Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Corex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corex is a cough syrup sold by Pfizer Inc.. It is available in India, Pakistan, Bangladesh and a few other South Asian countries. Corex is a prescribed medicine. Its active ingredients are chlorpheniramine maleate and codeine phosphate.

Anti-surge early warning control method of COREX gas compressor

ActiveCN102788004AEffective operating conditionsSolve the problem of high incidence of failurePump controlPositive-displacement liquid enginesFailure rateOperating point

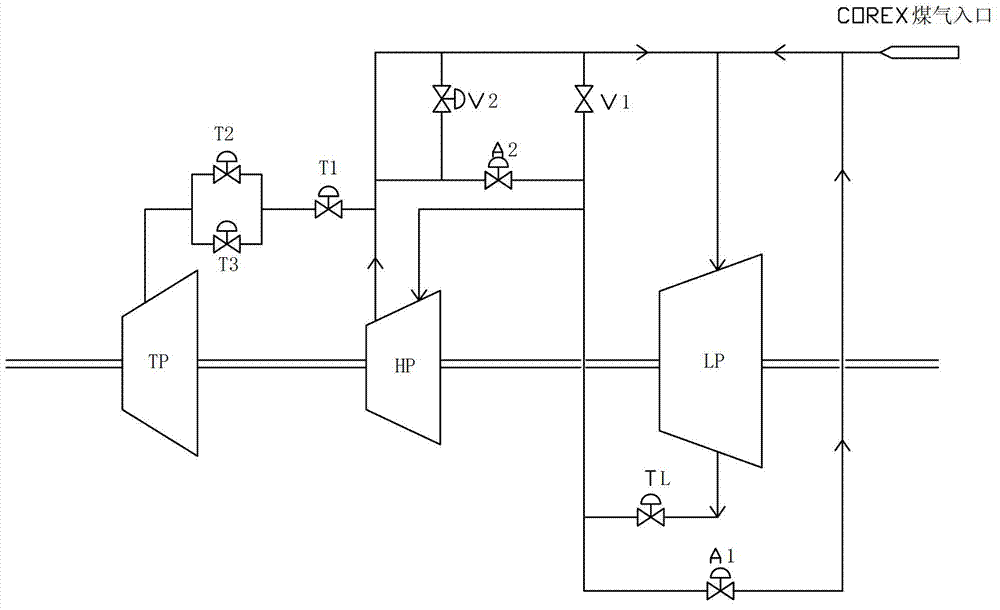

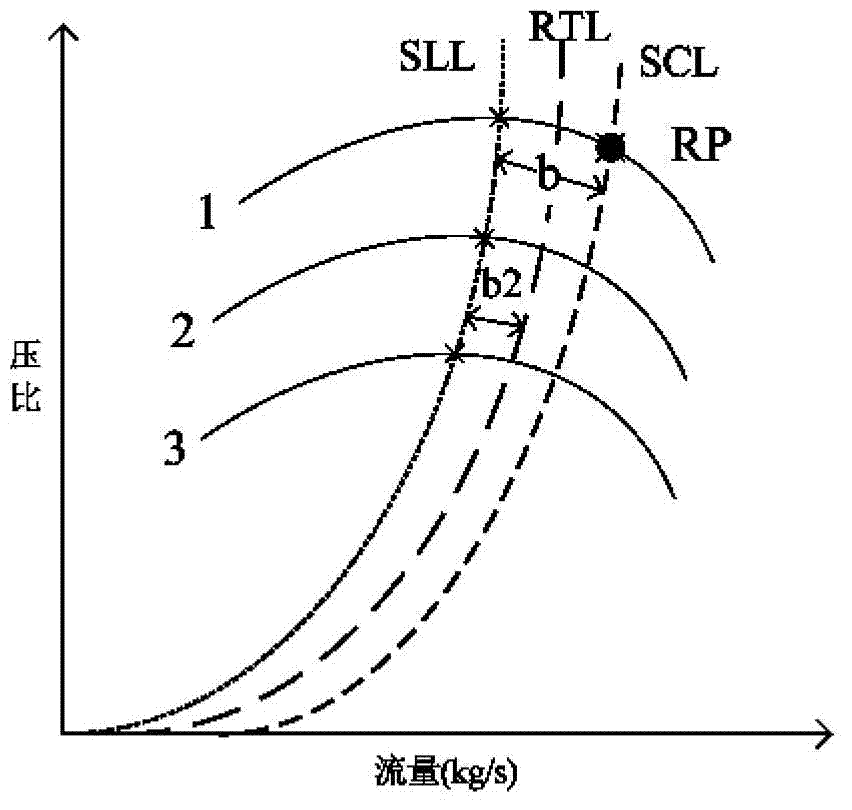

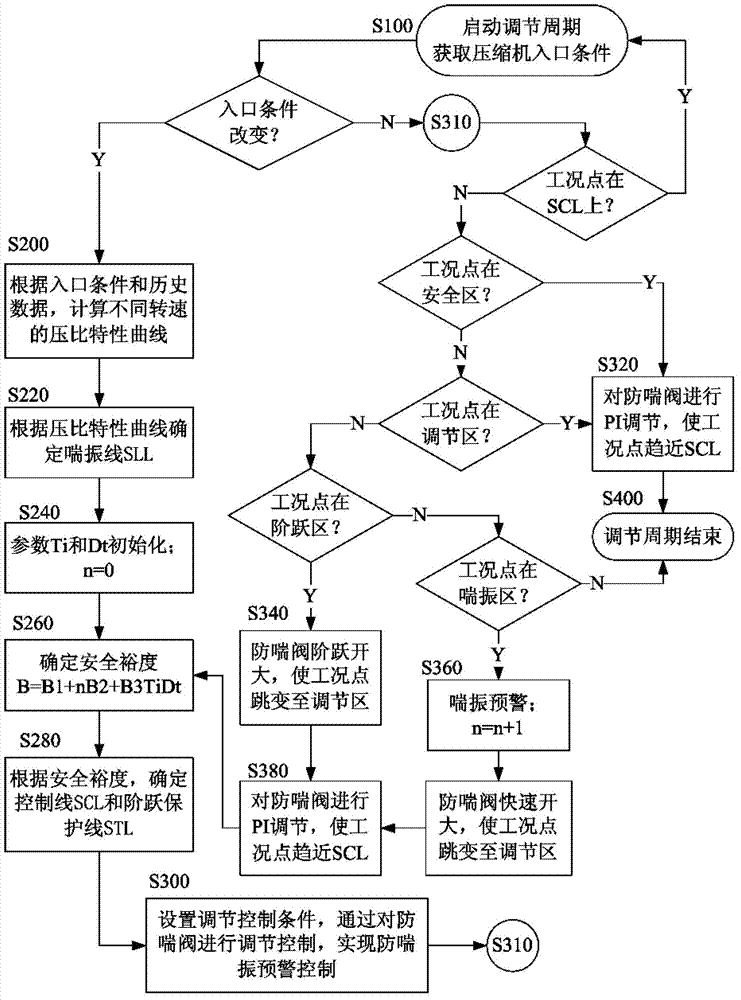

The invention discloses an anti-surge early warning control method of a COREX gas compressor, and relates to control over gaseous fuel supply of a gas turbine and a device, in particular to an anti-surge detection, early warning and adjustment control method of the gas compressor of a CCPP (Combined Cycle Power Plant). The method comprises the following steps of: acquiring compressor inlet conditions through a CCPP monitoring system; determining safety margin, a surge line, a control line and a step protection line; if an operating point (RP) is positioned in a control region adjacent to the control line, linearly adjusting the opening of an anti-surge valve by using a PI adjustment algorithm; and if the operating point is positioned in a control region adjacent to the surge line SLL, performing step control over the opening of the anti-surge valve. According to the method, effective early warning and control adjustment functions can be effectively generated for the operating conditions of a low-voltage coal crusher and a high-voltage coal crusher of the CCPP and an operation state of the entire gas system, the problem of high failure rate of the COREX combined gas-steam combined cycle generating unit can be effectively solved, and the safety and the stability of the unit are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for making iron by virtue of COREX furnace

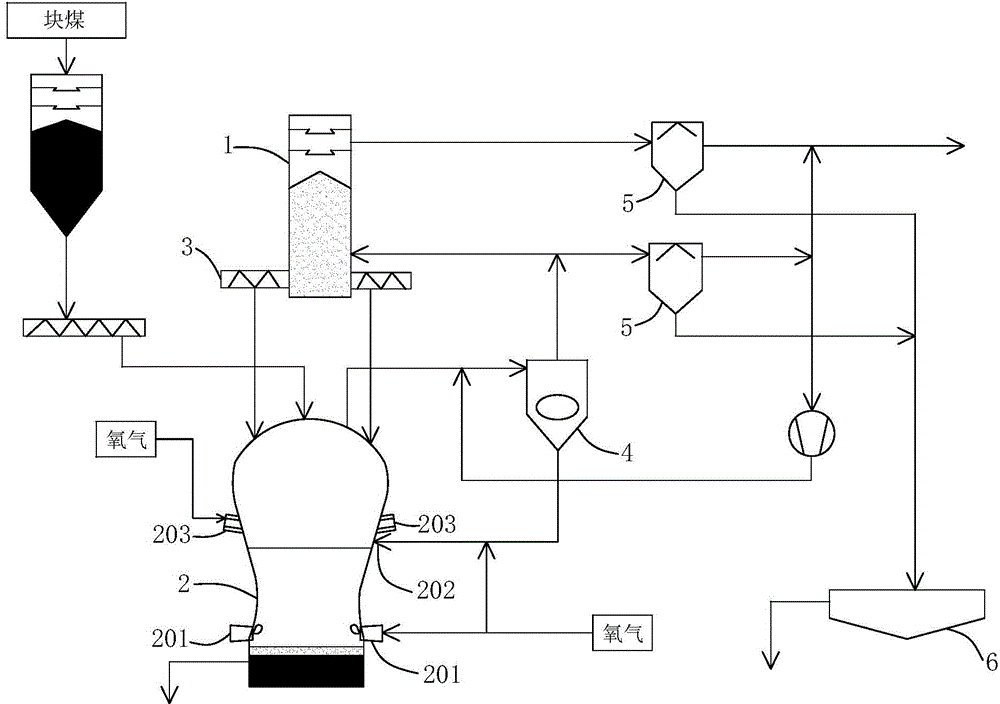

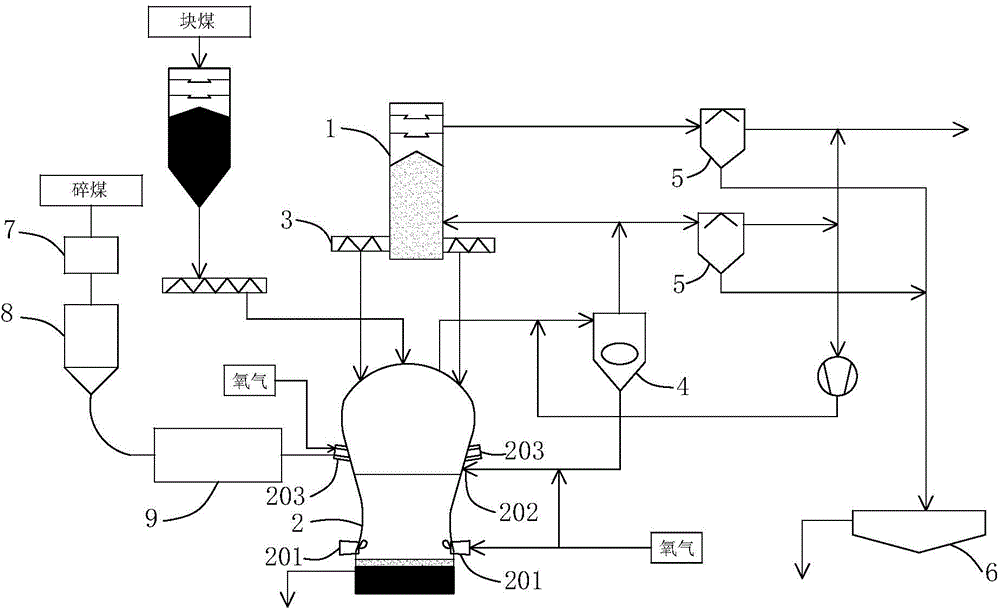

The invention discloses a process for making iron by virtue of a COREX furnace. The COREX furnace comprises a reduction vertical furnace, a fusion gasifying furnace and a washing tower, wherein the fusion gasifying furnace comprises a plurality of air holes and a plurality of oxygen burners, and oxygen is introduced into the fusion gasifying furnace at least through the air holes and the oxygen burners. The process comprises the following steps: (1) burning lump coals by virtue of oxygen introduced into the fusion gasifying furnace, so as to produce high-temperature coal gas; (2) collecting crushed coals obtained by sieving the lump coal, grinding and milling the crushed coals into powdered coal, and burning the powdered coal in a vault region of the fusion gasifying furnace, so as to produce high-temperature coal gas; (3) transmitting high-temperature coal gas to the reduction vertical furnace, so as to reduce iron-containing raw materials loaded into the reduction vertical furnace to be sponge iron; and (4) inputting sponge iron into the fusion gasifying furnace, and restoring sponge iron to be molten iron in the fusion gasifying furnace. By virtue of the process for making iron by virtue of the COREX furnace, the partial lump coals are replaced by virtue of powdered coal, so that the cost is saved.

Owner:BAOSHAN IRON & STEEL CO LTD

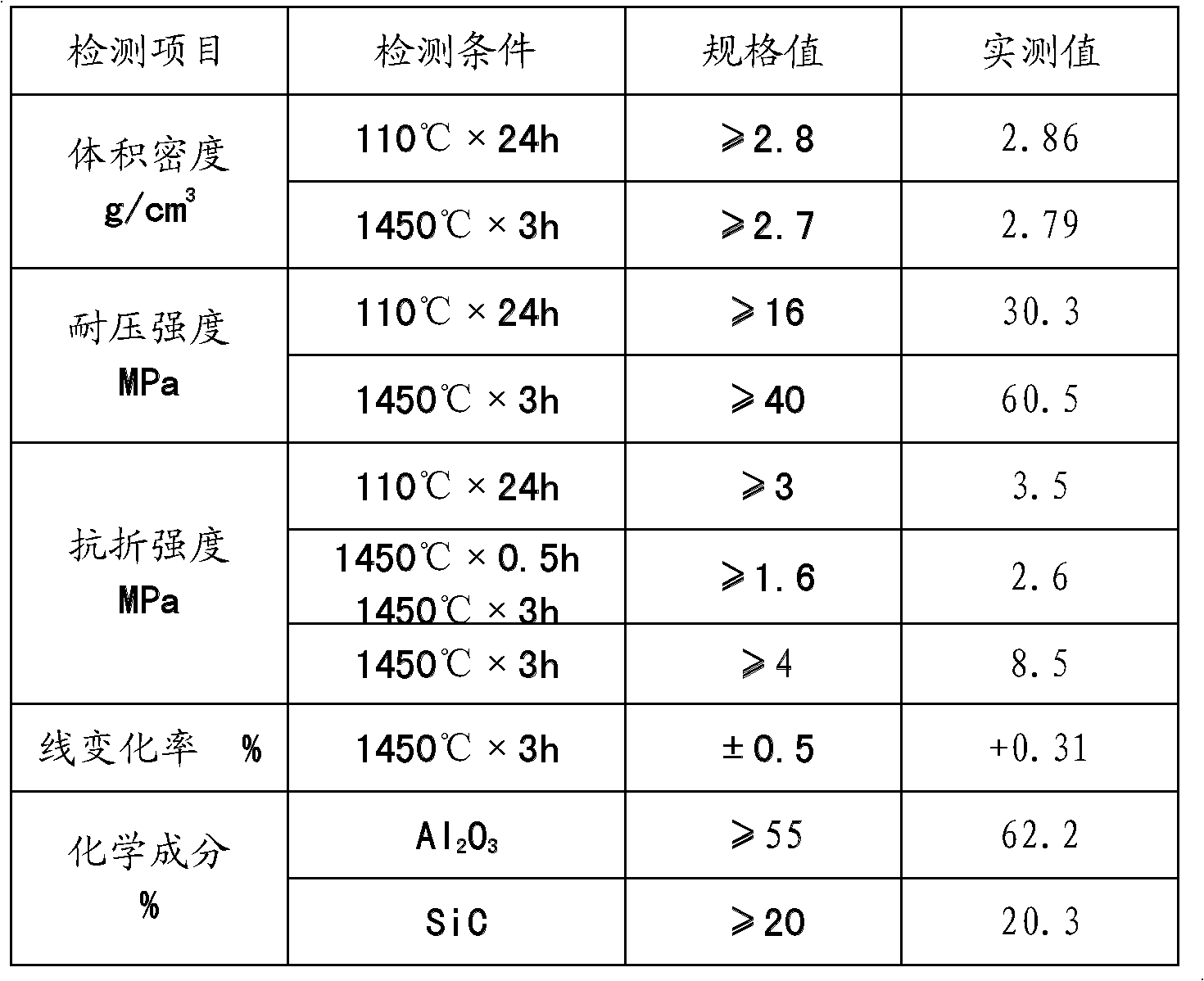

Fast-setting castable for main runner for COREX furnace and production technology thereof

The invention aims to provide a fast-setting castable for a main runner for a COREX furnace and a production technology thereof. The fast-setting castable for the main runner for the COREX furnace can be used for repairing the main runner within a short time in the thermal state as well as for tapping recovery, further ensures the consistency of production, is long in service life and convenient for repairing operation and reduces the labor intensity of workers. To achieve the effects, the fast-setting castable for the main runner for the COREX furnace is characterized in that the fast-setting castable comprises the following components: aluminas, silicon carbide, carbonaceous materials and additives. Through the technical scheme, the aluminas different in nature and grain size are mixed according to the specific percentage, and since the extra additives and the novel processing technique are adopted, the newly cast runner can allow 80,000 tons iron to be output; the service life of the fast-setting castable is more than twice of that of the former ordinary low cement castable; and furthermore, the fast-setting castable is particularly outstanding in fast-setting, can meet the requirements of on-site tapping within 8-hour operating time and has remarkable effect as a repairing material.

Owner:长兴煤山新型炉料有限公司

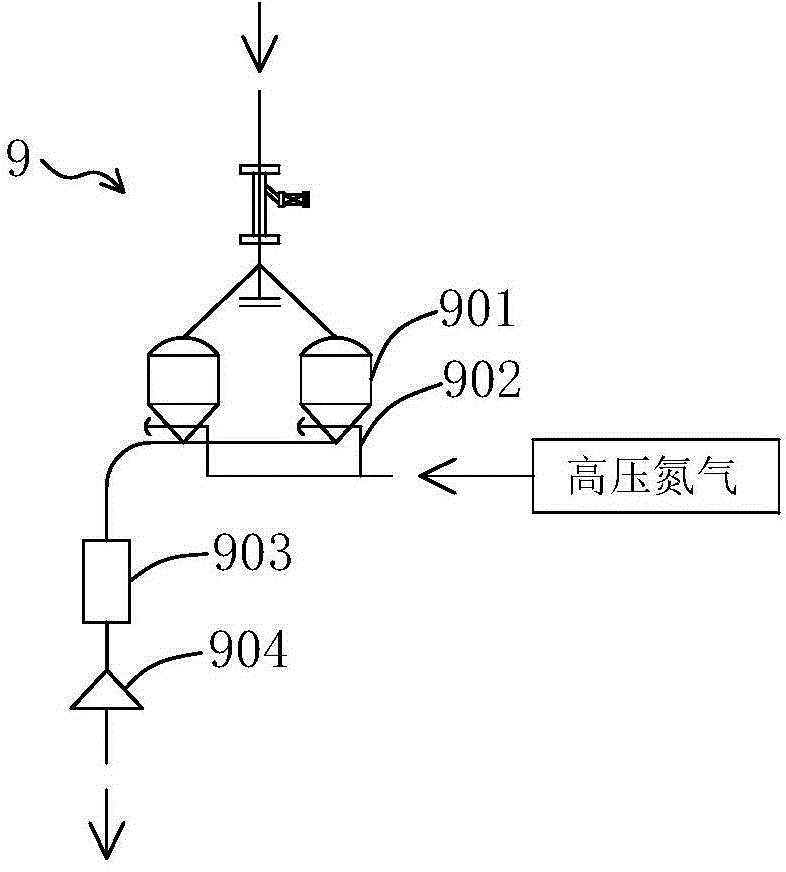

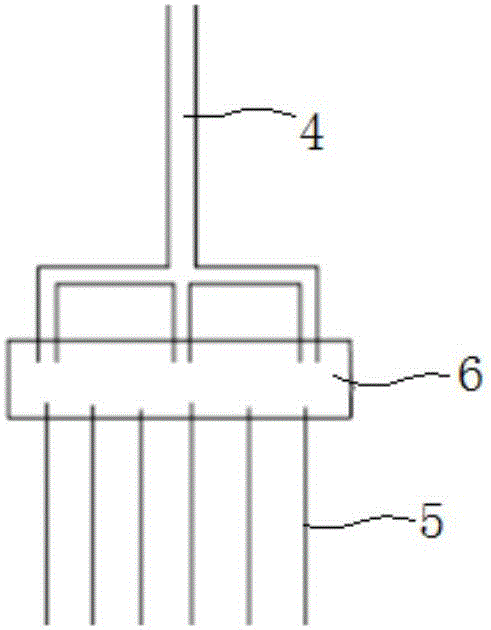

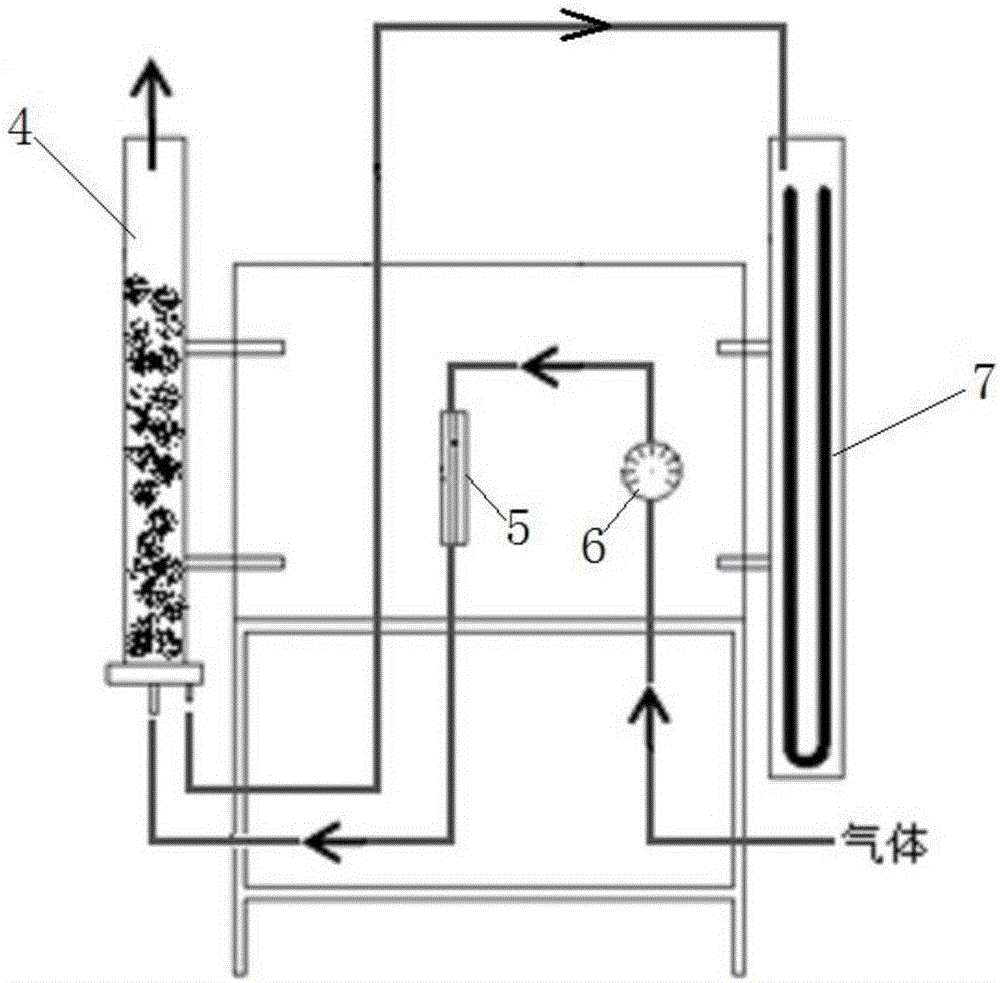

Coal fine preparation, blowing method and device from packed-bed smelting reduction furnace

The invention discloses a filling bed COREX stove braise preparing and blowing method which comprises the following steps of: a) putting mine run coal which is applicable to melting in the COREX stove and producing reducing gas into a run coal bin by crushing and screening the mine run coal into crushed coal; b) milling the crushed coal to minus 200 meshes and above 60 percent by a coal-milling device provided by a coal feeder and carrying out drying at the same time; and c) putting the finished braise into a pulverized coal bunker after the separation of gas and powder; loading the braise into 2 or 3 coal injecting tanks sequentially; transporting the braise to a distributor mechanism positioned at the top of a melting gasification furnace of the COREX stove by using pressured gas after the processes of pressurizing fluidization and gas supplement; distributing the braise to the blowing branch pipe which is led to the oxygen tuyere of the melting gasification furnace; spraying the braise into the melting gasification furnace by a coal injection gun. The method has the advantages that the in-place digestion and utilization of powder sifted range coal of the filling bed COREX stove is realized; and the total coal consumption of the COREX stove can be reduced by replacing part range coal; therefore, the cost of production is reduced; more optimized COREX melting reduction process and more flexible operation are realized.

Owner:BAOSTEEL ENG & TECH GRP +1

Corundum-mullite composite brick for COREX furnace and preparation method thereof

The invention discloses a corundum-mullite composite brick for a COREX furnace and a preparation method thereof. The raw materials of the corundum-mullite composite brick are composed of a corundum-mullite homogenized material, white corundum, andalusite, a-Al2O3 powder and binding clay, as well as paper pulp liquid waste. The preparation method comprises the steps of firstly, preparing raw materials with various particle sizes according to the ratio; then, using raw materials with particle sizes of 1-3mm and particle sizes smaller than 1mm as aggregate to perform dry mixing, adding a paper pulp liquid waste mixture, finally adding the residual raw materials, and milling to obtain a pug; sequentially performing material trapping, press forming and drying on the obtained pug, and finally roasting to obtain a product. The corundum-mullite composite brick produced in the invention has very low porosity, high compression strength and excellent thermal shock resistance and corrosion resistance, can completely satisfy the harsh application environment of the COREX furnace, and can prolong the service life.

Owner:TONGDA REFRACTORY TECH CO LTD +1

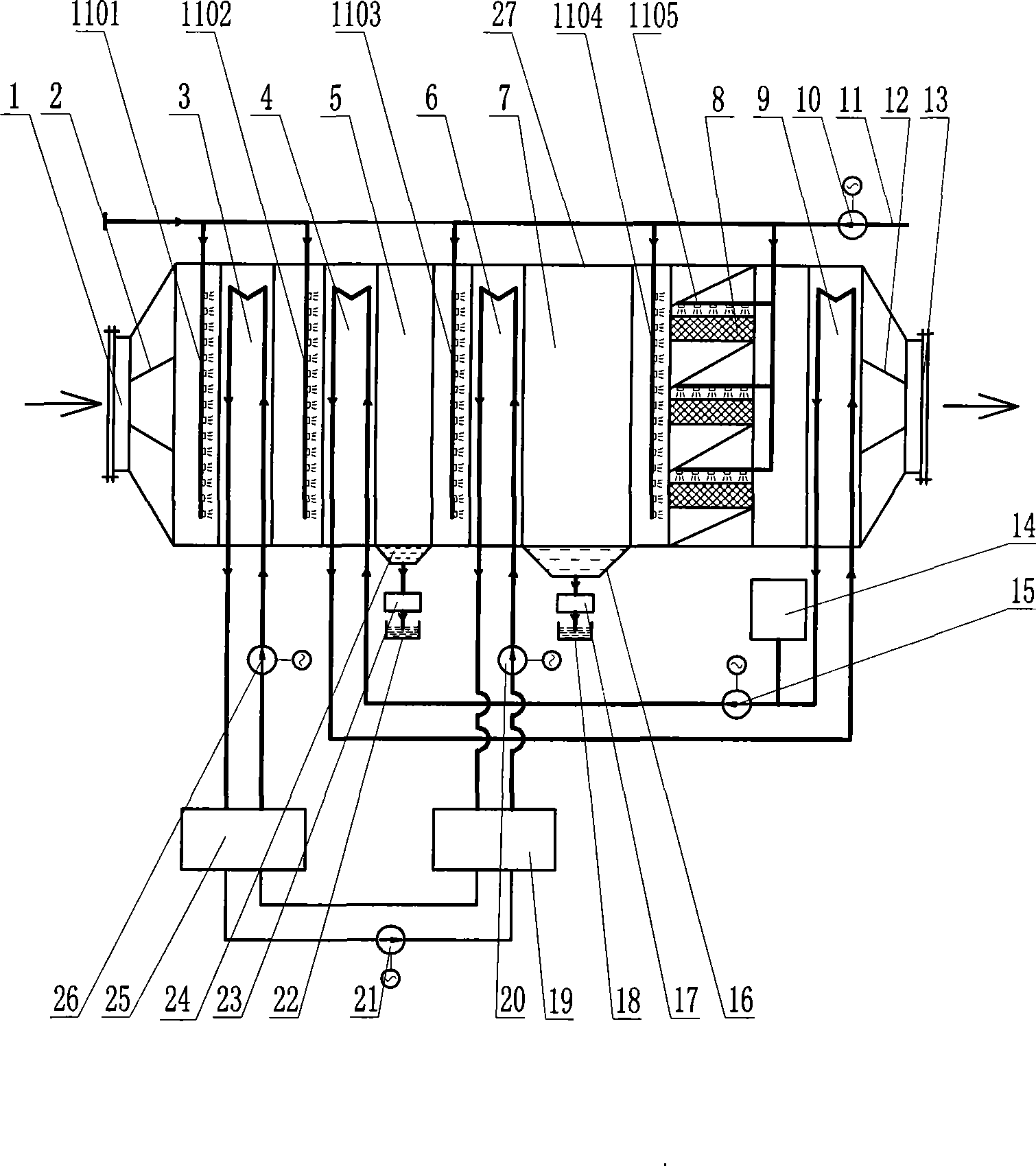

Dedusting and dehumidifying method for air with freezing method and equipment thereof

InactiveCN101480562AEmission reductionReduce pollutionDispersed particle separationVapor condensationAtmospheric airPollution

The invention relates to a dedusting and dehumidifying method and equipment thereof for furnace top coal gas of a blast furnace, a converter or a COREX furnace. The method comprises the steps of precooling, self-circulation cooling, re-cooling, demisting and self-circulation heating and rewarming. The equipment comprises a stream guide plate, a precooler, a self-circulation cooler, a first water discharge section, a cooler, a second water discharge section, a demister, a rewarming heater and an outlet stream guide plate which are sequentially arranged between a gas inlet and a gas outlet in a shell. The method and the equipment are used to reduce the emission of dust and the pollution to the air. The heat of gas at the inlet and the cold output of gas at the outlet are recycled so as to repeatedly utilize energy sources and save the energy source consumption; the relative humidity of coal gas treated by the method and the equipment is reduced, thereby the occurrence of condensed water in the process of pipeline conveying is reduced, the corrosion action to the pipeline is reduced and the safety is improved; in addition, the reduction of the relative humidity of the coal gas improves the thermal value of the coal gas.

Owner:无锡金龙石化冶金设备制造有限公司 +1

Flux-cored welding wire for downward vertically

InactiveCN1338352AEasy to controlBeautiful shapeWelding/cutting media/materialsSoldering mediaCarbon steelCorex

A flux-corex welding wire fed downward vertically for gas shielded welding is composed of skin made of low-carbon steel and flux core containing TiO2 (20-40 wt%), Al2O3 (1.2-7), ZrO2 (3-8.5), MgO (0.5-3), NaF+K2SiF6 (1.2-4), deoxidizing agent which is one or more of Si, Mn, Ti, Al and Mg (11-20), alloying agent which is one or more of Ni, Cr, MO, Cu and V (less than 5) and Fe (rest).

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

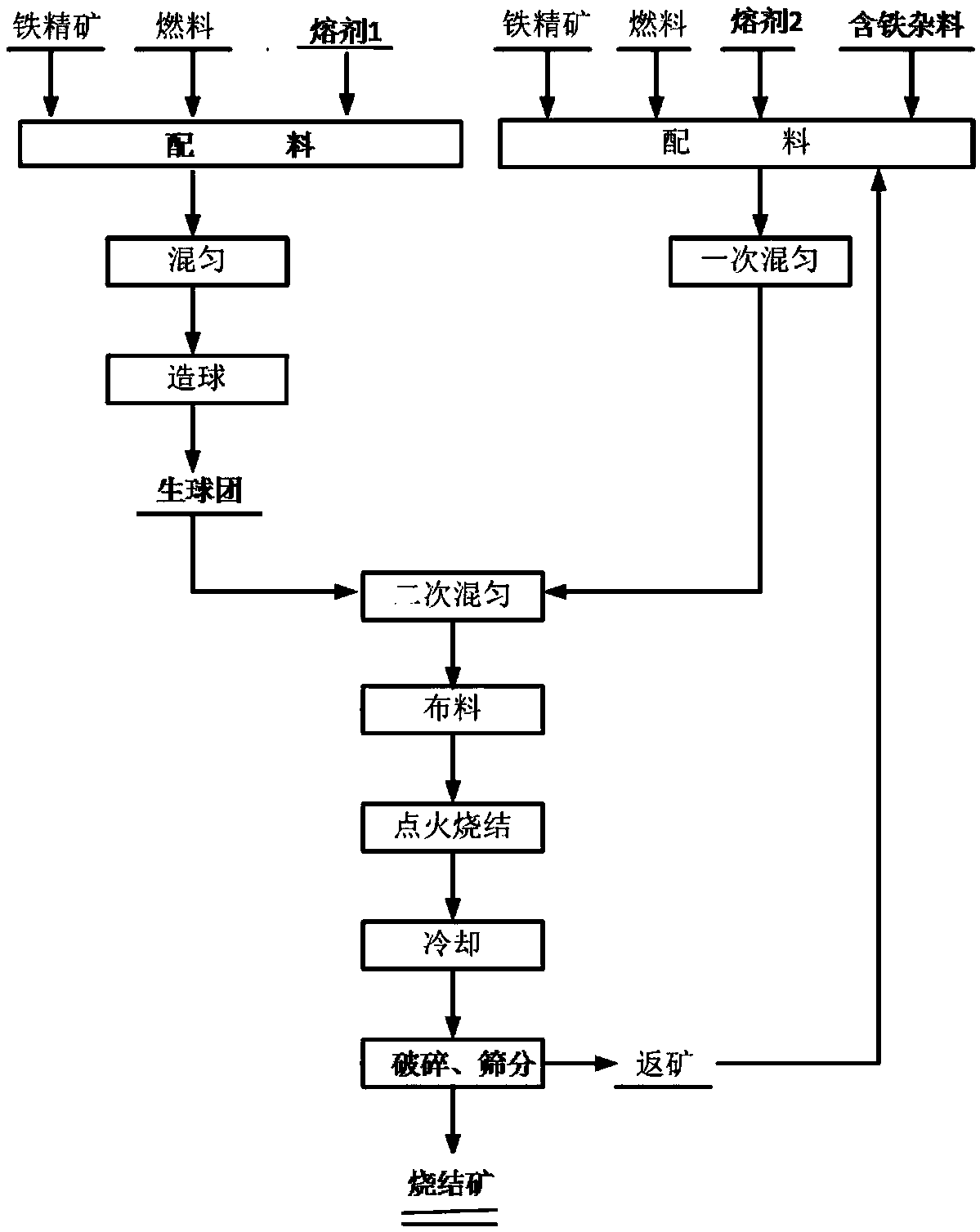

High quality sintered ores for COREX smelting reduction process for ironmaking and preparation method thereof

The invention provides high quality sintered ores for a COREX smelting reduction process for ironmaking and a preparation method thereof. The preparation method comprises the following steps: dividing30-50% of iron ore concentrate and 4-7% of flux 1 as well as 1.0-1.5% f a solid fuel from the total amount of iron ore concentrate for proportioning, and uniformly mixing the three to prepare flux carbon-burdened green pellets; proportioning the divided residual iron ore concentrate and iron-containing miscellaneous materials, return ores, flux 2 and the solid fuel and uniformly mixing the mixture to obtain a mixed material; and mixing, granulating, distributing, igniting, sintering, cooling, crushing and screening the obtained green pellets and the mixed material to obtain the sintered oresand the return ores. The sintered ores prepared by the method can meet the demand that the low-temperature reduction degradation value of the sintered ores in a COREX vertical furnace: RDI+6.3 is greater than or equal to 50% when the alkalinity is 1.8. The furnace mass ratio of the sintered ores can be greater than 50%, so that the cost of an ironmaking furnace burden can be lowered effectively.

Owner:CENT SOUTH UNIV

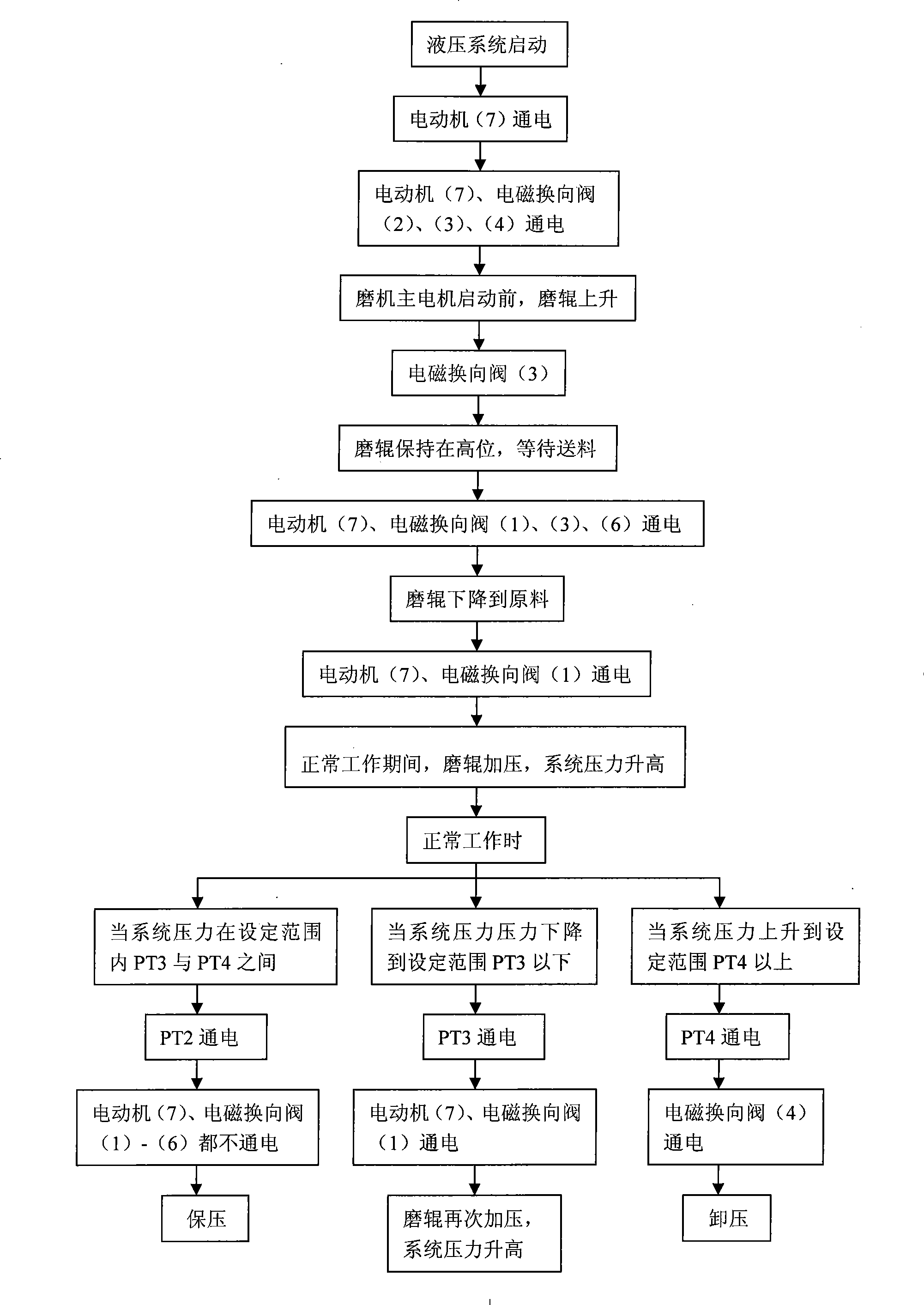

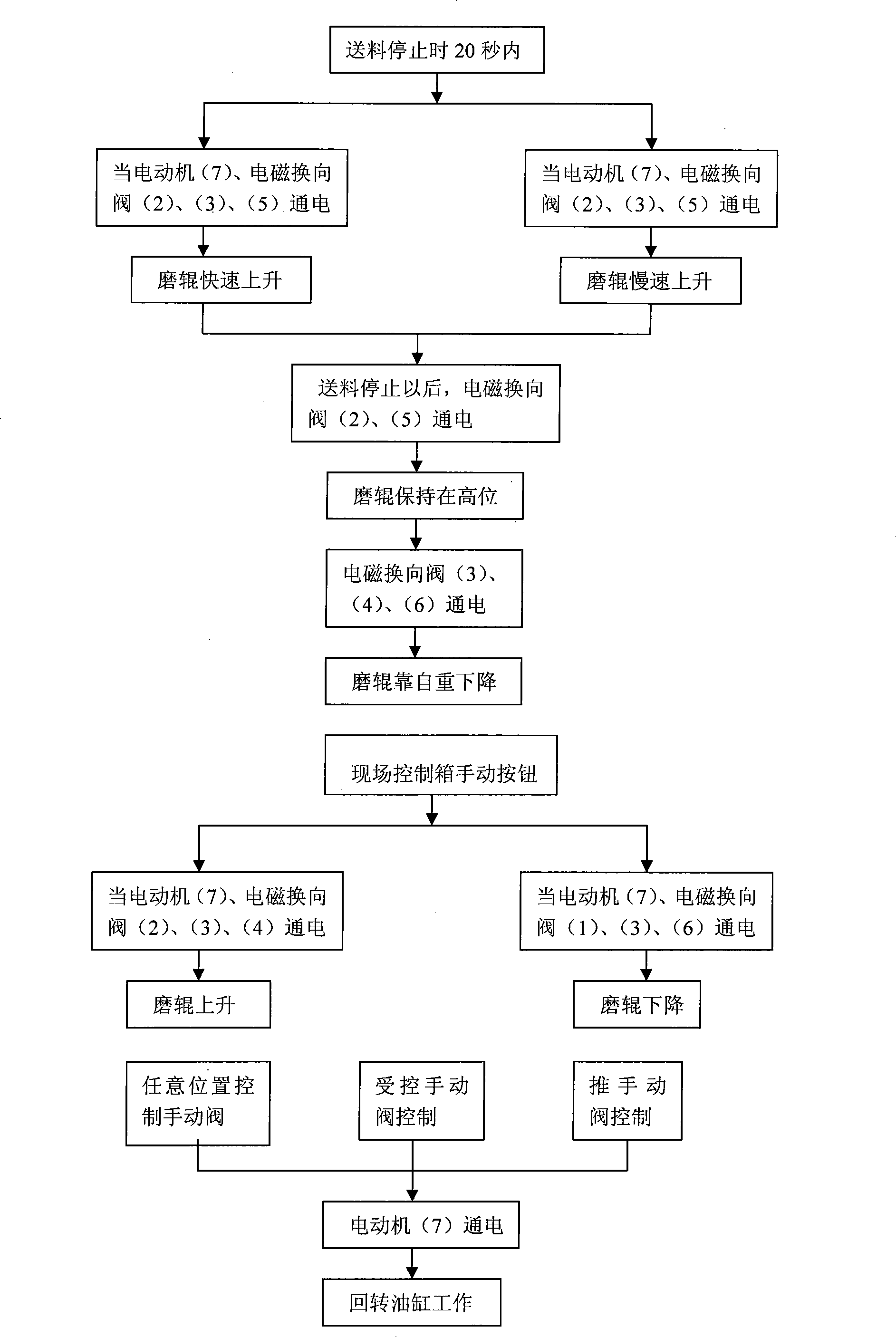

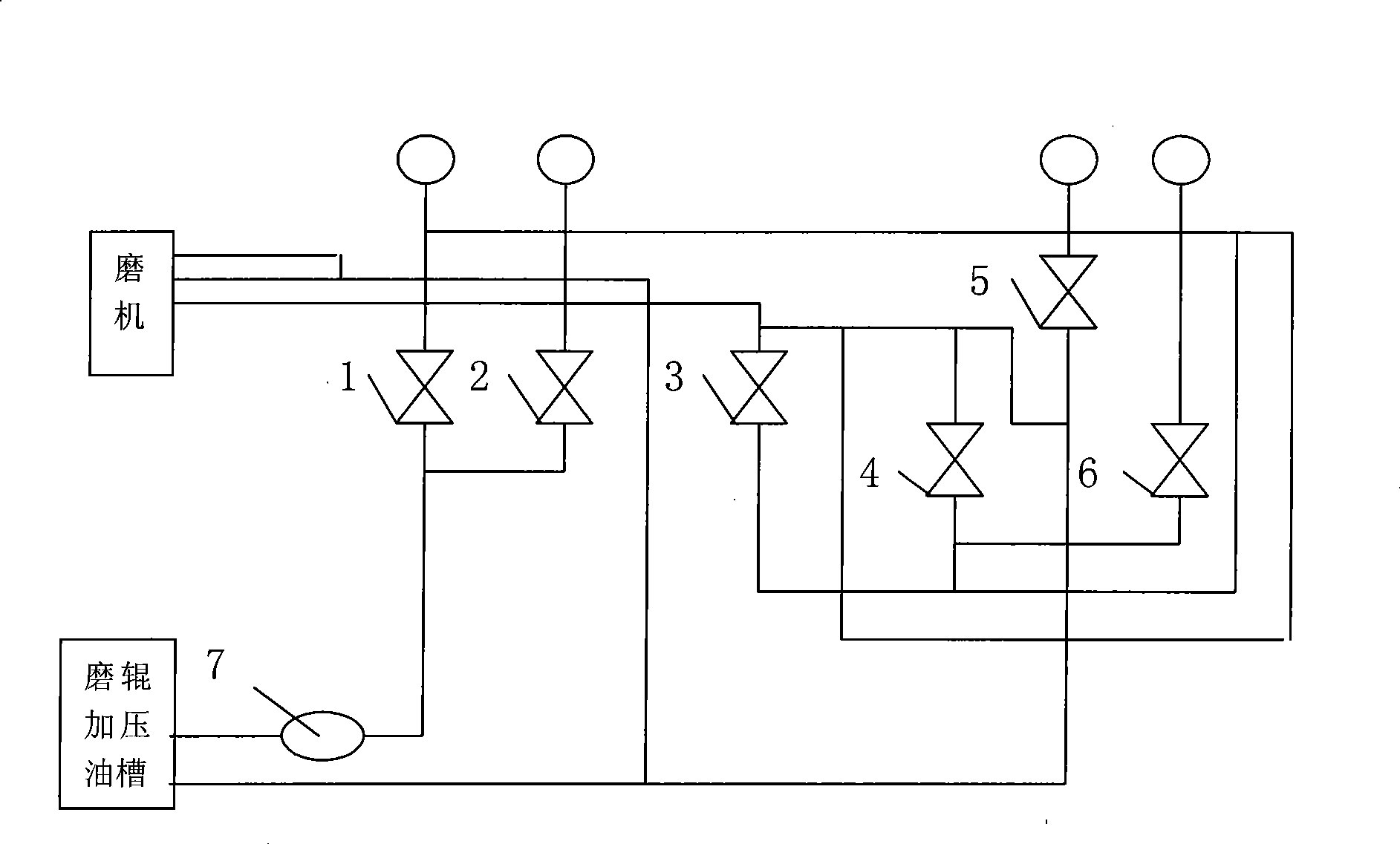

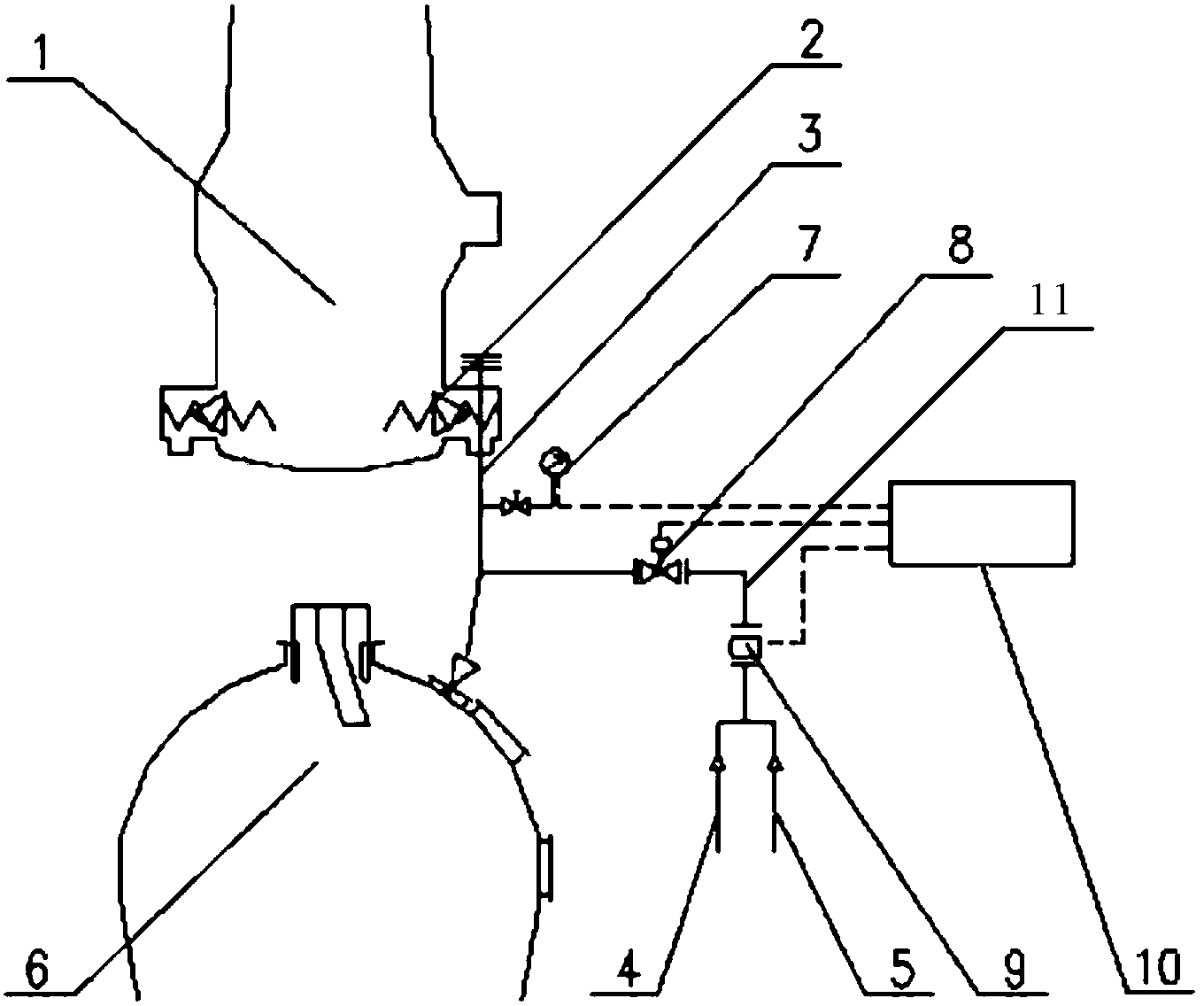

Hydraulic control method for COREX slag powder mill system

InactiveCN101424285AMeet the needs of the grinding processImproved hydraulic control methodServomotor componentsGrain treatmentsSlagEngineering

The invention discloses a hydraulic control method for a COREX slag pulverizing system and relates to the technical field of hydraulic control. A control operating system consists of an electromagnetic reversing valve (1), an electromagnetic reversing valve (2), an electromagnetic reversing valve (3), an electromagnetic reversing valve (4), and electromagnetic reversing valve (5), an electromagnetic reversing valve (6), an electromotor (7), a PT1 pressure sensor, a PT2 pressure sensor, a PT3 pressure sensor and a PT4 pressure sensor. According to the process flow, the hydraulic control method forms a logic relation of different working states through central control DCS operation, realizes a series of actions including the rising, declining, pressure maintaining of a grinding roller through controlling the switches of a plurality of the electromagnetic reversing valves, can automatically judge the needed adjustment under various operating conditions and realize the actions through controlling the electromagnetic reversing valves so as to make the whole system more intelligent. The hydraulic control method improves the prior inapplicable hydraulic control method, meets the requirement of the COREX slag pulverizing process, and has the characteristics of convenient operation, high intelligence degree and the like.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

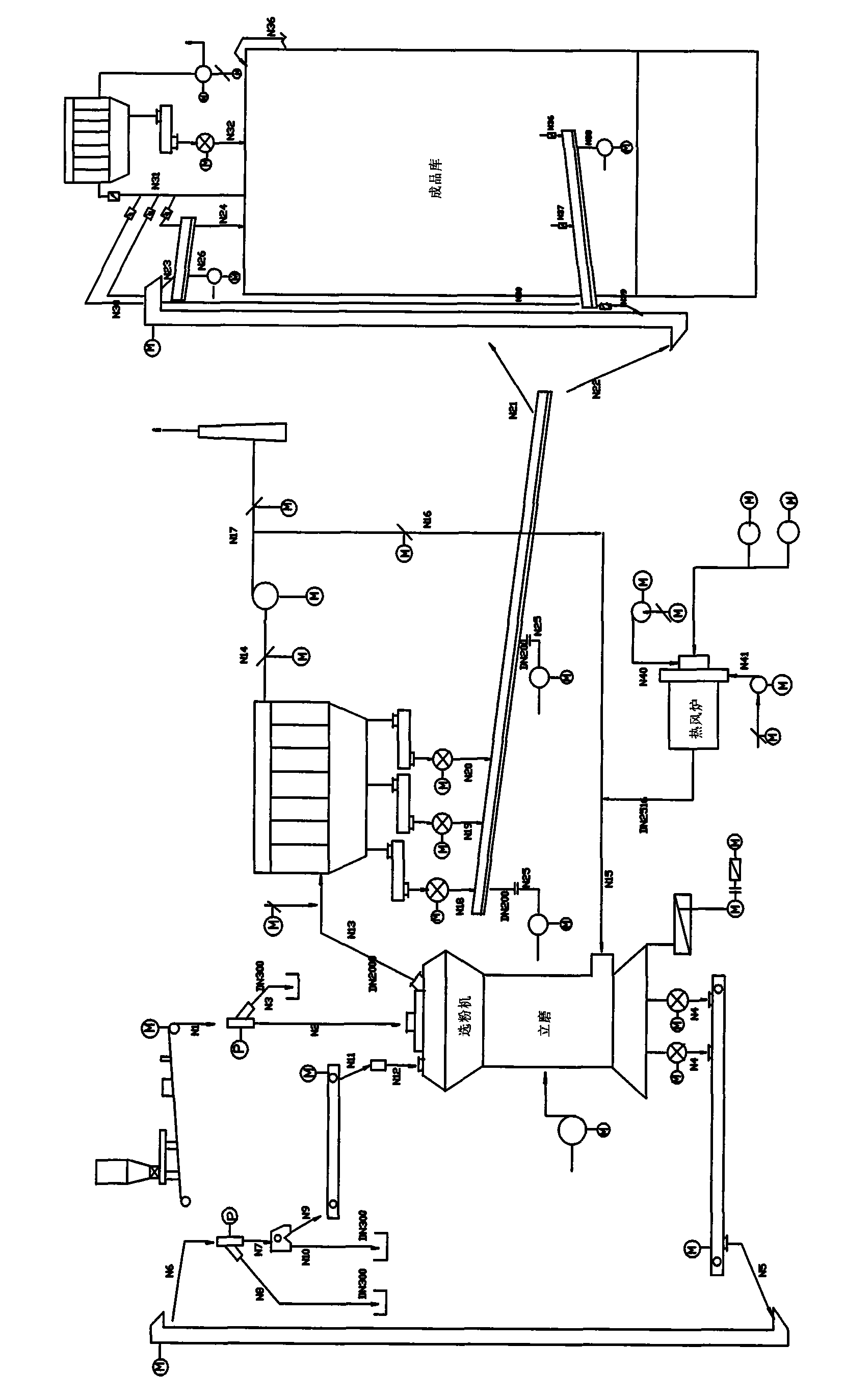

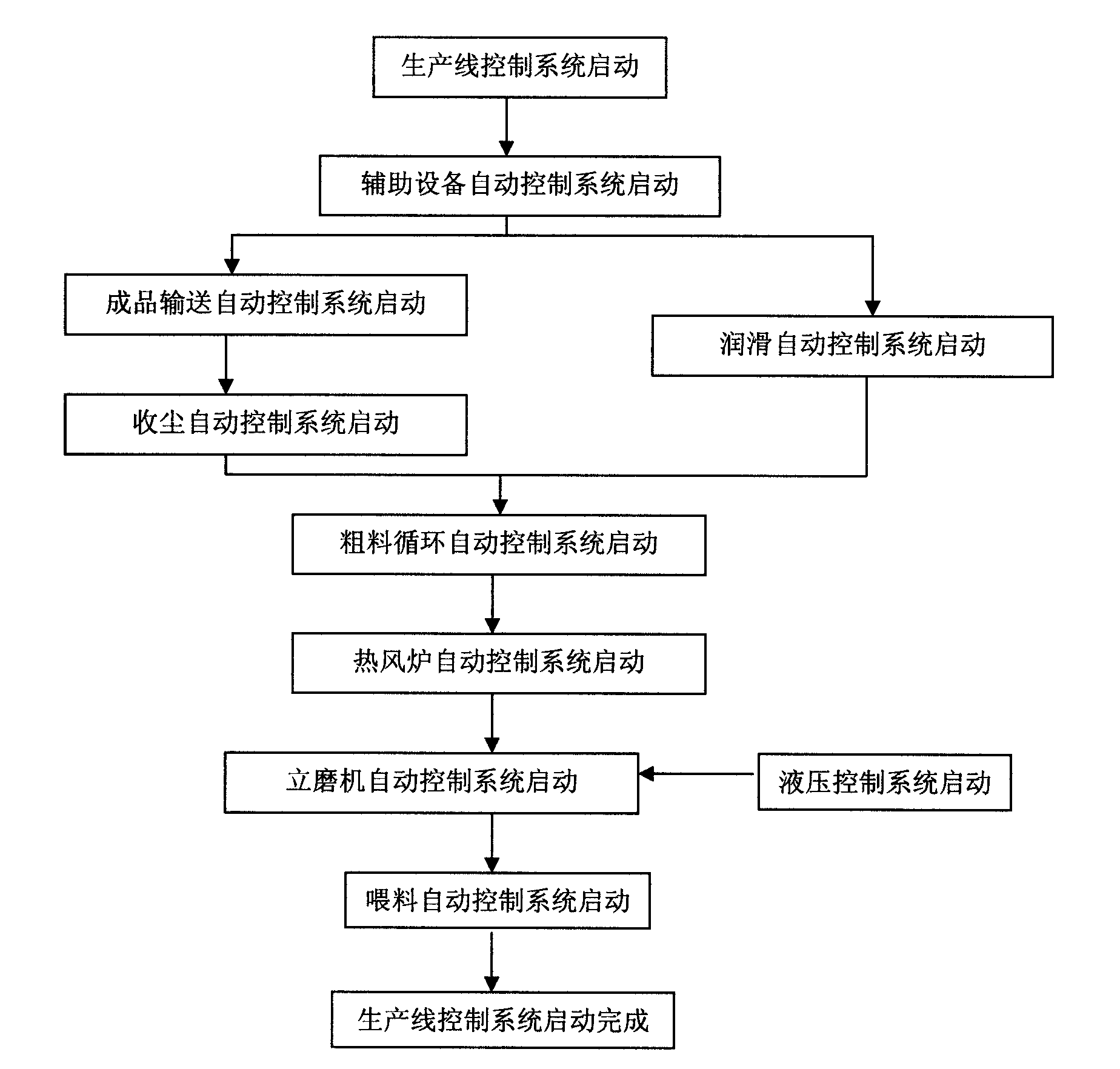

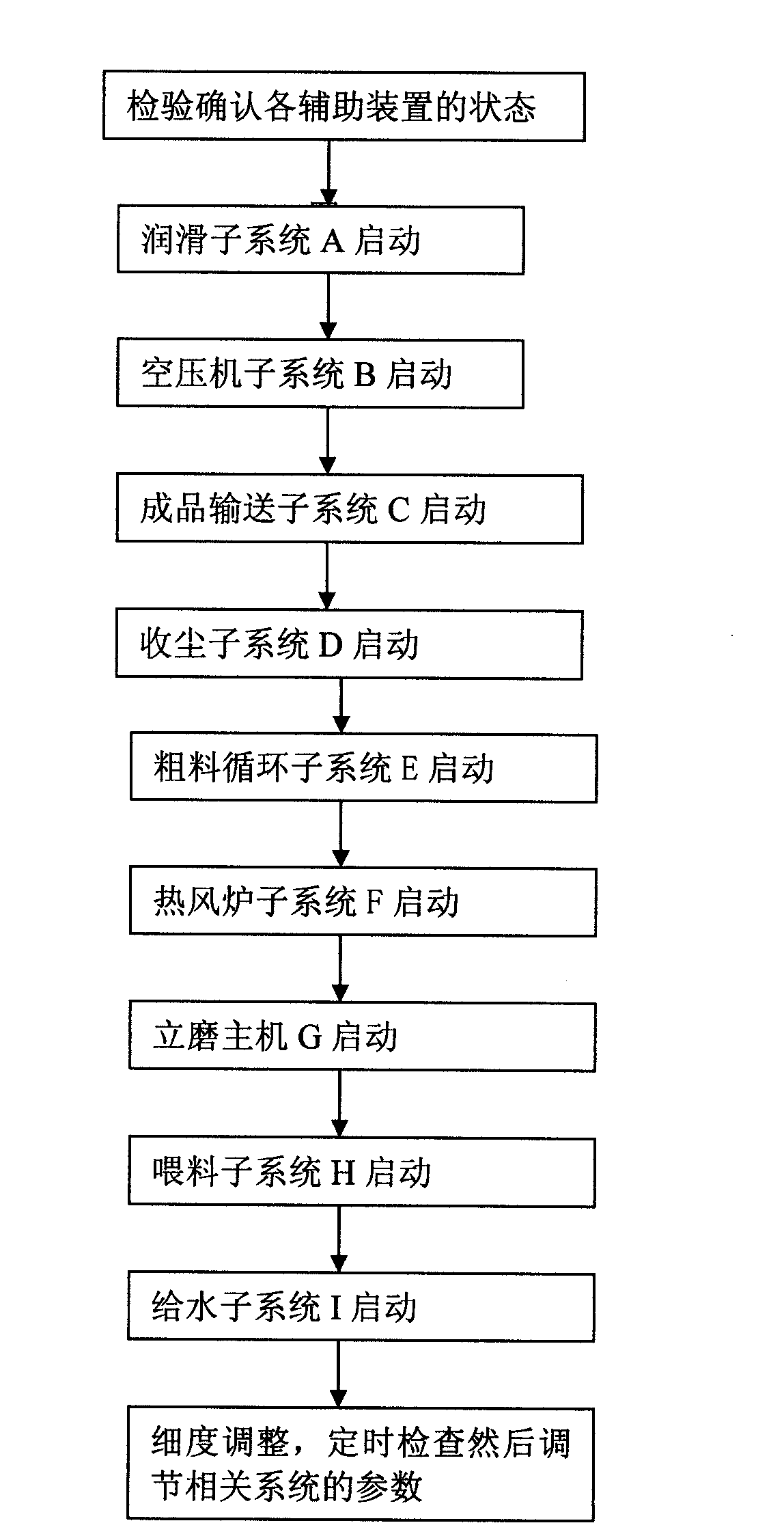

Start control process for COREX slag grinding production control system

ActiveCN101930226AEasy to operateImprove stabilityGrain treatmentsTotal factory controlSlagControl system

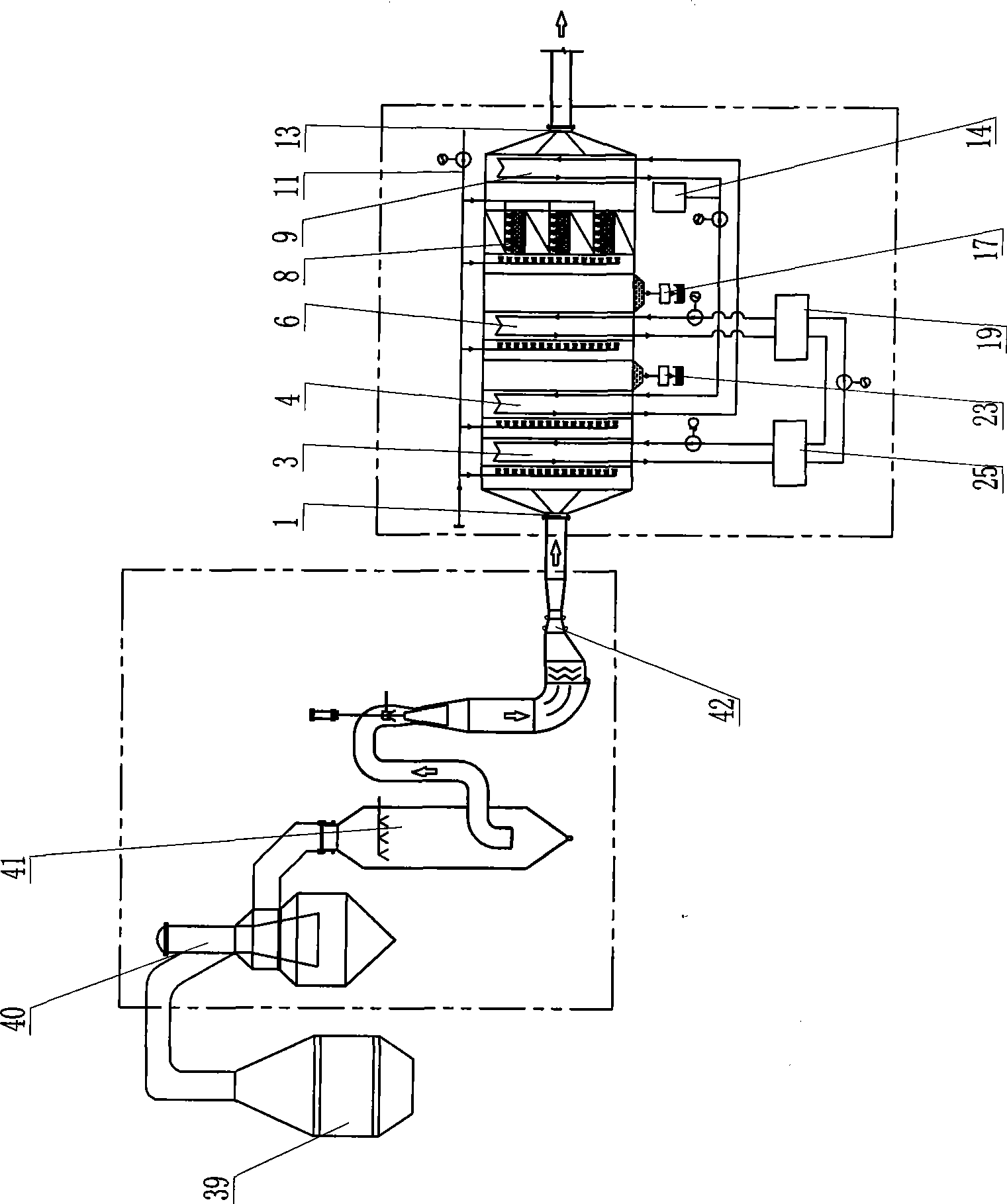

The invention relates to a start control process for a COREX slag grinding production control system. The control system comprises a vertical grinding host machine (G), and a lubricating sub-system (A), an air compressor sub-system (B), a finished product conveying sub-system (C), a dust collection sub-system (D), a crude material circulation sub-system (E) and a hot air furnace sub-system (F) serving as assistance, as well as a feeding sub-system (H) and a water supply sub-system (I). The start control process comprises the following concrete steps: (1) checking and confirming the state of each assisted device; (2) implementing start on each sub-system based on the sequence of A-I; and (3) adjusting fineness, regular checking, and adjusting parameters of related systems. The process recombines the sub-systems of the conventional process, strictly starts according to a certain sequence with rigorous procedure, and is advantageous to production operation and production stability; a related hydraulic unit is firstly started so as to contribute to normal operation of subsequent equipment and improve the service life of the equipment.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

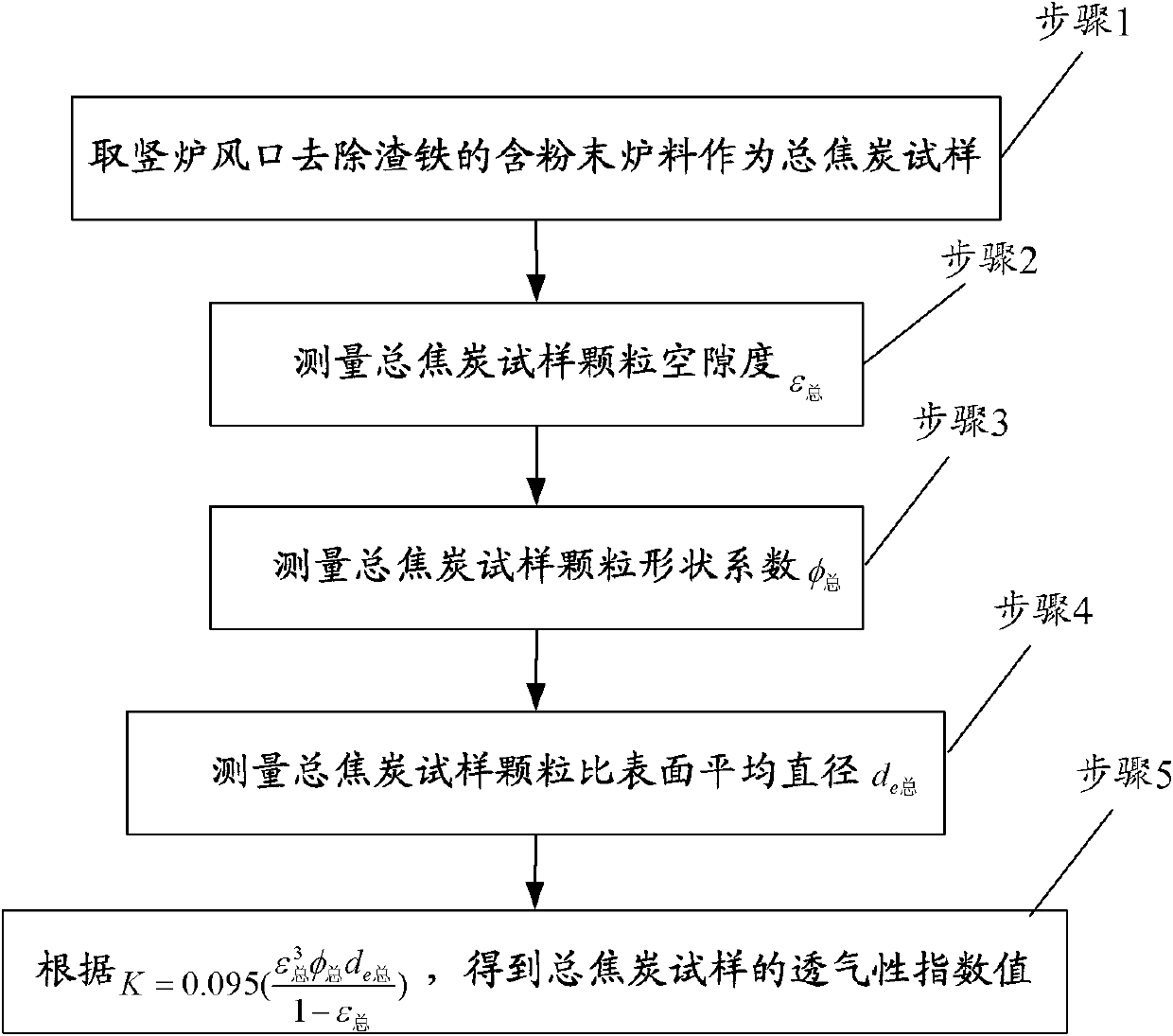

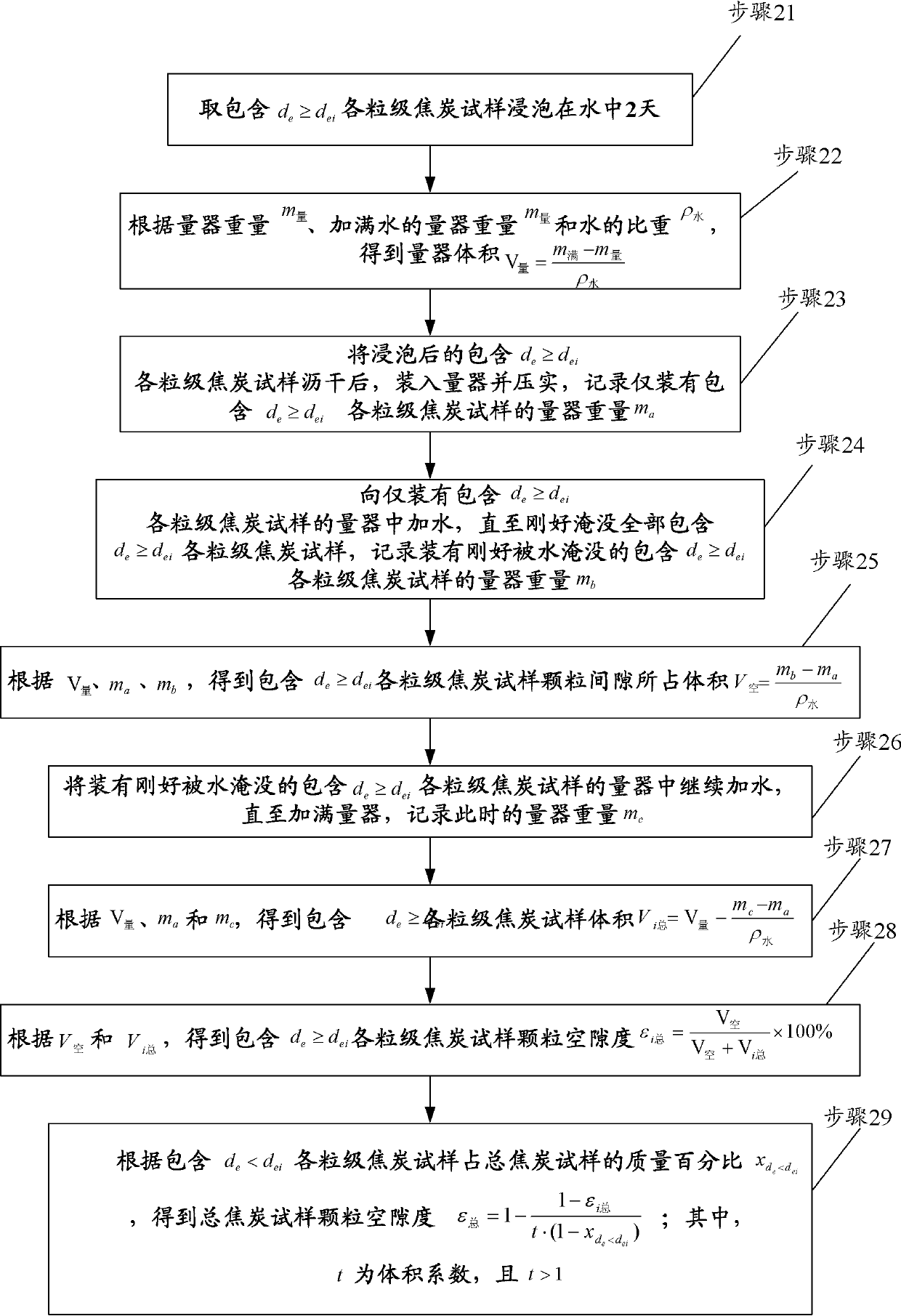

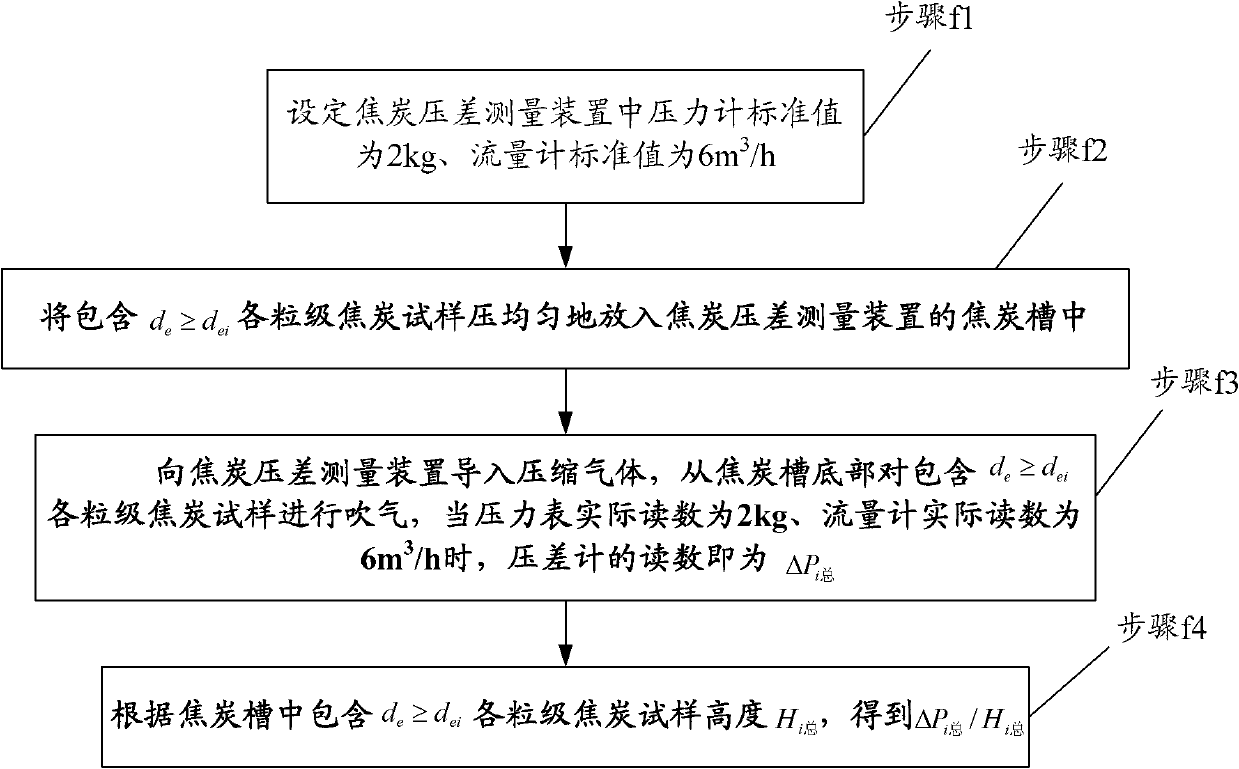

Method for measuring permeability index of front coke or carbocoal of COREX or blast-furnace tuyere

The invention discloses a method for measuring a permeability index of front coke or carbocoal of a COREX or a blast-furnace tuyere. The method comprises the following steps of: taking powder-containing slag-iron-free furnace burden at the blast-furnace tuyere as a total coke test sample; measuring a granule voidage E(total) of the total coke test sample; measuring a granule shape coefficient phi(total) of the total coke test sample; measuring granule specific surface average diameter de(total) of the total coke test sample; and obtaining a permeability index value of the total coke test sample according to a formula, FORMULA. By the method, the measurement of the furnace burden permeability index of the powder-containing furnace burden is realized; and the method can be widely applied tosmelting industries.

Owner:UNIV OF SCI & TECH BEIJING

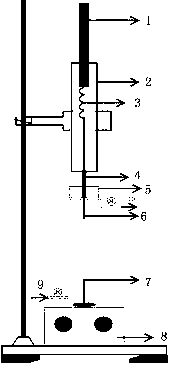

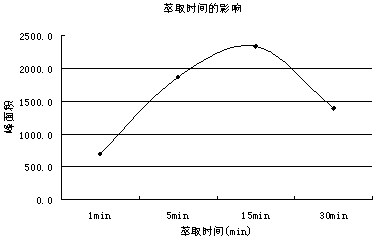

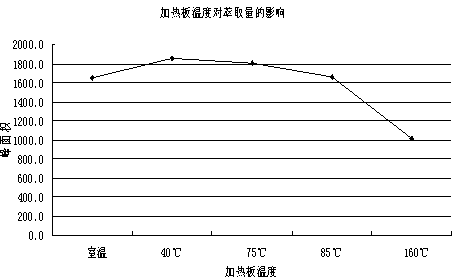

Application of solid phase microextraction in content analysis of naphthalene in Corex furnace gas

The invention relates to solid phase microextraction, particularly an application of the solid phase microextraction in content analysis of naphthalene in Corex furnace gas. The invention is characterized by inserting an extraction head of solid phase extraction capillary fibers in a sampling bottle, extracting naphthalene in the concentrated gas, and then carrying out sample injection analysis on the fibers in a gas phase gas phase analyzer. According to the invention, the acquisition process of naphthalene in gas is greatly simplified; by adopting the solid phase microextraction technique, the sensitivity of the analysis is greatly raised; the advantages of simpleness, fast analysis, good correctness, no toxicological harmless, no pollution and the like are achieved; and the process can be prevented from being influenced by water vapour and other impurities in gas simultaneously.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

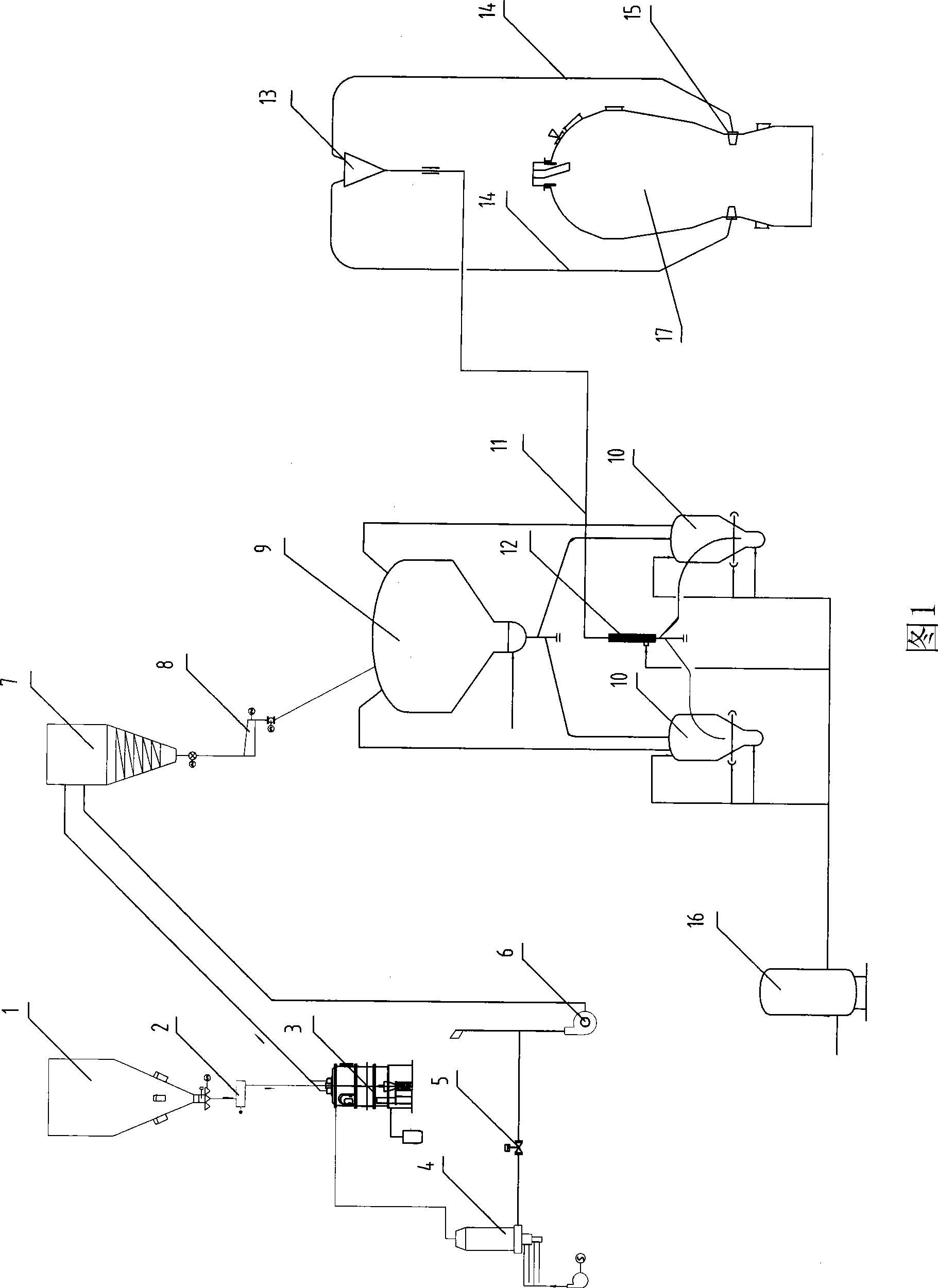

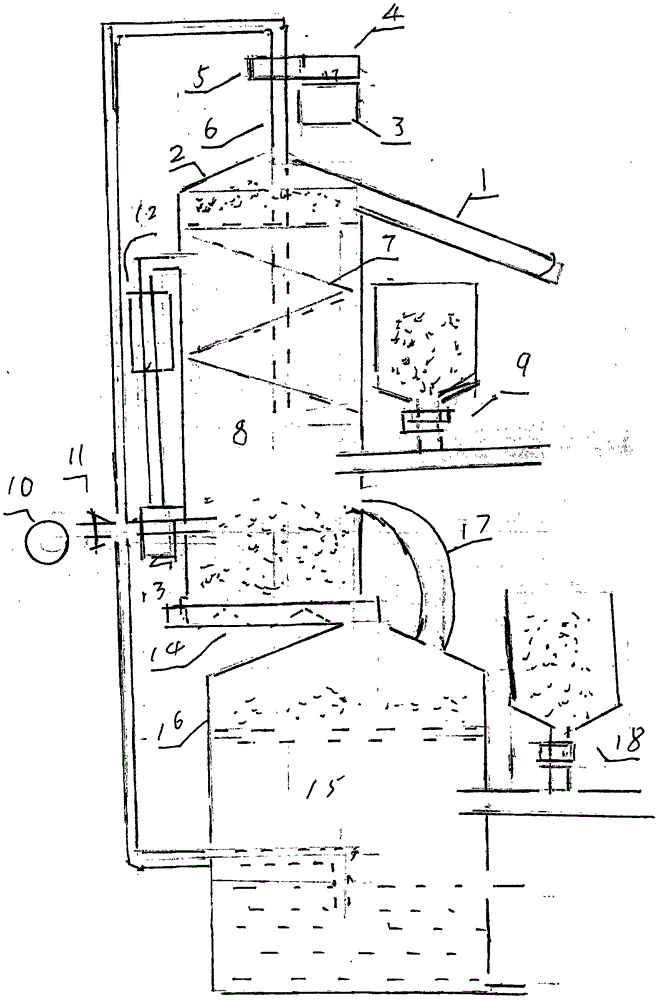

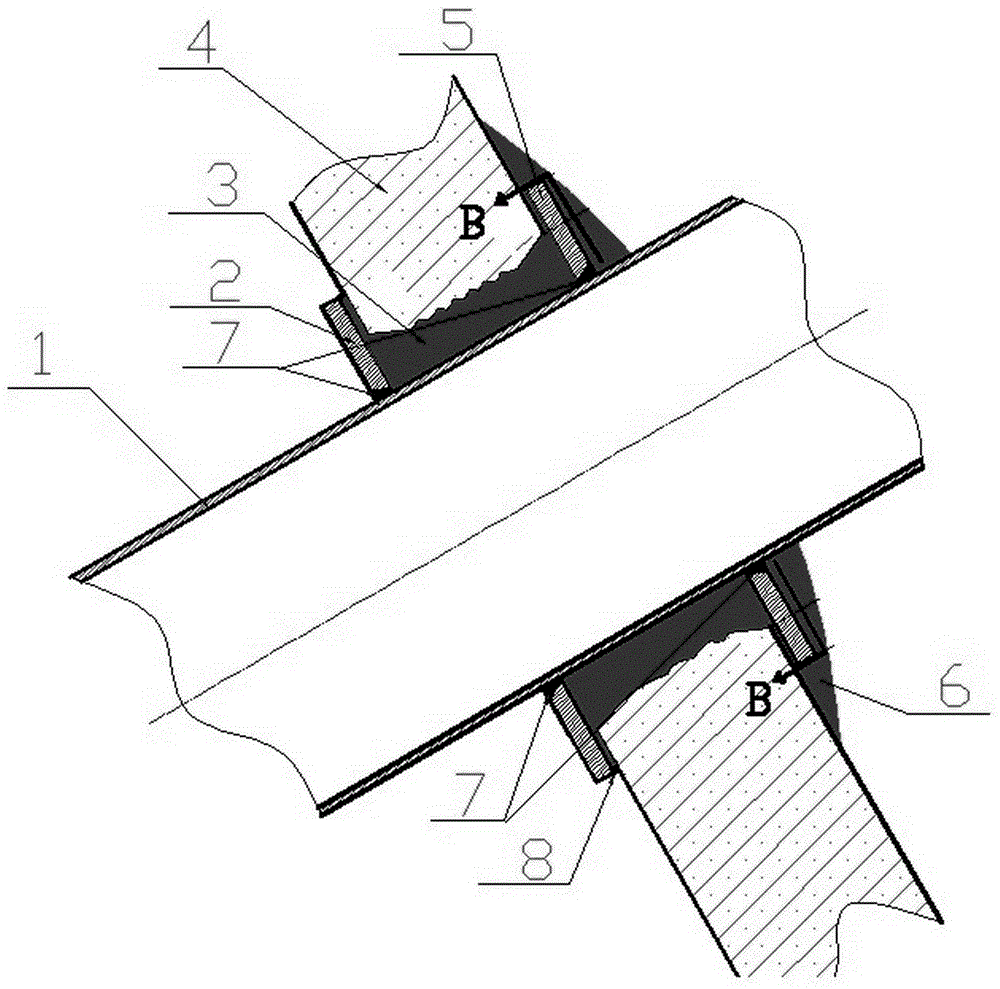

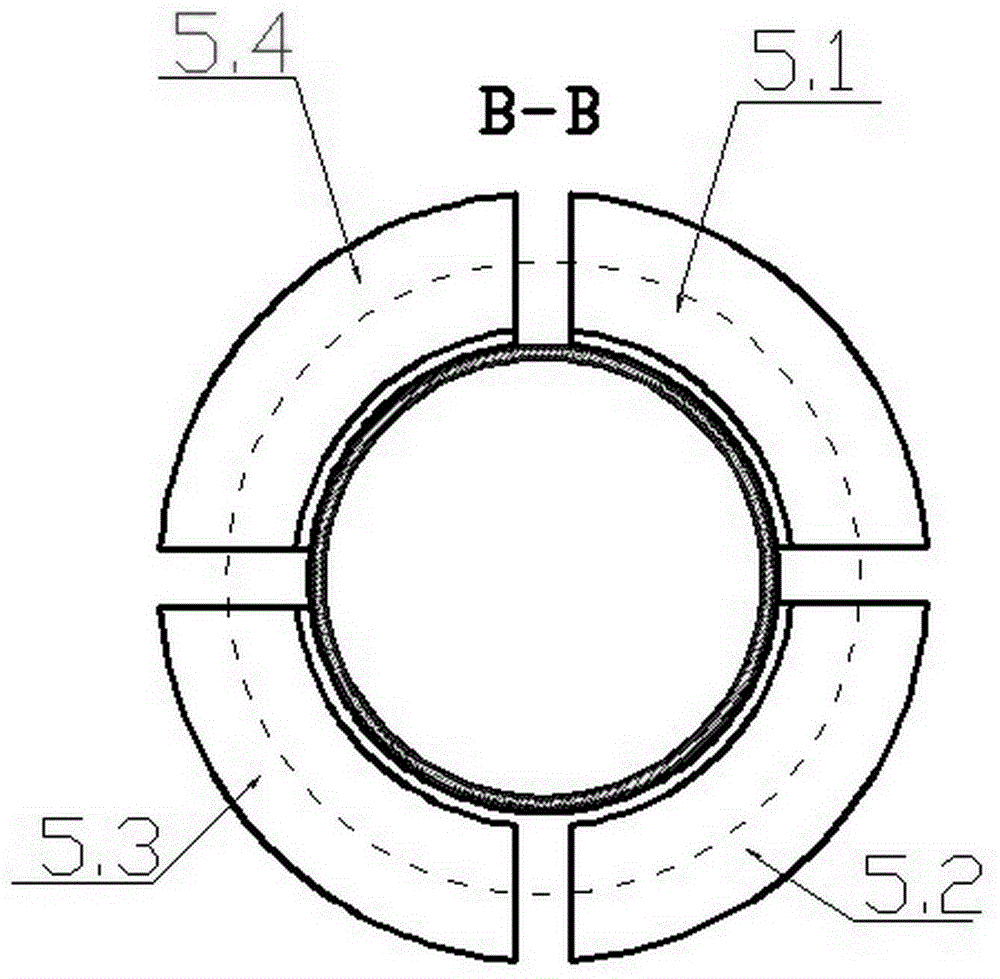

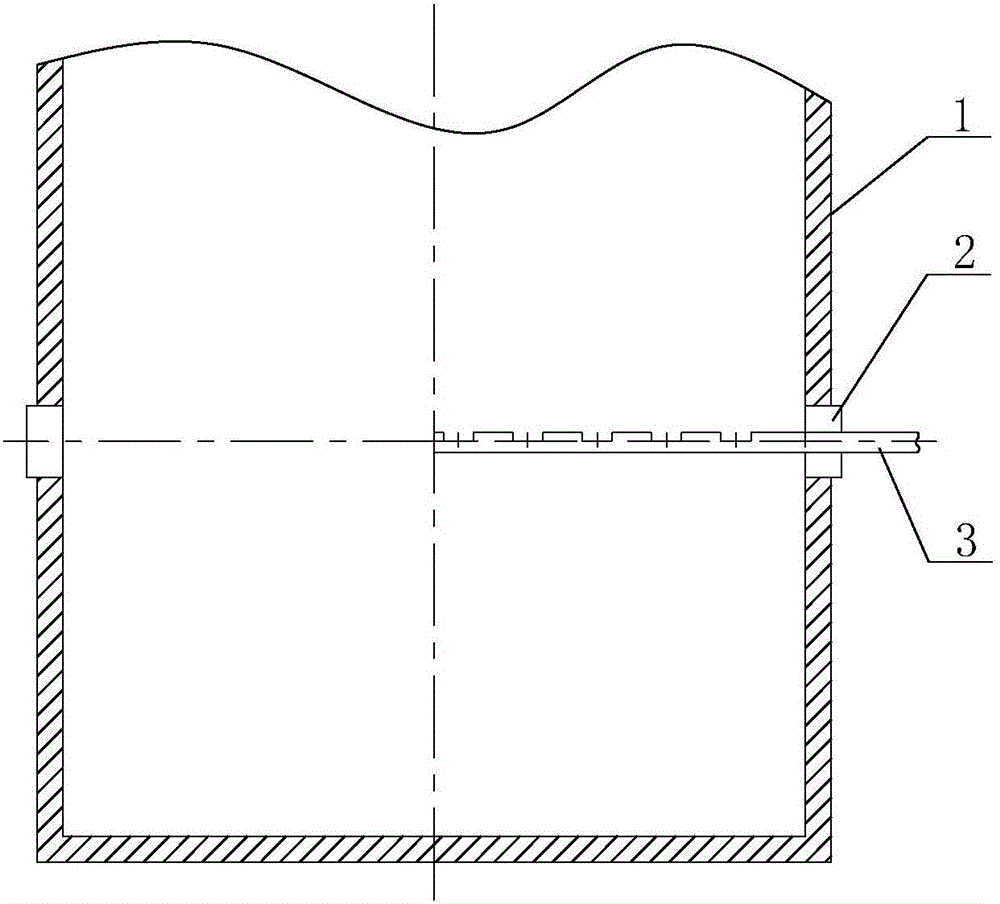

COREX smelting reduction iron making equipment and iron making method

The invention discloses COREX smelting reduction iron making equipment and an iron making method. A distributive raw material feeding device rotates to feed raw materials into a vertical furnace reduction furnace; and a spiral stirrer rotates to slide the raw materials along a spiral plate. Compressed carbon monoxide enters a hollow rotating shaft from the upper end for blowing out from the lower end. A pulverized coal spraying device 2 sprays pulverized coals into space of an exhaust insulation pipe of a smelting gasification furnace above an exhaust port of the vertical furnace reduction furnace; and the discharged pulverized coals are rich in oxygen, so that the pulverized coals are insufficiently burnt to heat the raw materials falling from the spiral stirrer. Carbon monoxide and iron ore powder in the spiral stirrer are reacted to generate carbon dioxide and sponge iron. Compressed and heated carbon monoxide enters sponge iron from the lower part of the vertical furnace reduction furnace. Sponge iron is conveyed on a fire grate of the smelting gasification furnace. The pulverized coal spraying device 1 sprays the pulverized coals below the fire grate in the smelting gasification furnace for combustion; and heat generated by combustion of the pulverized coals melts sponge iron and furnace slag falling on the fire grate. The heated carbon monoxide is blown into molten iron of the smelting gasification furnace.

Owner:张英华

Mullite brick used for furnace bottom of COREX furnace and its production method

The invention relates to a mullite brick used for furnace bottom of a COREX furnace, which comprises the following raw materials: 50-70% of mullite homogenizing material, 10-20% of white corundum, 10-20% of andalusite, 5-10% of a-Al2O3, 3-5% of clay, and paper pulp waste liquid accounting for 2-5% of total weight of the above raw materials. The porosity of the mullite brick is low which is less than 16.5%, the compression strength is greater than 100MPa, the thermal shock stability is greater than 30 times, refractoriness under load is greater than 1678 DEG C, all indexes are superior to those of common domestic corundum mullite bricks, and the mullite brick provided by the invention has the characteristics of high mechanical strength, high temperature resistance, erosion resistance and scouring resistance.

Owner:TONGDA REFRACTORY TECH CO LTD +1

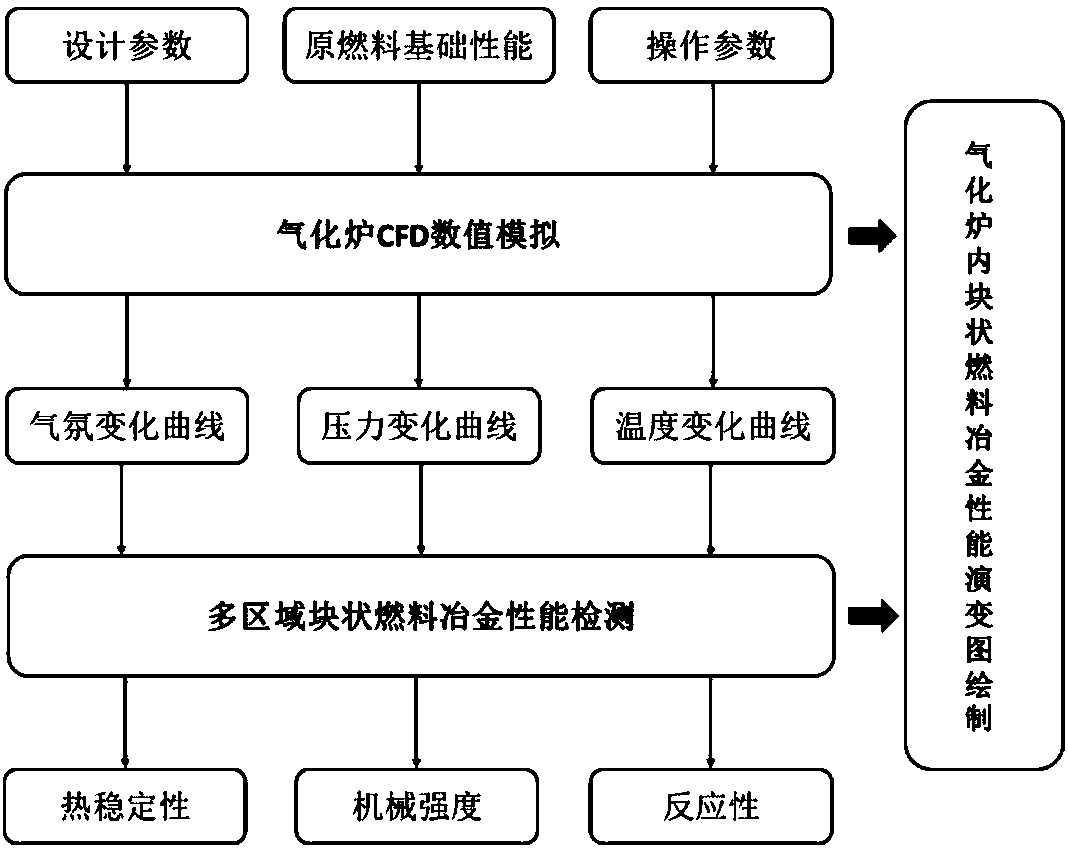

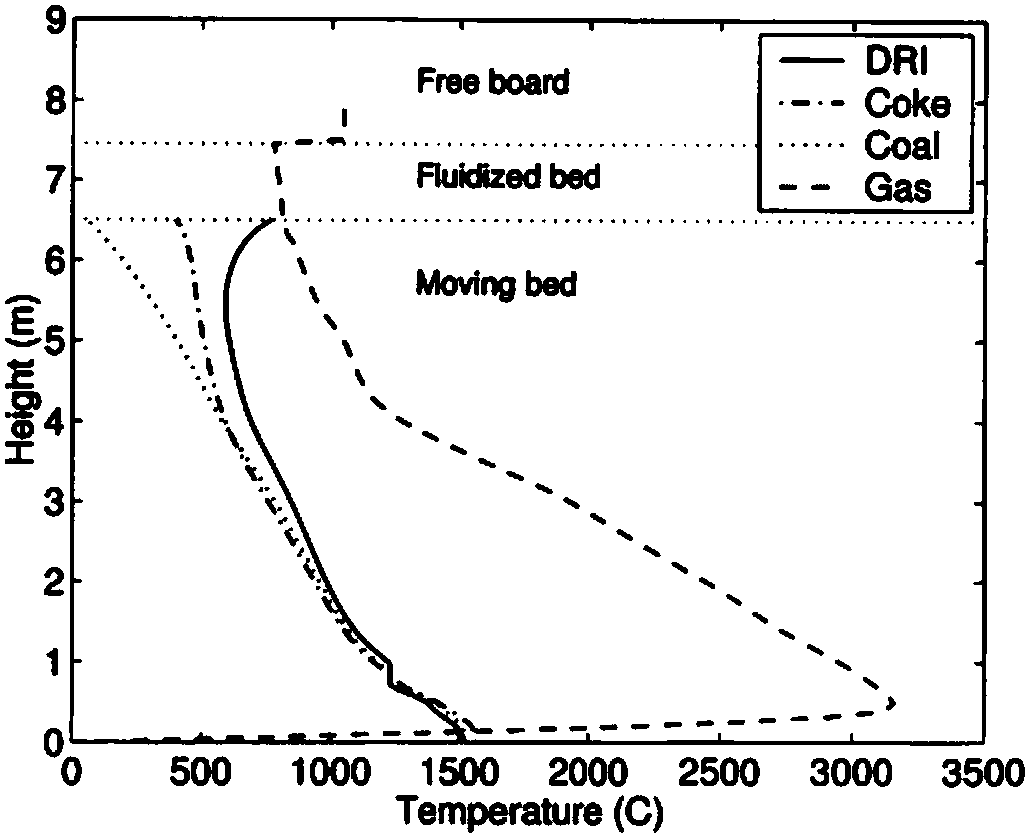

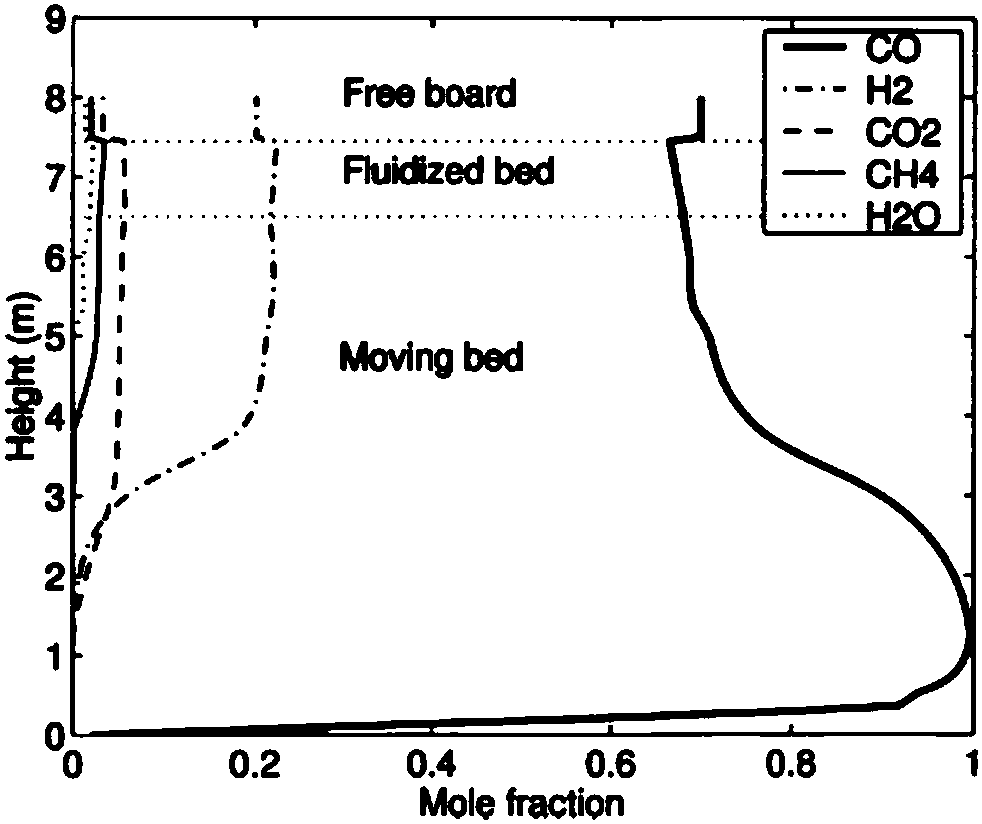

Method for drawing metallurgical performance evolution graphs of fuel in COREX gasification furnaces

ActiveCN107641675ASolve the comparison problemEfficient use ofSpecial data processing applicationsSystems analysisEngineering

The invention belongs to the technical field of non-blast furnace iron making, and particularly relates to a method for drawing metallurgical performance evolution graphs of fuel in COREX gasificationfurnaces. The method includes steps of 1), establishing height-temperature relations of fuel columns by means of CFD (computational fluid dynamics) simulation software modeling and numerical value emulation on the basis of design parameters of the COREX gasification furnaces, basic performance of crude fuel and operating parameters of gasification furnaces; 2), establishing corresponding relations between temperature values of simulation lumped fuel under the conditions of height values and metallurgical performance numerical values of the lumped fuel and further drawing temperature-performance relation curves of the lumped fuel; 3), carrying out mapping association on height-temperature relation curves of the fuel columns and the temperature-performance relation curves of the lumped fueland acquiring height displacement-performance evolution graphs of the lumped fuel by the aid of data processing software and drawing software which are combined with each other. The method has the advantages that performance evolution of different types of lumped fuel in the gasification furnaces can be pertinently systematically analyzed by the aid of the method, the method is beneficial to scientifically recommending adding proportions and utilization modes for the lumped fuel, blast furnaces can assuredly stably smoothly run, and different types of fuel can be optimally utilized.

Owner:WUHAN UNIV OF SCI & TECH

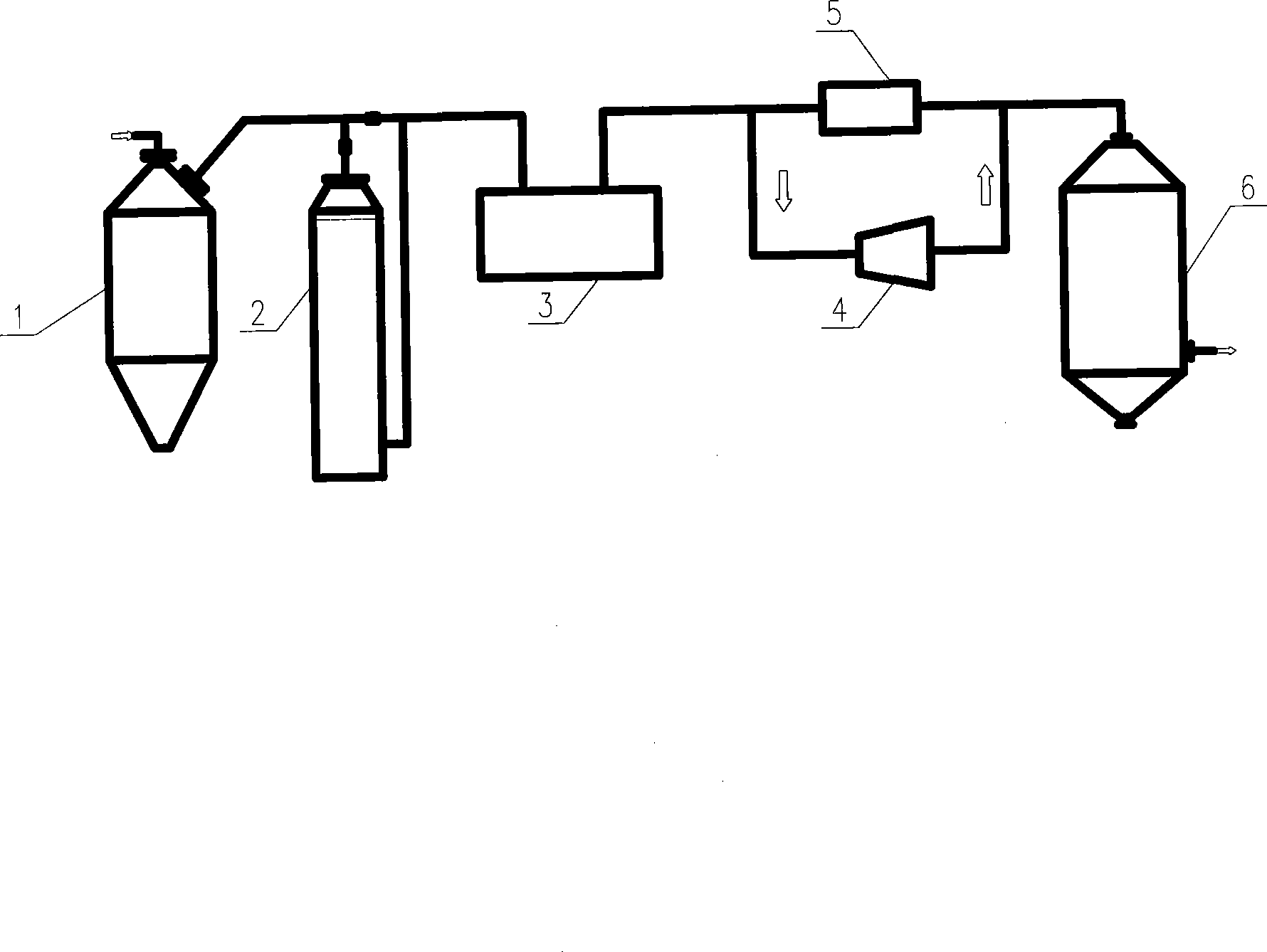

Purifying technique for roof gas of COREX melting reducing furnace

ActiveCN101200656AReduce consumption costReduce manufacturing costEnergy inputCombustible gas purificationEconomic benefitsEnergy recovery

The present invention belongs to the operation technical field, discloses an ironmaking furnace coal gas purification technology and especially relates to a technology of purifying the furnace top coal gas of a COREX smelting reduction furnace. The present invention aims at that the furnace top coal gas containing dust which is produced by the COREX smelting reduction furnace during the process of ironmaking is processed for removing partial dust by a primary dust remover; dry dust removing and purifying technology is used to purify coal gas; the coal gas after purification is processed for energy recovery by a TRT device or pressure reduction by a by-pass valve set and is put into a low pressure clean coal gas pipe net through a coal gas cooler for other users to use. The present invention reduces the use of cyclic water at the maximum, reduces the energy consumption and the production cost for reducing and ironmaking and at the same time keeps the quite high temperature of reducing and ironmaking coal gas, which is in favor of matching with the TRT to use the residual heat of coal gas to increase electricity generation and furthermore to improve the economic benefit.

Owner:CISDI ENG CO LTD

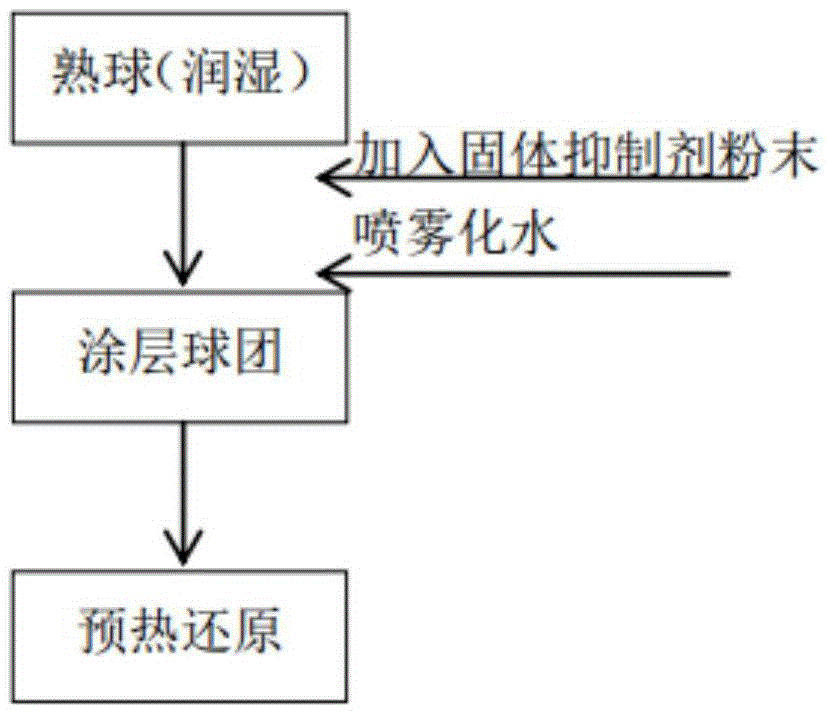

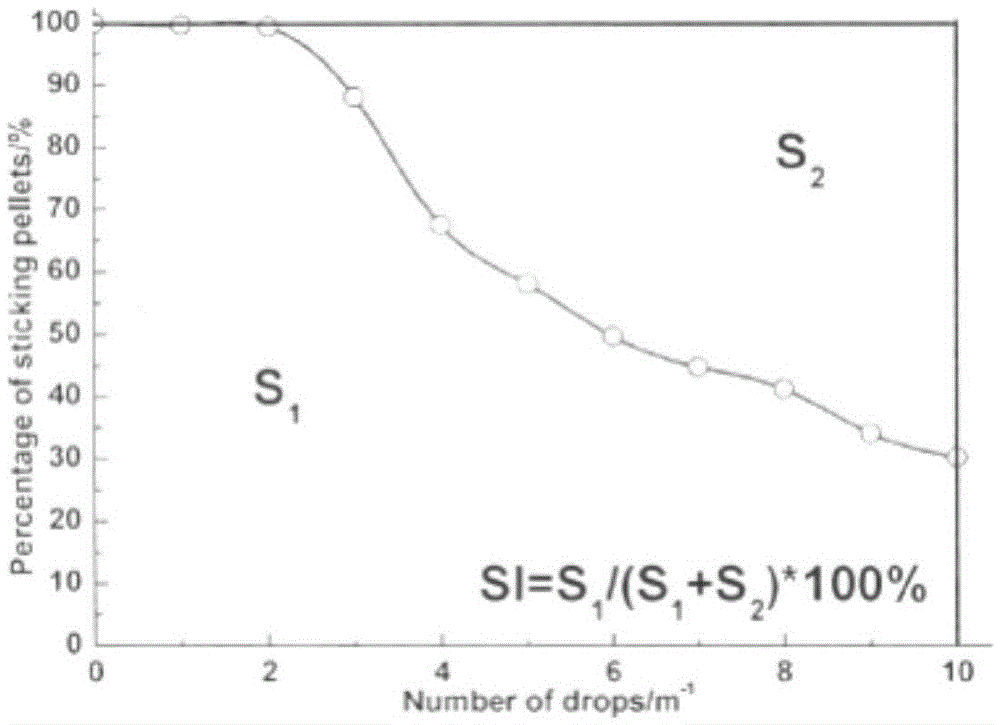

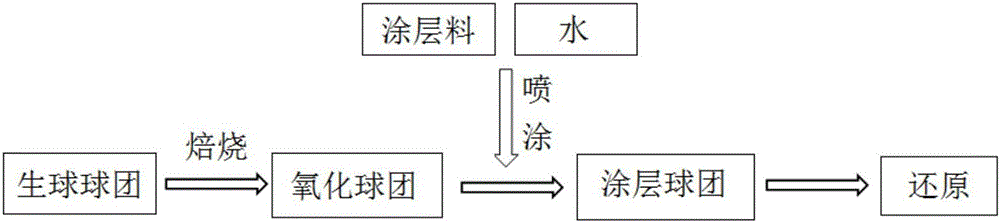

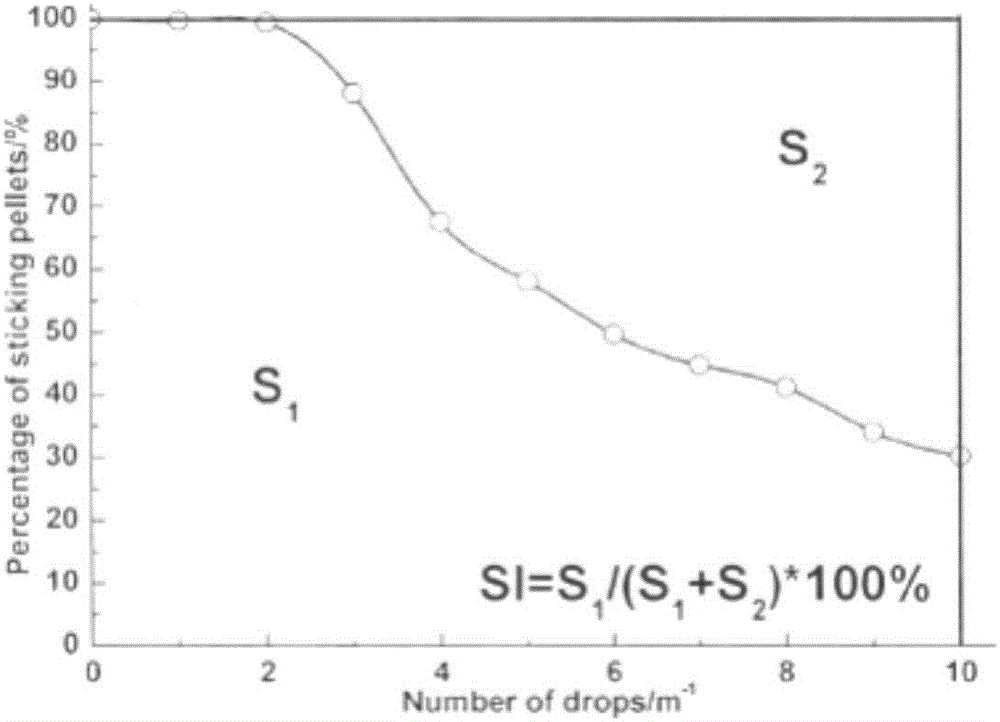

Method for inhibiting bonding of pellets in COREX shaft furnace

The invention discloses a method for inhibiting bonding of pellets in a COREX shaft furnace and belongs to the technical field of melt reduction ironmaking. The method comprises (1) roasting green pellets to obtain finished products of oxidized pellets, (2) placing the roasted oxidized pellets into a disc pelletizer, spraying water to wet the pellets, carrying out rotation of the pelletizer along with addition of solid inhibitor powder and spraying of a certain amount of water so that the pellets are uniformly coated with solid inhibitor layers and coated pellets are prepared, and (3) drying the coated pellets, adding the coated pellets into a load reduction furnace and carrying out reduction at a reduction gas temperature of 800-950 DEG C. The method can effectively improve the problem of the agglomeration of the pellets in the COREX shaft furnace process, is beneficial to smooth production of the pre-reduction furnace, improves utilization efficiency of the COREX shaft furnace, and reduces a direct reduction iron production cost. The reduced pellets have a bonding index less than 25%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Coating material capable of restraining pellet binding inside COREX shaft furnace and preparation and application method thereof

The invention discloses a coating material capable of restraining pellet binding inside a COREX shaft furnace and a preparation and application method thereof, and belongs to the technical field of smelting reduction iron-making. The coating material is composed of soft calcined dolomite, Ca(OH)2, anthracite and water. The mass proportion of the soft calcined dolomite to the Ca(OH)2 to the anthracite is 6:1:2-4:1:2. The mass sum of the soft calcined dolomite, the Ca(OH)2 and the anthracite accounts for 30%-35% of the total mass of coating mixed liquor. The preparation method of the coating material includes the following steps that (1) green pellets are roasted to form oxidized pellets; (2) the surface of each oxidized pellet is coated so that coating pellets can be prepared; and (3) the coating pellets achieve reduction. By means of the coating material capable of restraining pellet binding inside the COREX shaft furnace and the preparation and application method thereof, the binding phenomenon happening between the pellets inside the COREX shaft furnace can be effectively avoided; and meanwhile the metallization ratio cannot be lowered, direct motion of the shaft furnace and quality of the obtained product are guaranteed, and the production efficiency is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Anti-corrosion treatment method for bottom plate of COREX gas holder

InactiveCN112893055AExtended service lifeImprove toughnessPretreated surfacesSpecial surfacesElastomerPolyurea

The invention discloses an anti-corrosion treatment method for a bottom plate of a COREX gas holder. The anti-corrosion treatment method is implemented according to the following steps: 1, filling corrosion pits by using electric welding; 2, carrying out sand blasting to remove rust; 3, cleaning: cleaning the qualified surface with alcohol or acetone before coating first primer; 4, spraying a polyurea elastomer, namely starting to spray a polyurea elastomer anticorrosive material by adopting a polyurea elastomer spraying machine under the conditions that the pressure is 2,500 / 3,200 psi, the system temperature is 60-75 DEG C and the raw material temperature is kept above 20 DEG C after each system runs normally; constructing at the temperature 3 DEG C higher than the dew point temperature, conducting spraying operation by mixing the materials according to the volume ratio of 1: 1, performing temperature control during polyurea spraying construction, detecting the temperature of a raw material barrel firstly and keeping the temperature at 19 DEG C or above, not connecting a spray gun firstly, measuring the temperature of an output tail end of a heating hose, wherein the temperature ranges from 60 DEG C to 70 DEG C, and checking the thickness of a coating on a steel substrate through a thickness gauge, wherein the thickness is not less than 1.5 mm; and conducting an adhesive force test after each coating construction; and 5, conducting electric spark testing.

Owner:XINJIANG BAYI IRON & STEEL

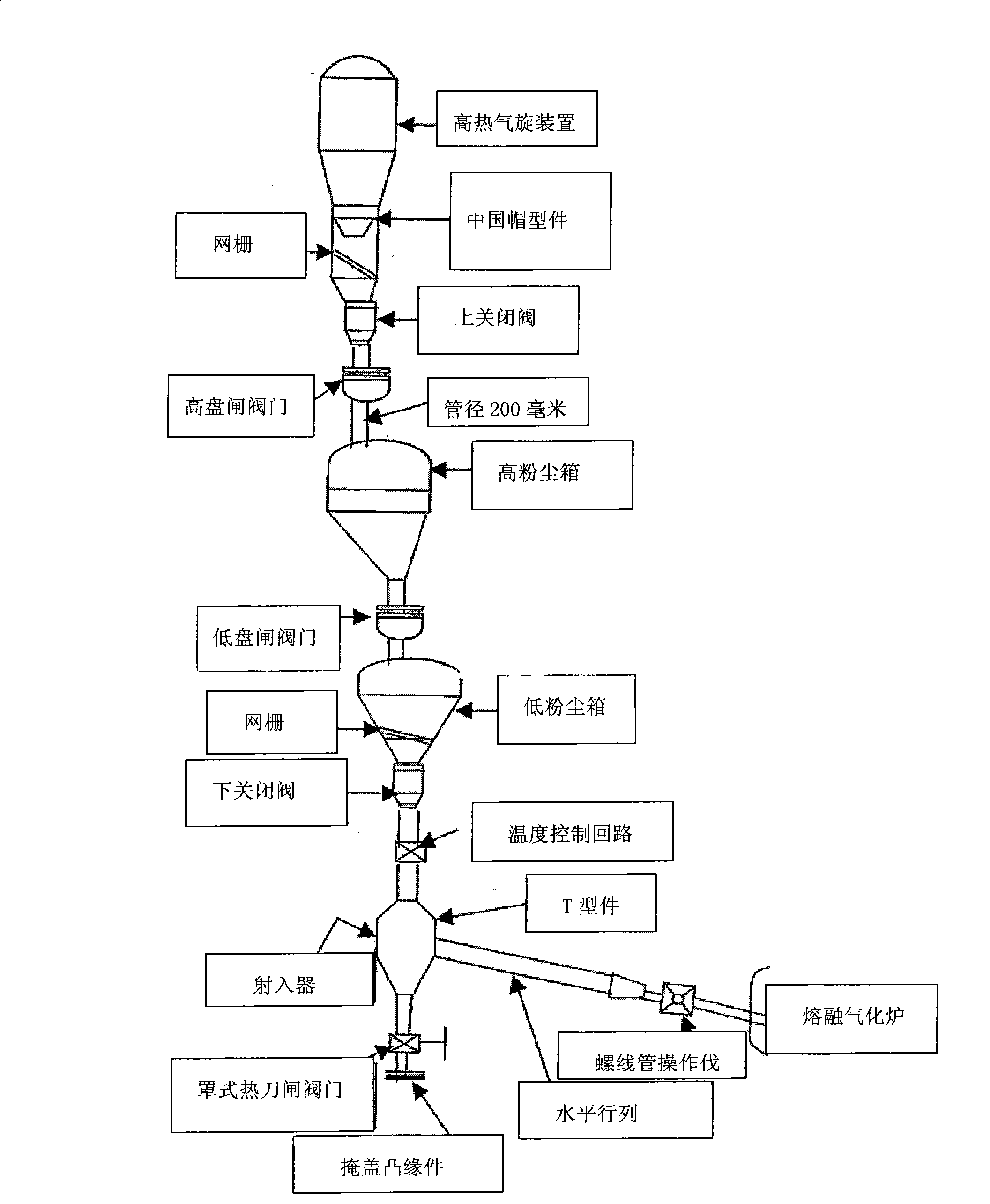

Blocking cleaning process for COREX smelting reduction furnace dust-removal system

InactiveCN101571357AImprove the blocking effectMeet the needs of productionMechanical apparatusShaft furnaceGratingNitrogen

The invention discloses a blocking cleaning process for a COREX smelting reduction furnace dust-removal system, which comprises blocking cleaning of a dust recycling system and heat whirlwind blocking cleaning. The blocking cleaning of the dust recycling system comprises the following steps of clearing a collection tank, clearing a TP chamber, and clearing a fluid dust bin. The heat whirlwind blocking cleaning comprises the following steps of connecting a bent pipe on a fifth valve, opening the valve, observing the blanking situation of a dustbin on a ground floor; and opening a nitrogen valve of the TP chamber to introduce nitrogen according to the requirement. Or the heat whirlwind blocking cleaning comprises the following steps: poking an accumulated material from a bypass of the bent pipe by a steel bar; then removing a corrugated tube of a hydraulic ball valve on the upper part, and poking the accumulated material from the bottom to top by the steel bar; observing the situation of the accumulated material on heat whirlwind, and when the accumulated material is lower than the lower edge of a man hole, clearing the accumulated material on a grating in the heat whirlwind by operating personnel; and closing a heat whirlwind large man hole, removing the bent pipe, and blocking a blind plate on the bent pipe. By adopting the proposal, the process can better complete the blocking cleaning work of the whole dust-removal system, and meets the production requirement. The process has the advantages of reasonable process, good blocking cleaning effect and the like.

Owner:MCC BAOSTEEL TECH SERVICE

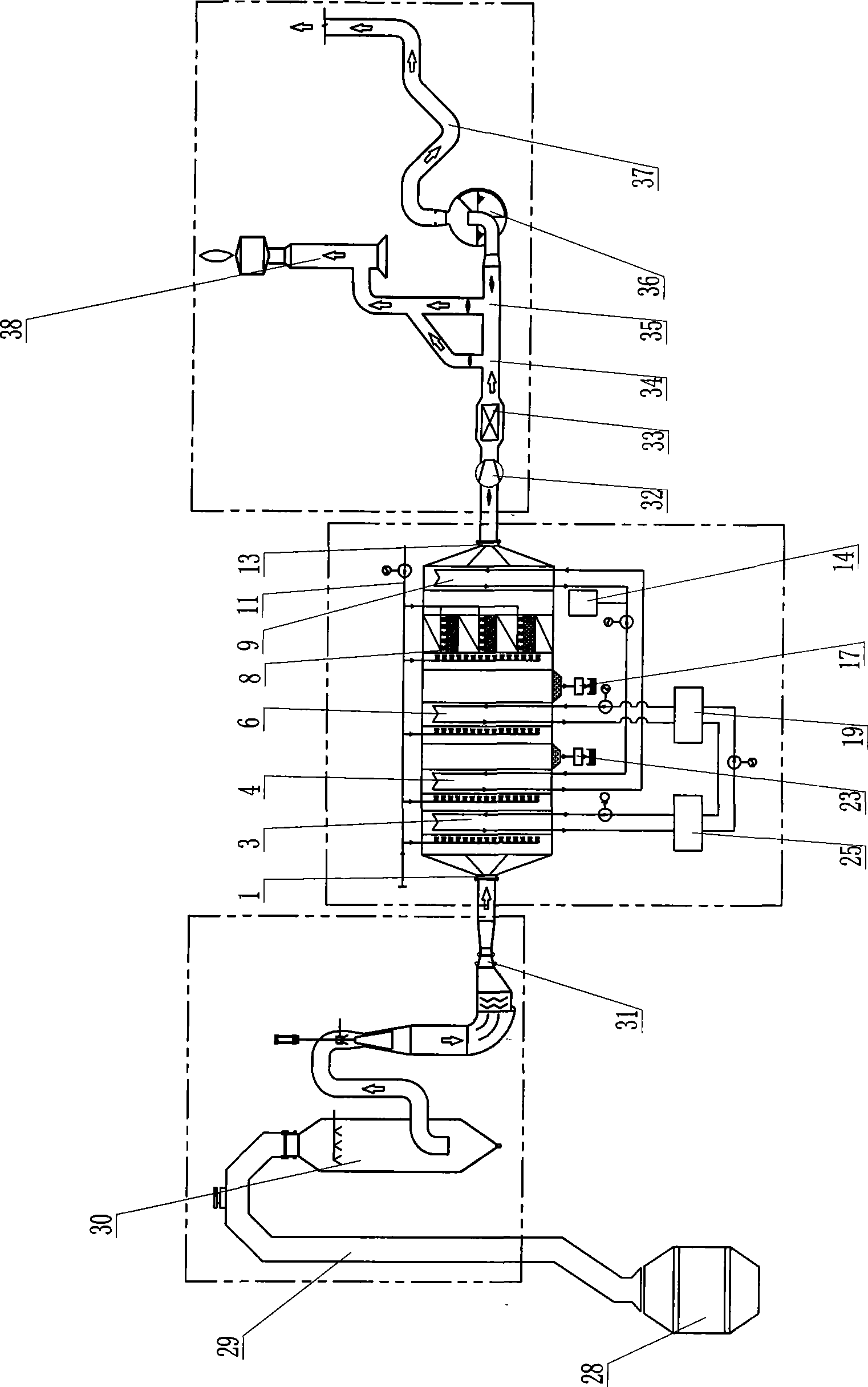

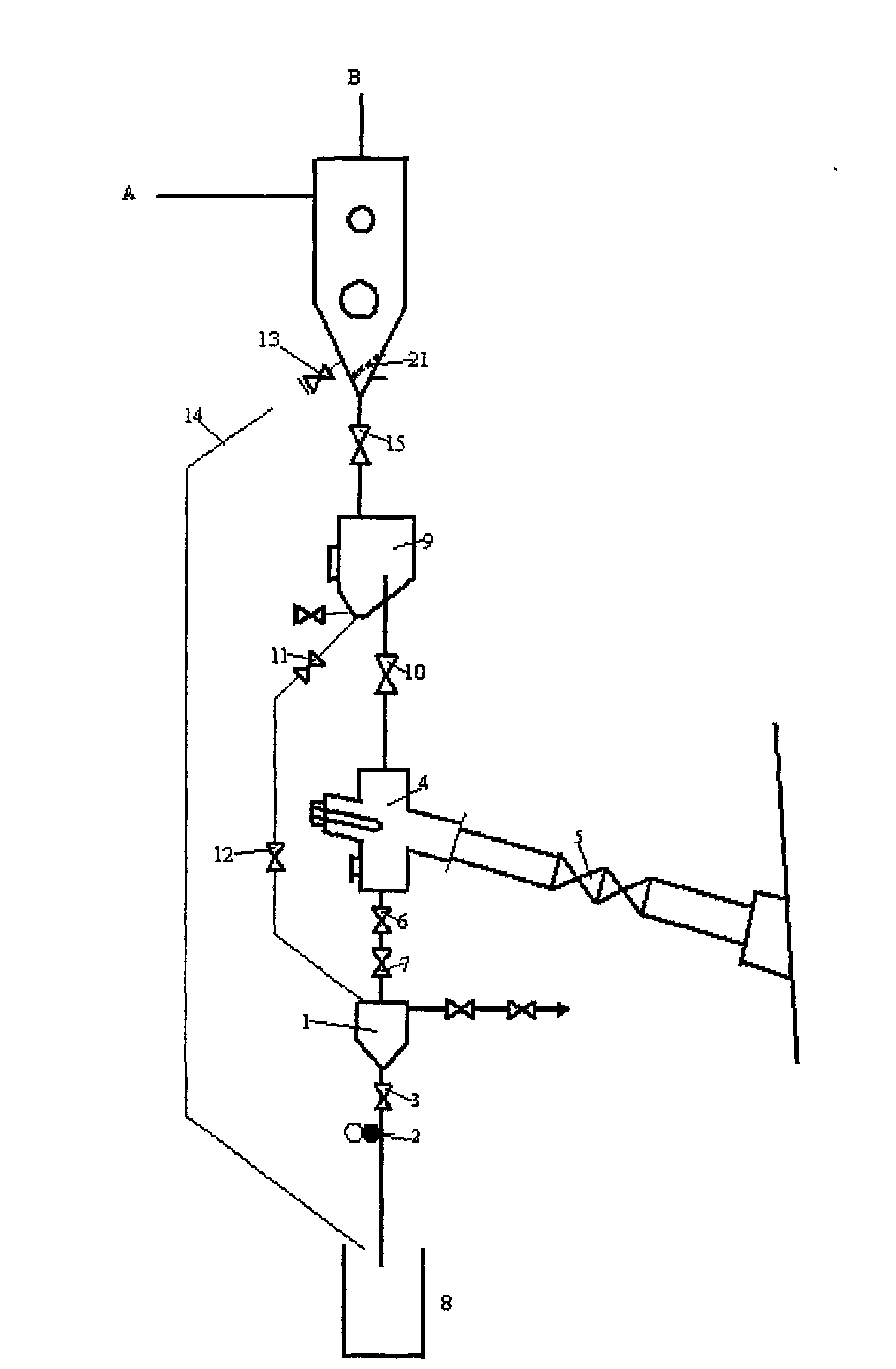

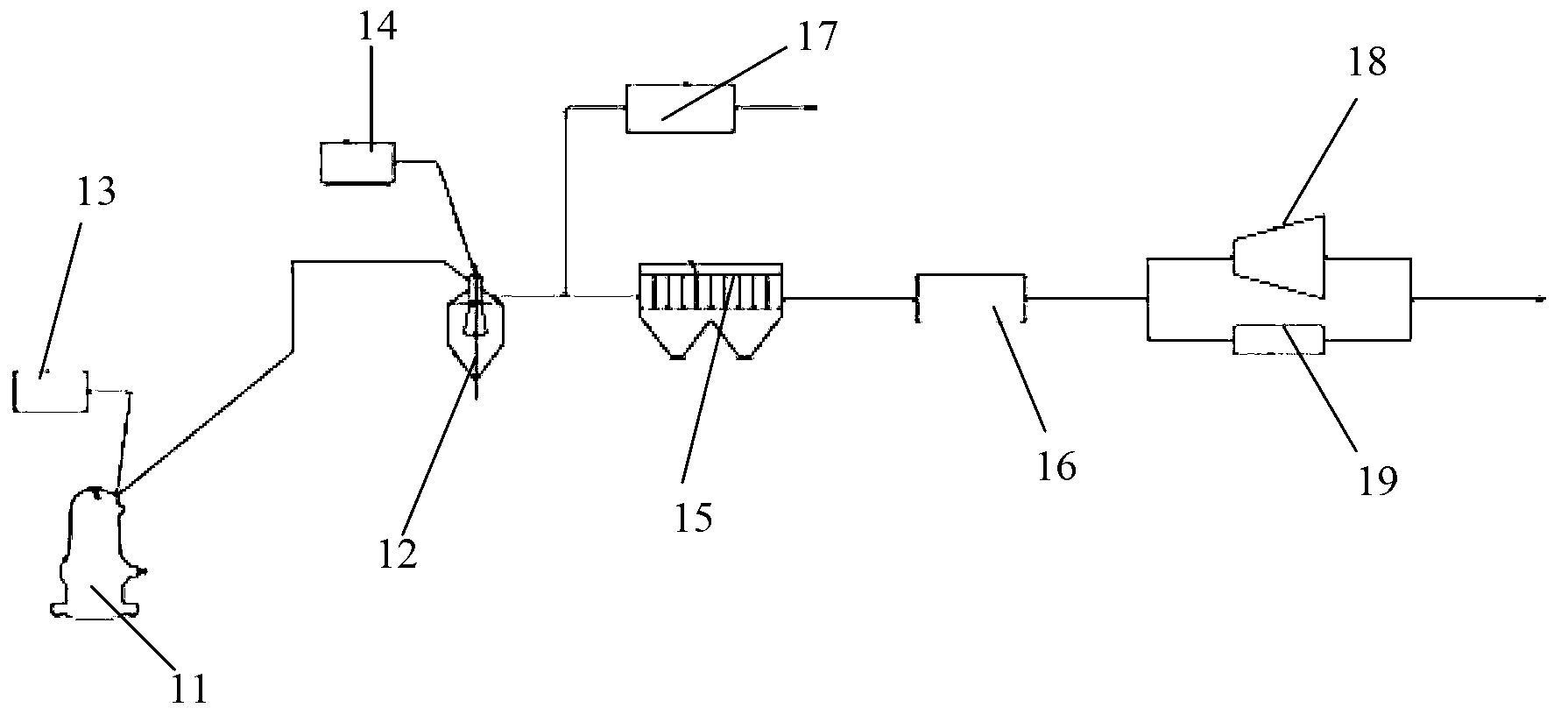

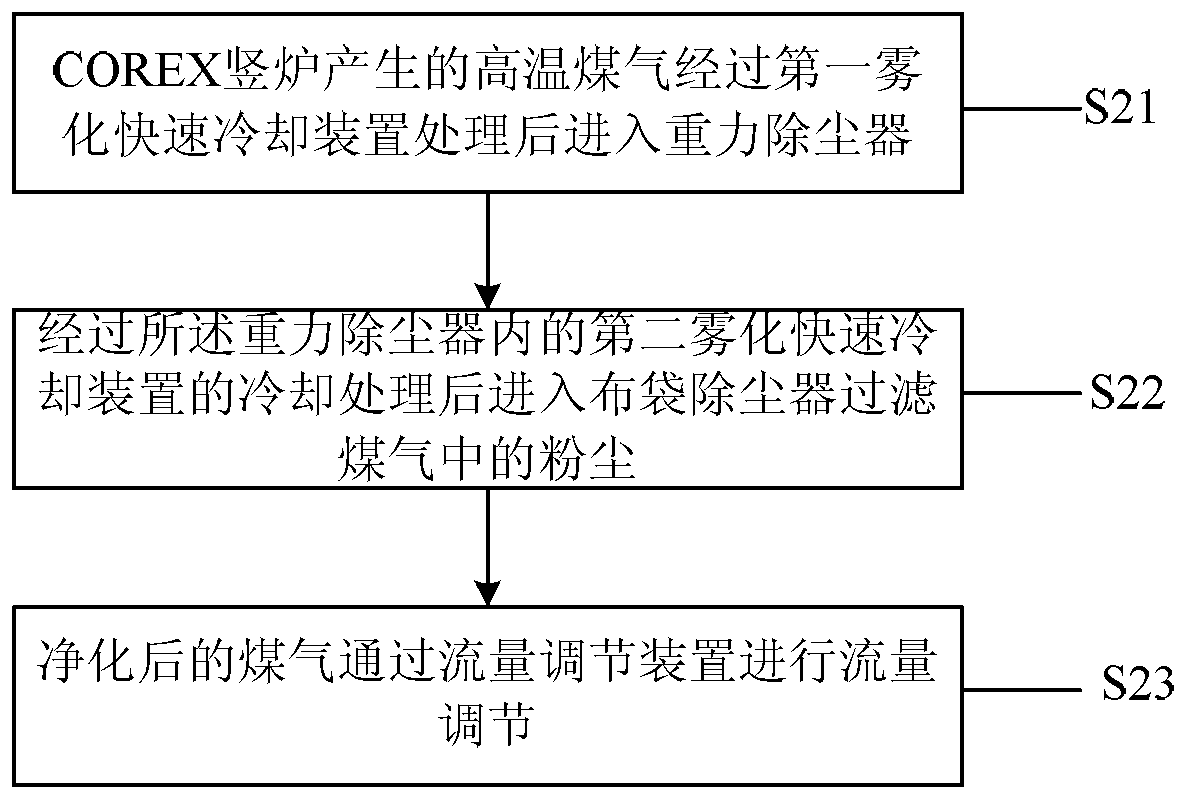

Treatment system of furnace top gas of COREX vertical furnace and treatment method thereof

ActiveCN103320563ALess investmentReduce differential pressureCombination devicesShaft furnaceCorexEngineering

The invention provides a treatment system of a furnace top gas of a COREX vertical furnace. The treatment system comprises the COREX vertical furnace and a gravity dust remover connected with the COREX vertical furnace; the treatment system of the furnace top gas of the COREX vertical furnace further comprises a first atomization rapid cooling device arranged on the furnace top of the COREX vertical furnace, a second atomization rapid cooling device arranged inside the gravity dust remover, a cloth bag dust remover connected with the gravity dust remover, and a flow adjusting device connected with the cloth bag dust remover. The invention further provides a treatment method of the treatment system of the furnace top gas of the COREX vertical furnace. According to the treatment system of the furnace top gas of the COREX vertical furnace, disclosed by the invention, on the basis of common gas dry-method dust-removing treatment configuration, adjustable and controllable atomization rapid cooling equipment and control technology, and gas flow adjusting and controlling equipment and technology are combined to realize the accurate online control on temperatures, flows and pressure of the gas; the flow adjusting device is simple in equipment and convenient to operate, and all valves of a valve group have different adjusting ranges and precisions, so as to meet the requirements on adjusting a gas amount when a working condition of the vertical furnace is changed.

Owner:BAOSTEEL ENG & TECH GRP

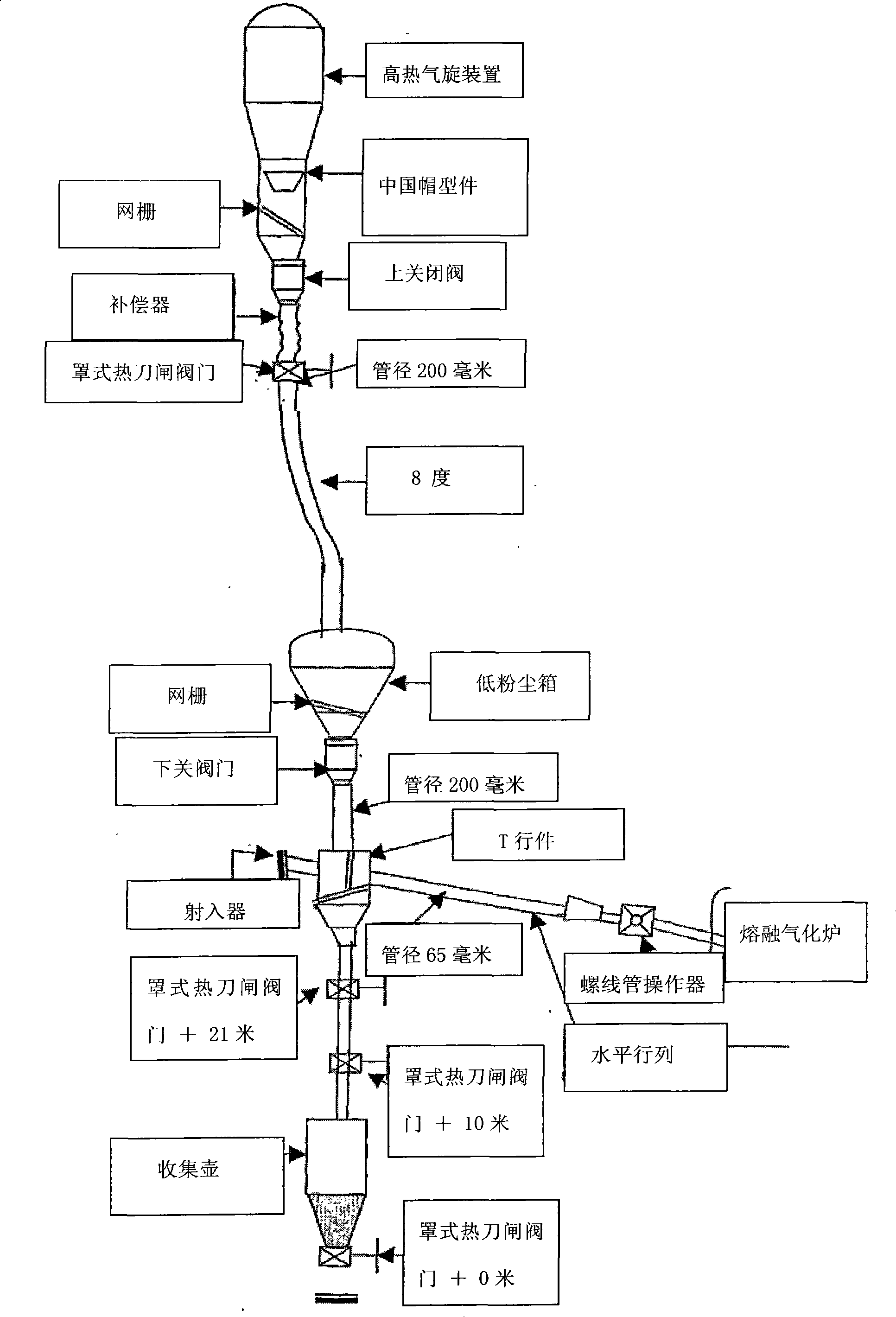

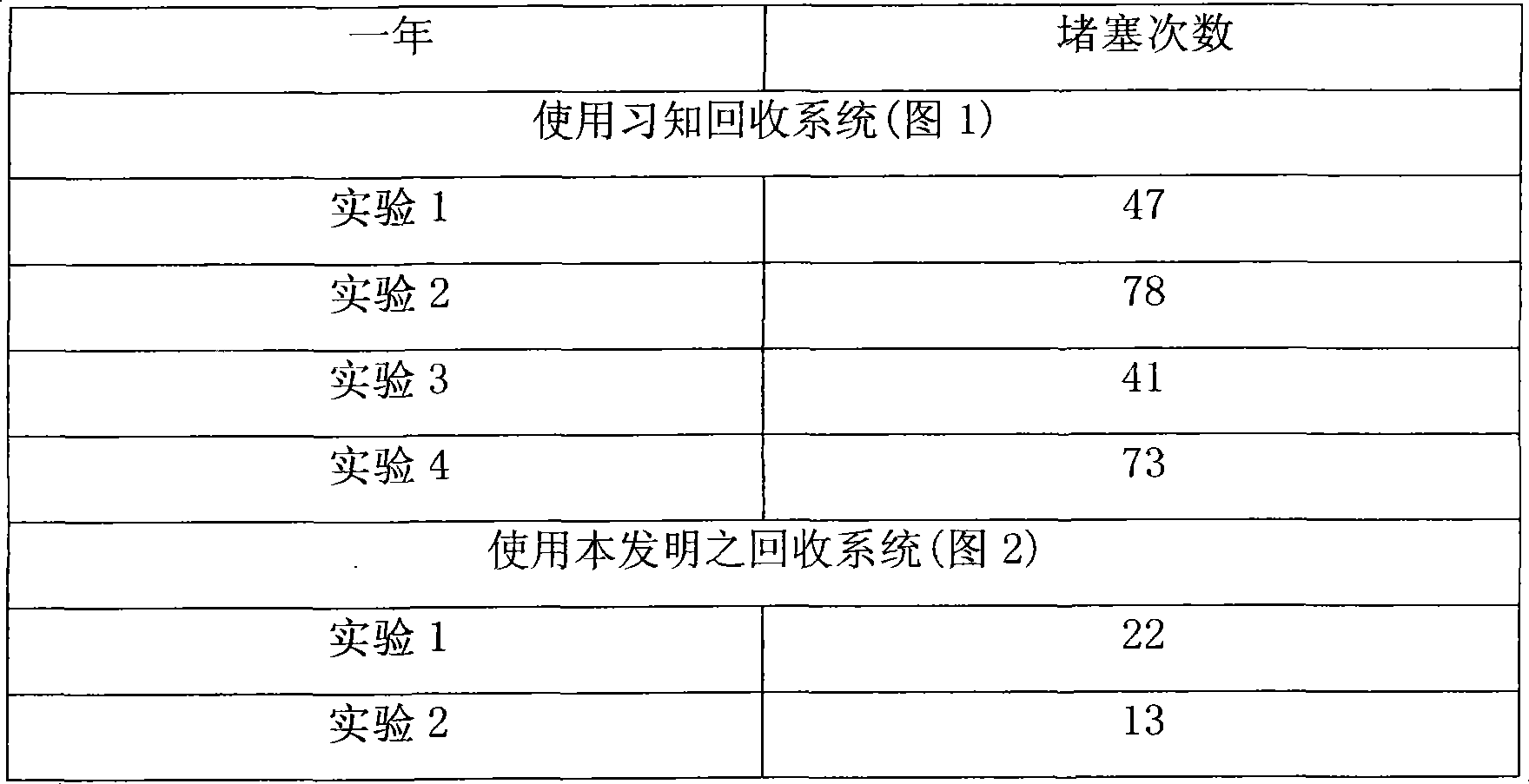

A dust recycling system for enhanced availability of Corex

ActiveCN101365810AAvoid downtimeImprove usabilityDispersed particle separationManufacturing convertersCycloneDust explosion

The present invention provides a dust recycling system for directly smelting reduction iron making process, which is used for increasing efficiency. The dust recycling system to capture dust from reduction gas and inject the same back into the melter gasifier for dust burning in a smelting reduction iron making process comprising a hot gas cyclone (HGC), a low dust bin (LDB) in operative connection to said hot gas cyclone for continuous flow of the captured dust through a hot knife gate and valve vertical pipelines provided at an inclination ranging from 4 to 12; said low dust bin (LDB) further operatively connected through a vertical pipeline and an inlet to a high dust volume T-piece (TP) comprising of injector and diffuser means; and a melter gasifier having dust burner to burn the dust thus recycled into the melter gasifier through said T-piece. The above system is adapted to favour effective and jam free transportation of dust from the hot gas cyclone to the dust burner and thereby improve plant availability / efficiency.

Owner:JSW STEEL LTD

Method for recycling slag from non-blast furnace ironmaking by COREX smelting reduction process

ActiveCN101613772ASolving RecyclingAvoid wastingRecycling and recovery technologiesProcess efficiency improvementSlagBlast furnace

The invention discloses a method for recycling slag from non-blast furnace ironmaking by a COREX smelting reduction process, which comprises the following steps that: firstly, COREX slag is processed into COREX slag powder; and the COREX slag powder is used in a gelatinous material for preparing concrete. After the concrete is naturally cured for 28 days, the strength of the concrete prepared by the formula of the 350 kg / m<3> gelatinous material disclosed by the invention reaches 32 to 48MPa, and the strength grade of the concrete reaches C30 to C40. Therefore, the method solves the problem of difficult COREX slag recycling and avoids resources waste and environmental pollution. And the recycling method is simple, easy to implement and practical and creates remarkable social, economic and environmental benefits.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for treating oily sludge by using corex furnace

The invention discloses a method for treating oily sludge by using a corex furnace. The method comprises the steps that firstly, the oily sludge is collected, the oily sludge and an emulsifying viscosity reducer are added into a mechanical stirring device according to the mass ratio of 20 to 1 for stirring for 30 minutes, so that the viscosity of the oily sludge is reduced, then the oily sludge enters an oily sludge tank, finally, the oily sludge with reduced viscosity is sprayed into an arch top area of the gasification furnace through a pressurization pump and a liquid injection nozzle for combustion decomposition, and the spraying pressure at the position of the liquid injection nozzle is 2 atmospheres; and the oily sludge is converted into coal gas for secondary utilization after beingsubjected to decomposition at the arch top of the corex furnace, and part of the material which cannot be decomposed enters furnace slag and is used as a building material for secondary utilization.

Owner:XINJIANG BAYI IRON & STEEL

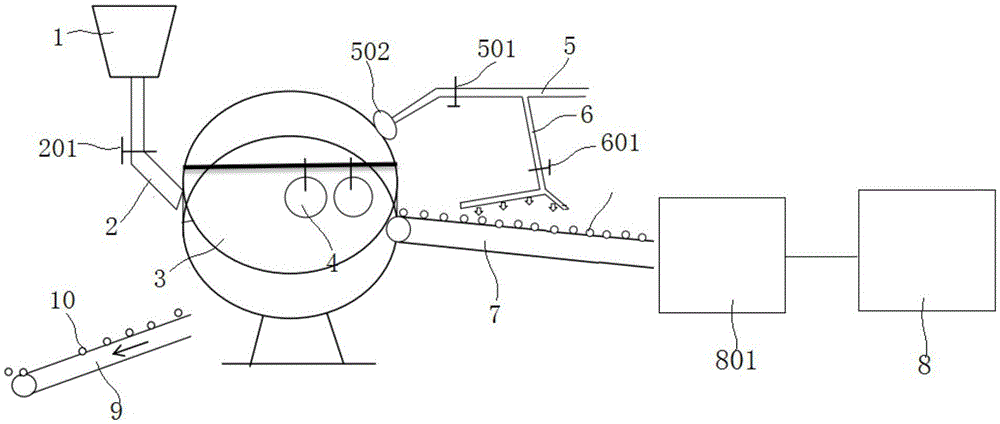

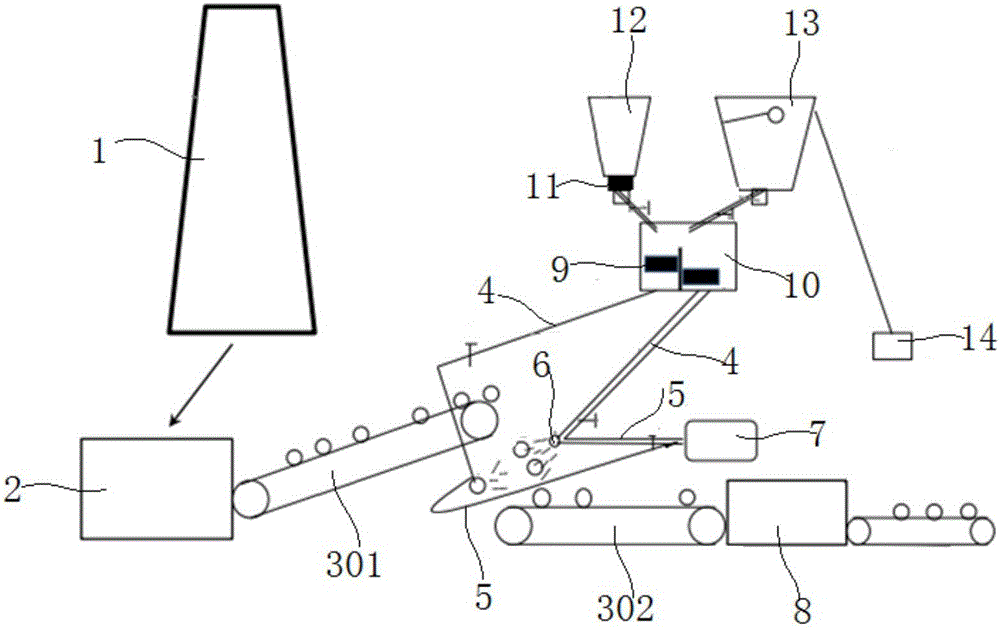

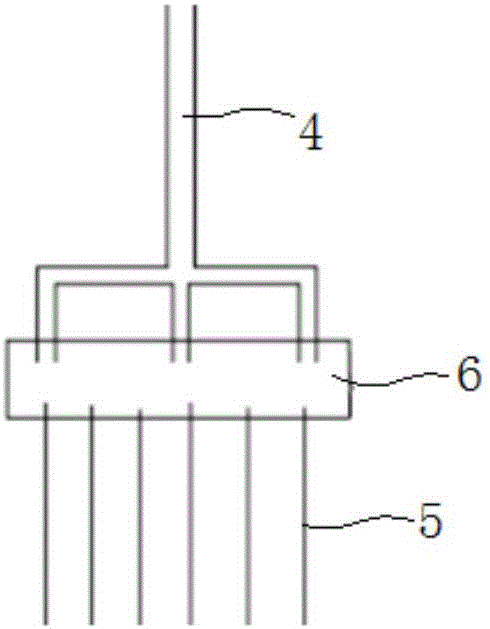

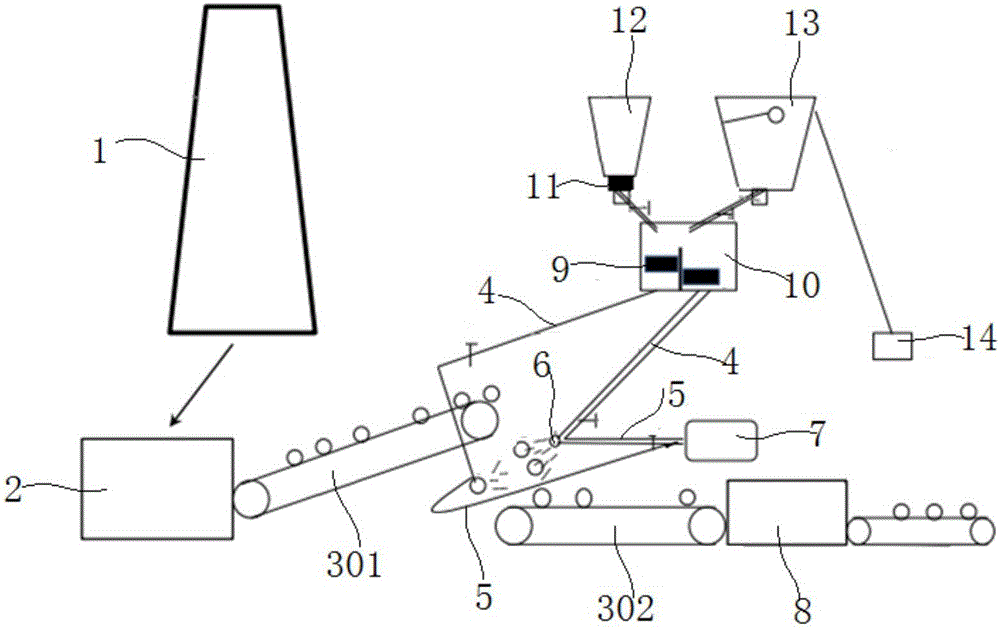

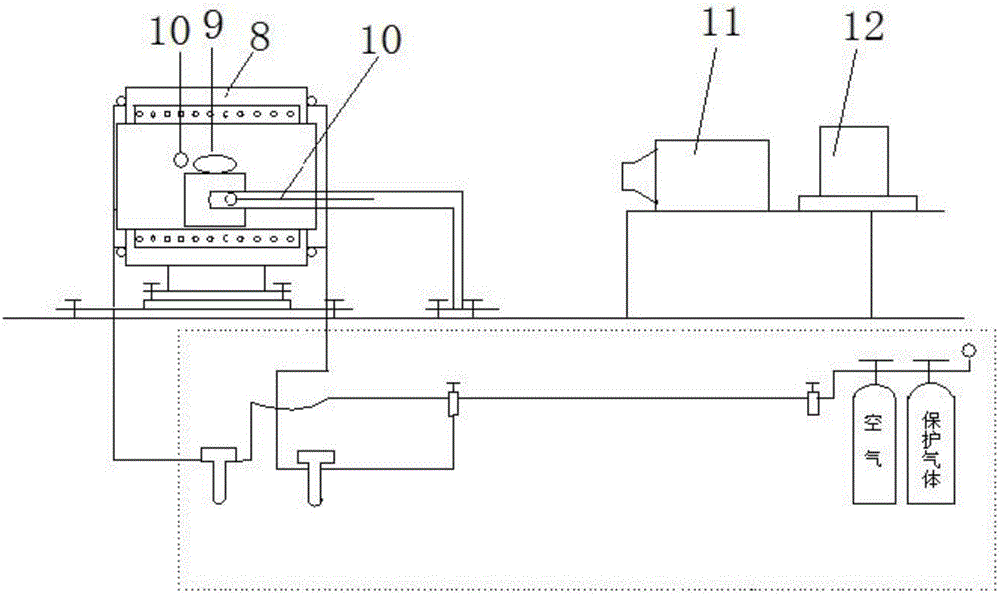

Production system for coated pellets of COREX shaft furnace

The invention discloses a production system for coated pellets of COREX shaft furnace and belongs to the technical field of pellet production equipment. The production system comprises a roasting furnace, a conveying mechanism, a spraying mechanism and a mixing tank, wherein the roasting furnace is connected to a circular cooling area in a conveying manner. Oxidized pellets to be coated in the circular cooling area are conveyed through the conveying mechanism. The spraying mechanism is positioned above the conveying mechanism. Through the spraying mechanism, a coating mixed liquor inside the mixing tank is sprayed onto the surface of the oxidized pellets to be coated. By the production system for production of the coated pellets, the caking problem of pellets in a COREX shaft furnace technology can be effectively improved, and the system is also beneficial to direct motion of a COREX pre-reduction shaft furnace and helps raise utilization efficiency of COREX shaft furnace equipment and reduce production cost of direct reduction iron. Caking index of reduced pellets is less than 25%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

COREX method for reducing coal gas components through coal gas blending adjustment

The invention discloses a COREX method for reducing coal gas components through coal gas blending adjustment. The COREX method comprises the following steps: step I, coal blending, wherein the types of several kinds of lump coal are gas coal (Ad=4-5, Vd=37-42), steam coal 1 (Ad=5-6, Vd=26-30) and steam coal 2 (Ad=2-3, Vd=24-26); the particle size of the three kinds of coal is 0-60 mm; the supplying amount of the gas coal takes up 38-42% of the weight of the whole matching coal; the supplying amount of the steam coal 1 takes up 18-21% of the weight of the whole matching lump coal; the supplying amount of the steam coal 2 takes up 37-44% of the weight of the whole matching lump coal. According to the COREX method, through the cooperation of different lump coal, the effective components in reduced coal gas are increased, the reduction metallization ratio of ore is increased, the coke consumption during the COREX reduction process is reduced, and the production cost is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Technology for preventing seepage of suspended water cooling pond wall of corex furnace by means of reaming, pipe penetrating and blocking

The invention discloses a technology for preventing seepage of a suspended water cooling pond wall of a corex furnace by means of reaming, pipe penetrating and blocking. The technology comprises the steps that firstly, an original pipe penetrating hole in the pond wall is reamed, and after reaming is finished, a pipe is sleeved with an inner flange piece in advance, the inner flange piece is closely attached to the pond wall, and then the inner ring of the inner flange piece and the outer wall of the pipe are fully welded; grouting at the initial stage is carried out, grouting and tamping are firstly carried out in a cavity formed by the pipe and the lower portion of the pond wall, the weight ratio of components, namely, high-strength quick-dry contraction-free cement mortar to small gravel to alkyd enamel to water, of grout during grouting at the initial stage is 4:1:1:8, outer flange pieces are used for blocking, then the pipe wall is beaten every other 20 min to 30 min to generate vibration, gaps are filled till the cavity is thoroughly full, and the outer flange pieces are covered with wool felt; and secondary smearing is carried out, after 3 days to 5 days, coating is smeared to the outer surfaces of the outer flange pieces, the weight ratio of components, namely, high-strength quick-dry contraction-free concrete mortar to washed-out sand to paint to water, of the coating is 4:1:1:4, and water can be injected for testing after standing is carried out for 2-3 days and impurities in a pond are cleared away.

Owner:XINJIANG BAYI IRON & STEEL

Determination method of material column liquid permeability index in COREX smelter-gasifier

InactiveCN106706494AThe determination method is simpleEasy to operatePermeability/surface area analysisSlagTest sample

The invention relates to a determination method of a material column liquid permeability index in a COREX smelter-gasifier. The determination method comprises the following steps: 1) sampling: taking tuyere test samples on a central plane of a tuyere of the COREX smelter-gasifier from the tuyere to different positions of the center of the COREX smelter-gasifier through a tuyere sampling device along the radial direction of the COREX smelter-gasifier; coding the obtained tuyere test samples; 2) screening the tuyere test samples to separate out carbon coke / semi-coke, furnace dreg and iron; combining the carbon coke / semi-coke to form a tuyere carbon coke test sample and combining the furnace dreg to form a tuyere furnace dreg test sample; 3) determining the voidage epsilon and the pressure difference P of the tuyere carbon coke test sample, and the temperature strength Q of the tuyere furnace dreg test sample respectively through corresponding tests; 4) calculating according to a formula to obtain the liquid permeability index L of the tuyere test samples at different positions (wherein the formula is shown as the description). The determination method provided by the invention is high in operability and is simple and feasible; the determined material column liquid permeability index can be used for effectively evaluating the activity of a hearth of the COREX smelter-gasifier.

Owner:UNIV OF SCI & TECH LIAONING

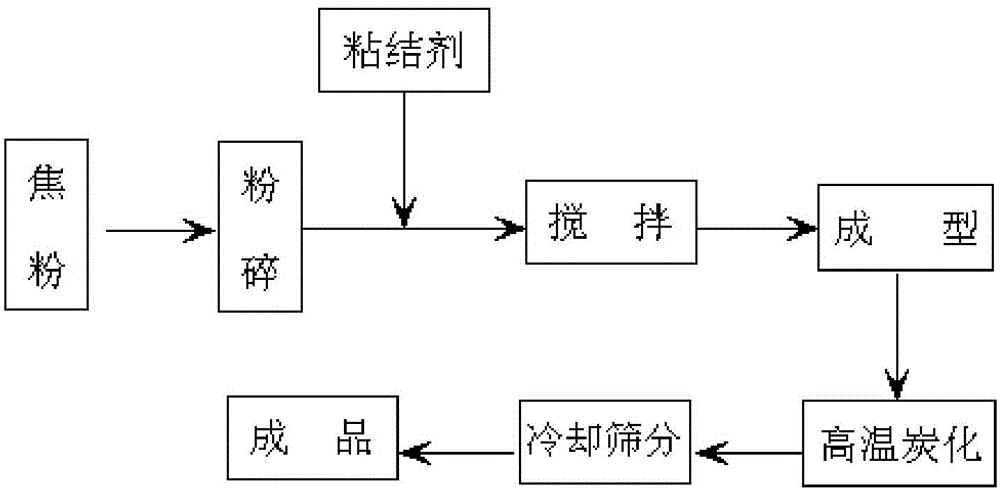

Formed coke preparation method for replacing carbon raw material used for electric furnace steel making with COREX coke powder

ActiveCN105018122AReduce manufacturing costReduce electrode consumptionSpecial form destructive distillationSteelmakingCarbon graphite

Owner:BAOSHAN IRON & STEEL CO LTD

Device and method of COREX melting reduction ironmaking

The invention provides a device and a method of COREX melting reduction ironmaking. The device comprises a reduction shaft furnace and a melting gasifier, the reduction shaft furnace is connected with the melting gasifier through a down pipe. The device for the COREX melting reduction ironmaking also comprises a temperature measurement thermocouple, a controller, a regulating valve, a flowmeter and gas pipes. The controller is connected with the temperature measurement thermocouple, the regulating valve and the flowmeter. The gas pipes comprise a cold coal gas pipe and a transmission pipe, gas passing through the transmission pipe to enter the down pipe comprises cold coal gas, and the flowmeter and the regulating valve are both arranged on the transmission pipe. The controller controls the regulating valve according to feedback data of the flowmeter and the temperature measurement thermocouple, and then opening / closing and amount of the gas passing through the gas pipes to enter the down pipe are regulated and controlled. The device and the method employ the temperature measurement thermocouple and the cold coal gas to monitor the temperature in the down pipe, and reduce the impact of the gas going into the reduction shaft furnace on temperature.

Owner:上海宝锋工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com