Composite shear wall with concrete-filled steel tube frames and double steel plates with concealed bracings and construction method thereof

A technology of concrete filled steel tube and combined shear wall, which is applied in the direction of wall, building component, earthquake resistance, etc., can solve the problems of unfavorable seismic performance of the whole structure, prone to brittle failure, poor ductility, etc., to avoid adverse effects, simplify construction procedures, The effect of improving ductility and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

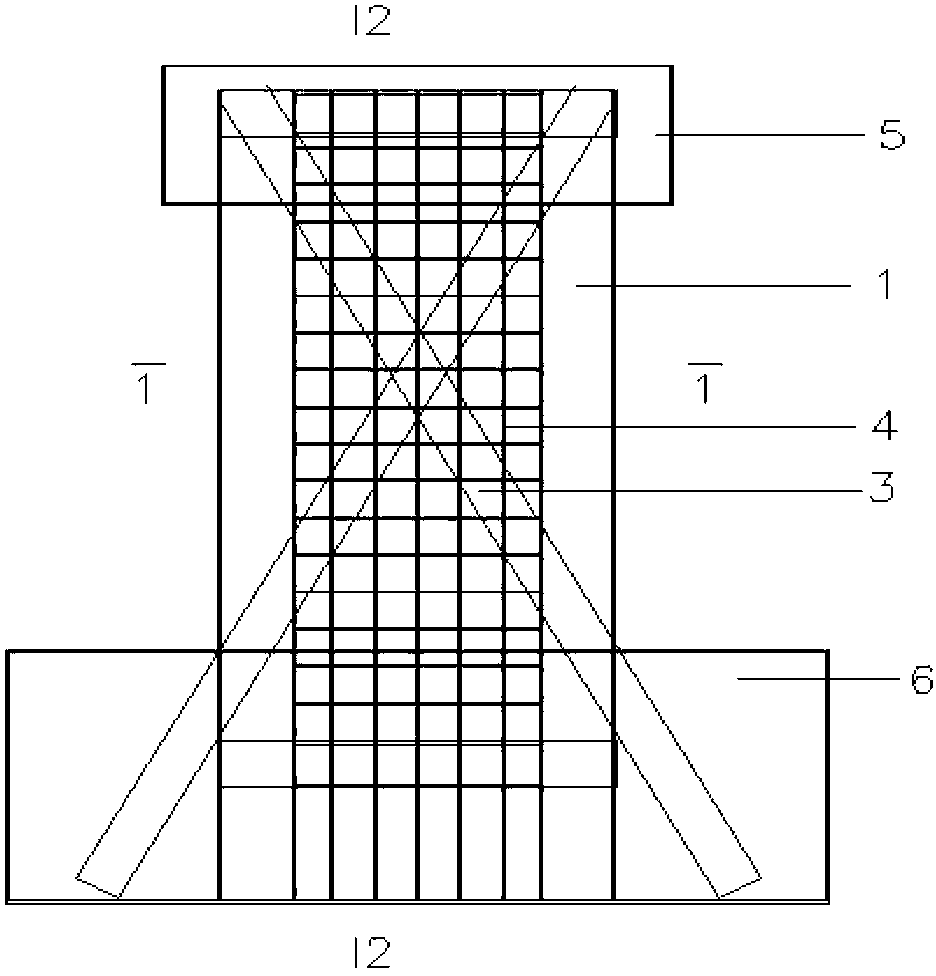

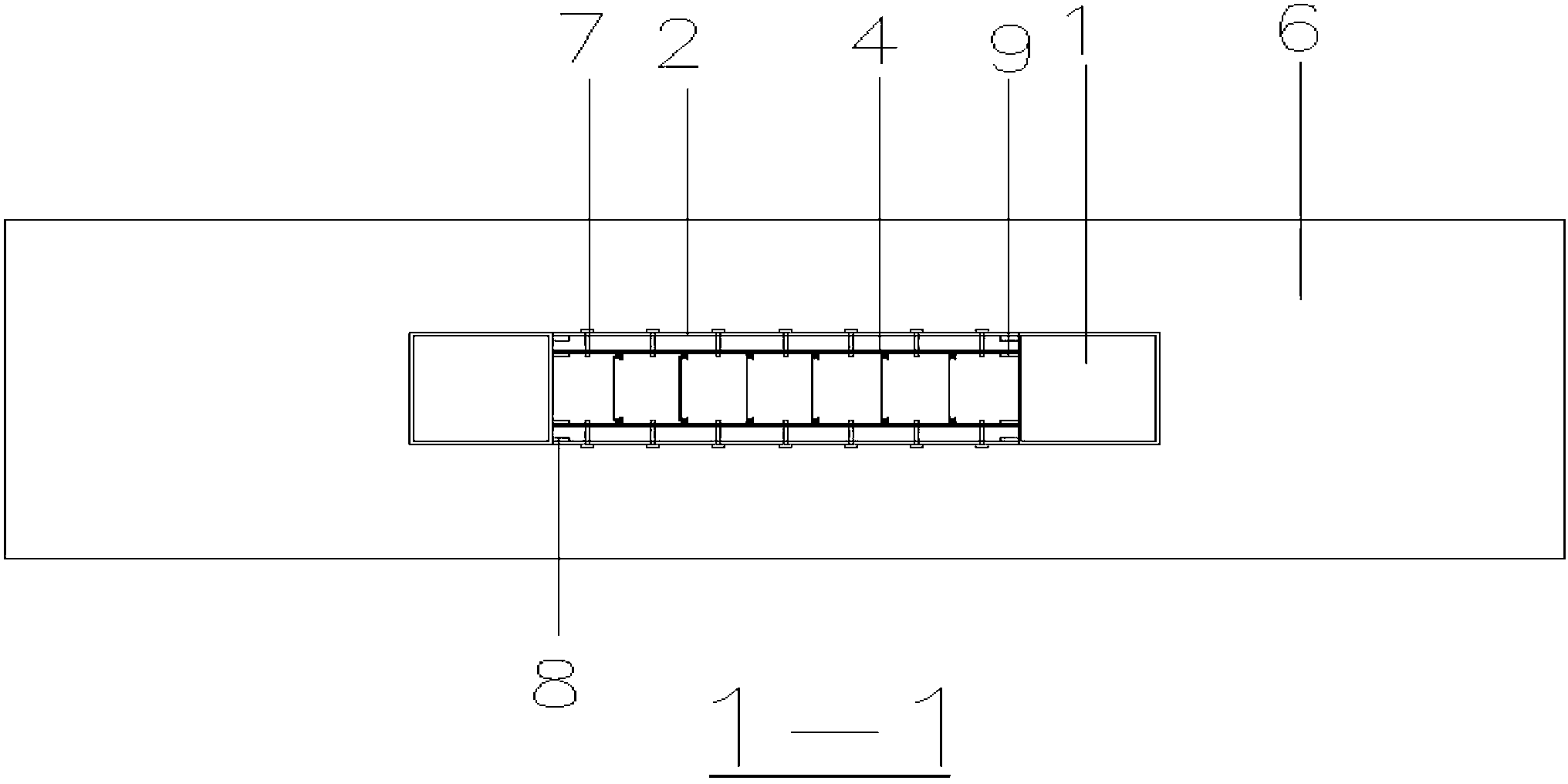

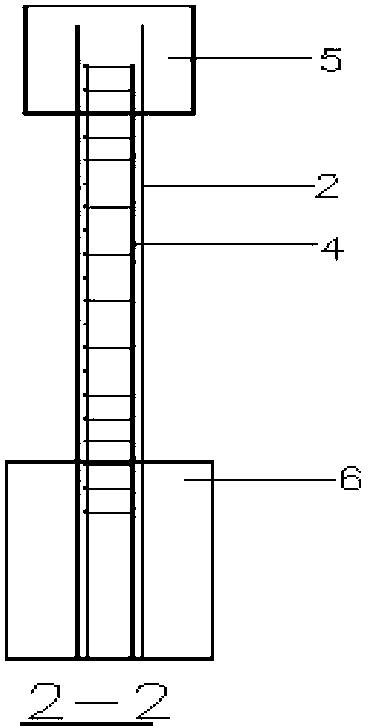

[0023] The steel tube concrete frame double steel plate concealed support combined shear wall such as Figure 1 ~ Figure 3 . The steel tube concrete frame double steel plate concealed support combined shear wall of this embodiment includes a steel tube concrete frame 1, a wall and a hidden support steel plate 3. The concrete filled steel tube frame 1 is filled with concrete, and the steel tube upper wall of the steel tube concrete frame 1 Welding is used to fix the steel connecting ribs 9 of the horizontally distributed steel bars that make up the distributed steel mesh 4 and the vertical steel slats 8 used to fix the steel plates 2 on both sides; there is a hidden support steel plate 3 inside the wall, and the hidden support steel plate 3 consists of two The mild steel plate crosses into an X shape, diagonally across the steel tube concrete frame 1, the lower part directly extends to the foundation beam 6, the upper part extends to the upper frame beam 5, and the hidden suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com