Water-resisting returnable multi-stage buffer fractured self-deformation self-latching shot hole stopper

A technology of plugging and self-deformation, which is applied in blasting and other directions, can solve problems such as unsatisfactory application and uncoordinated development, and achieve the effects of reducing the probability of gas explosion, achieving homogenization, and reducing the consumption of explosives per unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

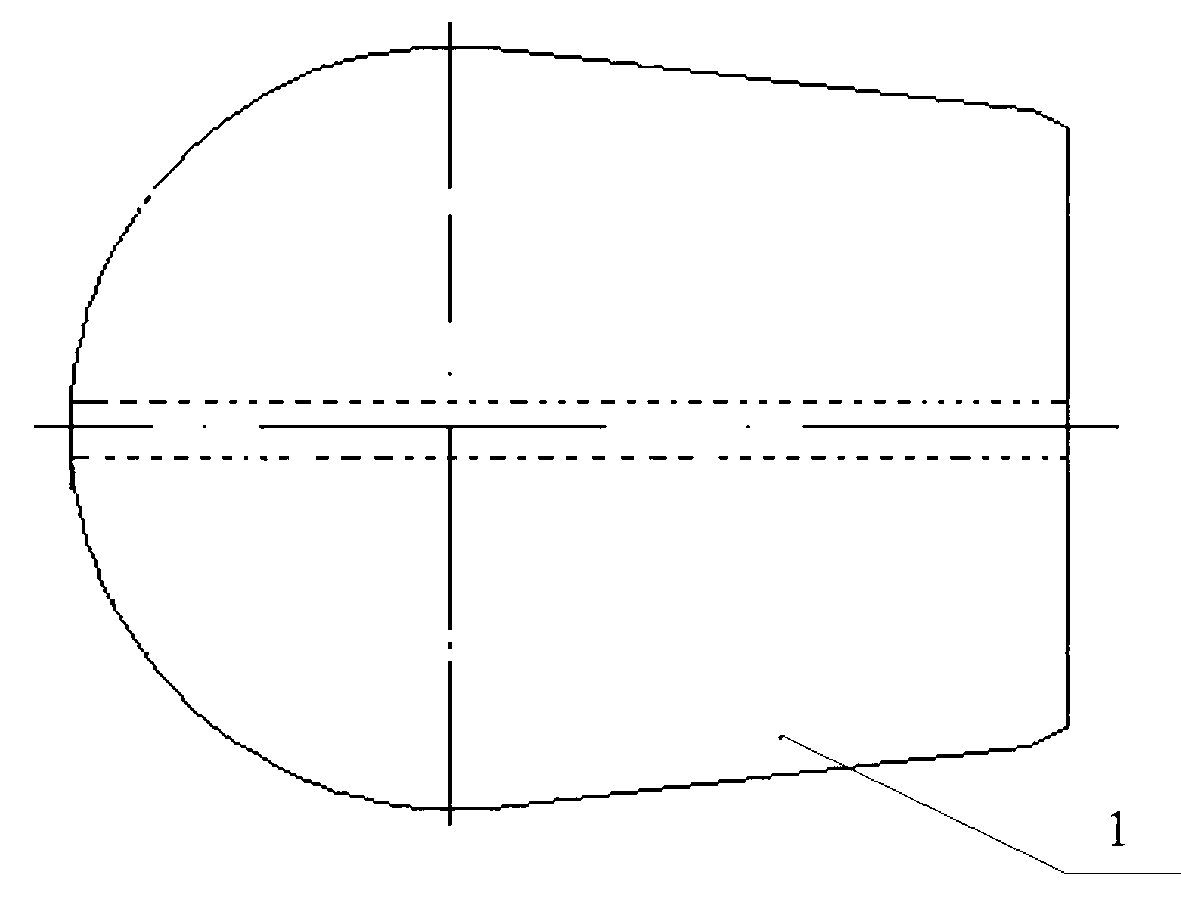

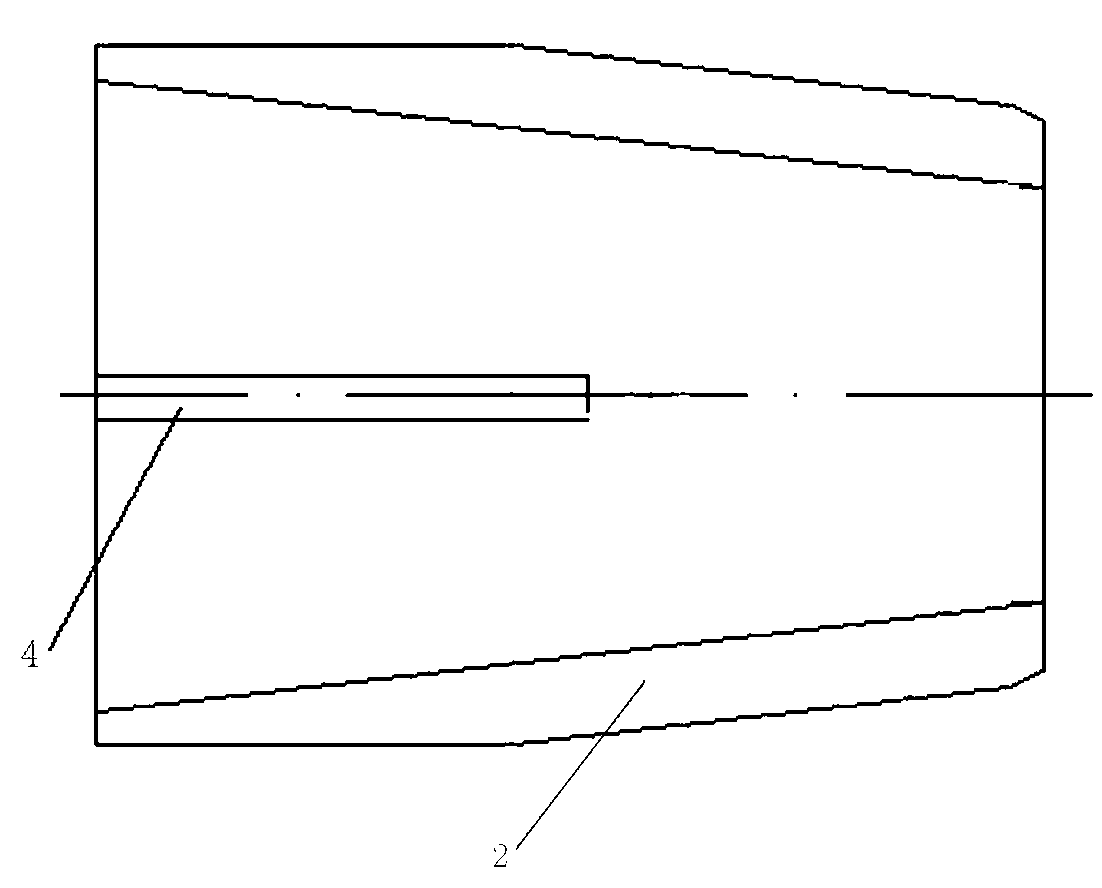

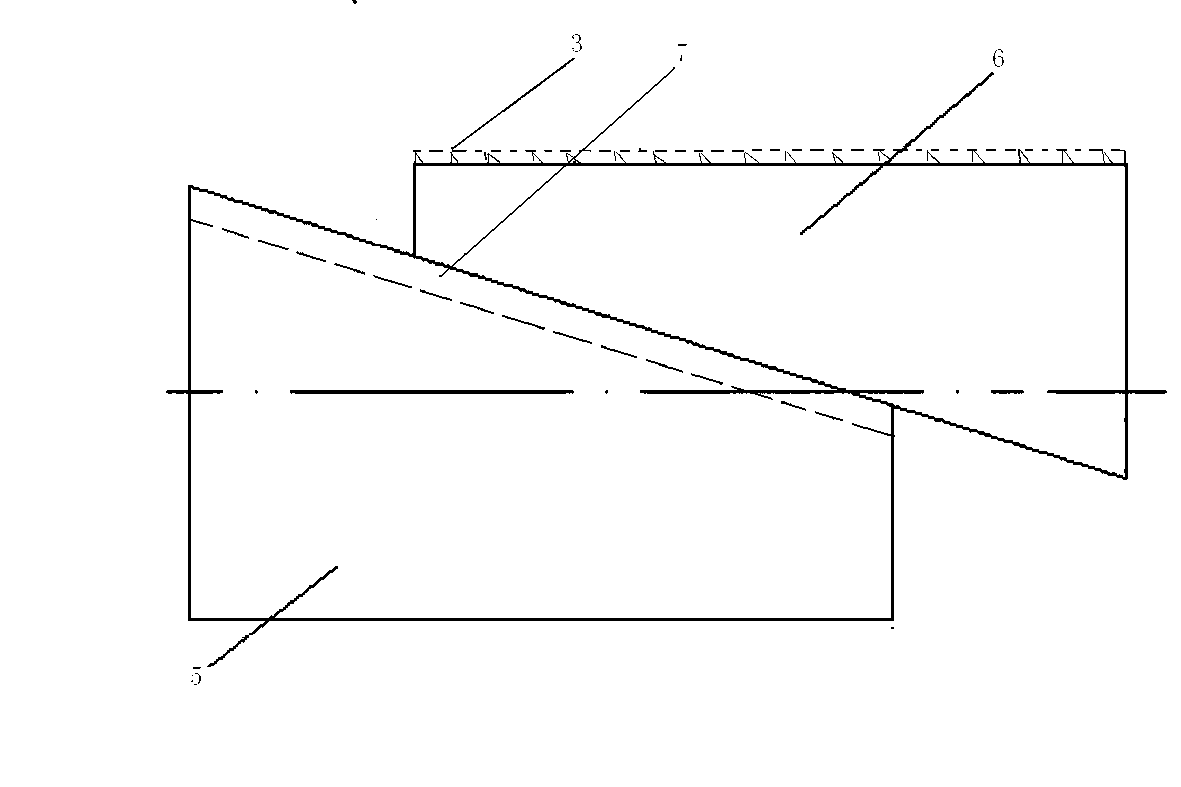

[0053] Such as figure 1 , 2, 3, and 4, a water-resistant and reversible multi-stage buffer expansion self-deformation self-locking blasthole plug consists of three parts: an expansion plug 1, several expansion tubes 2, and a wedge-shaped plug complete set of products. The expansion plug 1 and the expansion rings 2 are sequentially plugged and connected, and the wedge-shaped blocker is arranged behind the expansion ring and close to the blasthole opening, including two wedge-shaped blocks used in conjunction. Its principle is designed by adopting multi-level and various types of expansion control principles. The action of the explosion stress wave (shock wave) pressure or the water pressure of the water gun cement on the expansion plug will cause the expansion plug to move to the blast hole, and the advancement of the expansion plug will inevitab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com