Integrated bathroom base plate and manufacturing method thereof

A bathroom and overall technology, applied in the field of bathroom, can solve the problems of poor surface touch, insufficient strength, insufficient rigidity, etc., and achieve the effect of light and firm transportation and installation, high production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

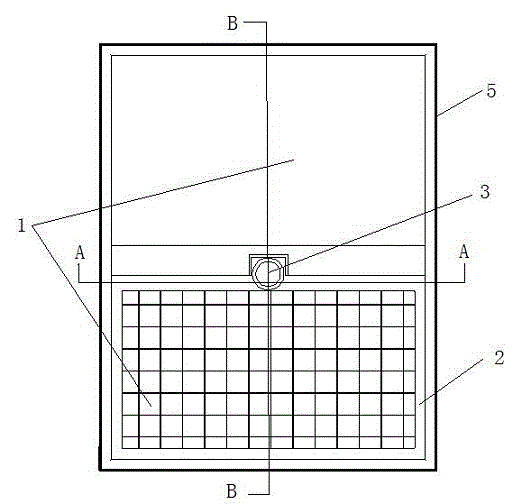

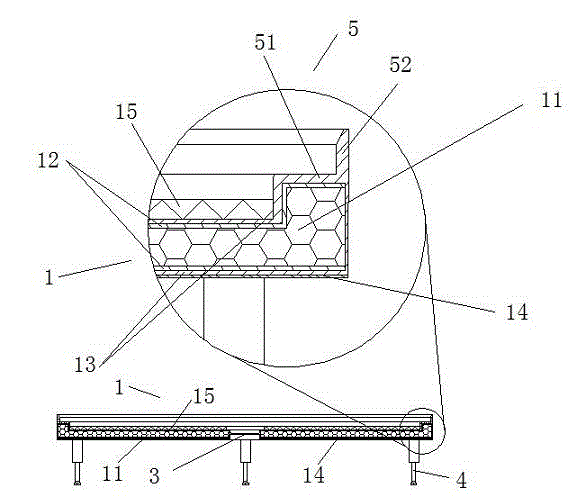

[0042] A whole bathroom chassis, such as Figure 1 to Figure 4 As shown, it includes a tray body 1, and the tray body 1 can be divided into two parts according to needs, one of which is a toilet, equipped with toilets, wash basins and other equipment, and the other part is a bath room, including one or the other in a bathtub or a shower. A variety of equipment, the disc body 1 is made of lightweight honeycomb composite material, the disc body 1 includes a honeycomb middle layer 11, an adhesive layer 12, a surface layer 13, a waterproof layer 14 and a surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com