Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

A high-speed motor, air suspension technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of low power density, high gear transmission noise, high noise, improve the magnetic field strength and rotational speed, reduce noise and The effect of mechanical loss and improving the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

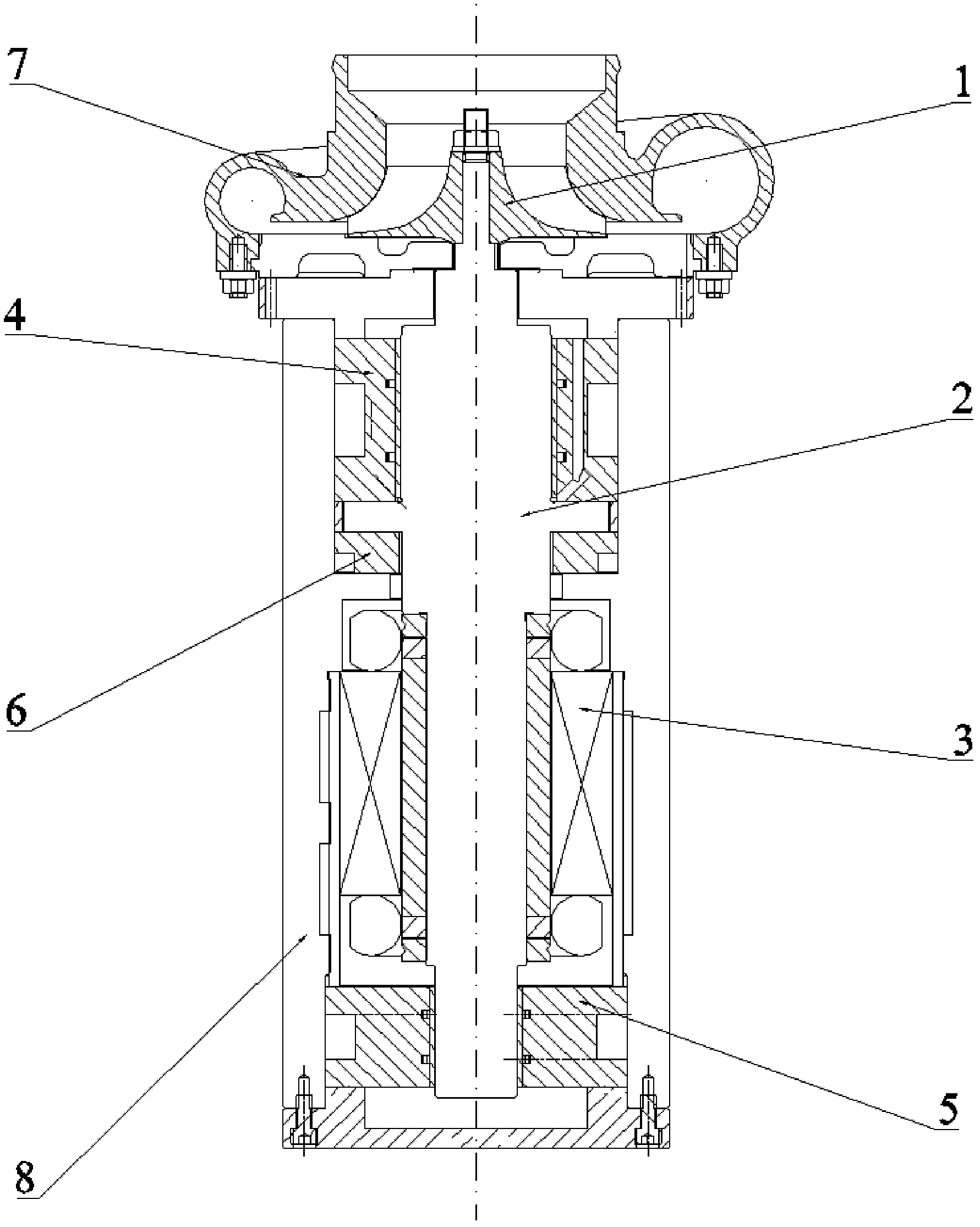

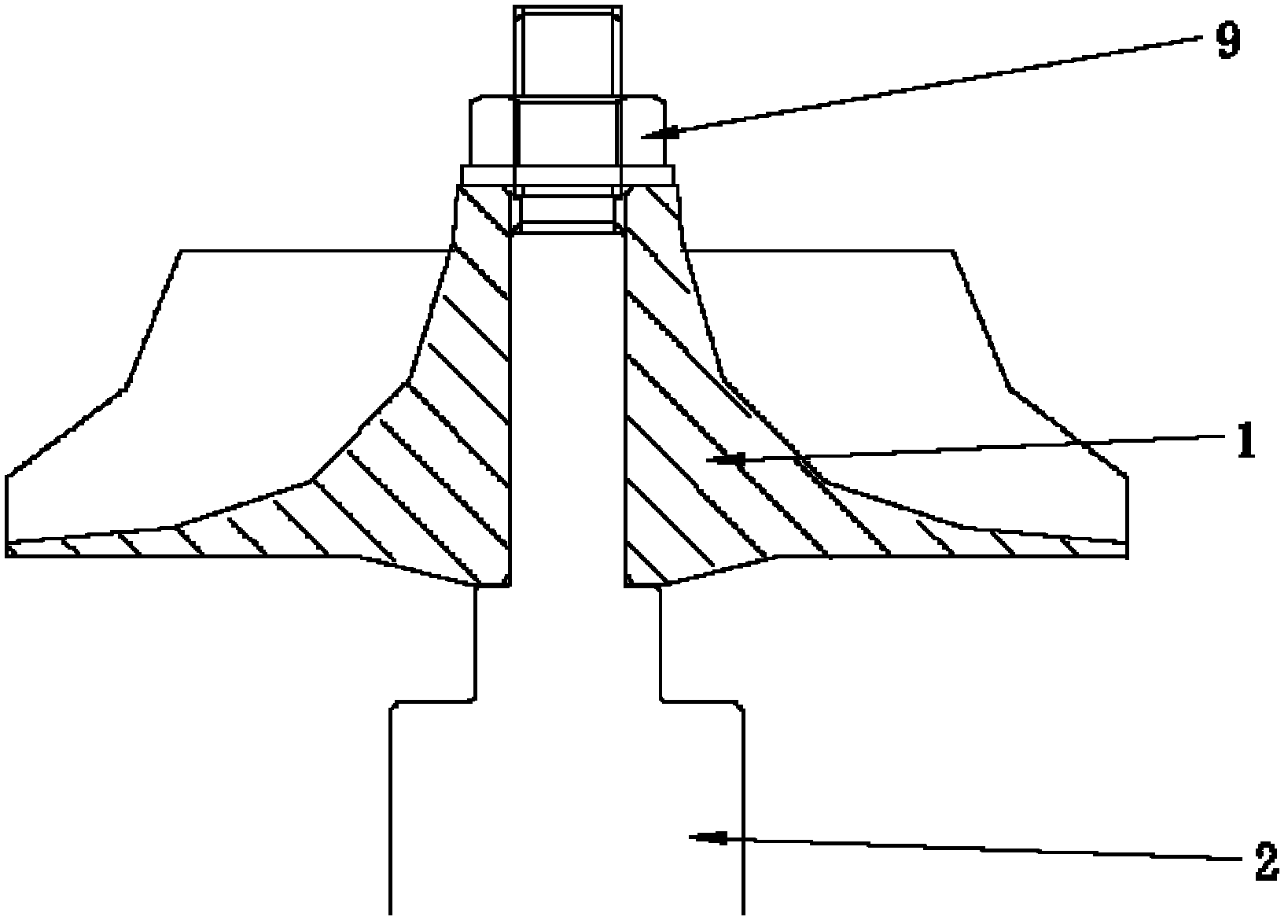

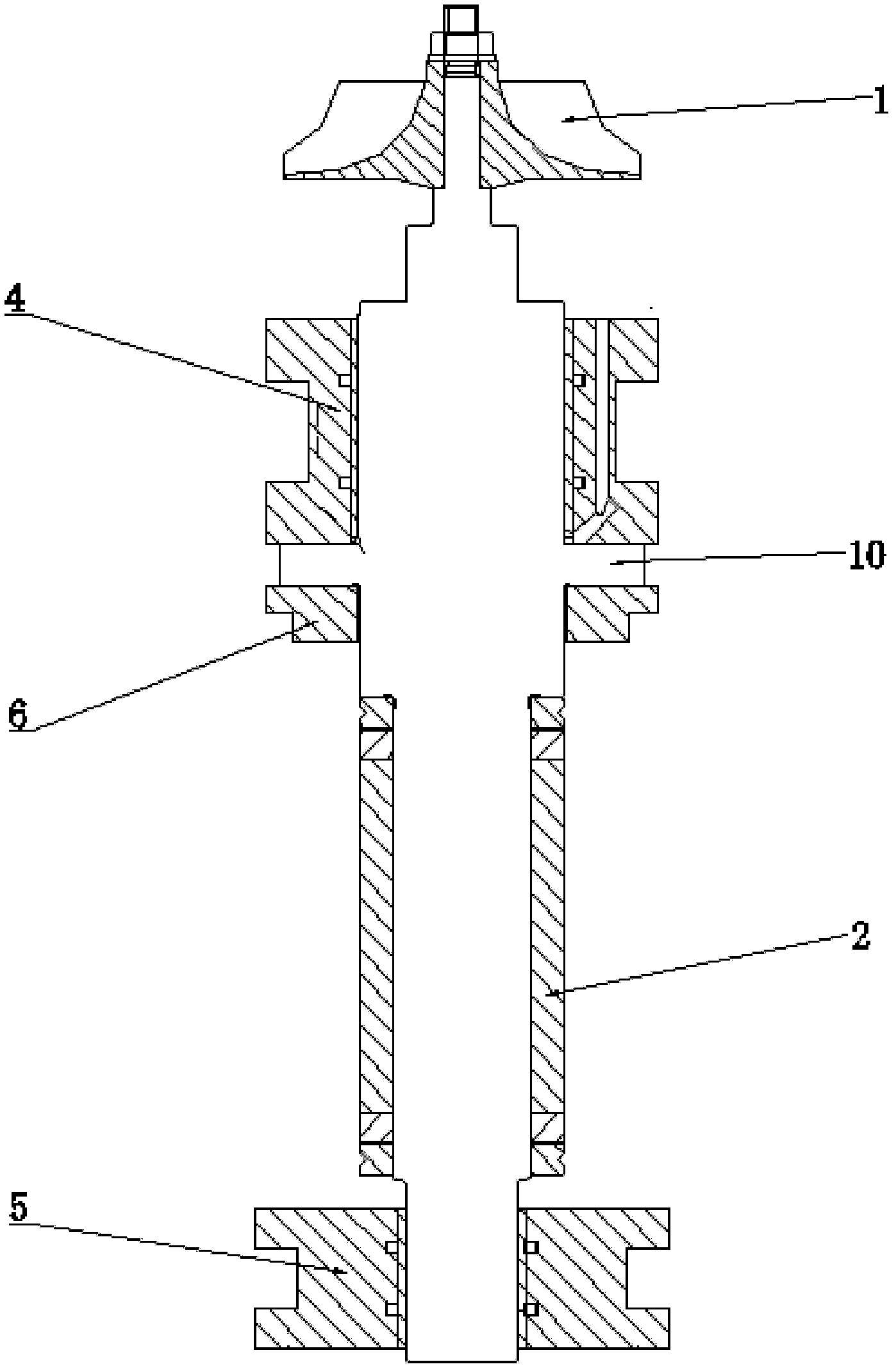

[0020] The invention is an air suspension air supply adjustable high-speed motor direct drive blower, such as figure 1 As shown, it includes compressor impeller 1, permanent magnet synchronous motor rotor 2, motor stator 3, front radial air bearing 4, rear radial air bearing 5, axial thrust air bearing 6, volute 7 and motor housing 8.

[0021] One end of the permanent magnet synchronous motor rotor 2 is connected to the compressor impeller 1, the motor stator 3 drives the permanent magnet synchronous motor rotor 2 to rotate, the front radial air bearing 4, the rear radial air bearing 5, and the axial thrust air bearing 6 are suspended and supported permanently Magnetic synchronous motor rotor 2, volute 7 surrounds compressor impeller 1, motor housing 8 surrounds motor stator 3, front radial air bearing 4, rear radial air bearing 5, axial thrust air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com