Slag adhering method for water-cooled wall electric furnace

A water-cooled wall and electric furnace technology, which is applied in the field of high-temperature metallurgy, can solve the problems of short service life of electric furnace and rapid corrosion of furnace lining, and achieve the effect of improving service life and eliminating erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

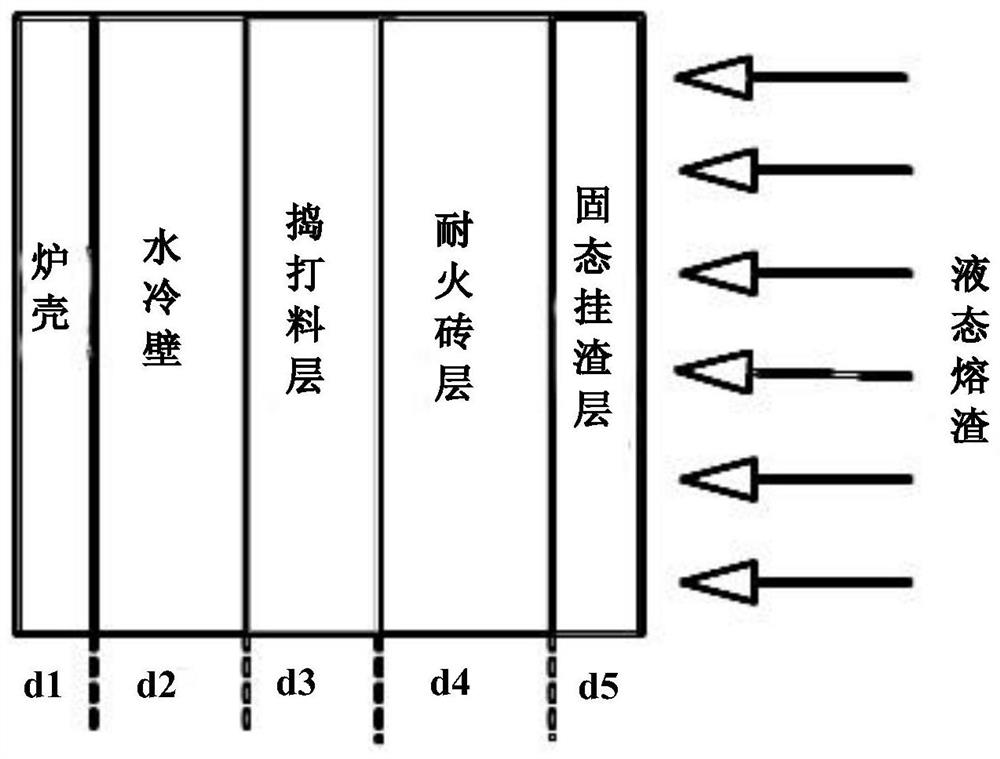

[0035] A company's 25.5MVA circular electric furnace was used to prepare TiC-containing slag, and the raw material used was TiO 2 Titanium-containing blast furnace slag and metallurgical coke with a content of 22-23%. Such as figure 1 As shown, the furnace wall of the electric furnace is the furnace shell, the water wall, the ramming material layer and the refractory brick layer from the outside to the inside. use as Figure 2-3 The water-cooled wall structure of the electric furnace lining is shown, in which the wall body 1 is made of cast iron, the cooling water pipe 2 is made of stainless steel, the distance between the water pipes is D=100mm, the inner diameter is 56mm, and the water flow velocity in the pipe is designed to be 1.2m / s. The ramming material layer is made of graphite, with a thickness of 75mm, and the refractory brick layer is made of magnesia carbon bricks containing 10% carbon, with an initial thickness of 345mm. After smelting to 500 furnaces, a solid s...

Embodiment 2

[0037] A company's 25.5MVA circular electric furnace was used to prepare TiC-containing slag, and the raw material used was TiO 2 Titanium-containing blast furnace slag and metallurgical coke with a content of 22-23%. Such as figure 1 As shown, the furnace wall of the electric furnace is the furnace shell, the water wall, the ramming material layer and the refractory brick layer from the outside to the inside. use as Figure 2-3 The water-cooled wall structure of the electric furnace lining is shown, in which the wall body 1 is made of cast iron, the cooling water pipe 2 is made of stainless steel, the distance between the water pipes is D=100mm, the inner diameter is 56mm, and the water flow velocity in the pipe is designed to be 1.2m / s. The ramming material layer is made of silicon carbide, with a thickness of 40mm, and the refractory brick layer is made of magnesia carbon bricks containing 18% carbon, with an initial thickness of 345mm. After smelting to the 420 furnace,...

Embodiment 3

[0039] A company's 25.5MVA circular electric furnace was used to prepare TiC-containing slag, and the raw material used was TiO 2 Titanium-containing blast furnace slag and metallurgical coke with a content of 22-23%. Such as figure 1 As shown, the furnace wall of the electric furnace is the furnace shell, the water wall, the ramming material layer and the refractory brick layer from the outside to the inside. use as Figure 2-3 The water-cooled wall structure of the electric furnace lining is shown, in which the wall body 1 is made of cast iron, the cooling water pipe 2 is made of stainless steel, the distance between the water pipes is D=100mm, the inner diameter is 56mm, and the water flow velocity in the pipe is designed to be 1.2m / s. The ramming material layer is made of silicon carbide, with a thickness of 20mm, and the refractory brick layer is made of magnesia carbon bricks containing 18% carbon, with an initial thickness of 230mm. After 260 furnaces of smelting, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com