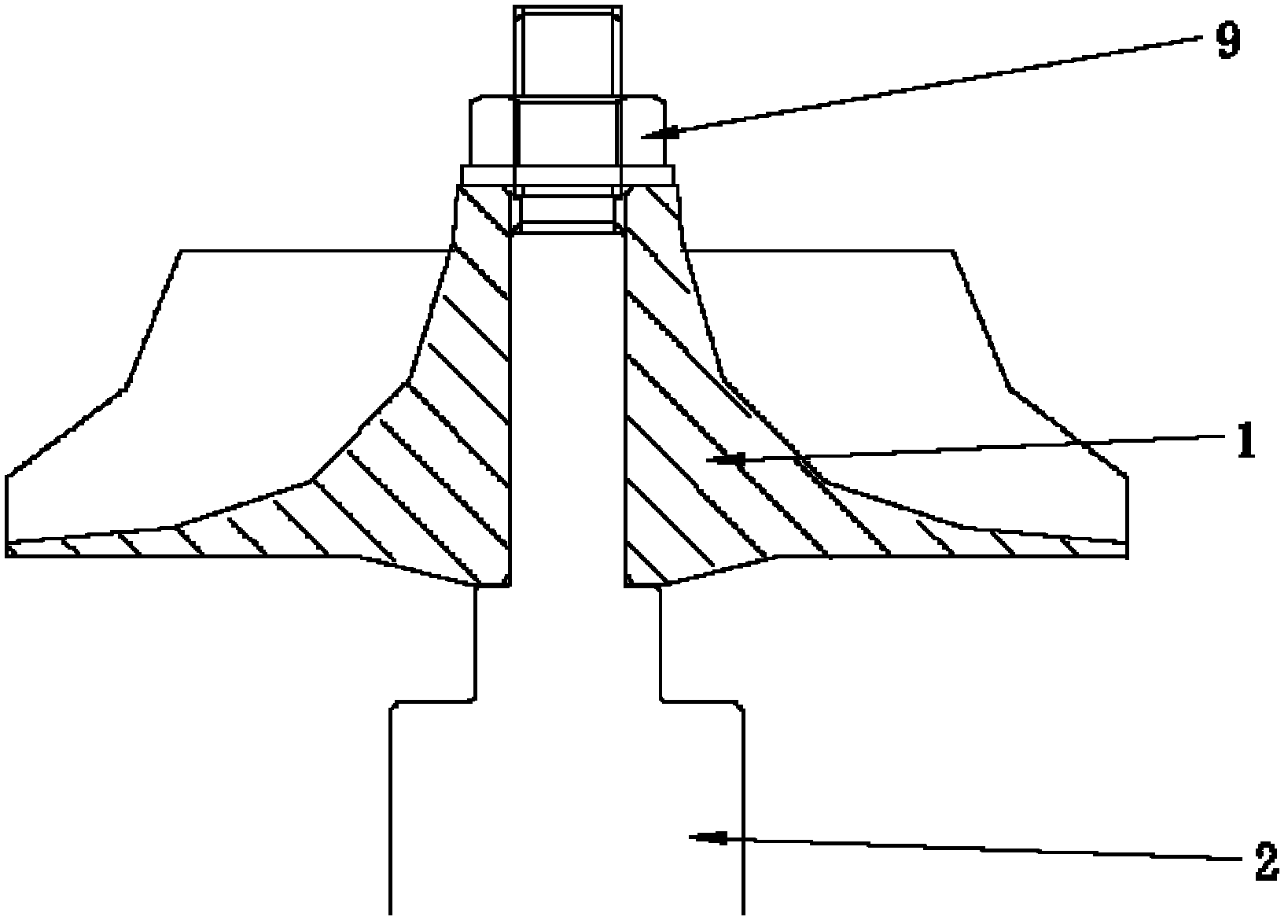

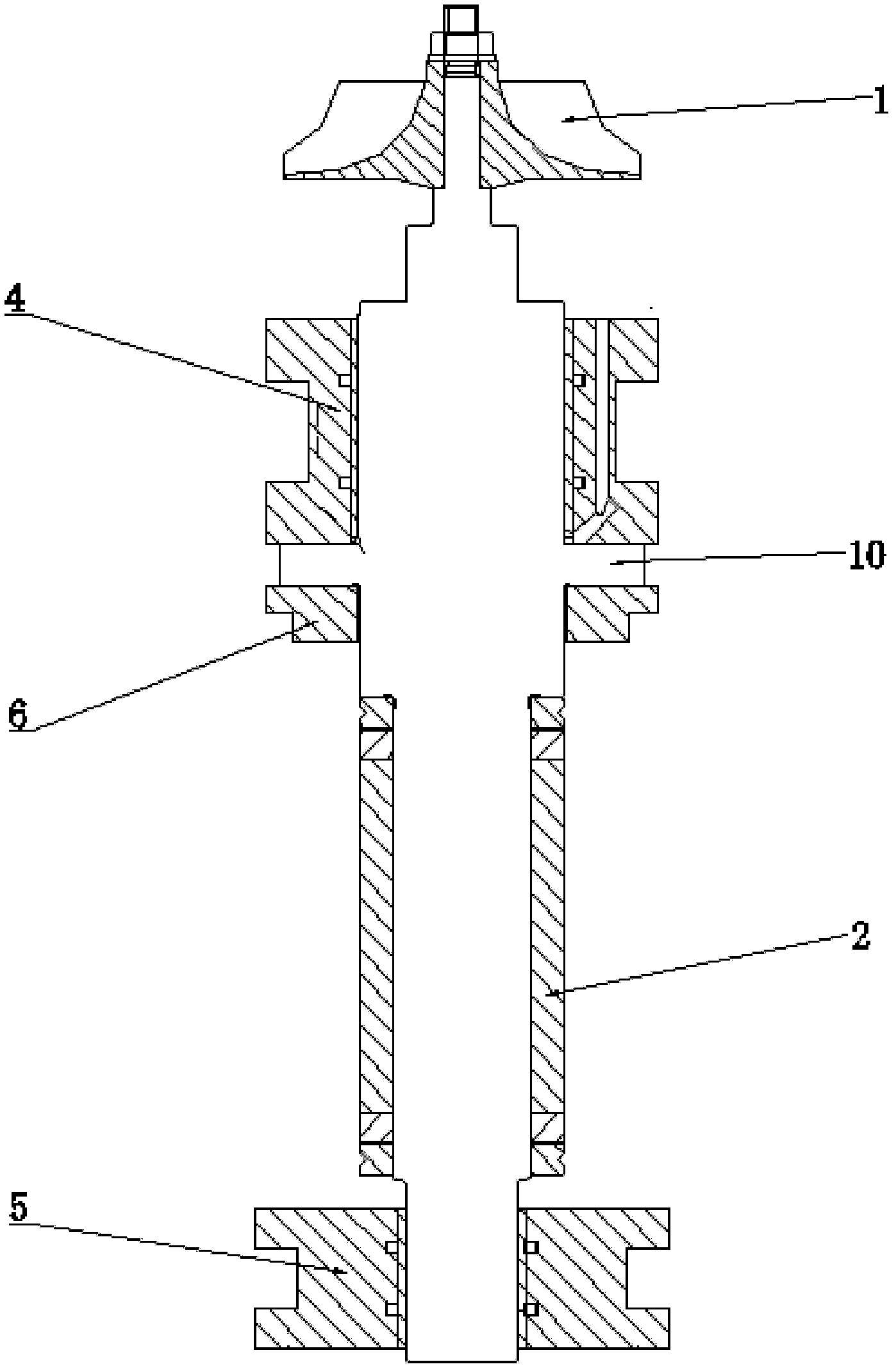

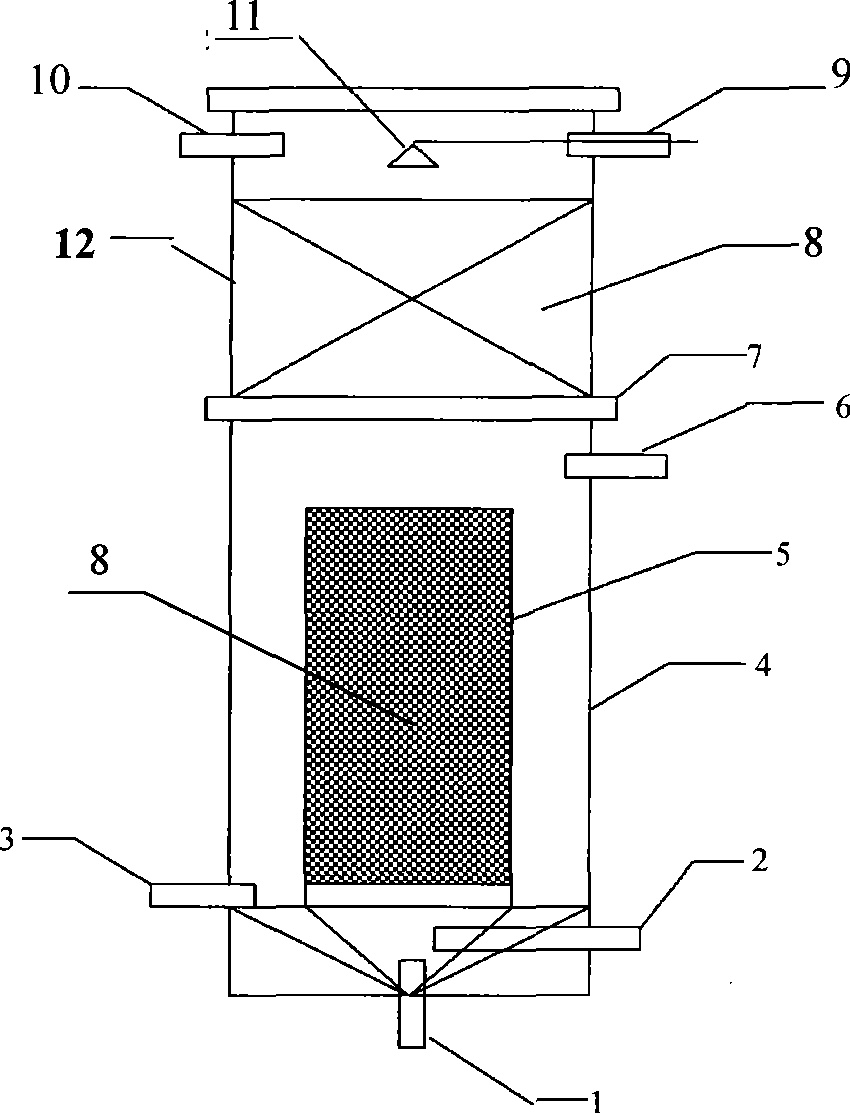

Submodule unit of voltage source transverter based on full control components

ActiveCN103036452AEasy to transport and installClear installationConversion constructional detailsElectrical apparatus contructional detailsWater pipeTransverter

The invention provides a submodule unit of a voltage source transverter based on full control components. The voltage source transverter is a three-phase six-bridge structure. Each bridge arm comprises a plurality of submodules which are connected in series. Each submodule comprises electric power components such as a capacitor, insulated gate bipolar translators (IGBT) modules with a structure of a semi-bridge, wherein the capacitor and the IGBT modules are connected in parallel. The submodule unit of the voltage source transverter based on the full control components further comprises a main support structure, a support plate, a connecting water pipe, radiators and the like. The main support structure is used for supporting the electric power components of the submodule unit, the support plate, the connecting water pipe and the radiators. The support plate is perpendicular to a base of the main support structure. The support plate is provided with the two radiators which are symmetrically arranged. The radiators are connected through the connecting water pipe. Two IGBT modules of each submodule are respectively arranged on the two radiators. The bottom of the capacitor of the each submodule is fixed on the base of the main support structure through bolts. The submodule unit of the voltage source transverter based on the full control components is a self-contained electrical system, is capable of expanding according to the need of the system, and is independent in structure and convenient to install and transport.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Module-assembly type domestic waste sorting device

InactiveCN101716586ACreate pollutionSmall footprintSolid waste disposalClimate change adaptationMagnetic separatorSlide plate

The invention discloses a module-assembly type domestic waste sorting device which comprises a box body and also comprises a domestic waste feeding section, a broken bag winnowing section, a magnetic separating section, a water content sorting section and an organic matter section which are arranged in the box body. The box body is externally provided with different domestic waste collecting boxes which correspond to all the sections; the domestic waste feeding section is provided with a domestic waste inlet and an automatic conveying belt which is arrange at the bottom of the domestic waste inlet; the broken bag winnowing section is provided with a knife-type multipurpose roller screen, a domestic waste hopper, an automatic conveying belt and a winnowing machine which is arranged on the side part of the broken bag winnowing section; the magnetic separating section is provided with a magnetic separator and an automatic conveying belt; the tail end of the automatic conveying belt in the broken bag winnowing section extends to the top of the magnetic separator; the water content sorting section comprises a slide plate and water tanks which are connected in sequence by pipes and are used for separating solid from liquid; the organic matter section comprises a water tank and an automatic conveying belt, wherein the water tank is connected with the water tank in the water content sorting section by pipes, and the automatic conveying belt is used for conveying the domestic waste to the domestic waste collecting boxes. The module-assembly type domestic waste sorting device has novel structure, adopts the totally-sealed Module-assembly type and is convenient to install and transport.

Owner:SHANGHAI BILI ENVIRONMENTAL PROTECTION TECHCO

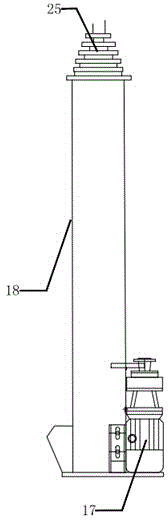

Optical rainfall detecting method, detecting device and light guide device

ActiveCN104950352AAchieve closureAvoid corrosionRainfall/precipitation gaugesOptical light guidesLight energyLight guide

The invention discloses an optical rainfall detecting method, a detecting device and a light guide device. The optical rainfall detecting method includes transmitting parallel light onto the light guide device, repeatedly totally reflecting the parallel light in comprehensive fields of the light guide device and then ejecting the parallel light to certain positions according to preset directions; enabling light energy amplitude and frequency detectors to receive light signals via light receiving elements, detecting fluctuation frequencies and fluctuation amplitude of the light signals and transmitting detection signals to a central processing unit; enabling the central processing unit to acquire rainfall speeds and rainfall amounts according to the received detection signals. The parallel light is emitted by program-controlled light sources positioned inside the detecting device. The light receiving elements are located at the certain positions. The optical rainfall detecting method, the detecting device and the light guide device have the advantages that parts of the light can be refracted and scattered to air when raindrops drop on the surfaces of the light guide device, the light can leak when transmitted in the light guide device, light energy received by the light receiving elements can be reduced, the amplitude of reduction of the light energy can be directly affected by contact areas of the raindrops and the light guide device, accordingly, the sizes of the raindrops can be indirectly computed by the aid of reduction amplitude values, and the quantities of the raindrops can be computed according to frequencies of amplitude change of the light energy.

Owner:SANHE WENKONG COMP TECH CO LTD

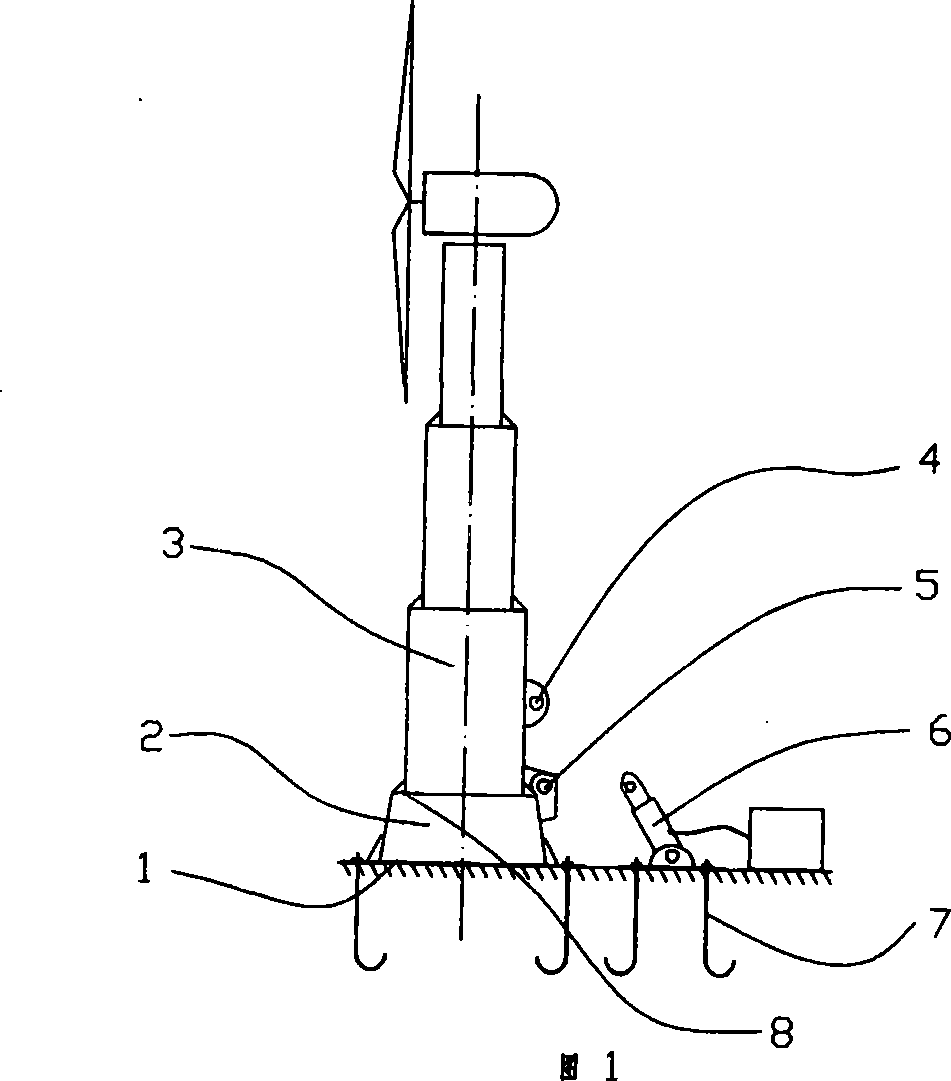

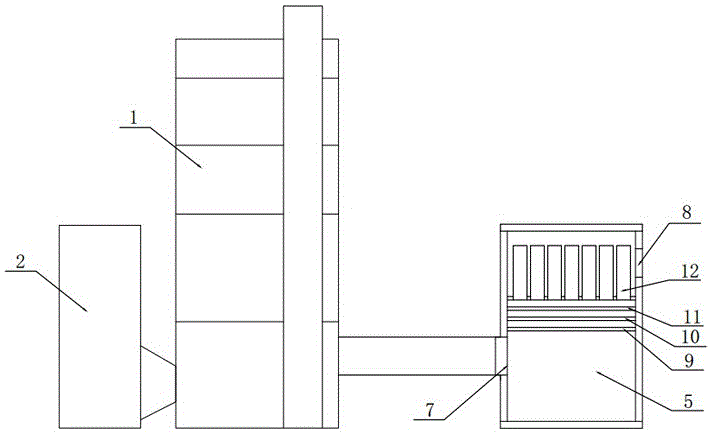

Aerogenerator tower frame apparatus and its use method

InactiveCN101429923AEasy to transport and installSolve the problem of inconvenient installation and high maintenance costWind motor supports/mountsMachines/enginesEngineeringSmall footprint

The invention relates to a wind power generator tower truss device and using methods thereof. The tower truss consists of a pedestal and a tower body hinged with the pedestal through a hinge; a connecting ear is arranged on the outer surface of the lower part of the tower body; the device also comprises a mandril mechanism which can be connected with the connecting ear. The using methods comprises a method of erecting the tower body and a method of putting the tower body down; and the mandril mechanism can be convenient to erect the tower body and put the tower body down. The wind power generator tower truss device changes the structural form of the prior integrated tower truss, changes the tower body into a combined structure hinged and connected by the pedestal and the tower body, and is convenient to mount and maintain; and the device integrates the advantages of convenient mounting and transportation of an inhaul cable tower truss, absorbs the advantages of attractive appearance, firmness and durability of a conicity tower, has the advantages of low transportation cost, small occupied area, attractive appearance and the like and simultaneously solves the problems that the routine tower has inconvenient mounting and high maintenance cost.

Owner:尤林

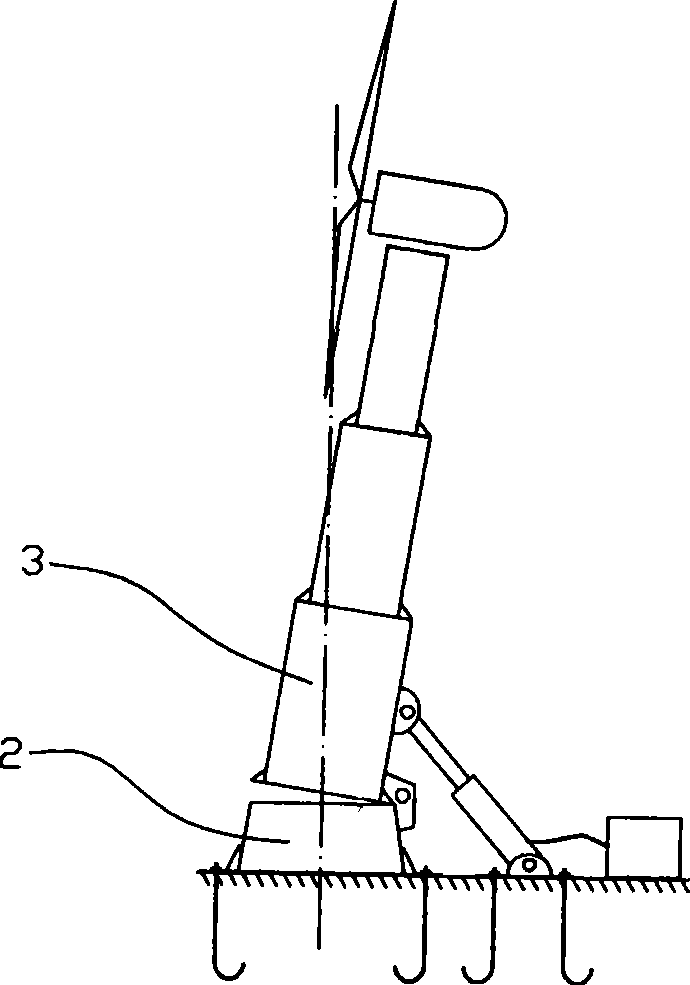

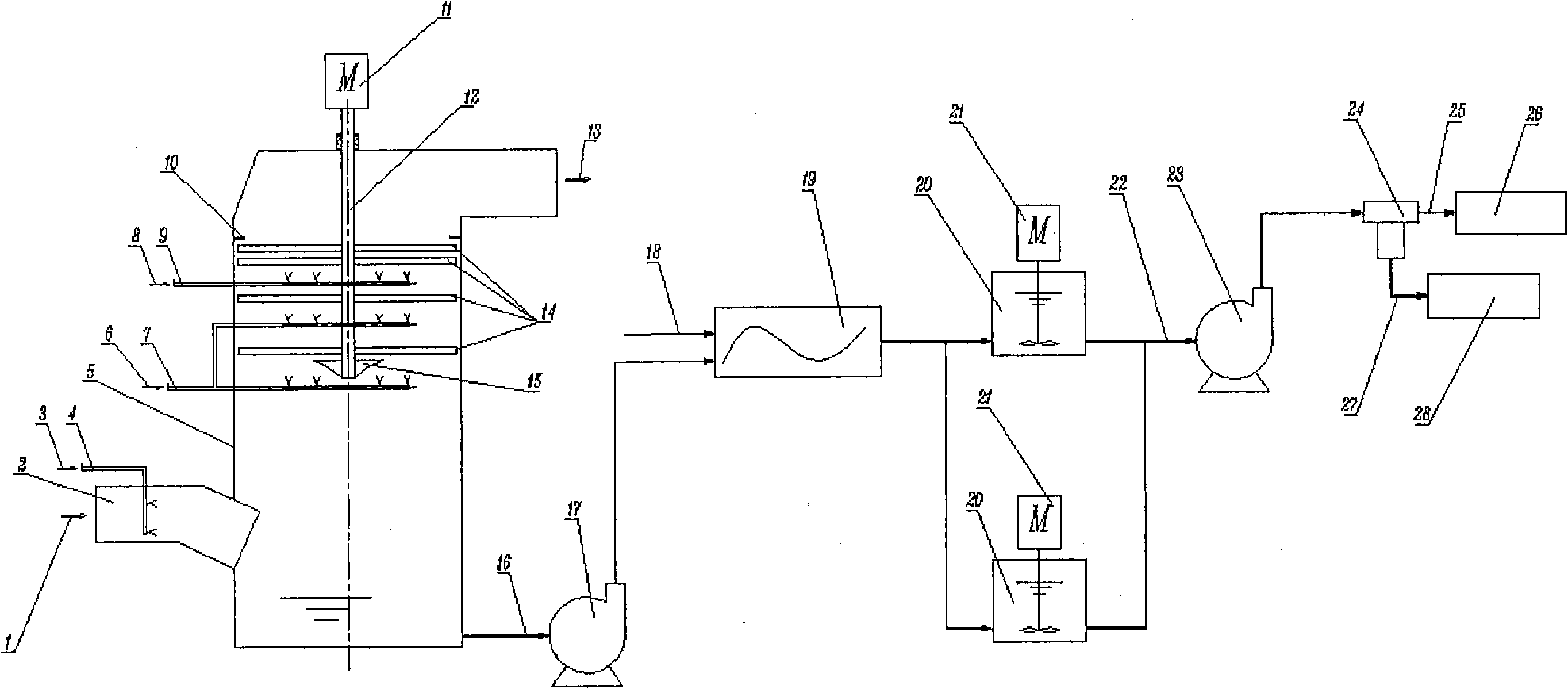

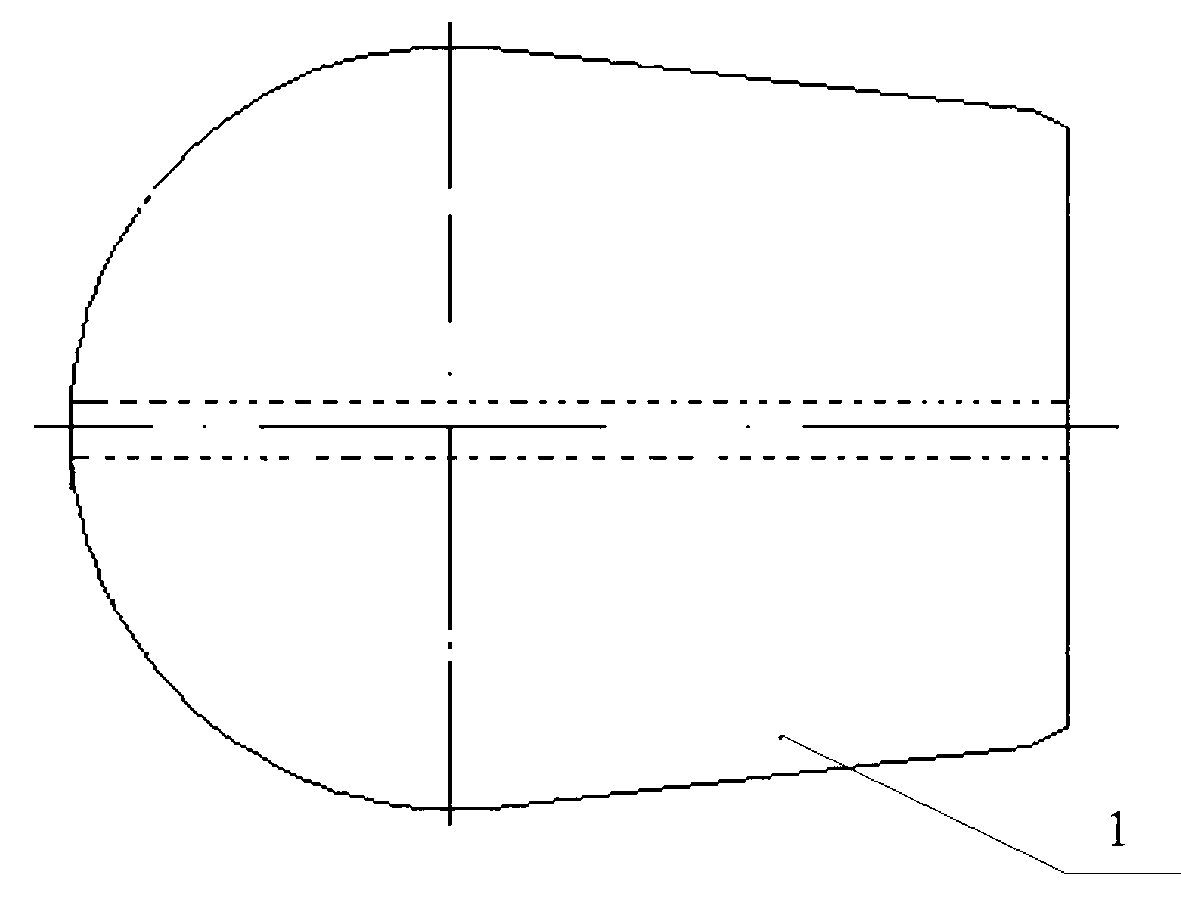

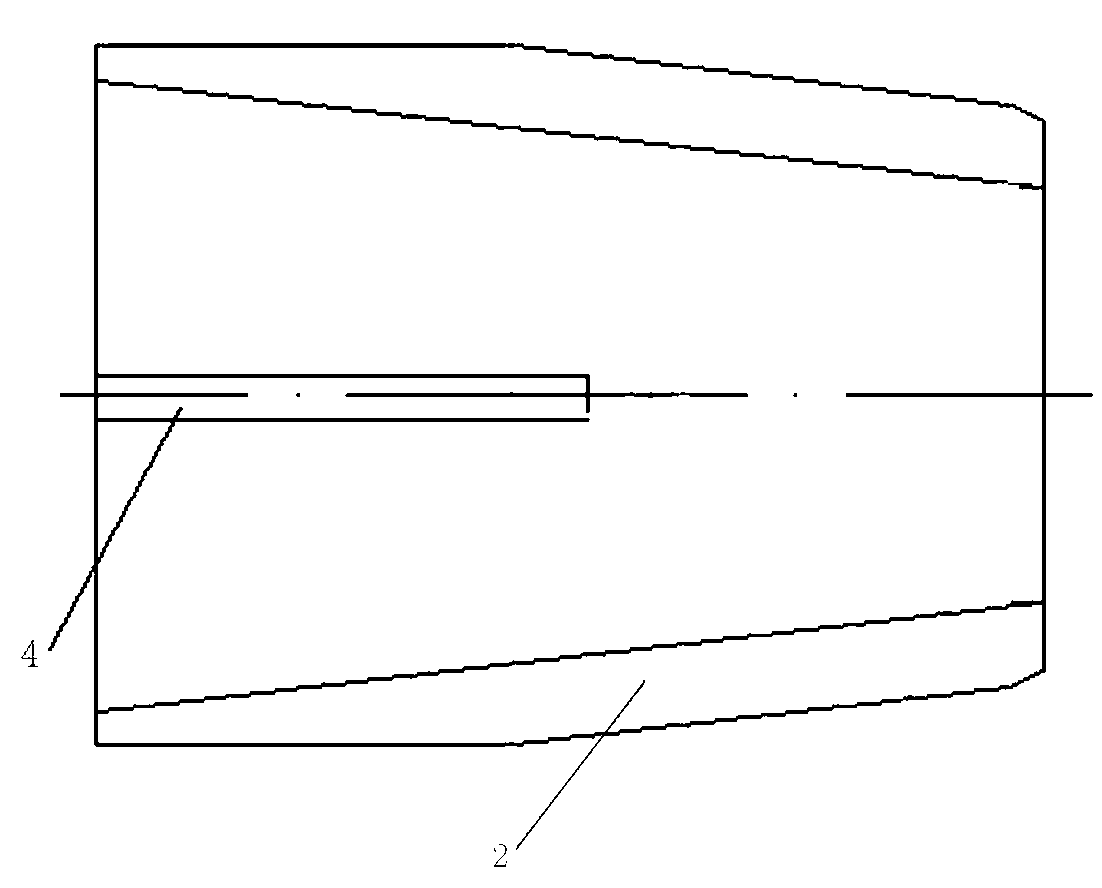

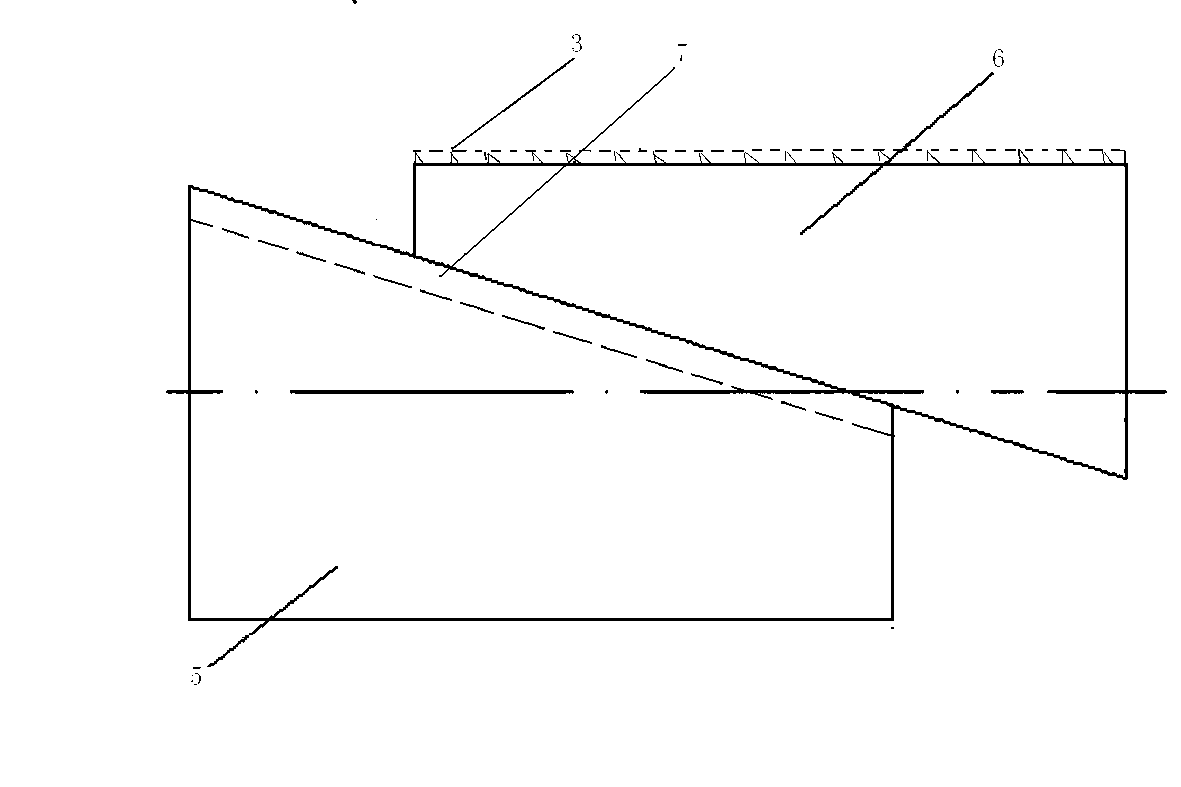

Production process for removing carbon dioxide from smoke and preparing ammonium compound fertilizer and light calcium carbonate

InactiveCN101890283AReduce volumeSmall footprintCalcium/strontium/barium carbonatesProductsCycloneAmmonium compounds

The invention relates to a production process for removing carbon dioxide from smoke and preparing ammonium compound fertilizer and light calcium carbonate. The process comprises the following steps of: performing gas-liquid two-phase high strength mass transfer absorption reaction on the primary smoke through a super-gravity field absorption tower by using dilute aqueous ammonia as an absorbent to remove carbon, discharging the treated smoke through a chimney, and performing further reaction treatment on byproducts of the carbon removal reaction to obtain the ammonium compound fertilizer and the light calcium carbonate with good economic values. The whole set of reaction and separation device for supporting the process comprises the super-gravity field absorption tower, a static mixer 19, a deep reaction tank 20, a cyclone 24, an ammonium compound fertilizer reclaiming system 26, a light calcium carbonate reclaiming system 28, various pumps and the like, wherein the super-gravity field absorption tower is used at a chemical reaction absorption section for removing the carbon dioxide. The brand-new process has the advantages of high efficiency, low investment and low running expense.

Owner:刘海清

Water-resisting returnable multi-stage buffer fractured self-deformation self-latching shot hole stopper

The invention belongs to the technical field of shot hole blocking in engineering blasting, and particularly relates to a water-resisting returnable multi-stage buffer fractured self-deformation self-latching shot hole stopper which solves the problems that various defects exist in existing stemming or stemming stopper, the existing stemming or stemming stopper is very undesirable in application, and the existing stemming or stemming stopper is inconsistent with the development of a modernized mine. The water-resisting returnable multi-stage buffer fractured self-deformation self-latching shot hole stopper comprises a fracturing stopper, a plurality of fracturing rings and a wedge stopper, wherein the fracturing stopper, the fracturing rings and the wedge stopper are sequentially arranged from a shot hole bottom to a shot hole opening, the fracturing stopper and the fracturing rings are sequentially in plug-in type connection, the wedge stopper is arranged behind the fracturing rings and close to the shot hole opening, and the wedge blanking stopper comprises two wedge blocks which are in matching use. The water-resisting returnable multi-stage buffer fractured self-deformation self-latching shot hole stopper disclosed by the invention has the beneficial effects of fast stopping speed, good stopping effect, safety and environment protection, no pollution, incombustibility, low cost, water resistance, quick exit performance when suffering from a blown-out shot and no secondary disaster.

Owner:DATONG COAL MINE GRP +1

Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

ActiveCN102200136AReduced noise and mechanical lossesImprove machine efficiencyPump componentsPump installationsSynchronous motorImpeller

The invention discloses an air-suspension air-supply-adjustable air blower directly driven by a high-speed electric machine. The air blower comprises a compressor impellor, a permanent magnetic synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing, a scroll and a motor shell; one end of the permanent magnetic synchronous motor rotor is connected with the compressor impellor; the rotor stator drives the permanent magnetic synchronous motor rotor to rotate; the front radial air bearing, the rear radial air bearing and the axial thrust air bearing support the permanent magnetic synchronous motor rotor in a suspension mode; the scroll is arranged at the periphery of the compressor impellor; and the motor shell is positioned at the peripheries of the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnetic synchronous motor rotor. According to the invention, through driving the compressor impellor directly by the permanent magnetic synchronous motor rotor of the high-speed electric machine, a complex and expensive speeding system is omitted, noises and mechanical loss are reduced, the integral machine efficiency can be improved, the system is simple, and the air blower provided by the invention is convenient to install and transport.

Owner:宁波虎渡能源科技有限公司

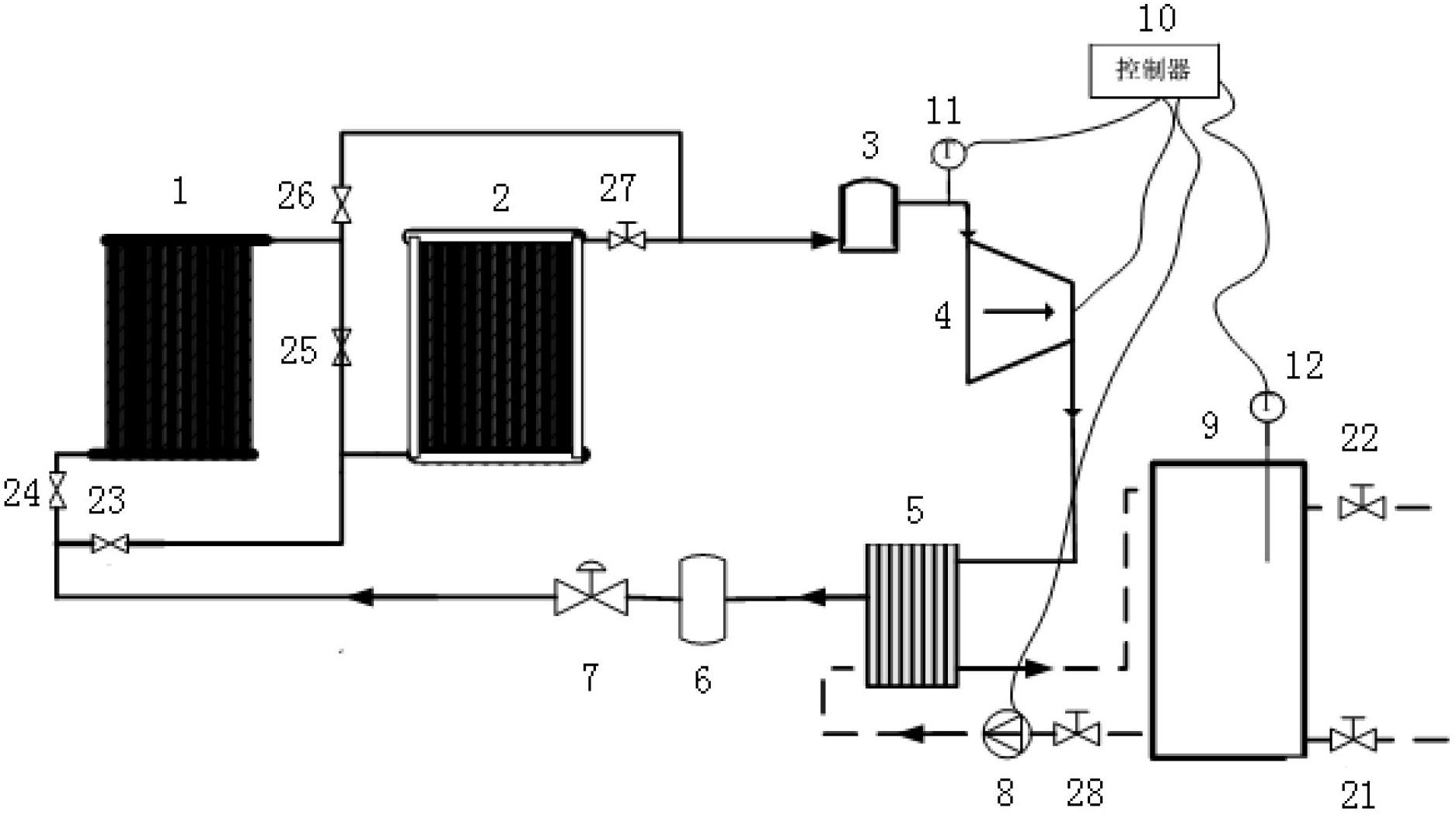

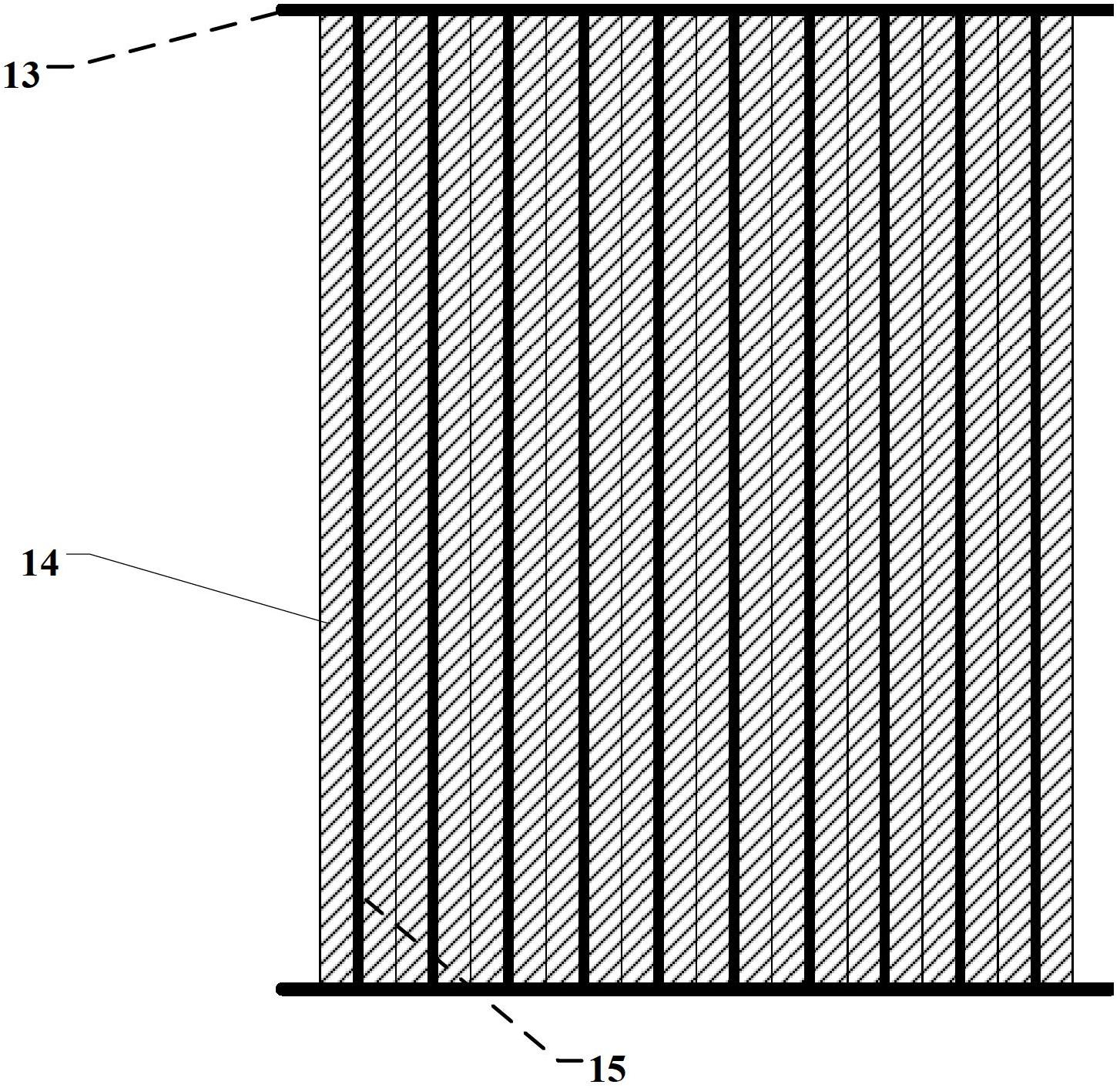

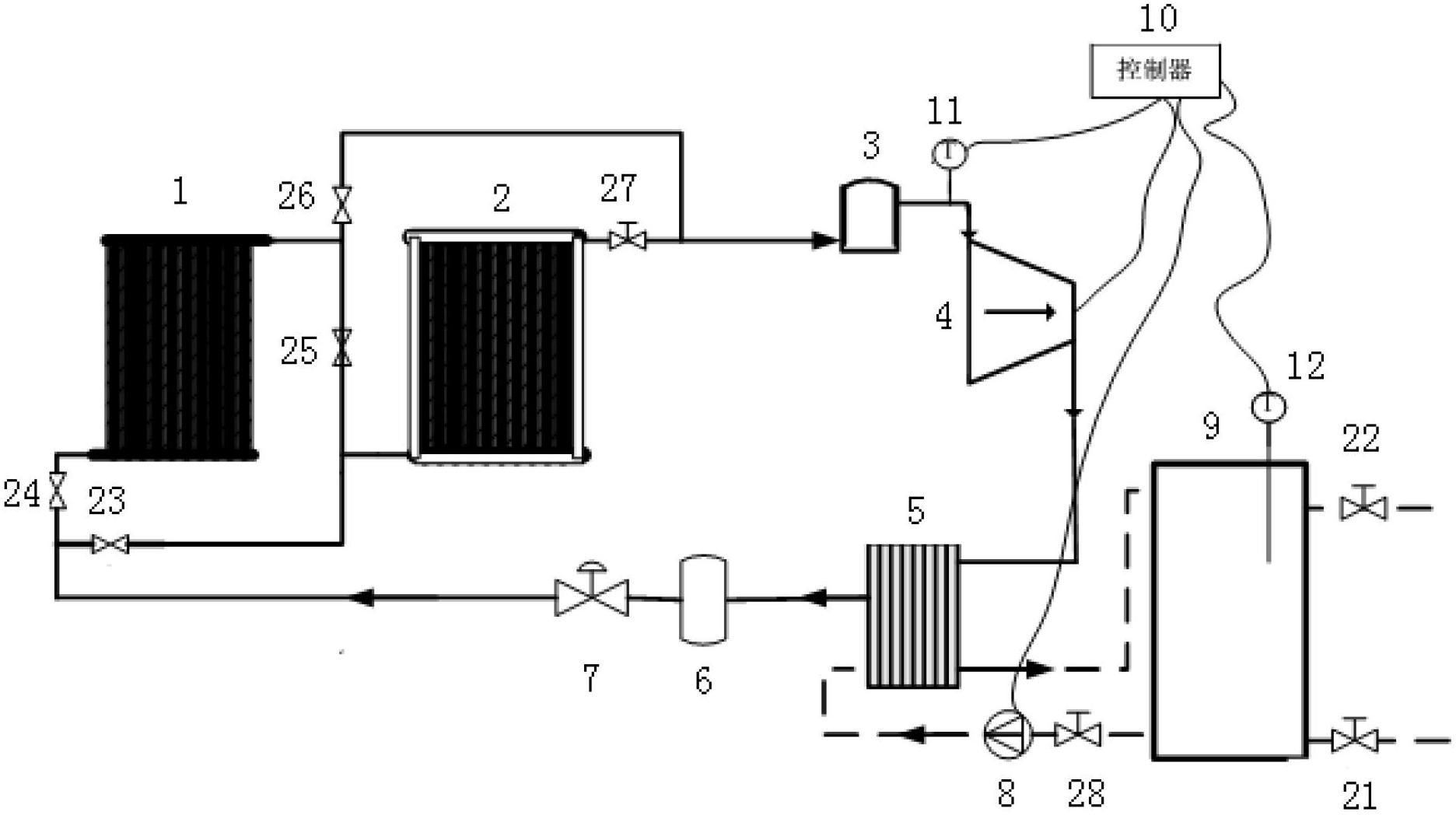

Direct-expansion solar heat pump water heating system

InactiveCN102645044ABalanced utilizationSmall pressure lossSolar heating energySolar heat devicesEnvironmental resistanceGlass cover

The invention discloses a heat absorption core of a collector used for a solar heat pump water heating system, a naked plate type collector, a collector with a glass cover plate as well as a direct-expansion solar heat pump water heating system. The naked plate type collector and collector with the glass cover plate are connected through an electromagnetic valve and a refrigerant copper pipe and, a PLC (Programmable Logic Controller) controls the open and close of the electromagnetic valve according to different external conditions so as to realize the separated operation and series operation of the naked plate type collector and the collector with the glass cover plate. Refrigerant gas through evaporation and compression enters a plate-type heat exchanger so as to carry out countercurrent flow heat exchange with circulating water, hot water temperature is fed back to a controller through a temperature sensor, and the controller controls the open and stop of a compressor. With the structure, the system has the advantages of high energy efficiency ratio, good environmental adaptation, simple structure and the like and is environment-friendly and energy-saving.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

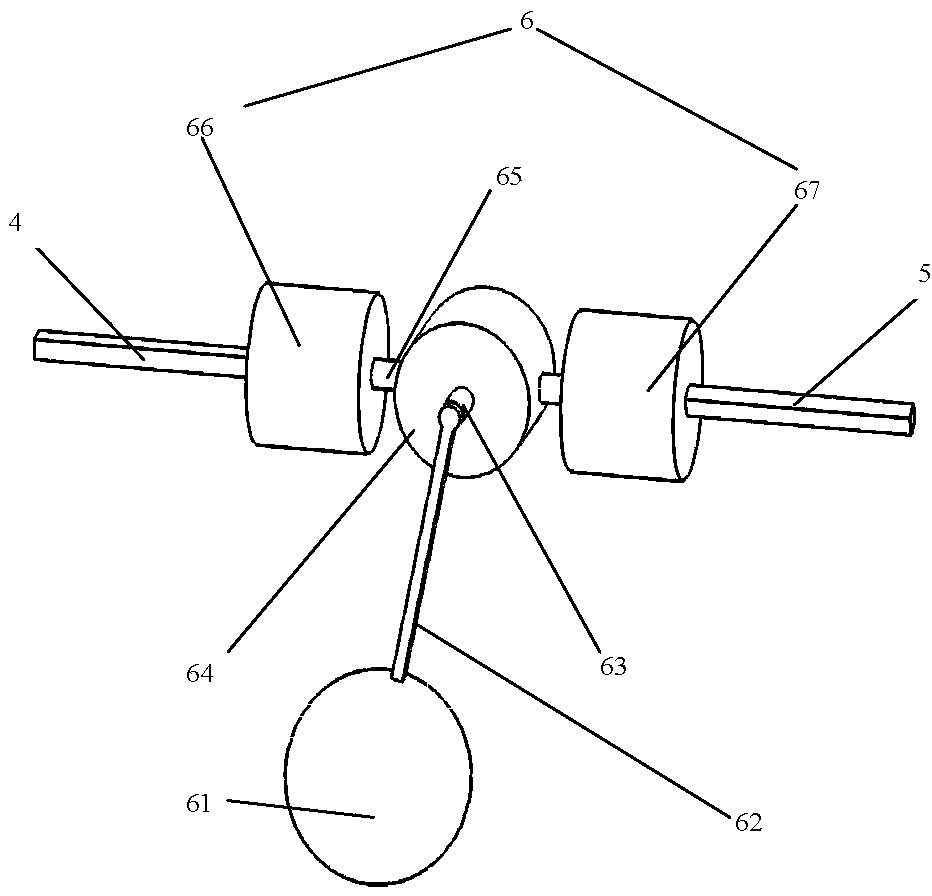

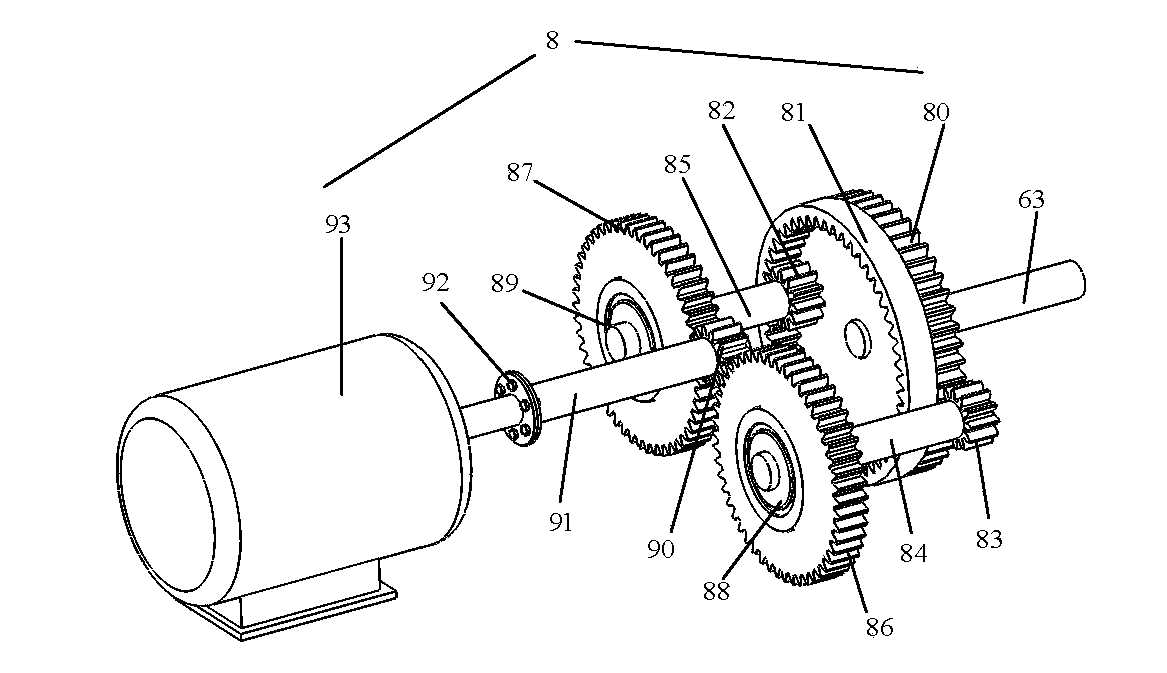

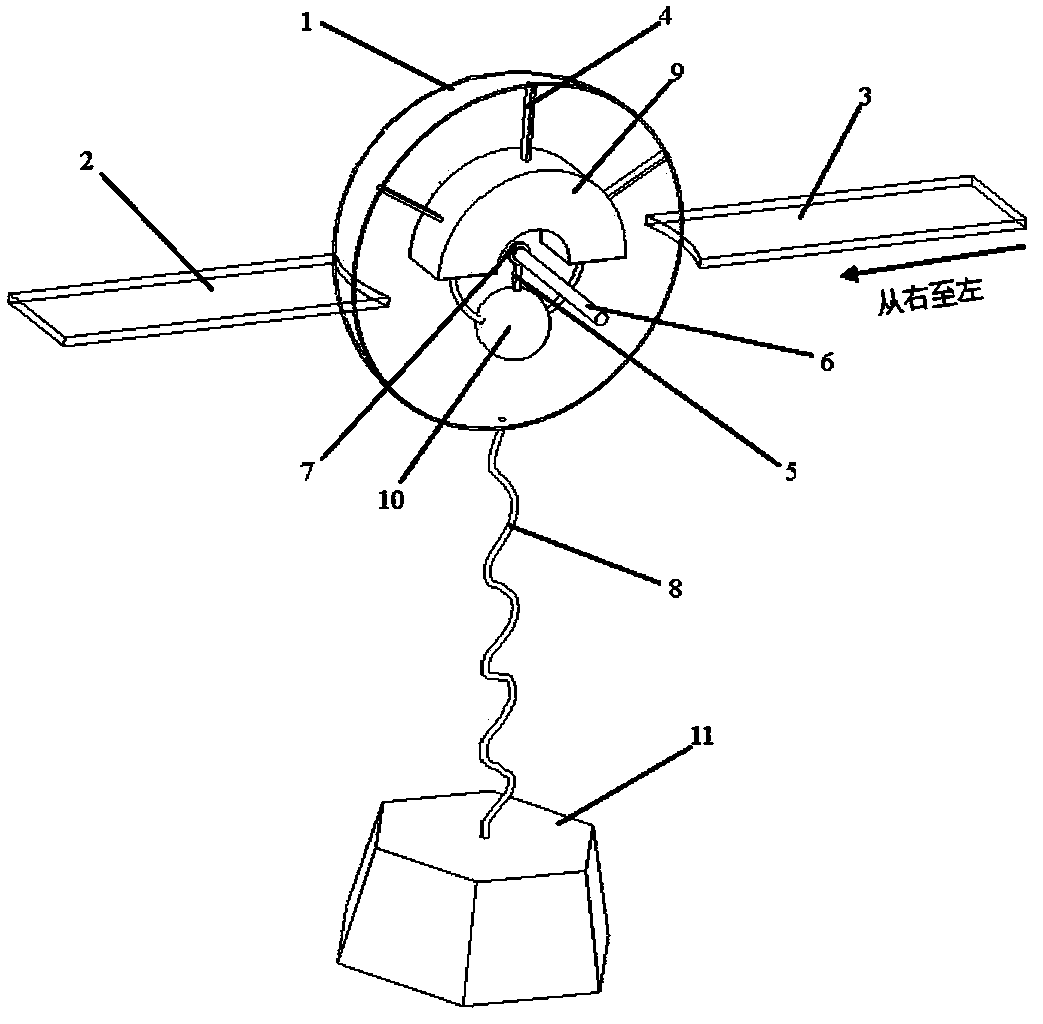

Spherical pendulum direct drive type wave power generation device

InactiveCN103807086ANot easy to corrodeExtended service lifeMachines/enginesEngine componentsRotational axisOcean bottom

The invention discloses a spherical pendulum direct drive type wave power generation device which comprises a spherical case, a supporting frame, a plurality of sets of floating plates, a mooring rope, a seabed weight, an internal case device and a generating mechanism. The spherical case is connected with the seabed weight through the mooring rope. The floating plates are fixedly welded to the periphery of the exterior of the spherical case. The two ends of the internal cabin device are fixedly connected with the spherical case through the supporting frame. The whole device can collect wave power in different directions under the inertia effect of a heavy punch, and the vertical reciprocating motion of waves can be converted into the single-direction rotating motion of a rotating shaft, so that a permanent magnet generator is driven to generate electricity. The wave power generation device can collect the wave power in the different directions and is high in wave power conversion efficiency, all energy conversion and transmission devices are arranged in the sealed spherical case and do not make contact with seawater, and therefore seawater corrosion is prevented, the corrosion resistance is high, and transporting, installing and debugging are convenient.

Owner:JIMEI UNIV

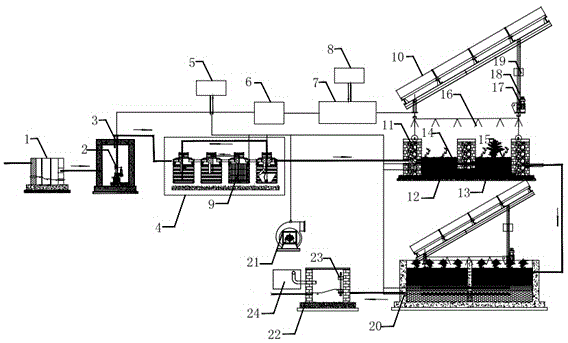

Multistage-series constructed wetland sewage treatment system and method based on solar energy

ActiveCN104876399ARealize photoelectric conversionLow costMultistage water/sewage treatmentEnergy based wastewater treatmentConstructed wetlandWater treatment system

The invention discloses a multistage-series constructed wetland sewage treatment system and method based on solar energy, which are used for multistage biochemical treatment on sewage. The sewage treatment system comprises an A<2> / O treatment device and a constructed wetland treatment system, which are connected in series; the constructed wetland treatment system is formed in such a way that a vertical flow constructed wetland and a horizontal flow constructed wetland are connected in series, and arranged in a shed film photovoltaic solar greenhouse with a ventilation device; an amorphous silicon film solar panel is laid on the outer surface at the top of the shed film photovoltaic solar greenhouse; when sun light energy irradiates the amorphous silicon film solar panel, one part of sun light energy is converted into electric energy, while the other part of sun light energy penetrates the amorphous silicon film solar panel to be used for plant photosynthesis. The sewage treatment system is high in efficiency, and the shed film photovoltaic solar greenhouse meets the illumination and temperature requirements of plants in normal growth in all seasons, achieves the low-cost solar energy generation, and has favorable economic benefits and environmental benefits.

Owner:ZHEJIANG CREATE ENVIRONMENTAL TECH

Biological treatment apparatus and method for wastewater containing volatile organic matter

InactiveCN101481171AEasy to transport and installSimple process daily operationDispersed particle separationSustainable biological treatmentWater dischargeAtmospheric air

The invention relates to a device and a method for the biological processing of waste water containing volatile organic substances. The main part of the device comprises a liquid-phase biological fluidized bed and a gas-phase biological dripping filtration bed which are coupled, a porous flow guiding cylinder is arranged in the liquid-phase biological fluidized bed, a compound magnetic polyurethane foam carrier is filled in the porous flow guiding cylinder, and the bottom of the porous flow guiding cylinder is provided with a micropore aeration system to provide sufficient oxygen for biological oxidizing reaction. A compound magnetic polyurethane foam carrier is filled in the gas-phase biological dripping filtration bed to further degrade the volatile organic chemical compound generated in the biochemical process to thoroughly degrade the volatile organic substances. The device has high sewage processing efficiency, ensures the water quality of processed water reaches the national first-grade waste water discharge standard, and eliminates the atmosphere pollution by the volatile organic compound in the biochemical process. The device of the invention has simple structure, small occupied land, low investment, high waste water processing efficiency and low energy consumption, and is suitable for the processing and the recovery of the waste water containing volatile organic substances.

Owner:深圳市中拓天达环保科技有限公司

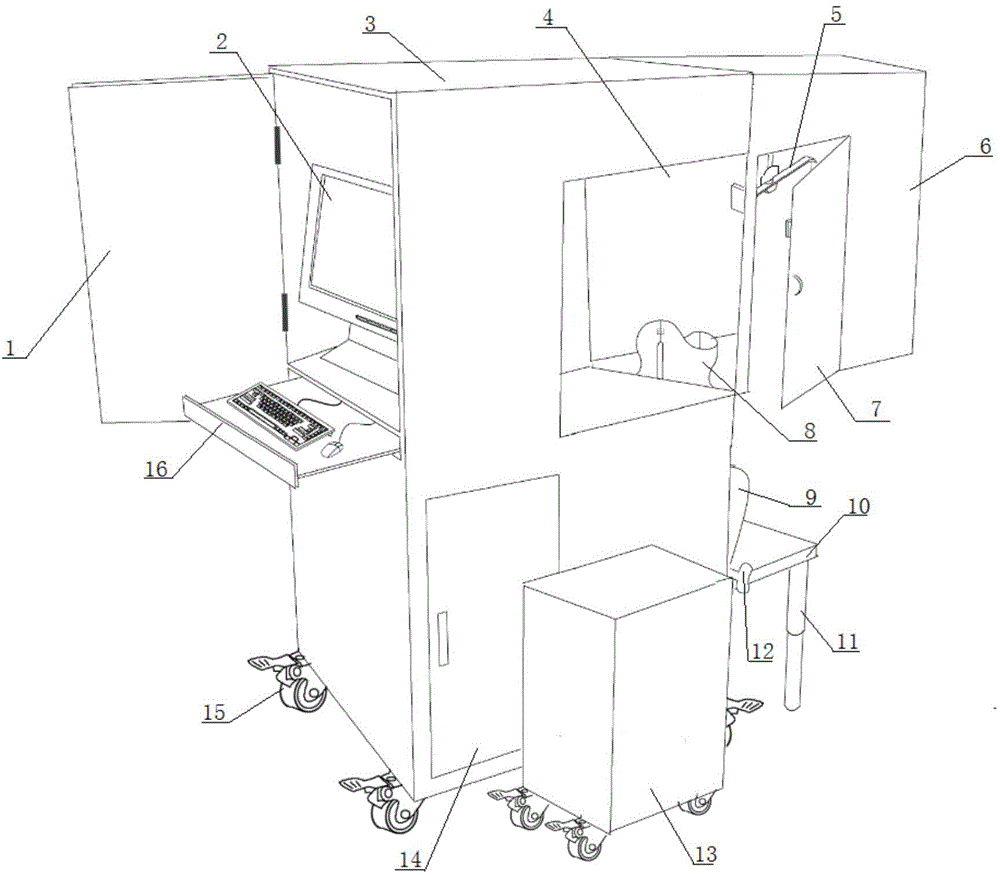

Cerebral cortex transcranial magnetic stimulation three-dimensional positioning navigation system and method

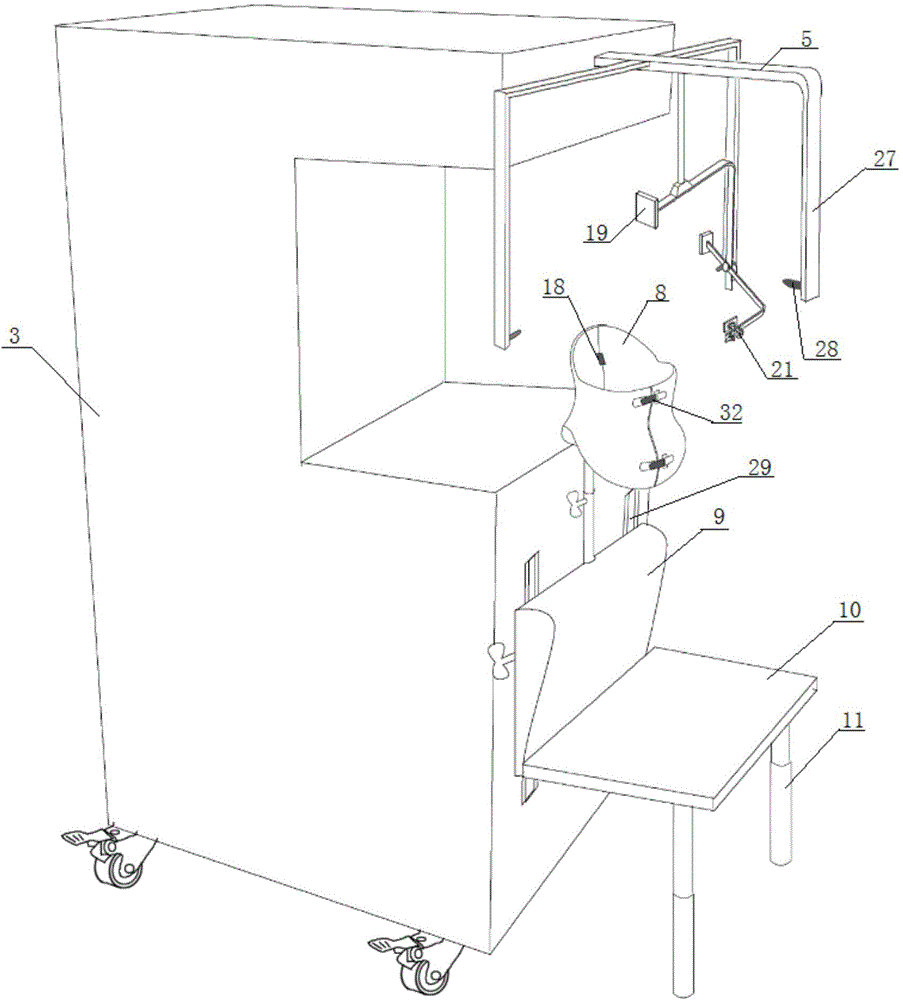

ActiveCN104436443ASystematize the treatment processGuaranteed accuracyElectrotherapyDiagnostic recording/measuringMotor driveNavigation system

The invention discloses a cerebral cortex transcranial magnetic stimulation three-dimensional positioning navigation system and method. The navigation system comprises a fixing device, a navigation device and an auxiliary positioning device, wherein the fixing device comprises a fixer, and the navigation device is arranged above the fixing device and comprises a first motor and a second motor driven by the first motor; the auxiliary positioning device comprises a conformal mask and positioners arranged around the conformal mask, and positioning holes are formed in the conformal mask; the first motor and the second motor are connected to one controller. According to the navigation method, through a coordinate conversion method, the position of a nidus in a scintigram is made to correspond to the position in an actual coordinate system, then, the motors are driven for navigation, and a basis is laid for subsequent treatment. Through the device and method, the nidus can be accurately and rapidly positioned and stimulated, and good equipment and a good research idea are provided for transcranial magnetic stimulation treatment.

Owner:苏州脑控脑科学技术有限公司

Moveable fabricated construction operating platform mechanism and construction method thereof

PendingCN106677513AAvoid shakingSimplified transportation and installationBuilding repairsBuilding support scaffoldsSteel columnsHanging basket

The invention belongs to the field of steel structure building, and particularly relates to a movable fabricated construction operating platform mechanism and a construction method thereof. The platform mechanism comprises supporting steel columns and an inter-column steel beam vertically and fixedly connected with the supporting steel columns. A to-be-installed steel beam reinforcing element is arranged on the lower portion of the inter-column steel beam. A movable platform is arranged on the upper portion of the inter-column steel beam and can move or can be fixed on the steel beam through nylon wheels or clamping screws correspondingly. Hanging baskets are arranged on the two sides of the platform, and the bottoms of the hanging baskets are connected through stabilizing support rods. The movable fabricated construction operating platform mechanism is a safe and reliable operating platform for suspended operation; and the movable fabricated construction operating platform mechanism of the fabricated structure is high in turnround rate and adaptability, and capable of being widely applied to the construction operation of reinforcing, coating, welding and the like of the bottoms of the steel beams.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for prefabricated building

The invention provides a construction waste-containing high-strength light-weight composite PC (polycarbonate) mortar board for a prefabricated building. The mortar board comprises an inner PC board layer, an outer PC board layer and a filling material layer arranged between the inner PC board layer and the outer PC board layer. A preparation method of the mortar board comprises the following steps of performing hammering, vibrating, crushing, grinding and other processes on concrete and brick slag in construction wastes to form a regenerated building aggregate; performing high-speed rotation on the regenerated building aggregate to obtain regenerated micro powder, and collecting the regenerated micro powder; mixing the regenerated building aggregate, the regenerated micro powder, a polymer, cement, rice hulls and straws, basalt fibers and glass fibers, ceramsite and other auxiliaries to obtain the PC board layers; mixing polystyrene foam, asbestos foam or nano-sized aerogel with the polymer to obtain the filling material layer; and finally, compounding the PC board layers and the filling material layer to obtain the construction waste-containing high-strength light-weight composite PC mortar board for the prefabricated building. The preparation method is simple; and as regenerated building agricultural wastes are taken as a large part of raw materials, on the basis of guaranteeing high strength and light weight, the cost is reduced, and the mortar board is green and environment friendly.

Owner:SHAOXING YISHENG MORTAR

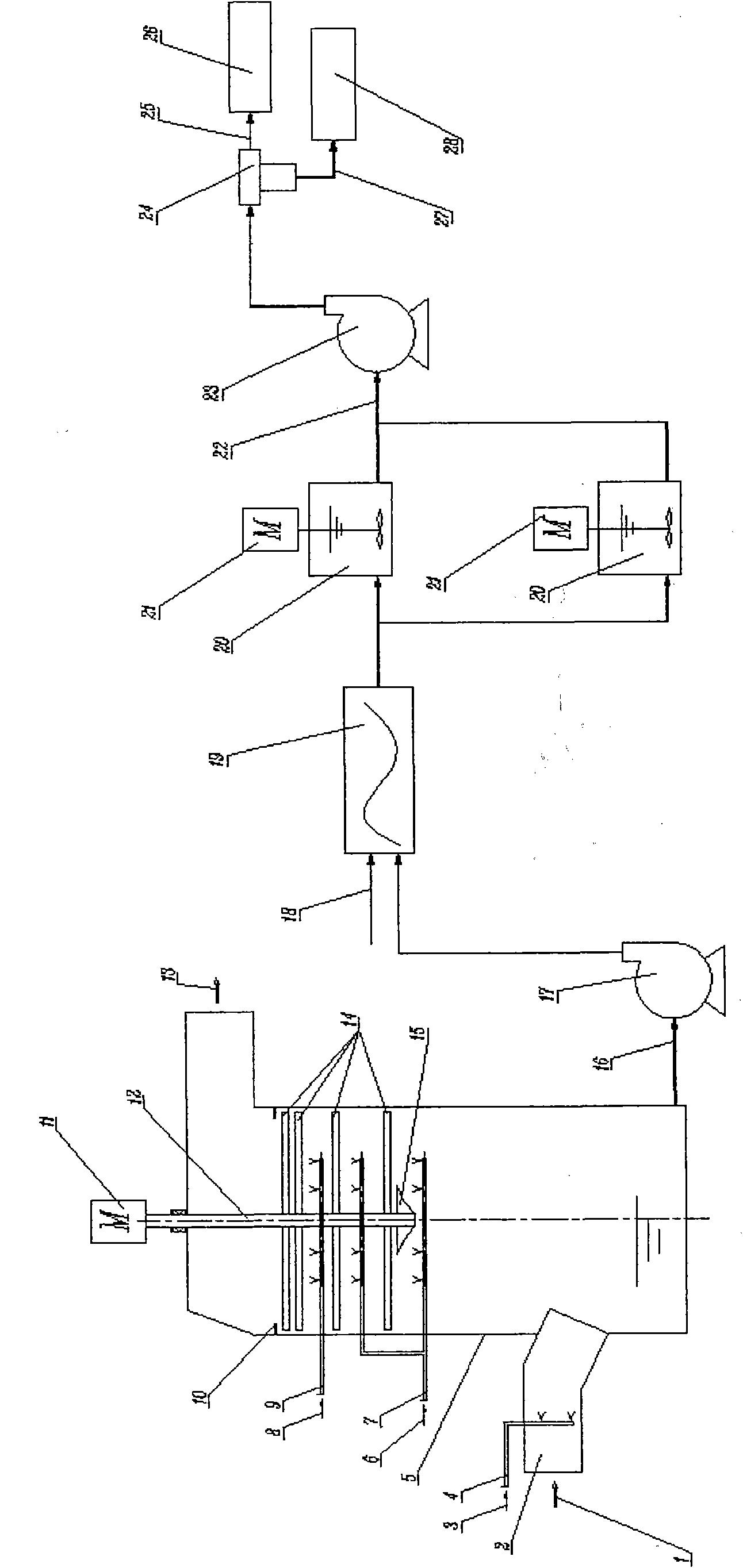

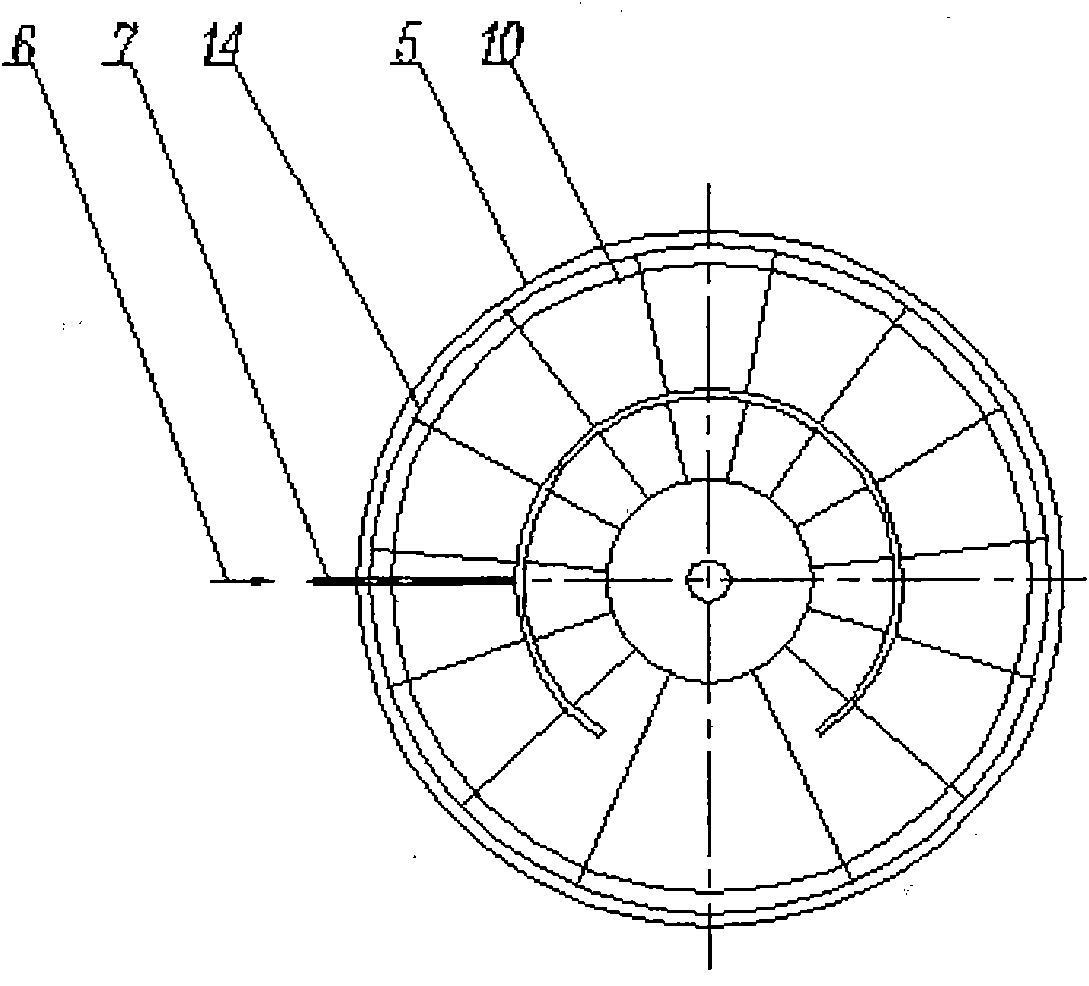

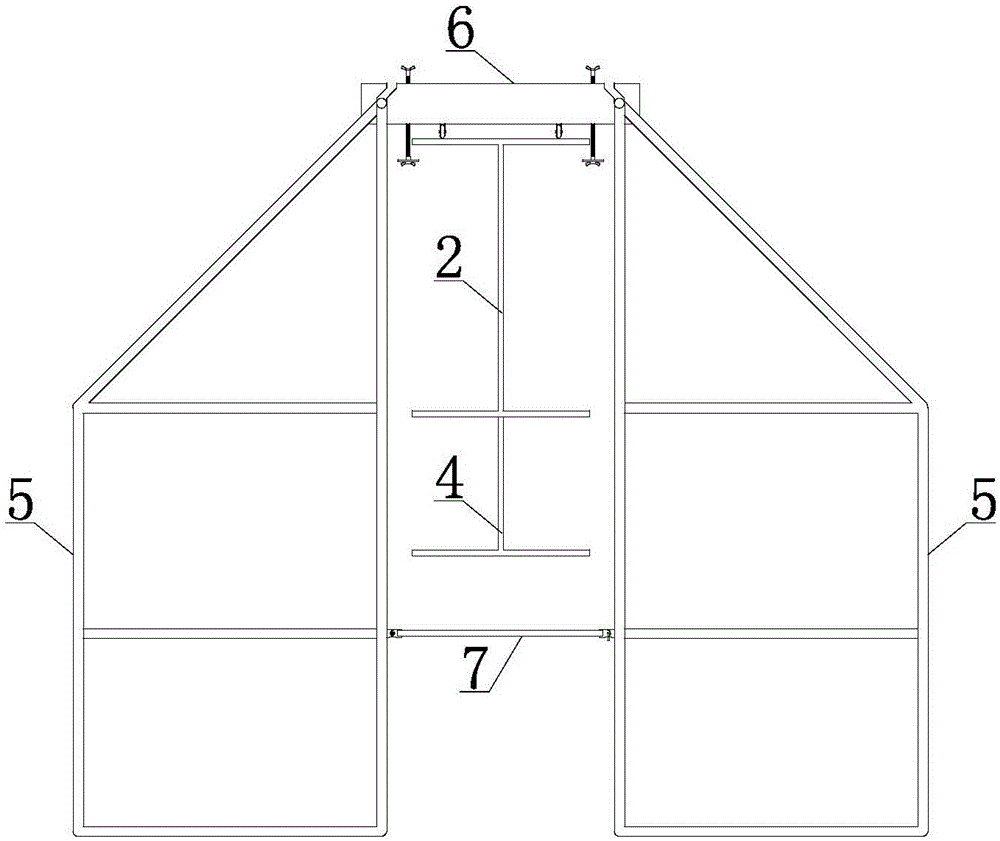

Cereal drying machine

InactiveCN105104522AWill not affect healthWon't breakFood processingClimate change adaptationCold airPulp and paper industry

The invention relates to the field of cereal drying, and in particular relates to a cereal drying machine. The cereal drying machine comprises a drying tower (1) and a heat pump (2) which is communicated with the drying tower (1) and is used for providing hot air for the drying tower, wherein the heat pump (2) comprises a pump shell (3) and an evaporator (4) arranged in the pump shell; the cereal drying machine is characterized by further comprising a dust collection room (5) which is communicated with the drying tower (1) and is used for collecting waste air discharged by the drying tower; and a defrosting heating device is arranged on the evaporator (4). The cereal drying machine can efficiently filter the discharged waste air, and the phenomenon that cold air is generated at an air outlet where the evaporator is positioned during defrosting of the evaporator is avoided.

Owner:浙江天洲制冷机电有限公司 +1

Multi-point multi-frequency three-dimensional transcranial magnetic stimulation system and intracranial and extracranial coordinate conversion method

ActiveCN104474636AGood effectAdjustable frequencyElectrotherapyDiagnostic recording/measuringAnatomyNeck position

The invention discloses a multi-point multi-frequency three-dimensional transcranial magnetic stimulation system and an intracranial and extracranial coordinate conversion method. The system comprises a fixing device, a stimulation device and an auxiliary positioning device, wherein the fixing device fixes the neck position of a patient, the stimulation device carries out fixed point magnetic stimulation on the patient, and the auxiliary positioning device is used for determining a positioning point in an auxiliary way for realizing the intracranial and extracranial coordinate conversion. Meanwhile, the coordinate conversion method provided by the invention can conveniently and fast realize the intracranial and extracranial coordinate conversion, and is matched with the system, and an all-around automatic transcranial magnetic stimulation treatment scheme is provided. The device has the advantages that the structure is simple, the function is practical, an effective device is provided for transcranial magnetic stimulation treatment, and a novel study idea is provided.

Owner:苏州脑控脑科学技术有限公司

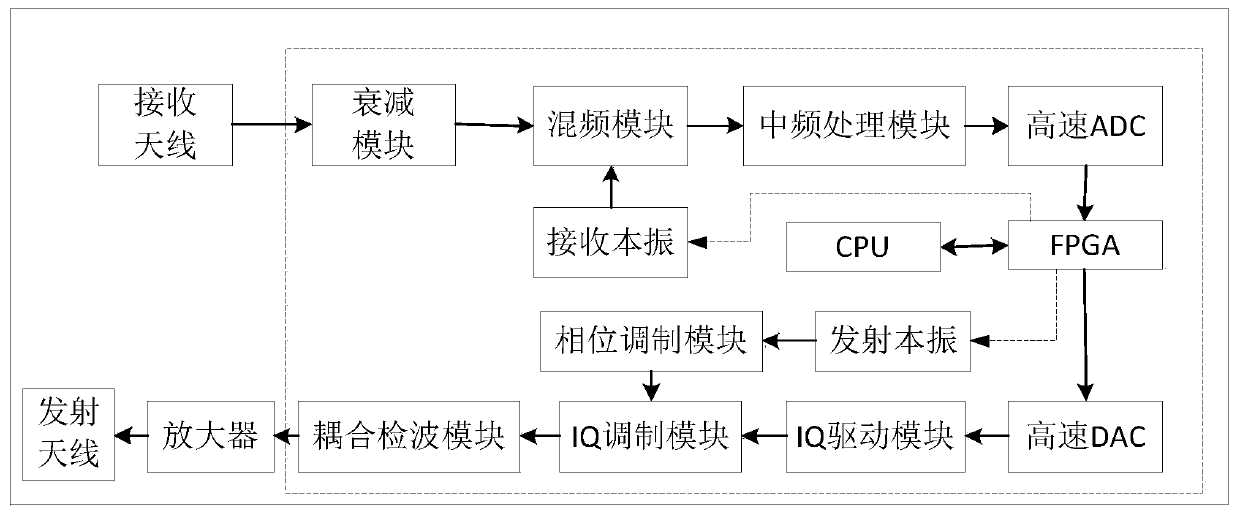

Unmanned aerial vehicle real-time tracking and rapid countermeasure integrated control system and method

ActiveCN110247729AQuick discoveryNarrow instantaneous spectrumCommunication jammingFrequency spectrumIntermediate frequency

The invention discloses an unmanned aerial vehicle real-time tracking and rapid countermeasure integrated control system and method. The system comprises a receiving antenna, an attenuation module, a frequency mixing module, an intermediate frequency processing module, a high-speed ADC, an FPGA, a high-speed DAC, an IQ driving module, an IQ modulation module, a coupling detection module, an amplifier and a transmitting antenna which are sequentially connected. The frequency mixing module is connected with the receiving local oscillator; the FPGA is connected with the CPU; the transmitting local oscillator is connected with the IQ modulation module through the phase modulation module; according to the method, an efficient digital signal processing algorithm is adopted to realize real-time processing of unmanned aerial vehicle signals; capturing and analysis of the frequency hopping signal are completed within an extremely short time, the target signal is identified, the countering signal is transmitted to the target, the countering signal can track hopping of the frequency hopping signal, the instantaneous frequency spectrum of the countering signal is narrow, only the instantaneous frequency spectrum of the frequency hopping signal needs to be covered, power is saved, and the influence on the electromagnetic environment is reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

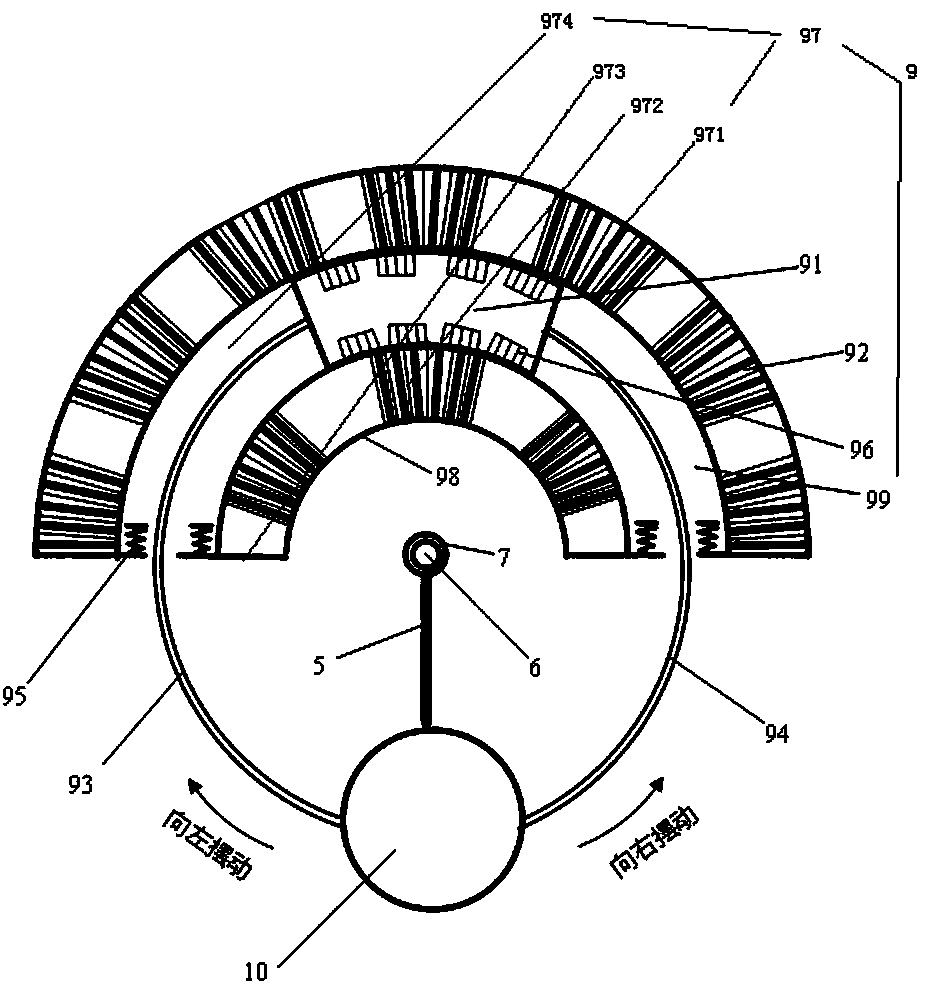

Spherical pendulum arc type wave power generation device

InactiveCN103807087ASimple structureHigh conversion and transmission efficiencyMachines/enginesEngine componentsSpherical pendulumSeawater

The invention discloses a spherical pendulum arc type wave power generation device which comprises a spherical case, a left floating plate, a right floating plate, a fixing frame, an oscillating rod, a horizontal supporting shaft, a bearing, a steel cable, an arc generator, a heavy punch, a seabed weight and the like. The spherical case is connected with the seabed weight through the steel cable. The left floating plate and the right floating plate are symmetrically welded to the outer wall of the spherical case. The arc generator is fixed to the inner wall of the spherical case through the fixing frame. The bearing is fixedly connected to the horizontal supporting shaft of the sphere center of the spherical case in a sleeved mode. The heavy punch is connected with the bearing through the oscillating rod. The wave power generation device is simple in structure, the number of the middle transmission and conversion processes of wave power is reduced to the minimum degree, and the conversion and transmission efficiency of the wave power is high. Meanwhile, a wave power transmission device and a wave power generating device are arranged in the sealed spherical case, no motion parts are arranged outside the spherical case, and therefore the wave power generation device can not be corroded by seawater easily, and is long in service life and convenient to install, transport, debug and maintain.

Owner:JIMEI UNIV

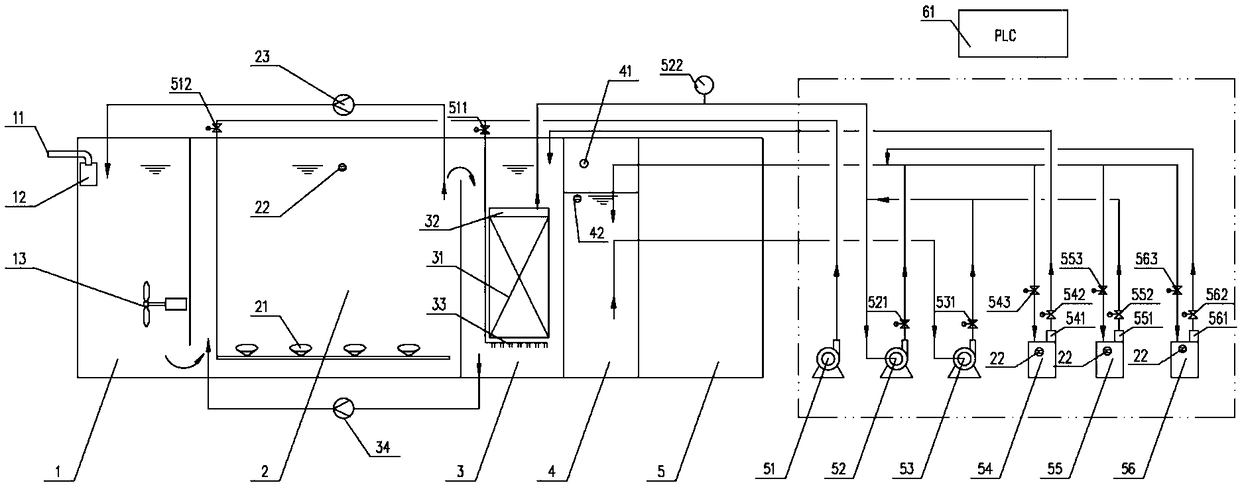

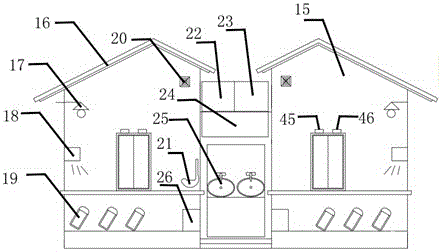

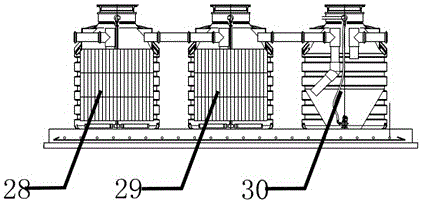

Rainwater wash-out ecological toilet based on solar power generation and sewage treatment method thereof

InactiveCN105036480APlay a blocking rolePlay a light-transmitting roleGeneral water supply conservationPhotovoltaicsConstructed wetlandEnvironmental resource management

The invention discloses a rainwater wash-out ecological toilet based on solar power generation. The rainwater wash-out ecological toilet based on solar power generation comprises a rainwater filtering and collecting system, a solar power generation and supply system, a PLC control system, an integrated public toilet body, a combined sewage treatment system and a composite artificial wetland system which are all sequentially connected. The solar power generation and supply system is arranged on the top of the integrated public toilet body and used for supplying power to the rainwater filtering and collecting system, the PLC control system, the integrated public toilet body, the combined sewage treatment system and the composite artificial wetland system. The rainwater filtering and collecting system is used for collecting rainwater and filtering and processing the rainwater, and then the rainwater can be supplied to the toilet. The combined sewage treatment system and the composite artificial wetland system are connected in series for use and used for processing drained water of the toilet. The PLC control system is used for performing automatic control over the whole system. The toilet supplies power through clean energy. The drained water of the toilet can be effectively processed, maintenance cost is low, and the ecological toilet has very important ecological benefits, economic benefits and social benefits.

Owner:杭州科瑞特环境技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com