Determination method of material column liquid permeability index in COREX smelter-gasifier

A technology for melting and gasification furnaces and measurement methods, which is applied to the analysis of materials, measurement devices, permeability/surface area analysis, etc. It can solve the problems of inflexible production, small average particle size of tuyere coke, poor hearth activity, etc., and achieve the measurement results Accurate and reliable, simple measurement method, convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

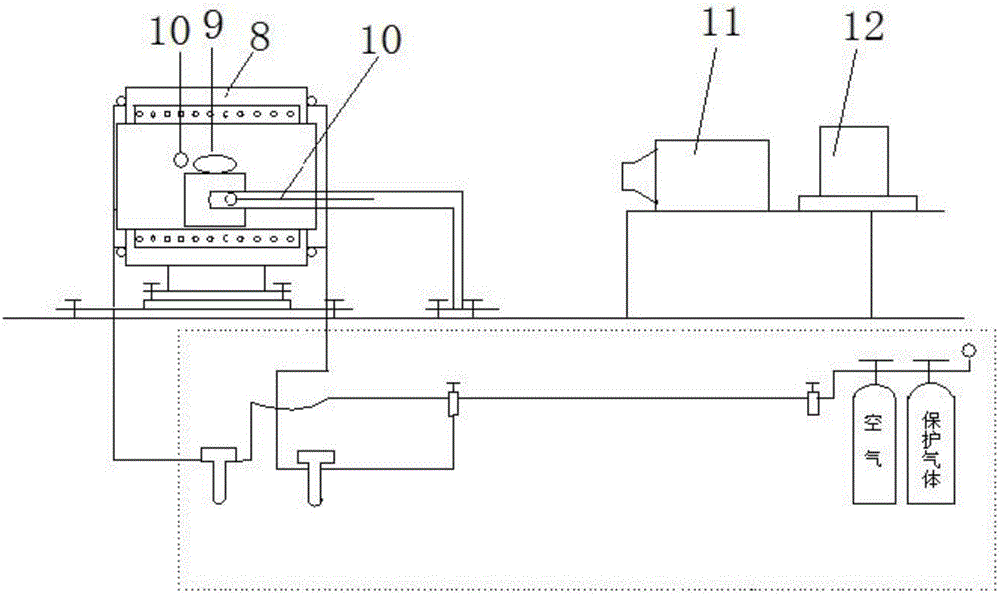

[0059] A method for measuring the liquid permeability index of a material column in a COREX melting gasifier according to the present invention comprises the following steps:

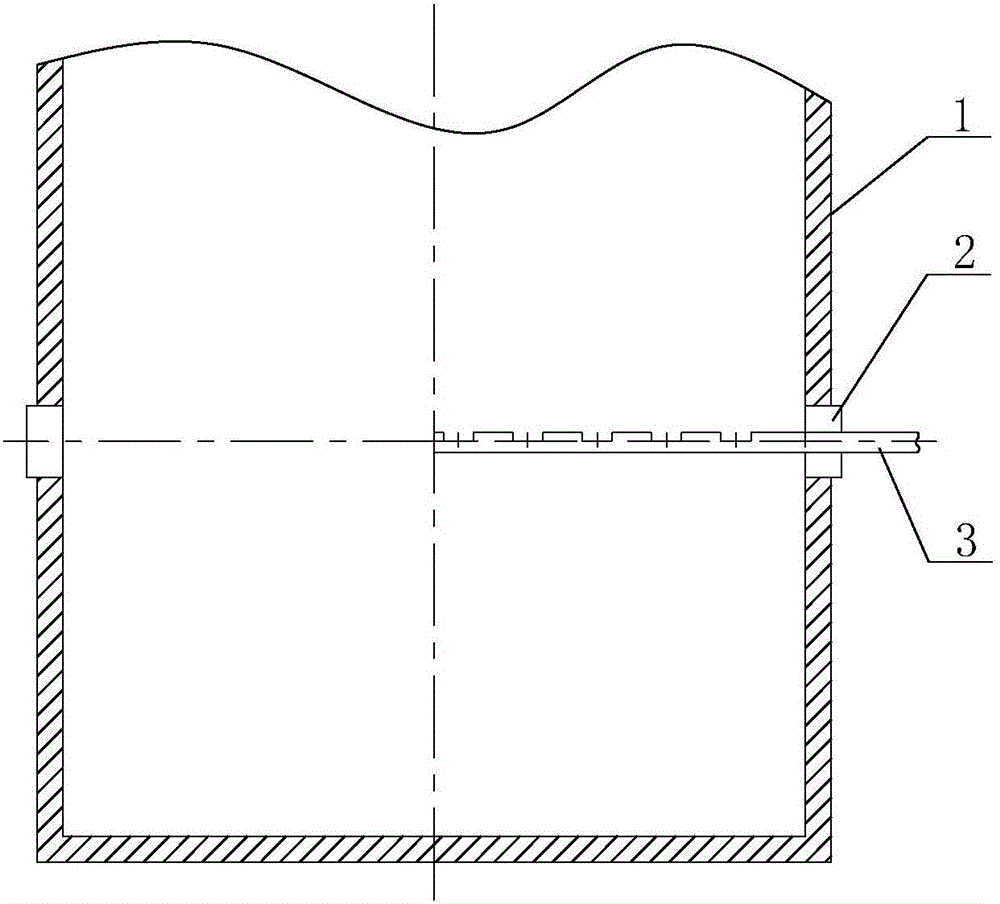

[0060] 1) Sampling, such as figure 1 As shown, on the center plane of the tuyere 2 of the COREX melting-gasifier, and along the radial direction of the COREX melting-gasifier 1, the tuyere samples are taken respectively from the tuyere 2 to the center of the COREX melting-gasifier 1 through the tuyere sampler 3, And number the tuyere samples obtained;

[0061] 2) Screen the tuyere samples to separate coke / semi-coke, slag and iron, form the coke / semi-coke into the tuyere coke sample, and form the slag into the tuyere slag sample;

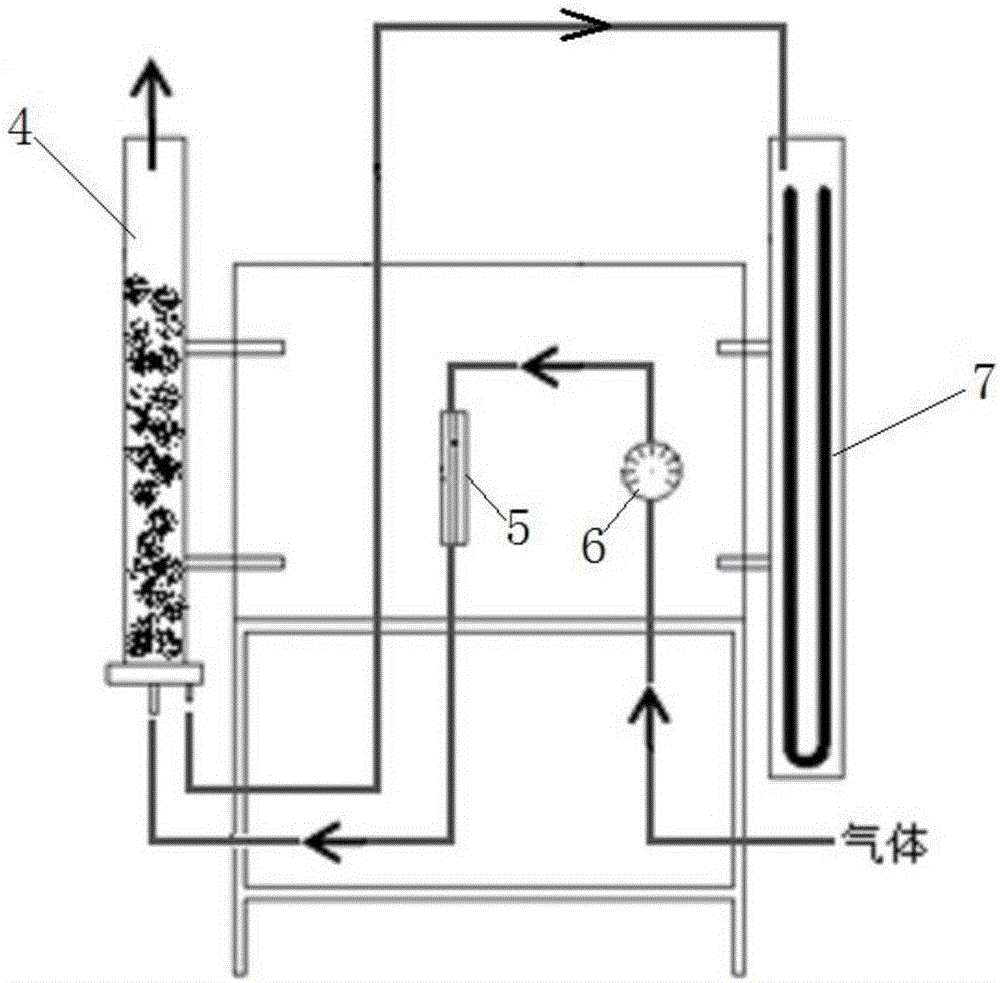

[0062] 3) Measure the porosity ε and pressure difference P of the tuyere coke sample and the temperature intensity Q of the tuyere slag sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com