Blast furnace packing layer air gap judgment method

A packing layer and air gap technology is applied in the field of judging the air gap of the blast furnace packing layer, and can solve the problems of inconvenient judgment of the air gap of the blast furnace packing layer and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for judging the air gap of a blast furnace packing layer, which includes the following steps:

[0038] S1: Three thermocouples are buried between the refractory brick layer of the blast furnace body and the furnace skin. The circumferential distance is generally maintained at a distance of 1.5 meters, and the longitudinal distance is generally maintained at a level of 0.5 meters. The temperature measured by the thermocouples indicates the temperature of the refractory bricks inside the blast furnace body.

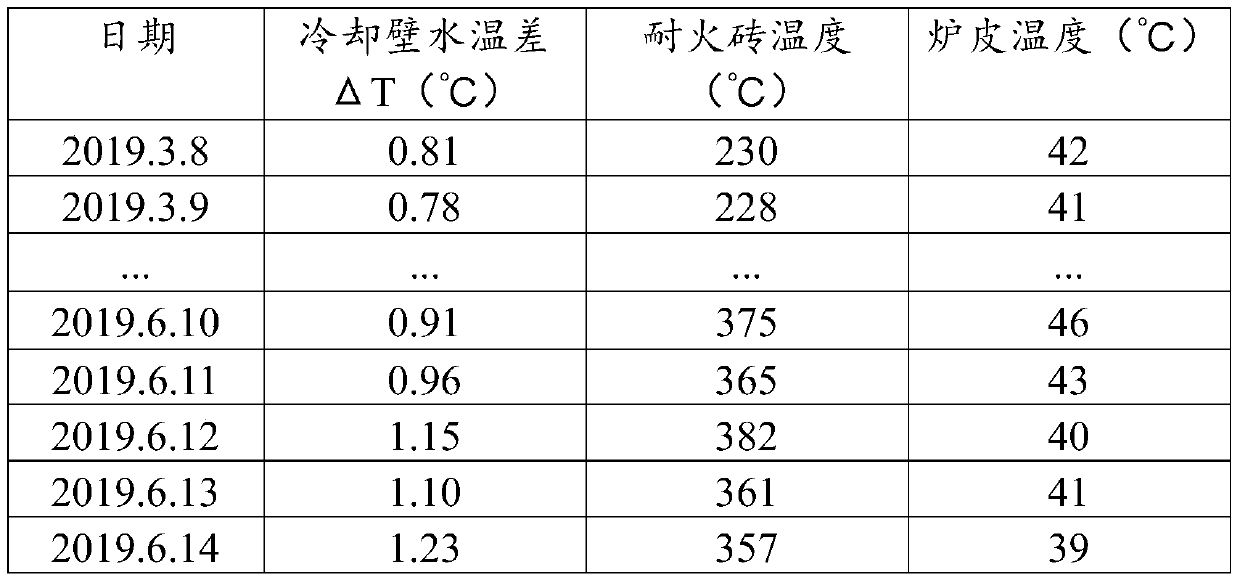

[0039] The water temperature of the stave is monitored for each layer of the blast furnace body and the inlet and outlet pipe heads of each stave, and the temperature difference of the stave water is obtained as ΔT, and the temperature of the refractory brick corresponding to each layer of the stave is monitored, and the temperature is recorded as t; the stave The corresponding furnace skin temperature is T 炉皮 . Temperature differen...

Embodiment 2

[0053] This embodiment provides a method for judging the air gap of a blast furnace packing layer, which includes the following steps:

[0054] S1: Three thermocouples are buried between the refractory brick layer of the blast furnace body and the furnace skin. The circumferential distance is generally maintained at a distance of 1.5 meters, and the longitudinal distance is generally maintained at a level of 0.5 meters. The temperature measured by the thermocouples indicates the temperature of the refractory bricks inside the blast furnace body.

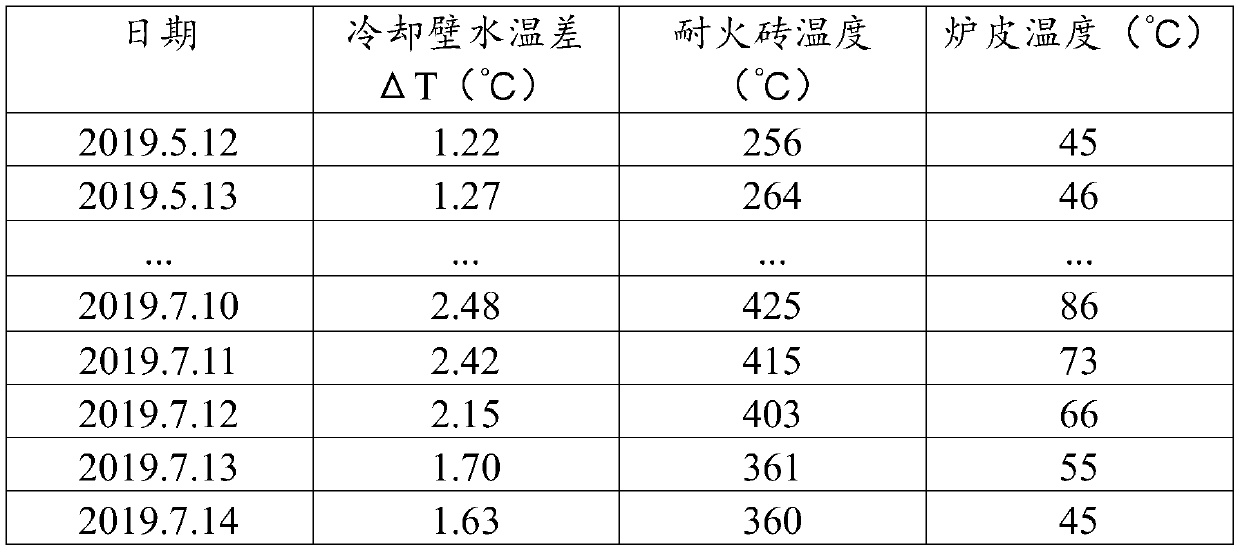

[0055] The water temperature of the stave is monitored for each layer of the blast furnace body and the inlet and outlet pipe heads of each stave, and the temperature difference of the stave water is obtained as ΔT, and the temperature of the refractory brick corresponding to each layer of the stave is monitored, and the temperature is recorded as t; the stave The corresponding furnace skin temperature is T 炉皮 .

[0056] Temperature...

Embodiment 3

[0070] This embodiment provides a method for judging the air gap of a blast furnace packing layer, which includes the following steps:

[0071] S1: Three thermocouples are buried between the refractory brick layer of the blast furnace body and the furnace skin. The circumferential distance is generally maintained at a distance of 1.8 meters, and the longitudinal distance is generally maintained at a level of 0.6 meters. The temperature measured by the thermocouples indicates the temperature of the refractory bricks inside the blast furnace body.

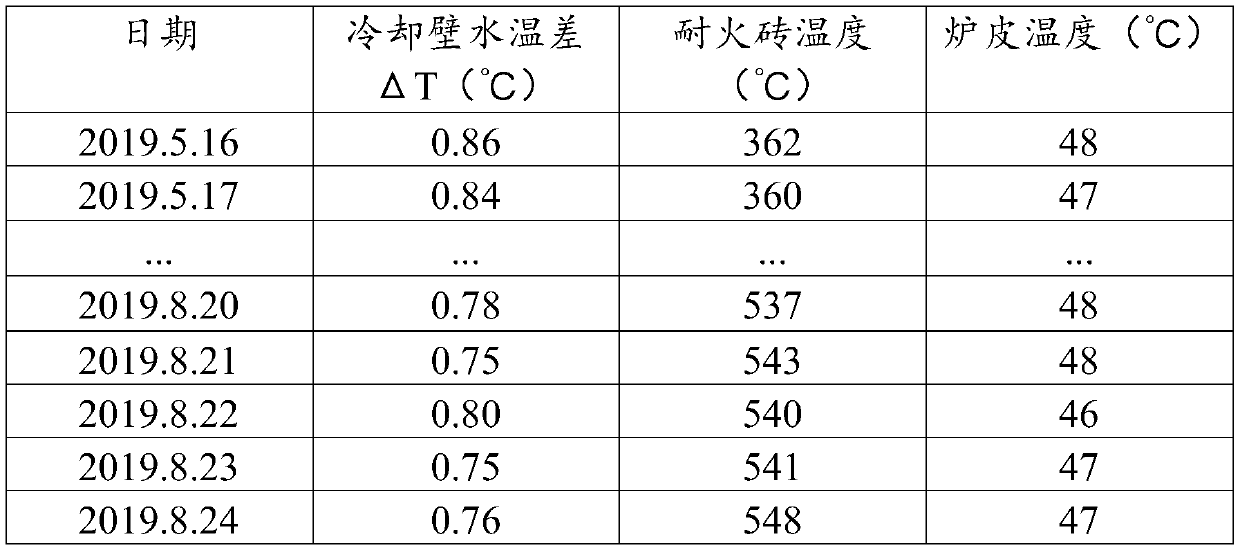

[0072] The water temperature of the stave is monitored for each layer of the blast furnace body and the inlet and outlet pipe heads of each stave, and the temperature difference of the stave water is obtained as ΔT, and the temperature of the refractory brick corresponding to each layer of the stave is monitored, and the temperature is recorded as t; the stave The corresponding furnace skin temperature is T 炉皮 .

[0073] The water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com