Cell box

A battery box and battery technology, which is applied to secondary batteries, battery pack components, battery temperature control, etc., can solve the problems of high manufacturing cost and complex processing technology, and achieves reduction of parts, simple processing technology, and reduction of the number of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The "front", "rear", "left", "right", "upper" and "lower" mentioned in the text are all referred to the components of the battery box and the placement state of the battery box in the drawings.

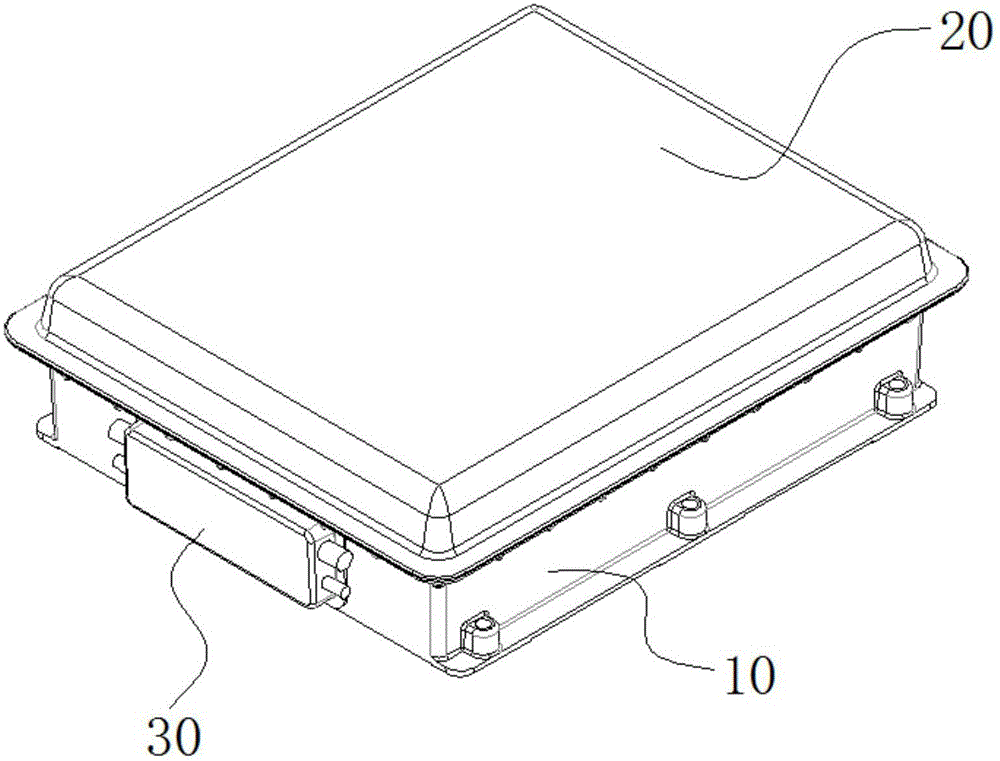

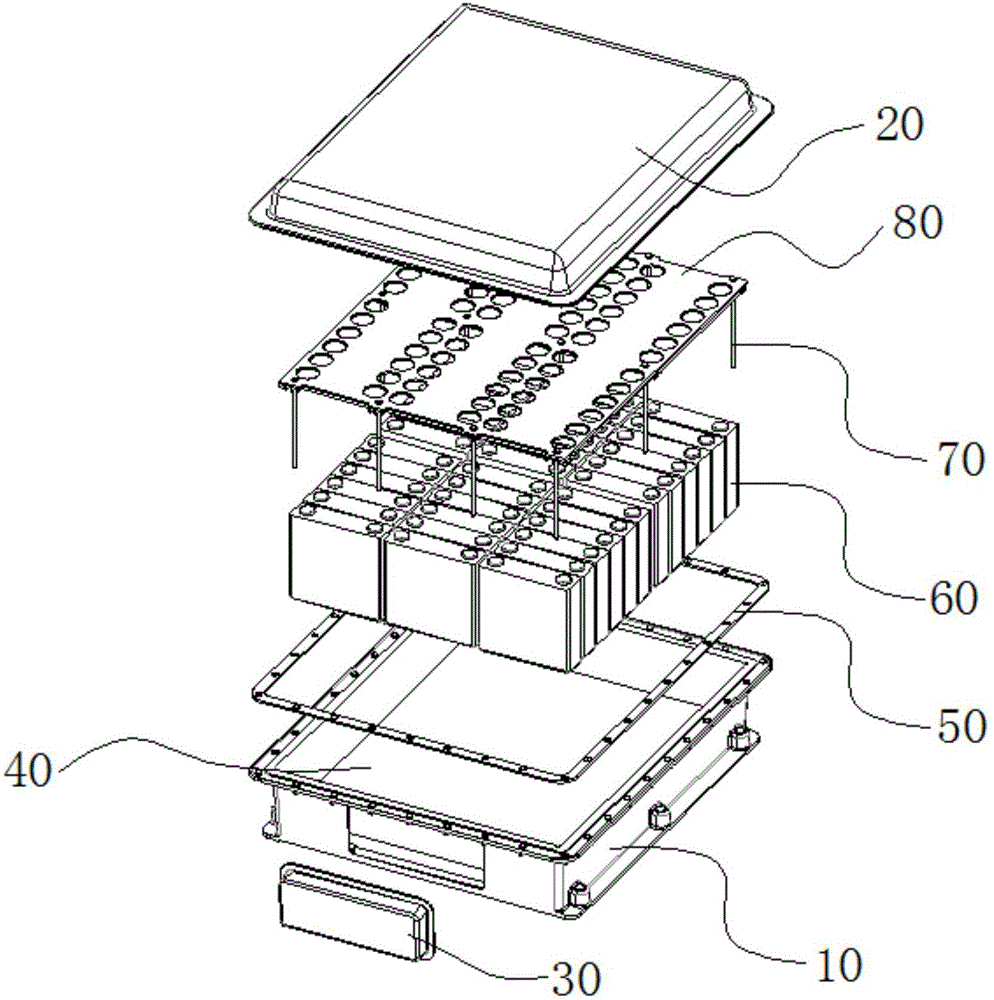

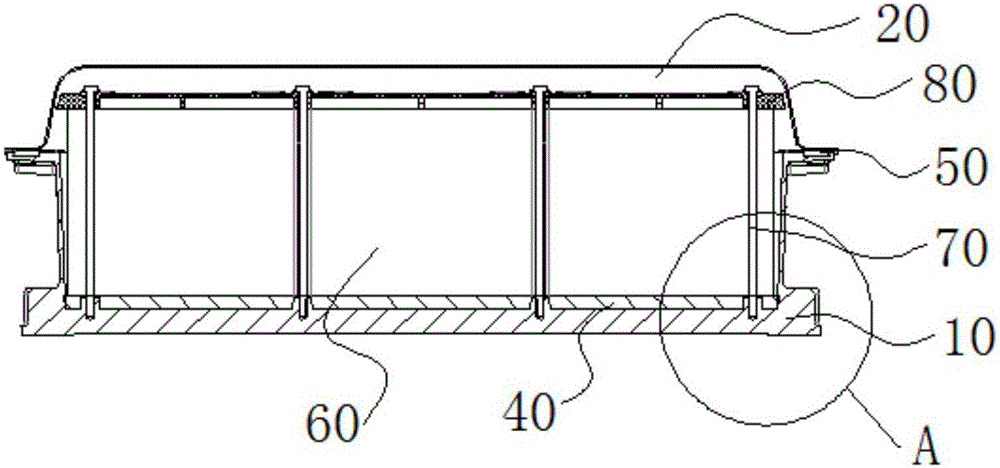

[0033] The embodiment of the present application provides a battery box, such as figure 1 As shown, it includes a battery box 10 and a battery box cover 20. The battery box cover 20 is fastened with the battery box 10, and the inside of the two forms a closed accommodation space. The accommodation space is arranged with battery cells 60, and the batteries 60 are connected to each other. The extreme end is closer to the battery box cover 20 than the bottom of the battery cell, and the bottom of the battery box 10 is filled with structural glue 40 ; In order to facilitate the monitoring of the state of the entire battery box, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com