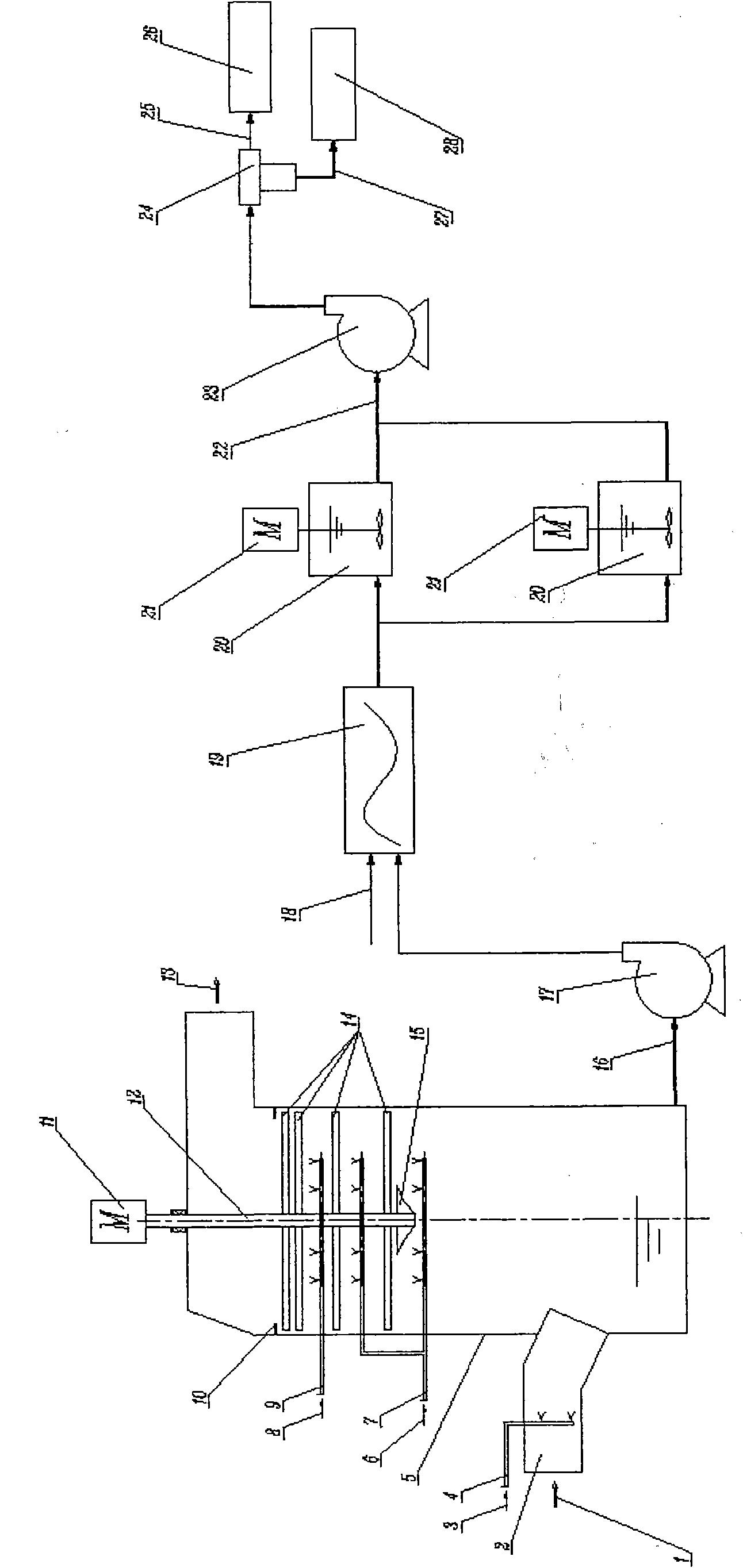

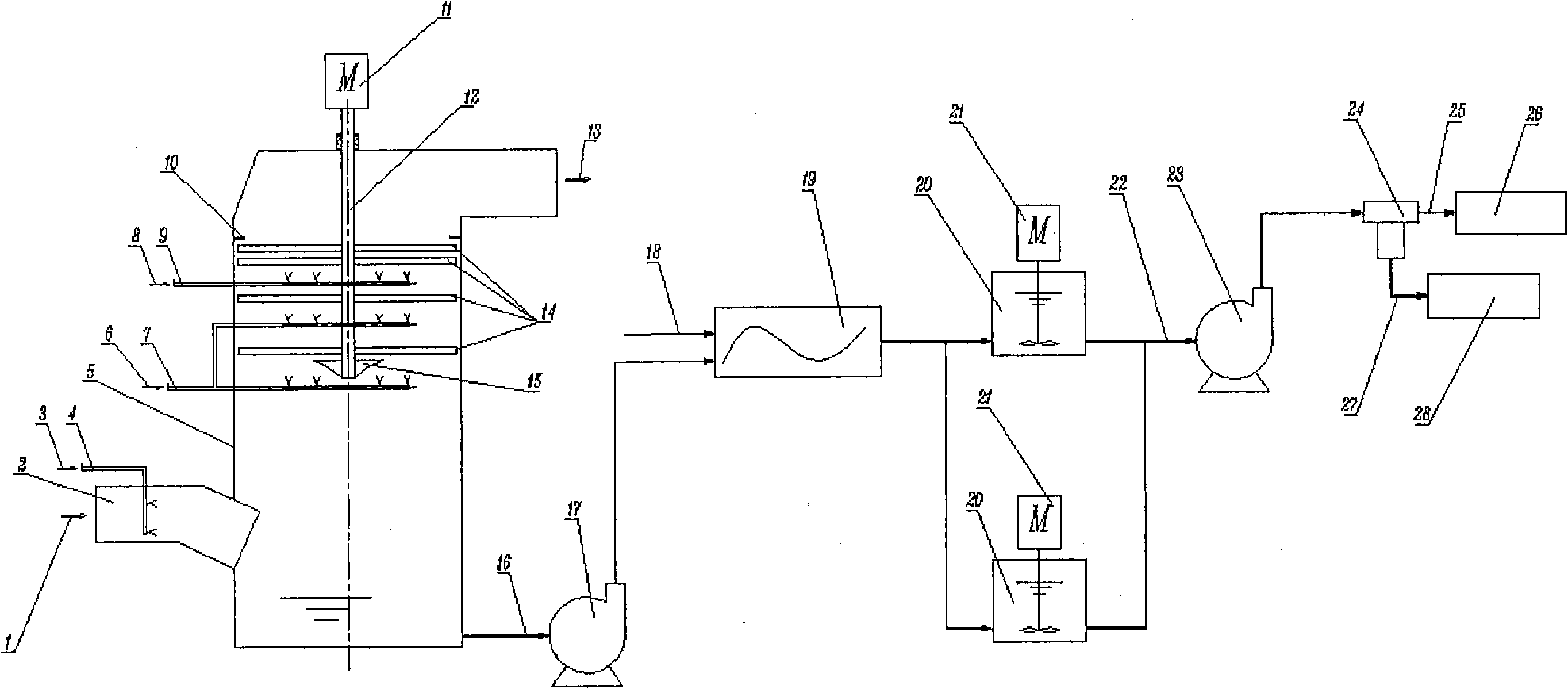

Production process for removing carbon dioxide from smoke and preparing ammonium compound fertilizer and light calcium carbonate

A light calcium carbonate, production process technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, products, etc., can solve the problems of high operating cost and high construction cost, and achieve convenient operation and maintenance management, low investment, The effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

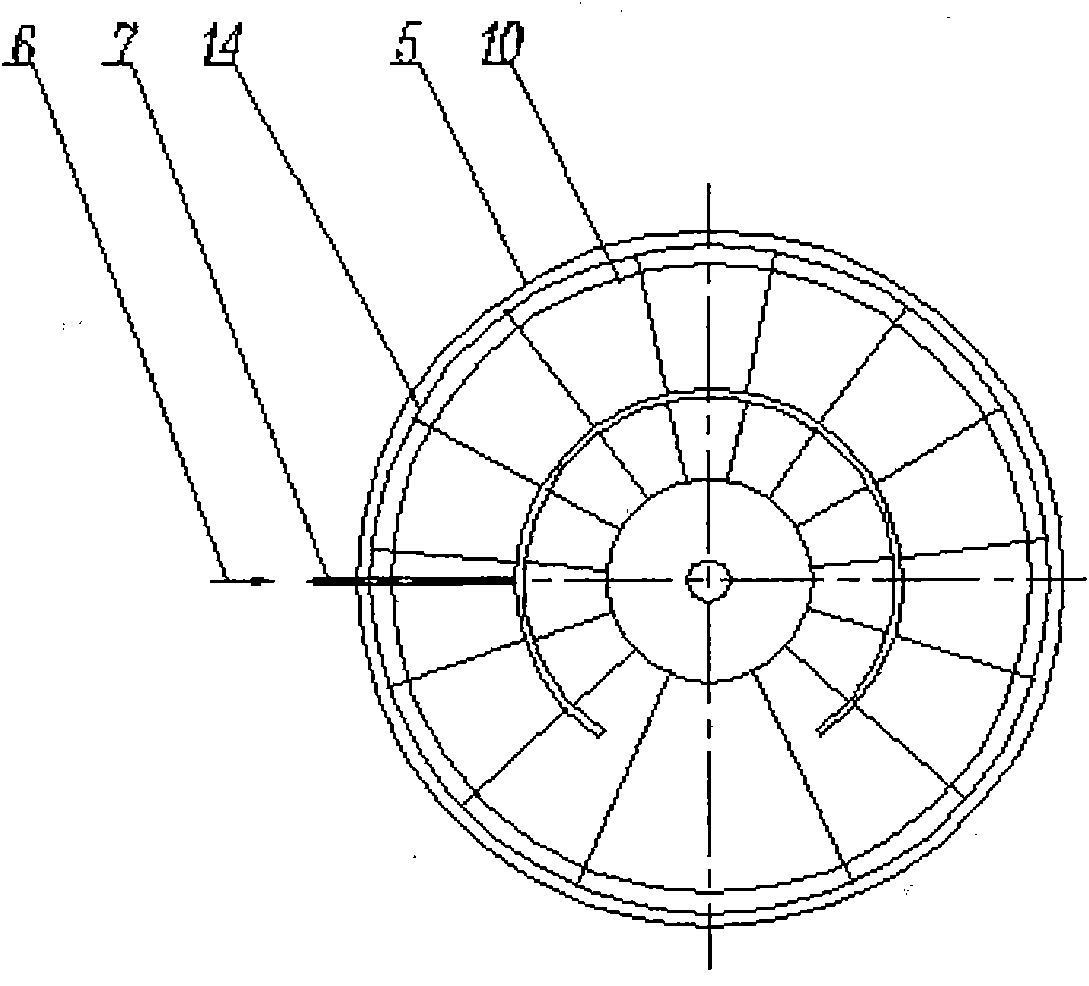

Method used

Image

Examples

Embodiment

[0042] Taking the decarbonization of flue gas from a 40T coal-fired boiler as an example, the explanation is as follows:

[0043] The flue gas volume at the entrance of the supergravity field absorption tower is 60000Nm 3 / h, CO 2 The concentration is 225g / Nm 3 , NH 3 ·H 2 O and CO 2 The molar ratio is 1.01, CaSO 4 with (NH 4 ) 2 CO 3 The molar ratio is 0.9. Under the above conditions, the flue gas CO at the outlet of the supergravity field absorption tower 2 The concentration is 33g / Nm 3 , CO 2 The removal rate can reach 85%, the output of light calcium carbonate is 10t / h, and the output of ammonium compound fertilizer is 13t / h, which can bring considerable benefits to the enterprise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com