Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Firebrick layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

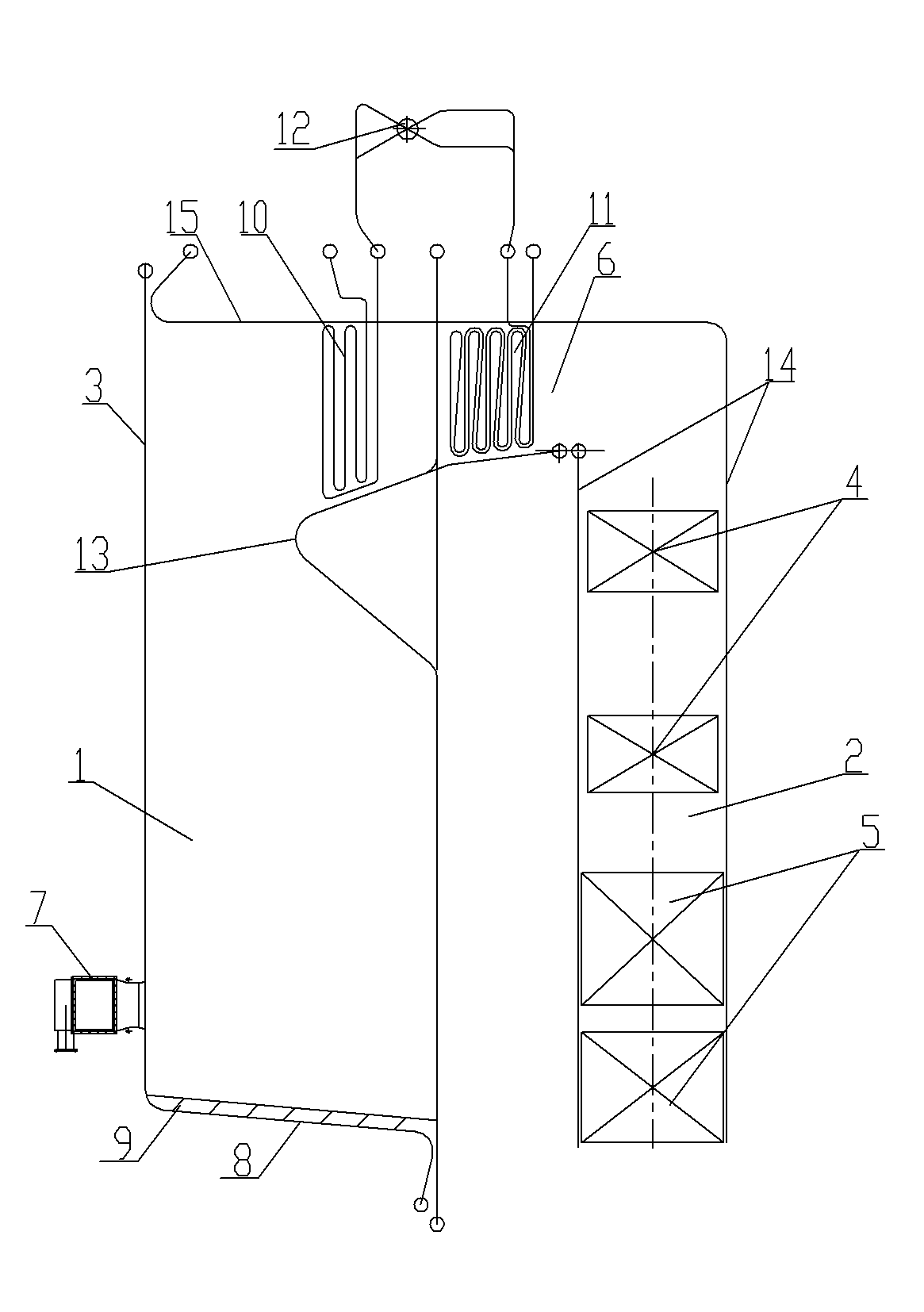

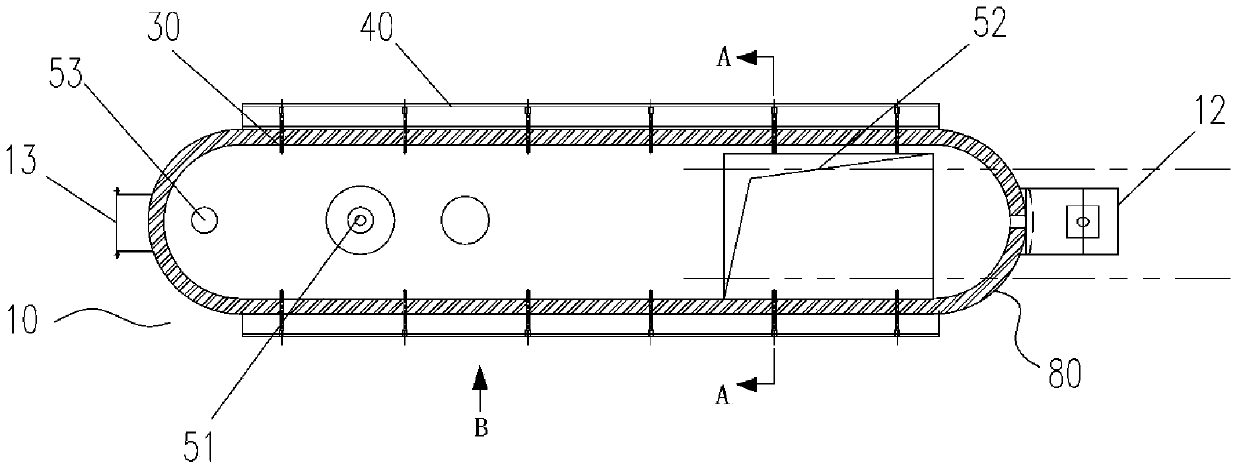

Improved type side-blowing molten pool smelting furnace

ActiveCN105698529ADry fastSpeed up decompositionIncreasing energy efficiencyCrucible furnacesSlagStraight segment

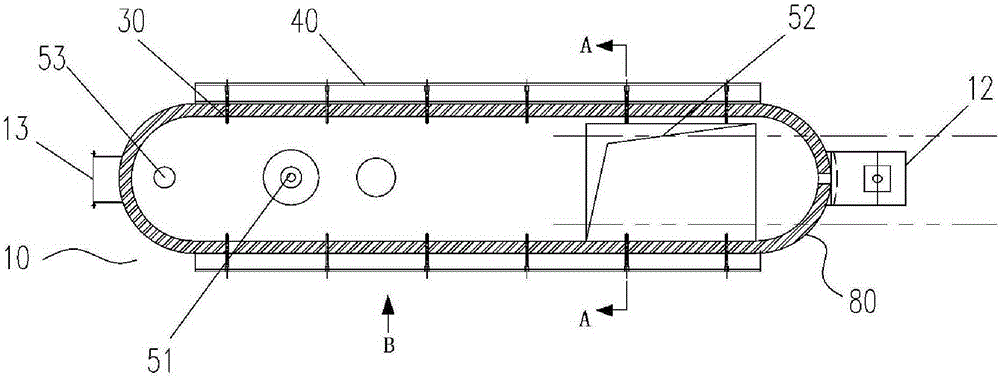

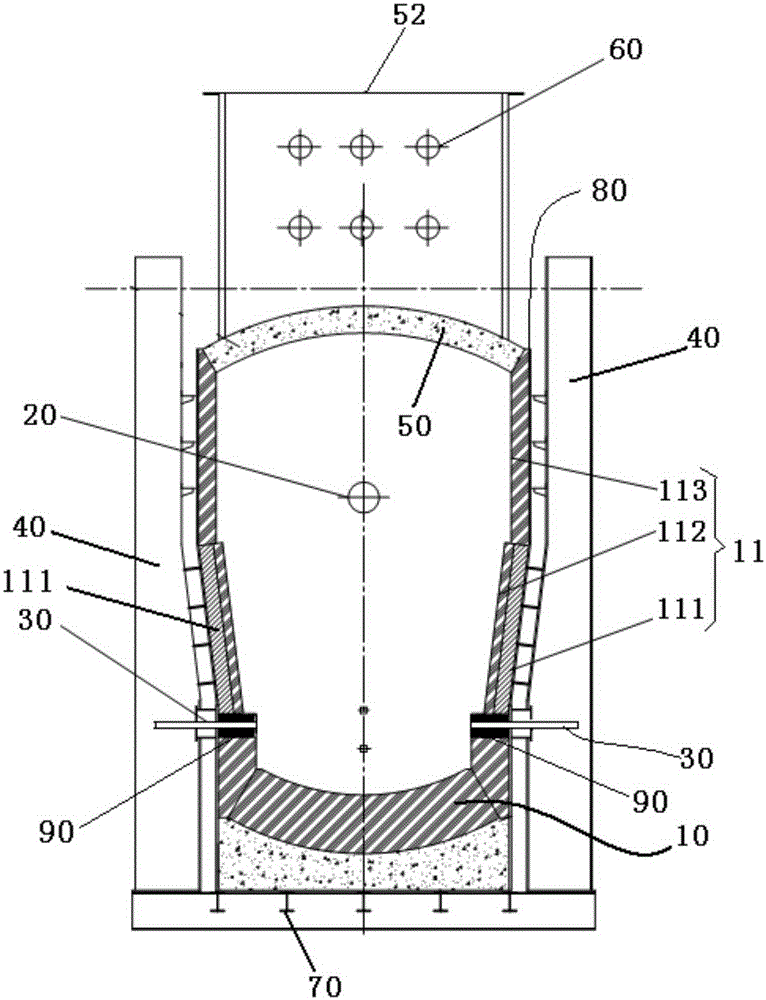

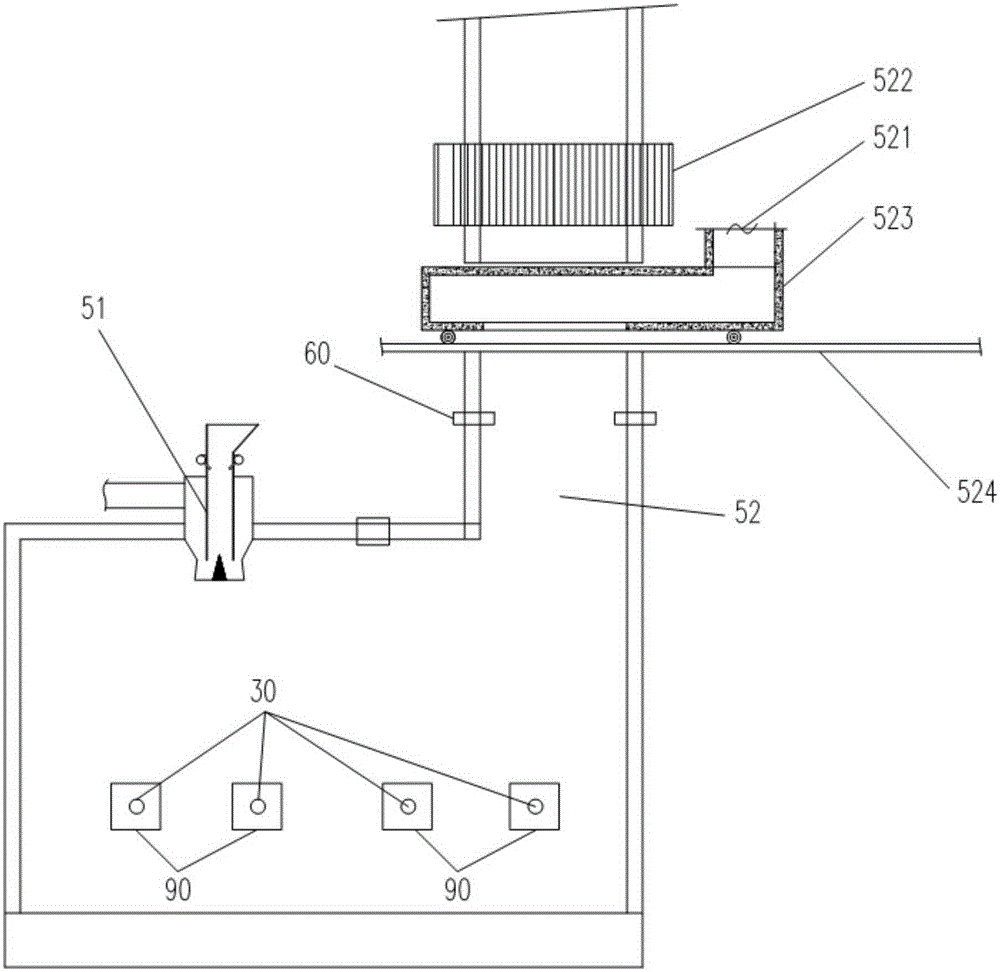

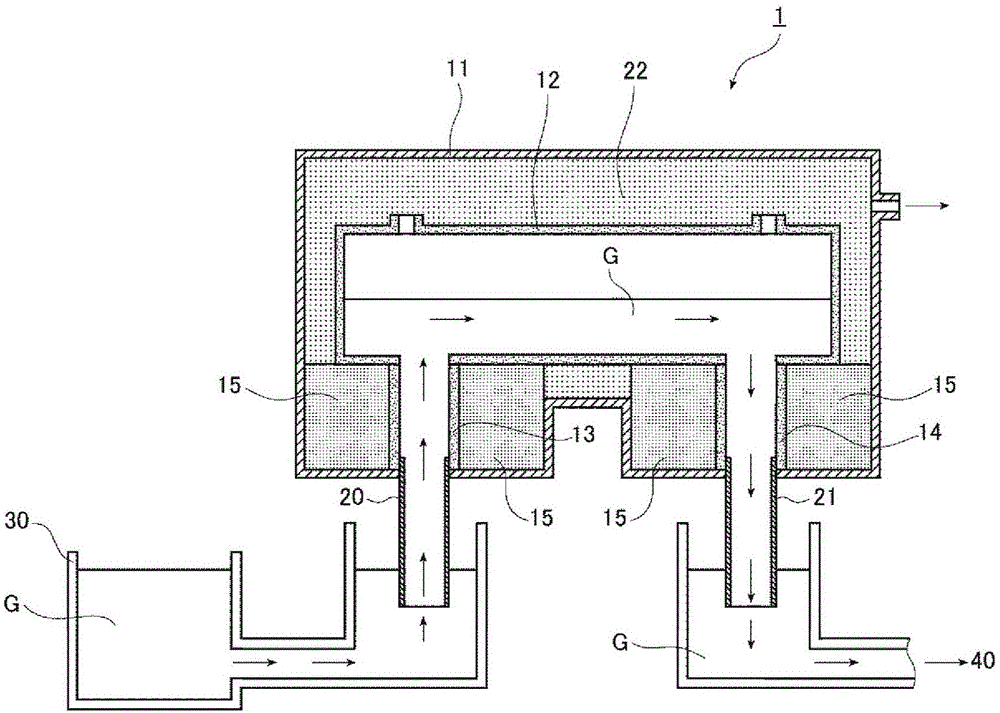

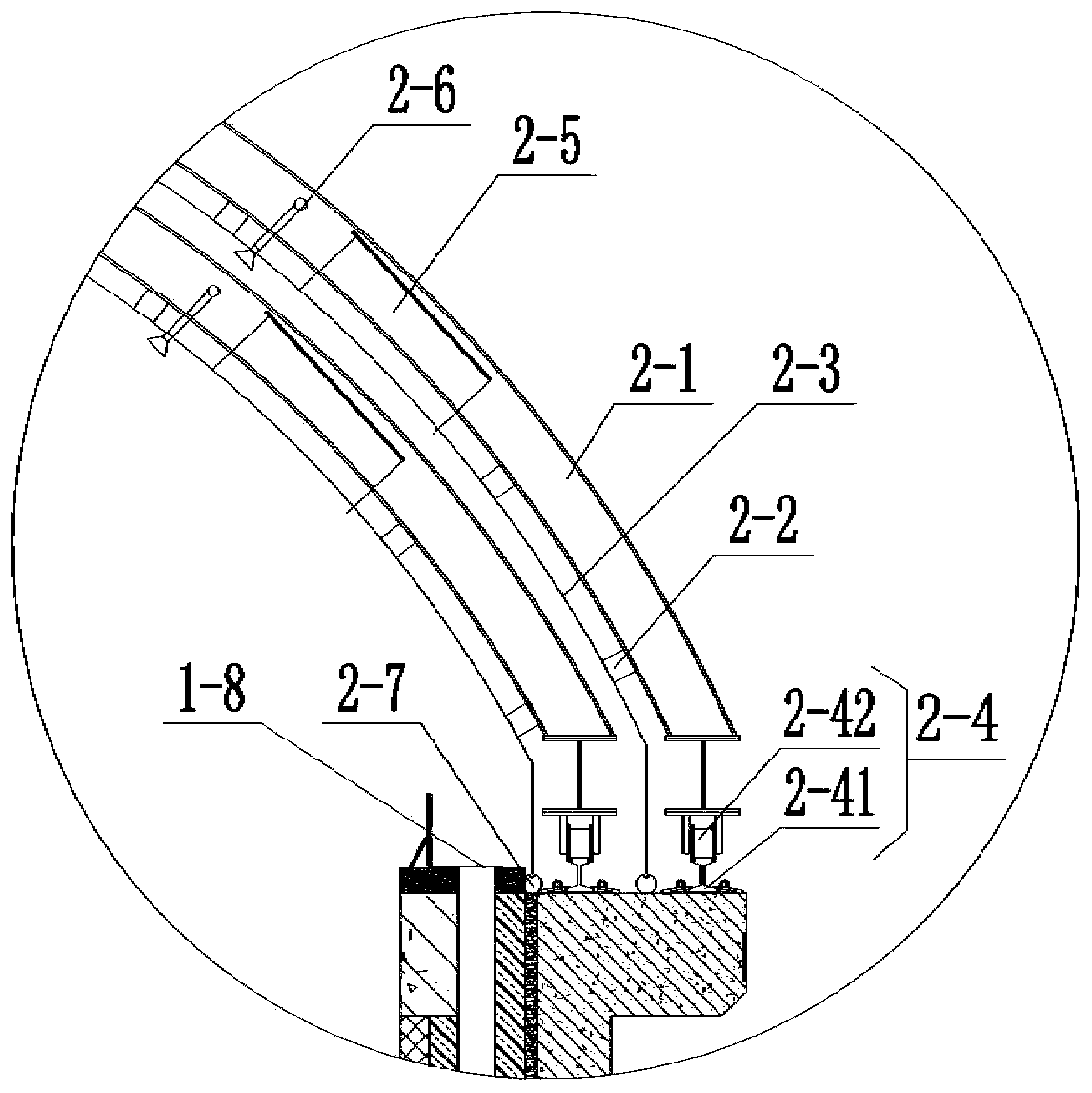

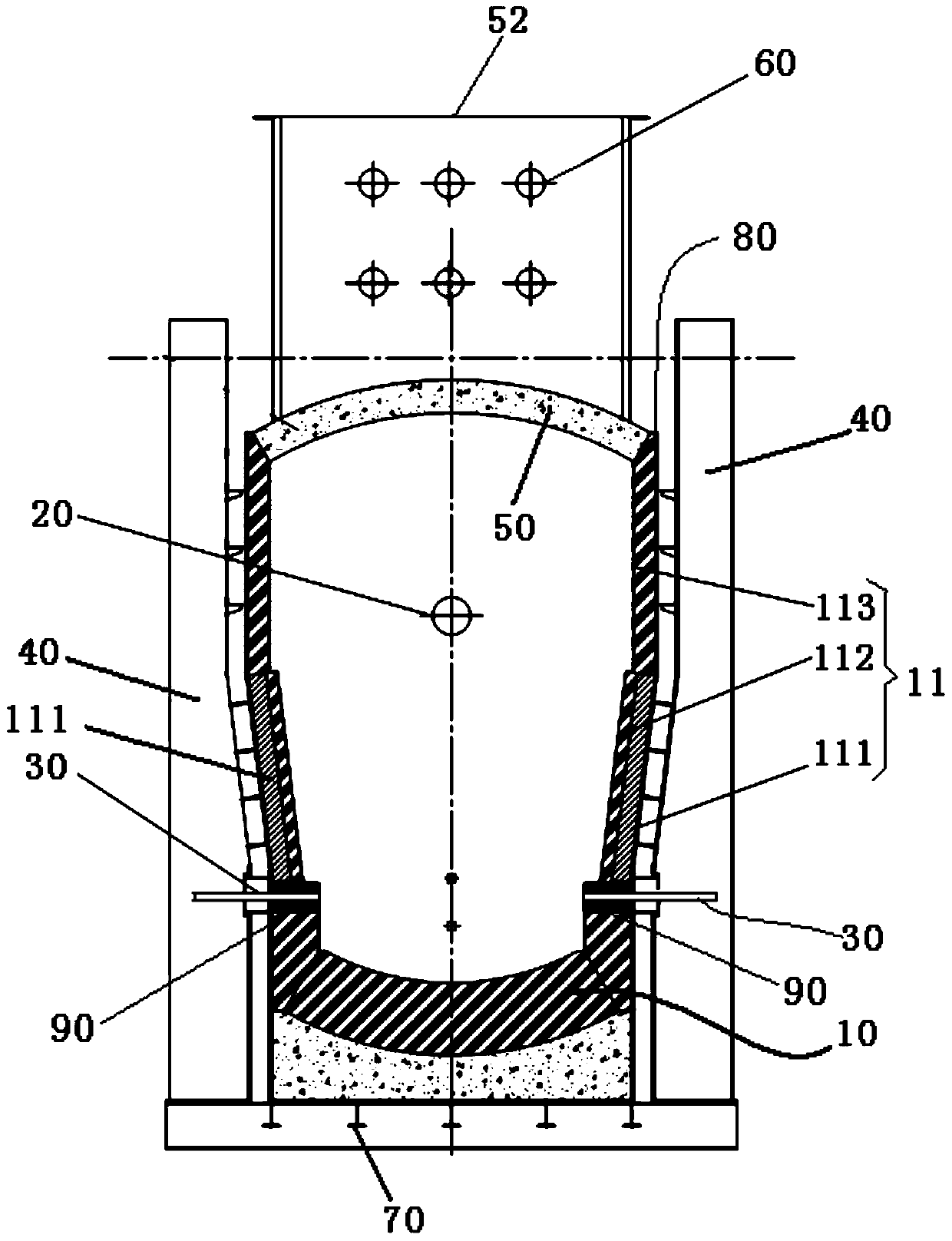

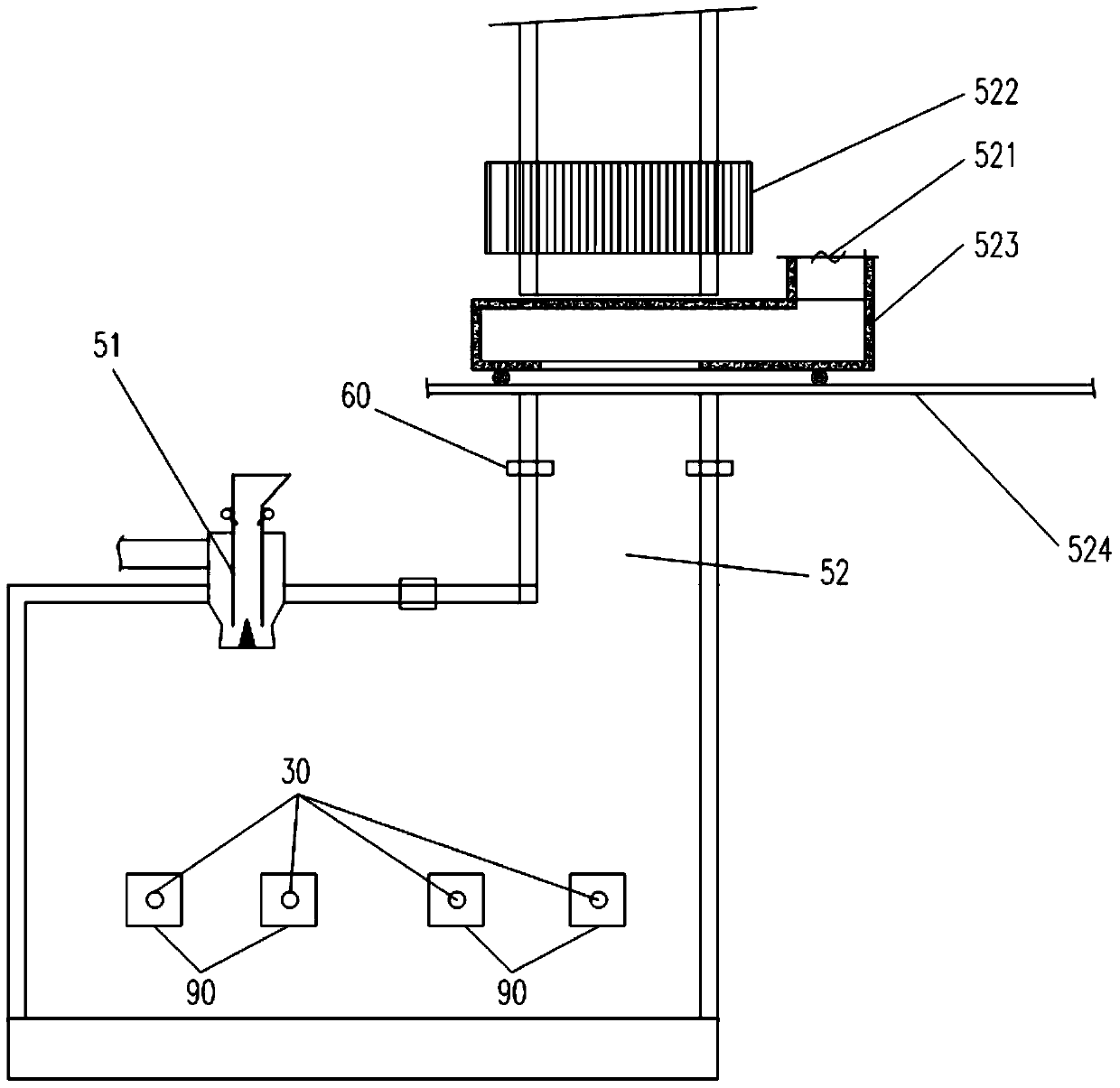

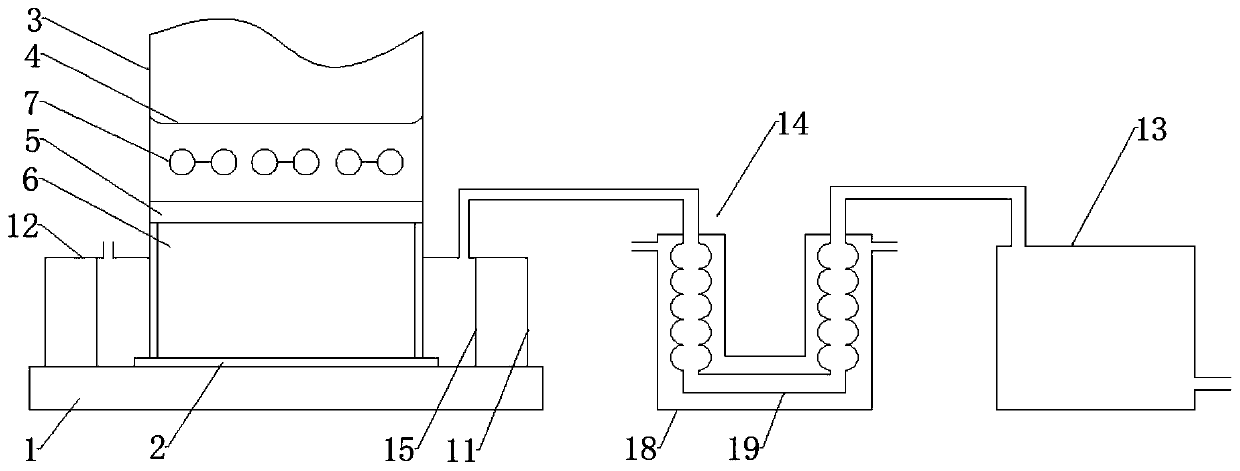

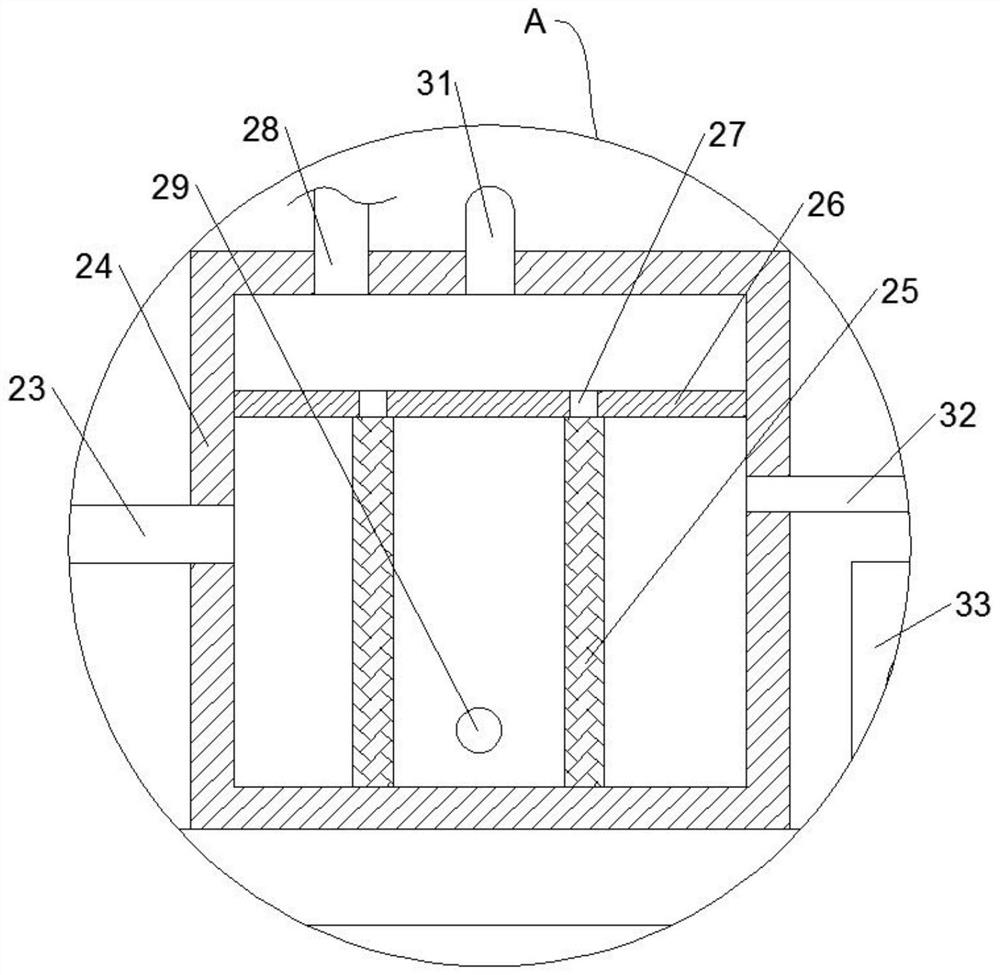

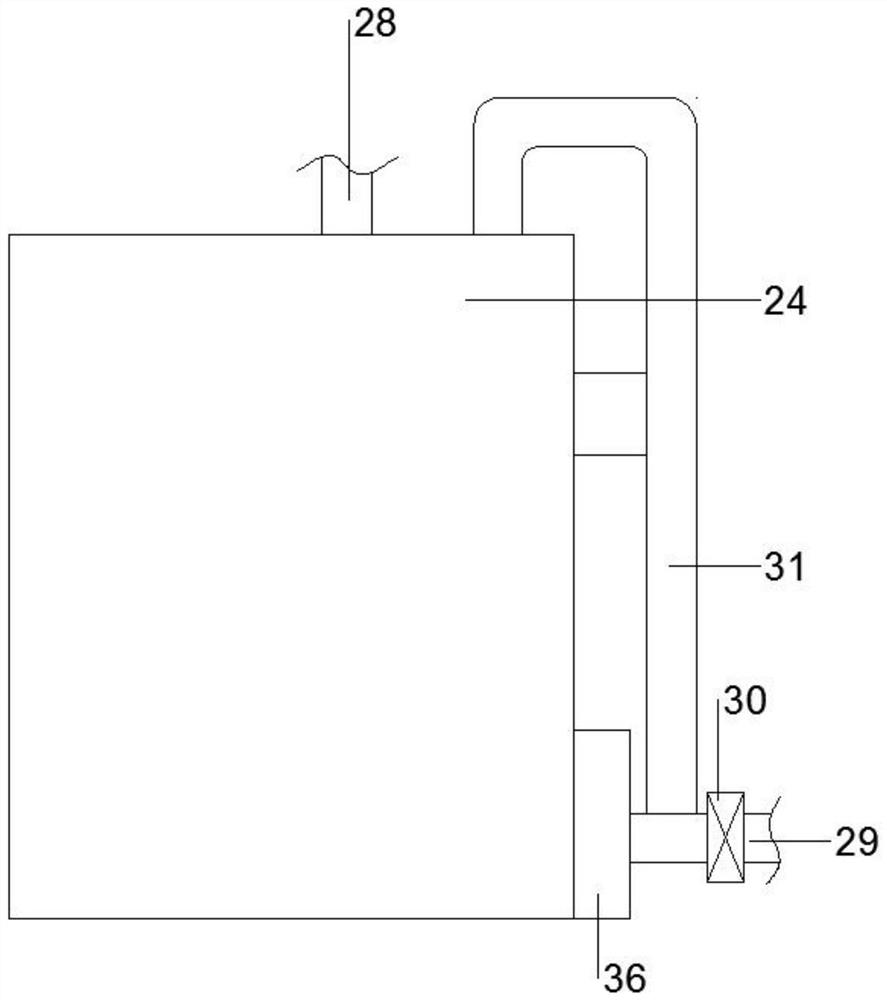

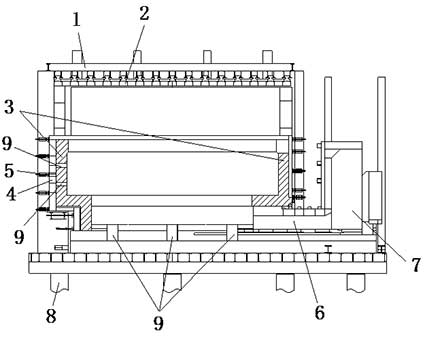

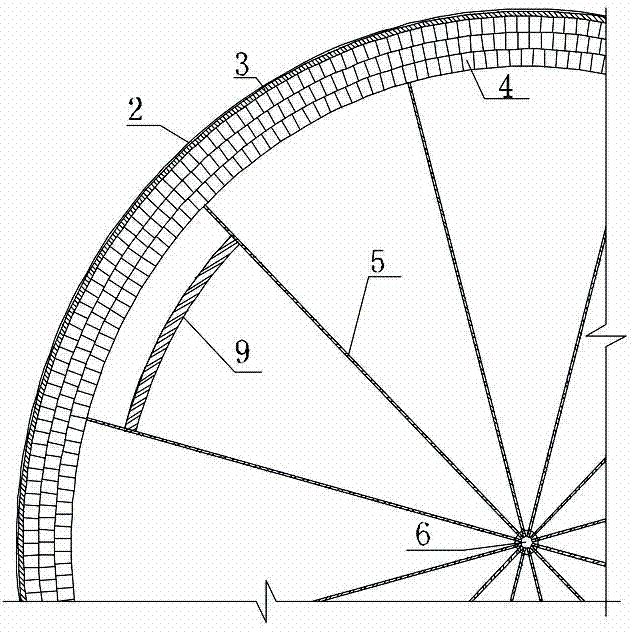

The invention provides an improved type side-blowing molten pool smelting furnace. The improved type side-blowing molten pool smelting furnace comprises a long round furnace body, a furnace cylinder, a furnace top, a furnace body frame structure and a plurality of multi-channel spray guns. The multi-channel spray guns are arranged on the two sides of the long round furnace body correspondingly. The long round furnace body is formed by a furnace body protective plate in an enclosed mode. A water sleeve is installed on the lower portion of the inner side of the furnace body protective plate. A first firebrick layer is further inlayed in the inner side of the water sleeve. A second firebrick layer is arranged on the water sleeve and the first firebrick layer and installed on the inner side of the furnace body protective plate. The furnace cylinder is arranged at the bottom of the long round furnace body. The long round furnace body is provided with a metal discharge outlet and a slag outlet. The furnace body frame structure comprises steel vertical pillars, cross beams and pulling rods. The multi-channel spray guns are arranged on the two sides of the middle straight segment of the long round furnace body, and the output ends of the multiple multi-channel spray guns extend into the long round furnace body. By means of the improved type side-blowing molten pool smelting furnace, the problem that in the prior art, the temperature in a molten pool smelting furnace is difficult to control can be solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

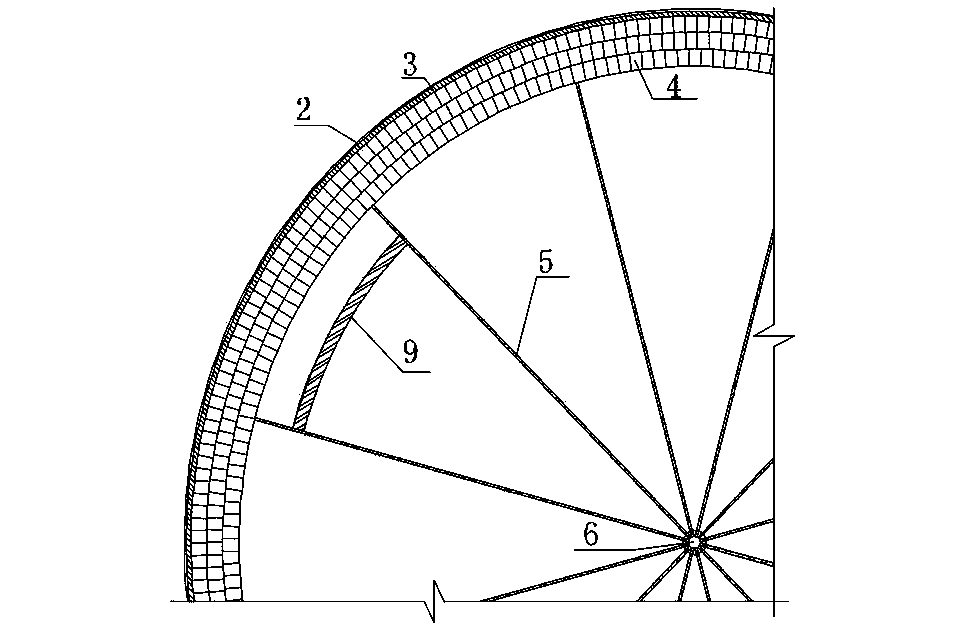

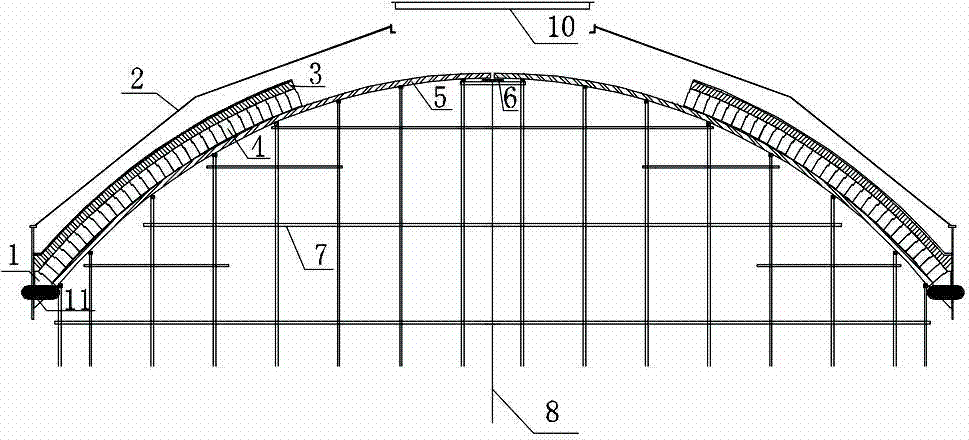

Construction method for spherical furnace top of industrial furnace

ActiveCN103673621AReduce cleanup workloadReduce usageLinings repairFurnace crowns/roofsMetallurgyFire brick

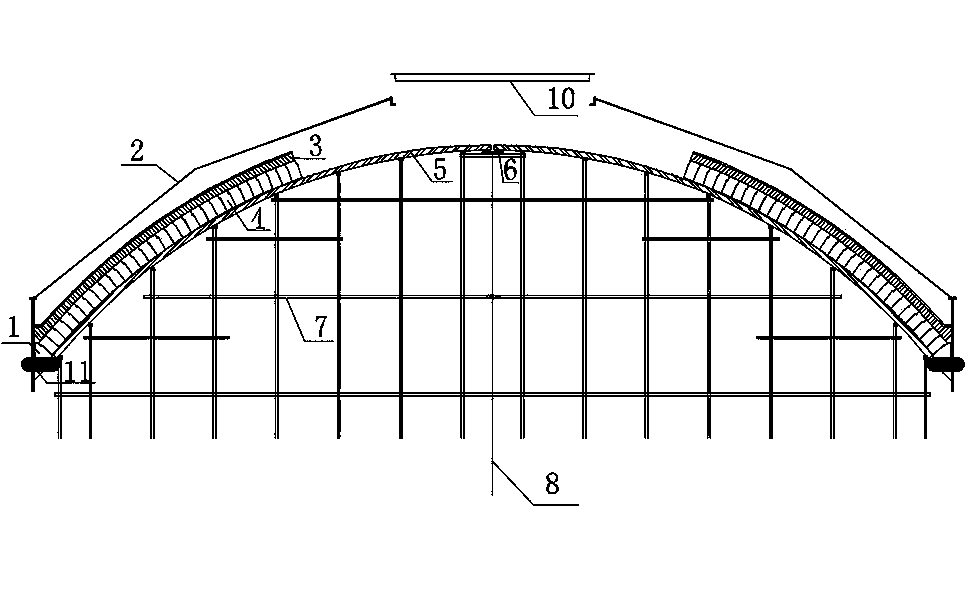

The invention discloses a construction method for a spherical furnace top of an industrial furnace. Firstly, a steel furnace shell is mounted, the elevation and the like of steel supporting plates at the arch springing positions of a globe-roof are rechecked, a vertical control line is arranged from the center of the furnace bottom to the center of the furnace top in a drawn mode, a supporting frame is erected in a furnace body, and a round top plate is arranged in the center of the top; multiple vertical arc plates are then manufactured and are fixed on the round top plate and the supporting frame, and the elevation and the radius of each layers of refractory bricks are marked on the corresponding vertical arc plates; multiple horizontal arc plates are manufactured; the refractory bricks at the arch springing positions are constructed first, the refractory bricks are constructed upwards in sequence, the vertical radian and the elevation of the refractory bricks are controlled by using the vertical arc plates, and the horizontal radius of the refractory bricks is controlled by using the horizontal arc plates; one heat preservation brick layer is constructed after one certain layer of the refractory bricks are constructed, and the construction is carried out in the way until the construction of all the refractory brick layers and the construction of all the heat preservation brick layers are completed; a steel cover plate of the furnace top is mounted in a hanging mode to seal the steel furnace shell. The construction method for the spherical furnace top of the industrial furnace has the advantages of being economical in used material, simple in working procedure, low in cost and the like, and can ensure construction quality more easily.

Owner:五矿二十三冶建设集团有限公司

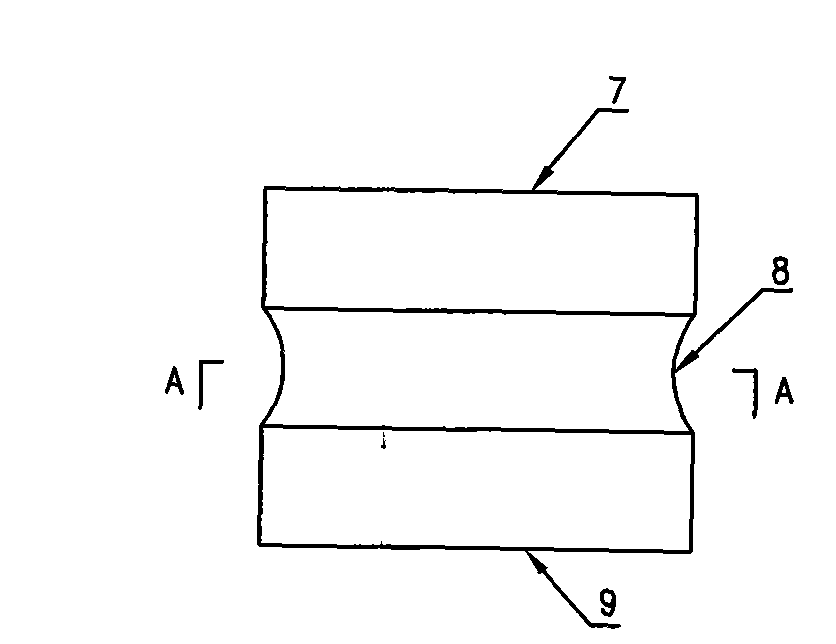

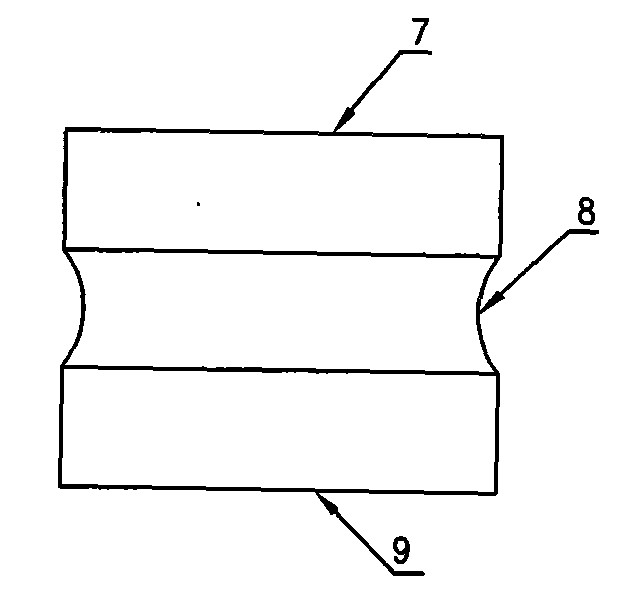

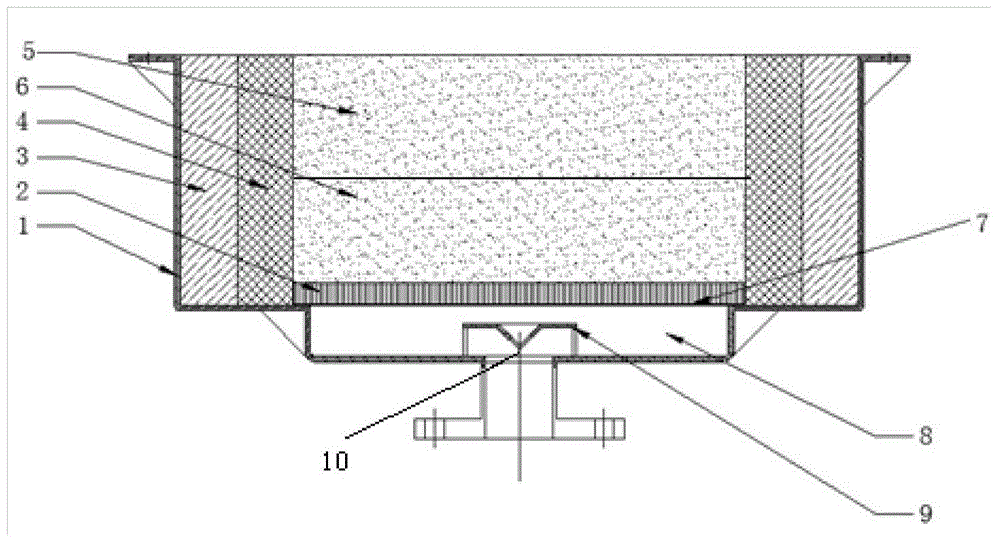

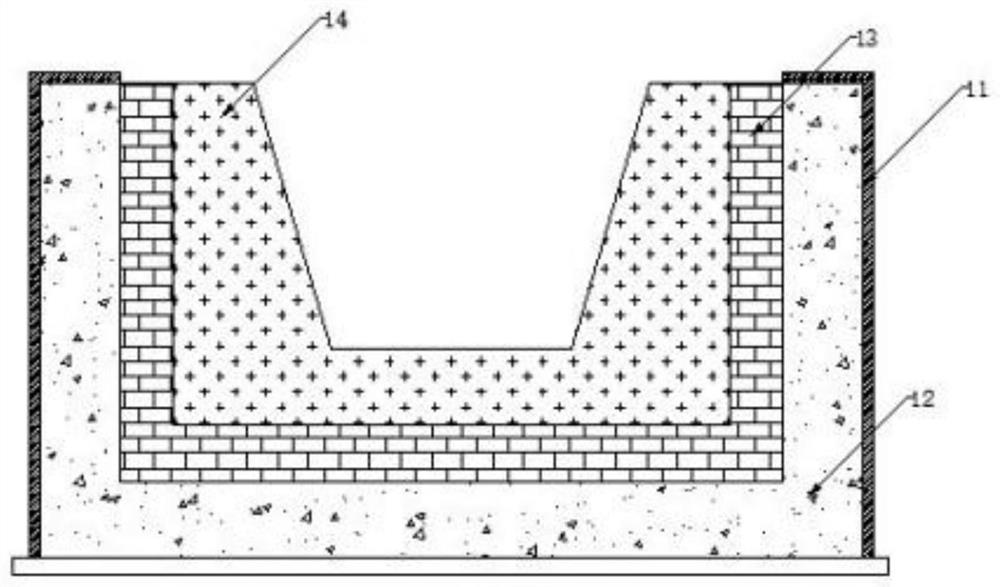

Furnace hearth of maintaining room of aluminum alloy melting furnace built by combining casting materials with precast bricks

InactiveCN101672576APrevention of straight seamsAvoid Shrinking Through SeamsLinings repairFire brickContact layer

The invention discloses a furnace hearth of a maintaining room of an aluminum alloy melting furnace built by combining casting materials with precast bricks. The furnace hearth overcomes the problem of shrunken pass-through sews in the furnace hearth of the existing maintaining room. The furnace hearth is characterized in that a firebrick layer is an aluminum liquid contact layer which is paved bycombining the high alumina casting materials with the precast bricks, and the middle positions of the precast bricks are previously provided with ring-shaped grooves on the height direction. The furnace hearth has the benefits that the building process of the furnace hearth of the maintaining room of the aluminum alloy melting furnace is simple and fast due to the structure built by combining thehigh alumina casting materials with the precast bricks, and quincuncial piles-shaped technology seams are formed on the surface of an aluminum liquid contact layer due to the convex-concave-shaped technology seams are formed between the precast bricks and the high alumina casting materials on the perpendicular direction, thereby preventing the furnace hearth from having straightway sews along theheight direction thereof, preventing the baked furnace hearth from having longer and irregular shrunken pass-through sews, being capable of completely removing the thermal expansion stress in the process of dispelling under the condition that the stability of the precast bricks main body structure and the quality is guaranteed, leading the furnace hearth not to be uplifted, and obviously improving the building quality and the service life of the furnace hearth.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

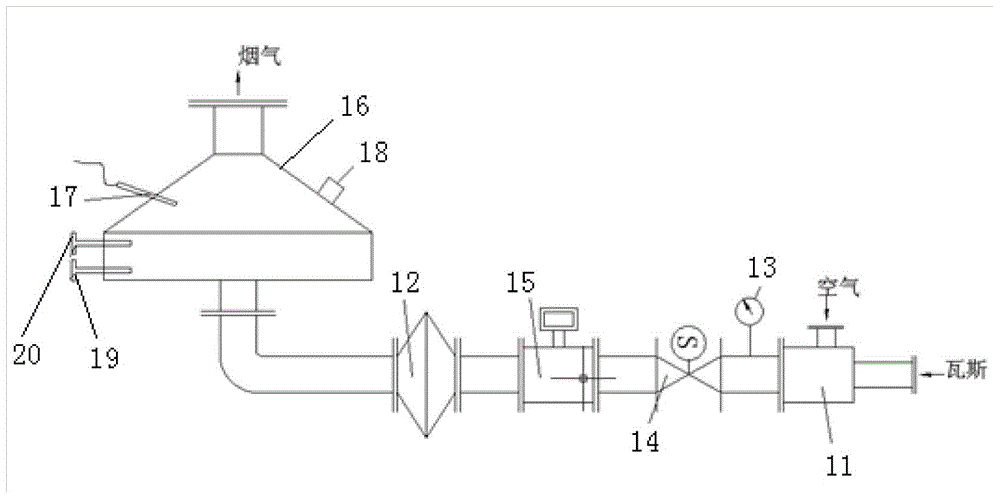

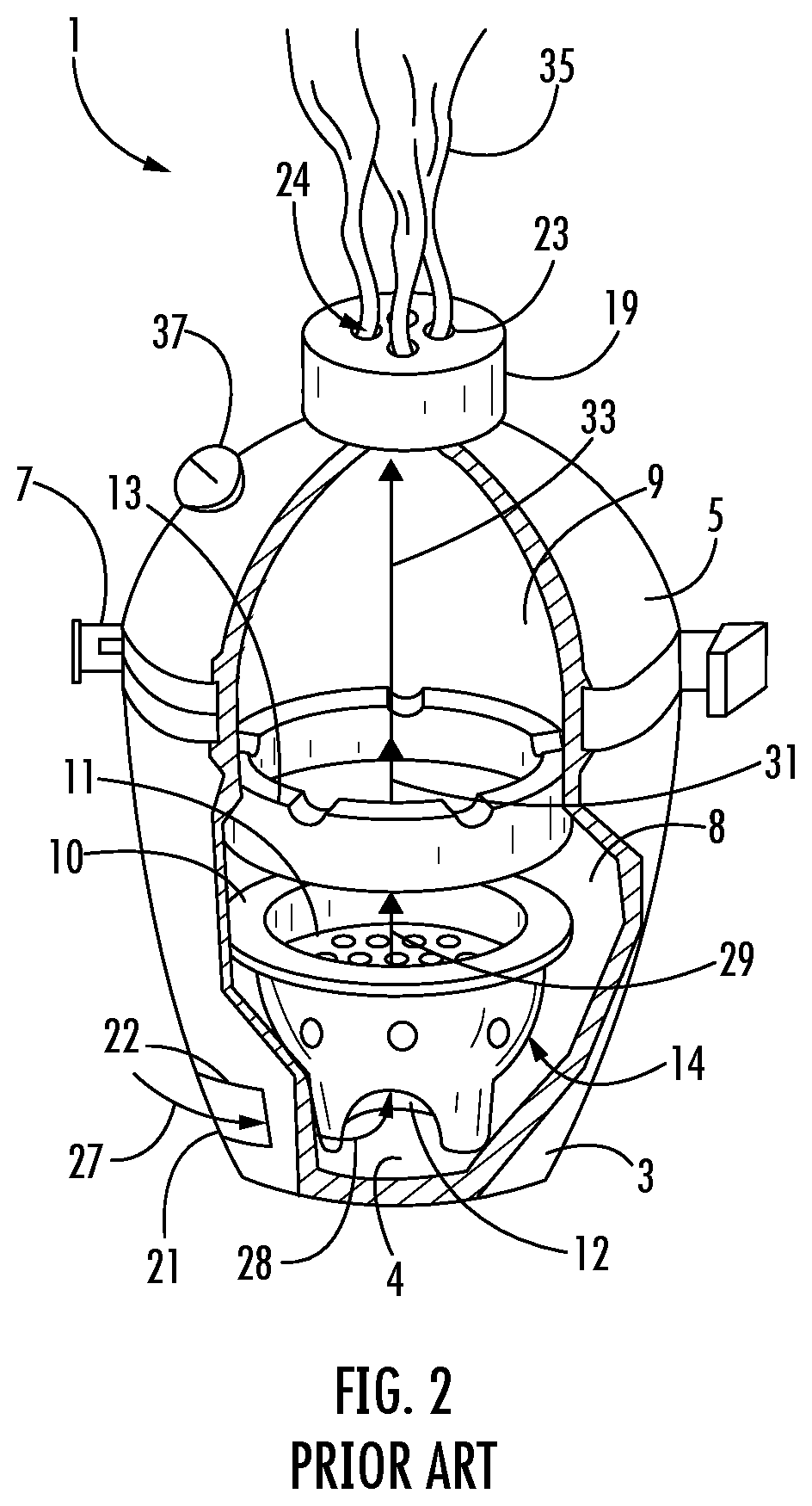

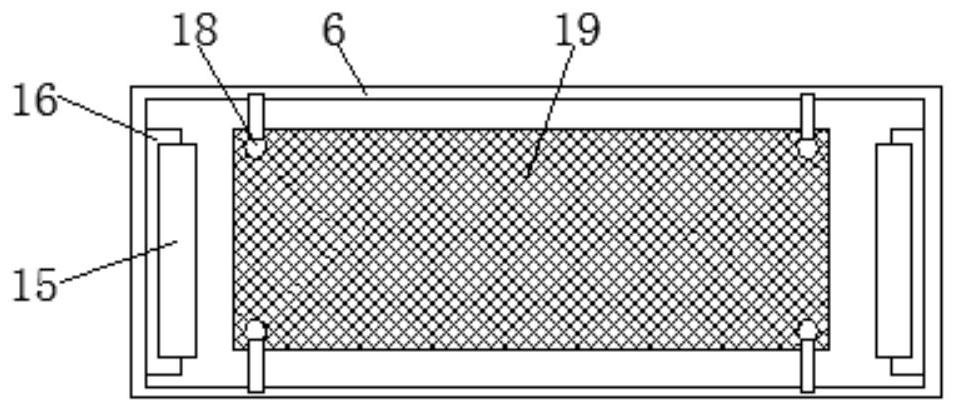

Low-concentration coal bed gas or gas combustor and matched system thereof

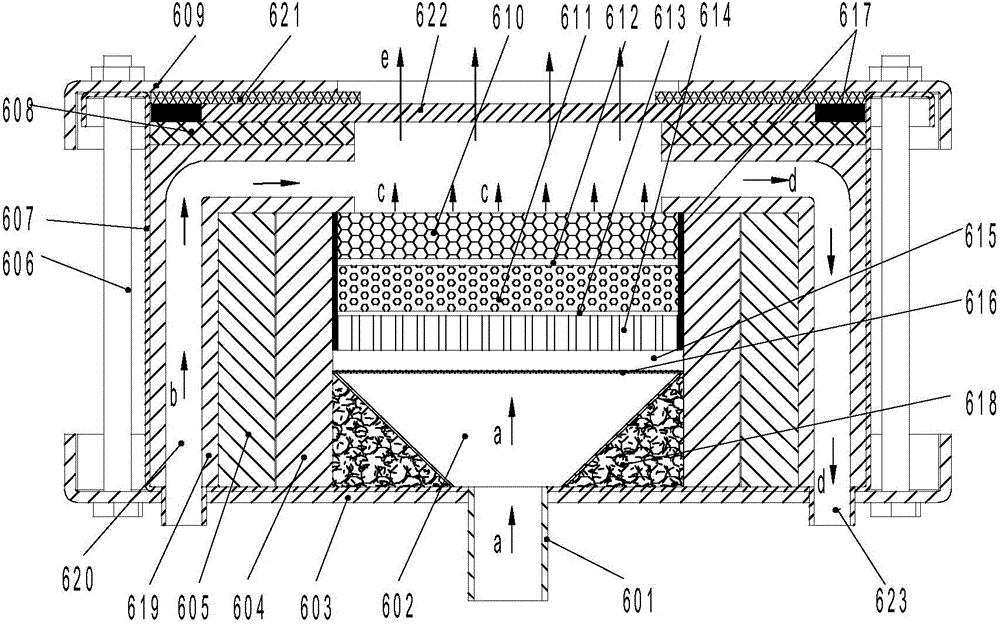

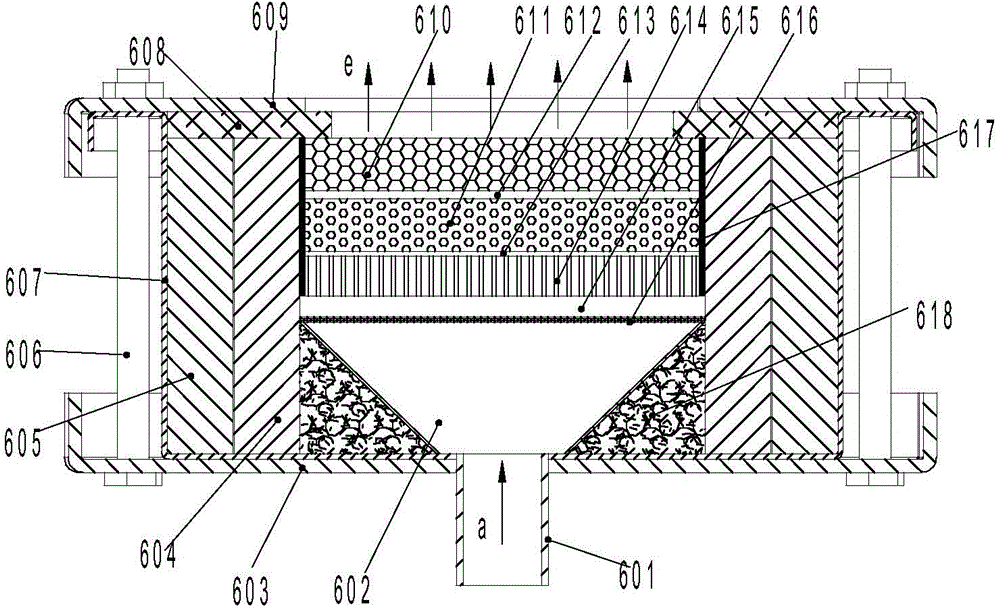

The invention discloses a low-concentration coal bed gas or gas combustor and a matched system thereof. The low-concentration coal bed gas or gas combustor comprises a metal housing, wherein the edge of the top end of the metal housing is connected with a boiler through a connection flange; a ceramic fiber layer is attached to the inner wall of the metal housing; a fireproof brick layer is attached to the inner side of the ceramic fiber layer; a porous medium layer upper part, a porous medium layer lower part, a ceramic honeycomb panel, a heat-resistant metal wire mesh and an uniform-pressure air chamber are sequentially arranged at the interior of the fireproof brick layer from top to bottom; the four sides of the heat-resistant metal wire mesh are fixed on the metal housing and are used for supporting the porous medium layer upper part, the porous medium layer lower part and the ceramic honeycomb panel; the uniform-pressure air chamber is formed between the heat-resistant metal wire mesh and the bottom of the metal housing; a coal bed gas or gas inlet is formed in the bottom of the metal housing at the center of the uniform-pressure air chamber; a baffle plate is arranged at the coal bed gas or gas inlet. The low-concentration coal bed gas or gas combustor has the beneficial effect that the combustor can be used for combusting the low-concentration coal bed gas or gas.

Owner:CHINA UNIV OF MINING & TECH

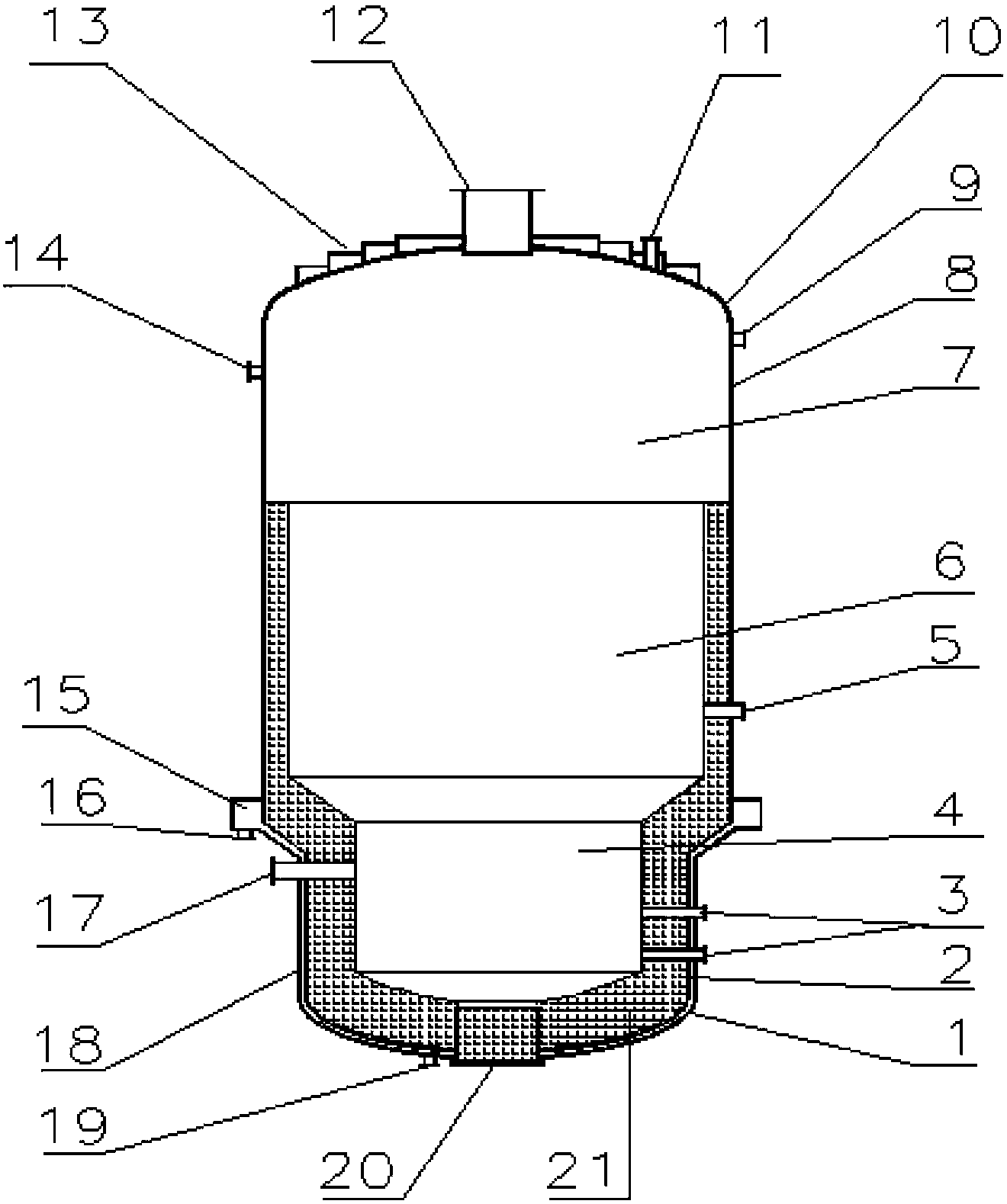

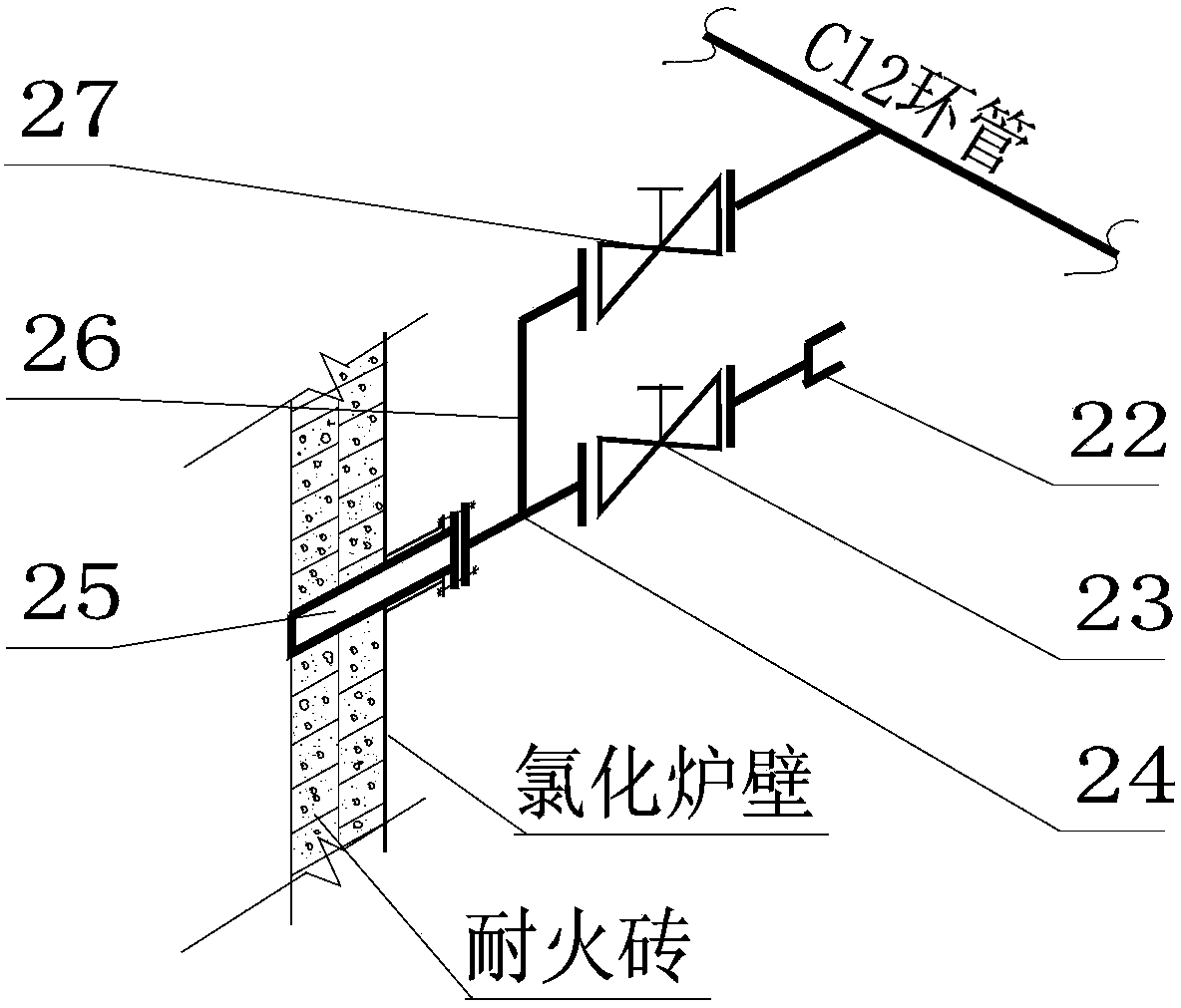

Sieve plate-free fluidizing chlorination furnace

ActiveCN103408067ALong continuous running timeAvoid demandingTitanium halidesGas solidComposite ceramic

The invention discloses a sieve plate-free fluidizing chlorination furnace with the function of discharging slag from the upper part and the side of the fluidizing chlorination furnace. The fluidizing chlorination furnace is a tank body which adopts a steel structure and comprises an upper cylindrical cylinder body, a lower cylindrical cylinder body, an upper papilionaceous sealing head and a lower papilionaceous sealing head, wherein the diameter of the upper cylindrical cylinder body is different from that of the lower cylindrical cylinder body. A chlorine gas inlet chamber is arranged at the bottom of the fluidizing chlorination furnace; a material fluidizing section is arranged in the middle of the fluidizing chlorination furnace; a gas-solid separation section is arranged at the upper part of the fluidizing chlorination furnace. The chlorine inlet chamber and the material fluidizing section are lined with refractory bricks; the inner surface of the gas-solid separation section is covered with high-temperature-resistant anti-corrosive composite ceramic paint so as to prevent high-temperature chlorine gas from corroding the gas-solid separation section; a gas outlet is formed in the central position of the upper sealing head; fine-particle slag is discharged from the gas outlet along with airflow after chlorination reactions; a side slag discharge port is formed in the side wall of the upper part of the chlorine gas inlet chamber and used for discharging coarse-particle slag discontinuously; two layers of chlorine gas inlet pipes, which are designed specially, are arranged in the chlorine gas inlet chamber; each chlorine gas inlet pipe orifice is provided with a blowing block joint; the chlorine gas inlet pipes are inserted into the refractory brick layer and extend to the chamber of the fluidizing chlorination furnace; chlorine gas and blowing block airflow are prevented from impacting the refractory brick layer.

Owner:甘肃德通国钛金属有限公司 +1

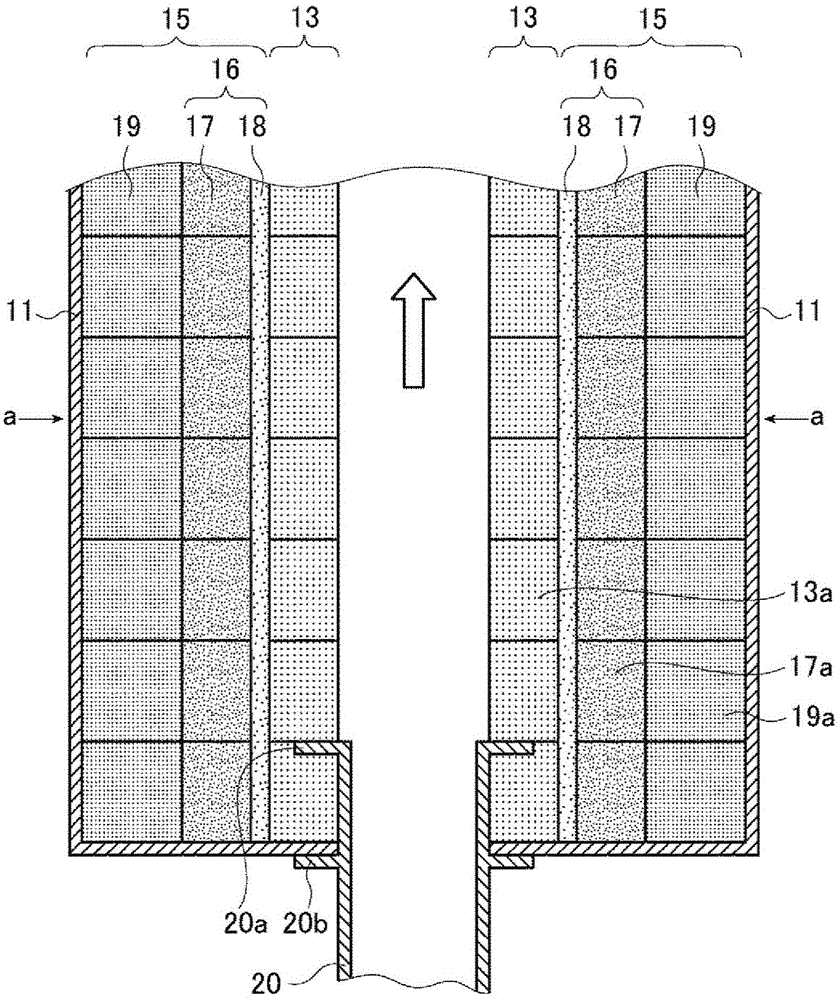

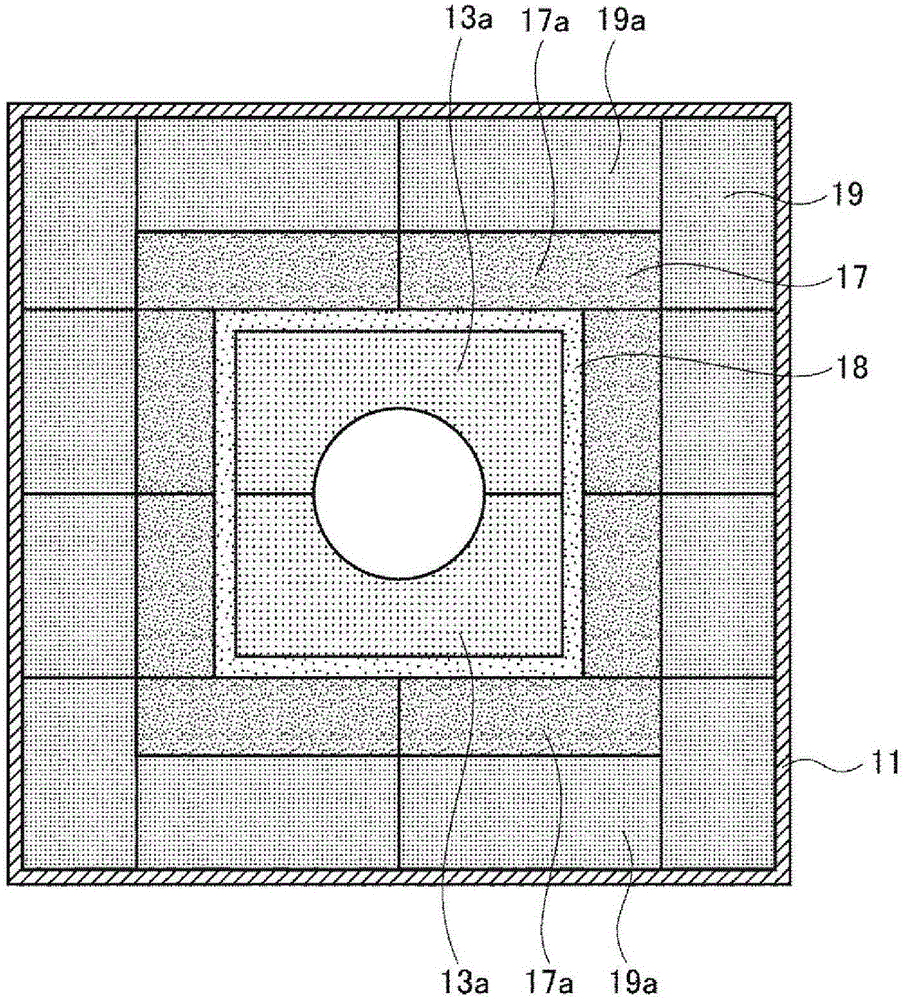

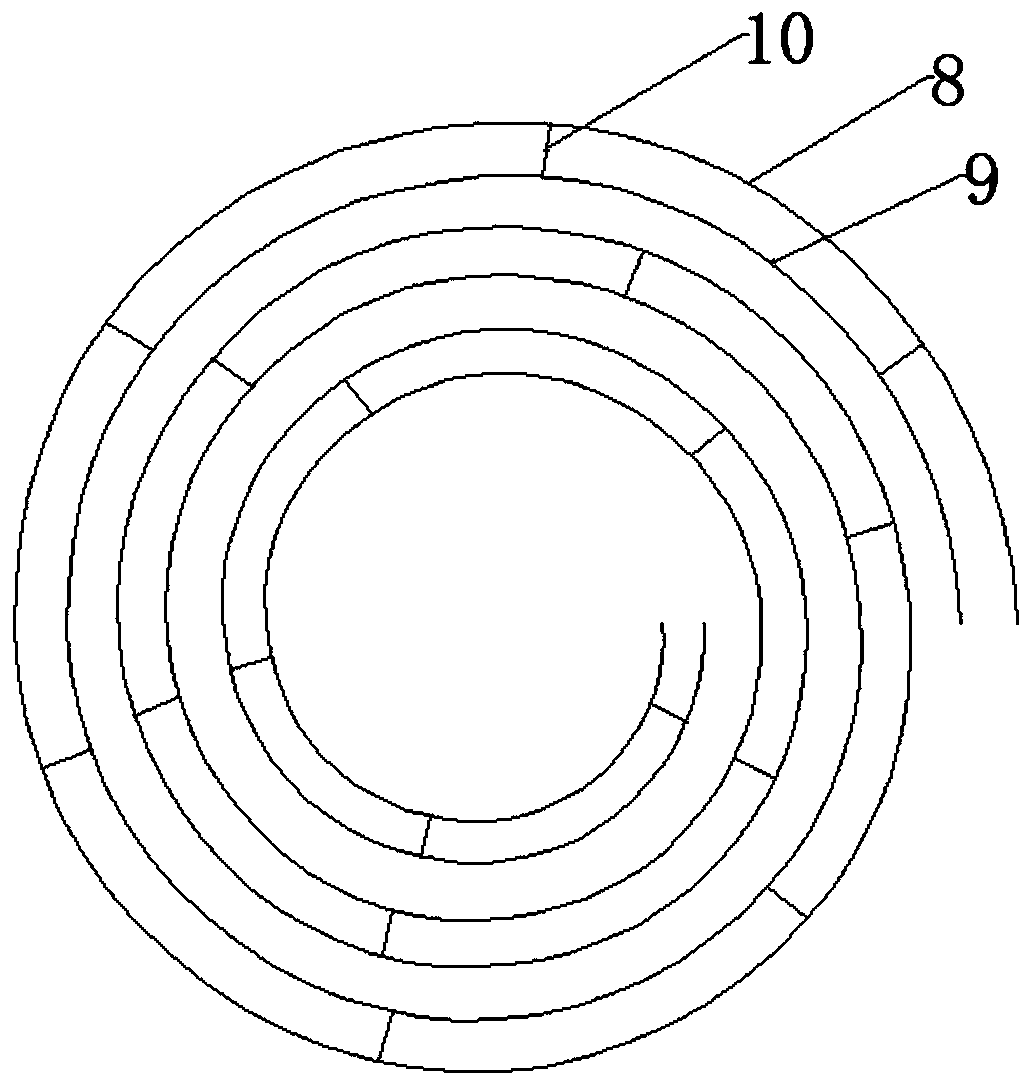

Molten glass conduit structure, and device and method using conduit structure

Provided are: a molten glass conduit structure, in which the erosion of a solid heat insulating material constituting a backup of a conduit can be prevented by a molten glass that exudes from a joint part between electrocast bricks constituting the conduit, without using any cooling means, and which can be manufactured at a reduced cost; a vacuum defoaming device using the conduit structure; and a method for vacuum defoaming a molten glass using the vacuum defoaming device. The molten glass conduit structure, said conduit structure comprising a conduit and a backup provided on the periphery of the conduit, is characterized in that: the conduit is a hollow tube having electrocast bricks disposed in the longitudinal direction and circumferential direction thereof; the backup comprises a refractory layer provided on the outside of the conduit and a heat insulating material layer provided on the outside of the refractory layer; the refractory layer comprises a refractory brick layer consisting of refractory bricks disposed in the longitudinal direction and circumferential direction of the conduit and a monothilic refractory layer that is formed by laying a monothilic refractory, said monothilic refractory containing, in terms of mass percentage of oxide(s), 30-100% of Al2O3 and 0-70% of SiO2, and then sintering the monothilic refractory; the heat insulating material layer comprises a solid heat insulating material layer comprising a solid heat insulating material disposed in the longitudinal direction and circumferential direction of the conduit; and the electrocast bricks constituting the conduit, the monothilic refractory constituting the monothilic refractory layer and the refractory bricks constituting the refractory brick layer are selected in such a manner that, when the molten glass passes through the conduit, a site being at the same temperature as the pour point of the glass is positioned within the heat insulating material layer.

Owner:AGC INC

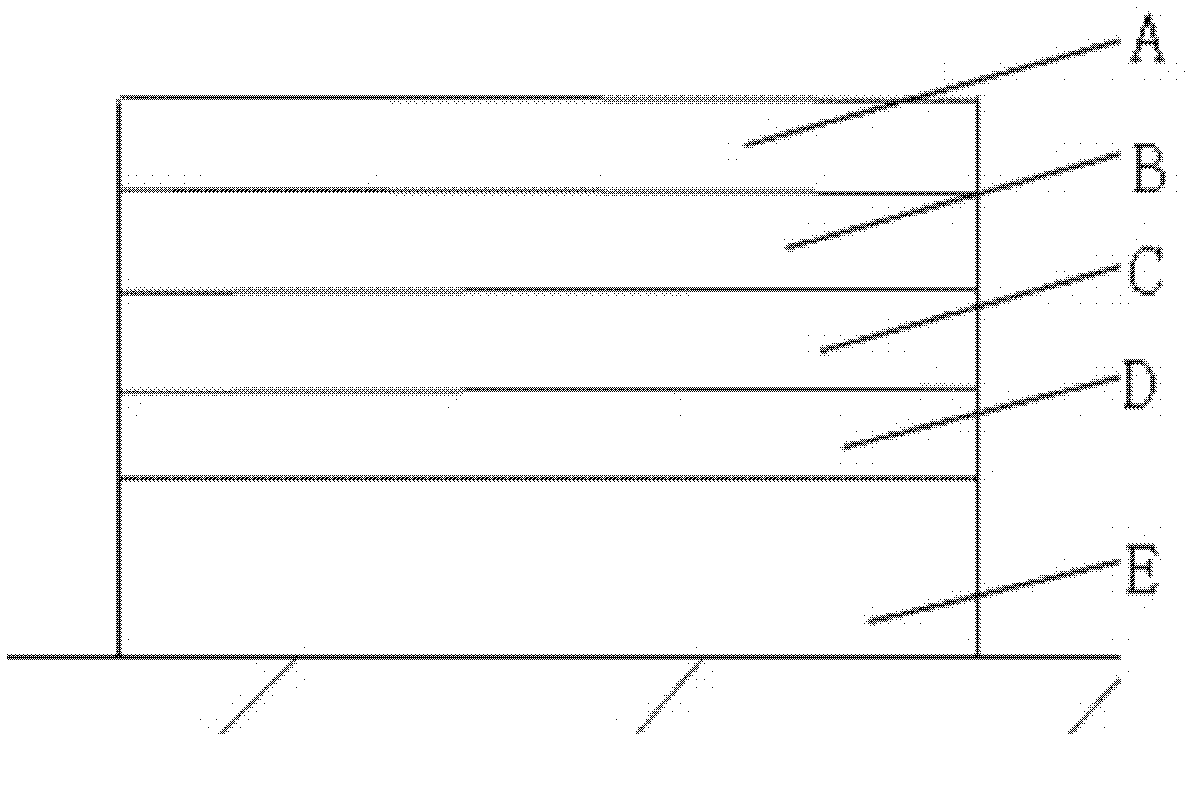

Rotary hearth furnace hearth structure

InactiveCN102586540AAddress Dimensional Stability IssuesAnti-slag erosion performanceManufacturing convertersCarbon compositesThermal insulation

The invention discloses a rotary hearth furnace hearth structure. The rotary hearth furnace hearth structure which is a multilayer structure sequentially comprises, top to down, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a mullite firebrick layer, a high-alumina brick layer, and a light-weight thermal-insulation brick layer. So the comprehensive hearth has a special slag erosion resistance and a metal and liquid slag adhesion resistance, and the dimension stability problem of expend with heat and contract with cold of the hearth is solved.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

De-oiling furnace for waste oil catalyst

The invention discloses a de-oiling furnace for waste oil catalyst, comprising a furnace body; the furnace body is provided with a material inlet and a material outlet; a furnace grate for sending material is disposed in the furnace body; wherein the material inlet and the material outlet are both provided with a cooling device; and a pre-heating chamber, a burning chamber and a cooling chamber are orderly arranged between the material inlet and the material outlet; a firebrick layer is set in the burning chamber; and the furnace wall of the burning chamber is provided with a ventilation door connected with a ventilation room; and the end part of the furnace grate is further provided with a slag remover; a water heating pot cylinder is disposed in the furnace above the burning chamber; the water heating pot cylinder is provided with a drainage pipeline. The invention is featured in simple structure and smart design; the oil, sulfur and carbon compound are removed from the waste oil catalyst by the way of burning; and the heat produced by waste heat is used for heating the media, so as to supply industrial production or other occasions which need high-temperature media.

Owner:DALIAN DONGTAI RESOURCE RENEWABLE

Efficient and environment-friendly silicon carbide smelting furnace

PendingCN110849151AImprove insulation effectEfficient storageSilicon carbideWaste heat treatmentCarbide siliconReinforced concrete

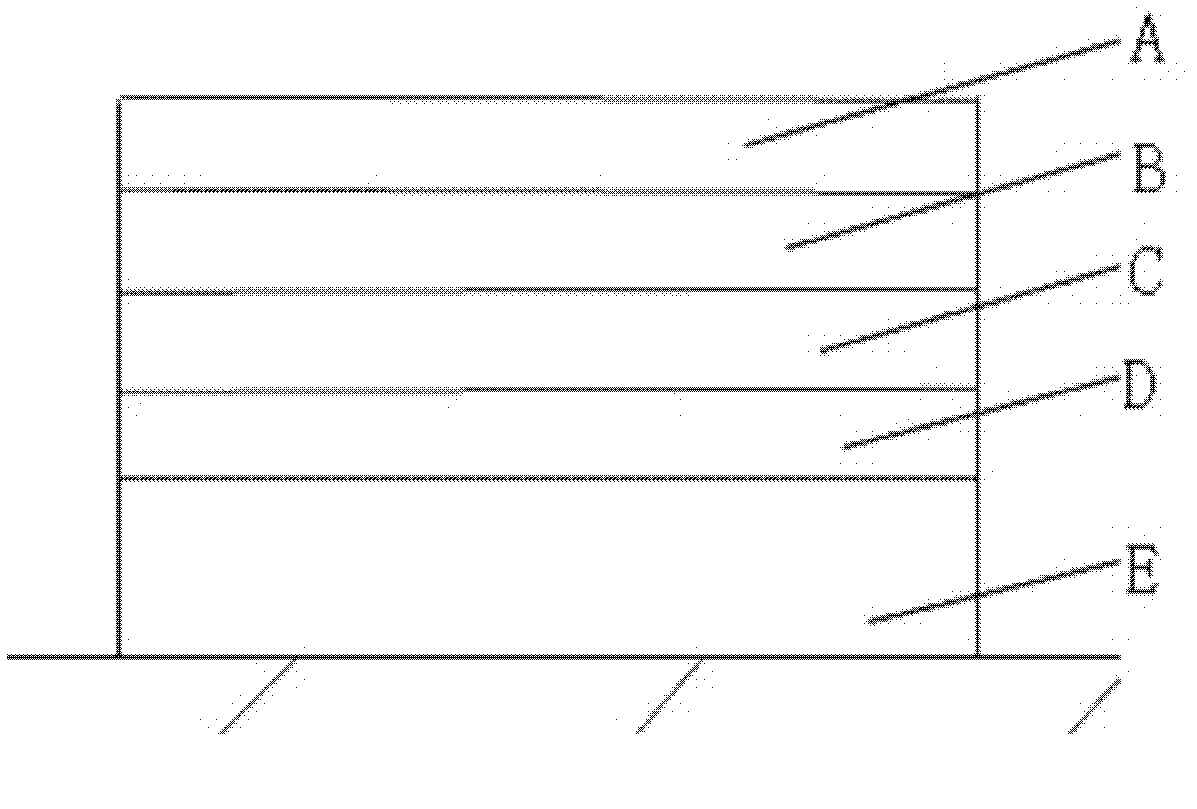

The invention belongs to the technical field of silicon carbide machining, and relates to an efficient and environment-friendly silicon carbide smelting furnace. The efficient and environment-friendlysilicon carbide smelting furnace comprises a furnace body and a smoke dust collecting cover. The furnace body comprises side walls. Each side wall comprises a reinforced concrete layer, a foam glassplate, a refractory fireclay brick layer, a combustion chamber interlayer and a composite refractory brick layer, wherein the reinforced concrete layer, the foam glass plate, the refractory fireclay brick layer, the combustion chamber interlayer and the composite refractory brick layer are sequentially arranged from outside to inside. The smoke dust collecting cover comprises collecting cover units. Each collecting cover unit comprises a cross beam, a purline, a cover surface and a sliding mechanism. Each cover surface is of an arc-shaped surface structure, the smoke dust collecting cover is located above the furnace body, and rails are fixed to the reinforced concrete layers of the side walls through fixed seats. According to the silicon carbide smelting furnace, the multi-layer structureside walls are combined with the arc-shaped collecting cover, and the silicon carbide smelting furnace is good in heat insulating effect, low in environmental pollution and low in operating cost andcan be used for large silicon carbide smelting.

Owner:宁夏天净隆鼎碳化硅有限公司

Maintenance method of blast furnace main channel

InactiveCN111778373AEliminate potential safety hazardsReduce even ironBlast furnace detailsDischarge devicesInsulation layerFire brick

The invention discloses a maintenance method of a blast furnace main channel. The maintenance method comprises the following steps of replacing an old steel tank with a new steel tank, respectively arranging a refractory brick layer and a heat insulation layer at the bottom and the side surface of the new steel tank, and sequentially arranging a bottom permanent layer and a prefabricated part layer on the refractory brick layer, wherein a hole for arranging a thermocouple is reserved on the surface, close to a heat insulation layer, of each prefabricated part in the prefabricated part layer, and the thermocouple penetrates through the heat insulation layer through shells at two sides of the steel tank and is inserted into the hole of the prefabricated part; and then, hanging a mold above the bottom permanent layer and the prefabricated part, and pouring refractory materials among the permanent layer, the prefabricated part layer and the mold to form a working layer. According to the maintenance method of the blast furnace main channel, the working layer of the main channel covers the large-volume and firm prefabricated part, so that the structure is stable. Even if the prefabricated part is damaged, a certain damaged prefabricated part can be lifted out for replacement, and the process is simple. Meanwhile, the thermocouple is additionally arranged, so that an operator can judge the working condition of the working layer of the corresponding area in real time, an accurate maintenance scheme is provided, the maintenance period is prolonged, and the service life of the main channel is prolonged.

Owner:武汉钢铁有限公司

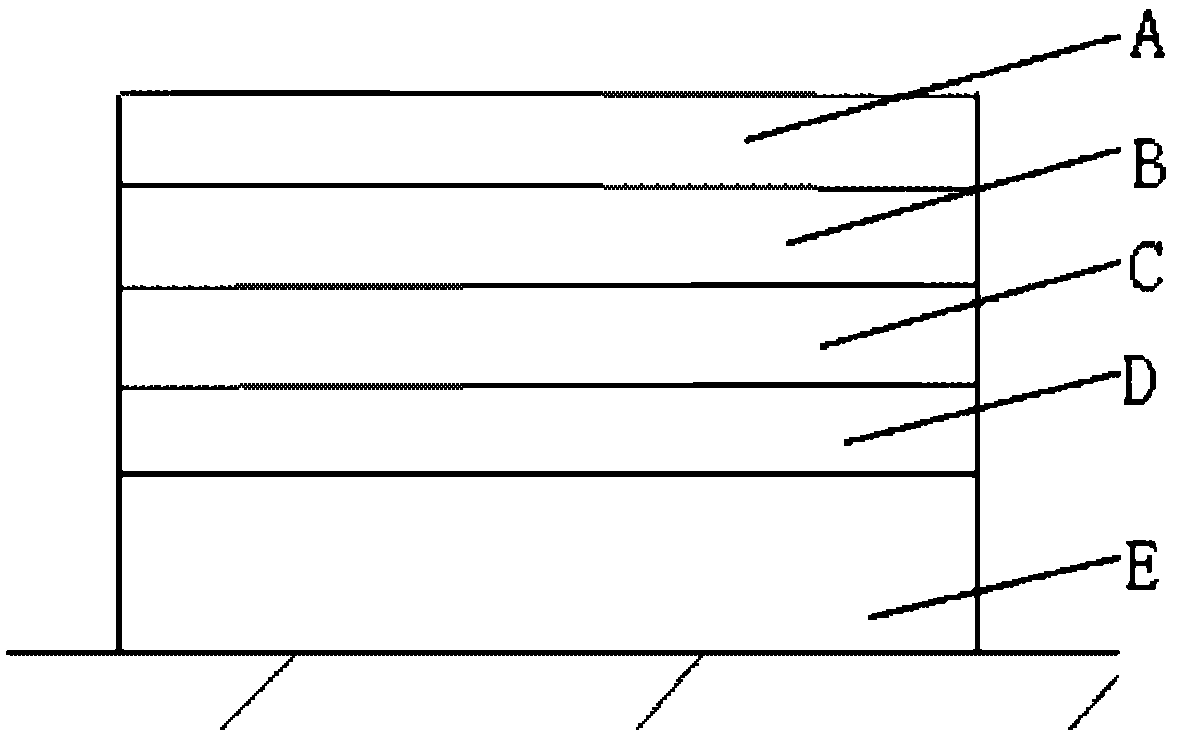

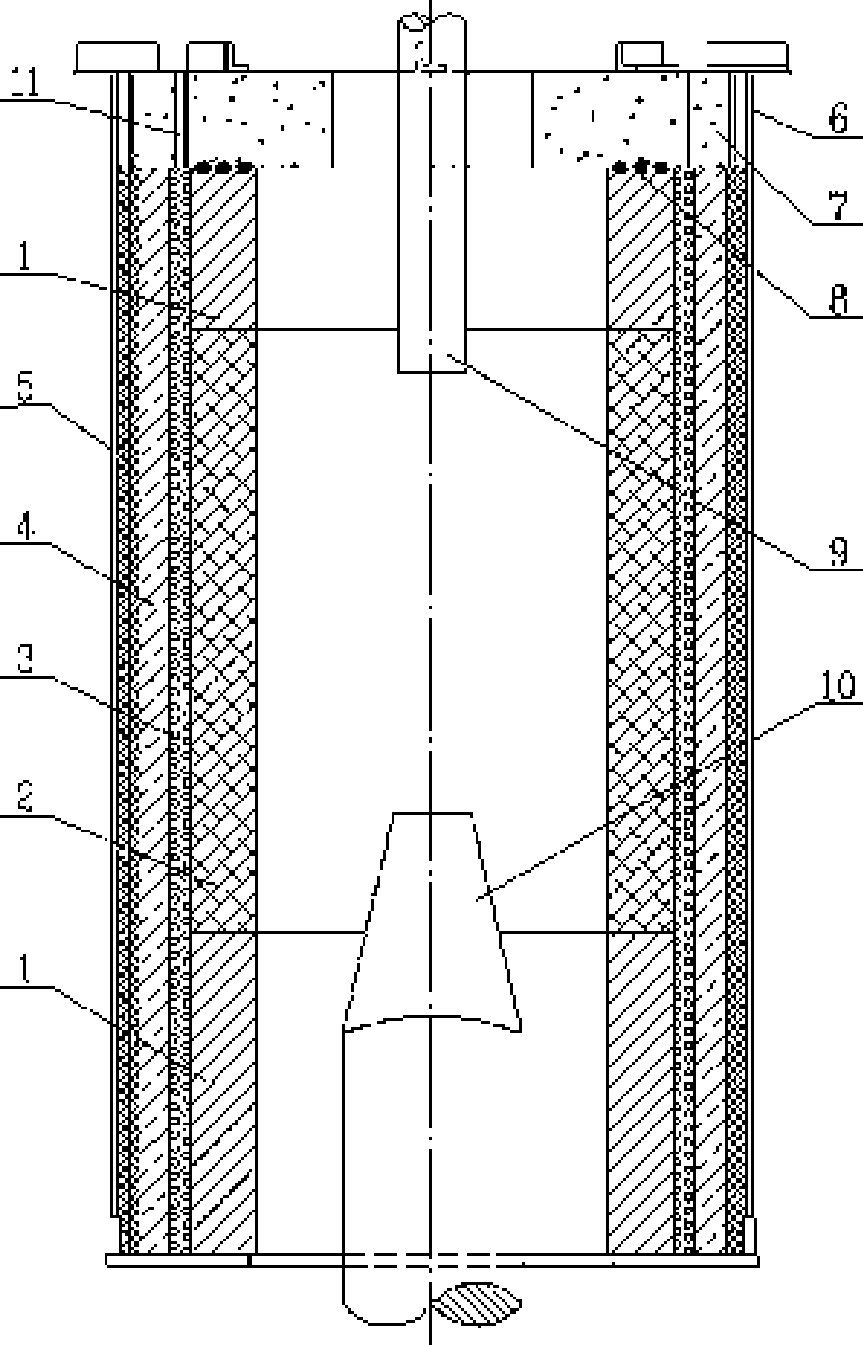

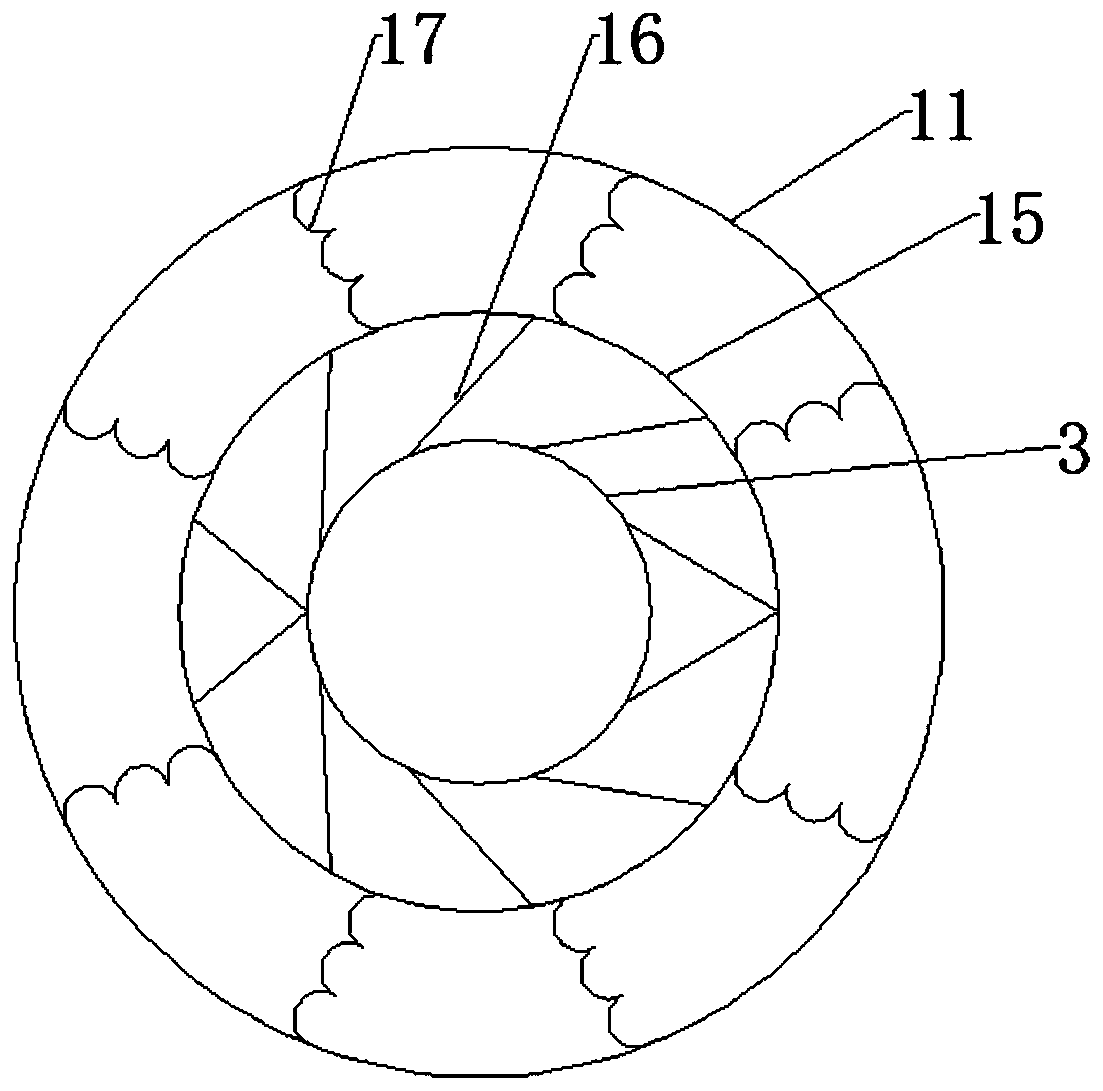

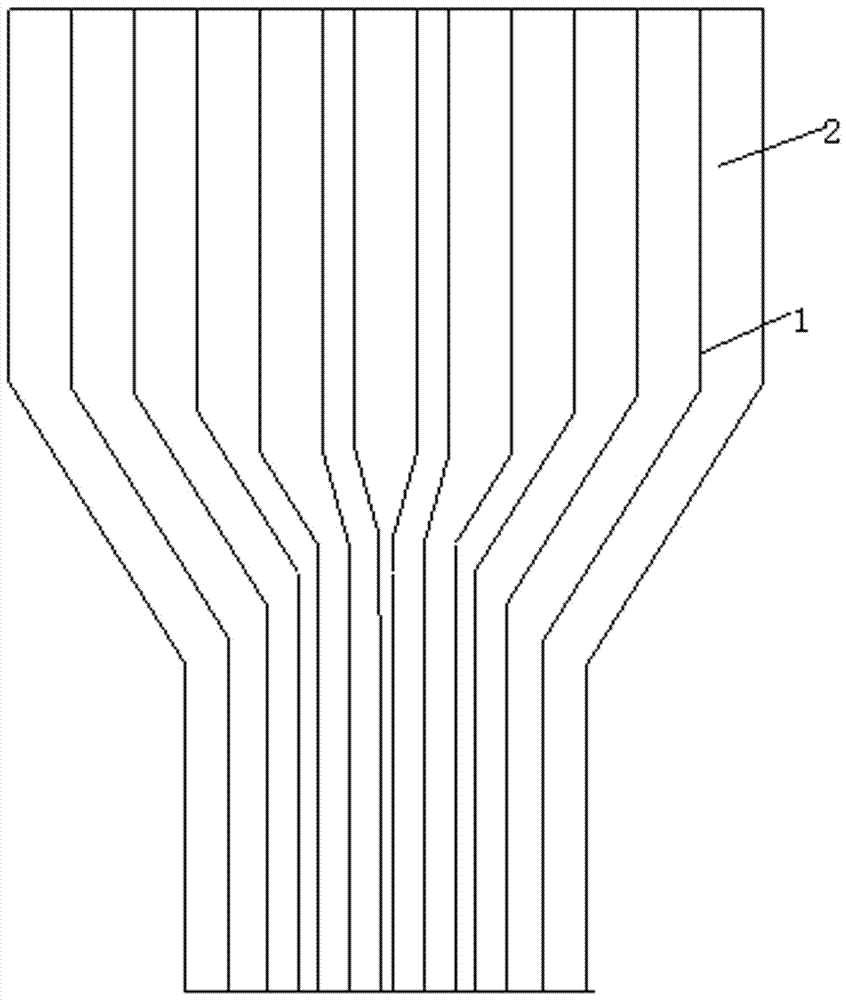

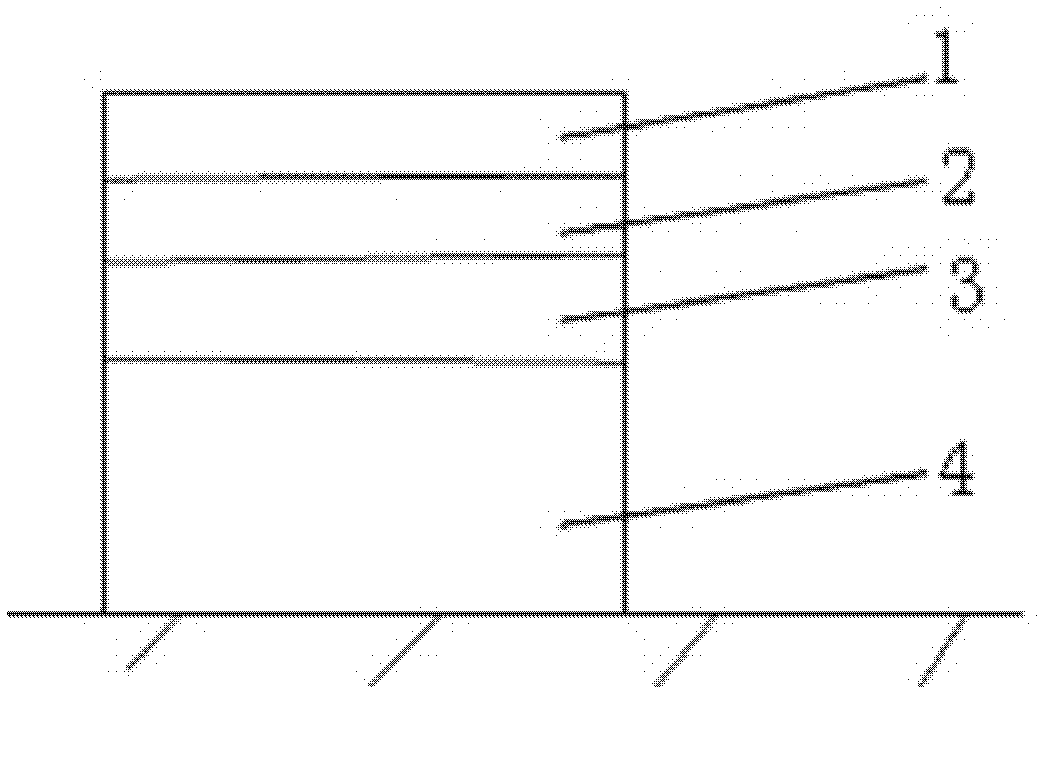

Lining structure of electrical calcination furnace

ActiveCN101446471AEliminate damageIncrease temperatureElectric heating for furnacesMonolithic liningsInsulation layerFire brick

The invention discloses a lining structure of an electrical calcination furnace. The lining structure comprises a furnace shell (6) and a furnace cover (7); a refractory brick layer which is close to the center of the furnace is divided into two parts, that is, an end refractory brick part (1) positioned in low-temperature areas of the upper end and the lower end and a middle refractory brick part (2) positioned in a high-temperature area; a refractory insulating particle layer (3) is positioned outside the end refractory brick part (1) and the middle refractory brick part (2), an insulating layer (4) is positioned outside the refractory insulating particle layer (3), a ceramic fiber layer (5) is positioned outside the insulating layer (4), and the furnace shell (6) is positioned outside the ceramic fiber layer (5); and an upper electrode (9) is positioned in the center of the upper part of the furnace body, and a lower electrode (10) is positioned in the center of the lower part of the furnace body. The lining structure has the advantages of simple construction, wide temperature operating range, stable service performance, long service life, guaranteed quality and capacity of the product, high utilization rate of the electrical heat energy as well as low operation and maintenance cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

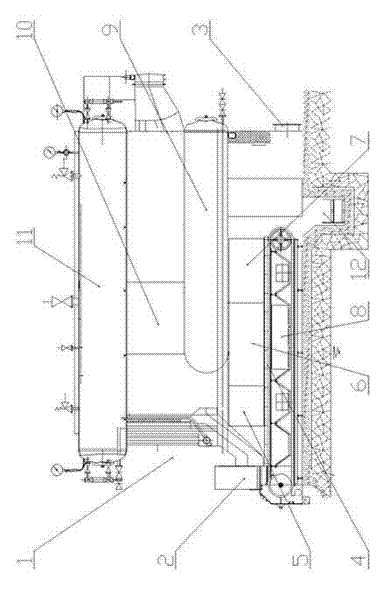

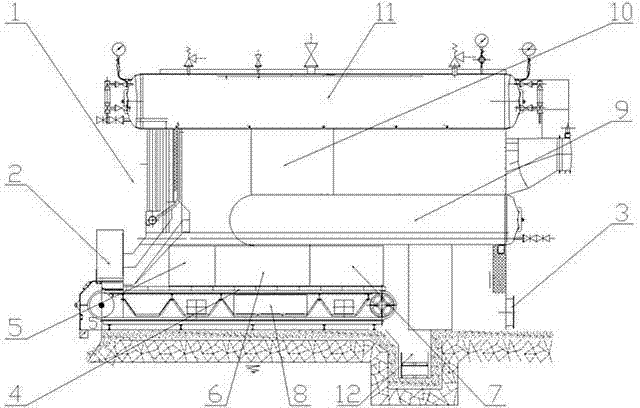

High heating value gas boiler

Owner:WUXI HUAGUANG BOILER

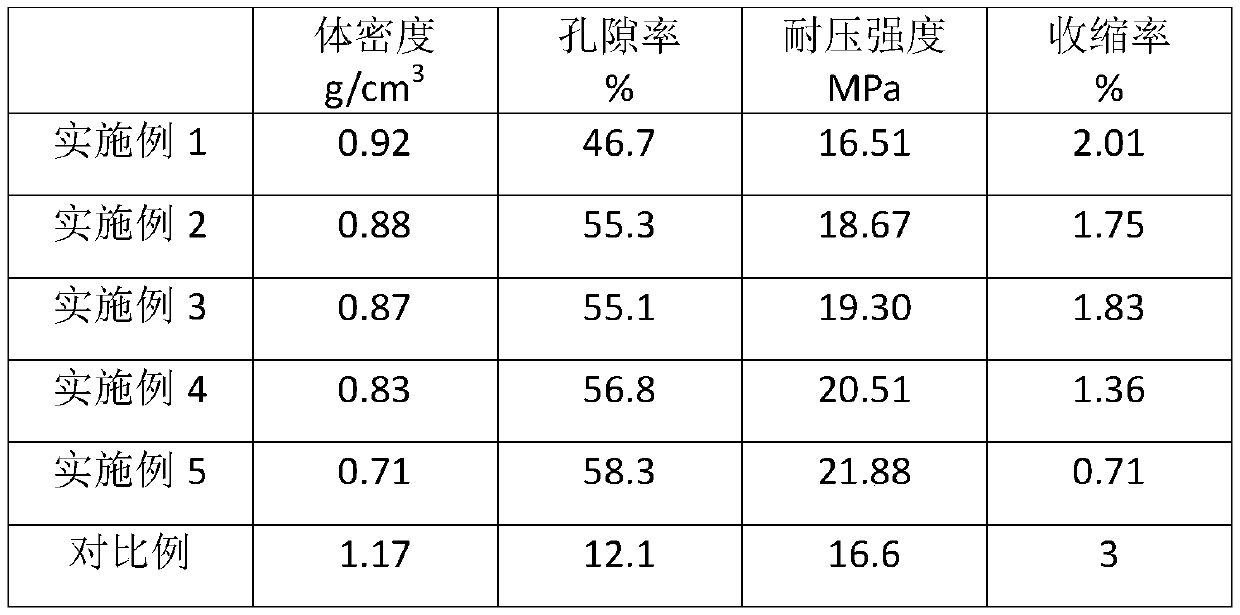

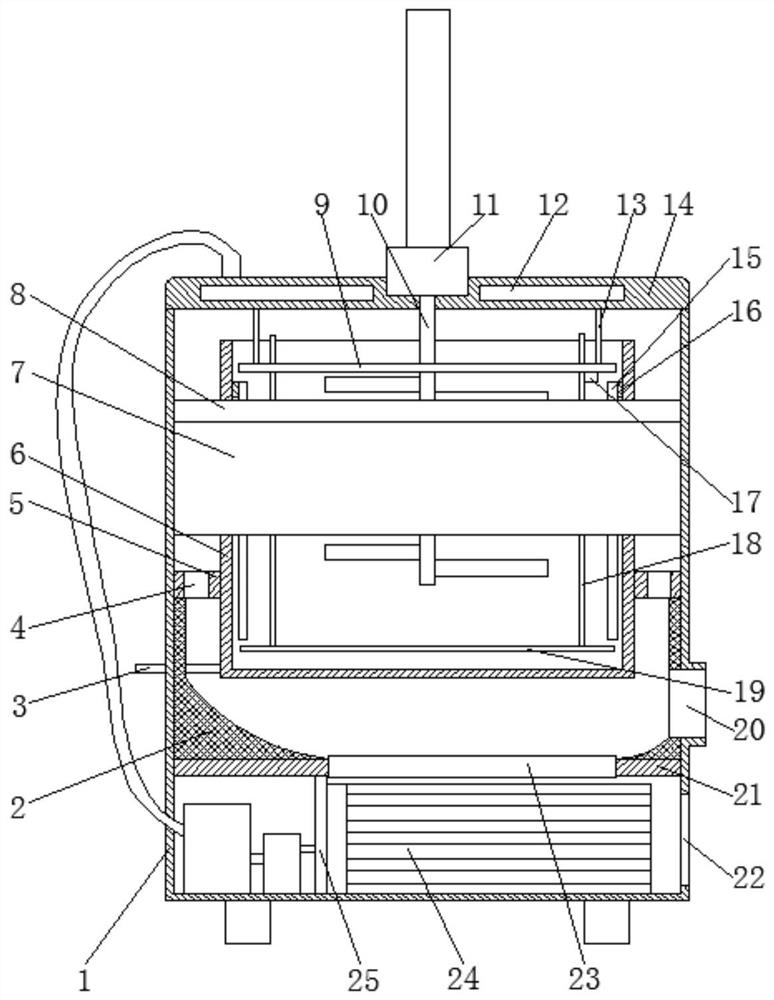

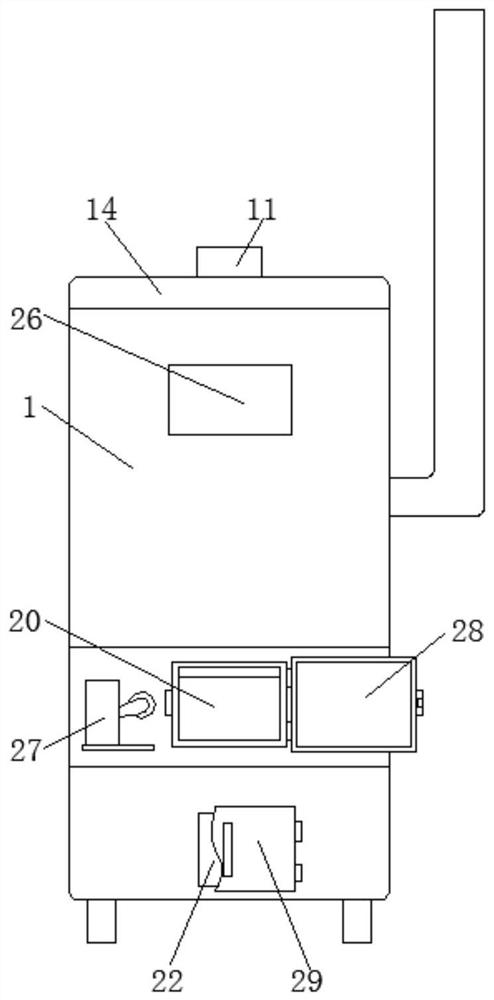

Safe and energy-saving smelting furnace body and smelting device employing same

The invention discloses a safe and energy-saving smelting furnace body and a smelting device employing same and belongs to the technical field of smelting devices. The smelting furnace body includes ashell and a lining arranged therein, wherein the lining includes a refractory brick layer made of light-weight mullite bricks. The light-weight mullite brick is mainly prepared from, by weight, 40-55parts of aluminum oxide aggregate, 15-20 parts of coal gangue, 5-10 parts of fly ash, 3-8 parts of silicon carbide, 3-8 parts of an expansion agent, 8-20 parts of a binding agent, and 5-10 parts of apore forming agent, the content of Al2O3 in the aluminum oxide aggregate being 40-100%, the expansion agent being at least one of andalusite, kyanite and sillimanite, the binding agent being at leastone of clay and sodium carboxymethylcellulose, and the pore forming agent being at least one of graphite, polyethylene, polypropylene and polystyrene. The smelting furnace body is good in stability,is not liable to be burnt-through and is low in construction cost.

Owner:郑州市振峰矿山机器有限公司

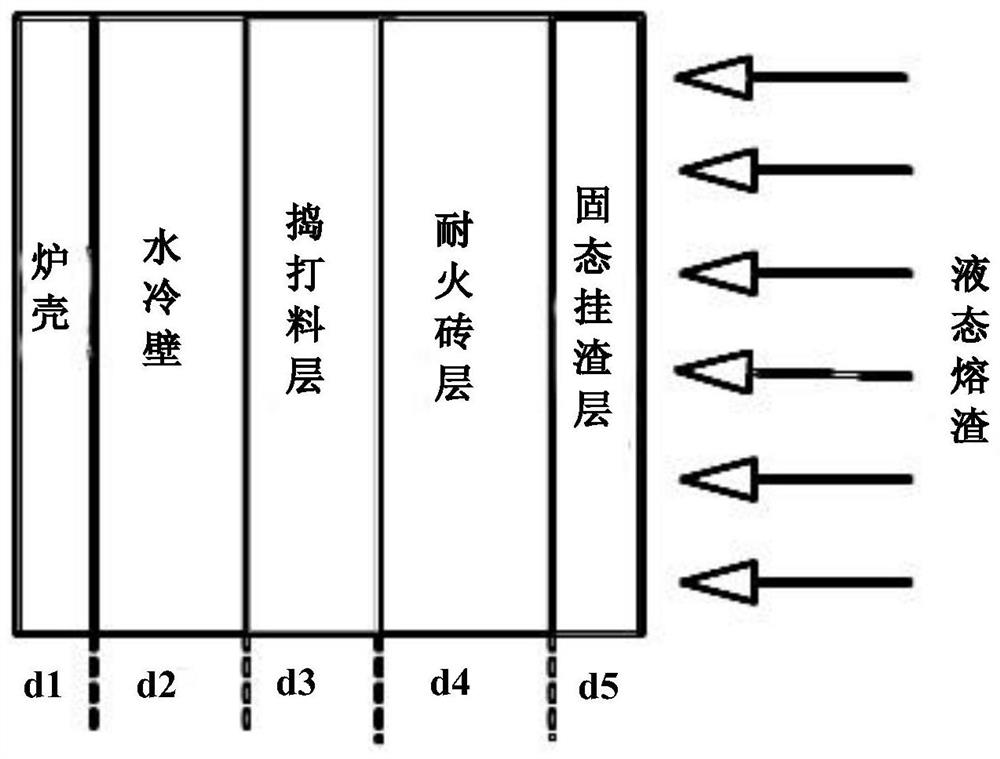

Slag adhering method for water-cooled wall electric furnace

InactiveCN111876552ASlow down or even eliminate erosionExtended service lifeElectric furnaceLiquid slagSmelting process

The invention relates to a slag adhering method for a water-cooled wall electric furnace. The method comprises the following steps: in the electric furnace smelting process, components on the surfacepart of a refractory brick layer of an electric furnace lining react with liquid slag to form a high-melting-point substance, and under the cooling action of a water-cooled wall of the electric furnace lining, the formed high-melting-point substance is condensed on the surface part of the refractory brick layer to form a solid slag adhering layer. By means of the method, the furnace lining and thehigh-temperature slag can be isolated, the solid slag adhering layer is automatically thickened and thinned along with reduction and increase of the temperature of a molten pool in the smelting process, erosion of the slag to the refractory brick layer can be remarkably relieved or even eliminated, and therefore the service life of the furnace lining of the electric furnace is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Improved side-blown molten pool melting furnace

ActiveCN105698529BDry fastSpeed up decompositionIncreasing energy efficiencyCrucible furnacesSlagStraight segment

The invention provides an improved type side-blowing molten pool smelting furnace. The improved type side-blowing molten pool smelting furnace comprises a long round furnace body, a furnace cylinder, a furnace top, a furnace body frame structure and a plurality of multi-channel spray guns. The multi-channel spray guns are arranged on the two sides of the long round furnace body correspondingly. The long round furnace body is formed by a furnace body protective plate in an enclosed mode. A water sleeve is installed on the lower portion of the inner side of the furnace body protective plate. A first firebrick layer is further inlayed in the inner side of the water sleeve. A second firebrick layer is arranged on the water sleeve and the first firebrick layer and installed on the inner side of the furnace body protective plate. The furnace cylinder is arranged at the bottom of the long round furnace body. The long round furnace body is provided with a metal discharge outlet and a slag outlet. The furnace body frame structure comprises steel vertical pillars, cross beams and pulling rods. The multi-channel spray guns are arranged on the two sides of the middle straight segment of the long round furnace body, and the output ends of the multiple multi-channel spray guns extend into the long round furnace body. By means of the improved type side-blowing molten pool smelting furnace, the problem that in the prior art, the temperature in a molten pool smelting furnace is difficult to control can be solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Gas catalytic flameless near-infrared heating annealing furnace

ActiveCN104962716AImprove thermal efficiencyEvenly distributedFurnace typesHeat treatment furnacesFurnace temperatureCombustor

The invention relates to a gas catalytic flameless near-infrared heating annealing furnace, and relates to an annealing furnace. The gas catalytic flameless near-infrared heating annealing furnace comprises a furnace shell, a furnace liner, a heating system, a cooling system and a transport system, wherein a fire-resisting material layer is arranged between the furnace shell and the furnace liner, the heating system is embedded in the fire-resisting material layer and is a gas catalytic flameless near-infrared heating porous medium burner, the heating system comprises a burner body, a heat preservation layer and a refractory brick layer, a pre-mixed gas dispersing chamber, a perforated plate, a pre-mixed gas homogenizing chamber, a flame-preventing screen plate and a foam ceramic plate are arranged in the refractory brick layer, the bottom of the pre-mixed gas dispersing chamber is communicated with a pre-mixed gas supply pipe, and heat-preserving cotton is arranged between the periphery of the pre-mixed dispersing chamber and the refractory brick layer; the upper end surface and the lower end surface of the burner body are connected together by virtue of an upper pressing plate, a lower pressing plate and a connecting piece. The gas catalytic flameless near-infrared heating annealing furnace is high in heat efficiency, complete in burning, low in pollutant emission and applicable to the annealing process needing the protection of atmosphere in the furnace, has characteristics of high temperature, low energy consumption, high yield, low repair cost and the like and is likely to popularize and use.

Owner:北京秦冶众智科技有限公司

Pigpen cooling system

InactiveCN104871982AReduce the temperatureControl temperature and humidityAnimal housingInsulation layerWater source

The invention relates to the technical field of pig breeding, and especially relates to a pigpen cooling system. The system comprises a pigpen. The wall of the pigpen is composed of an inner layer, a middle layer and an outer layer. The middle layer is a heat insulation layer, and the inner and outer layers are concrete layers or firebrick layers. The inner layer is provided with air vents. An atomization nozzle is arranged between the inner layer and the middle layer, and is connected to a water pipe. The water pipe is connected to a groundwater well through a water pump. A fan is arranged on one side of the atomization nozzle. The system is simple in structure and novel in design, and underground water source is employed in the system; in the summer, temperature in the pigpen can be reduced, good ventilation effects are achieved, and the humiture in the pigpen can be effectively controlled; and in the winter, the water in the water pipe can be connected to the water pump in a boiler, so that heat insulation effects are achieved, and the equipment utilization rate is improved. The wall of the pigpen has three layers. The system is low in cost, has good using effects, is environment-friendly, and is anti-seismic.

Owner:TIANJIN JIXIAN YUANFENG LIVESTOCK FARMING PROFESSIONAL COOP

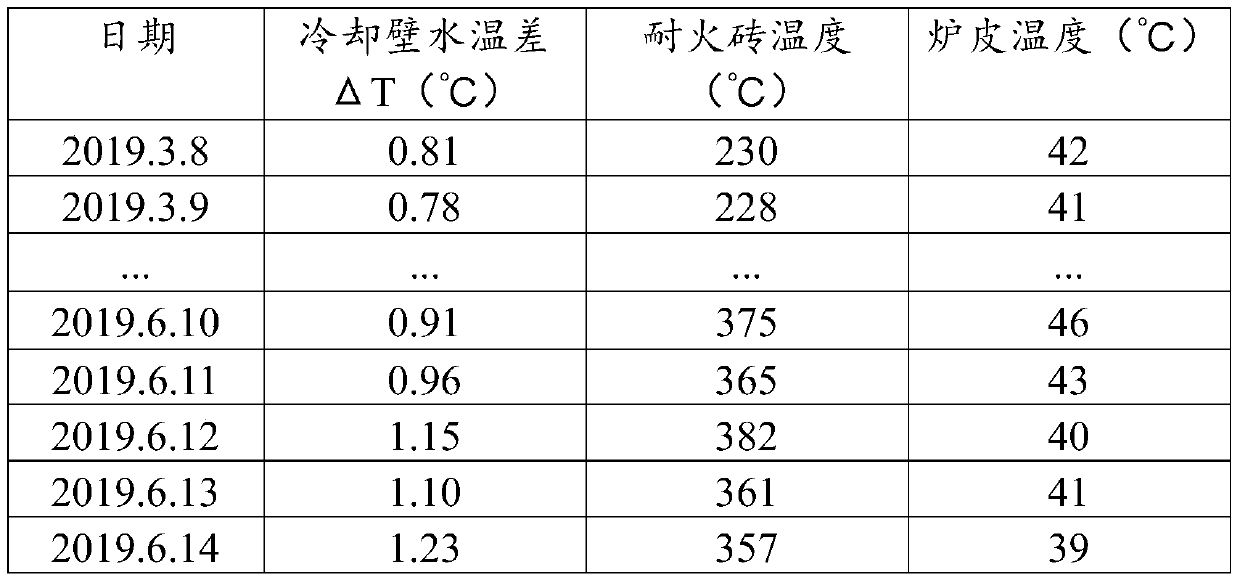

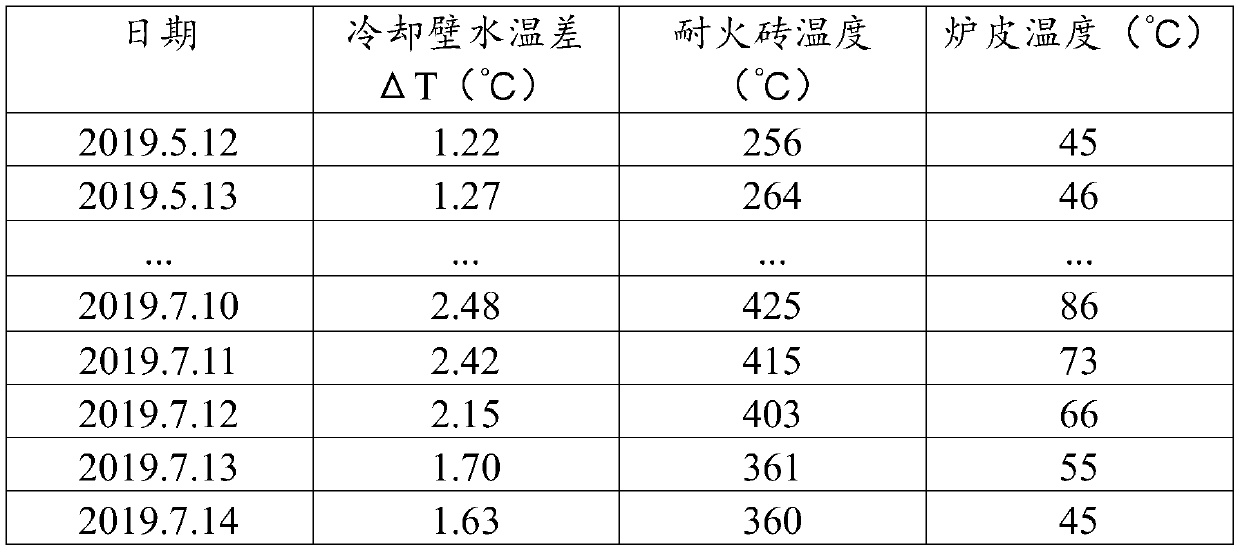

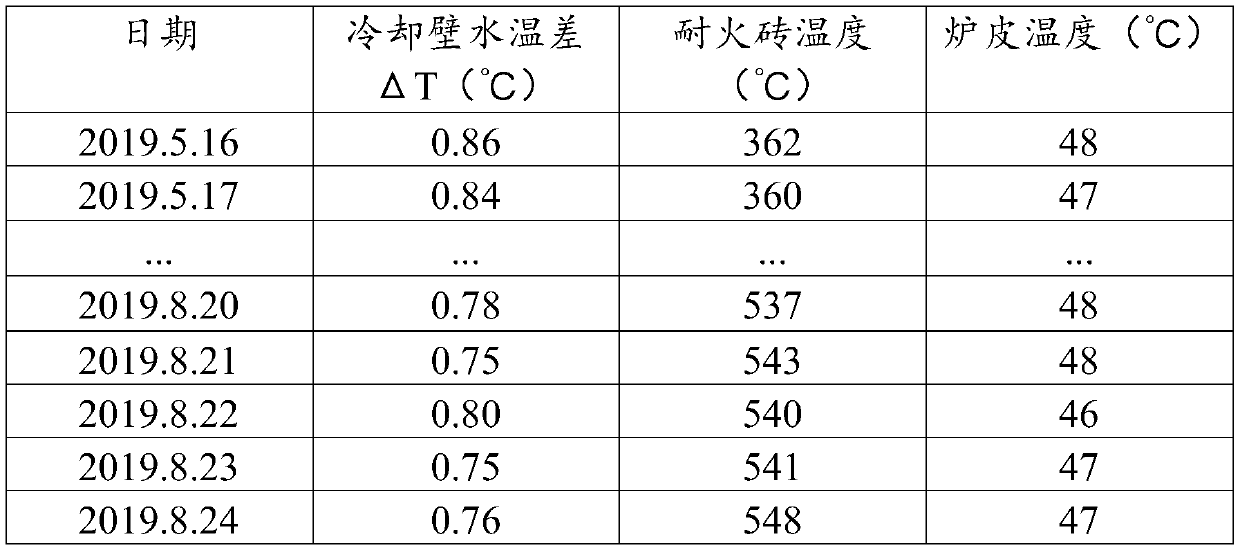

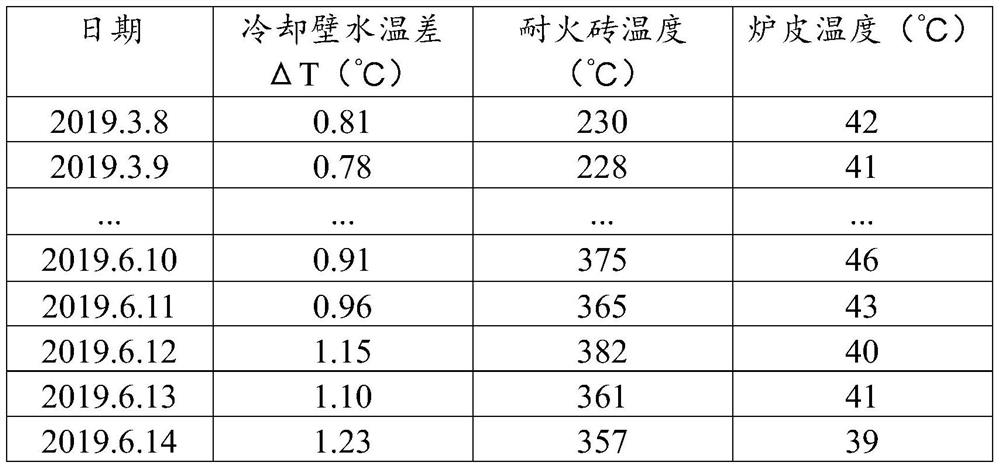

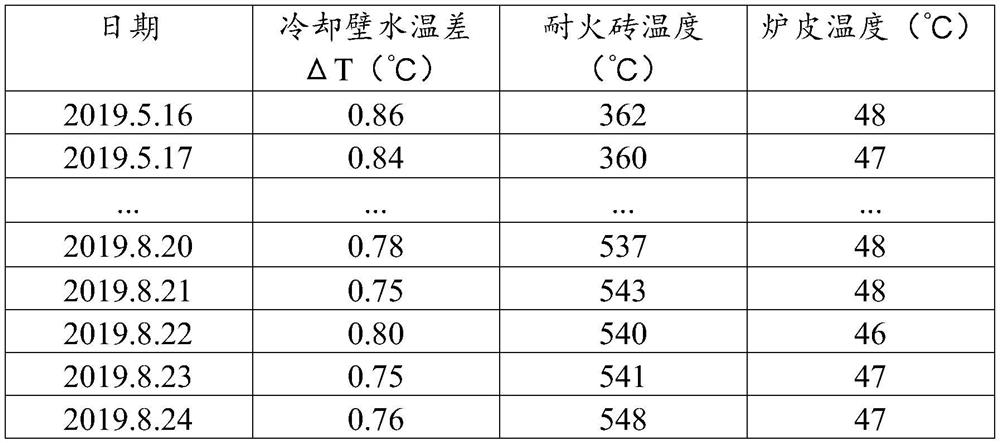

Blast furnace packing layer air gap judgment method

The invention relates to a blast furnace packing layer air gap judgment method, and belongs to the technical field of blast furnace ironmaking. The blast furnace packing layer air gap judgment methodcomprises the following steps: a reference energy transfer coefficient k1<reference> between a refractory brick layer and a cooling wall, a reference transfer coefficient k2<reference> between the cooling wall and a furnace shell and a reference transfer coefficient k3<reference> between the refractory bricks and the furnace shell are determined according to the refractory brick temperature corresponding to the cooling wall, the furnace shell temperature corresponding to the cooling wall and the water temperature difference of water inlet and outlet pipe heads of the cooling wall; and k1<measurement>, k2<measurement> and k3<measurement> obtained according to the current detection data and a relational expression are respectively compared with k1<reference>, k2<reference> and k3<reference>to judge whether an air gap exists in a packing layer of a blast furnace body and judge the change of the air gap. The judgment method is convenient for technicians in the field to judge the air gap,and can effectively guide the technicians of the blast furnace process to treat the air gap by adopting a grouting filling method.

Owner:SGIS SONGSHAN CO LTD

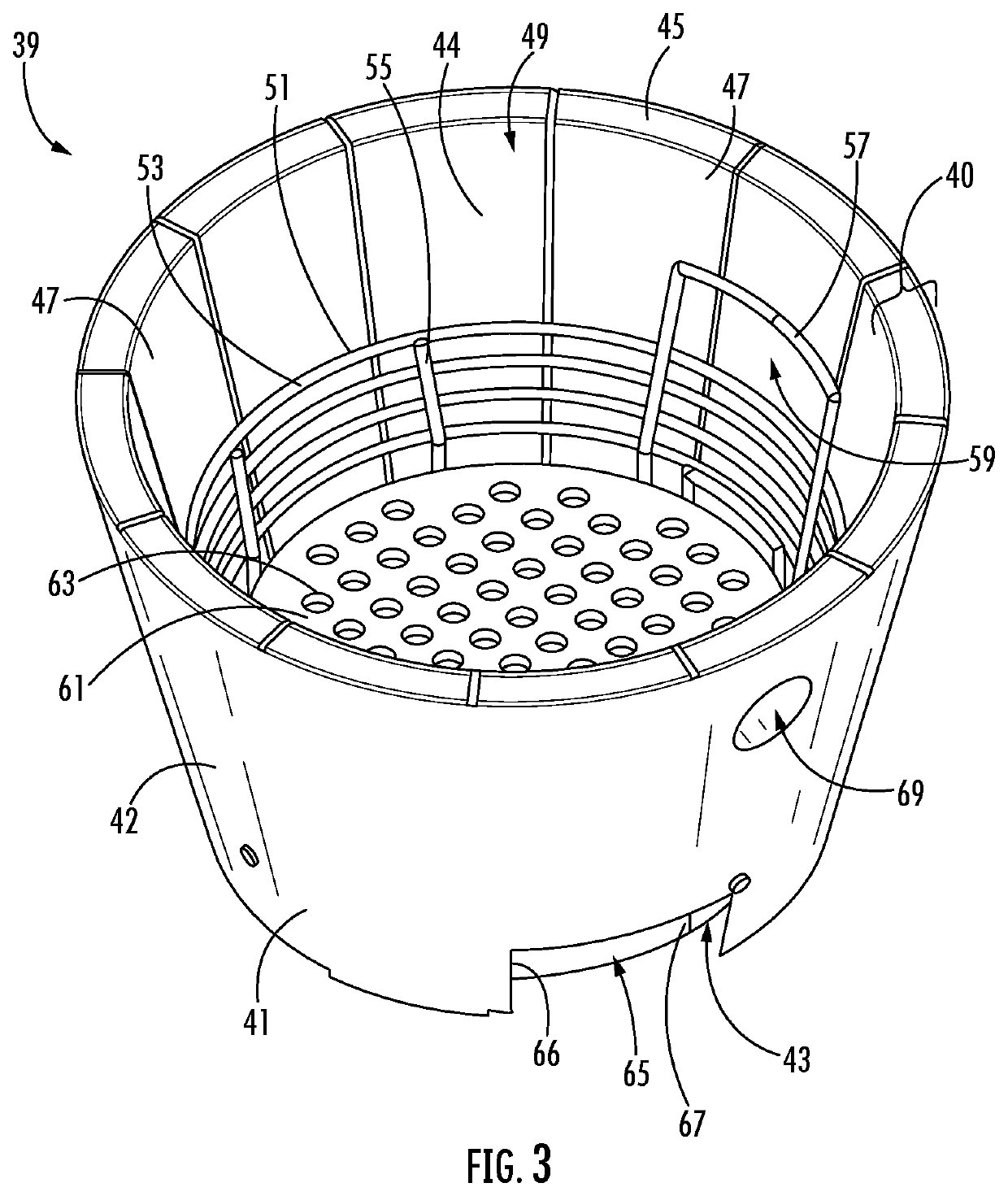

Firebox for grill

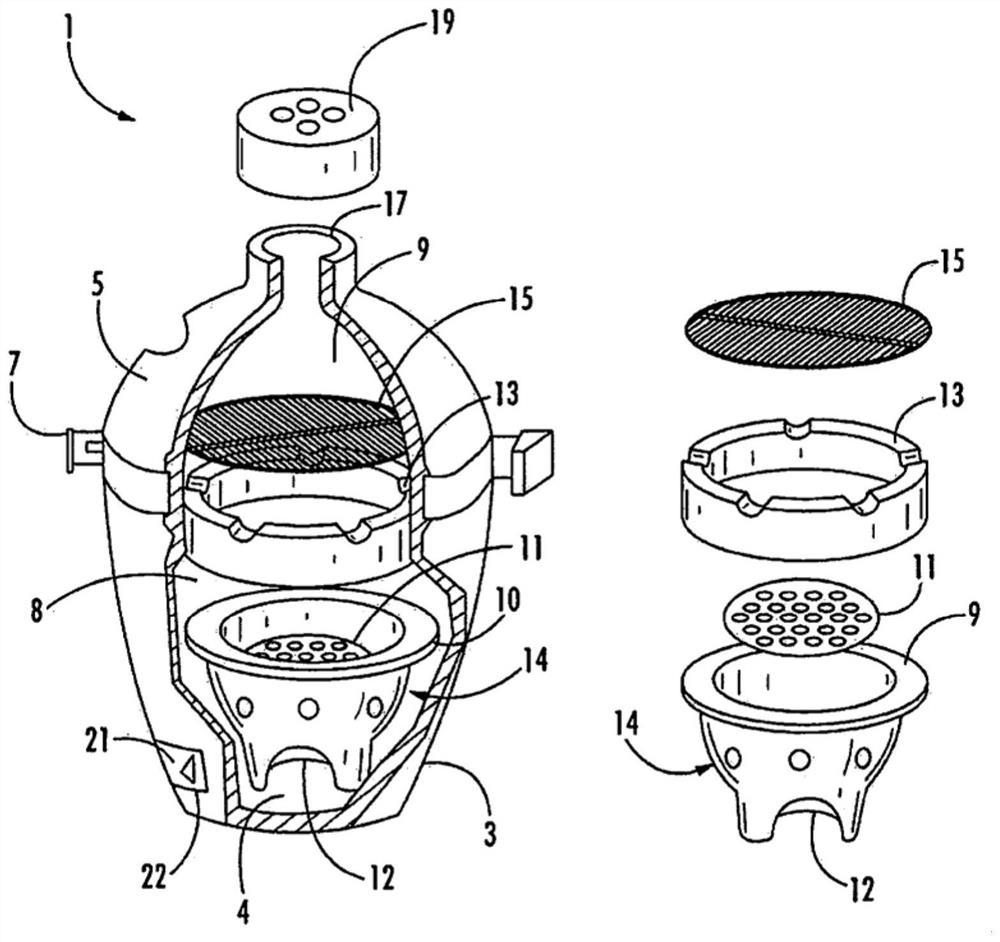

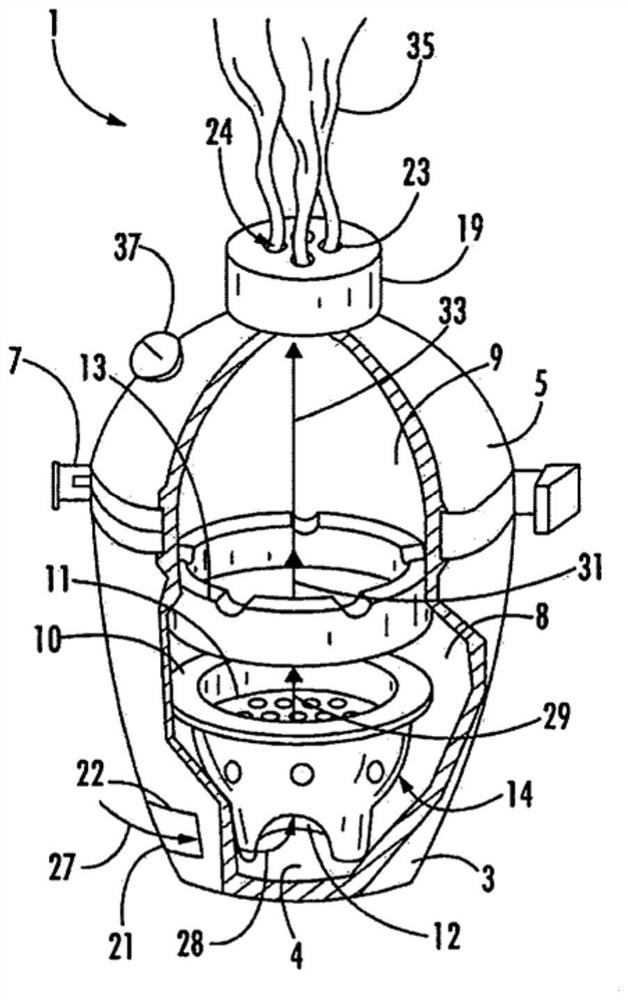

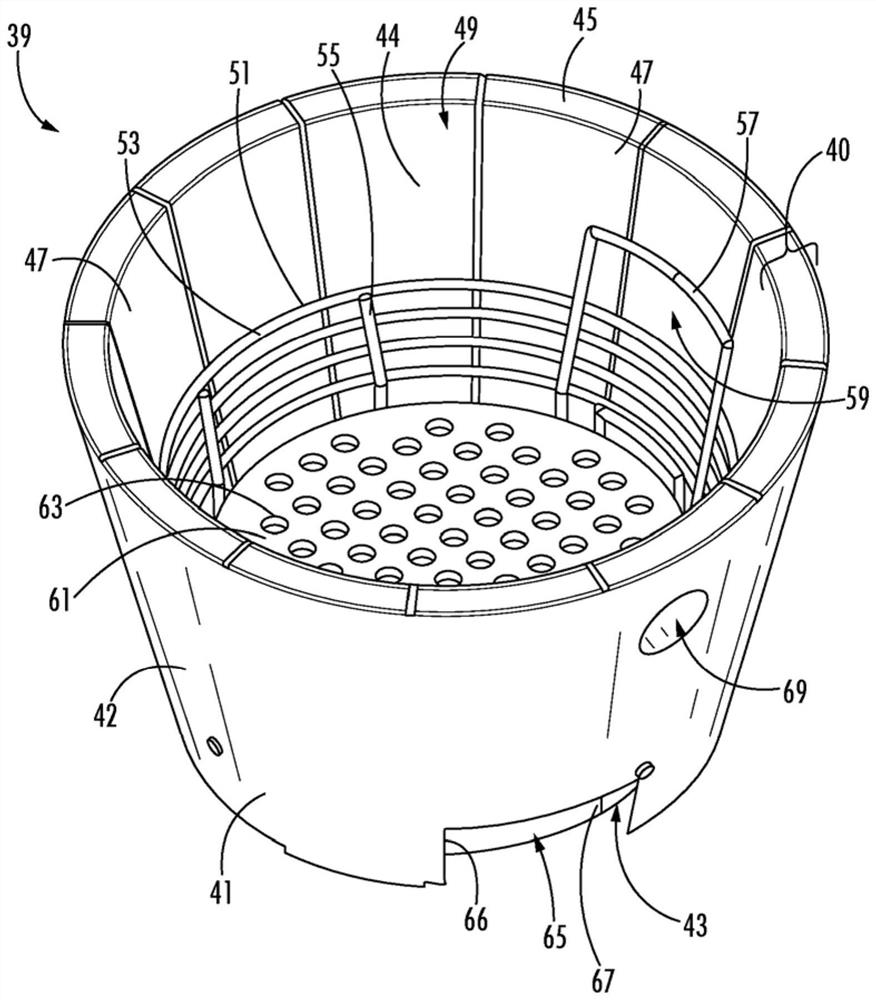

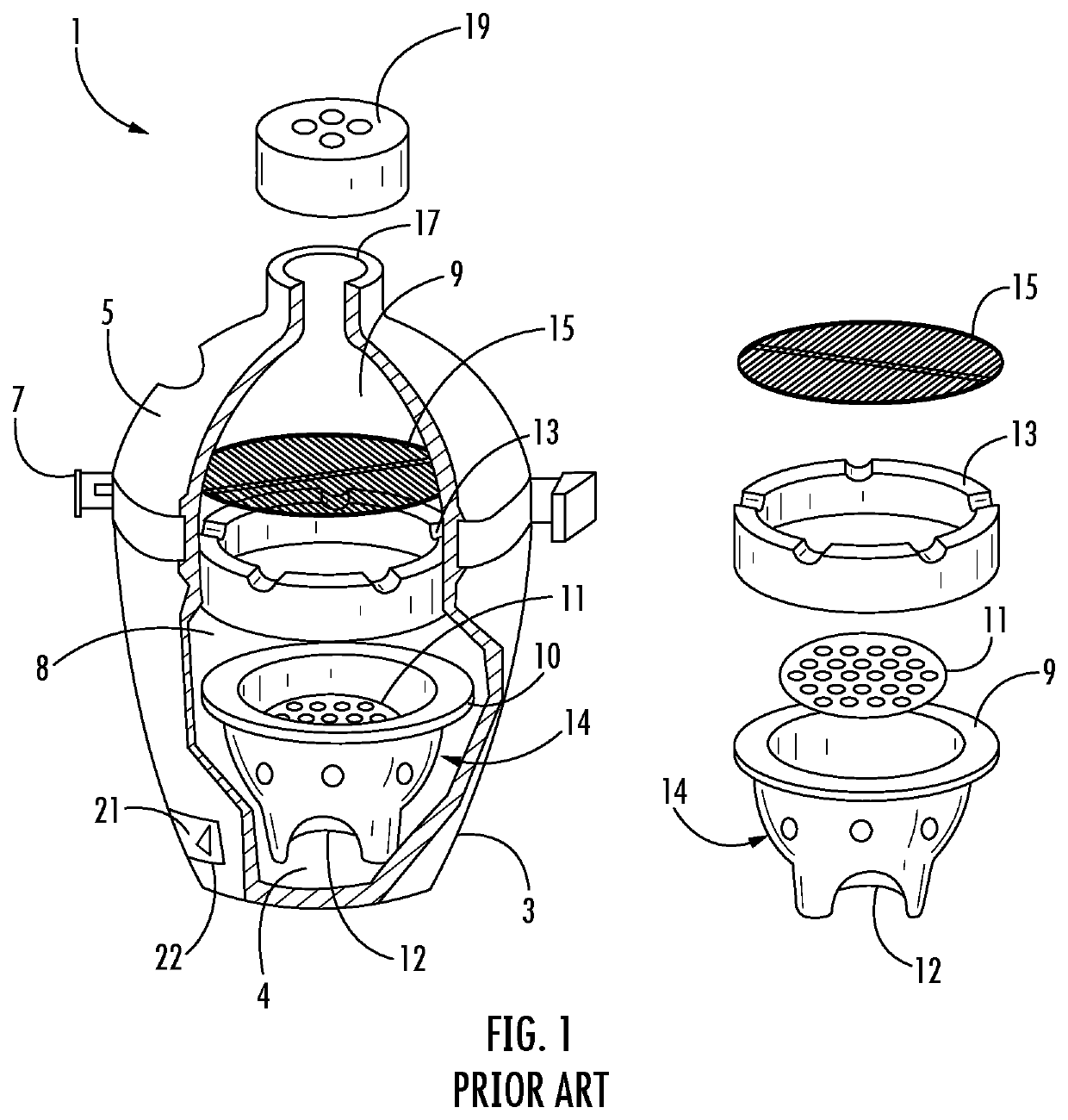

A firebox for a grill is provided. The firebox has a shell, an insulation layer, and a firebrick layer. The firebrick layer comprising a plurality of firebricks that form an inner peripheral surface of the firebox. The insulation layer formed between the firebrick layer and the shell or the insulation layer forming the outermost layer of the firebox. The shell preventing the collapse and / or unwanted airflow into the internal cavity of the firebox if a fracture is formed in the firebrick layer.

Owner:家用取暖器公司D B A 安全烤炉

Firebox for a grill

A firebox for a grill is provided. The firebox has a shell, an insulation layer, and a firebrick layer. The firebrick layer comprising a plurality of firebricks that form an inner peripheral surface of the firebox. The insulation layer formed between the firebrick layer and the shell or the insulation layer forming the outermost layer of the firebox. The shell preventing the collapse and / or unwanted airflow into the internal cavity of the firebox if a fracture is formed in the firebrick layer.

Owner:HOME FIRES INC D B A SAFFIRE GRILL CO

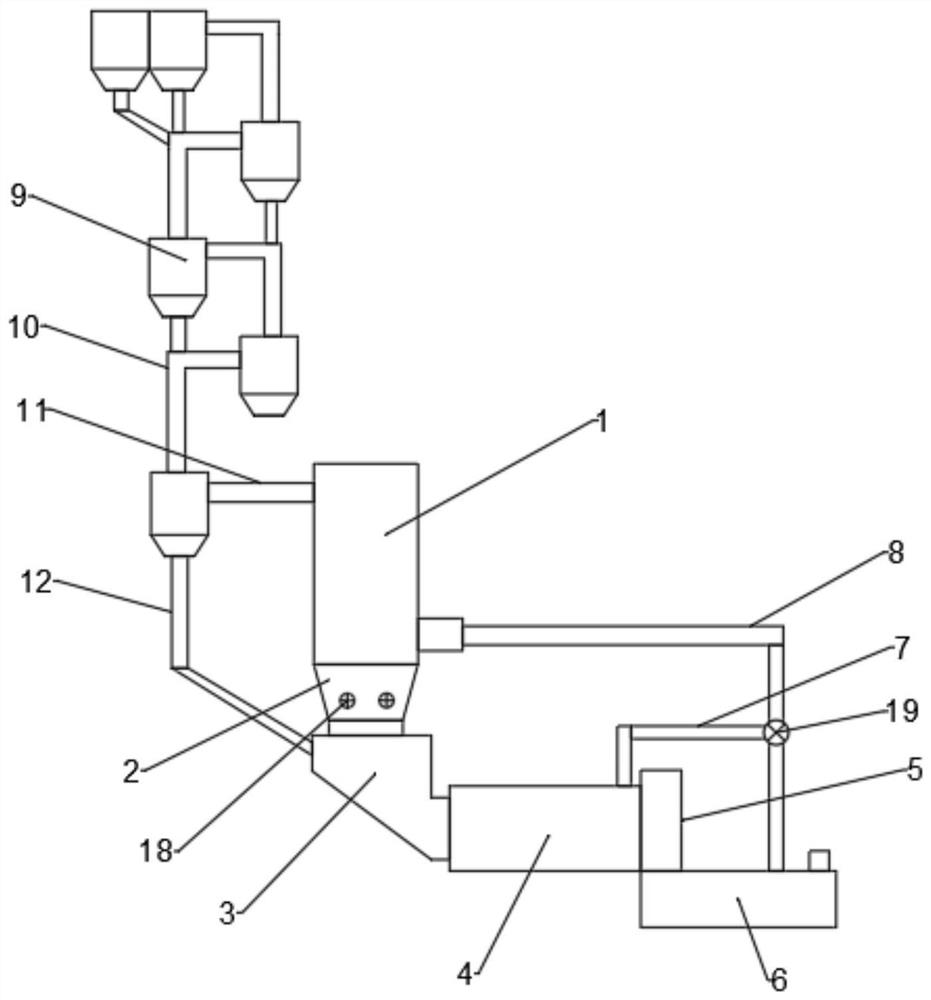

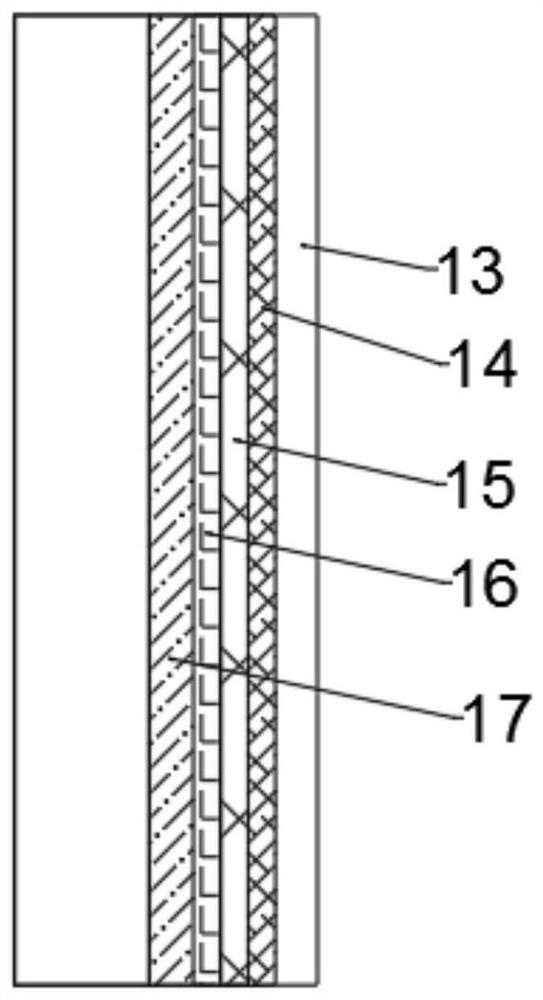

Dry-process cement firing system

PendingCN111912231AChange temperatureImprove reducibilityFurnace typesPreheating chargesInsulation layerThermodynamics

The invention discloses a dry-process cement firing system. The system comprises a decomposing furnace body, a reduction chamber is arranged at the lower end of the decomposing furnace body, a kiln tail smoke chamber is arranged at the lower end of the reduction chamber, a rotary cement kiln is arranged at one end of the kiln tail smoke chamber, and a fuel adding chamber is arranged at the end, away from the kiln tail smoke chamber, of the rotary cement kiln. A cooling machine is arranged at the lower end of the fuel adding chamber, a secondary air pipe is connected between the cooling machineand the rotary cement kiln, a tertiary air pipe is connected between the cooling machine and the decomposing furnace body, a kiln-entering raw material pipe connected with the kiln tail smoke chamberis arranged at the bottom end of a five-stage preheater, and a cement raw material adding port is formed in the five-stage preheater. The furnace wall of the decomposing furnace body is composed of ashell, a first heat insulation layer, a connecting felt layer, a second heat insulation layer and a refractory brick layer. Through the system, the temperature in a decomposing furnace in the cementfiring system is guaranteed, and the energy-saving effect is obvious.

Owner:SINOMA SUZHOU CONSTR

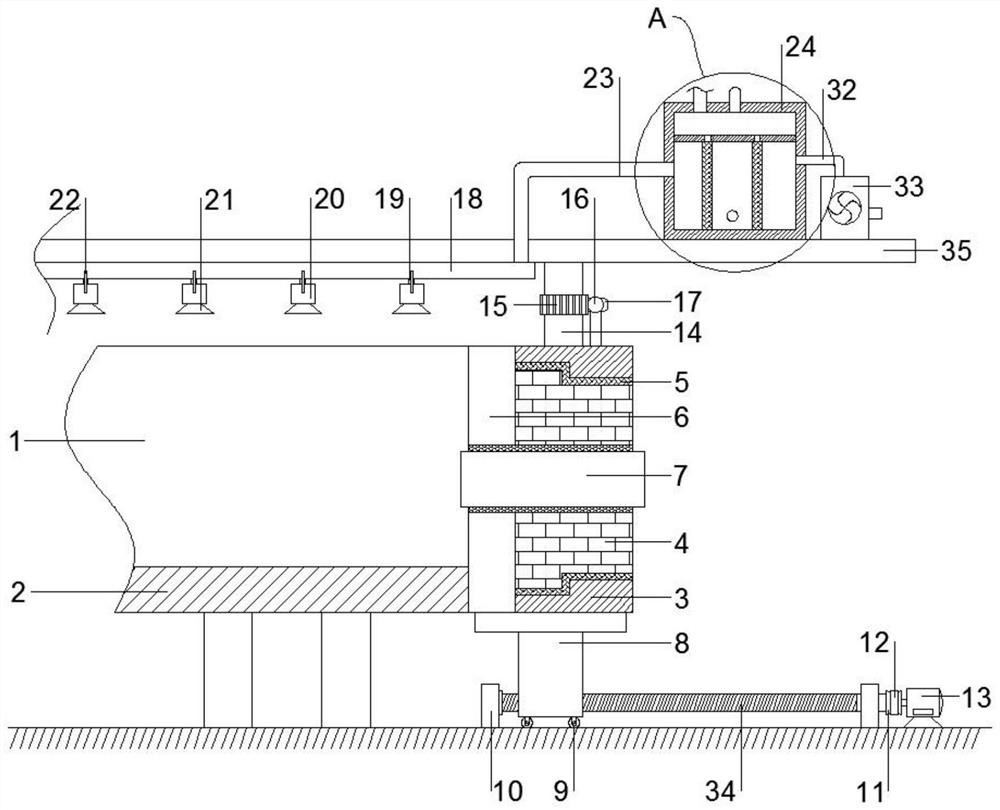

Blast Furnace Ironmaking Plant with Highly Sealed Bottom

ActiveCN108796154BImprove cooling effectReduce the temperatureBlast furnace detailsCooling devicesHeat conductingFire brick

The invention discloses a blast furnace ironmaking device with a high-leakproofness hearth. The blast furnace ironmaking device comprises a furnace foundation, a bottom plate, a furnace shell, a sealing plate, a first cooling device, a sealing device and a heat conducting isolation barrel, wherein a refractory brick layer and a concrete layer are sequentially horizontally arranged in a space formed by the sealing plate and the bottom plate from up to down; the first cooling device is arranged between the sealing plate and the upper surface of the refractory brick layer; the first cooling device comprises a first cooling pipe, a second cooling pipe and a plurality of heat conducting connecting plates which are in the shape of a mosquito-incense holder; the sealing device is arranged on theouter side wall of the bottom of the furnace shell; the sealing device comprises an integrally formed sealing barrel and a sealing round plate which is horizontally and fixedly connected to the upperend of the sealing barrel; two groups of drainage plates are vertically and fixedly connected between the heat conducting isolation barrel and the furnace shell; and two groups of heat conducting plates are vertically and fixedly connected between the heat conducting isolation barrel and the sealing barrel. According to the blast furnace ironmaking device, temperature of the hearth can be decreased, the hearth can be subjected to liquid seal, and leakproofness of the hearth is greatly improved.

Owner:BATOU LIGHT IND VOCATIONAL TECHN COLLEGE

Resistance furnace for silicon carbide micro powder production and using method thereof

PendingCN111998675AEasy to replaceAvoid damageFurnace typesSilicon carbideCarbide siliconInsulation layer

The invention discloses a resistance furnace for silicon carbide micro powder production and a using method thereof in the technical field of silicon carbide production. The resistance furnace comprises a furnace wall plate and a furnace bottom support; a supporting base is fixed to the bottom end of a reinforced concrete frame, the supporting base is symmetrically connected with screws in a threaded mode, the two screws are rotationally connected with a plane through supporting blocks, and the two screws are in transmission connection; the right end of one screw is connected with a first motor, an air suction hood, a purification box and a fan are arranged above the furnace wall plate, the air suction hood is in communication with the purification box, and the purification box is in communication with the fan. According to the resistance furnace for silicon carbide micro powder production and the using method thereof, a heat insulation layer, the concrete frame and a refractory bricklayer are detachably mounted at one end of the furnace wall plate, so that the refractory brick layer is convenient to replace, and the furnace wall plate and the resistance furnace can be prevented from being damaged; the air suction hood, the purification box, the fan and the like are added, the fan is started, harmful gas is absorbed into the purification box, harmful components in the gas areabsorbed by purification liquid when passing through a filter screen, the harmful gas can be well purified and discharged, and environment protection is facilitated.

Owner:连云港市沃鑫高新材料有限公司

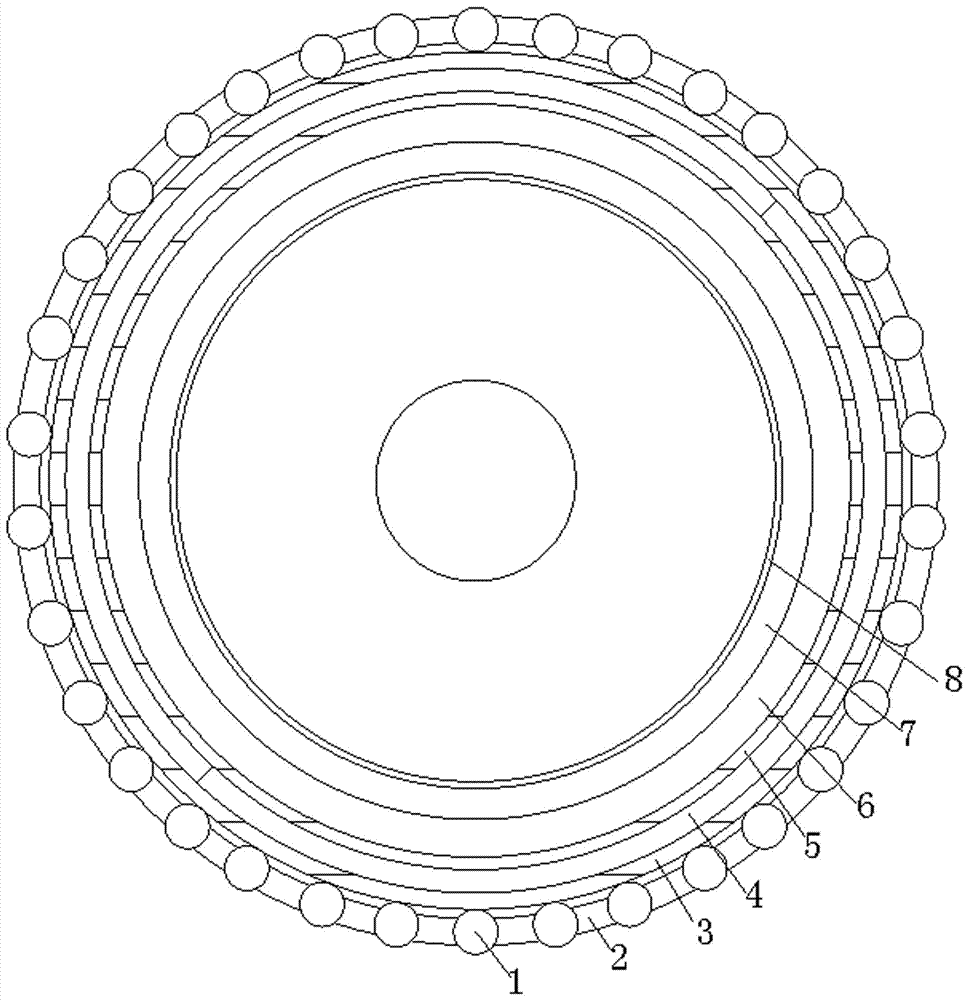

Circulating fluidized bed boiler cyclone separator composed of one-time bent pipe panel

PendingCN106979515AReduce manufacturing costShorten the manufacturing cycleFluidized bed combustionApparatus for fluidised bed combustionFluidized bedFire brick

The invention relates to a circulating fluidized bed boiler cyclone separator composed of a one-time bent pipe panel. The outer side of the cyclone separator is composed of the pipe panel; the pipe panel is composed of a plurality of one-time bent pipes and flat steel arranged between every two adjacent one-time bent pipes; a heat insulating layer is arranged on the inner side of the pipe panel; a heat insulating and fire resistance layer is arranged on the inner side of the heat insulating layer; a second heat insulating layer is arranged on the inner side of the heat insulating and fire resistance layer; a wear-resisting layer is arranged on the inner side of the second heat insulating layer; a fire resistance brick layer is arranged on the inner side of the wear-resisting layer; and a fixed layer is arranged on the inner side of the fire resistance brick layer. Each single bent pipe formed by pairing of original three-section bent pipes is subjected to one-time bending, paired assembling and welding of the single pipes in the assembling process are reduced or cancelled, the manufacturing cost is reduced, the manufacturing cycle is shortened, the working efficiency is improved, and the product quality is guaranteed.

Owner:江苏汇能锅炉有限公司

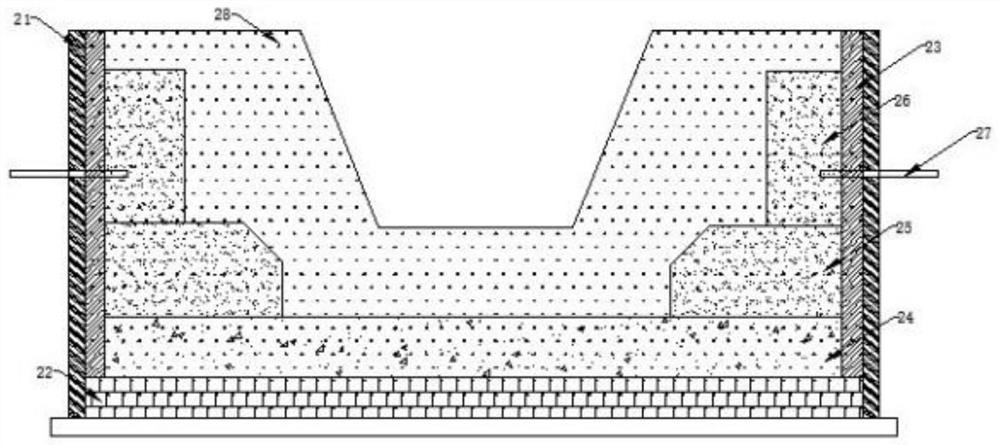

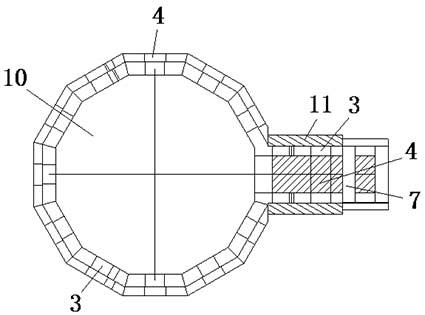

All-electric melting energy-saving melting furnace for borosilicate float glass production, use method and product

PendingCN114436503AImprove problems such as difficult to controlImprove product qualityElectric furnaceFire brickHeat conservation

The invention relates to the technical field of all-electric melting furnaces, in particular to an all-electric melting energy-saving melting furnace for borosilicate float glass production, a using method and a product. The all-electric melting energy-saving melting furnace comprises a steel structure framework, the bottom of the steel structure framework is a stand column supporting furnace outer layer steel structure of a steel-concrete structure, and a heat preservation brick layer is arranged on the inner wall of the steel structure framework; the steel structure framework is of a dodecahedron vertical funnel structure, the steel structure framework and the heat preservation brick layer are connected through adjusting bolts, a refractory brick layer is arranged on the inner wall of the heat preservation brick layer, electrode holes are formed in the side wall of the refractory brick layer, and a top cover hanging brick is arranged at the top end of the inner wall of the heat preservation brick layer. The method is convenient to operate and high in operability.

Owner:QINHUANGDAO HONGHUA SPECIAL GLASS CO LTD

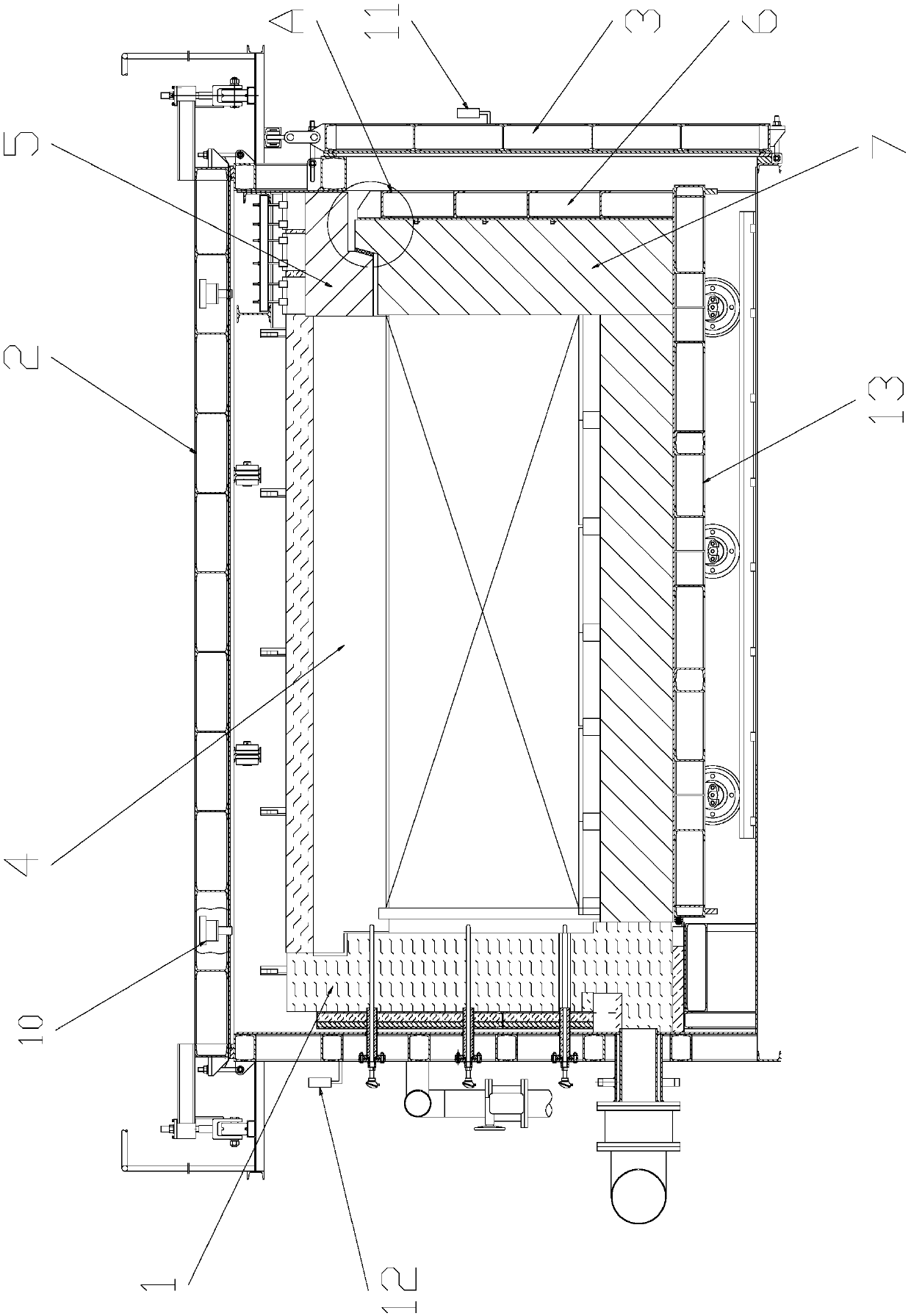

Nitriding sintering furnace

InactiveCN111089485AFilled tightlyIncrease temperatureFurnace safety devicesFurnace typesInsulation layerThermal break

The invention belongs to the technical field of industrial kilns, and particularly relates to a nitriding sintering furnace. The nitriding sintering furnace comprises a furnace body provided with a nitriding chamber, a furnace cover, a kiln car capable of entering and exiting the nitriding chamber and a furnace door used for closing the furnace body; a heat insulation layer is arranged in the furnace body; the side wall, for closing the nitriding chamber, of the kiln car is of a composite structure; the composite structure comprises a steel structure layer and a refractory brick layer arrangedon one side, close to the nitriding chamber, of the steel structure layer; a heat insulation channel is formed between the heat insulation layer and the refractory brick layer and comprises a first channel, a second channel and a third channel; the first channel, the second channel and the third channel sequentially communicate from bottom to top; and the second channel is obliquely arranged andis filled with a heat insulation medium. According to the nitriding sintering furnace, tight filling of the heat insulation medium between the kiln car and the furnace body can be ensured during sintering each time, so that the continuous heat insulation effect is ensured, and the furnace door is prevented from overheating.

Owner:HANJIANG HONGYUAN XIANGYANG SILICON CARBIDE SPECIAL CERAMICS

Construction method for spherical furnace top of industrial furnace

ActiveCN103673621BReduce cleanup workloadReduce usageLinings repairFurnace crowns/roofsMetallurgyFire brick

The invention discloses a construction method for a spherical furnace top of an industrial furnace. Firstly, a steel furnace shell is mounted, the elevation and the like of steel supporting plates at the arch springing positions of a globe-roof are rechecked, a vertical control line is arranged from the center of the furnace bottom to the center of the furnace top in a drawn mode, a supporting frame is erected in a furnace body, and a round top plate is arranged in the center of the top; multiple vertical arc plates are then manufactured and are fixed on the round top plate and the supporting frame, and the elevation and the radius of each layers of refractory bricks are marked on the corresponding vertical arc plates; multiple horizontal arc plates are manufactured; the refractory bricks at the arch springing positions are constructed first, the refractory bricks are constructed upwards in sequence, the vertical radian and the elevation of the refractory bricks are controlled by using the vertical arc plates, and the horizontal radius of the refractory bricks is controlled by using the horizontal arc plates; one heat preservation brick layer is constructed after one certain layer of the refractory bricks are constructed, and the construction is carried out in the way until the construction of all the refractory brick layers and the construction of all the heat preservation brick layers are completed; a steel cover plate of the furnace top is mounted in a hanging mode to seal the steel furnace shell. The construction method for the spherical furnace top of the industrial furnace has the advantages of being economical in used material, simple in working procedure, low in cost and the like, and can ensure construction quality more easily.

Owner:五矿二十三冶建设集团有限公司

Judgment Method of Air Gap in Filling Layer of Blast Furnace

The application relates to a method for judging the air gap of a filling layer of a blast furnace, which belongs to the technical field of blast furnace ironmaking. The method for judging the air gap of the blast furnace filling layer includes determining the reference energy transfer coefficient between the refractory brick layer and the stave according to the temperature of the refractory brick corresponding to the stave, the temperature of the furnace skin corresponding to the stave, and the water temperature difference between the inlet and outlet water pipe heads of the stave k 1基 , the reference transfer coefficient k between stave and furnace skin 2基 And the reference transfer coefficient k between the refractory brick and the furnace skin 3基 . K obtained according to the current detection data and relational formula 1测 、k 2测 、k 3测 respectively with k 1基 、k 2基 、k 3基 Compare and judge whether there is an air gap in the filling layer of the blast furnace body and the change of the air gap. This judging method is convenient for those skilled in the art to judge the air gap, and can effectively guide blast furnace technicians to control the air gap by grouting and filling.

Owner:SGIS SONGSHAN CO LTD

Rotary hearth furnace hearth structure

InactiveCN102586540BAddress Dimensional Stability IssuesManufacturing convertersCarbon compositesThermal insulation

The invention discloses a rotary hearth furnace hearth structure. The rotary hearth furnace hearth structure which is a multilayer structure sequentially comprises, top to down, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a carbon composite material layer which contains 8-45% of graphite and 92-54% of fused magnesia magnesium oxide, a mullite firebrick layer, a high-alumina brick layer, and a light-weight thermal-insulation brick layer. So the comprehensive hearth has a special slag erosion resistance and a metal and liquid slag adhesion resistance, and the dimension stability problem of expend with heat and contract with cold of the hearth is solved.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

A secondary zinc oxide leaching device

The invention provides a secondary zinc oxide leaching device, which relates to the technical field of recycling. This zinc oxide leaching device includes a shell, the inner bottom of the shell is provided with a heat exchange tube group, the inner wall of the shell is fixedly connected with a horizontal partition at the lower part, and the middle part of the horizontal partition is provided with an ash drain, The inner wall of the housing and the upper surface of the horizontal partition are provided with a refractory brick layer, the inner wall of the housing and the upper surface of the refractory brick layer is fixedly connected with a lower mounting plate, and the middle part of the lower mounting plate is provided with a leaching pool , the outer surface of the leaching tank is fixedly connected with a discharge pipe at the lower part. Through the leaching tank, the electrode sheet and the heating and roasting of the leaching tank, different structural and functional combinations can separate different components in secondary zinc oxide under different conditions. The overall structure is compact and occupies a small area. The role of the smoke adsorption layer It can absorb the coal smoke and then discharge it, which is friendly to the environment and can clean the leaching tank.

Owner:衡阳百赛化工实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com