Dismounting and transporting trolley

A technology of trolleys and frames, which is applied in the field of dismantling and reversing trolleys, which can solve the problems of affecting production progress, long construction time, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

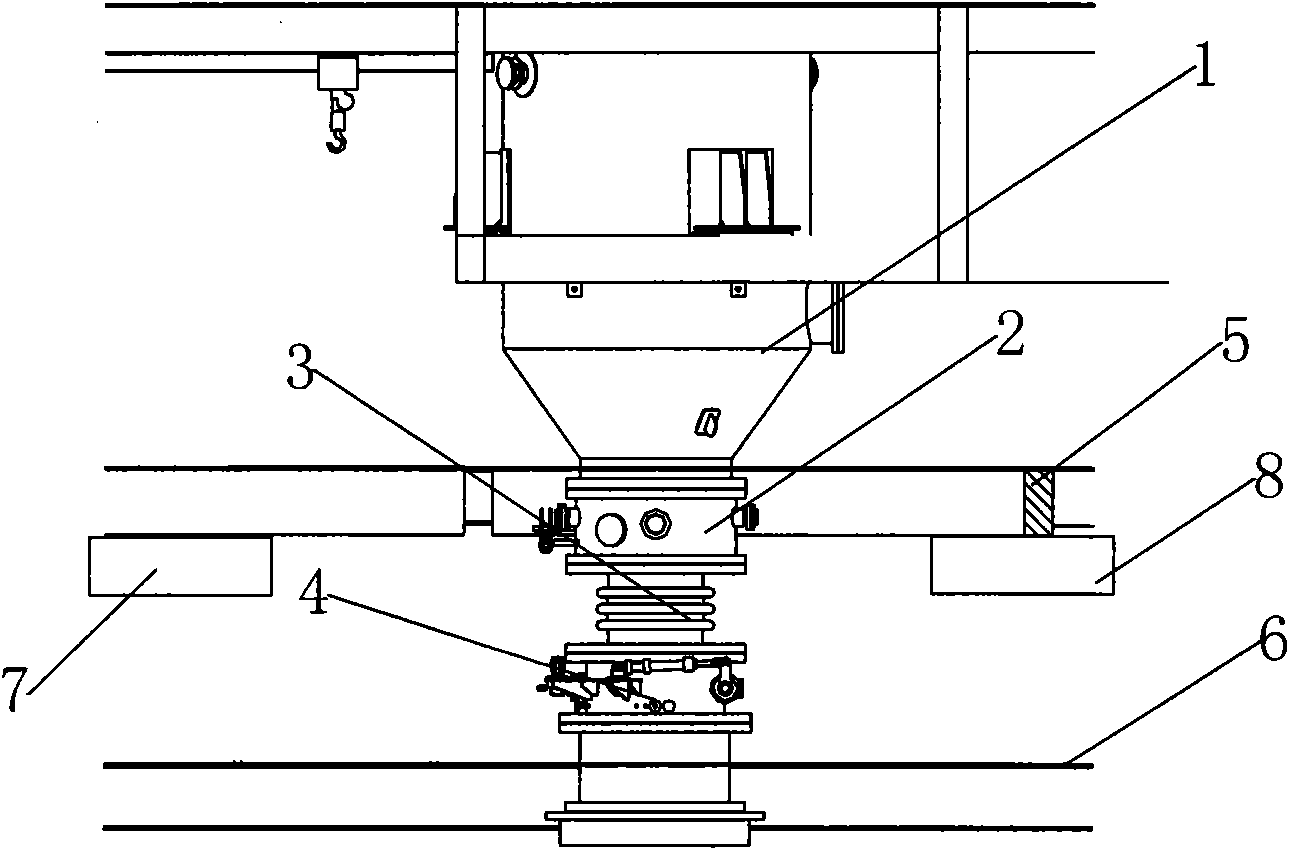

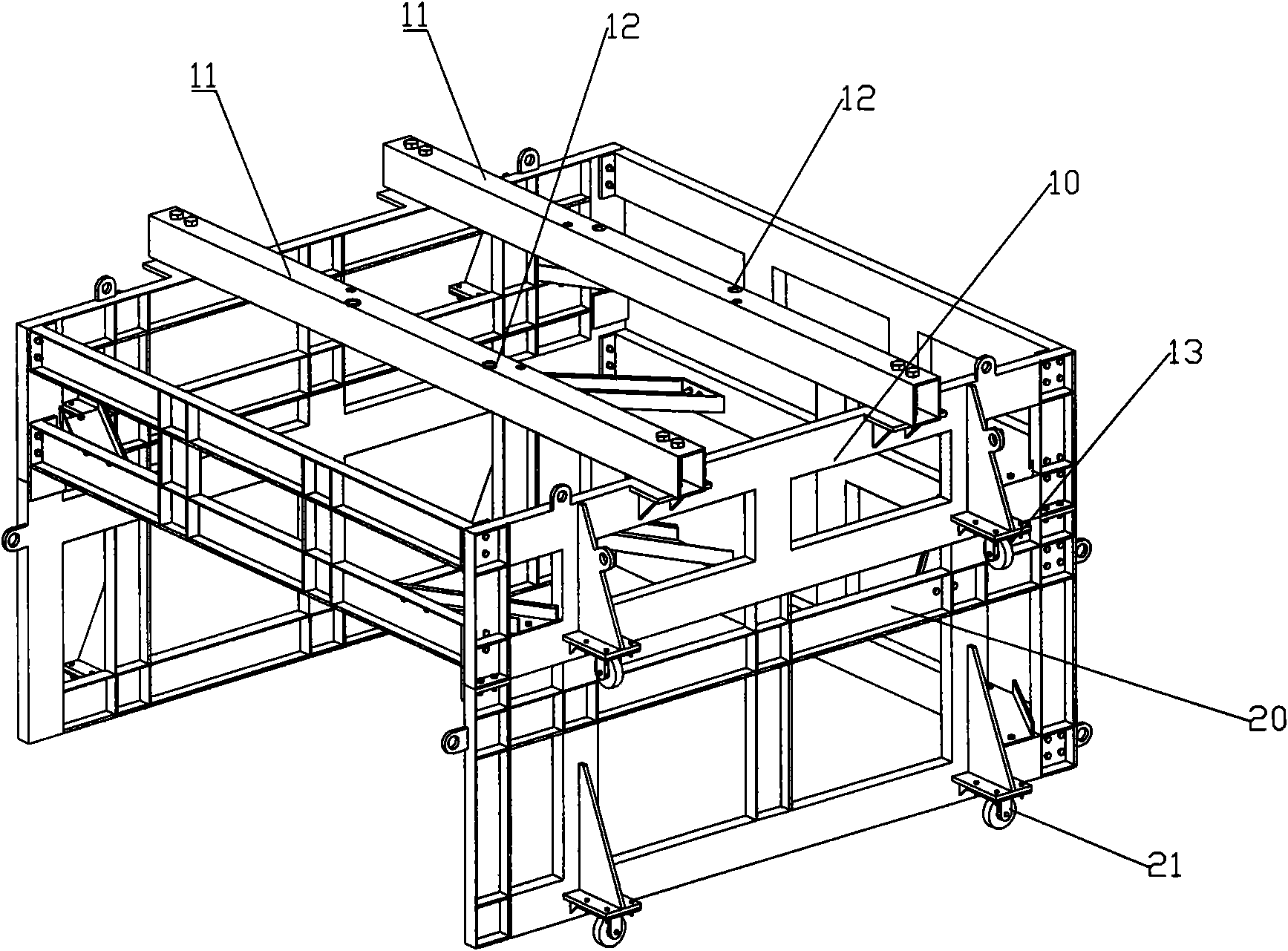

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 2 As shown, the disassembly and reversing trolley includes an upper trolley 10 and a lower trolley 20, the upper trolley 10 is located above the lower trolley 20, and the lower trolley 20 is detachably connected to the upper trolley 10 by bolts. The upper trolley 10 is provided with two supporting rods 11 arranged in parallel. The supporting rods 11 are provided with bellows flange surface fixing holes 12. The bellows flange surface fixing holes 12 are connected with the bellows flange surface of the COREX-C3000 shaft furnace corresponding to the threaded holes on the

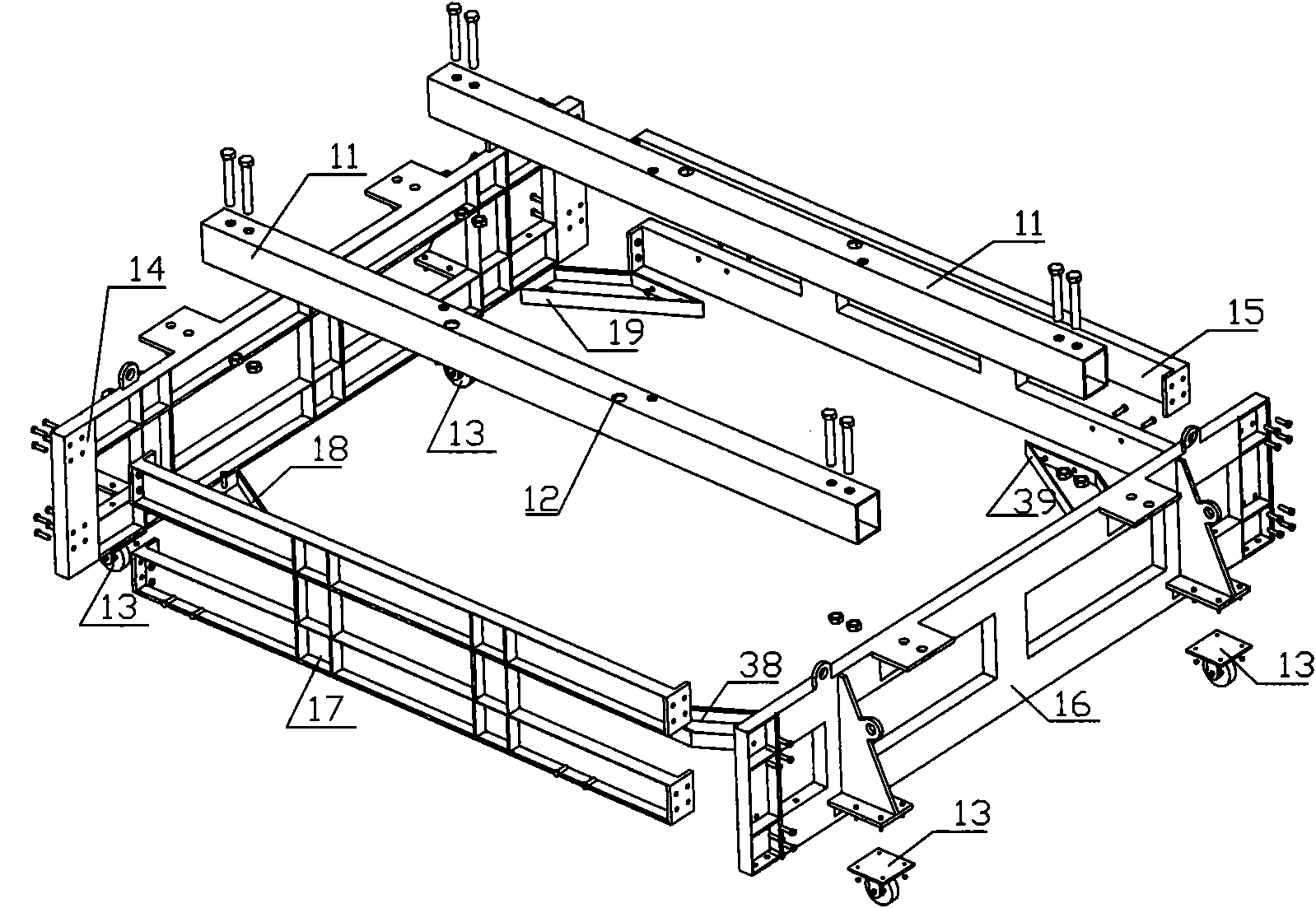

[0021] Such as image 3 As shown, the upper trolley 10 includes a closed upper frame body, which is composed of four upper frame baffles 14, 15, 16, 17 connected in sequence, and an upward inclined support is provided between the upper frame baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com