Novel plastic thermal-insulation wallboard

A technology of thermal insulation wall panels and plastic panels, which is applied to building components, layered products, buildings, etc., can solve the problems of low resource recycling and poor thermal insulation performance, and achieve the effects of convenient operation, low weight and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and embodiments.

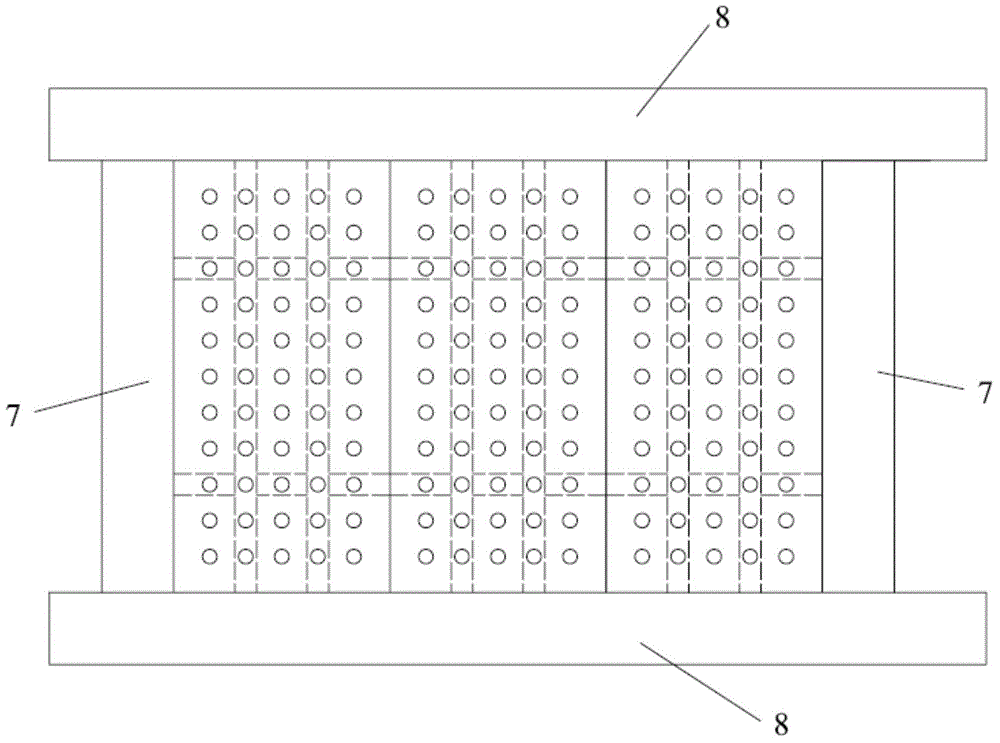

[0026] Such as Figure 1-6 As shown, a new type of plastic thermal insulation wall panel includes a plastic panel core 1, a metal wire mesh sheet 2 and a mortar layer 3. The thickness of the plastic panel core 1 is designed according to the wall size, and the surface of the plastic panel core 1 Rough, with a cavity inside, in order to enhance the overall in-plane strength and rigidity of the plastic plate core 1, vertical and horizontal hidden ribs 5 are arranged inside; in order to leave a space between the plastic plate core 1 and the metal wire mesh 2 for painting The mortar layer 3, the outer surface of the plastic core body 1 is regularly arranged with protrusions 4 at a certain interval along the vertical and horizontal directions. The top of the protrusions 4 is provided with a circular hole or a circular hole-shaped fixing member 6 for passing through the wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com