A secondary zinc oxide leaching device

A secondary zinc oxide leaching technology, applied in the field of secondary zinc oxide leaching equipment, can solve the problems of single separation function or separation components, inconvenient cleaning, etc., and achieve the effects of small footprint, promotion of cleaning process, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

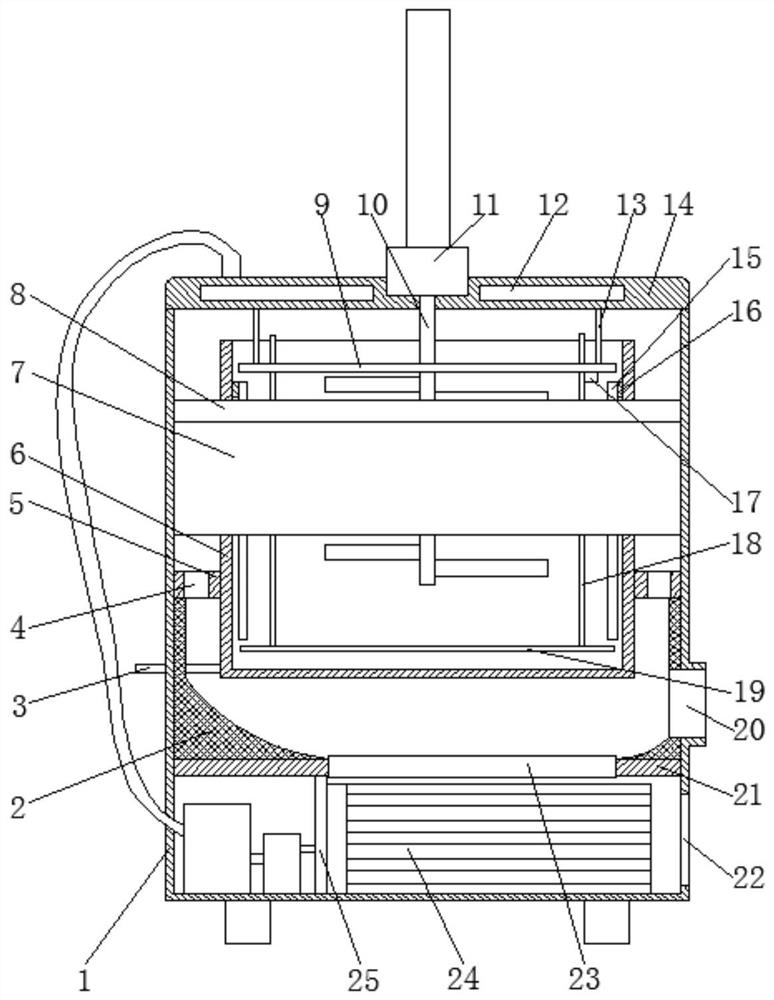

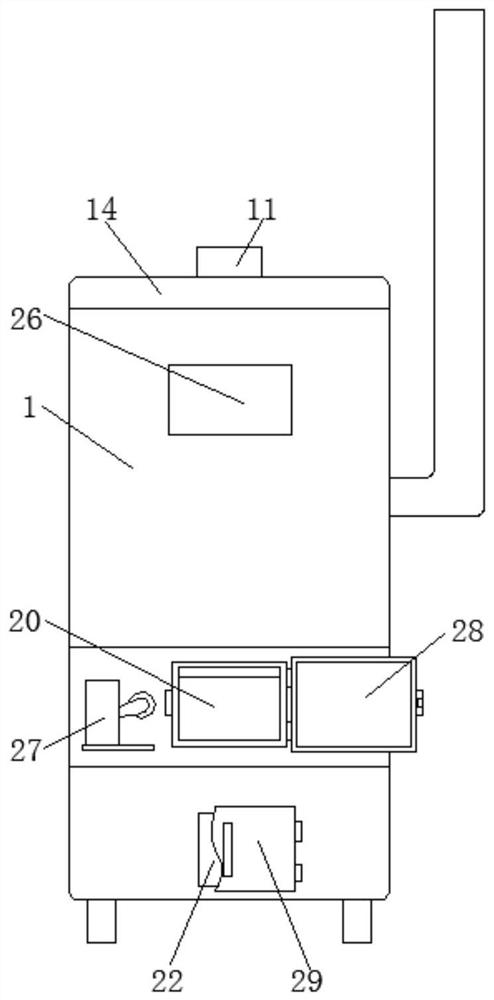

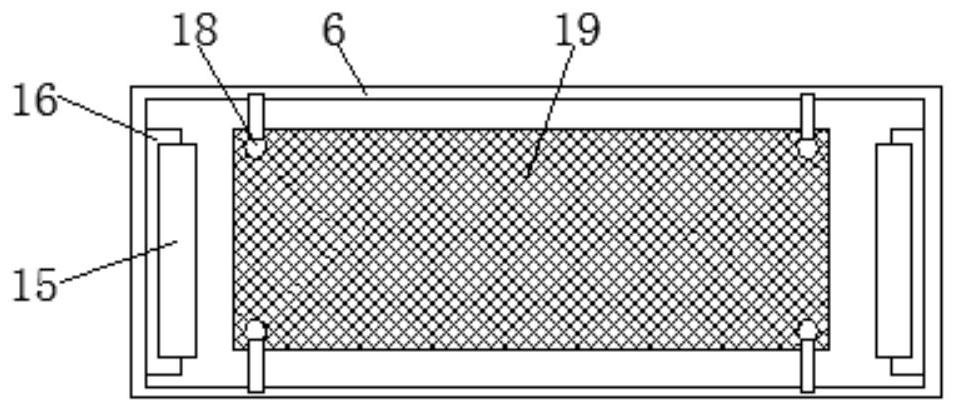

[0031] Such as Figure 1-6 As shown, the embodiment of the present invention provides a secondary zinc oxide leaching device, which includes a casing 1, the inner bottom of the casing 1 is provided with a heat exchange tube group 24 for waste heat utilization, and the inner wall of the casing 1 is fixedly connected with a horizontal Partition 21, the middle part of horizontal partition 21 is provided with ash drain 23, used for burning coal ash to fall, the inner wall of shell 1 and the upper surface of horizontal partition 21 is provided with refractory brick layer 2, the inner wall of shell 1 and is located in refractory The upper end surface of the brick layer 2 is fixedly connected with a lower mounting plate 5, and the middle part of the lower mounting plate 5 is provided with a leaching tank 6 for placing secondary zinc oxide. The leaching solution such as sulfuric acid of secondary zinc oxide and cleaning water are discharged, the discharge pipe 3 passes through the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com