Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

693results about How to "Effective temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

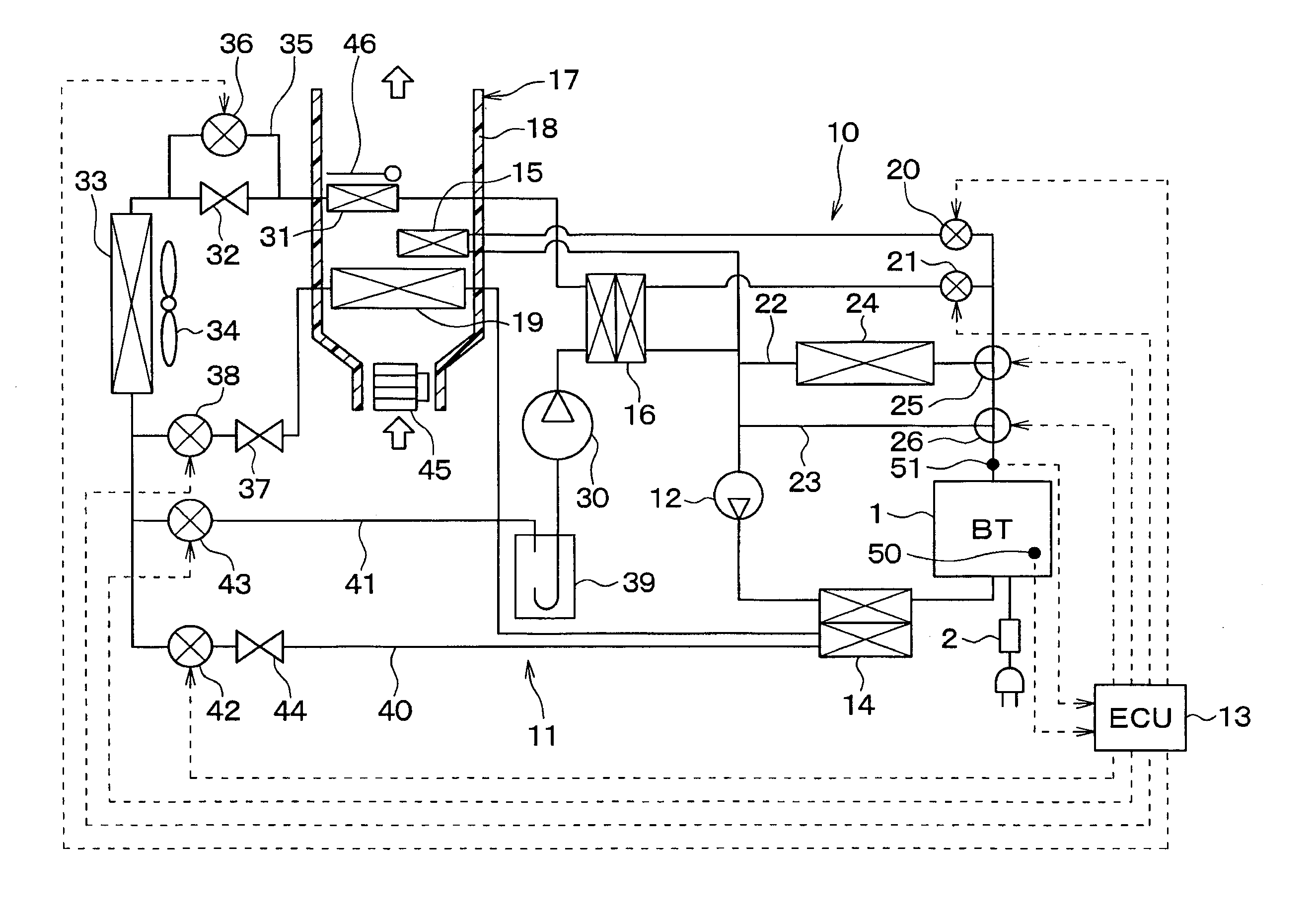

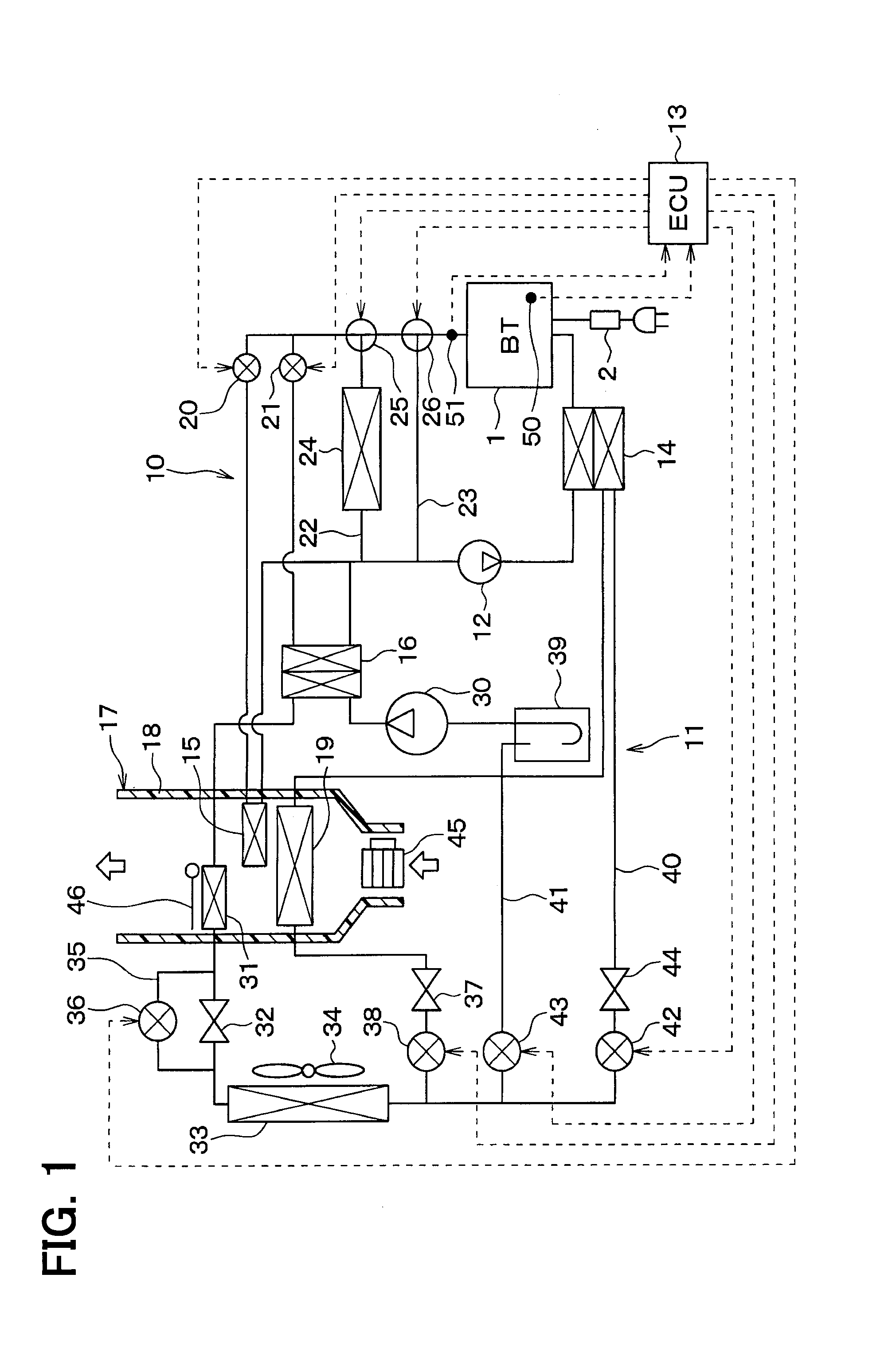

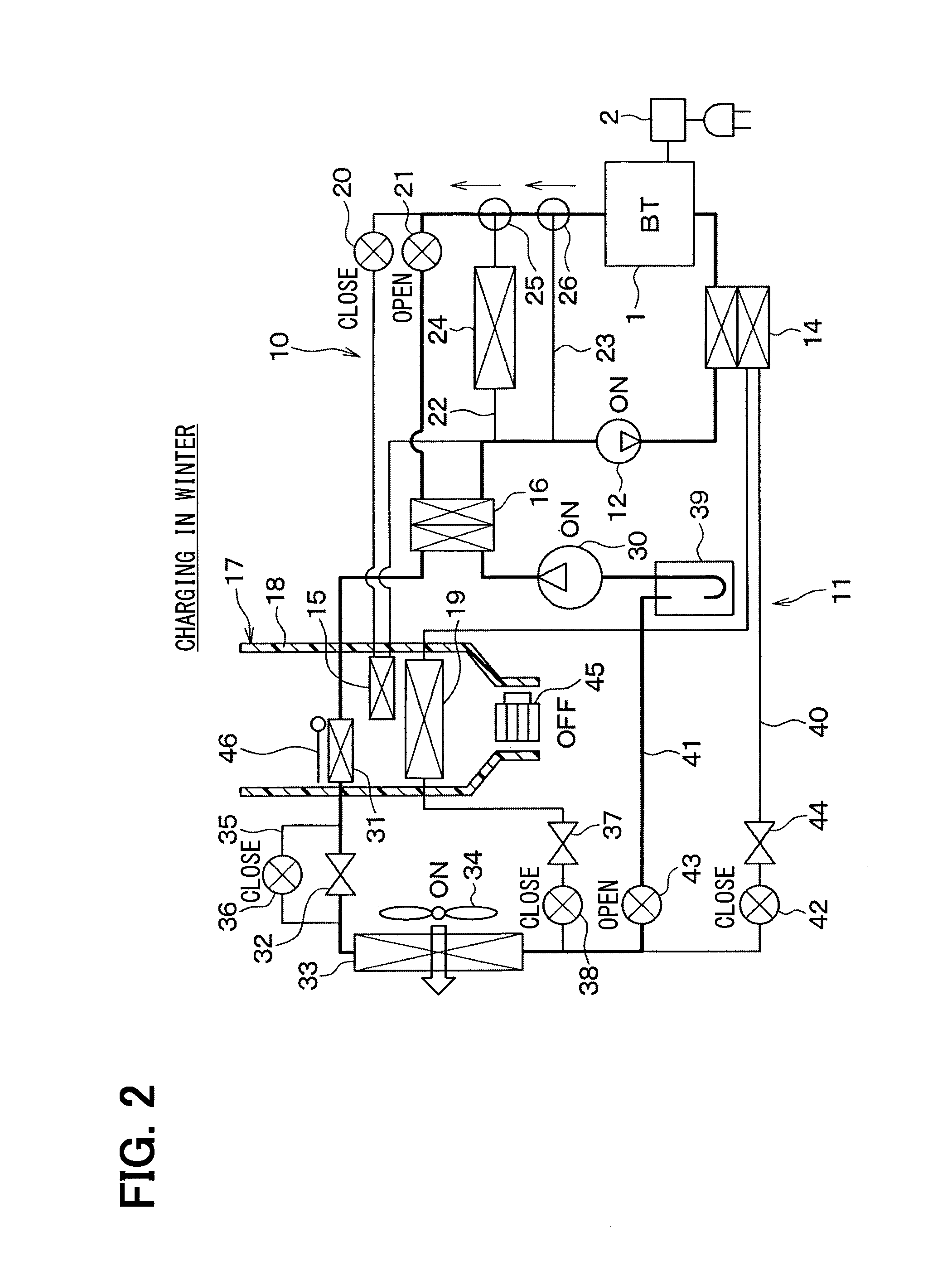

Vehicle temperature control apparatus and in-vehicle thermal system

InactiveUS20140041826A1Increase subcoolingImprove efficiencyTemperatue controlPower to auxillary motorsTemperature controlIn vehicle

A vehicle temperature control apparatus for controlling temperature of a temperature control object, which is at least one of inside air of a vehicle compartment and a vehicle component, includes a heat capacitive element capable of storing heat, a refrigeration cycle in which heat is absorbed from a low temperature side and is dissipated to a high temperature side, a heat exchanger that causes the heat capacitive element to exchange heat with refrigerant of the refrigeration cycle, and a heat dissipation portion which dissipates heat in the refrigerant of the refrigeration cycle to the temperature control object. Thus, a temperature control by using the heat capacitive element can be effectively performed.

Owner:DENSO CORP

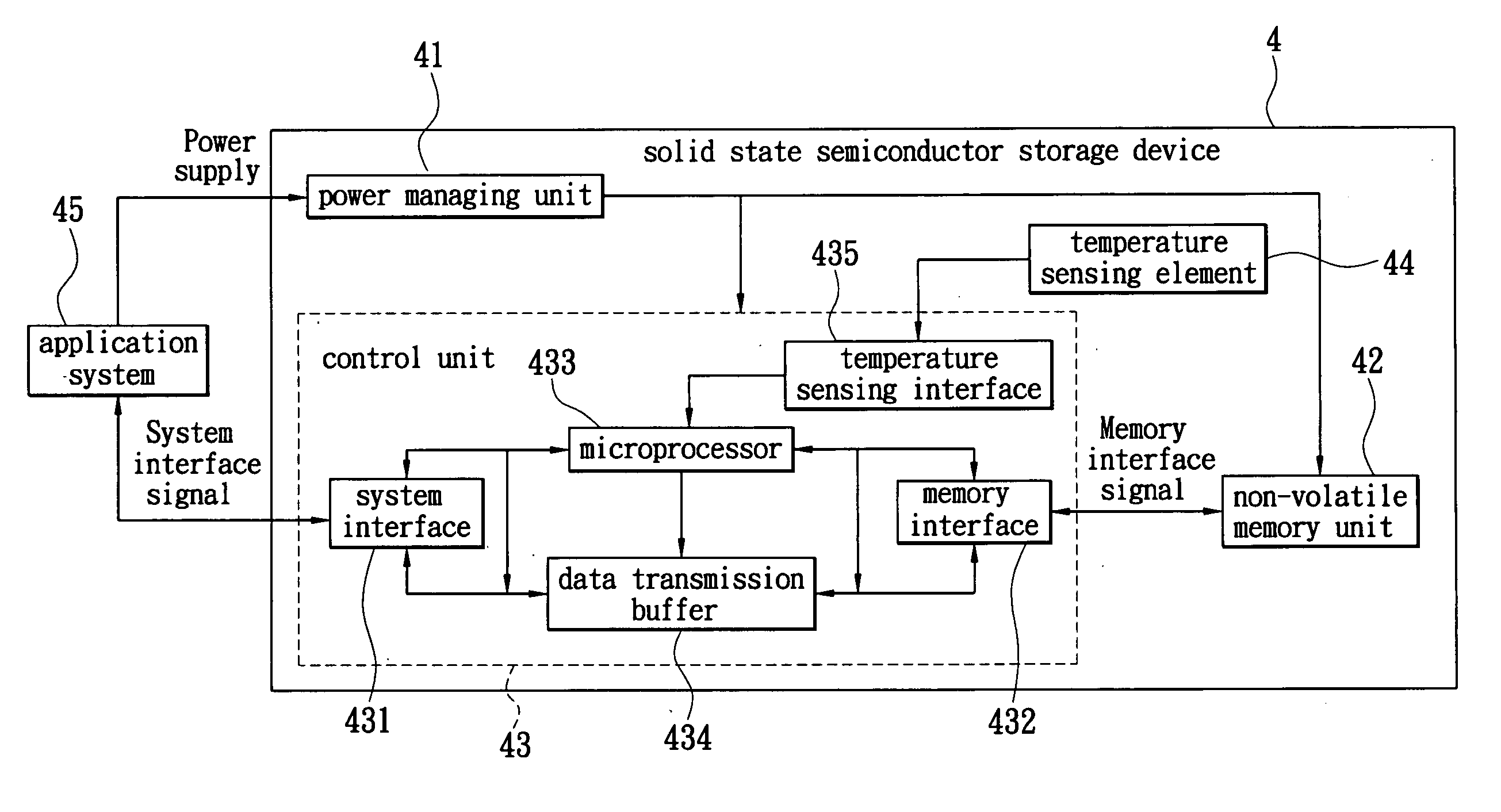

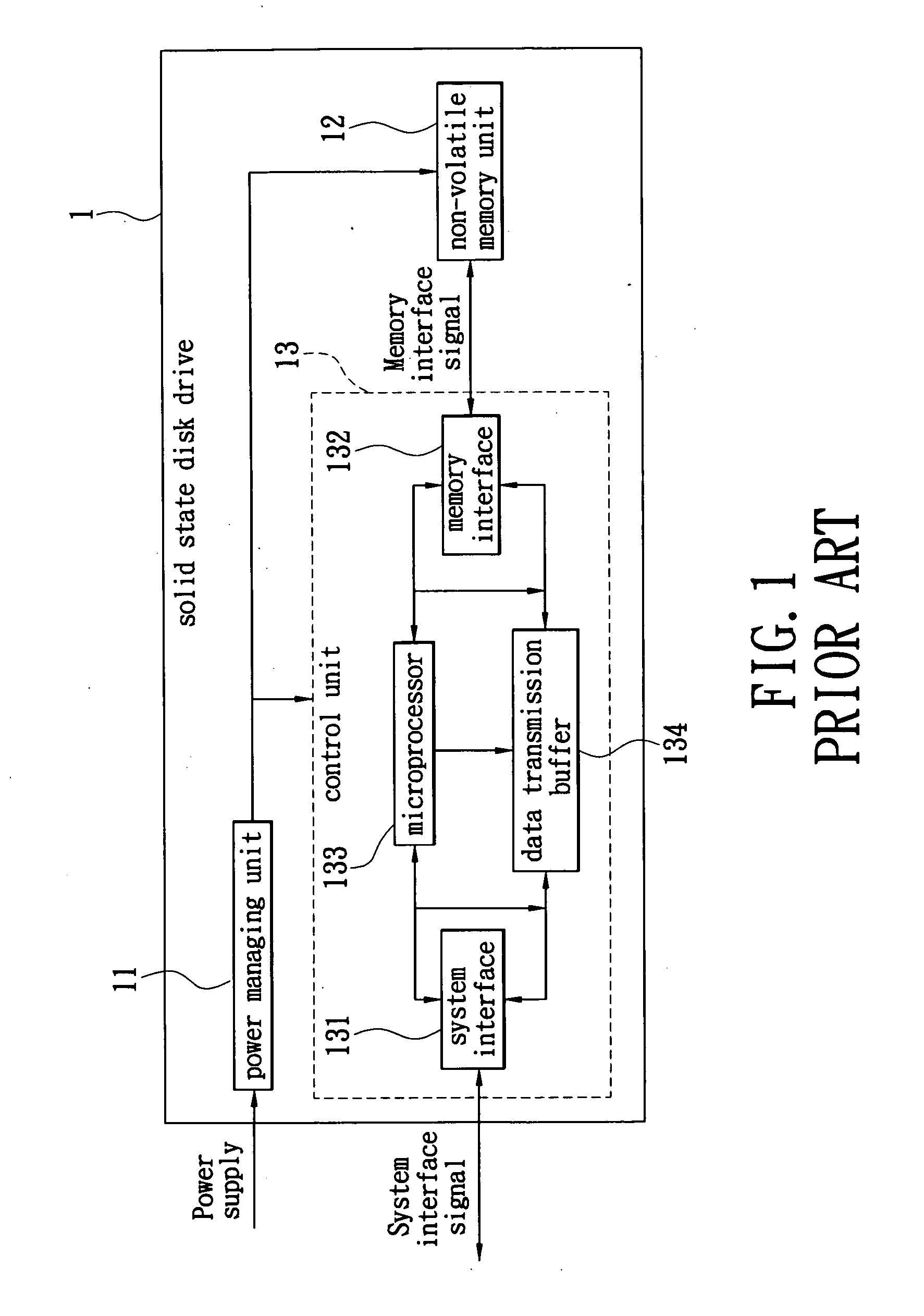

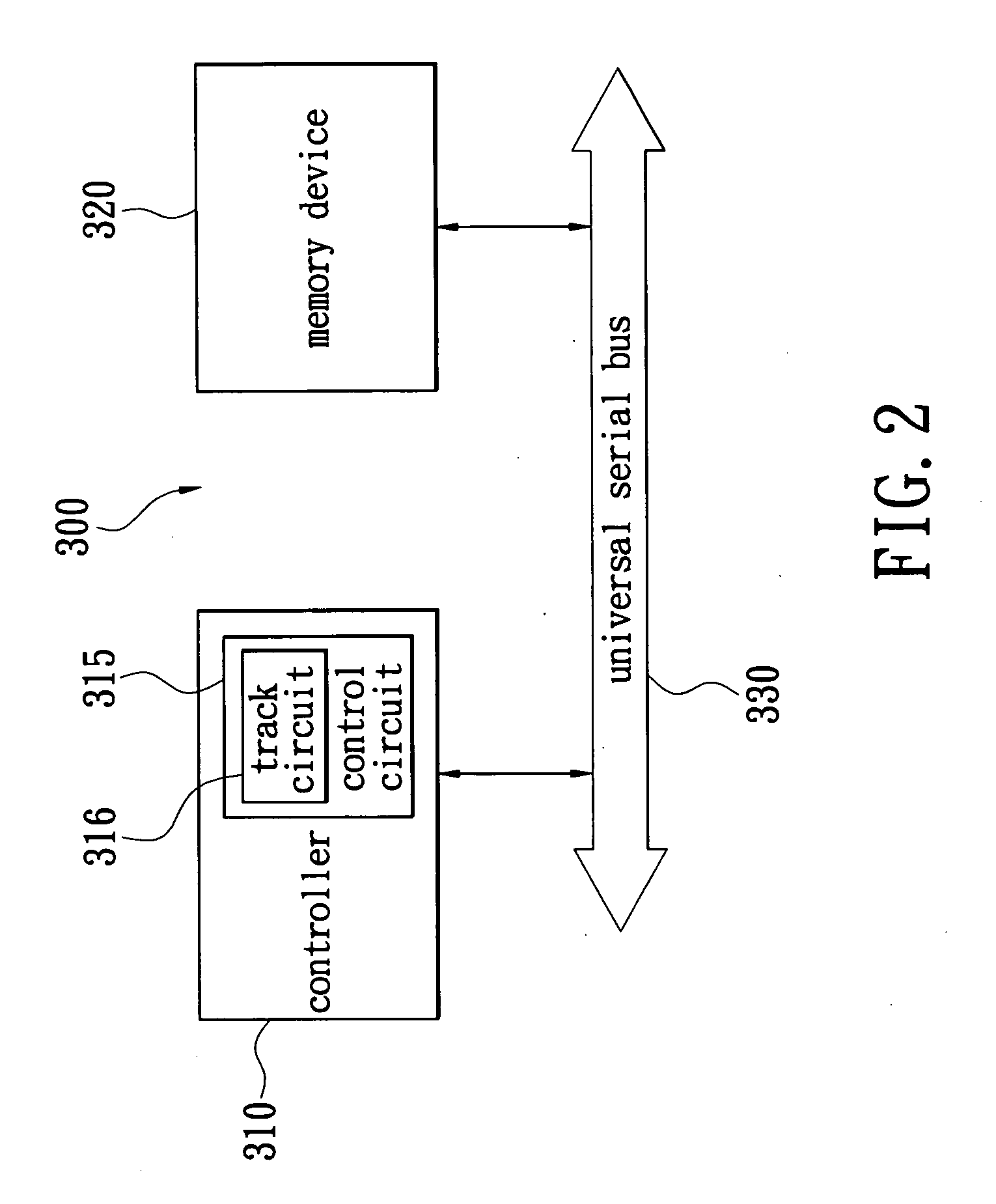

Solid state semiconductor storage device with temperature control function, application system thereof and control element thereof

ActiveUS20090091996A1Effective temperature controlDigital storageTemperature controlSemiconductor storage devices

A solid state semiconductor storage device with temperature control function comprises a non-volatile memory unit, a temperature sensing element, and a control unit. The temperature sensing element is used for sensing the operation temperature of the solid state semiconductor storage device so as to provide a temperature sensing signal to the control unit. According to the temperature sensing signal, the control unit controls the operation mode of the solid state semiconductor storage device for achieving the function of temperature control.

Owner:ADATA

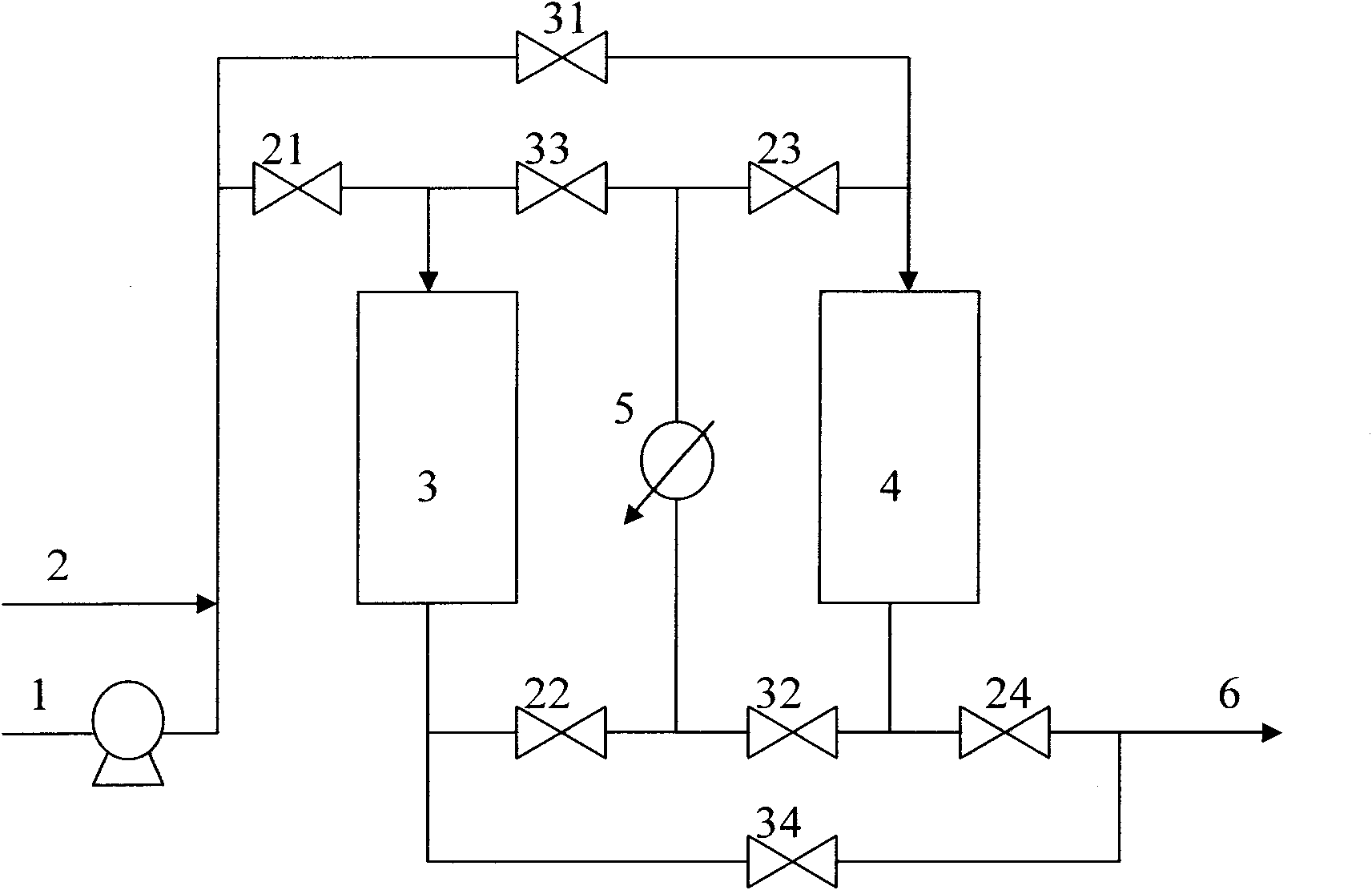

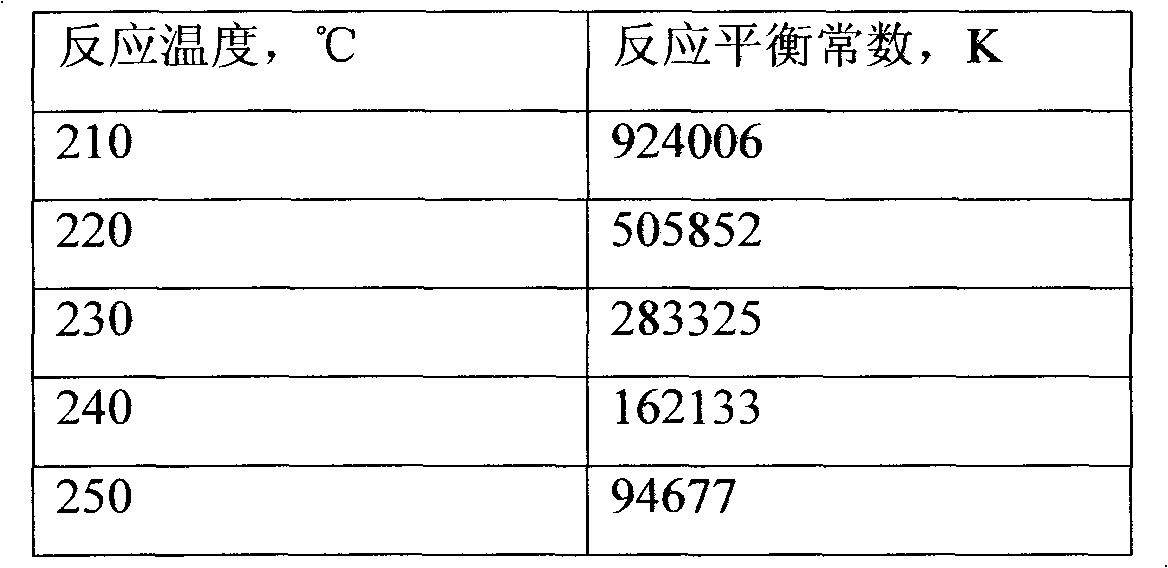

Method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed

ActiveCN102311787AEffective temperature controlTemperature controlLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesHydrogenAlkene

The invention discloses a method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed, which is provided with two reaction sections. Reaction material cooling operation is carried out between the two reaction sections, the mixture of C4 fraction raw material and hydrogen is cooled after passing through the first reaction section, then enters the second reaction section, non-precious metal hydrofining catalysts are arranged in the two reaction sections, and a reaction material flow switching device is arranged between an inlet and an outlet of the two reaction sections to change the sequence of the reaction material flow entering the two reaction sections. The method disclosed by the invention solves the problem that the olefin content does not reach the standard due to thermodynamic control factors, simultaneously the catalysts are entirely fully utilized, and the operating cycle can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Battery pack apparatus with heat supply and discharge

InactiveUS7230404B2Improve variationEffective temperature controlBatteries circuit arrangementsCell temperature controlEngineeringBattery pack

A battery pack apparatus includes a battery pack having multiple rechargeable batteries arranged in parallel and heat medium passages formed therebetween. The battery pack apparatus also includes a heat insulation cover formed of a heat insulation material that covers a circumferential surface of the battery pack substantially entirely. A supply passage and a discharge passage are provided between the heat insulation cover and the battery pack. The supply passage supplies a heat medium to the heat medium passages while the discharge passage discharges the heat medium from the heat medium passages. The battery pack apparatus also includes a supply device that supplies the heat medium to the supply passage.

Owner:PANASONIC EV ENERGY CO LTD

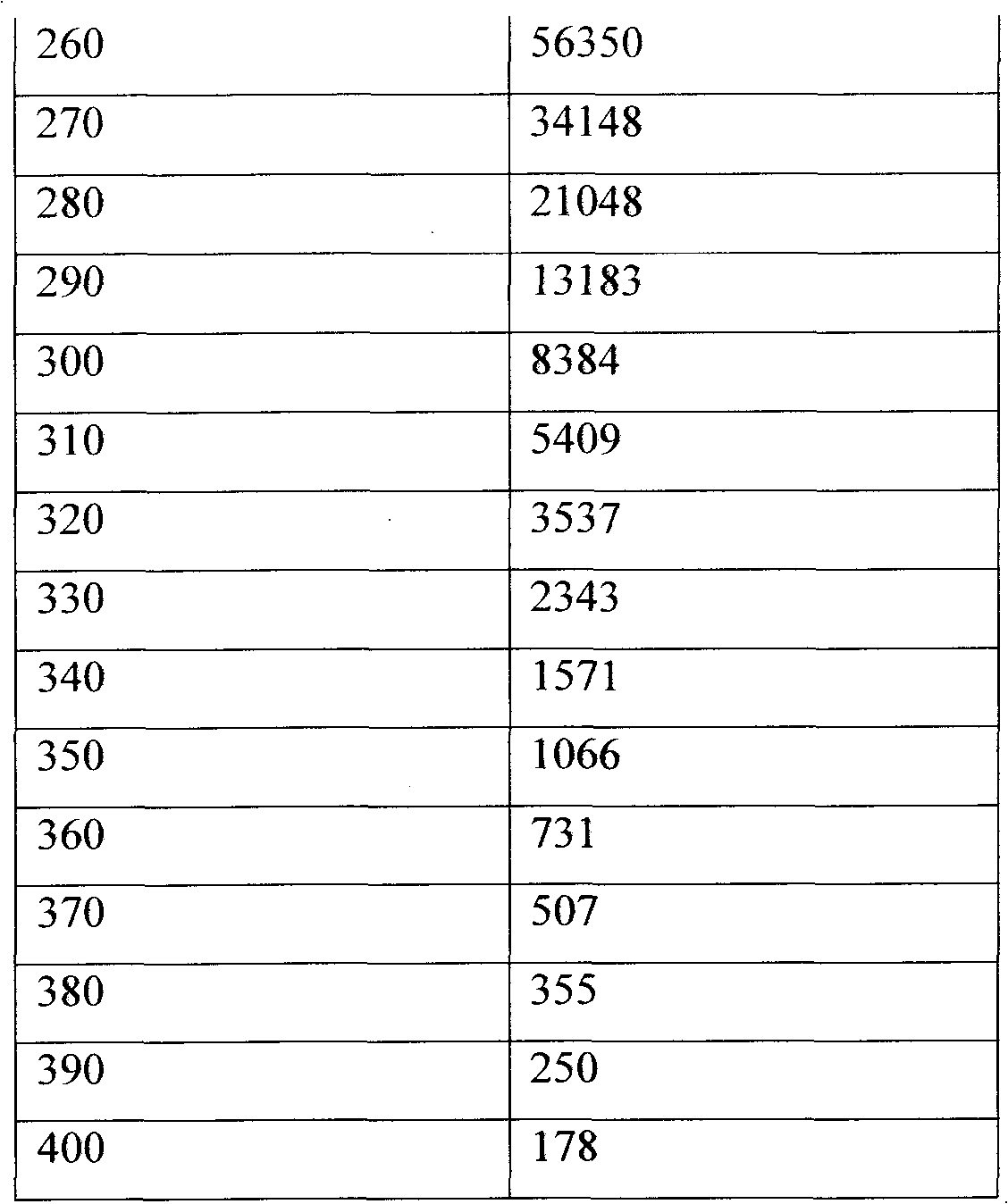

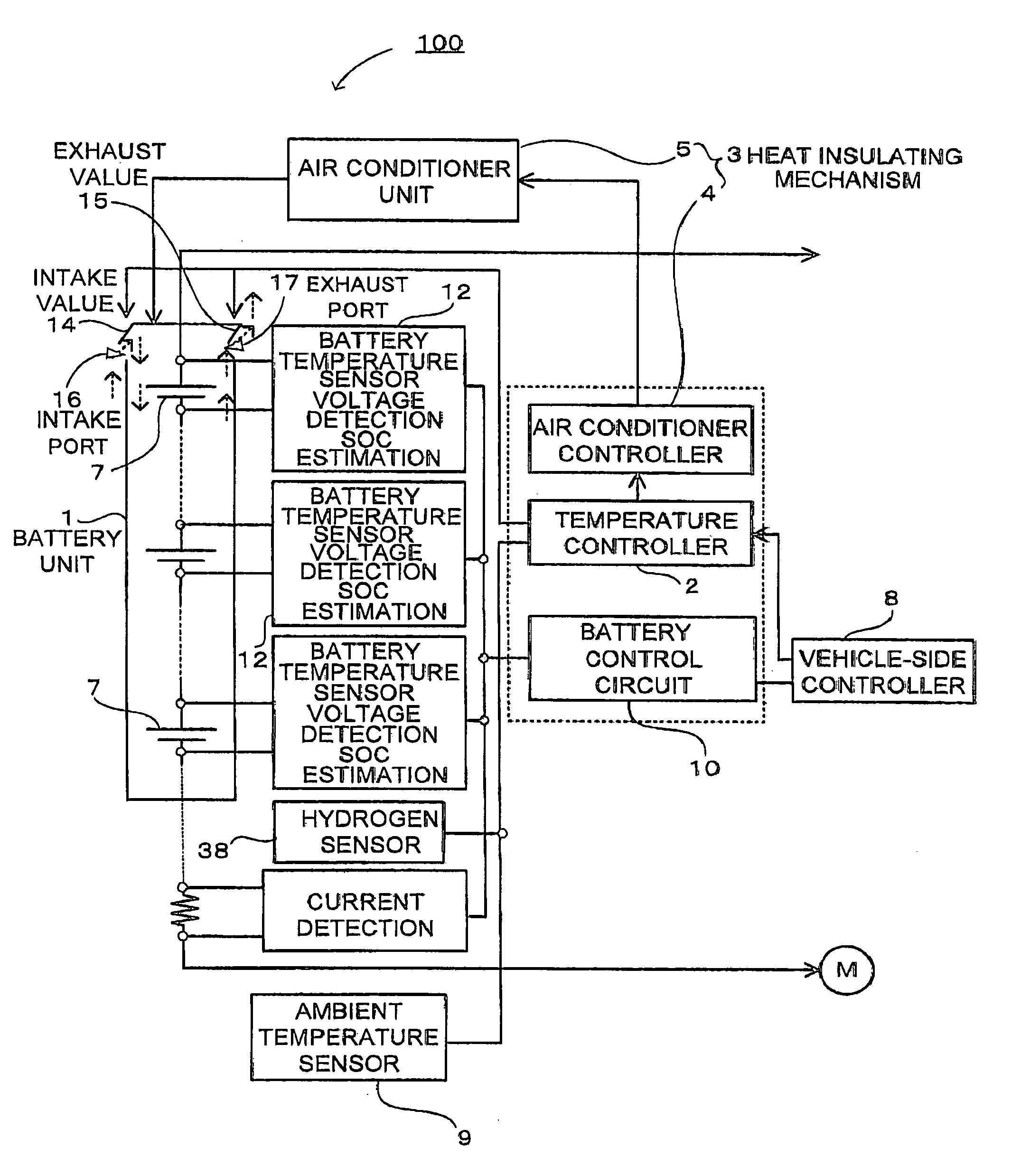

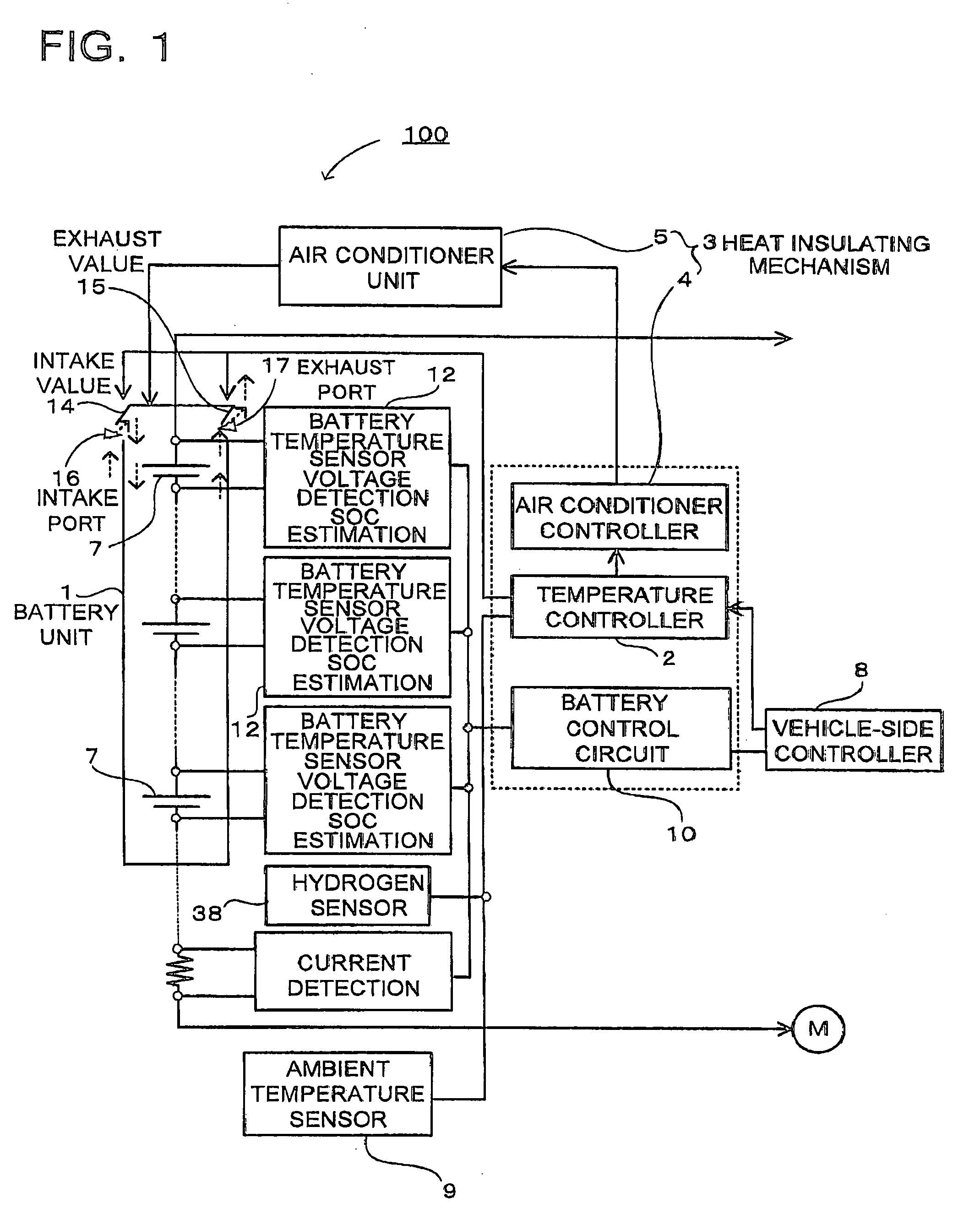

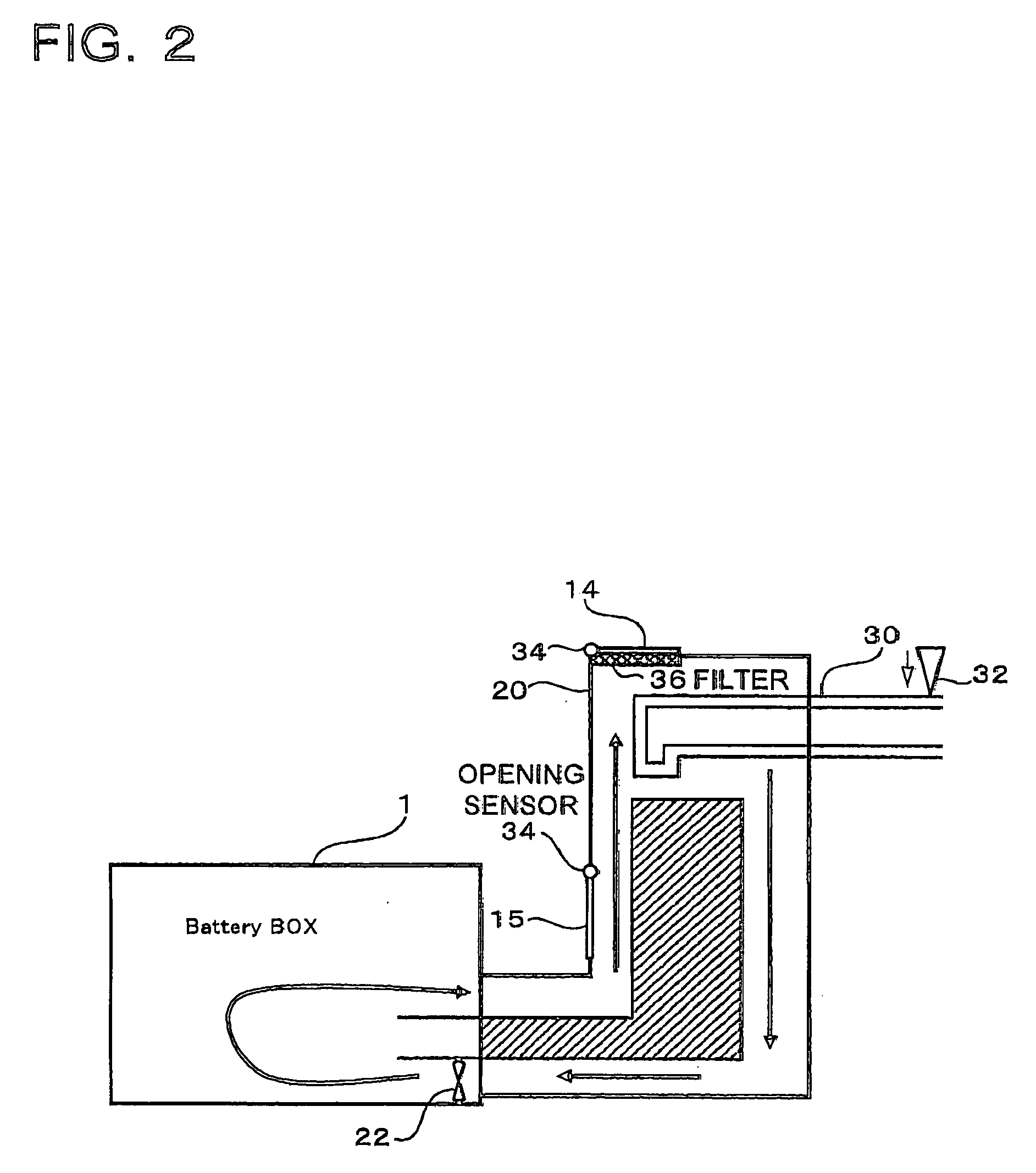

Power supply device for vehicle

InactiveUS20060036883A1Suppress power consumptionSave energyCell temperature controlVolume/mass flow measurementTemperature controlElectrical battery

The invention provides a power supply device for a vehicle, for driving a motor which is mounted on a vehicle and makes the vehicle travel. The power supply device for a vehicle includes: a battery unit having a plurality of secondary batteries; a battery temperature sensor for detecting temperature of a secondary battery included in the battery unit; a heat insulating mechanism for controlling the temperature of the secondary battery; an outside air temperature sensor for detecting the temperature of air on the outside of the vehicle; an intake port for taking the outside air to the battery unit in the vehicle; an intake valve for opening / closing the intake port; and a temperature controller for controlling opening / closing of the intake valve on the basis of the temperature difference between the outside air temperature detected by the outside air temperature sensor and the battery temperature detected by the battery temperature sensor.

Owner:SANYO ELECTRIC CO LTD

Heat-conducting thermosetting molding composite material and application thereof

The invention discloses a heat-conducting thermosetting molding composite material and application thereof. The heat-conducting thermosetting molding composite material comprises the following basic components in percentage by weight: (1) 15-65% of thermosetting matrix resin; (2) 20-80% of heat-conducting filler with a thermal conductivity greater than 1 W / m.DEG C; and (3) other additives, such as a toughening agent, an enhancer, a stabilizer and the like. The invention also discloses application of the heat-conducting thermosetting molding composite material in manufacturing LED (light emitting diode) lighting heat-radiation components. The molding temperature of the composite material can be controlled to below 220 DEG C that is the general soldering operation temperature, so that the assembly process of an LED lamp and a heat radiator and the molding process of a thermosetting material heat radiator can be integrated, and the substrate surface or heat-conducting metal support of the LED lamp can be directly connected with the heat-conducting material; and the molding die of the composite material and auxiliary systems thereof have the characteristics of effective heat insulation and temperature control and easy cleaning, and can effectively lower the processing and manufacturing cost of the LED lamp and improve the heat radiation capability of the LED heat radiator, thereby reducing the operating temperature of LED devices.

Owner:HEFU NEW MATERIAL TECH WUXI

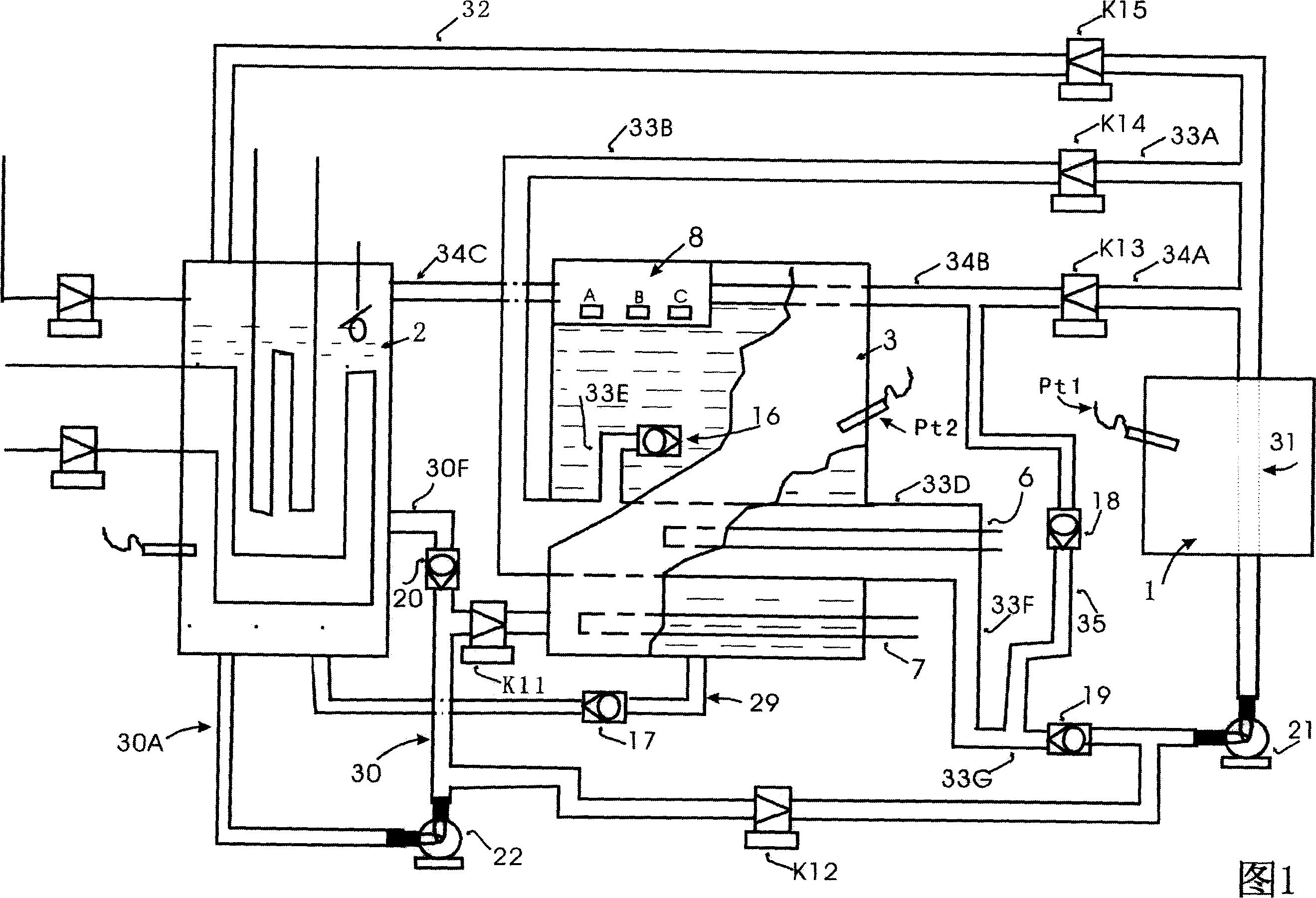

Temperature control system and method for power battery pack of electric vehicle

InactiveCN1866608AExtend your lifeImprove performanceTemperatue controlElectric propulsion mountingTemperature controlPower battery

The invention discloses a motorcar dynamic battery bag temperature control system and control method, which comprises the following parts: driving device, currency pipe, temperature sensor, electronic control unit 5 and circulating dielectric heat-exchanging device, wherein the output of dynamic battery bag 1 connects inlet of driving device, whose output connects the inlet of dynamic battery bag 1 through currency pipe; the temperature signal is sent from temperature sensor to electronic control unit, which controls start and stop for driving device; the circulating dielectric heat-exchanging device and driving device are cascaded between inlet and outlet of dynamic battery bag 1. The invention guarantees battery to work within normal temperature scale, which lengthens battery lifetime and improves battery property.

Owner:BYD CO LTD

Roller press combination grinding device

ActiveCN101134175AEliminate wear and tearAdapt to the requirements of different statesGrain treatmentsMetallic materialsOperation mode

The present invention relates to one kind of combined rolling press grinding apparatus, and belongs to the field of inorganic non-metal material grinding technology. The combined rolling press grinding apparatus includes one dispensing mechanism, one lifting and conveying mechanism, one rolling press, one ball mill, one powder concentrator, one dust collector and one fan. The present invention has the advantages of low milling loss, simple structure, several operation mode, high grinding efficiency, low power consumption, etc.

Owner:天津椿本输送机械有限公司 +1

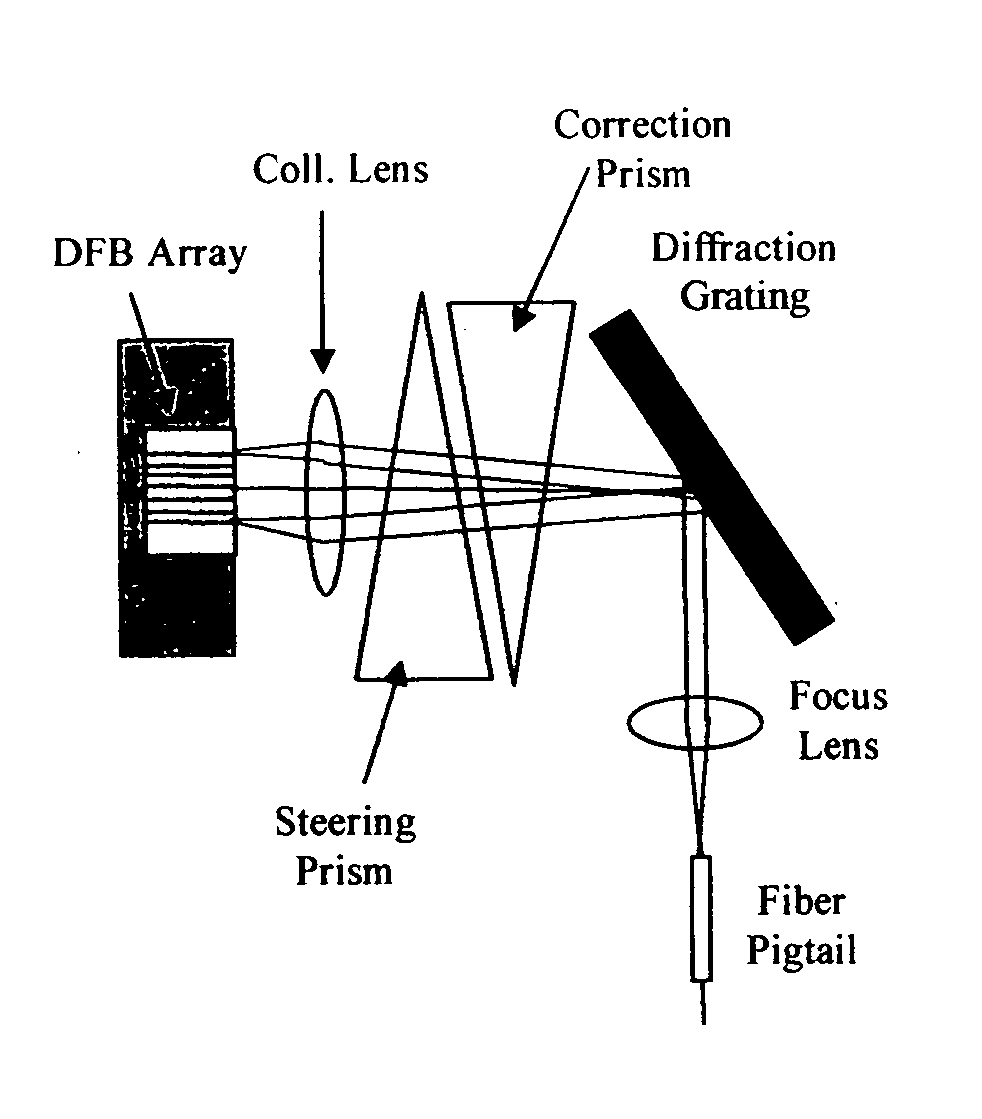

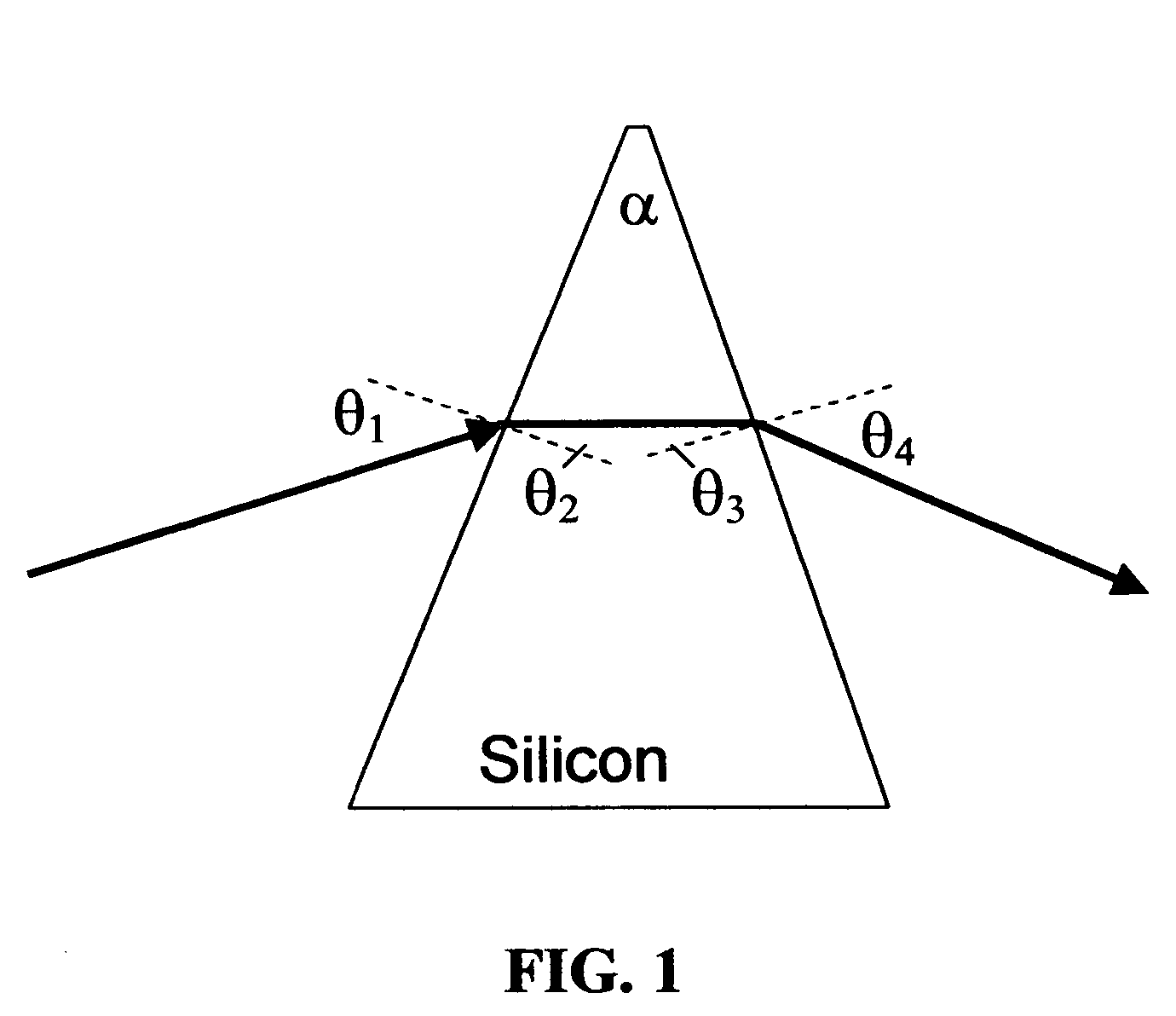

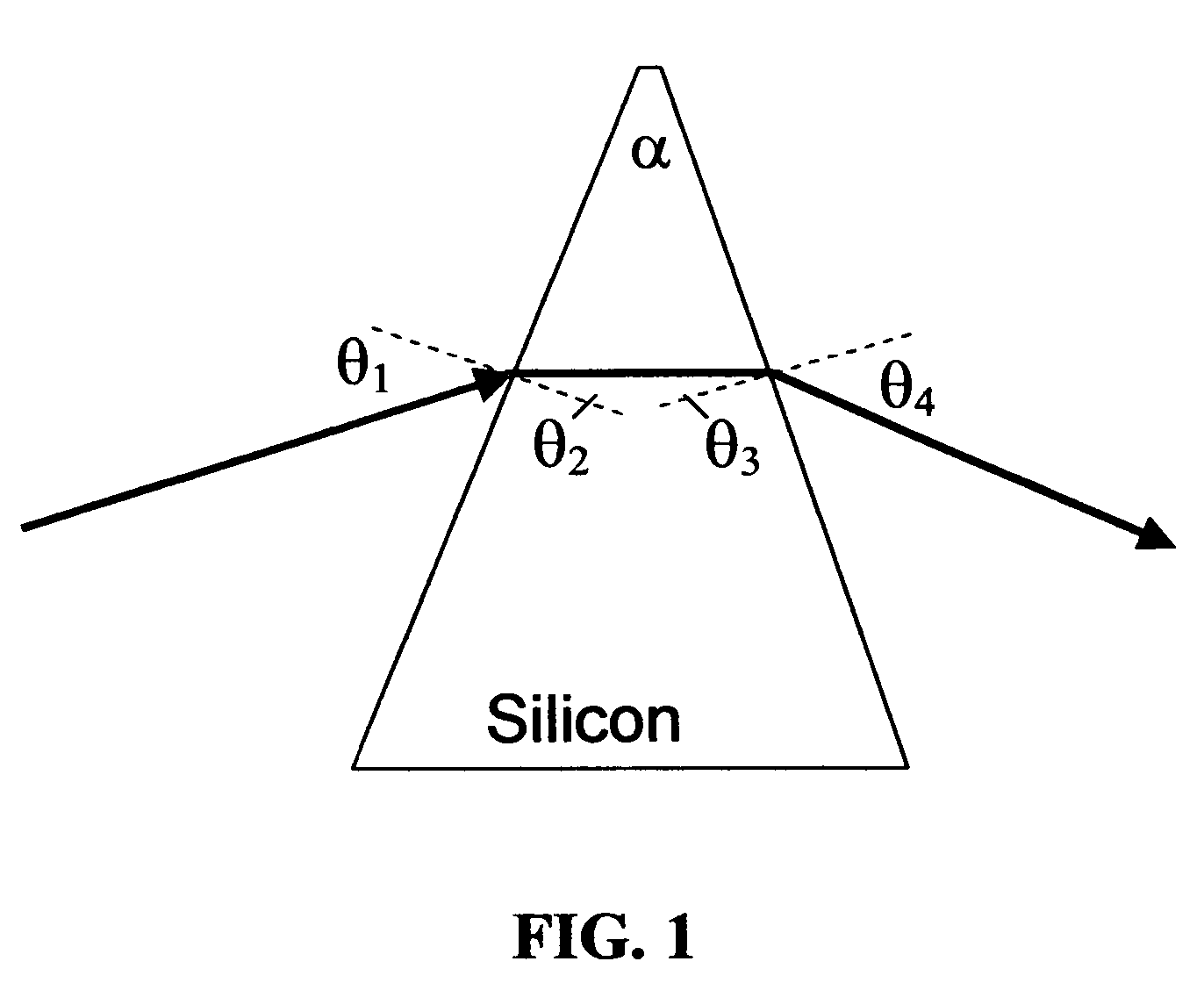

Optical beam steering for tunable laser applications

ActiveUS20050129072A1Function increaseLow costLaser optical resonator constructionSemiconductor laser arrangementsCouplingLight beam

Apparatus is disclosed for optically steering an optical beam, the apparatus comprising a pair of optical prism components arranged together with a diffraction grating so as to allow efficient coupling of an array of spectrally and spatially offset laser diodes to a common optical fiber. A method of optically steering at least one of a series of optical beams is disclosed, the method comprising providing a pair of optical prism components comprising a thermo-optic material; actuating at least one of the components so as to steer at least one of the series of optical beams received from an array of spatially and spectrally offset lasers.

Owner:II VI DELAWARE INC

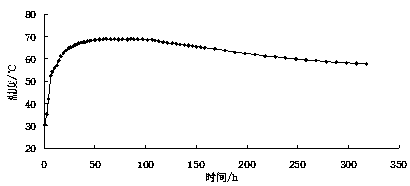

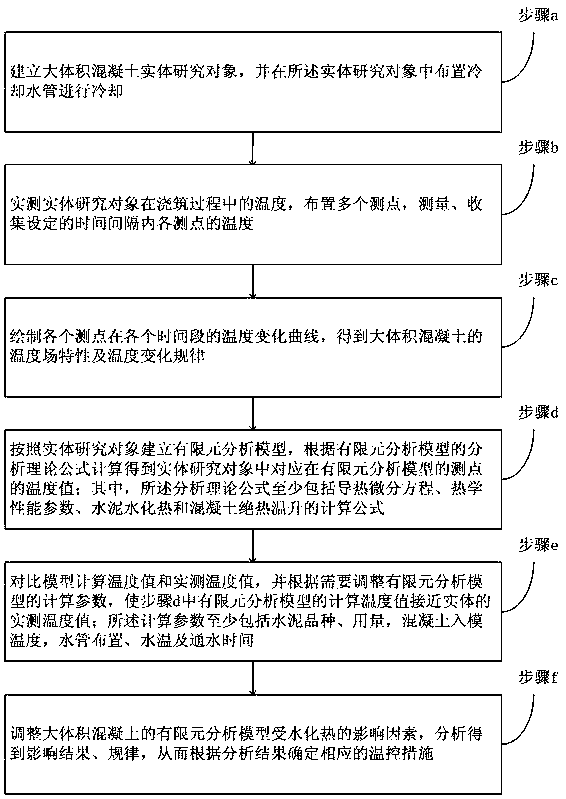

Mass concrete-based temperature field research method and temperature control method

InactiveCN108133111ANo crackImprove effectivenessGeometric CADDesign optimisation/simulationTemperature controlResearch Object

The invention discloses a mass concrete-based temperature field research method and a mass concrete-based temperature control method. The research method comprises the following steps of: establishinga mass concrete entity research object; measuring temperatures, in a pouring process, of a plurality of measurement points of the entity, and drawing corresponding temperature change curves to obtaintemperature field characteristics and a temperature change law; establishing a finite element analysis model according to the entity research object and automatically calculating temperatures of thecorresponding measurement points; adjusting temperature field calculation parameter of the model through comparing the calculated temperature values of the model with the actually measured temperaturevalues; and finally adjusting influence factors influencing hydration heat in a mass concrete model, carrying out analysis to obtain an influence result and an influence law, and adopting a corresponding temperature control method according to the result and the law. According to the mass concrete-based temperature field research method and the mass concrete-based temperature control method, fissures are prevented from occurring in mass concrete, and the pouring quality of concrete and the total quantity of projects are ensured.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Power supply device for vehicle

InactiveUS7143724B2Suppress power consumptionSave energyDigital data processing detailsCell temperature controlTemperature controlElectrical battery

A power supply device for a vehicle, for driving a motor which is mounted on a vehicle and makes the vehicle travel. The power supply device for a vehicle includes: a battery unit having a plurality of secondary batteries; a battery temperature sensor for detecting the temperature of a secondary battery; a heat insulating mechanism for controlling the temperature of the secondary battery; an outside air temperature sensor for detecting the temperature of air outside of the vehicle; an air intake port for taking the outside air to the battery unit in the vehicle; an intake valve for opening / closing the intake port; and a temperature controller for controlling the opening / closing of the intake valve on the basis of the temperature difference between the outside air temperature detected by the outside air temperature sensor and the battery temperature detected by the battery temperature sensor.

Owner:SANYO ELECTRIC CO LTD

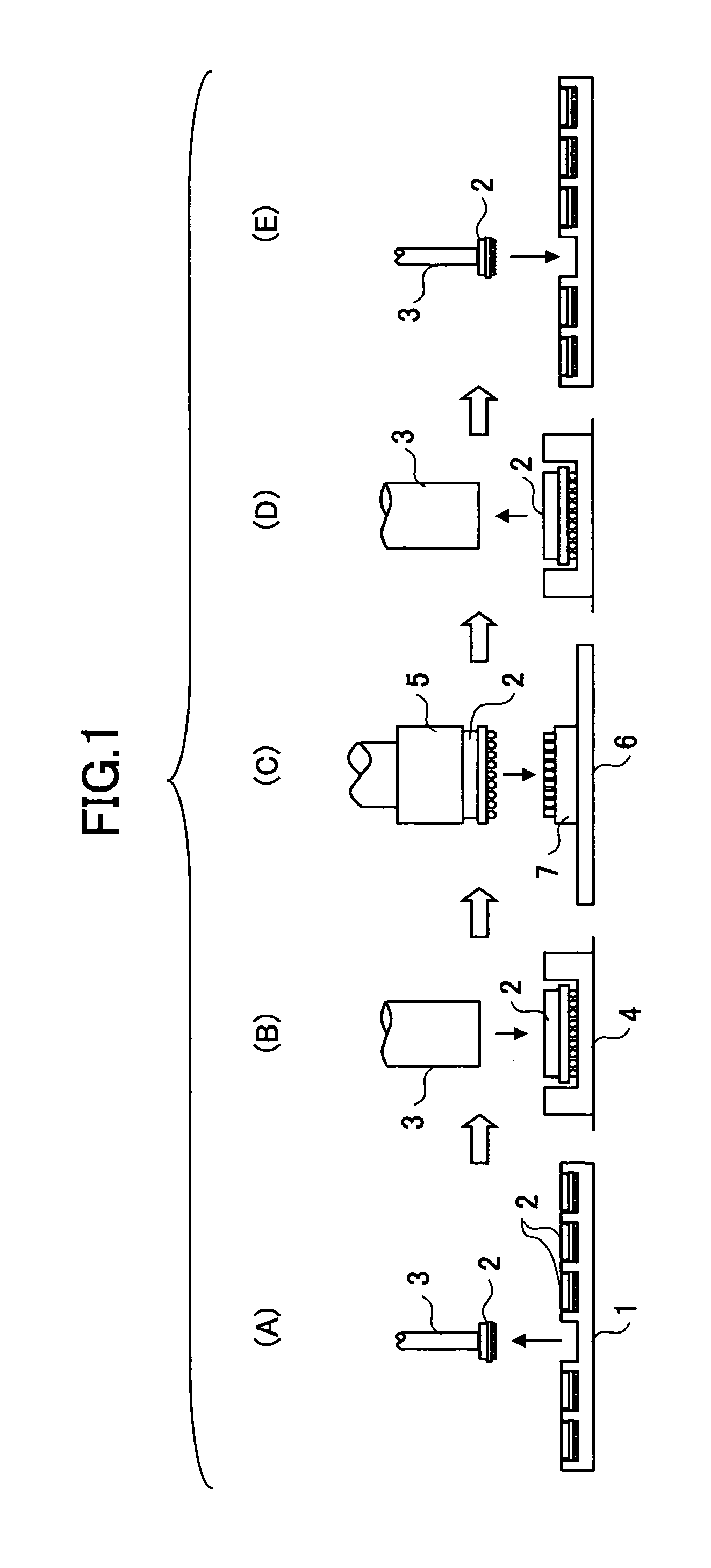

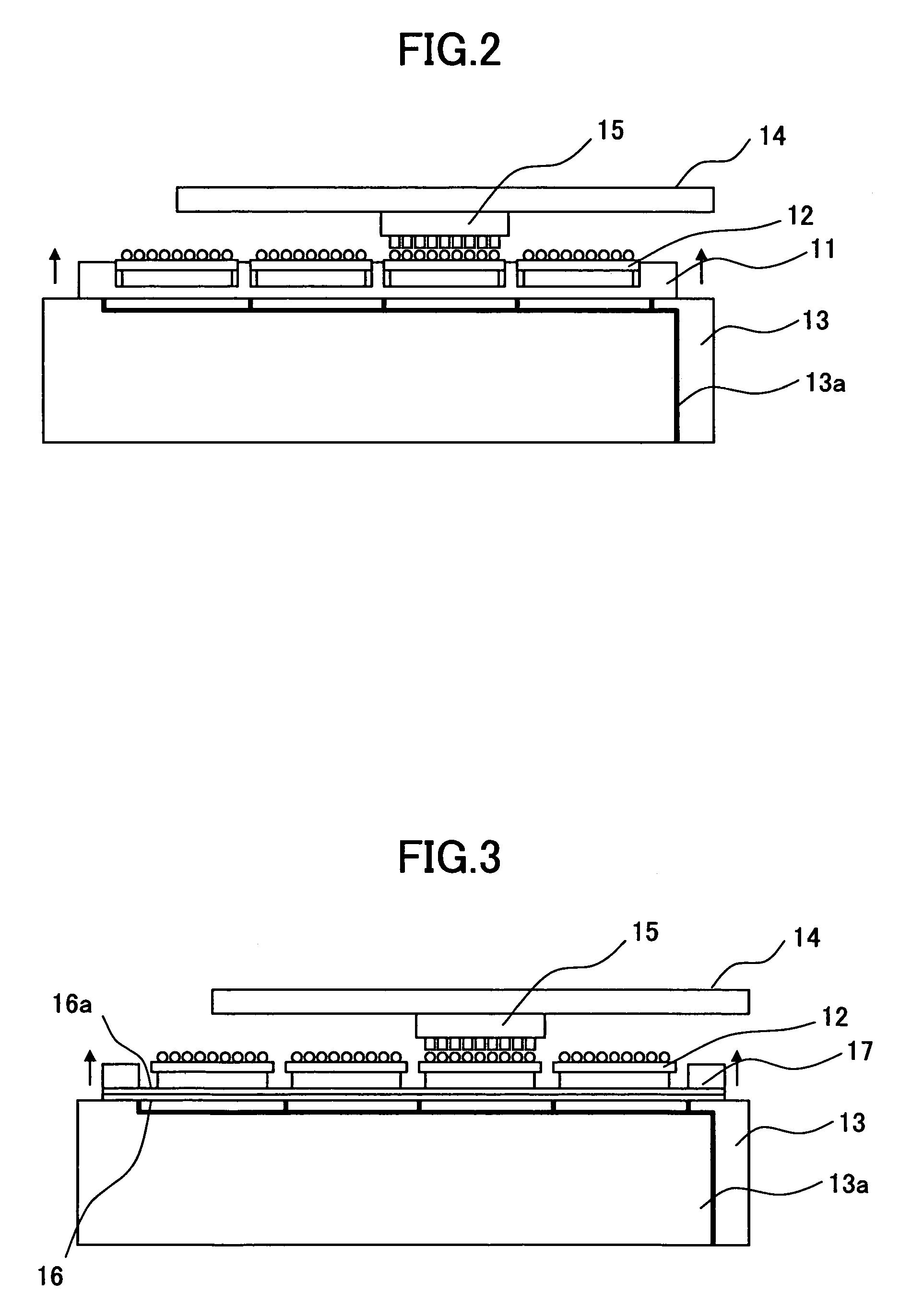

Load lock apparatus, processing system and substrate processing method

InactiveUS20060231027A1Improve thermal conductivityEffective temperature controlLiquid fillingSemiconductor/solid-state device manufacturingTemperature controlEngineering

A load lock apparatus including a carry port provided on a side of a carry-in / out section for carrying a substrate in / out from / to the outside, and a carry port provided on a side of a processing section for processing the substrate, includes: a temperature controlling plate for controlling a temperature of the substrate, the temperature controlling plate configured including a plate body made of a porous material and a temperature controlling gas supply path for supplying a temperature controlling gas controlled in temperature to the plate body. The temperature controlling gas passes through the plate body, blows out from a surface of the plate body, and is supplied to the substrate.

Owner:TOKYO ELECTRON LTD

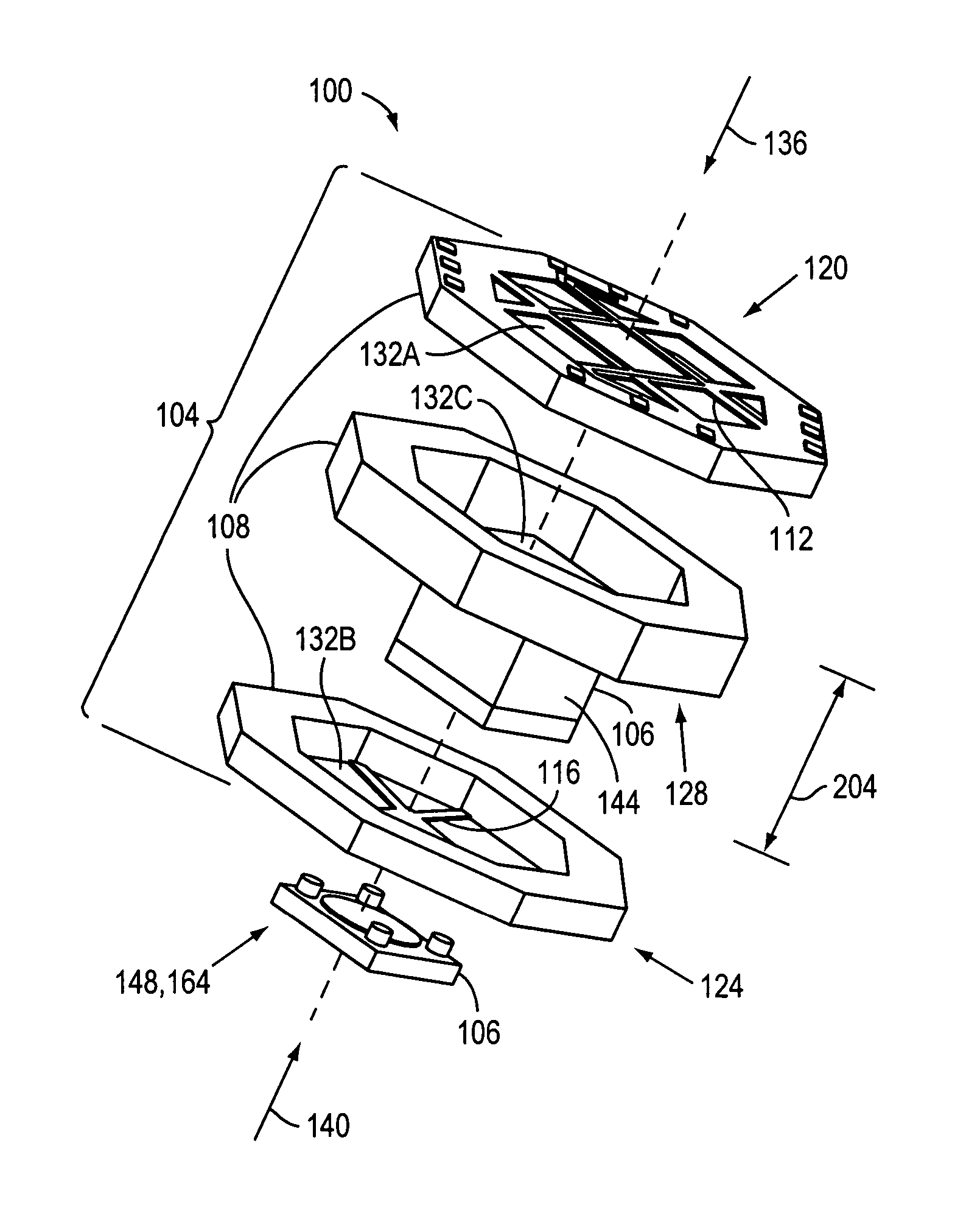

Apparatus and system for suspending a chip-scale device and related methods

ActiveUS7215213B2Stably suspendEffective temperature controlApparatus using atomic clocksSolid-state devicesEngineering

A suspension of a chip-scale device is accomplished using a suspension frame and at least one first tether. The chip-scale suspension frame defines a first plane and an opening through the suspension frame. At least one first tether crosses the opening at a first angle relative to the first plane and can be used to position the chip-scale device at least partially within the opening.

Owner:CHARLES STARK DRAPER LABORATORY

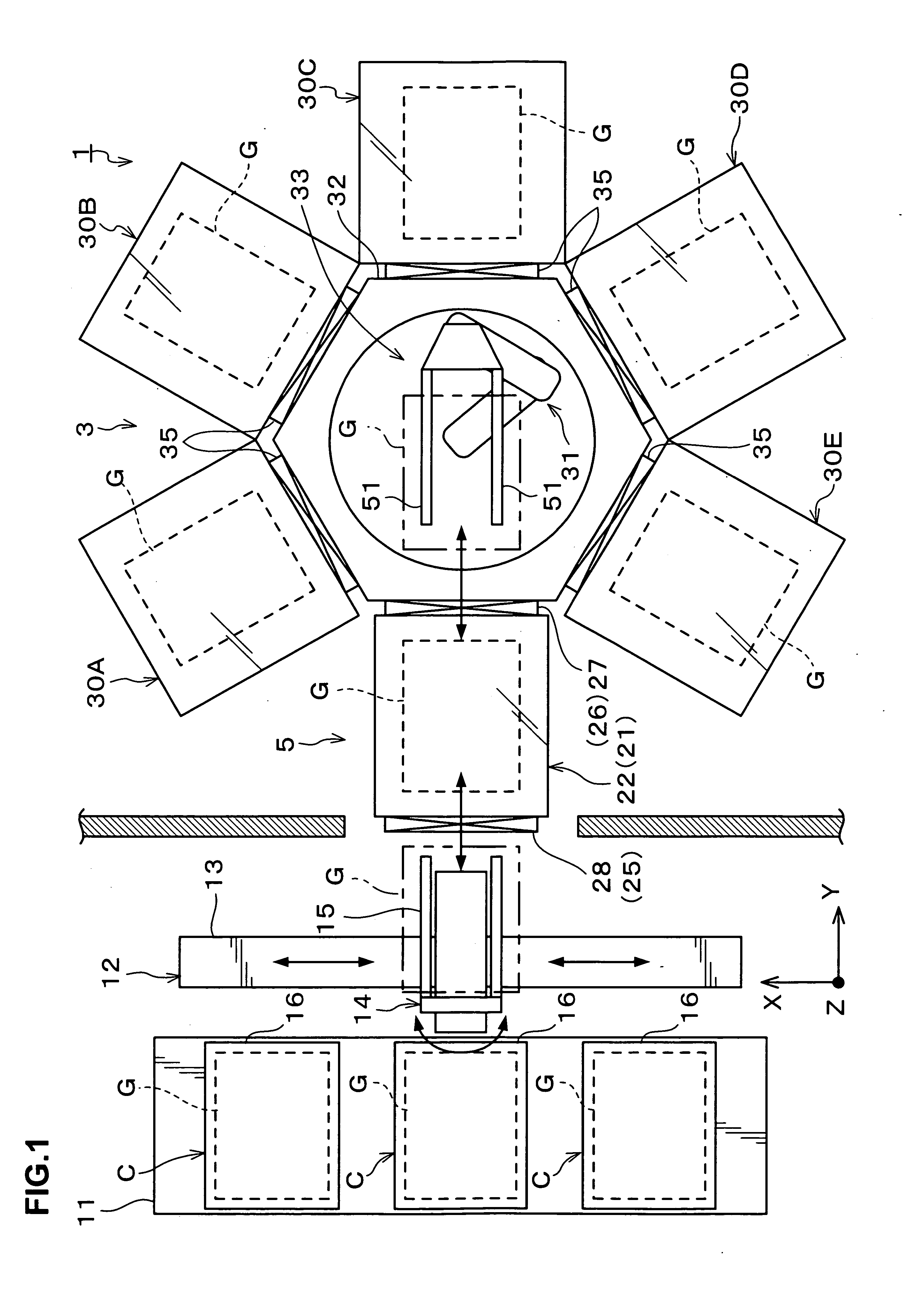

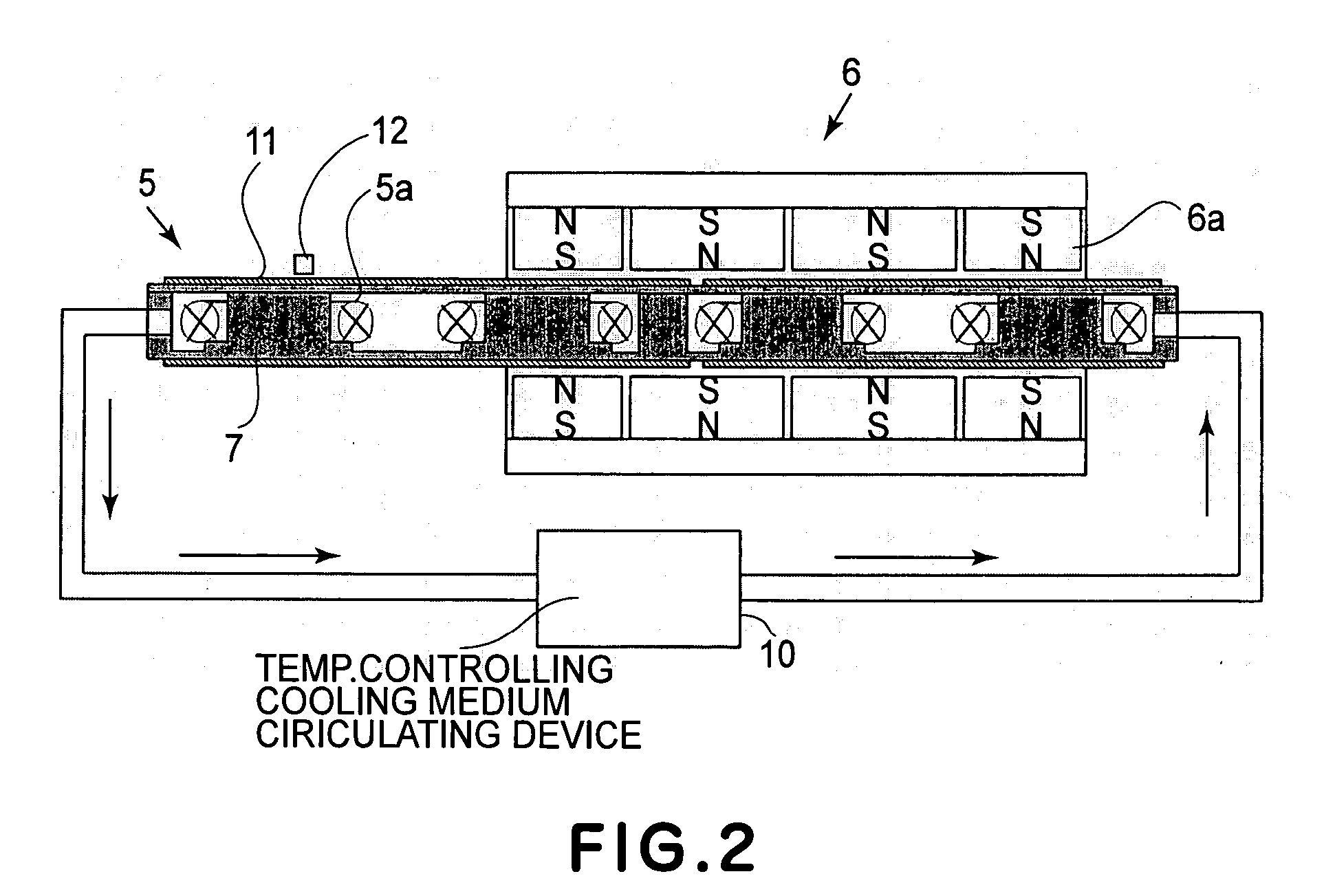

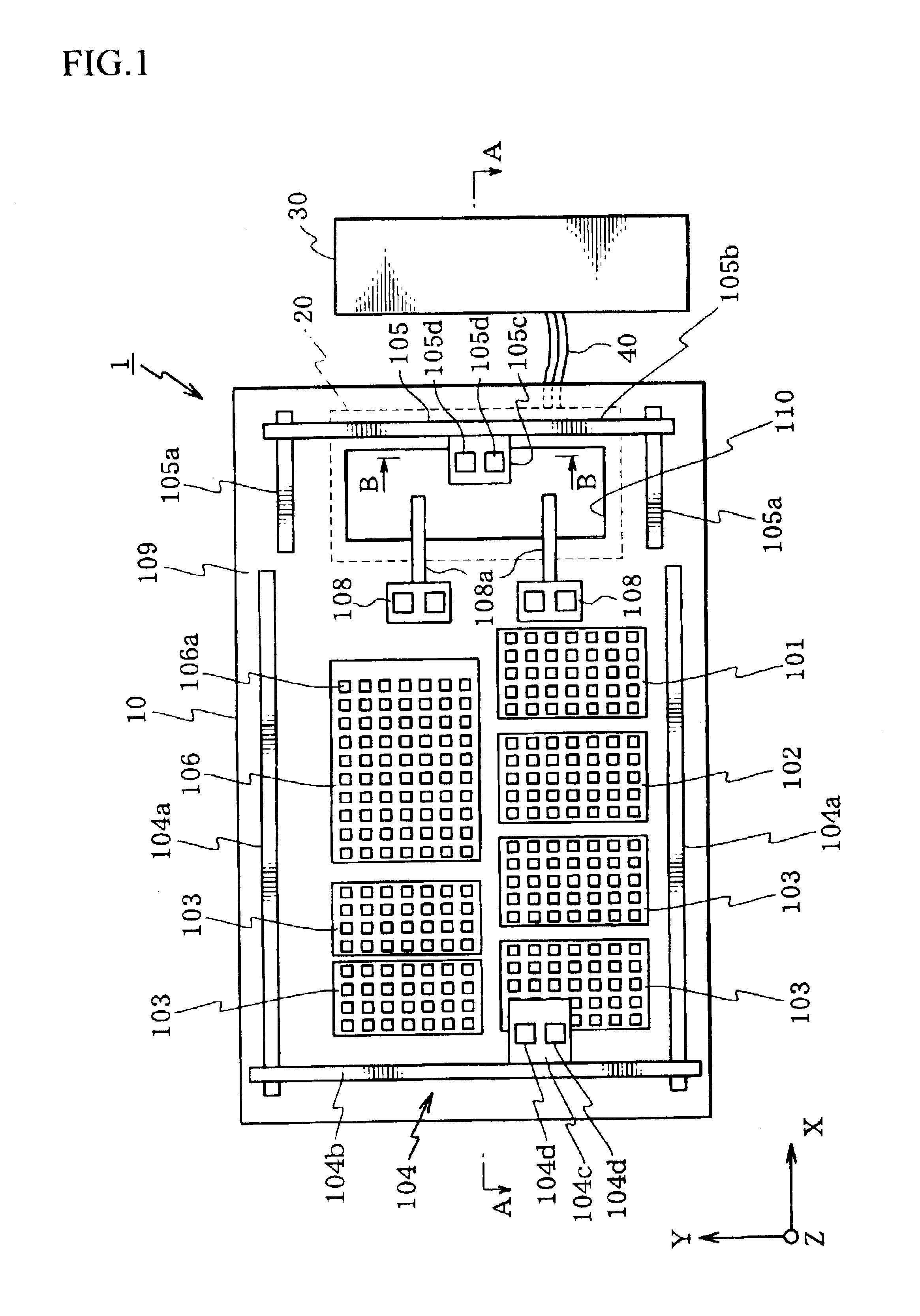

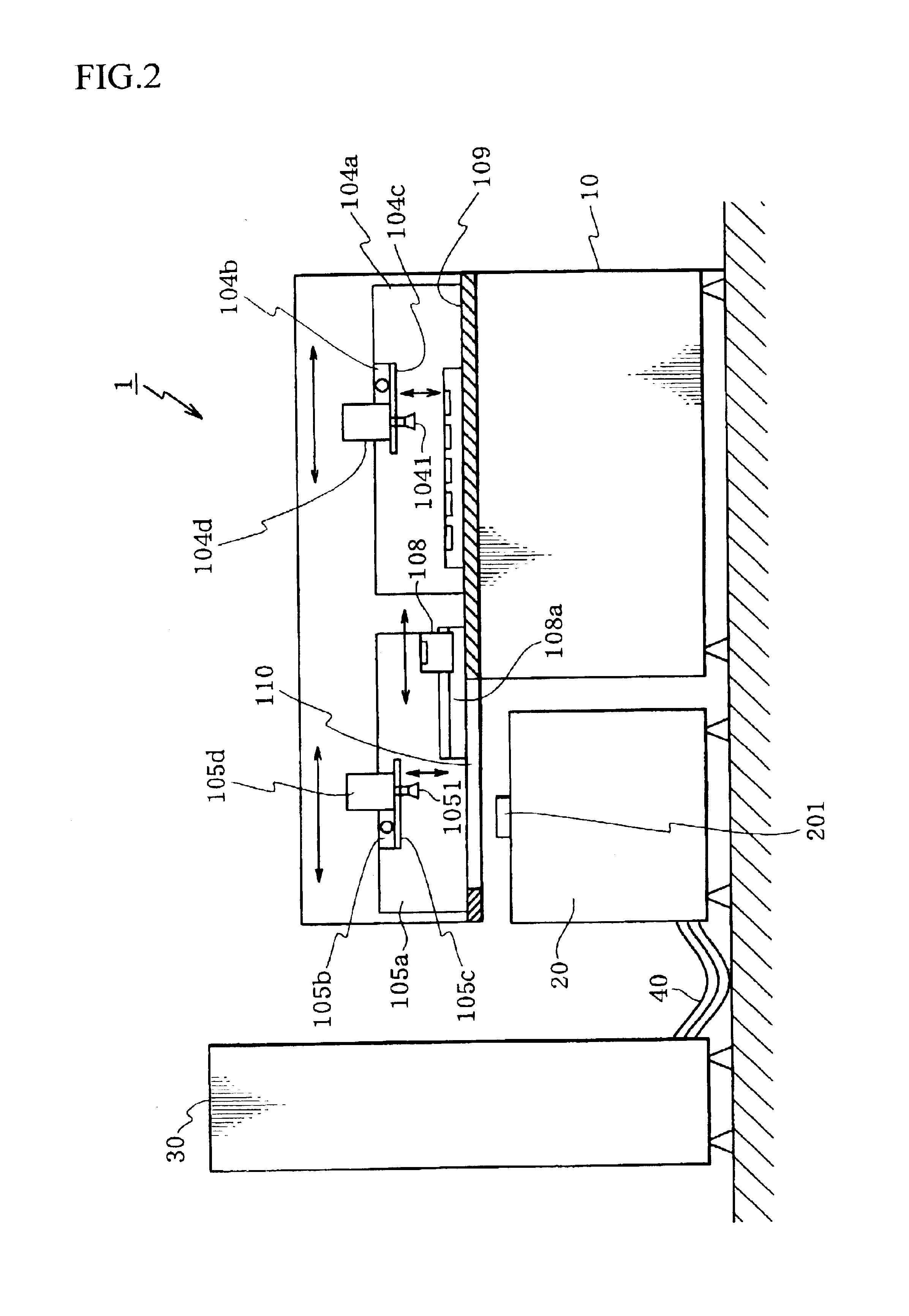

Positioning system and linear motor

ActiveUS20060220478A1Effective temperature controlGood effectAC motor controlPhotomechanical apparatusEngineeringLinear motor

Disclosed is a positioning system and an exposure apparatus having the same, wherein in accordance with an aspect of the present invention the positioning system includes a stage being movable and being configured to carry an object thereon, an interferometer configured to measure a position of the stage, a driving system configured to drive the stage, and a heater provided between a light path of the interferometer and a coil which is a component element of the driving system. In one preferred form of the present invention, the heater has a film-like shape or it is formed as a portion of a cooling jacket that is configured to cover the coil.

Owner:CANON KK

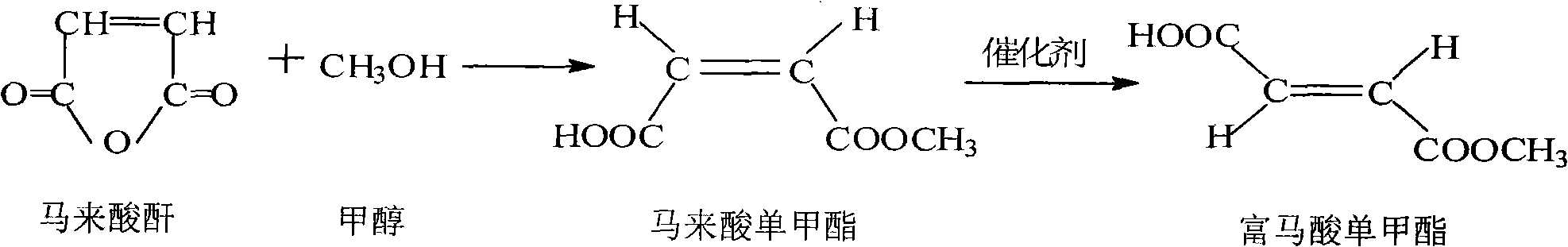

Preparation method of monomethyl fumarate

InactiveCN101774913ANo emissionsShort reaction timeOrganic compound preparationCarboxylic acid esters preparationIsomerizationDistillation

The invention discloses a preparation method of monomethyl fumarate. A main material of maleic anhydride and methanol are subjected to alcoholysis reaction, thus producing monomethyl maleate, which is then isomerized to produce the monomethyl fumarate. The preparation method comprises the following steps: the main material of the maleic anhydride and the methanol are subjected to the alcoholysis reaction, thus producing the monomethyl maleate; then the monomethyl maleate solution is added with ethyl acetate and is then added with fumaryl chloride at 80-100DEG C for reacting for 60-120 minutes, then the ethyl acetate is removed by distillation, water is added, the product is heated to dissolve, and after cooling, centrifugal separation and vacuum drying, the monomethyl fumarate is obtained. The alcoholysis reaction process can be completed at room temperature, which saves energy and has short reaction time; and the isomerization reaction of the monomethyl maleate and the alcoholysis reaction of the maleic anhydride can adopt the same set of equipment, and the isomerization reaction can be carried out as soon as the alcoholysis reaction is completed, thus having no need for new devices.

Owner:HENAN UNIVERSITY

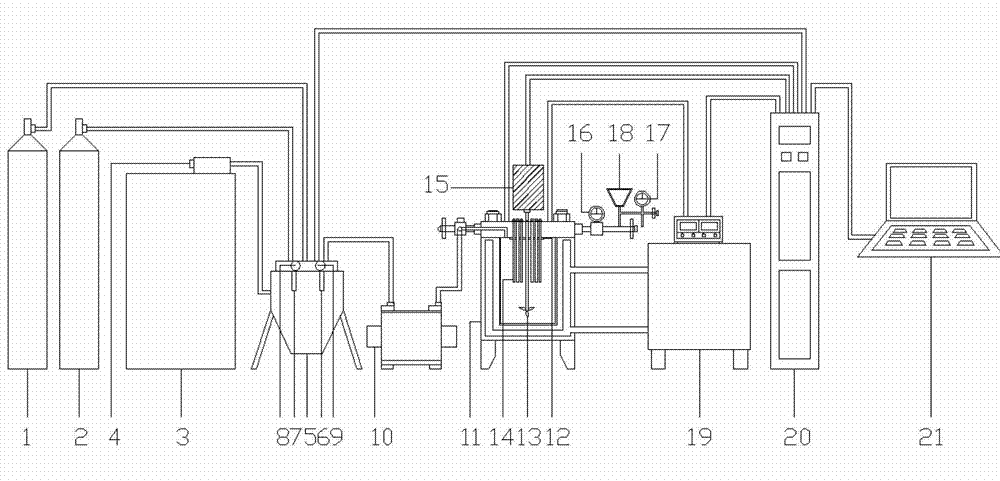

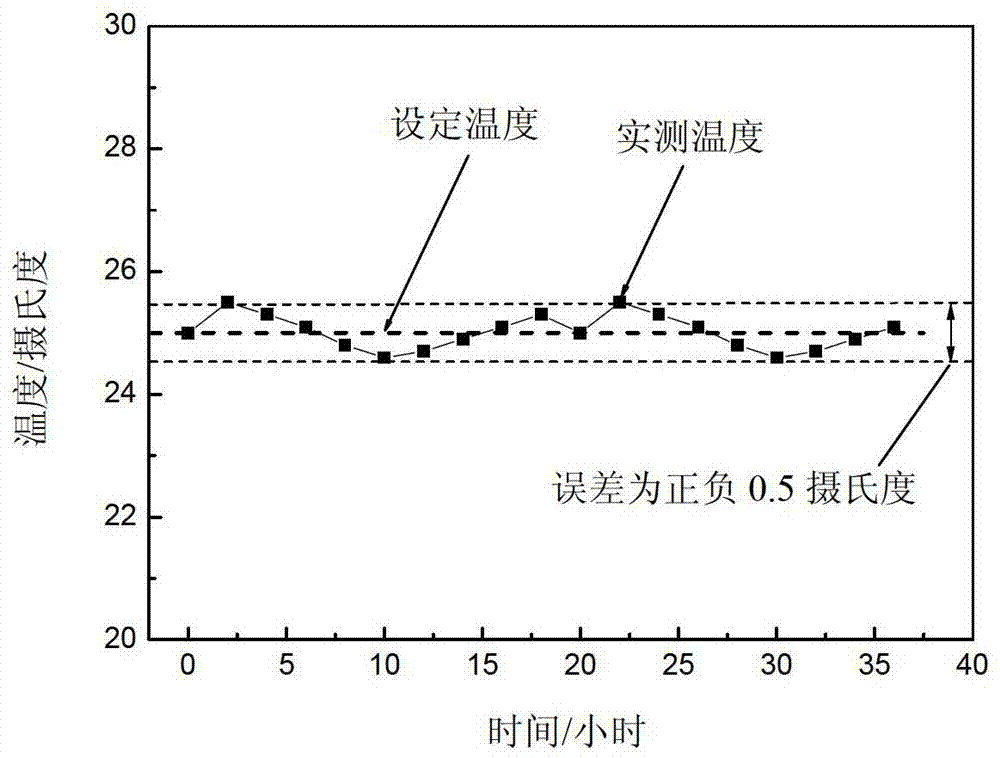

Abyssal environment simulation device suitable for testing material corrosion behavior

InactiveCN103196819AEasy to useDissolved oxygen content stable controlWeather/light/corrosion resistanceHydraulic pumpNitrogen gas

The invention provides an abyssal environment simulation device suitable for testing material corrosion behavior. The abyssal environment simulation device comprises a high pressure autoclave, a hydrostatic pressure control system of simulated abyssal environment and a simulated environment monitoring control system. The hydrostatic pressure control system of simulated abyssal environment comprises a nitrogen cylinder, an oxygen cylinder, a water tank, a liquid supply tank and a hydraulic pump, artificial sea water is stored in the water tank, a water pump injects the artificial sea water into the liquid supply tank, the nitrogen cylinder and the oxygen cylinder are connected with the liquid supply tank, and the hydraulic pump is connected between the liquid supply tank and the high pressure autoclave so as to inject the artificial sea water meeting the dissolved oxygen content into the high pressure autoclave; the simulated environment monitoring control system comprises a compound sensor, a working electrode, a reference electrode, a temperature control device, a singlechip signal processor and a computer. The abyssal environment simulation device can simulate the characteristic environment parameters, such as the hydrostatic pressure, the environment temperature, the dissolved oxygen content, the pH value, the flow rate and the salinity, of the corrosive medium for the material in the abyssal environment, and is used for testing the related corrosion electrochemistry behaviors of the material in the simulated abyssal environment.

Owner:三亚哈尔滨工程大学南海创新发展基地

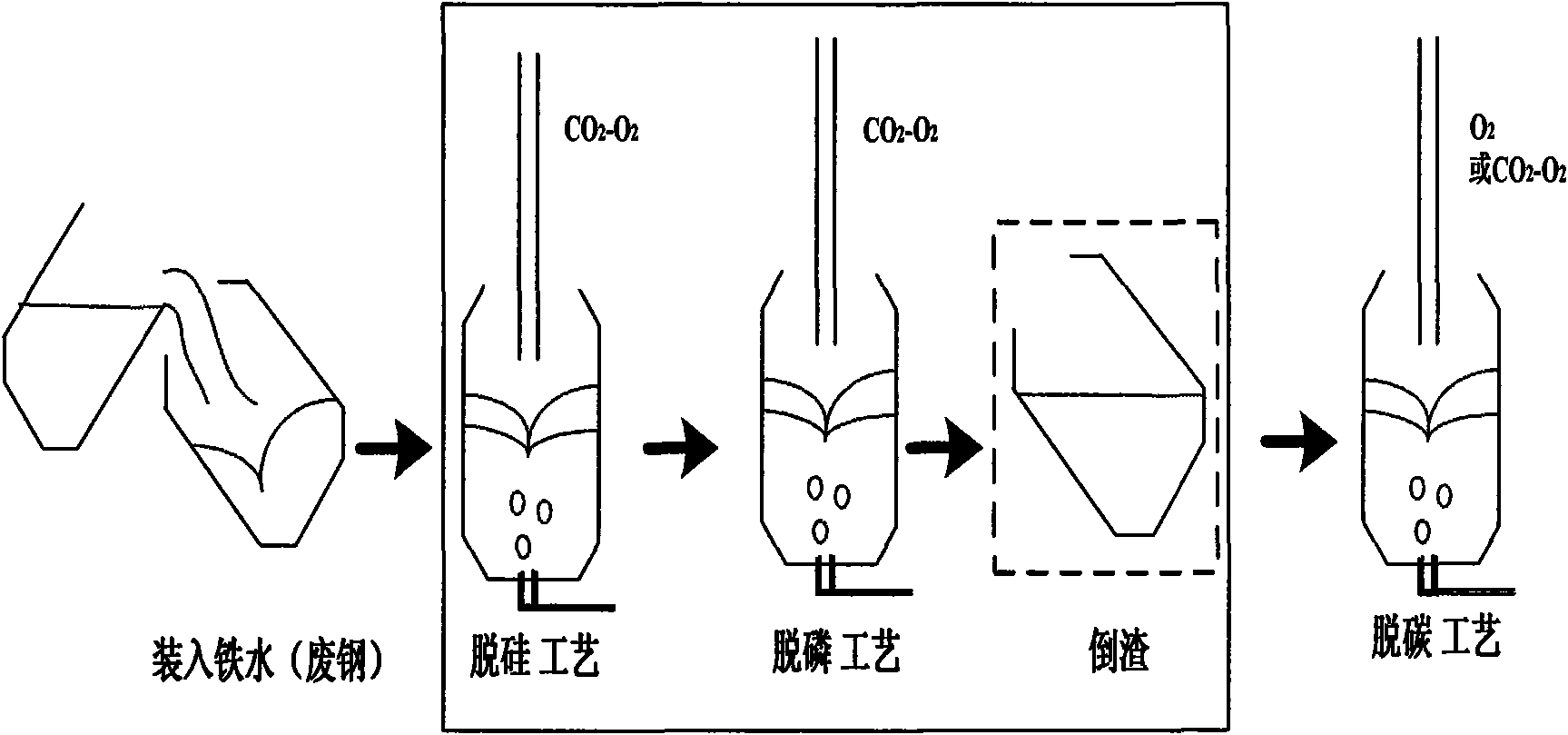

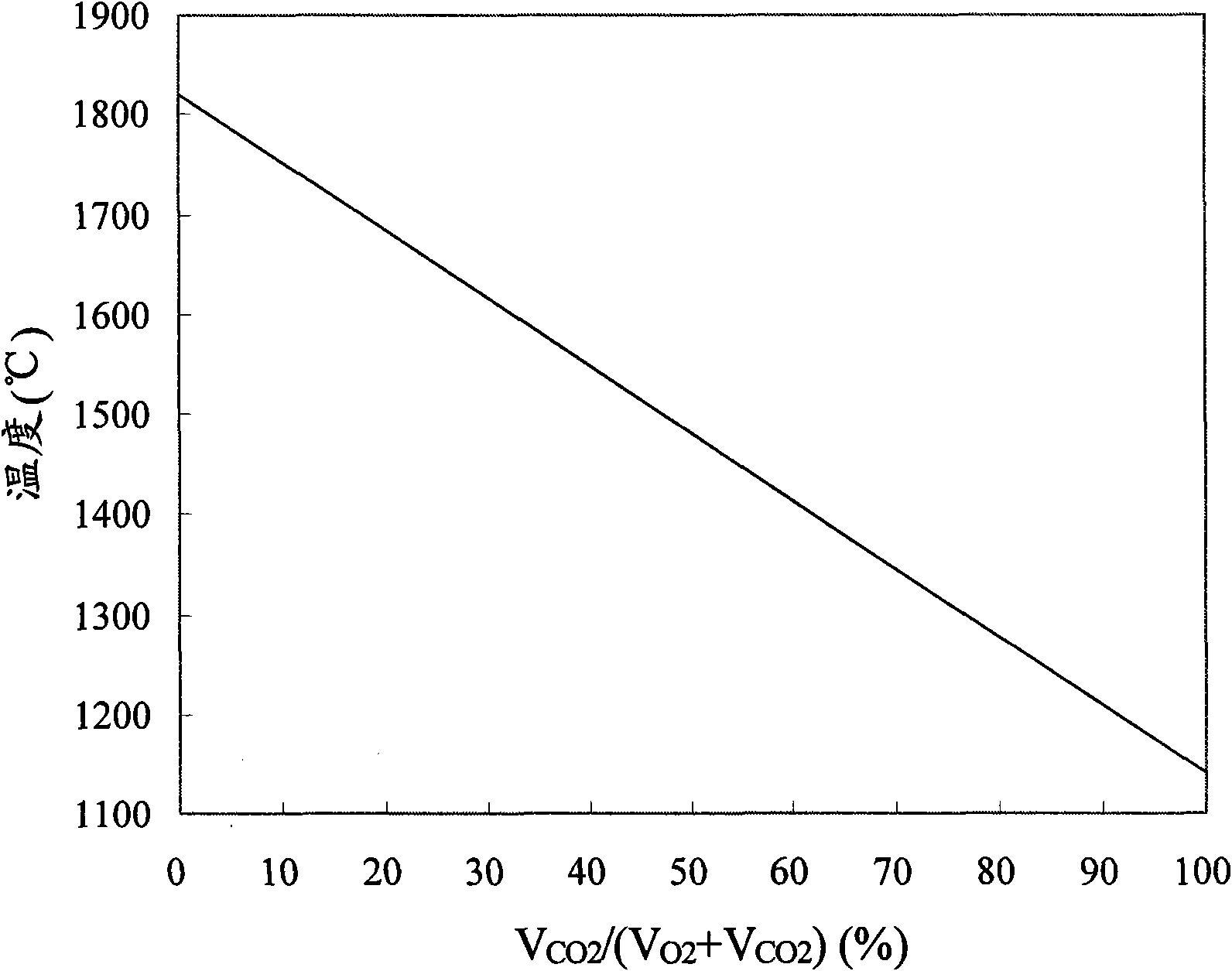

Method for controlling temperature of steelmaking melting pool of converter by blowing CO2 gas

InactiveCN101608250AAchieve diversificationEffective temperature controlManufacturing convertersSteelmakingMelting tank

The invention discloses a method for controlling temperature of a steelmaking melting pool of a converter by blowing CO2 gas, which belongs to the filed of convertor steel making and relates to a converter dephosphorization technology. The invention sprays CO2 gas (or mixed gas of CO2-O2) into the melting pool of the converter and realizes the smooth temperature increase of the melting pool by regulating the proportion of V[CO2] / (V[O2]+V[CO2]). The proportion of V[CO2] / (V[O2]+V[CO2]) is controlled at 10%-100% at the early and middle stages of melting (3-5min), the total flow rate of the blowing gas is 100-80000Nm / h, bottom blowing and strong stirring are adopted at this time, and the temperature is controlled between 1300 DEG C and 1400 DEG C. The proportion of V[CO2] / (V[O2]+V[CO2]) is adjusted and controlled at 10%-50% at the middle stage of melting according to desilication and dephosphorization situation and the temperature of the melting pool, and the flow rate of the blowing gas is 100-80000Nm / h. The method is applicable to the converter steel making of 30-300 tons, the dephosphorization rate can achieve 85%-95% by adopting the method, and the rephosphorization rate after slag dumping is lower than 3%.

Owner:UNIV OF SCI & TECH BEIJING

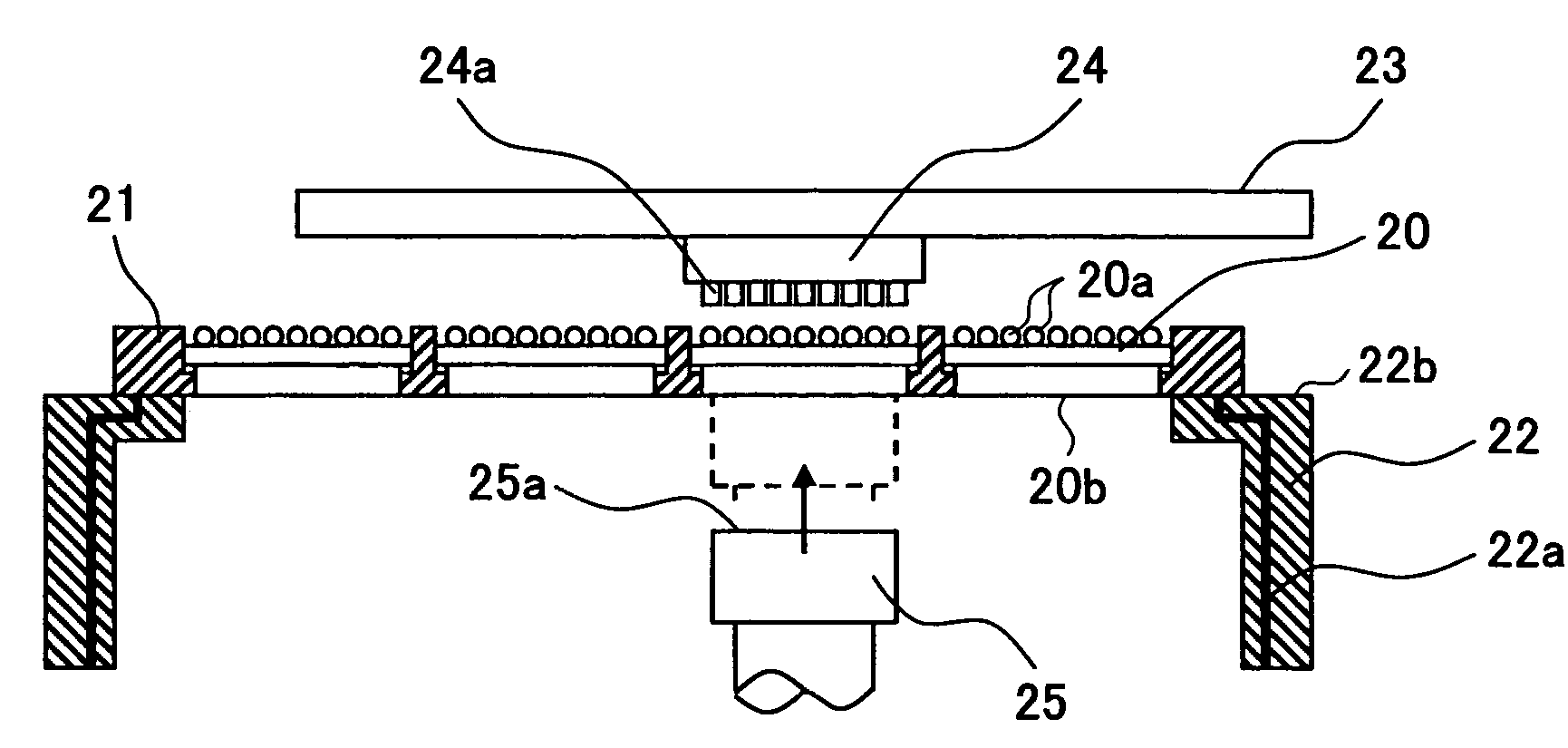

Testing device and testing method of a semiconductor device

InactiveUS7129726B2Simple structureEffective temperature controlSemiconductor/solid-state device testing/measurementContactless circuit testingHead pressingSemiconductor

Owner:SOCIONEXT INC

Method for culturing aweto in ghost moths breeding land

InactiveCN1970733AShorten the generation cycleShorten the production cycleFungiAnimal husbandryPlant rootsMoisture

The invention discloses a manufacturing method of Chinese caterpillar fungus, which is characterized by the following: establishing greenhouse booth moth culturing field according to culturing temperature and moisture; reducing the danger of natural enemy of moth to accelerate weak plant root of herb and bush; releasing certain quantity of moth fertilized ovum, larva, pupal or and imagine in the culturing field; elevating moth larva breeding density with 110-3500000 per hectareha; breeding the moth from one year to 6-8 years within 365-425d; forming sac fungus; collecting 530000-1570000 Chinese caterpillar fungus per hectareha.

Owner:SUN YAT SEN UNIV

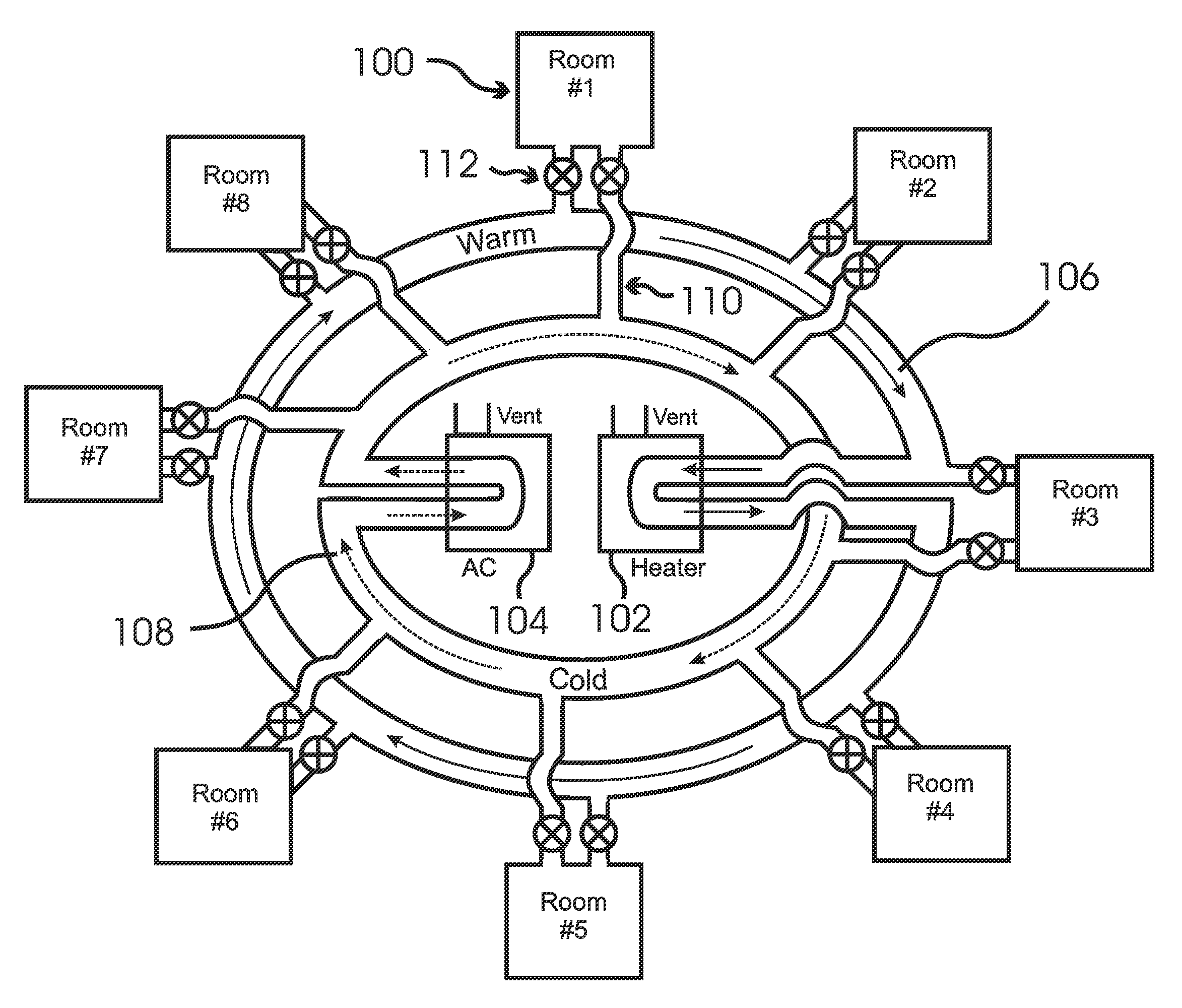

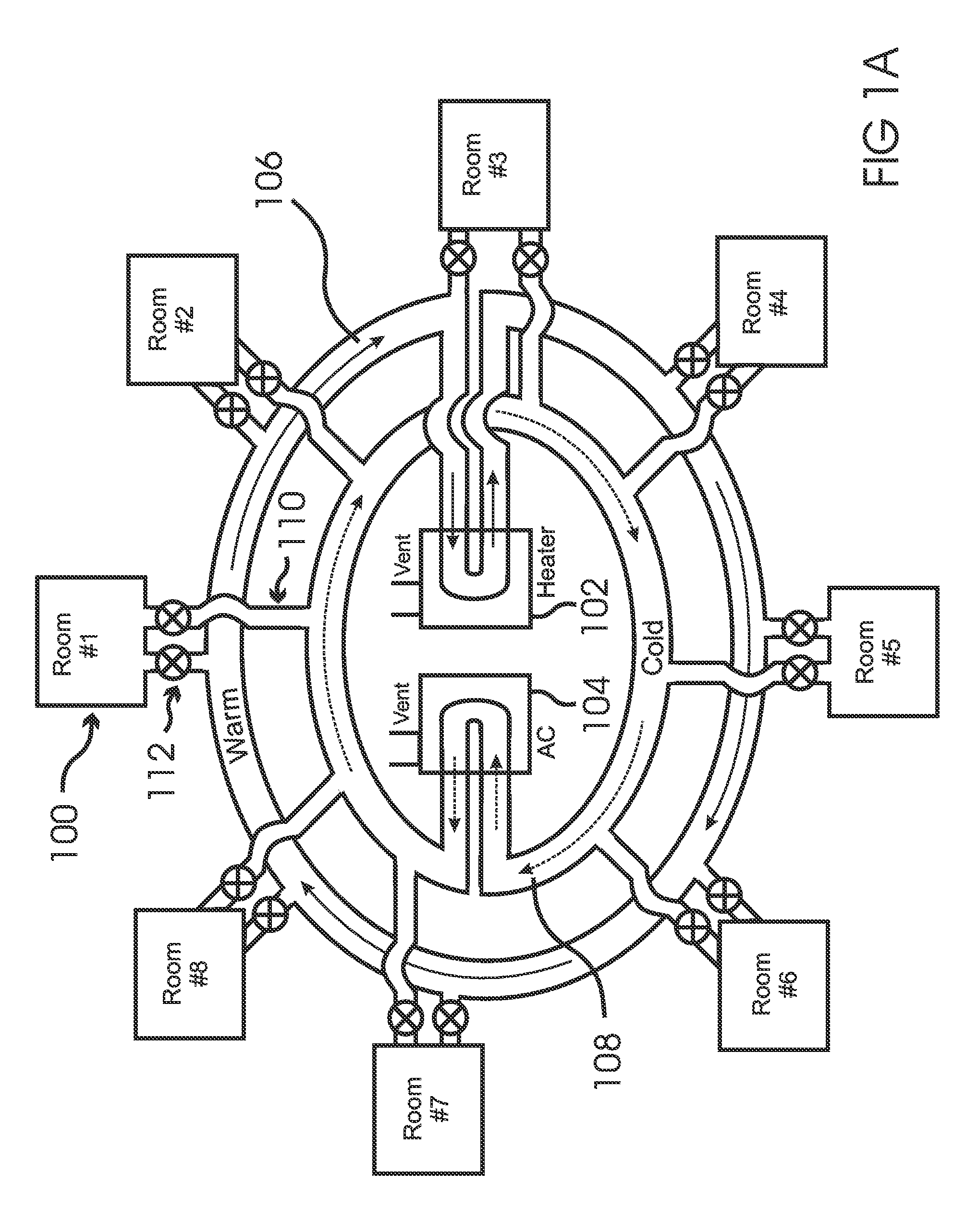

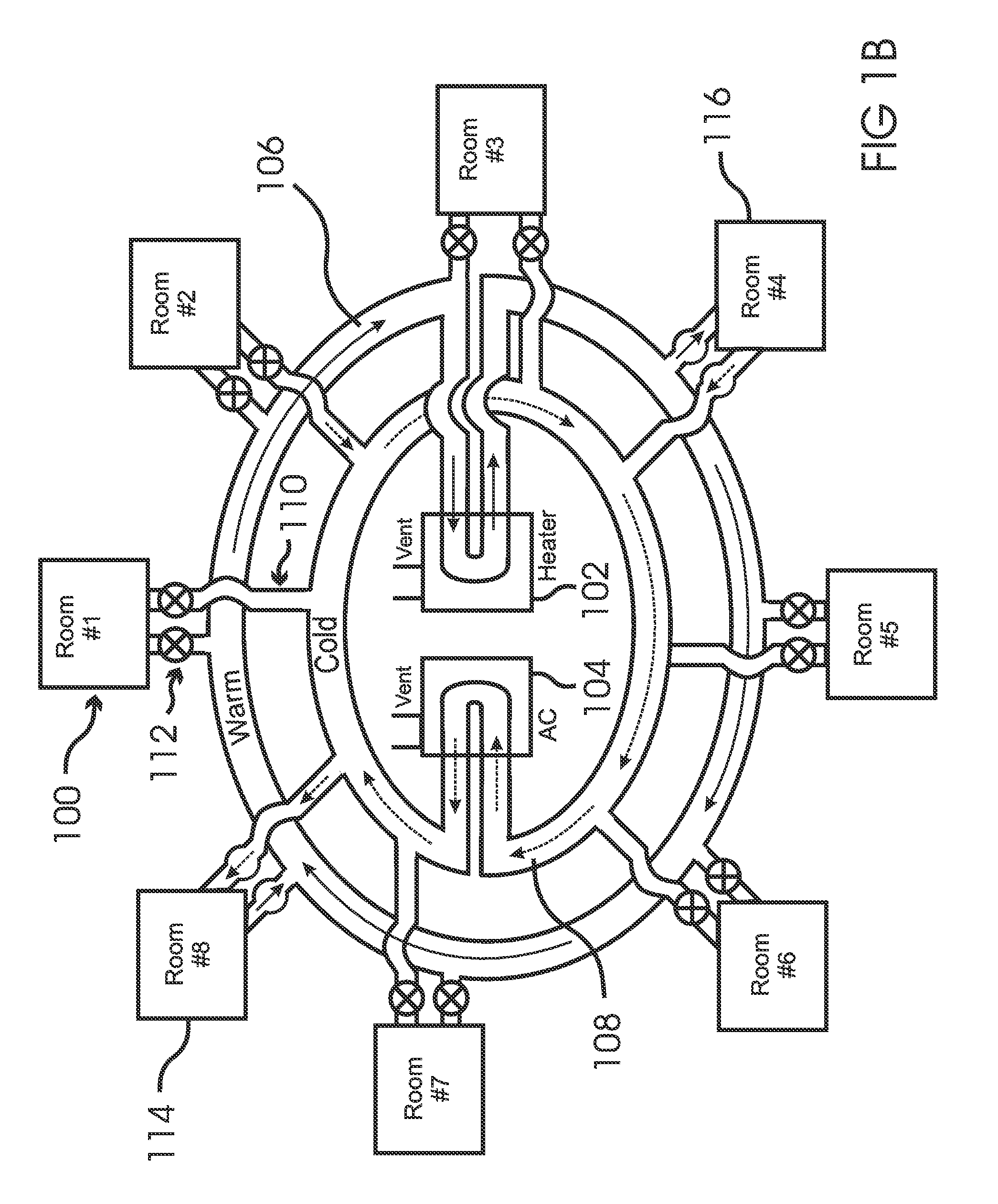

Apparatus and Method for Flexibly and Efficiently Varying Air Temperatures in Multiple Rooms

InactiveUS20090255997A1Maximize comfortEfficient and flexible and agileEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsEngineeringAir exchange

The invention enables coordinated, flexible, agile, and energy efficient temperature variation among a plurality of rooms, as found in a hotel, an apartment building, or a group of exercise rooms, by transferring heat between the rooms. Air can be moved by fans and / or heat can be transferred by a heat pump. Heat transfer between exercise rooms can be powered partly by exertion of individuals in the rooms. Rapid air exchange can quickly equalize temperatures in adjacent rooms. Embodiments exchange heat between rooms and interior and / or exterior reservoirs of warmer and cooler air and / or water, and some embodiments move air from the reservoirs into and out of the rooms. Heat can be pumped into or out of the system, and air and / or water can be added or extracted from the reservoirs. In some embodiments heat is moved sequentially through a variable series of rooms, creating a monotonic variation of temperatures.

Owner:GOLDMANN RICHARD DR

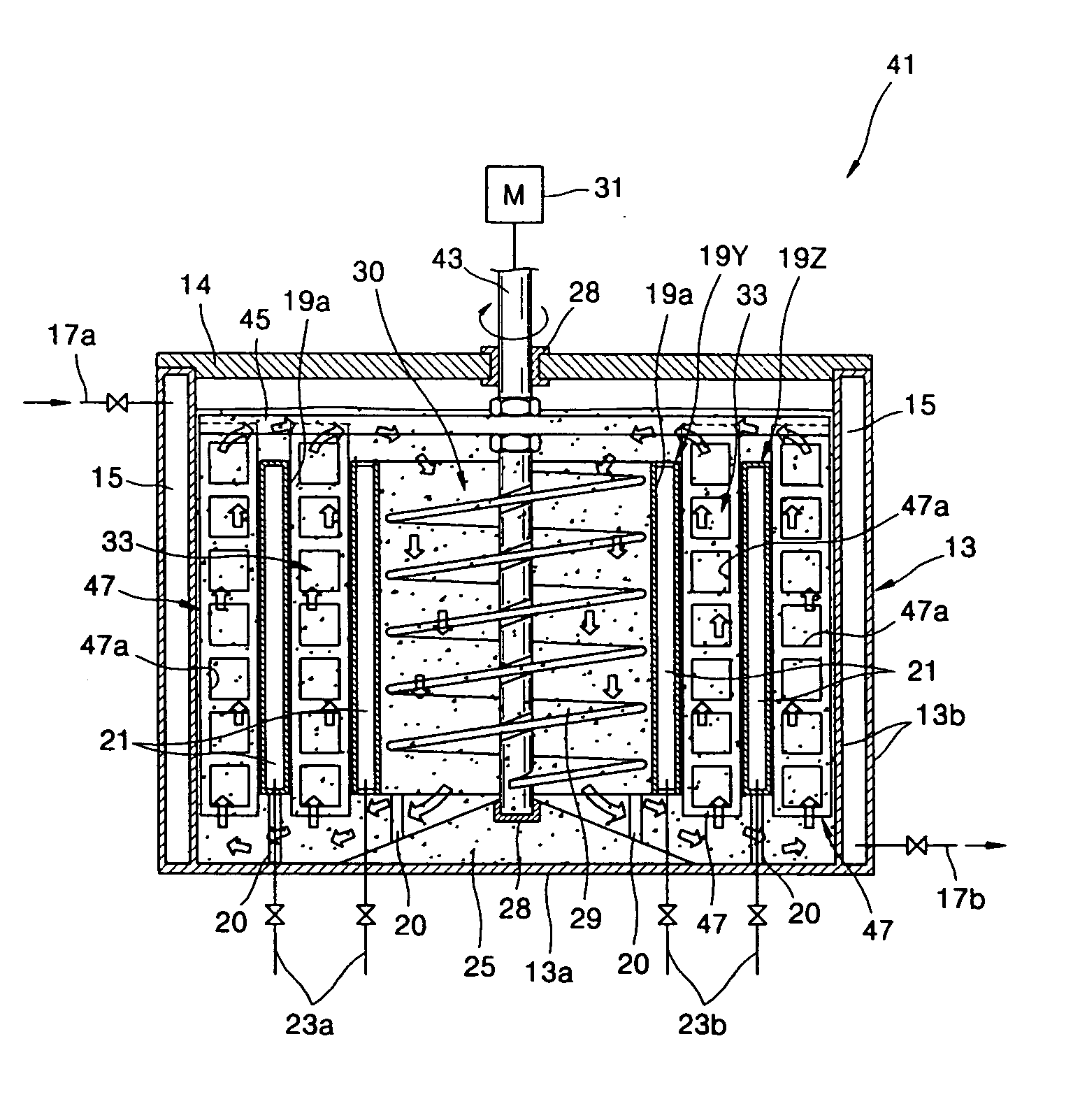

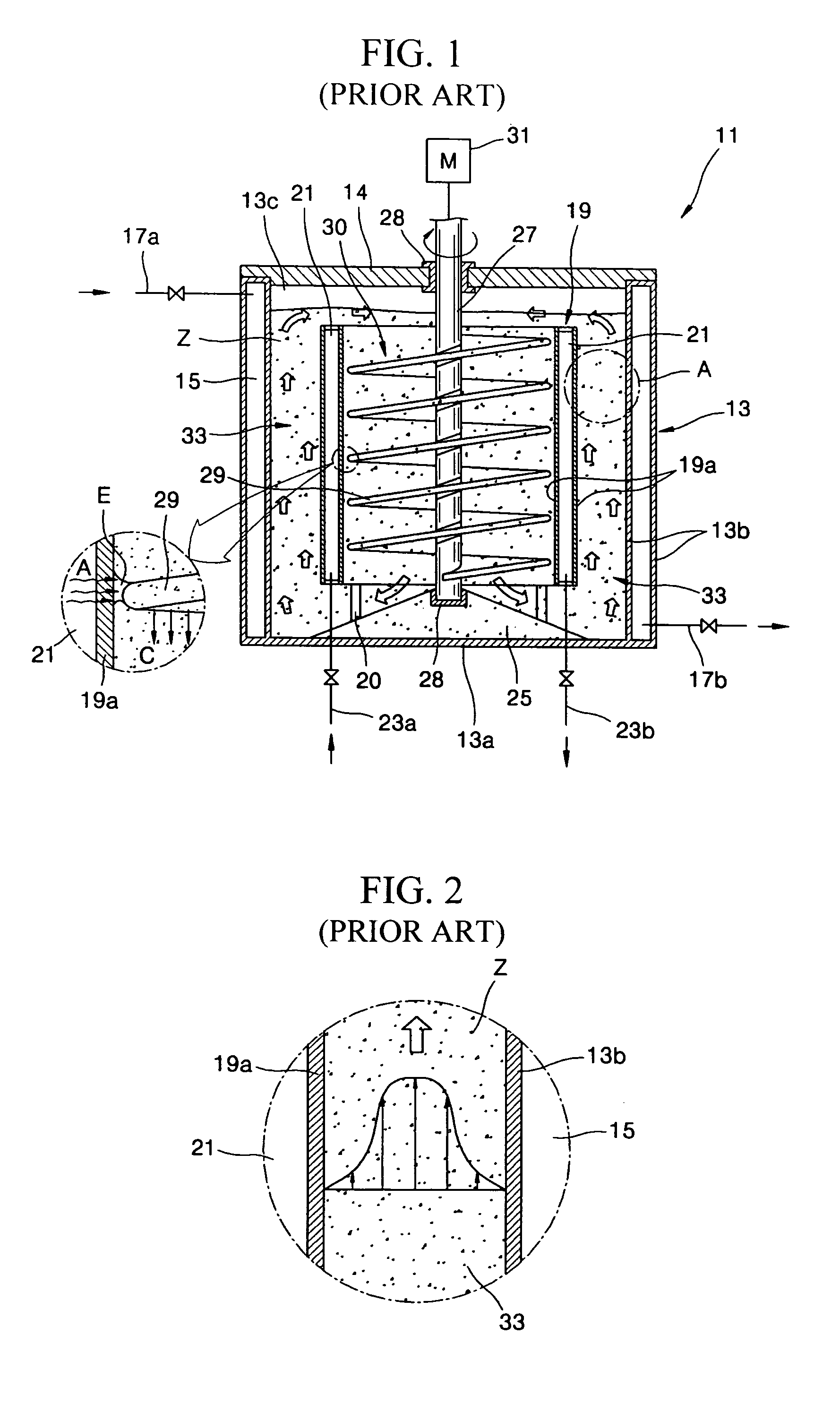

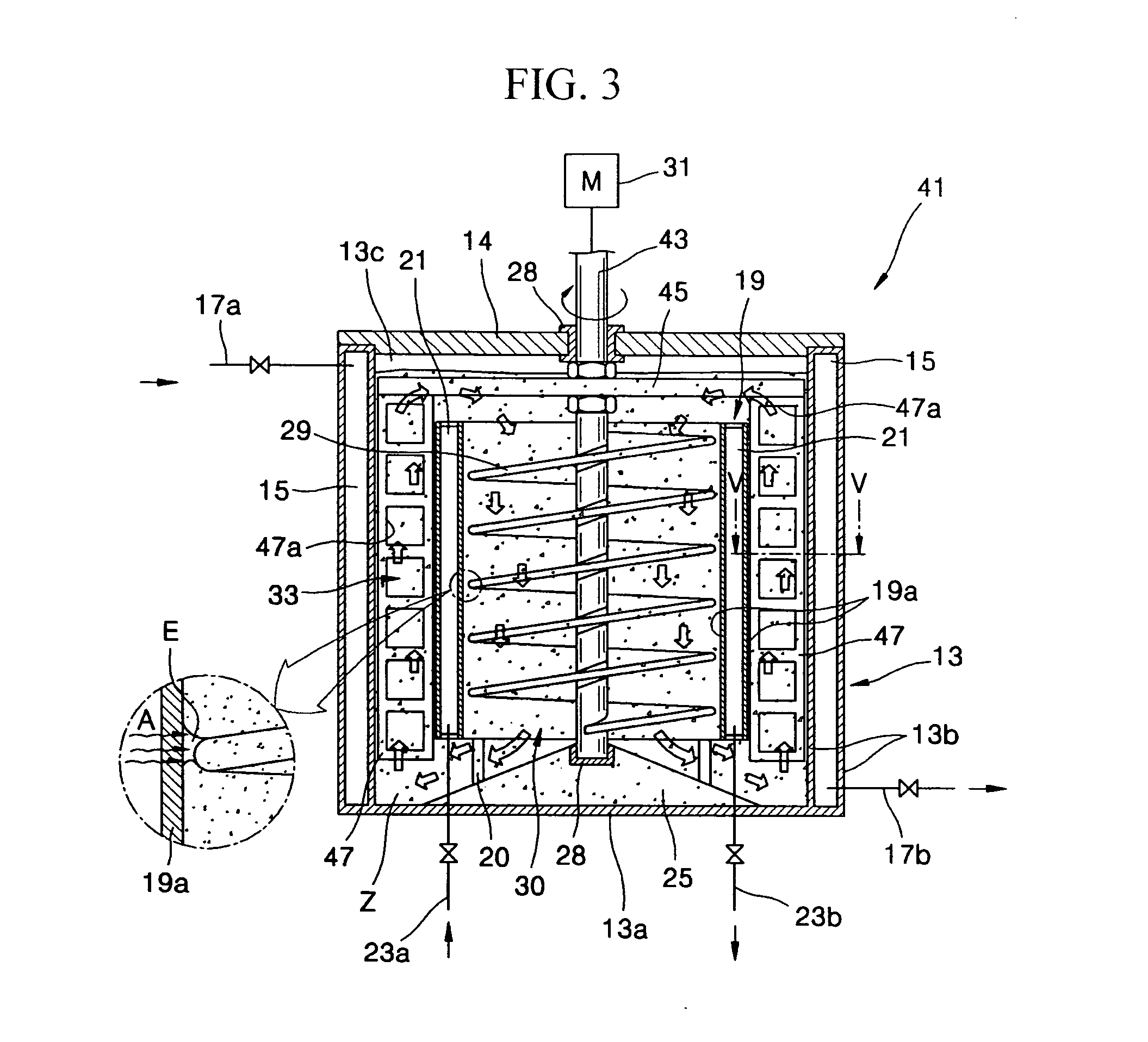

Apparatus for mixing viscous material

ActiveUS20070159919A1Promote heat exchangeConstant thickness and widthLiquid degasificationFlow mixersImpellerEngineering

An apparatus for mixing viscous material includes a chamber having a cylindrical sidewall and a bottom and receiving viscous material to be mixed; a cylindrical draft tube fixed at an inside center of the chamber to be spaced from the bottom and the sidewall and forming a space between the draft tube and the sidewall to allow passage of the viscous material, and including a heat medium passage therein; a carrying impeller installed in the draft tube and driven by a motor to transfer the viscous material above or below the draft tube and suck the viscous material in the space into the draft tube; and a sweeping impeller installed in the space and rotated in a circumferential direction by a motor to apply a pressure to the viscous material so that the viscous material in the space is not adhered to the draft tube and the sidewall.

Owner:LG CHEM LTD

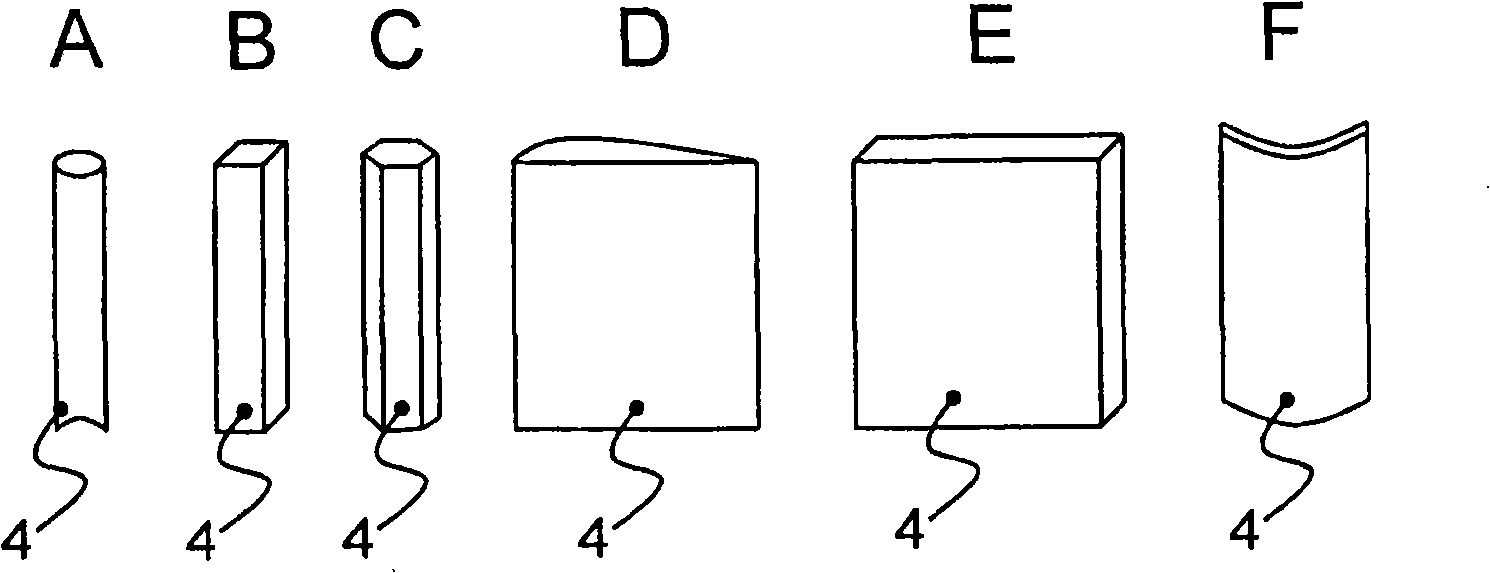

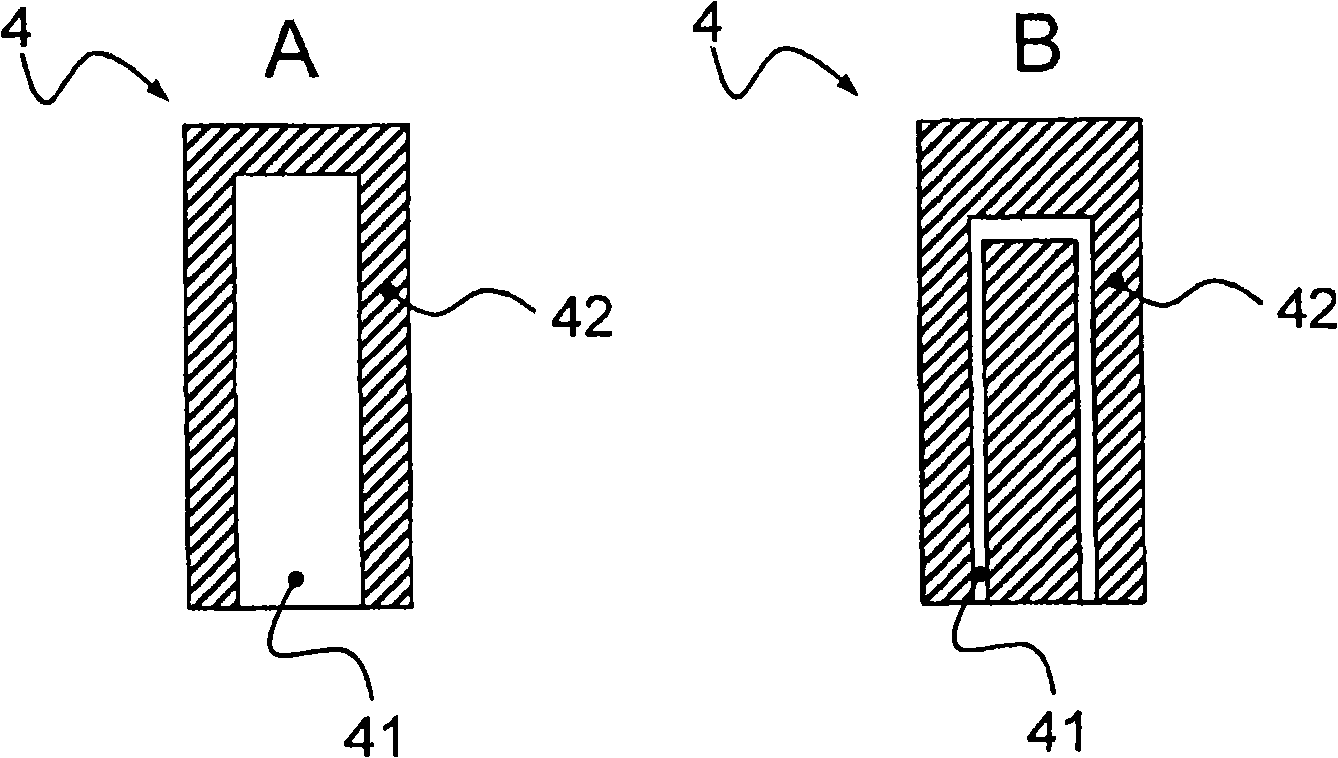

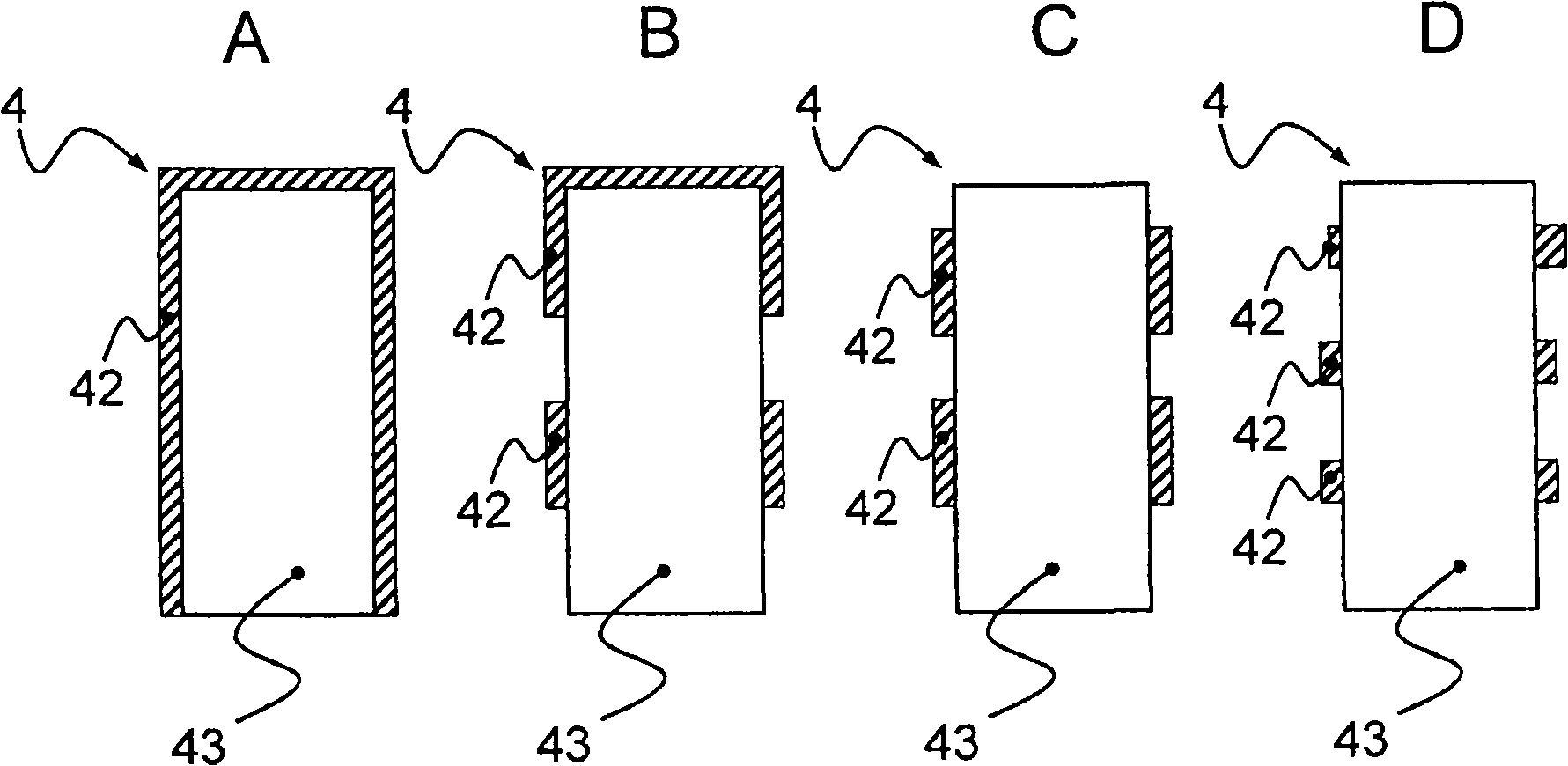

Method for temperature manipulation of a melt

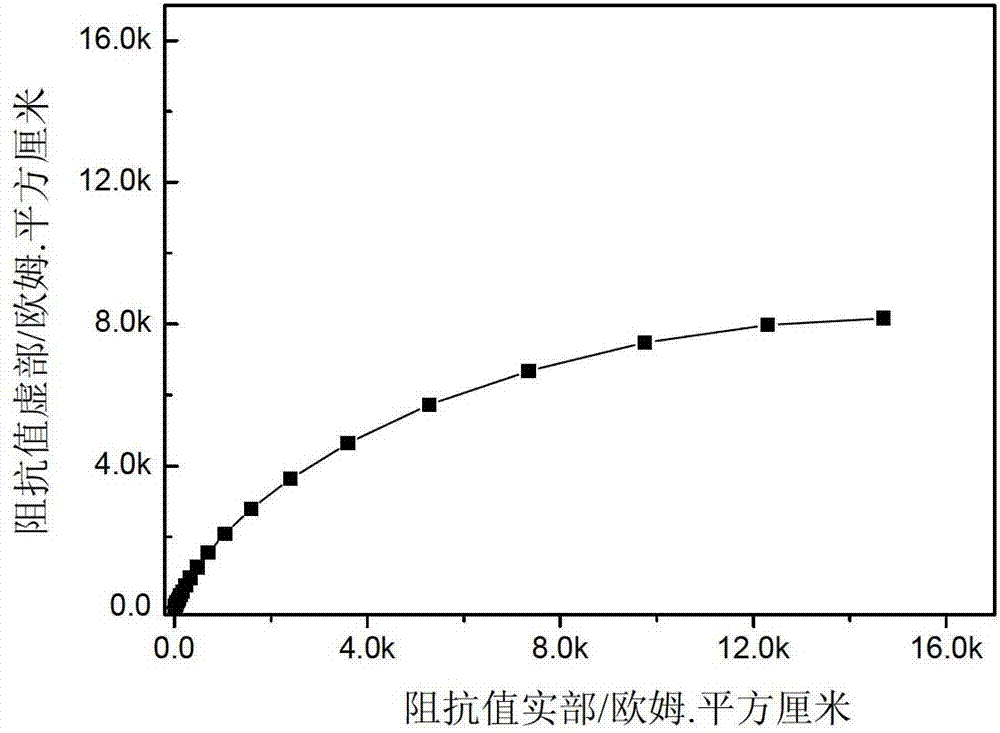

InactiveCN101405231AIncrease temperatureReduce the temperatureOhmic-resistance electrodesTank furnacesElectrical resistance and conductanceElectrical resistivity and conductivity

A method and device are disclosed for temperature manipulation of a melt even with conductivity below 10<-1> O <-1>cm<-1>, thus permitting refining of the melt at temperatures above 1700 DEG C. According to the method for temperature manipulation of a melt (16), in particular, in a refiner unit, the melt (16) is heated at least by ohmic resistance heating, at least two electrodes (4) are arranged in the melt (16) and at least a part of the melt (16) is cooled. The device (1) for temperature manipulation and / or refining and / or purification and / or homogenisation of a melt (16) comprises at least one arrangement for accommodating melt material (36, 16), defining an inner chamber and at least two electrodes (4) for ohmic resistance heating of the melt (16), wherein the electrodes (4) project into the inner chamber of the arrangement in particular of the vessel (2).

Owner:SCHOTT AG

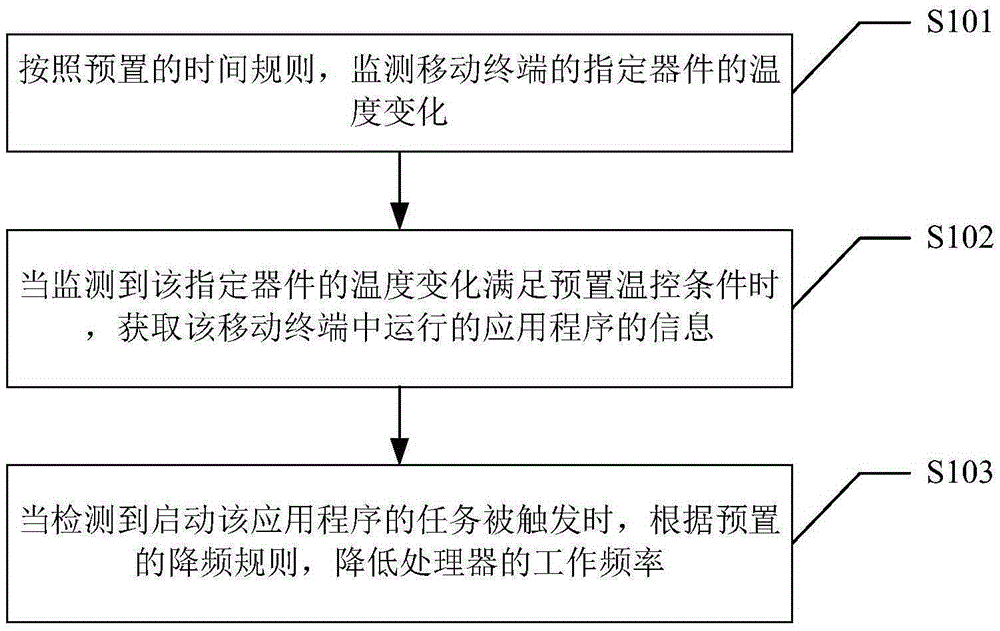

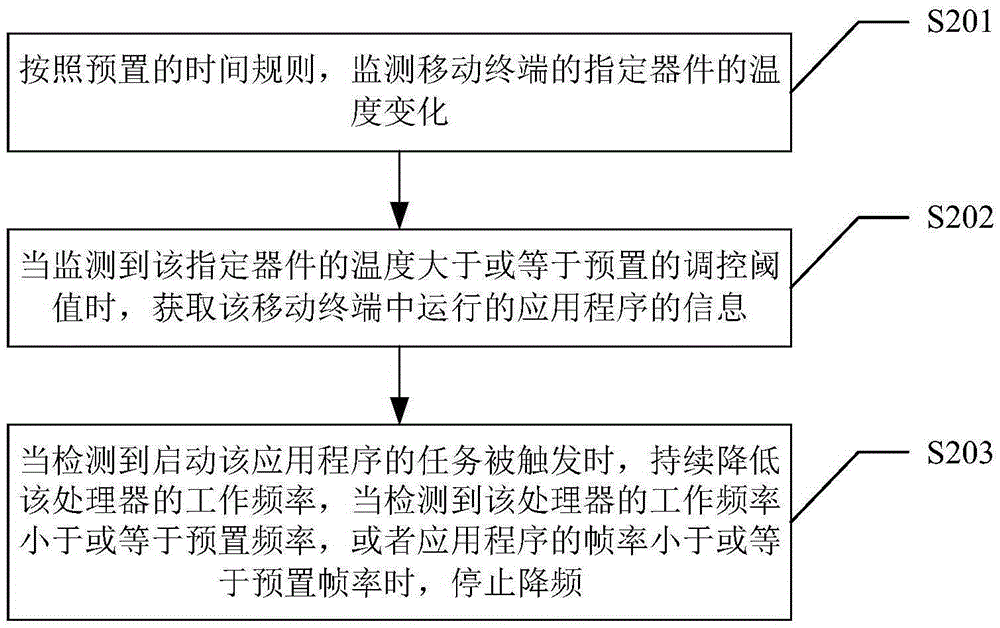

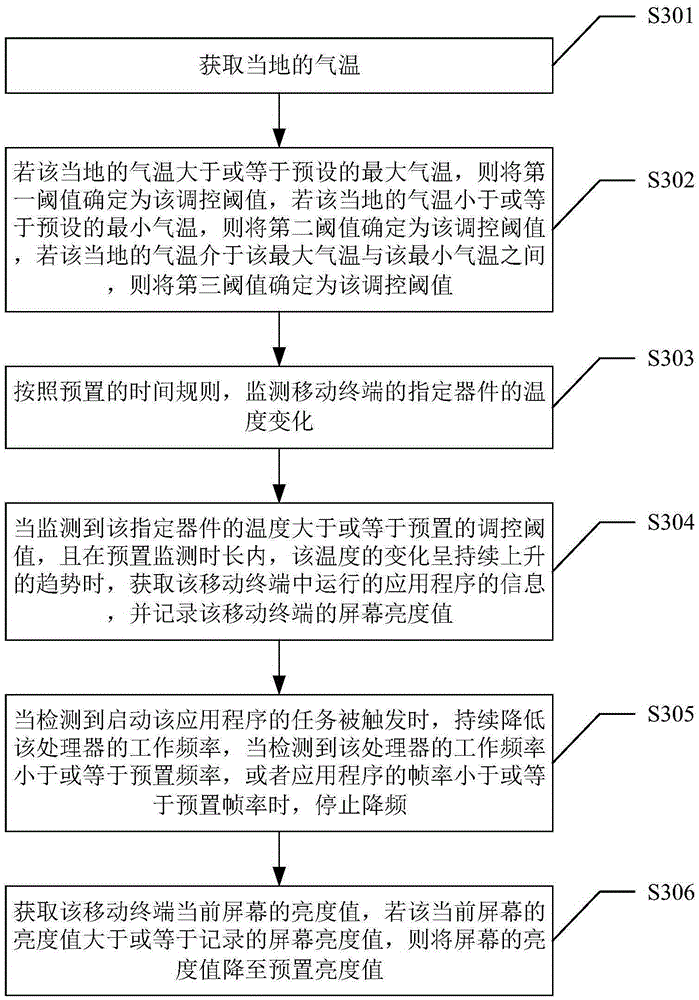

Processor temperature regulation method and apparatus

ActiveCN106557135AIncrease temperatureEffective temperature controlDigital data processing detailsAuxillary controllers with auxillary heating devicesTemperature controlOperating frequency

The present invention provides a processor temperature regulation method and apparatus. The method comprises: according to a preset time rule, monitoring a temperature change of a specified device of a mobile terminal; when it is monitored that the temperature change of the specified device meets a preset temperature control condition, acquiring information of an application that runs in the mobile terminal; and when it is detected that a task for starting the application is triggered, decreasing an operating frequency of a processor according to a preset down-conversion rule, so as to regulate a temperature of the processor. According to the method and apparatus provided by the present invention, before the application that can cause increase of the temperature of the processor is started, down-conversion processing is performed on the processor, so that the temperature of the processor can be effectively controlled.

Owner:BEIJING ERENEBEN INFORMATION TECH

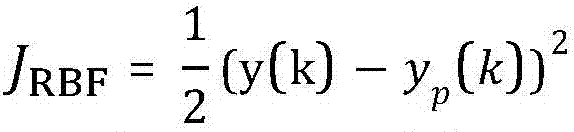

Nonlinear neural network optimizing PID control method for temperature of electric heating furnace

InactiveCN107045289ASolving Difficulties That Are Hard to BuildEffective temperature controlAdaptive controlControl systemControl engineering

The invention discloses a nonlinear neural network optimizing PID control method for the temperature of an electric heating furnace. An RBF neural network is trained offline according to historical input and output information of an electric heating furnace control system, neural network related parameters are obtained, and a trained neural network serves as a prediction model of the system; and the RBF neural network is combined with the PID controller, and the RBF neural network is used to self-set the parameters of the PID controller online. Thus, the difficulty in establishing a nonlinear electric heating furnace model is overcome, the RBF neural network is used to self-set the parameters of the PID controller, and the problem that the electric heating furnace control system is hard to set the parameters of the PID controller in the practical control process is solved.

Owner:HANGZHOU DIANZI UNIV

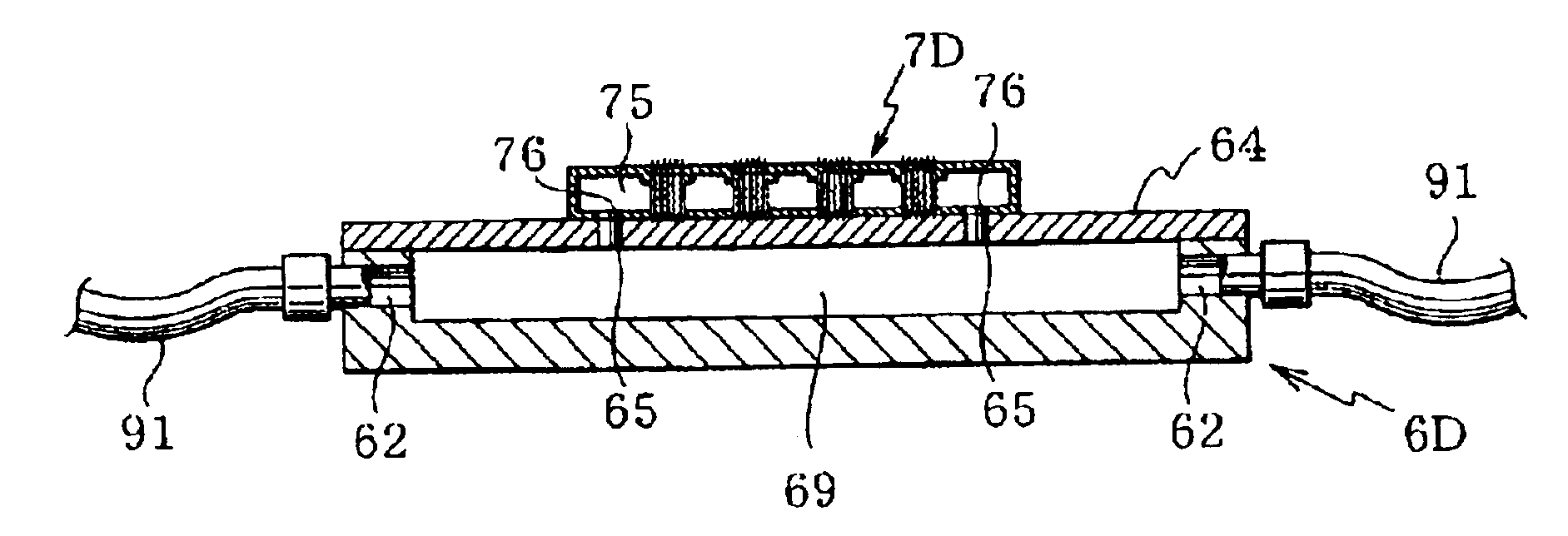

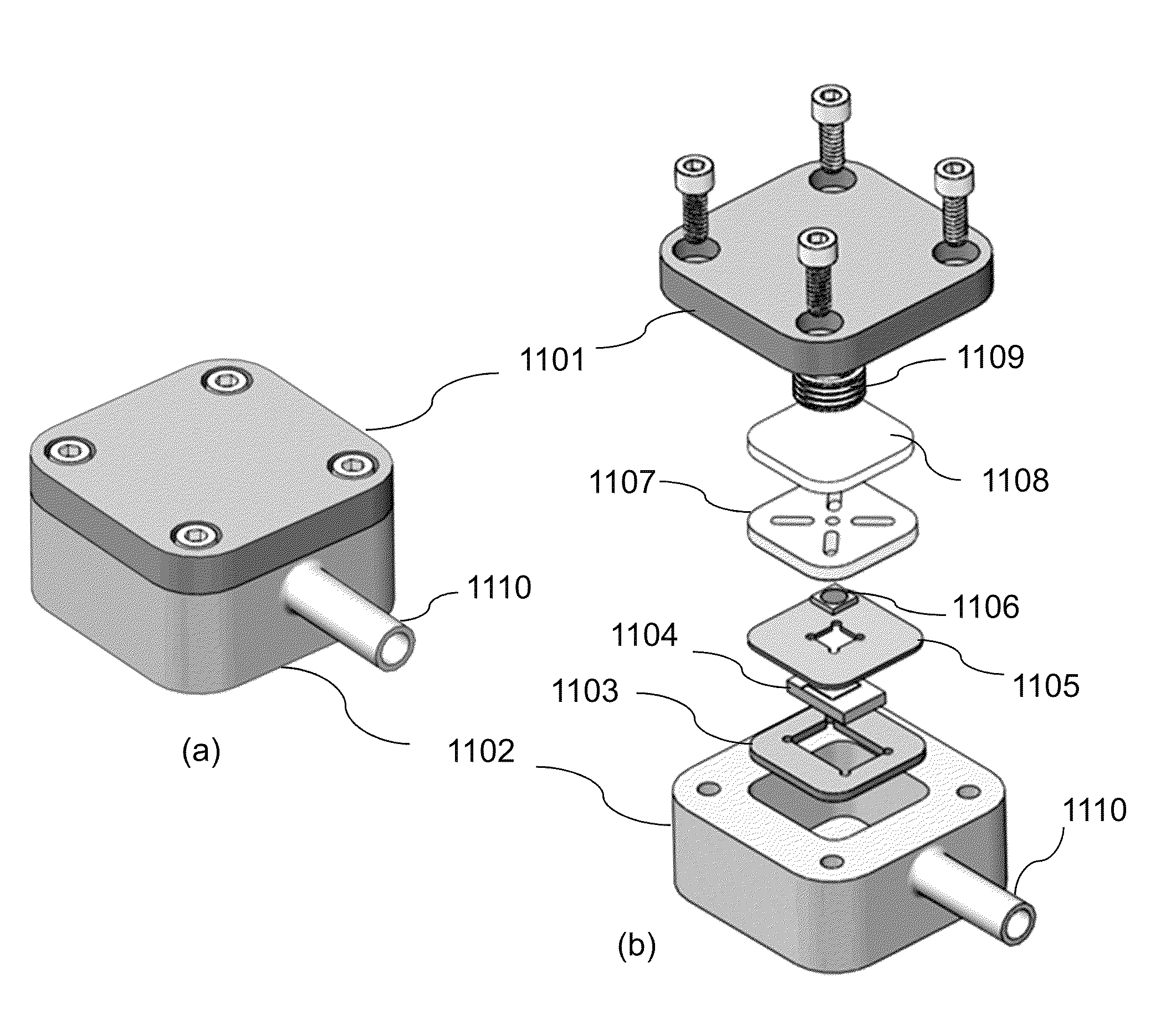

Electronic component testing socket and electronic component testing apparatus using the same

InactiveUS6932635B2Effective temperature controlEasy to controlCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringElectronic component

To control the temperature of an electronic component testing socket without mixing any noise into a test signal to be applied to an electronic component and a respond signal to be read from the electronic component when conducting a test on the electronic component, a first space 67 in the electronic component testing socket base 6 and a socket body inside space 75 in the electronic component testing socket 7 are connected via a gas outlet 65 and a gas inlet 76, and a second space 68 in the electronic component testing socket base 6 and a socket body inside space 75 in the electronic component testing socket 7 are connected via a gas inlet 66 and a gas outlet 77.

Owner:ADVANTEST CORP

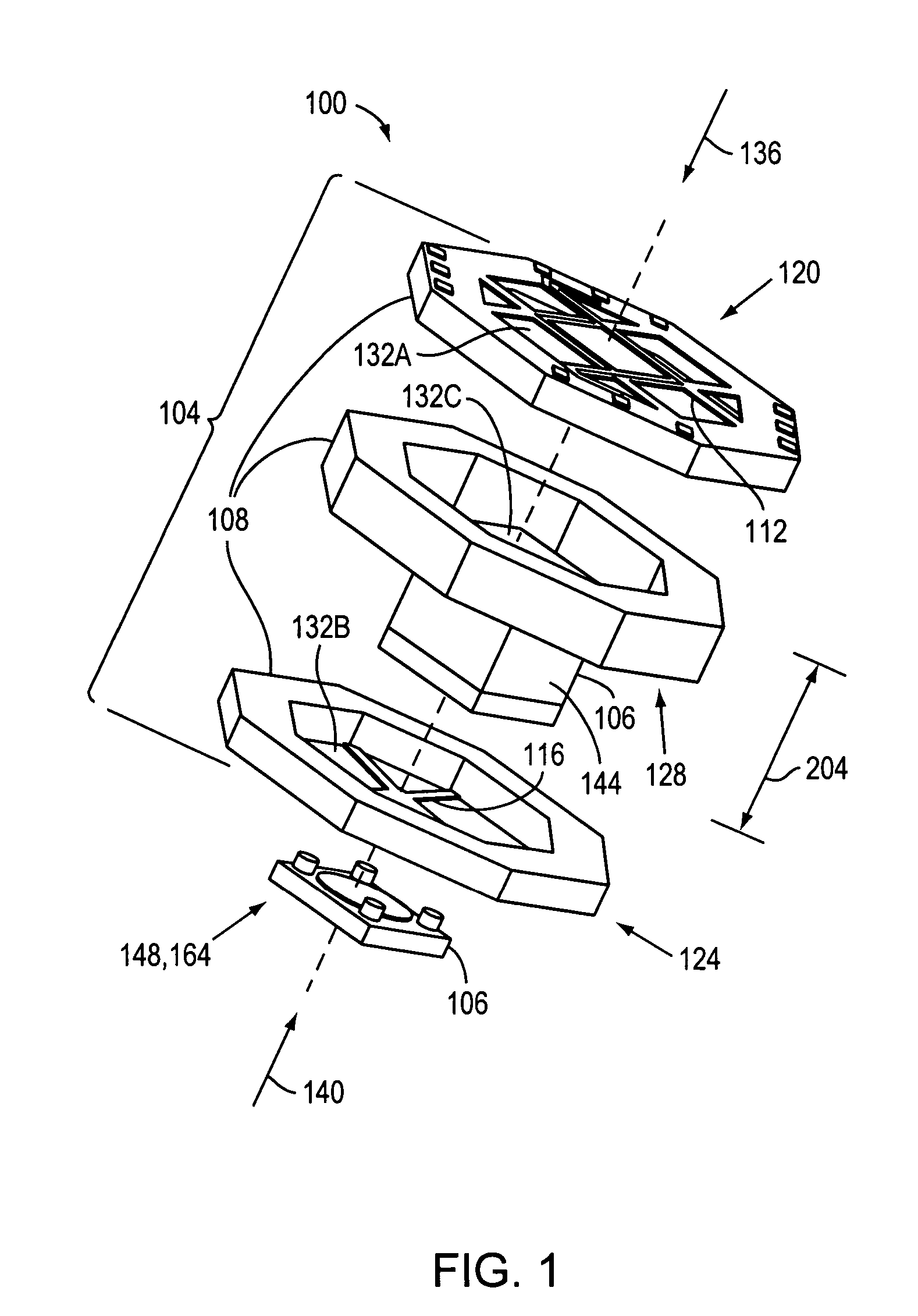

VCSEL packaging

ActiveUS9038883B2Improve performanceEffective temperature controlLaser detailsFinal product manufactureOptical ModuleBonding process

A process to bond VCSEL arrays to submounts and printed circuit boards is provided. The process is particularly suited to large area thin and ultra-thin VCSEL arrays susceptible to bending and warping. The process integrates a flatness measurement step and applying appropriate combination of pressure prior to bonding the VCSEL array to the submount or a printed circuit using a vacuum flux-less bonding process. The process is very promising in making very good quality bonding between the VCSEL array and a submount or a printed circuit board. The process is applied to construct optical modules with improved flatness that may be integrated with other electronic components in constructing optoelectronic systems.

Owner:PRINCETON OPTRONICS

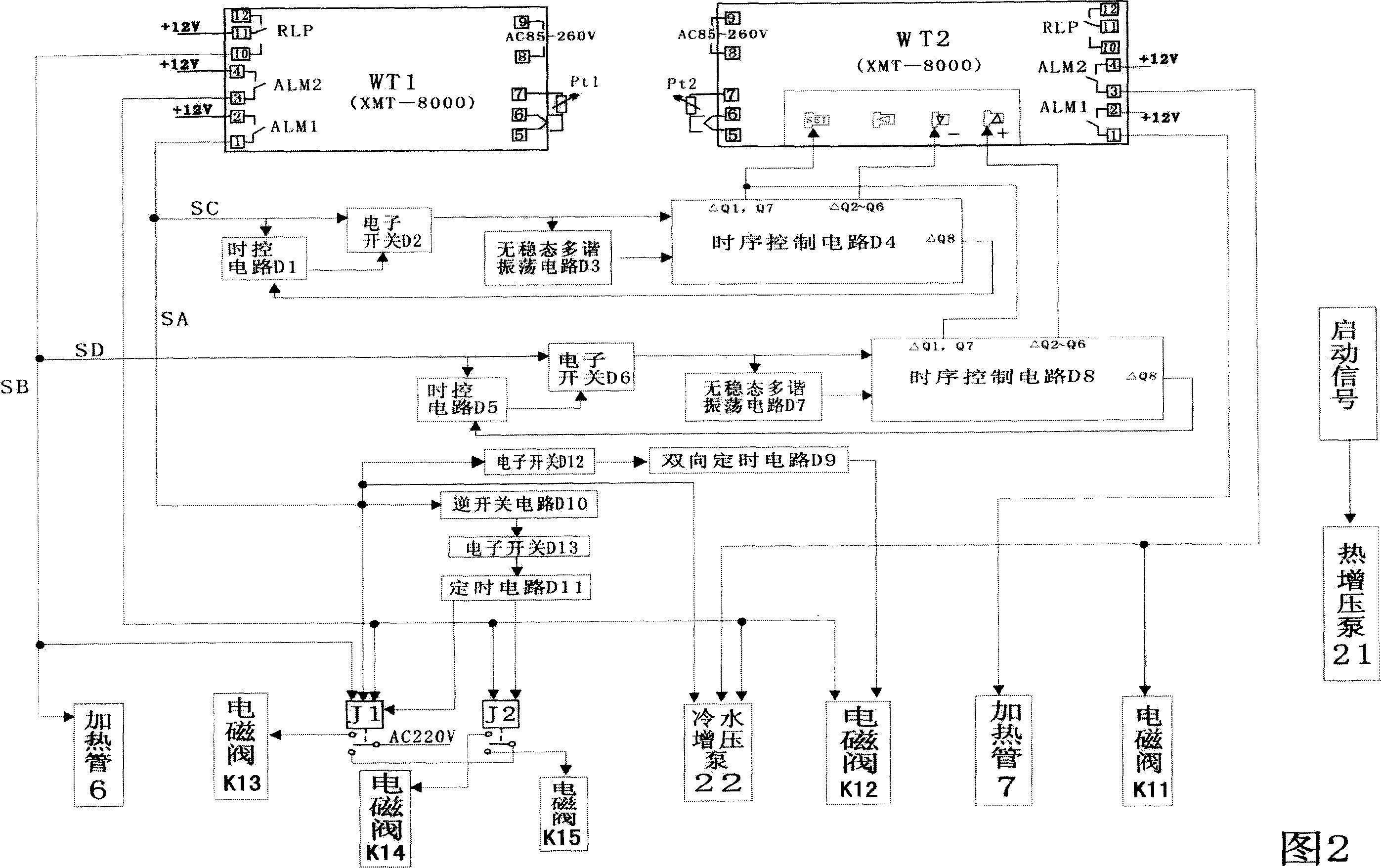

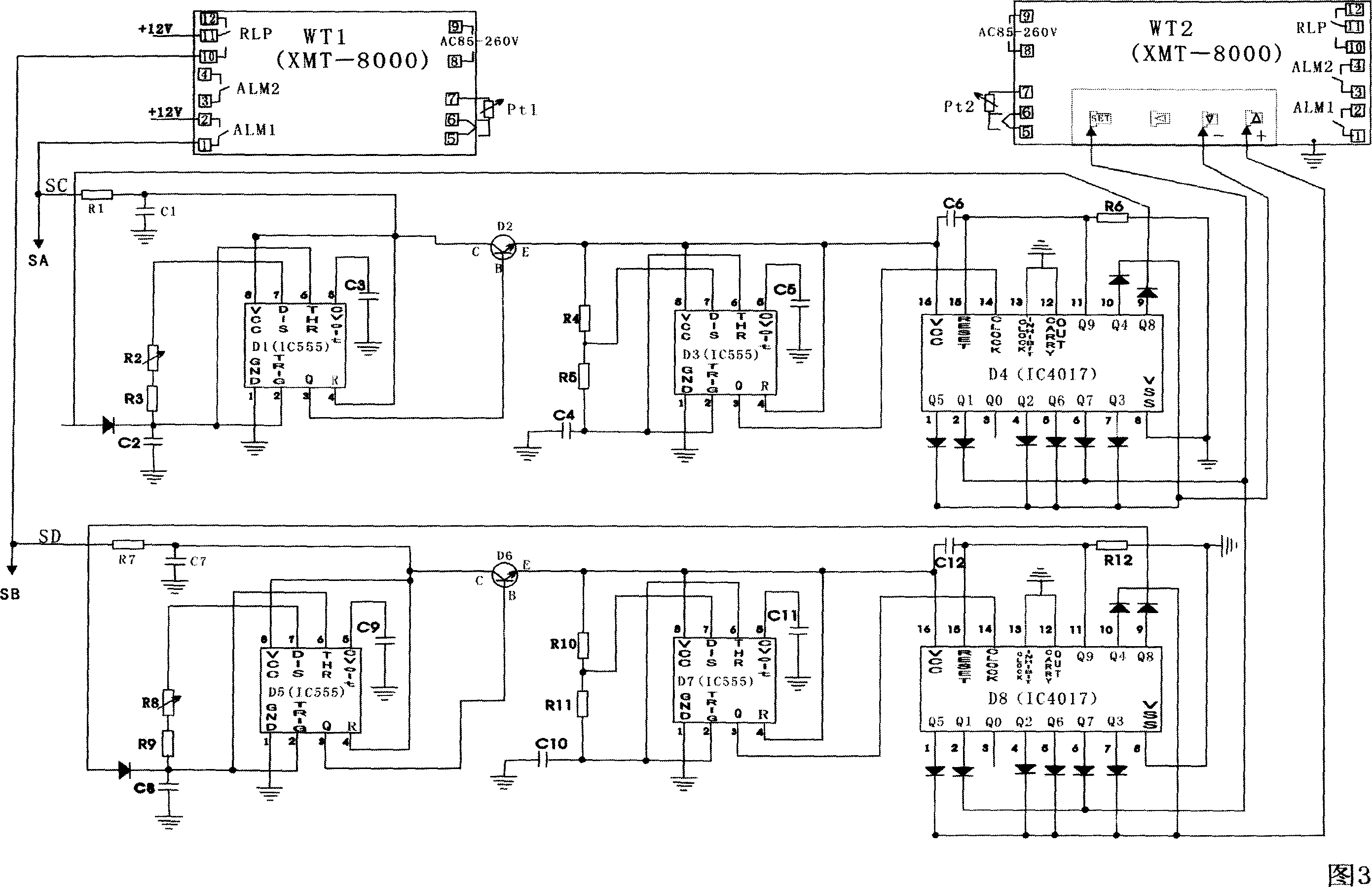

Automatic temperature control apparatus of mould

InactiveCN101013327ATemperature controlEffective temperature controlTemperature control with auxillary non-electric powerTemperature control using electric meansTemperature controlAutomatic control

The invention relates to the mold temperature control system, particularly a mold temperature automatic control device, which includes the heating circulation system, the cooling circulation system, and the operation working water tank circulation system, the output of the water tank temperature control device in the operation working water tank circulation system respectively connecting with the water tank cold compensation conditioning system and heating pipe control terminal, and the input connecting with the output of the temperature sensor in the water tank, the control end connecting with the output of the temperature sensor in the mold. Its purpose is to design the mold temperature automatic control device, which can effectively control the mold temperature, and avoid the mold temperature overshoot when the mold in the heating or cooling. Compared with the existing technology, it has the advantages of automatic mold temperature control, accurate control range, saving working, saving time, saving material, and saving energy.

Owner:李小卿

Optical beam steering for tunable laser applications

Owner:II VI DELAWARE INC

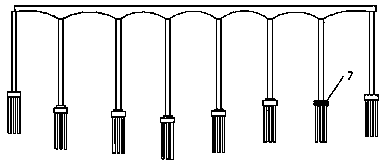

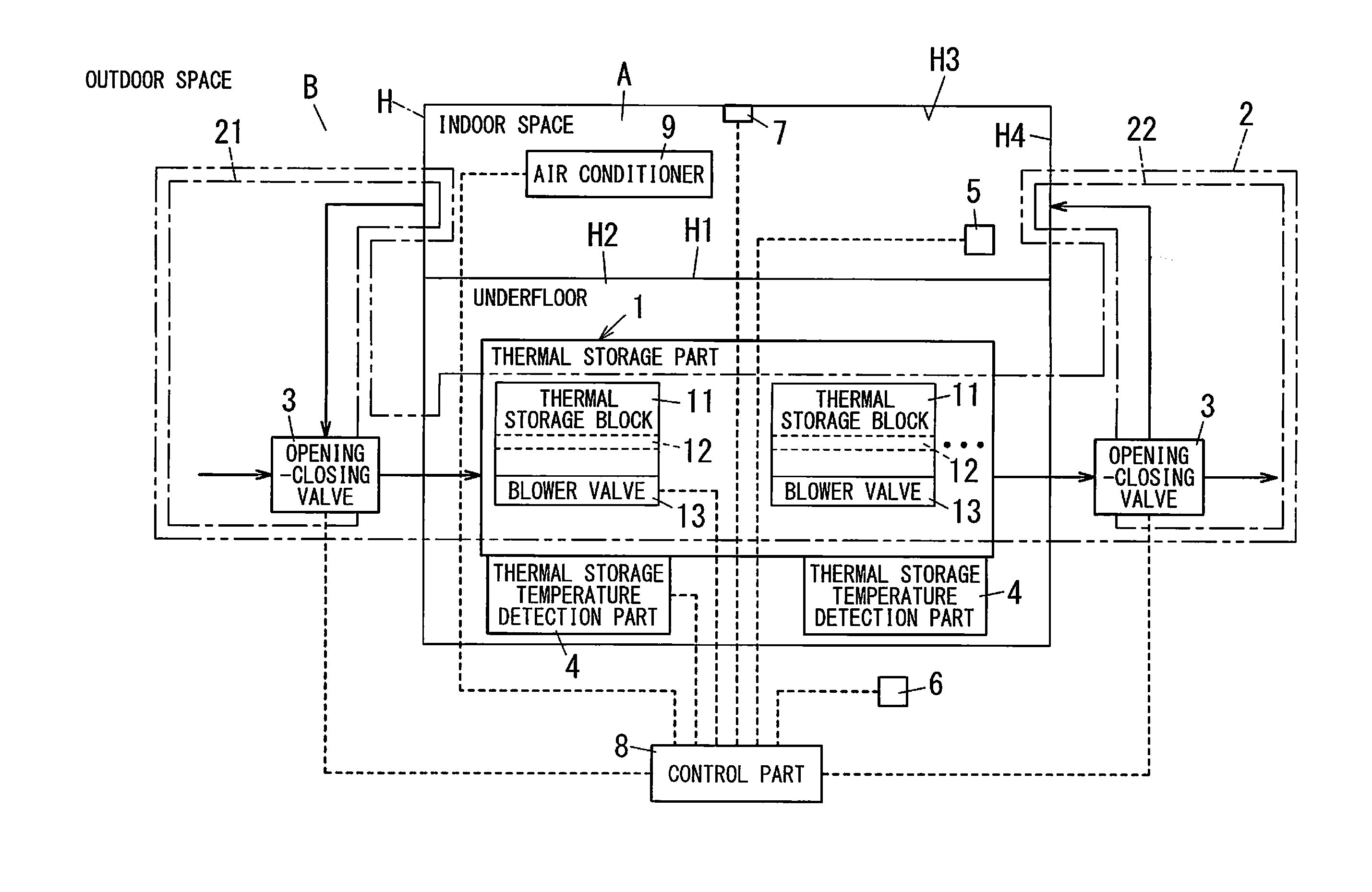

Thermal storage control system and thermal storage body used in same

InactiveUS20150276234A1Effective temperature controlEffective controlHot-air central heatingCentral heating with accumulated heatControl systemEngineering

The thermal storage control system includes a plurality of thermal storage, a ventilation pathway, a plurality of opening-closing members, and a control part. The plurality of thermal storage bodies are each provided with ventilation holes. The ventilation pathway is formed to include the ventilation holes and has a plurality of pathways from a first end to a second end so that air passes from the first end to the second end. The plurality of opening-closing members is configured to open or close the ventilation pathway. The control part is configured to individually switch control the plurality of opening-closing members. The control part is configured to switch a pathway through which an indoor air passes in the ventilation pathway by individually controlling opening and closing of the plurality of opening-closing members based on temperature of each thermal storage body and temperature of the indoor air.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

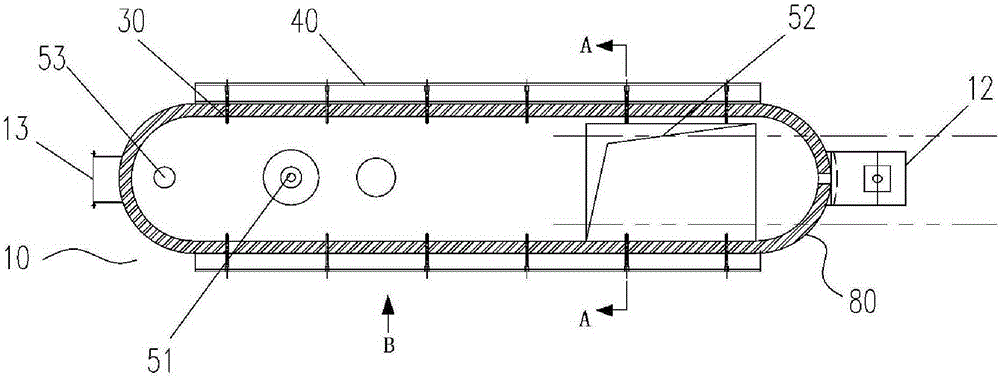

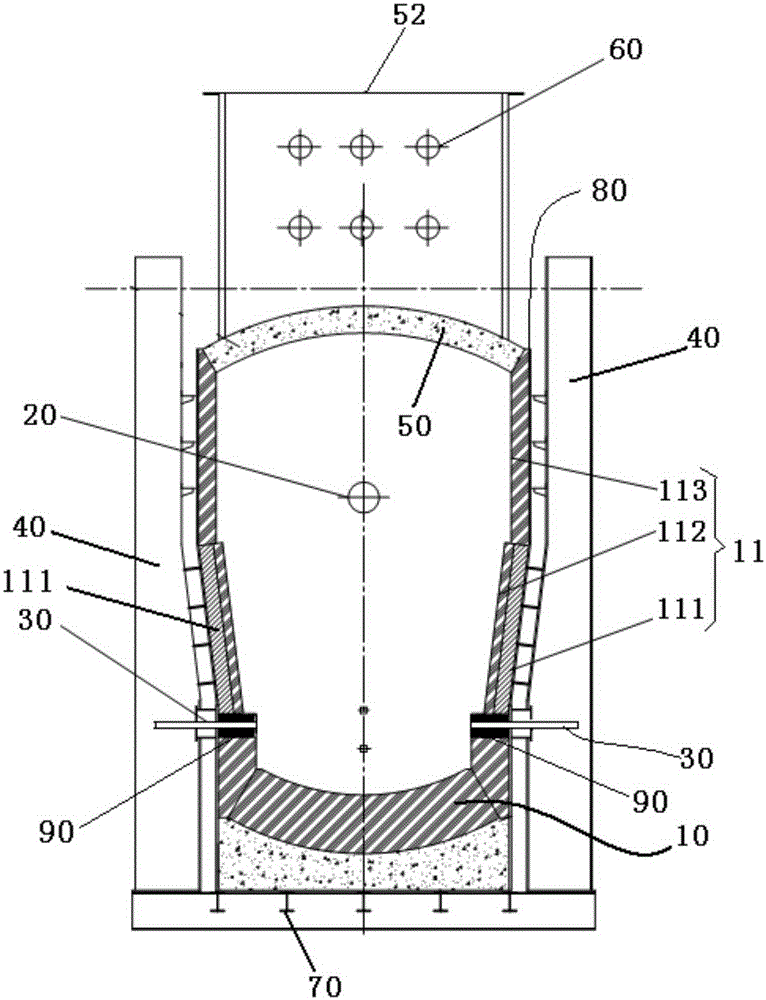

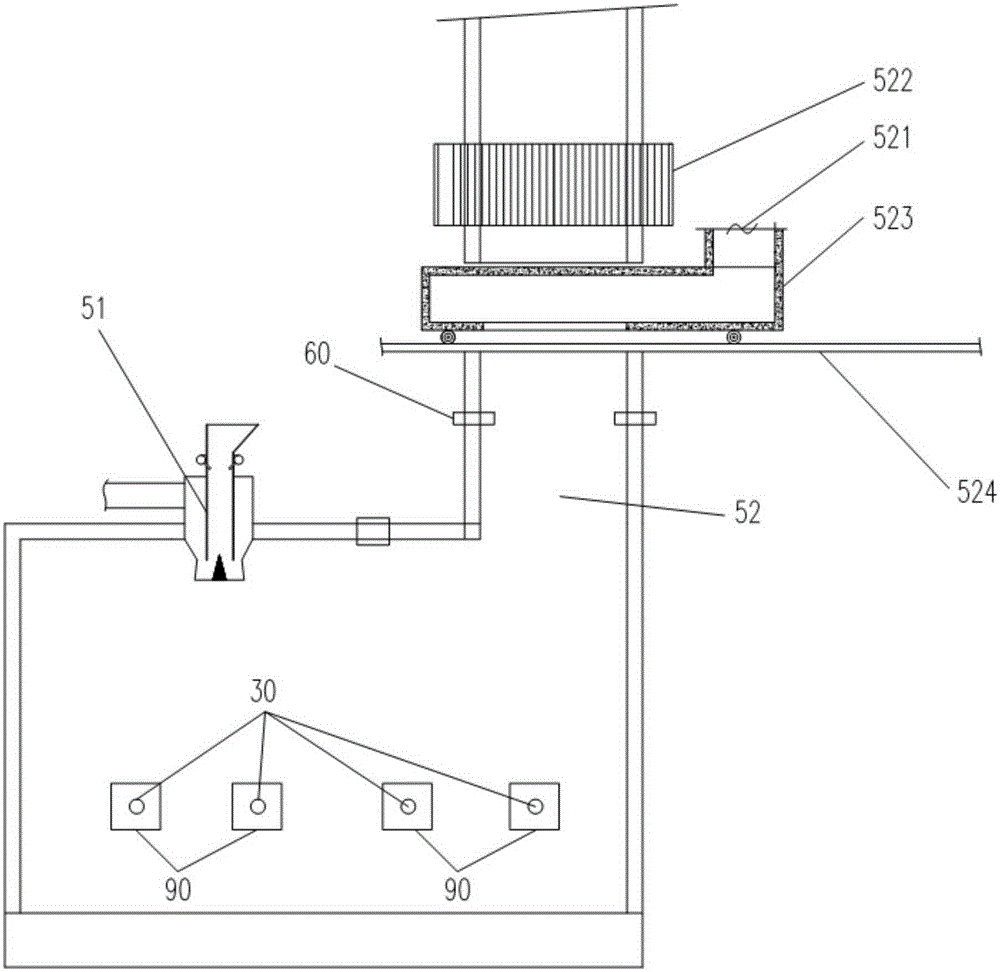

Improved type side-blowing molten pool smelting furnace

ActiveCN105698529ADry fastSpeed up decompositionIncreasing energy efficiencyCrucible furnacesSlagStraight segment

The invention provides an improved type side-blowing molten pool smelting furnace. The improved type side-blowing molten pool smelting furnace comprises a long round furnace body, a furnace cylinder, a furnace top, a furnace body frame structure and a plurality of multi-channel spray guns. The multi-channel spray guns are arranged on the two sides of the long round furnace body correspondingly. The long round furnace body is formed by a furnace body protective plate in an enclosed mode. A water sleeve is installed on the lower portion of the inner side of the furnace body protective plate. A first firebrick layer is further inlayed in the inner side of the water sleeve. A second firebrick layer is arranged on the water sleeve and the first firebrick layer and installed on the inner side of the furnace body protective plate. The furnace cylinder is arranged at the bottom of the long round furnace body. The long round furnace body is provided with a metal discharge outlet and a slag outlet. The furnace body frame structure comprises steel vertical pillars, cross beams and pulling rods. The multi-channel spray guns are arranged on the two sides of the middle straight segment of the long round furnace body, and the output ends of the multiple multi-channel spray guns extend into the long round furnace body. By means of the improved type side-blowing molten pool smelting furnace, the problem that in the prior art, the temperature in a molten pool smelting furnace is difficult to control can be solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com