Continuous catalytic reforming reactor

A catalytic reforming and reactor technology, applied in naphtha catalytic reforming and other directions, can solve problems such as sticking to the wall, difficulty, increase in volume, etc., and achieve the effects of being conducive to uniform distribution, convenient loading and unloading of catalysts, and uniform axial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

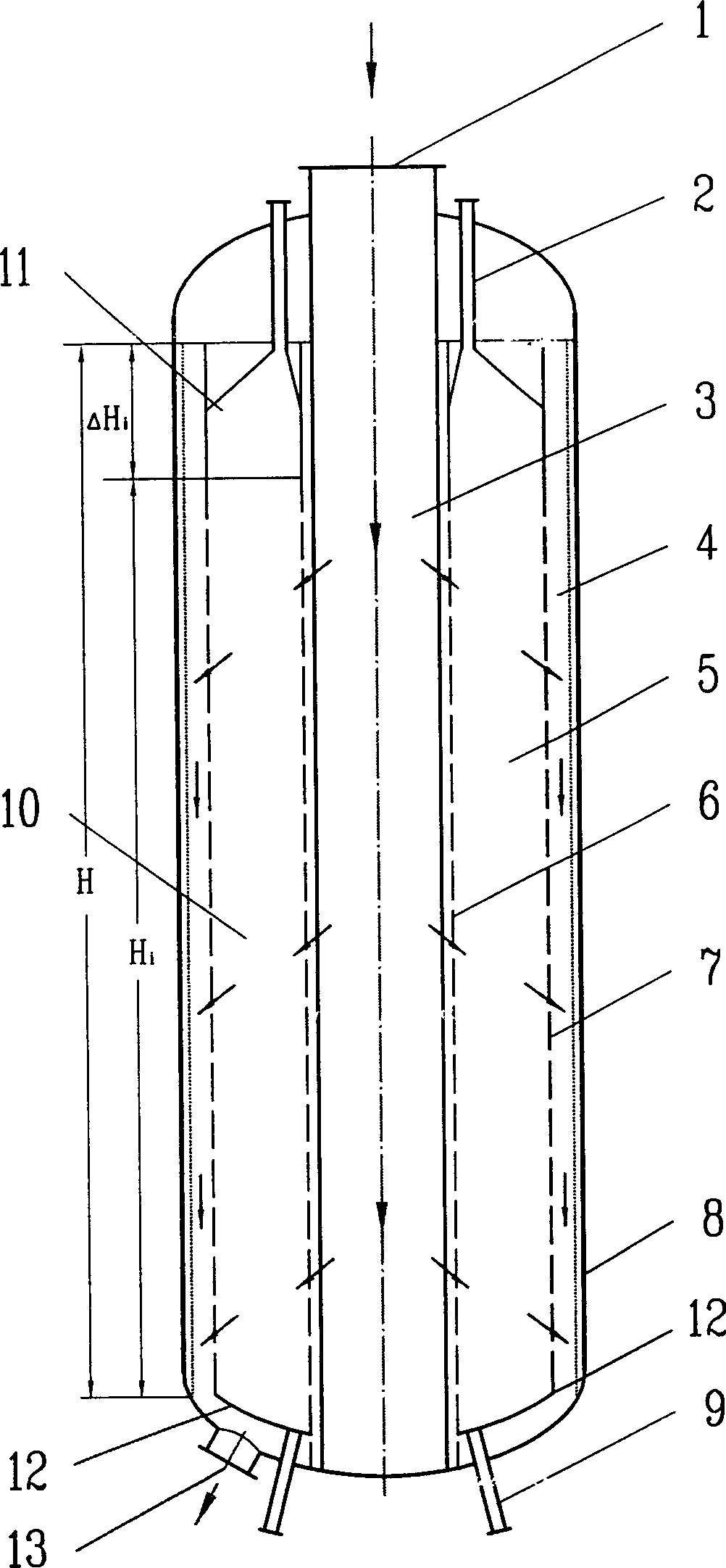

[0031] figure 1 The described reactor works like this:

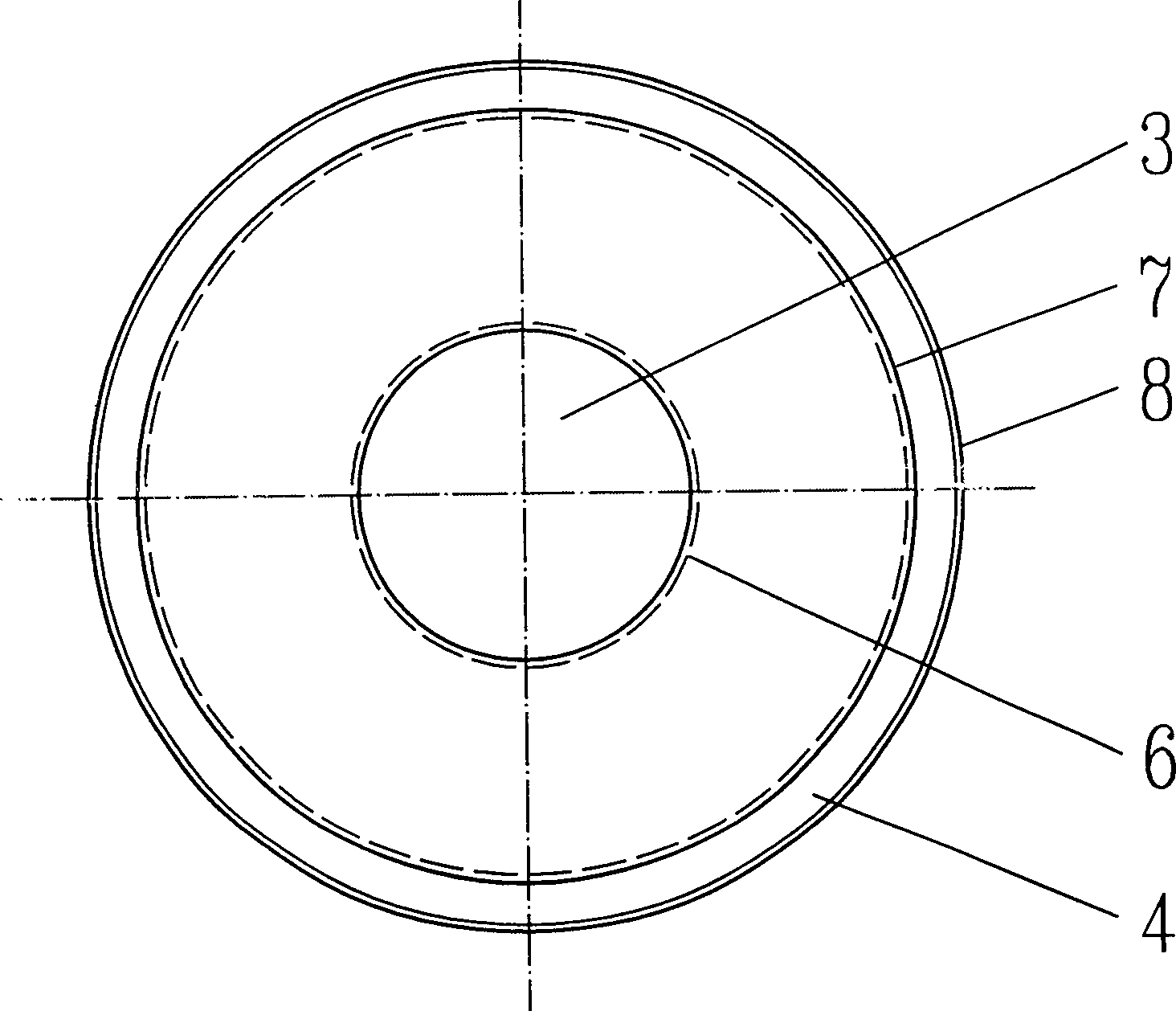

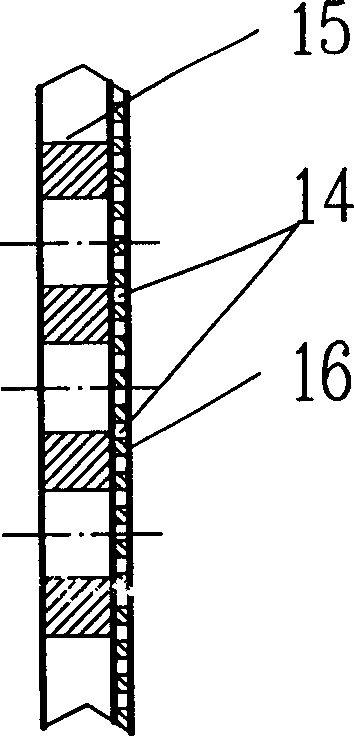

[0032] The molar ratio of hydrogen to hydrocarbon in the raw material is 1-3, the reaction temperature is 420-580°C, the reaction pressure is 0.2-0.8Mpa, and the weight space velocity is 0.5-2.5 hours -1 ,exist figure 1 The flow of the reaction material in the reactor shown is as follows: the reaction material enters the split flow channel 3 formed by the porous wall inner cylinder 6 from the reaction material inlet 1, and flows radially into the catalytic bed 10 through the distribution holes 14 on the porous wall inner cylinder 6 to carry out reaction, and then the reaction product enters the reaction product collecting flow channel 4 through the distribution hole 14 on the porous outer wall 7 from inside to outside, and flows out through the reaction product outlet 13 . After the catalyst particles flow into the catalyst bed from the catalyst feed pipe 2, they move axially from top to bottom, and then flow out of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com