Firebox for grill

A combustion chamber and grate technology, which is applied in the field of combustion chambers of ovens, can solve the problems of ceramic combustion chambers that are easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

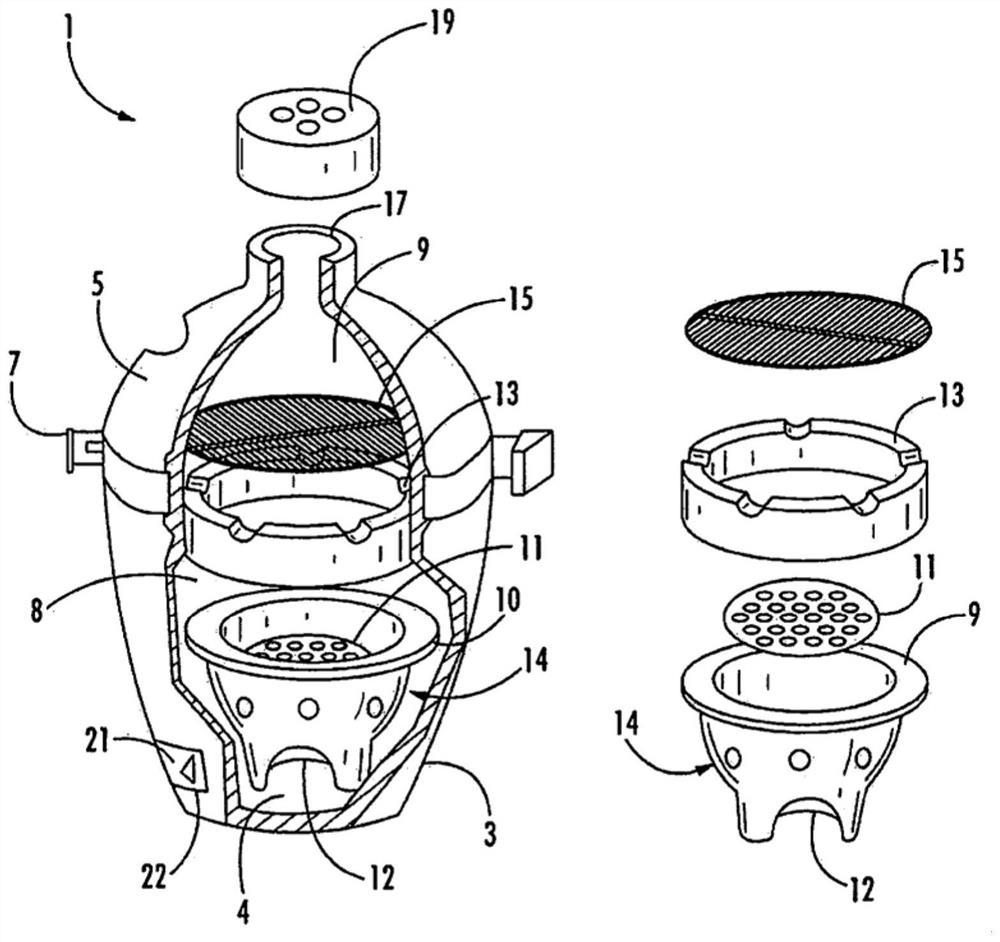

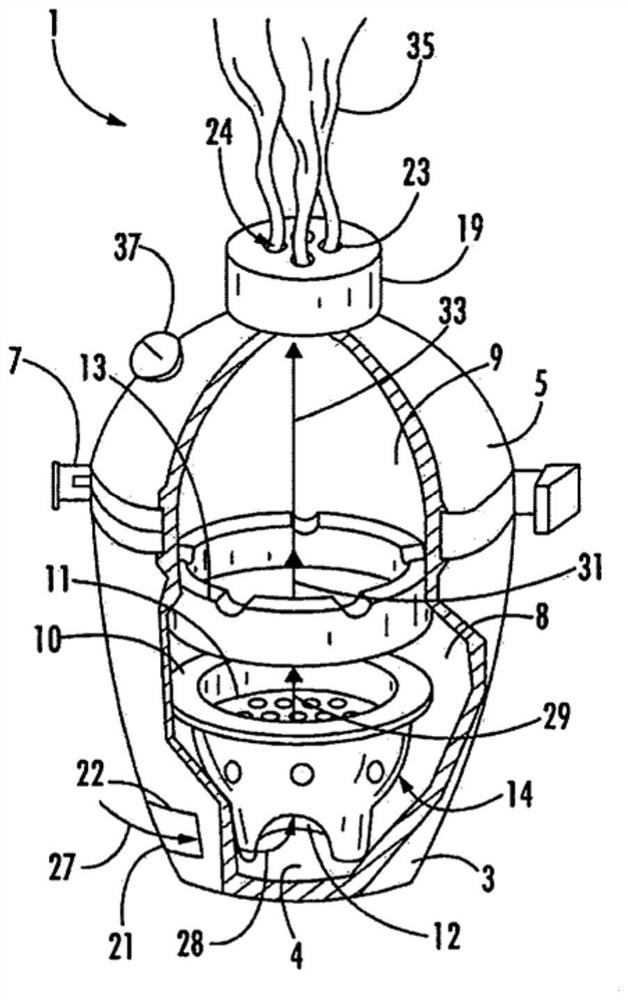

[0061] Figure 1 shows an example of an oven 1 known in the art. The oven 1 has a main body 3 and a cover 5 . The lid 5 can be opened and closed on the main body 3 using the handle 7 .

[0062] The oven 1 comprises a lower interior cavity 8 defined by a body 3 and an upper interior cavity 9 defined by a cover 5 .

[0063] At the bottom of the lower cavity 8 of the body 3 is the bottom wall 4 . The one-piece designed ceramic combustion chamber 10 is inserted into the lower inner cavity 8 of the main body 3 and rests on the bottom wall 4 . The combustion chamber 10 holds a grate 11 which in turn will hold combustion material, such as blocks. A fire ring 13 is placed adjacent to the combustion chamber 10 and holds a grill grate 15 on which food cooked by the oven 1 is placed.

[0064] As shown in FIG. 1 , the main body 3 of the oven 1 has a vent door 21 movable from a fully closed position shown in FIG. 1 to a fully open position shown in FIG. 2 . The opening provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com