Device and method of COREX melting reduction ironmaking

A technology of spiral device and melting gasifier, which is applied in the field of smelting reduction ironmaking, and can solve the problems of depletion of gas quality in gasifier, lower operating rate, and jamming of discharging equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

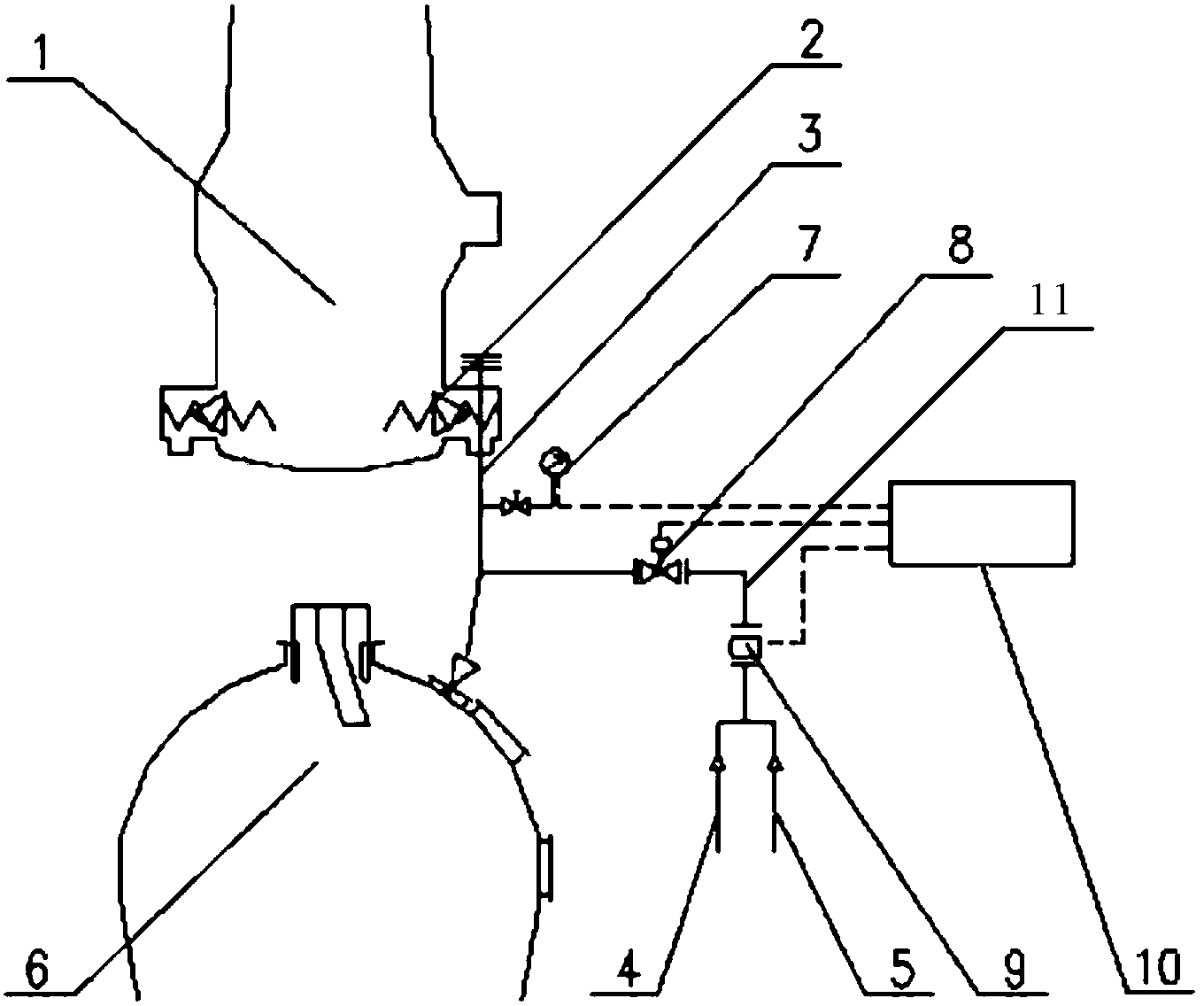

[0019] The following will combine figure 1 The COREX smelting reduction ironmaking device and method provided by the present invention are described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can implement it without changing the spirit and content of the present invention Modify and polish.

[0020] compare figure 1 According to the structural schematic diagram of the COREX smelting reduction ironmaking plant shown in this embodiment, the usual COREX smelting reduction ironmaking plant is composed of at least two parts, the upper part is the reduction shaft furnace 1, and its main function is to oxidize iron in the ore. The material is reduced to metallic iron and heated to 650-700°C, so that the iron-containing raw material is reduced to sponge iron, which is discharged from the spiral device at the bottom of the reduction shaft furnace 1, and enters the melting and gasifying furnace 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com