Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "Reduce cleanup workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

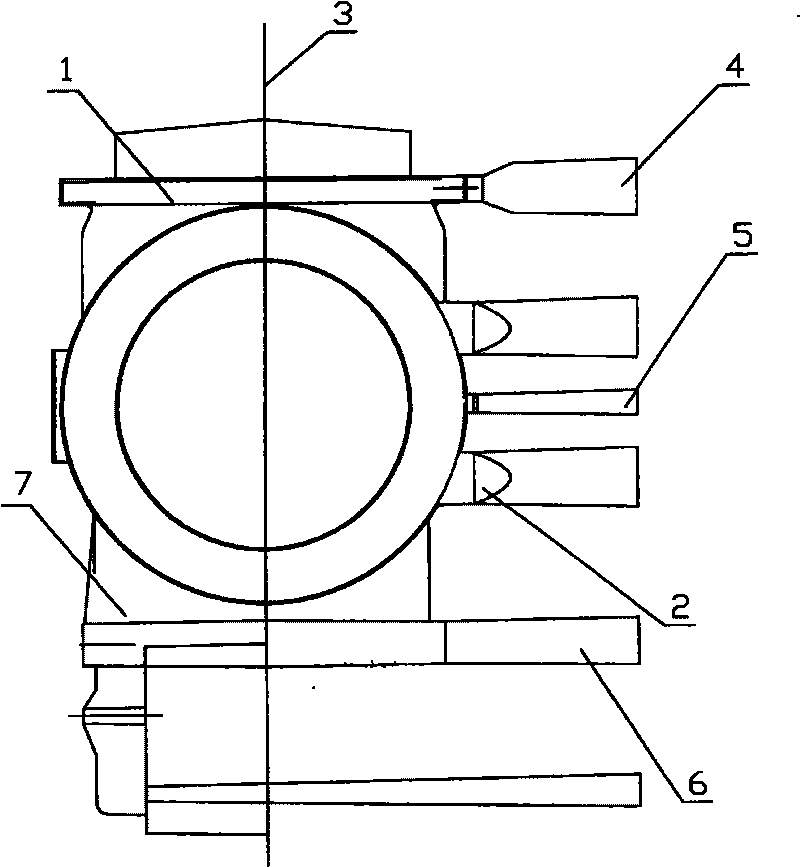

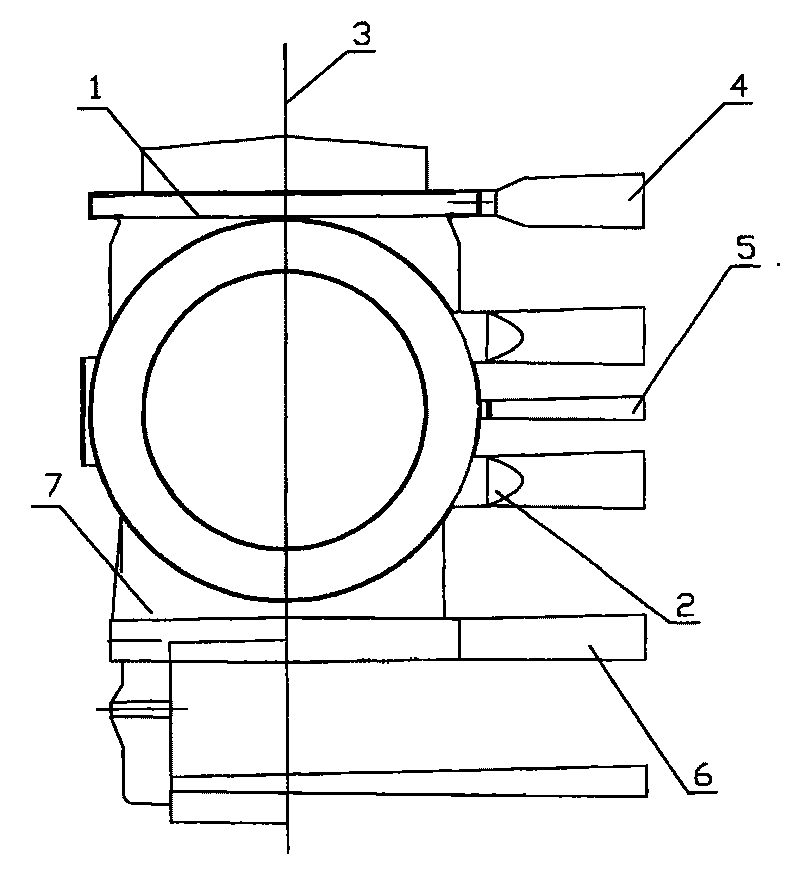

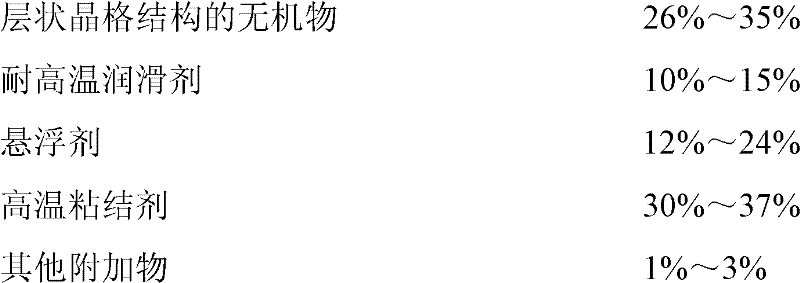

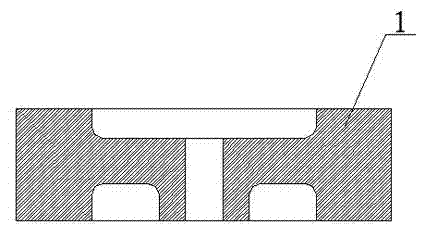

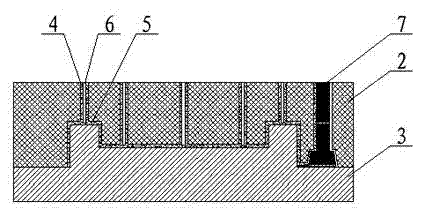

Method for producing voltage-bearing aluminum alloy tank body of ultra-high voltage switch by V-process

ActiveCN101693282AImprove mechanical propertiesImprove quality levelFoundry mouldsFoundry coresFoundryIntermediate frequency

The invention discloses a method for producing a voltage-bearing aluminum alloy tank body of an ultra-high voltage switch by a V-process, comprising the following steps: model making, thin film heating, thin film shaping (film absorbing), coating spraying, sandbox placing, ram-jolting by adding sand , back film covering, film loosening, core setting, box folding, pouring, removing box and shaking out. After the process is improved, an intermediate frequency furnace is utilized to melt and a crucible heat preserving furnace is utilized to modify and refine. When melting in the intermediate frequency furnace, microelements such as tombarthite and the like are replenished and a new non-stirring melting and refining technology is adopted so as to reduce oxide inclusion content in alloy liquid. Modification and refining treatment in the crucible heat preserving furnace ensures high purity degree and high component precision of aluminum liquid, and using pure aluminum alloy liquid can increase the ratio of acquiring qualified pressure-proof tank body foundry products.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

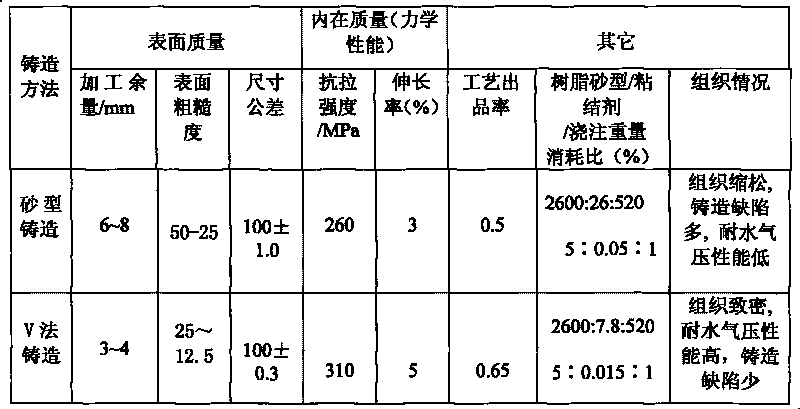

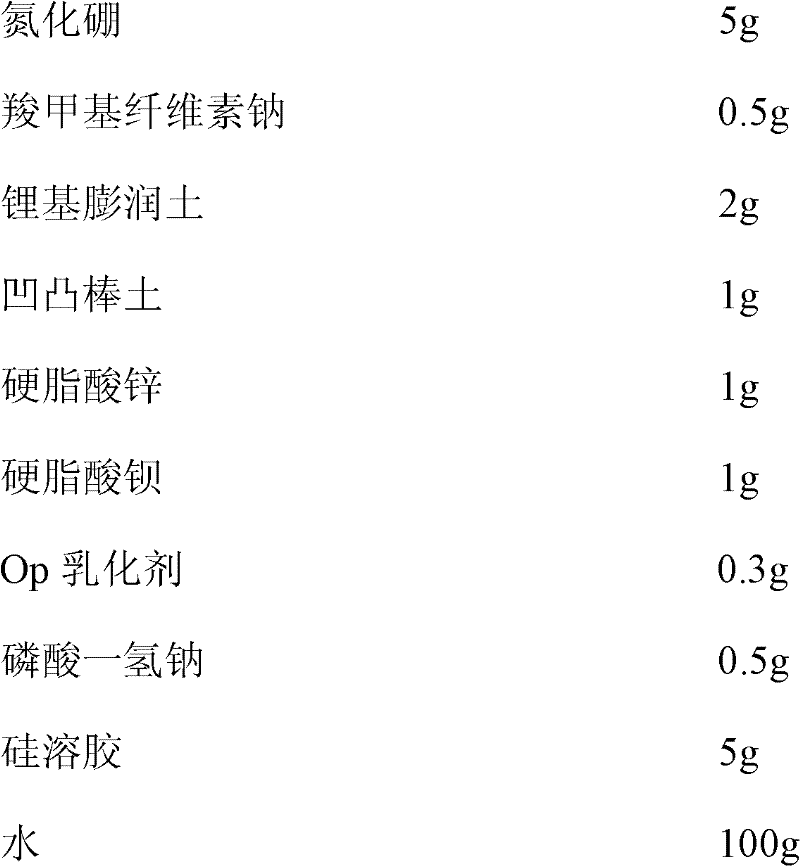

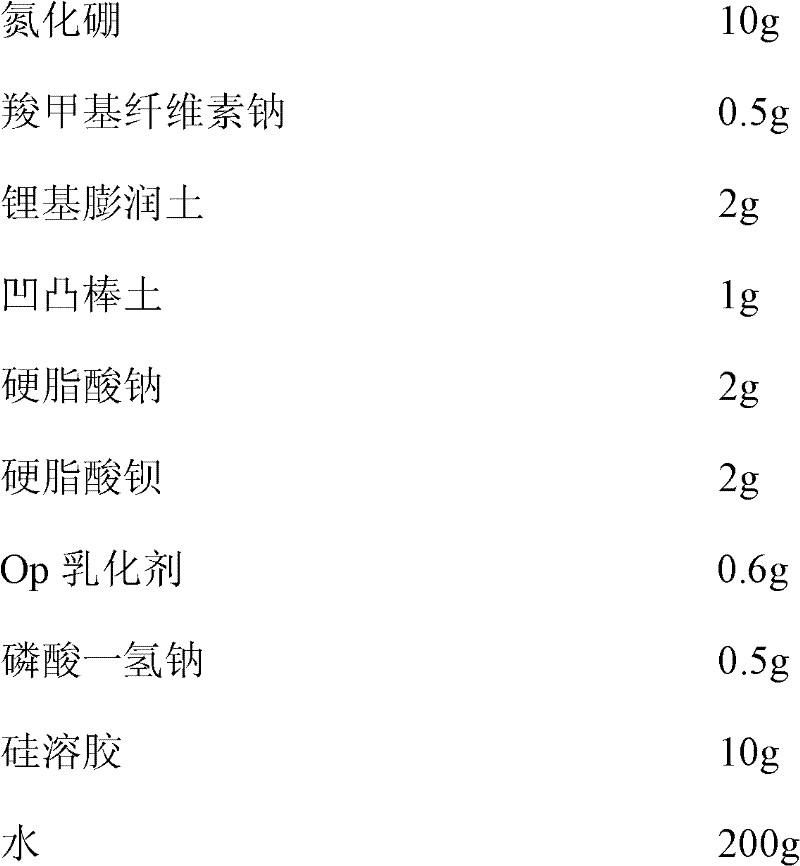

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

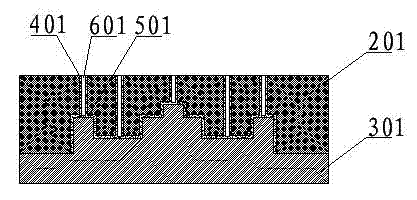

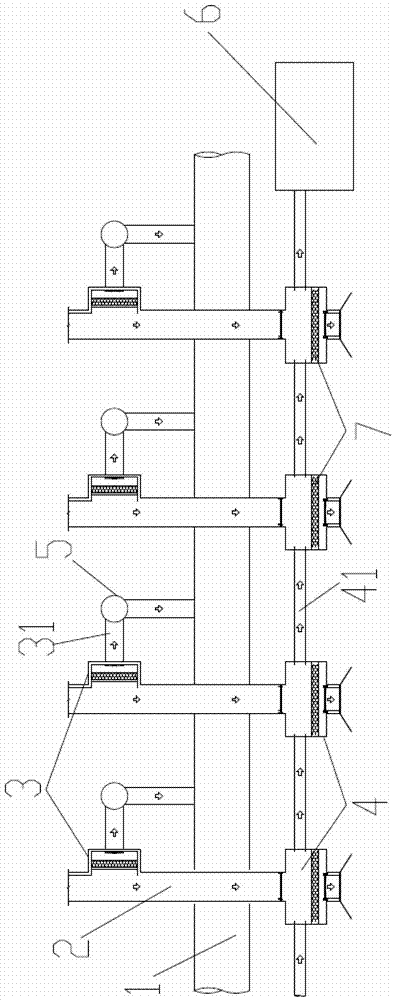

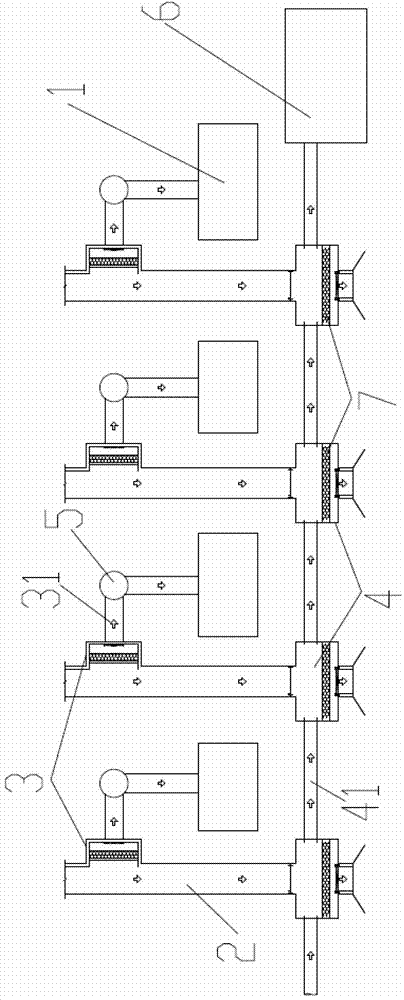

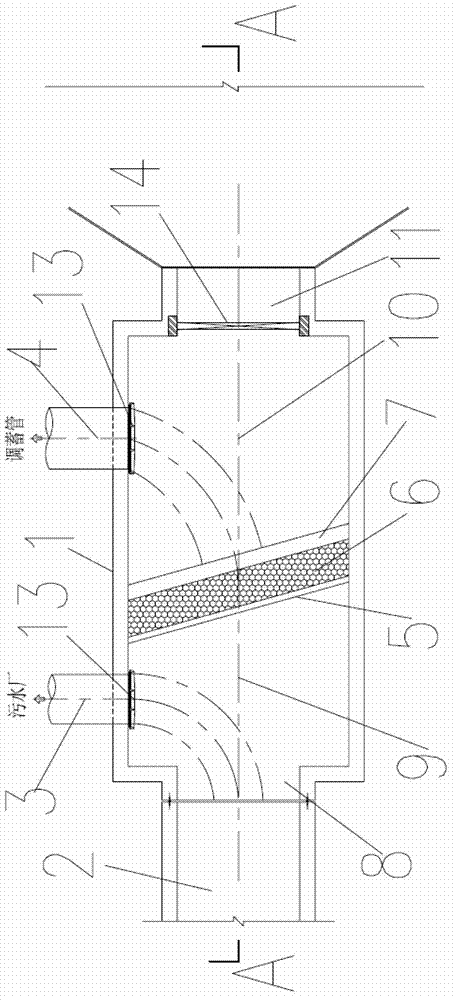

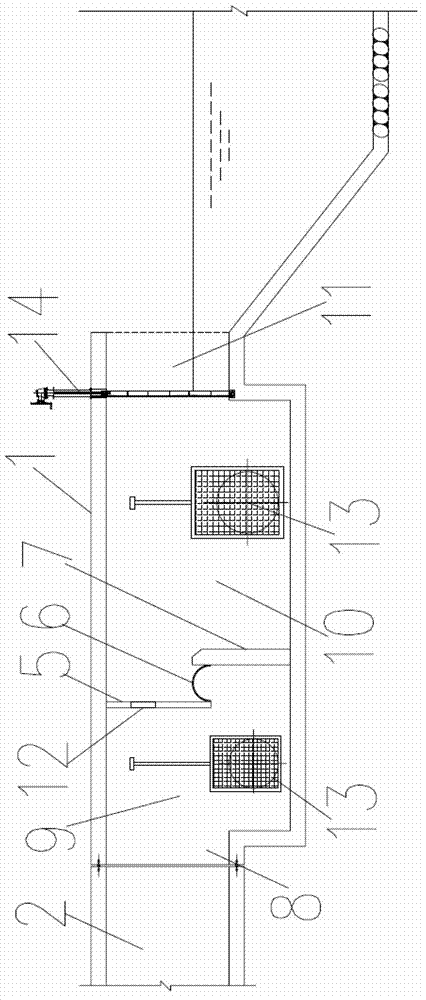

Separately-built type rainwater storage system

InactiveCN102776949ARealization of regulation and storage functionConducive to drainage regulation and storageFatty/oily/floating substances removal devicesSewerage structuresEngineeringSewage

The invention discloses a separately-built type rainwater regulation system, which is arranged on a plurality of different confluence tubes. The regulation system comprises a first interception well, a second interception well, a regulation tube, and filter layers which are arranged in the first interception well and the second interception well respectively; the first interception well is provided with a sewage interception tube which extends to a sewage plant, a drainage port connected with a river channel, and an end water inlet connected with the end parts of the confluence tubes; and the second interception well is provided with an initial rain interception tube which extends to the regulation tube, and a side water inlet connected with the side parts of the confluence tubes. The separately-built type rainwater regulation system disclosed by the invention is suitable for the current situation as well as still convenient and realizable in case of an insufficient site; simultaneously, the interception effect can be greatly improved, and the intercepted drought flow sewage is intercepted in the sewage treatment plant and rainwater is intercepted in the regulation tube, so as to reduce pollution on the river channel, and improve the regulation capacity of urban drainage.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

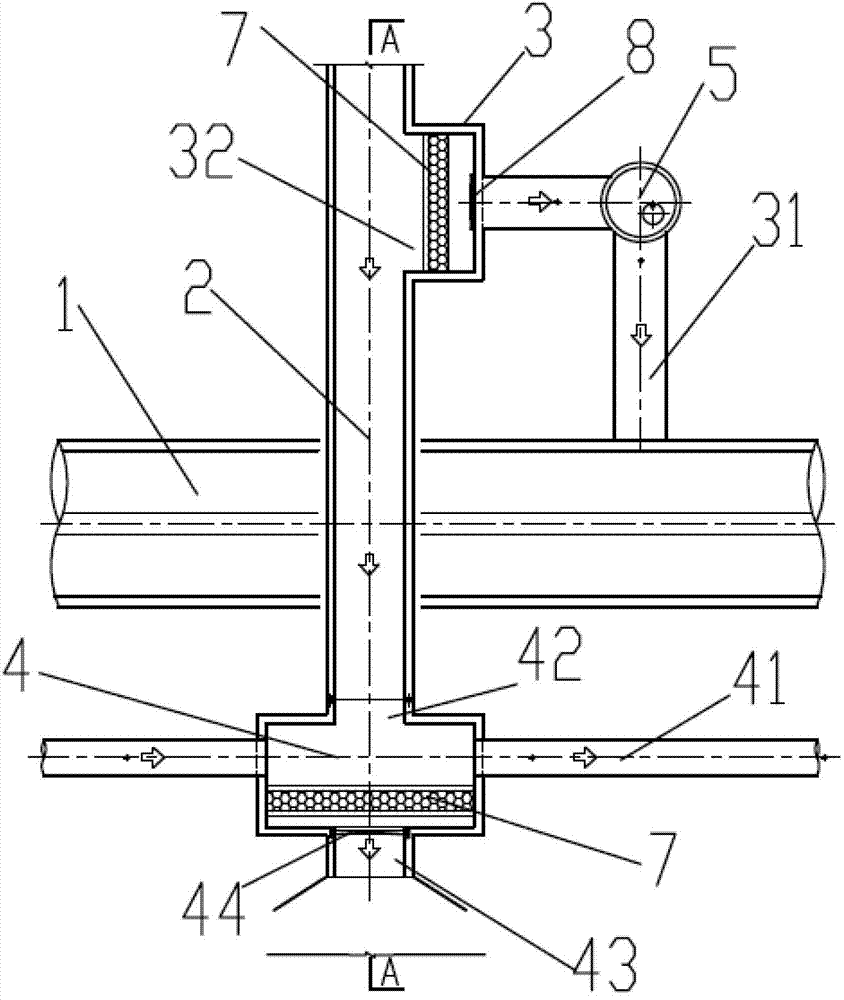

Dry weather flow and initial rainwater multifunctional catch basin for combined network

The invention discloses a dry weather flow and initial rainwater multifunctional catch basin for a combined network. The dry weather flow and initial rainwater multifunctional catch basin for the combined network comprises a basin body. The basin body is provided with an interceptor sewer extending to a sewage plant, an initial rainwater interceptor extending to a regulation and storage pipe, a water outlet communicated with a river channel, and a water inlet communicated with a combining pipe. The catch basin further comprises a filter layer disposed in the basin body. The filter layer is disposed between the water inlet and the water outlet so that a water inlet area close to one side of the water inlet and a water outlet area close to one side of the water outlet form in the basin body. The filter layer comprises a stop board disposed on the upper portion of the basin body, an overflow weir disposed on the lower portion of the basin body and a filter net disposed between the stop board and the overflow weir. The stop board is provided with through holes. The dry weather flow and initial rainwater multifunctional catch basin for the combined network has the advantages that the multifunctional catch basin is convenient to implement, the filter layer can be cleaned automatically, intercepting effect is improved, service life of the catch basin is prolonged, and river channel pollution is reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

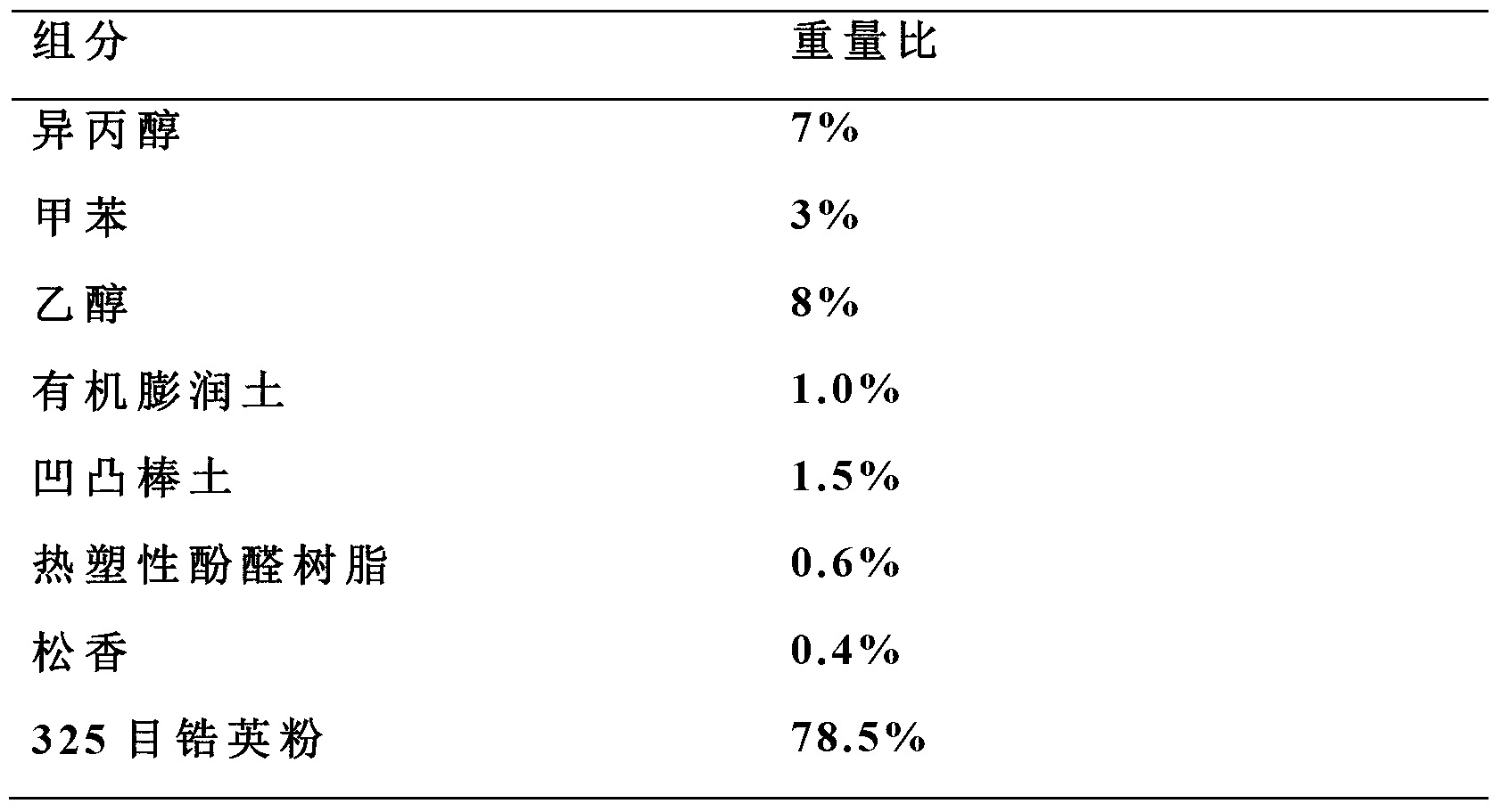

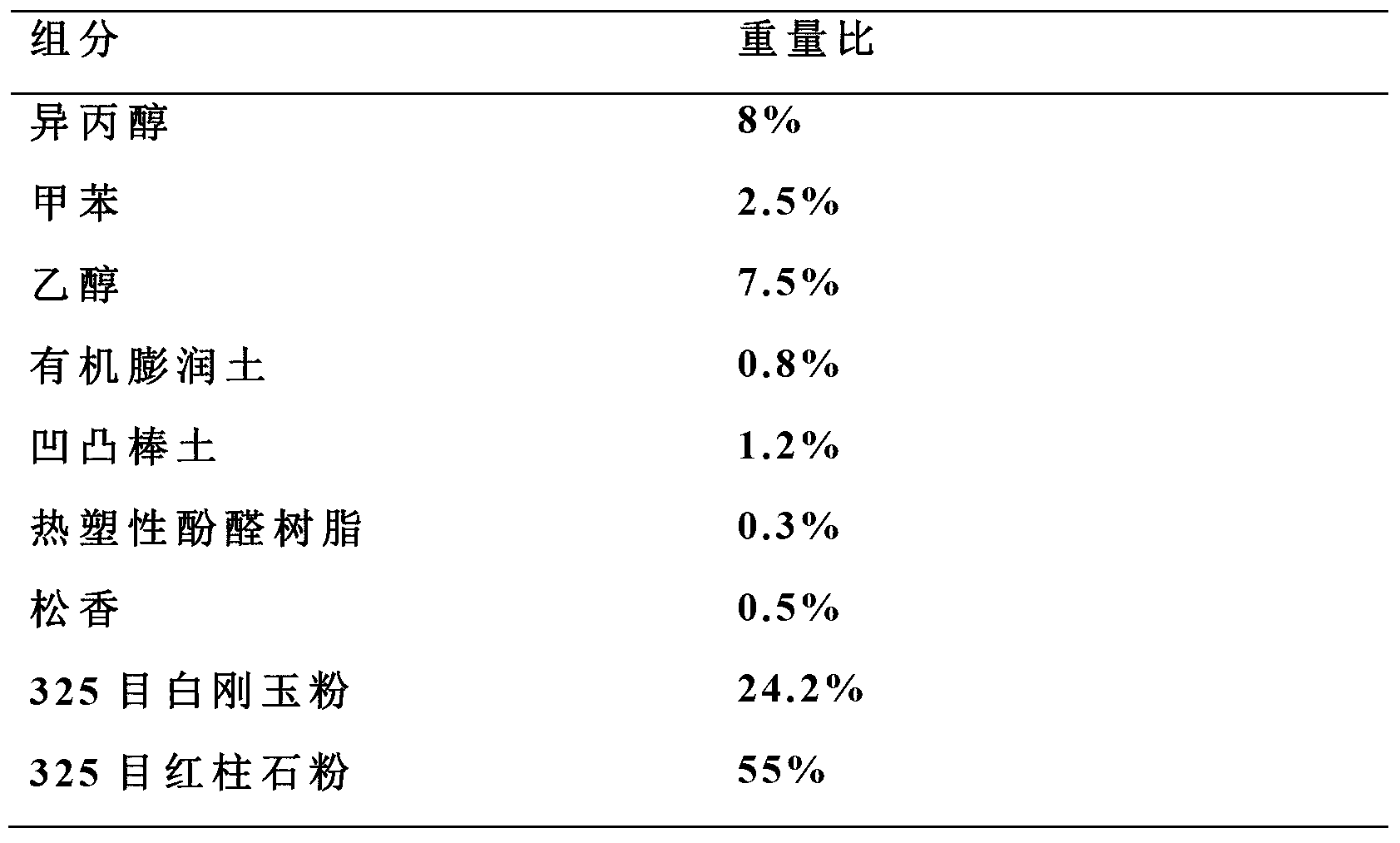

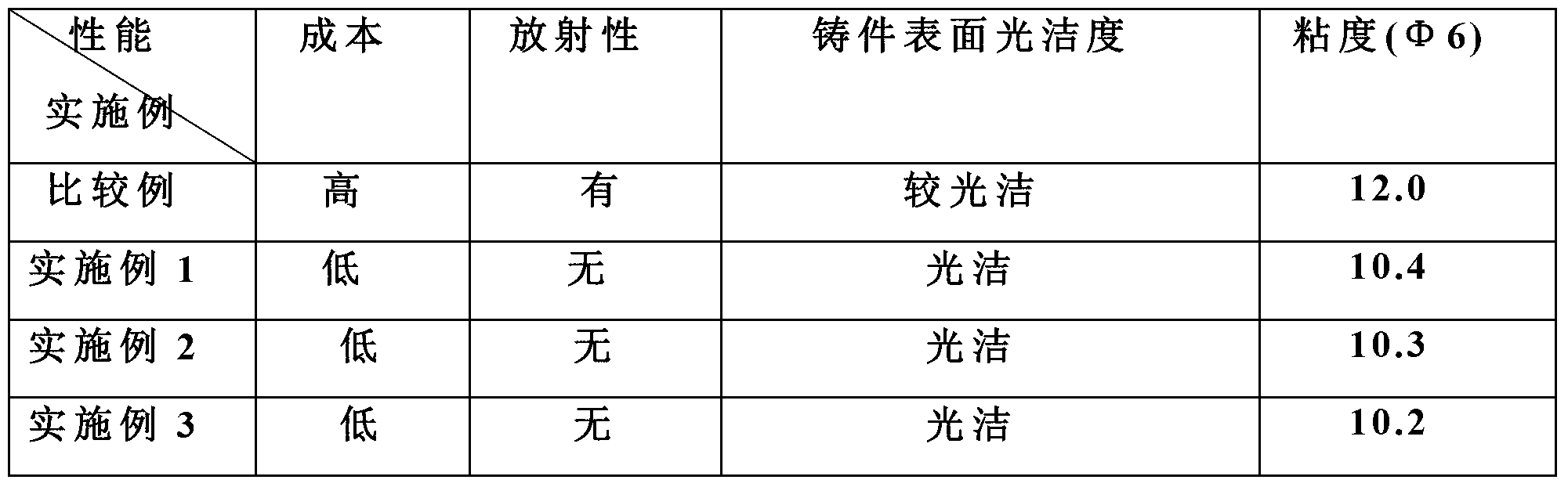

Zircon power alternative coating for casting and preparation method thereof

The invention discloses a zircon power alternative coating for casting, which is characterized in that a coating composition comprises carrier liquid consisting of isopropyl alcohol, toluene and ethanol, a suspending agent consisting of organobentonite and attapulgite, an adhesive consisting of thermoplastic phenolic resin and rosin, and refractory aggregate consisting of white alundum powder and andalusite powder. The coating composition comprises the following components by weight percent: 6-10 percent of isopropyl alcohol, 2-4 percent of toluene, 6-10 percent of ethanol, 0.5-1.5 percent of organobentonite, 1-2 percent of attapulgite, 0.2-1.0 percent of thermoplastic phenolic resin, 0.2-1.0 percent of rosin, 15-55 percent of white alundum powder and 15-55 percent of andalusite powder. Compared with the conventional common cast steel zircon power coating, the coating has high thixotropy and leveling property, is smooth and dense and has enough normal temperature and high-temperature strength, so that the casting roughness meets the quality requirement; and moreover, the zircon power alternative coating is low in gas outlet quantity and has proper shielding property, and the defects of the casting air holes can be obviously reduced.

Owner:SUZHOU XINGYE MATERIALS TECH

Water-based self-drying/quick-drying sand type casting coating and preparation method thereof

ActiveCN103878302AHigh refractorinessLow heat shrinkageFoundry mouldsFoundry coresCast ironEnvironmental geology

The invention provides a water-based self-drying / quick-drying sand type casting coating and a preparation method thereof, wherein the water-based self-drying / quick-drying sand type casting coating is high in drying speed, little in pollution / pollution-free, safe to use, low in manufacture cost and high in sintering and stripping rate. The preparation method takes natural fireproof materials which are not calcined or electrically molten, such as zircon powder, chromite powder or zirconic composite silicate mineral powder, as basic materials, adopts a normal-temperature cured-type modified macromoleclar polymer as a main normal-temperature self-drying / low-temperature quick-drying binder, takes a quick-drying type silicate binder as a main high-temperature binder, adopts an efficient composite suspension dispersant high in fire-resistant degree and low in hot shrinkage rate and is added with proper amounts of efficient water reducing agents and defoaming agents to prepare a steel-iron casting water-based self-drying / quick-drying coating which is high in content of solid (nonvolatile matter) and low in permeability. The water-based self-drying / quick-drying sand type casting coating is excellent in thixotropy, brushing property and quick-drying function, thereby achieving the aim of saving energy, improving the environment and improving the quality of castings. The water-based self-drying / quick-drying sand type casting coating is applicable to the field of casting coatings.

Owner:广东省铸力铸材科技有限公司 +1

Novel technology for casting engine cylinder body by lost foam

InactiveCN102310162ASmall sizeReduce reserved processing volumeFoundry mouldsFoundry coresSmelting processMetallurgy

The invention discloses a novel technology for casting an engine cylinder body by lost foam, and relates to the field of casting technologies. The novel technology is characterized by comprising the following steps of carrying out three-dimensional modeling by three-dimensional software, slitting the three-dimensional model obtained by the previous step into multiple model sheets, preparing molds for preparation of the model sheets, pouring expandable foam beads into the molds, carrying out heating and cooling processes to obtain lost foam model sheets of the engine cylinder body, drying the lost foam model sheets, bonding the dried lost foam model sheets into an integral body according to requirements, bonding a casting system on the bottom of the integral body to obtain a lost foam model, carrying out dip-coating treatment on the surface of the lost foam model by specialized paint 1 to 3 times, putting the lost foam model coated with the specialized paint into a drying room to carry out drying treatment, putting the dried lost foam model into a three-dimensional vibration sand box, adding gradually dry sand into the three-dimensional vibration sand box, covering a film on the surface of the three-dimensional vibration sand box to sealing the three-dimensional vibration sand box, pouring melt obtained by a smelting process into the casting system so that the lost foam model is melted and the melt occupies a space occupied originally by the lost foam model, and cooling the melt to solidification to obtain an engine cylinder body casting. The novel technology improves a qualified rate, saves resources and reduces a cost for enterprises.

Owner:CHUZHOU JINNUO INDAL

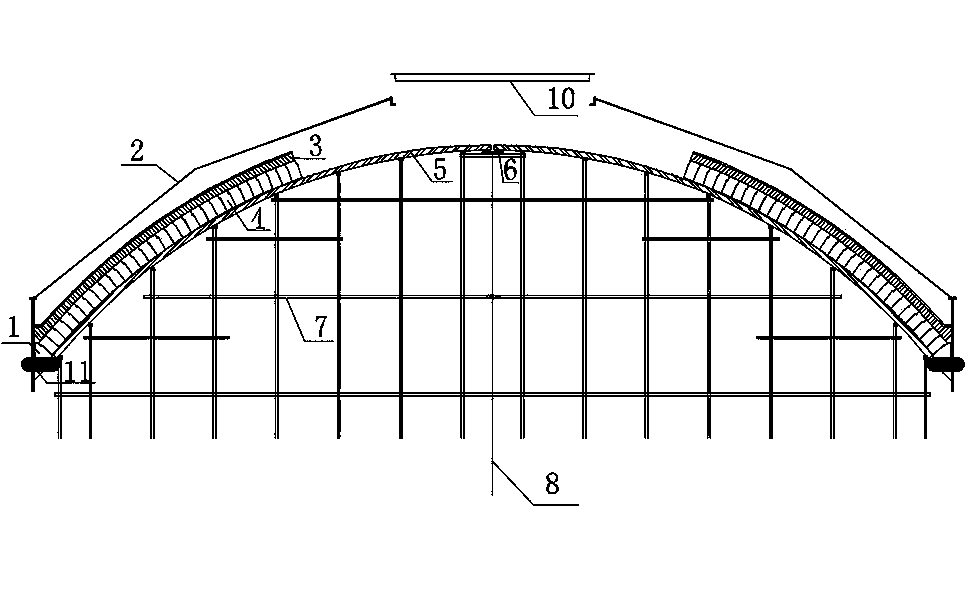

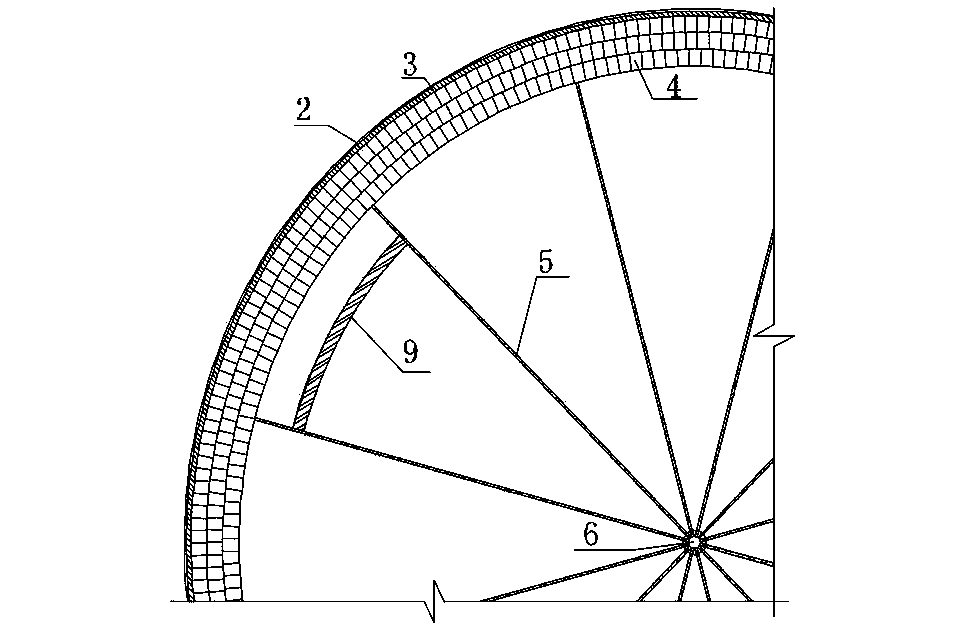

Construction method for spherical furnace top of industrial furnace

ActiveCN103673621AReduce cleanup workloadReduce usageLinings repairFurnace crowns/roofsMetallurgyFire brick

The invention discloses a construction method for a spherical furnace top of an industrial furnace. Firstly, a steel furnace shell is mounted, the elevation and the like of steel supporting plates at the arch springing positions of a globe-roof are rechecked, a vertical control line is arranged from the center of the furnace bottom to the center of the furnace top in a drawn mode, a supporting frame is erected in a furnace body, and a round top plate is arranged in the center of the top; multiple vertical arc plates are then manufactured and are fixed on the round top plate and the supporting frame, and the elevation and the radius of each layers of refractory bricks are marked on the corresponding vertical arc plates; multiple horizontal arc plates are manufactured; the refractory bricks at the arch springing positions are constructed first, the refractory bricks are constructed upwards in sequence, the vertical radian and the elevation of the refractory bricks are controlled by using the vertical arc plates, and the horizontal radius of the refractory bricks is controlled by using the horizontal arc plates; one heat preservation brick layer is constructed after one certain layer of the refractory bricks are constructed, and the construction is carried out in the way until the construction of all the refractory brick layers and the construction of all the heat preservation brick layers are completed; a steel cover plate of the furnace top is mounted in a hanging mode to seal the steel furnace shell. The construction method for the spherical furnace top of the industrial furnace has the advantages of being economical in used material, simple in working procedure, low in cost and the like, and can ensure construction quality more easily.

Owner:五矿二十三冶建设集团有限公司

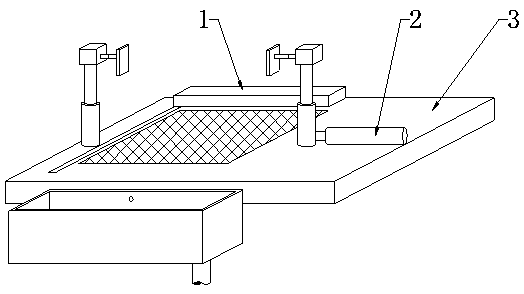

Vanishing mould casting technique of blast furnace cooling wall

InactiveCN101185963AFast preparationEliminate fire defectsFoundry mouldsFoundry coresGlass furnaceLight pollution

The invention discloses a lost foam casting process used for a blast furnace cooling wall, aiming to solve the problems of prior casting technique of blast furnace cooling wall that casting cost is high, casting quality is poor, labor intensity is high, working efficiency is low and manufacturing process has heavy pollution, etc. The invention has the advantages that the method is simple, the cost is low, the size of cast pieces is accurate, the surface is smooth, the working efficiency is higher the, labor intensity is lower, the manufacturing process has lighter pollution and is easy for control. The method of the process is as the following: 1) water tubes of the cooling wall are stewed and manufactured; 2) a cooling wall foam plastic model in which the cooling wall water tubes are arranged is manufactured; 3) refractory dope is painted on the surface of the foam plastic model and is dried for 30 to 48 hours at a temperature from 40 to 50 DEG C; 4) a casting system is assembled; 5) boxing-up, forming and vibration for shape are carried out; 6) vacuumizing casting is carried out, with vacuum degree from minus 0.02 to minus 0.08 MPa and casting temperature from 1000 to 1600 DEG C; after the casting, pressing time is 10 to 60 minutes; 7) shaking and cleaning are carried out.

Owner:肖燕鹏

Dual-compound wear-resisting hammer and manufacturing method thereof

The invention discloses a dual-compound wear-resisting hammer comprising a hammer handle and a hammer body; the hammer body is formed by compound casting of two kinds of metal liquids, and the hammer body is in casting connection with the solid hammer handle to form the hammer. The manufacturing method includes the following steps: step 1, manufacturing and casting a sand mold according to a structure of the hammer; step 2, processing the hammer handle with a low-alloy steel blank material, and preburying one end of the hammer handle into the casted sand mold of the hammer; step 3, selecting high-chromium cast iron and carbon steel, and carrying out quantitative pouring in sequence; and step 4, carrying out heat treatment. The dual-compound wear-resisting hammer not only can improve wear resistance of the hammer but also allows the hammer body and the hammer handle to be combined closely and not generate cracks, casting defects are overcome, the product yield is improved, the cleaning workload is reduced, and the quality and the service life of the hammer are improved substantially.

Owner:江苏长友特钢机械有限公司

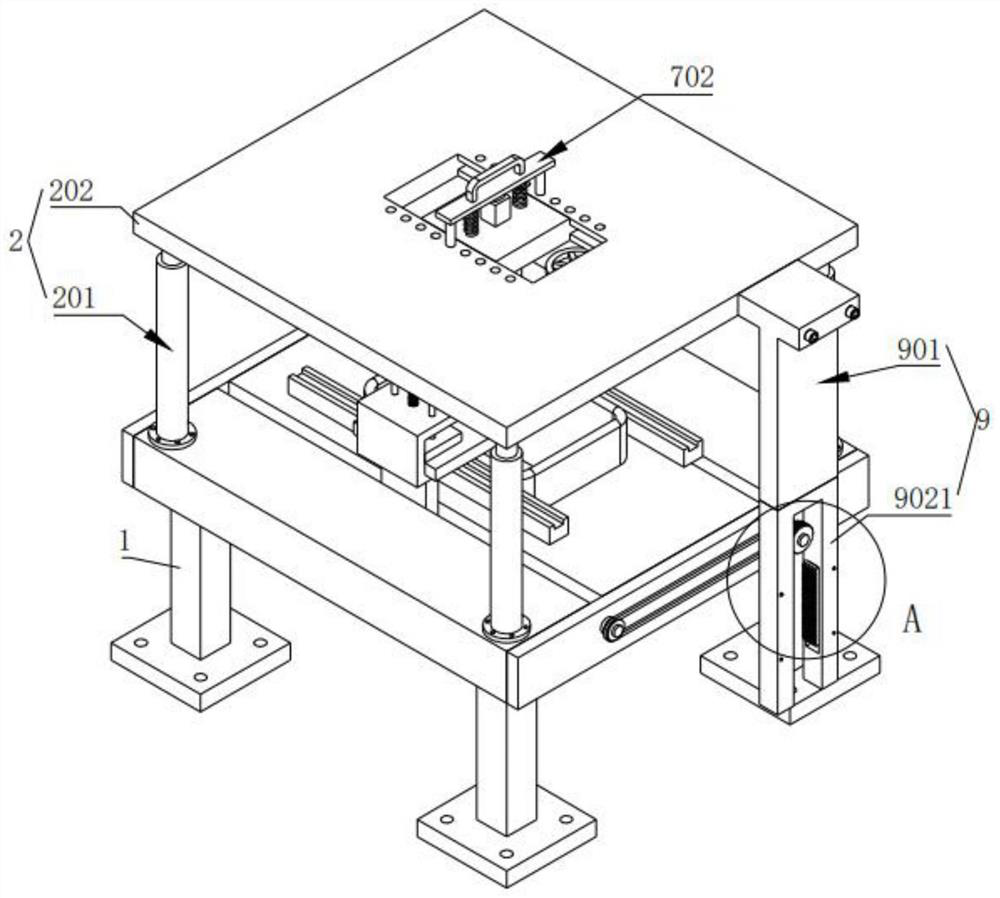

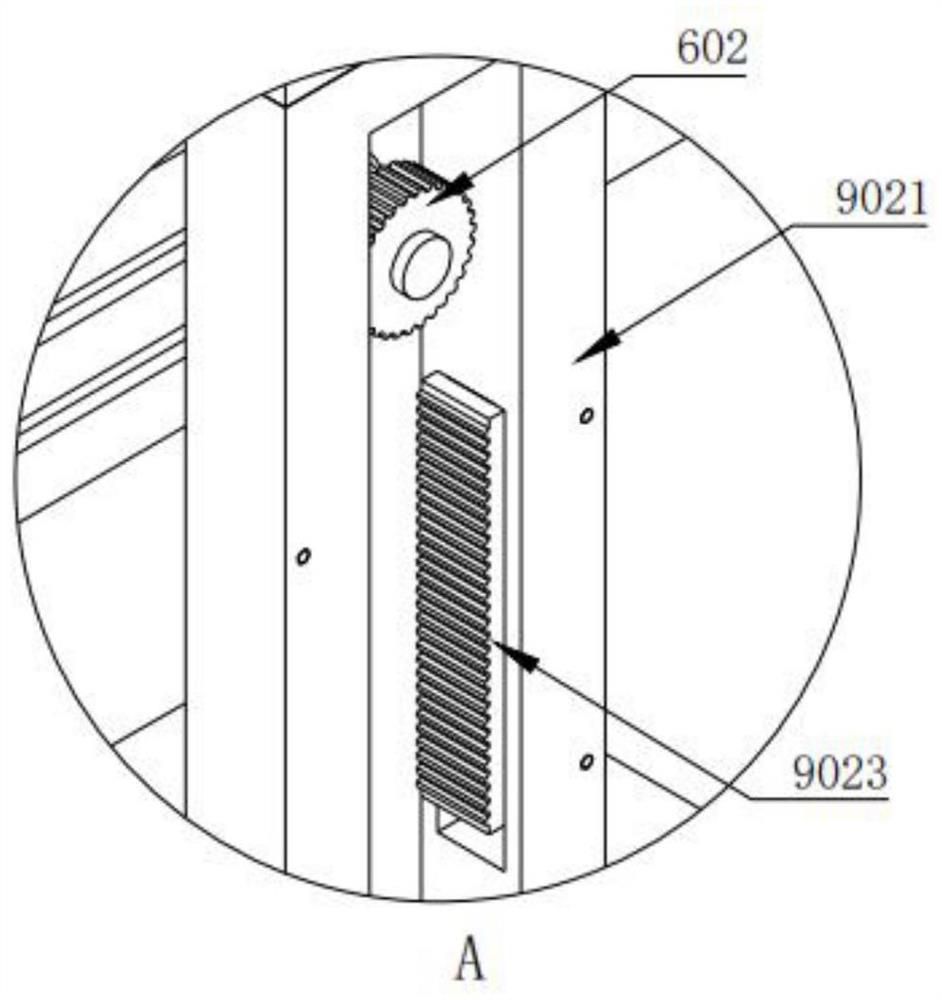

Tool for machining cubic shell

InactiveCN107825178AEasy to processReduce labor intensityPositioning apparatusMaintainance and safety accessoriesEngineering

The invention provides a tool for processing a cubic shell, which includes a through groove, a filter screen, a push plate, a negative pressure fan, a dust collection cover, a left splint, a right splint, a motor one, an electric cylinder one and an electric cylinder two, and the push plate is installed on On the upper end of the workbench, there is a through groove inside the workbench, and a filter is installed inside the through groove. The dust collection cover is assembled on the lower end of the workbench, and the lower end of the dust collection hood is equipped with a negative pressure fan. This design can hold cubes of various heights. The use range is wide, the electric cylinder one is set on the left end of the electric cylinder two, the electric cylinder one is equipped with the motor one, the left end of the motor one is equipped with the right splint, and the left splint is set on the left side of the right splint. The processing debris is collected and cleaned. The invention is convenient to use, easy to operate, good in stability, high in reliability, and reduces labor intensity.

Owner:卢正奎

Lightweight environment-friendly type pumice for ceramic ware and its production method and usage

InactiveCN1762910AStrong wear resistanceReduce cleanup workloadDry-cleaning apparatus for textilesCeramicwareSewage treatmentMetallurgy

The present invention relates to light environment friendly ceramic pumice and its manufacture and usage. The ceramic pumice is used widely in fading, fluffing, softening, ageing and other processing of clothing, fabric, cloth, etc. The ceramic pumice of the present invention contains no harmful matter, and results in simplified fabric cleaning post-treatment and no environmental pollution. Treating fabric with the ceramic pumice makes fabric soft, good look, personalized, permeable and comfortable.

Owner:何晓洪

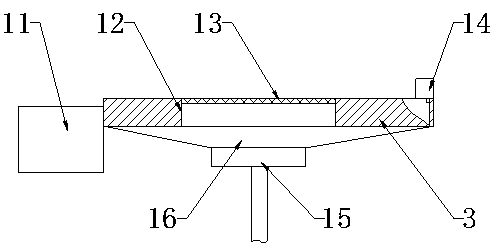

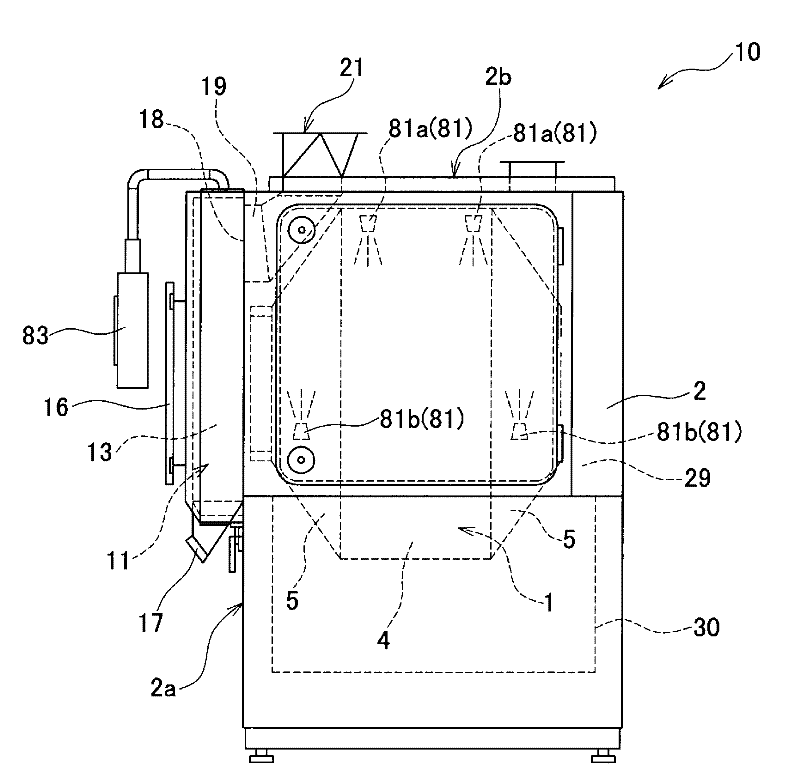

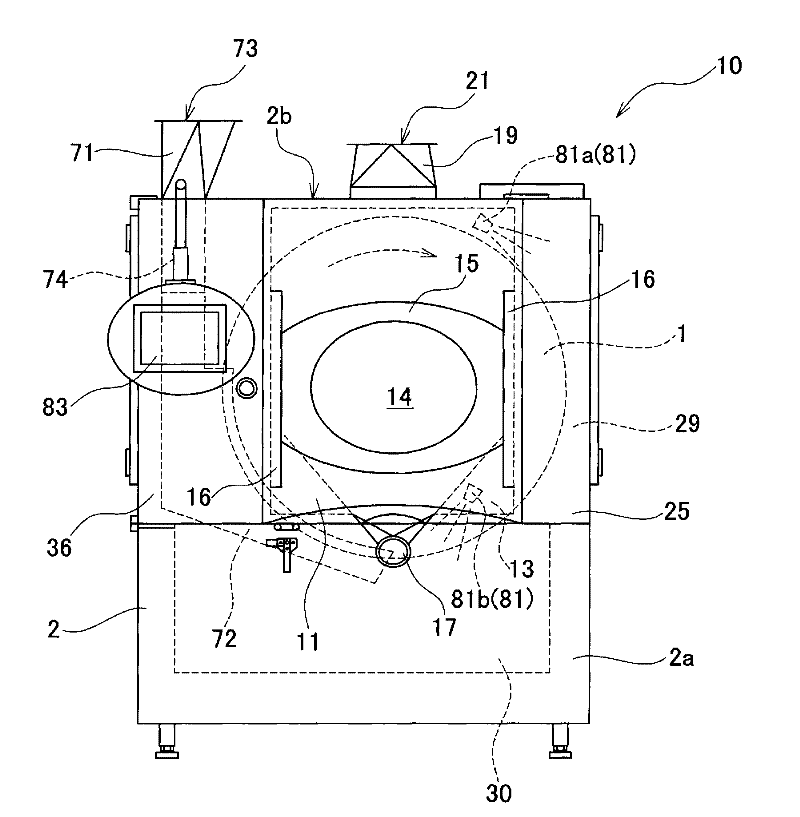

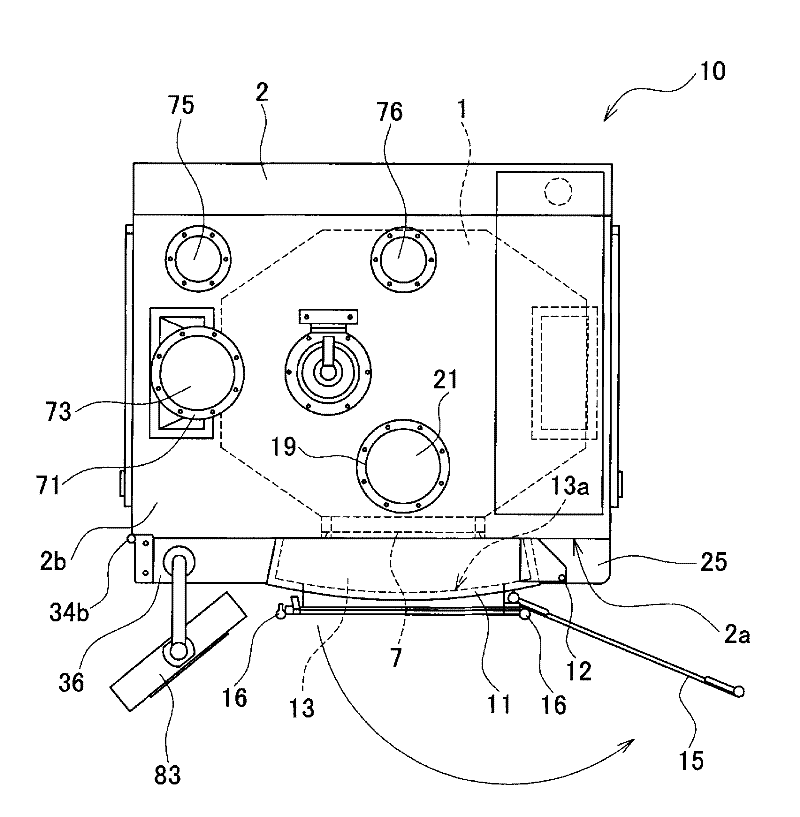

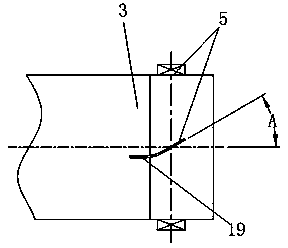

Pan coating device

ActiveCN102202778AReduce cleanup workloadReduce flow rateMaterial granulation and coatingLiquid surface applicatorsStable stateRotational axis

In a pan coating device (10) provided with a rotating drum (1) which rotates about a horizontal rotational axis line (O), an air supply chamber (13) with a larger cross-sectional area than that of an opening (7) in the front surface of the rotating drum is provided at the preceding stage of the opening (7). The air supply chamber (13) is formed inside a chamber door (11) attached to the front of a housing (2) with one end thereof communicating with the opening (7) and the other end thereof connected to an air supply duct (19) via an air supply hole (18). Air flowing into the air supply chamber (13) from the air supply duct (19) is reduced in flow velocity in the air supply chamber (13) and supplied from the opening (7) into the rotating drum (1) with the current thereof in a stable state.

Owner:FREUNT IND

Overlap welding method using ultrathin aluminum-steel compound transition joint

InactiveCN106513945AReduce splashingReduced post-weld cleaning workloadArc welding apparatusAluminiumWelding process

The invention relates to an overlap welding method using an ultrathin aluminum-steel compound transition joint. The method comprises the steps of: pre-welding treatment; and a method of welding aluminum first and then welding steel during welding. The patent provides the welding method of welding aluminum first and then welding steel. As the heat conductivity coefficient of aluminum is about 3 times that of iron. Heat dissipation of an aluminum-steel interface is facilitated if aluminum is welded first, and the peak temperature of the aluminum-steel interface in the welding process is reduced, so that continuous welding is guaranteed, and meanwhile, the aluminum-steel interface of the ultrathin aluminum-steel compound transition joint is not peeled off.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

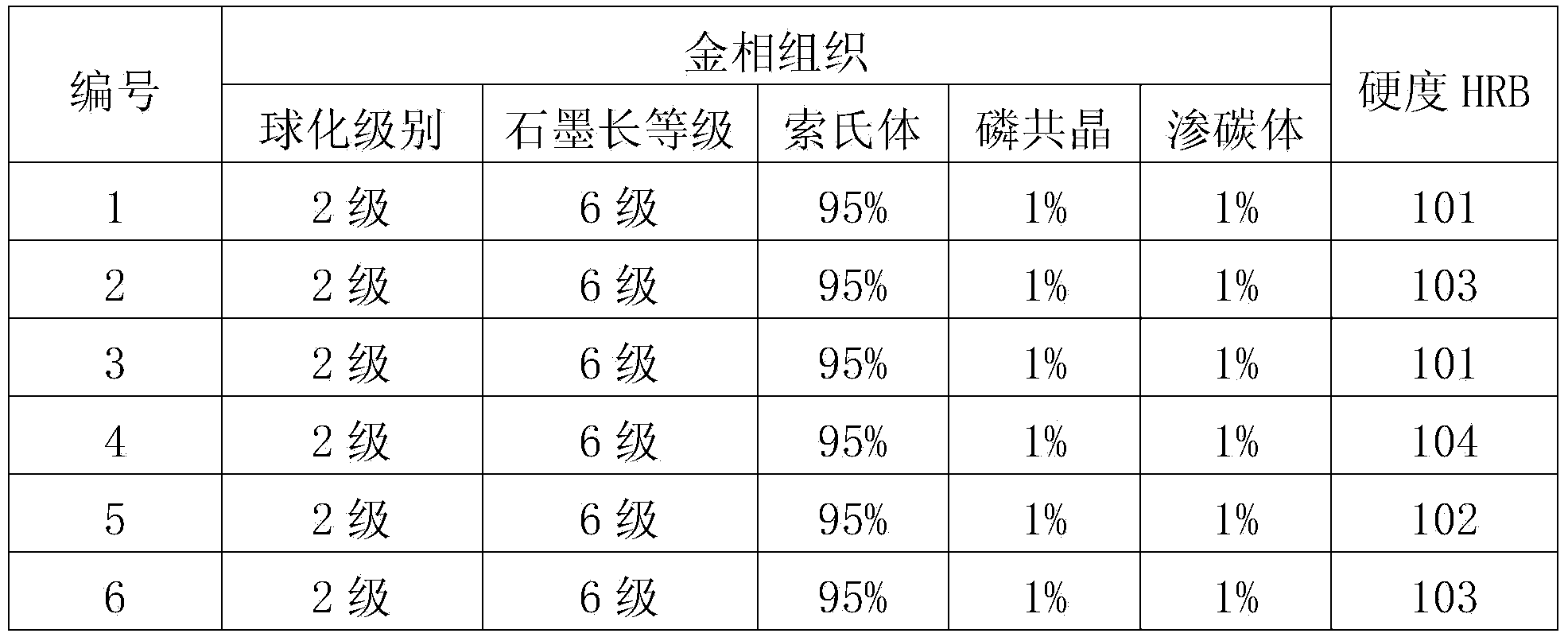

Method for casting piston ring by use of iron type sand coating cylinder

ActiveCN103394639AReduce cleanup workloadSmall machining allowanceFoundry mouldsMoulding machinesPiston ringHigh dimensional

The invention discloses a method for casting a piston ring by use of an iron type sand coating cylinder, which comprises the following steps of mould manufacturing, moulding, core settling, box closing, pouring, box opening, casting cleaning and machining, wherein the moulding is iron type sand coating moulding; the thickness of the sand coating layer of the iron type sand coating is 6-8mm; the poured molten iron comprises 3.6-3.9% of C, 1.9-2.2% of Si, 0.4-0.6% of Mn, less than 0.05% of P and less than 0.05% of S; the pouring temperature is 1,380-1,400 DEG C; the pouring time is 23-28 seconds; and a riser is not required for pouring. By adopting the method disclosed by the invention, the produced piston ring meets the performance requirements and has the advantages of high dimensional accuracy of the casting, small working allowance, high yield of the casting, high production efficiency and the like.

Owner:GUANGXI YULIN LANGTAI AUTO PARTS

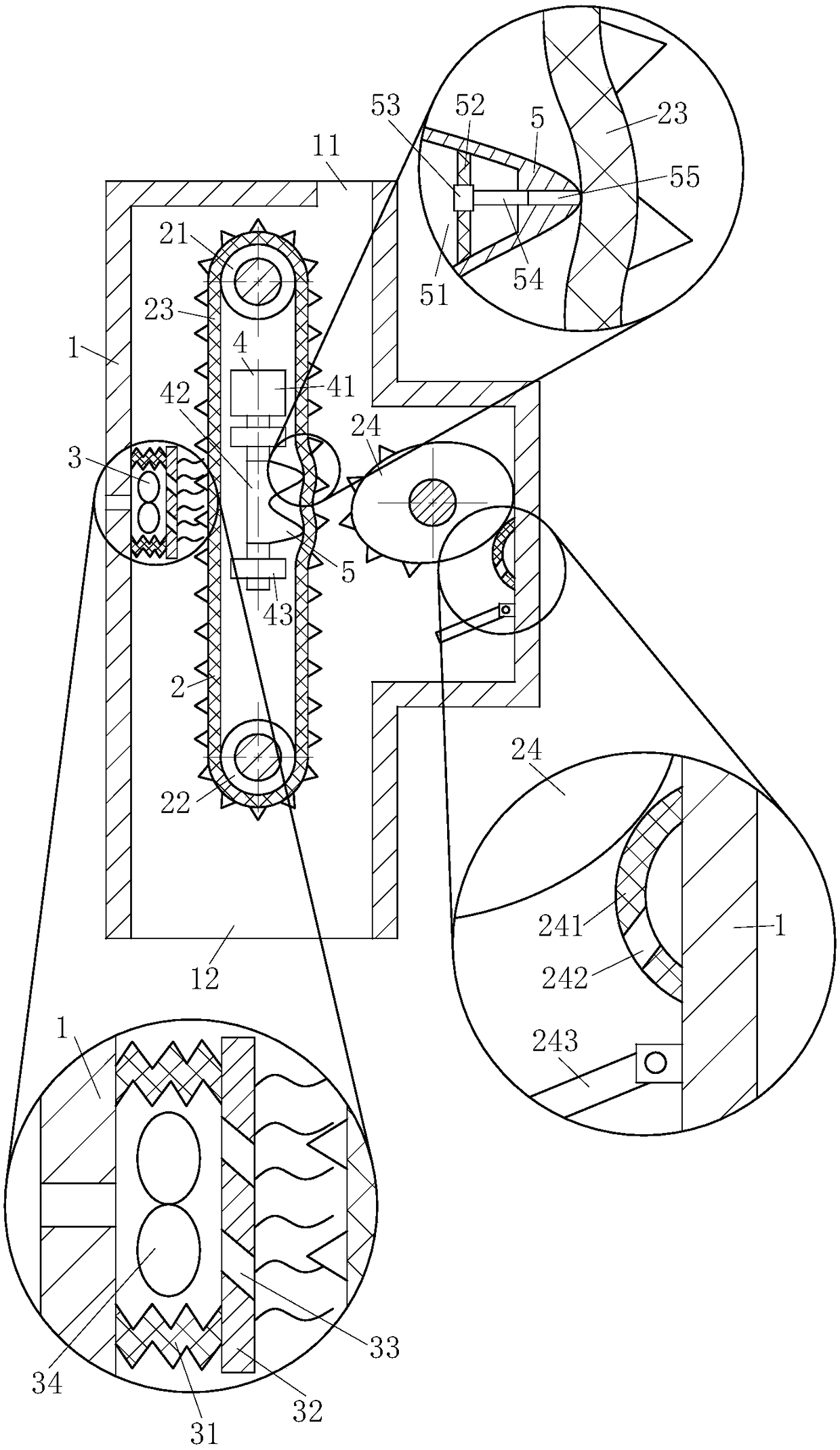

Tablet grinder for clinical medicine

ActiveCN108579969AImprove grinding efficiencyAvoid residueOral administration deviceCleaning using toolsEngineeringMechanical engineering

The invention belongs to the technical field of medical apparatuses, and in particular relates to a tablet grinder for clinical medicine. The tablet grinder for clinical medicine comprises a shell, agrinding module, a blowing module and a roll-compacting module, wherein a feed inlet is formed in one side of the top of the shell, and a discharge port is formed in the bottom of the shell; the grinding module is arranged in the shell and comprises a first roll shaft, a second roll shaft, an elastic abrasive belt, an elliptical wheel, a control motor and a stepping motor, and the grinding moduleis used for grinding tablets; the blowing module is fixedly mounted on the inner wall of the shell on one side of the grinding module for blowing medicinal powder adhered to the grinding module; and the roll-compacting module is mounted in the grinding module for being matched with the grinding module to grind the tablets. As the roll-compacting module is mounted in the grinding module for being matched with the grinding module to grind the tablets, the medicinal powder adhered to the grinding module is blown by arranging the blowing module. An air flow is generated by means of relative movement, so that on the one hand, residues of the medicinal powder are avoided, and on the other hand, the medicinal powder is guided and conveyed, and therefore, the tablet grinding efficiency is improved.

Owner:新昌县寅源医疗器械有限公司

High temperature sticking resistant composition for vanadium and titanium-containing molten iron desulphurization, high temperature sticking resistant agent, and application of

The invention discloses a high temperature sticking resistant composition for vanadium and titanium-containing molten iron desulphurization. The composition contains 45-75wt% of Al2O3, 5-15wt% of CaO, 15-30wt% of MgO and 5-10wt% of V2O3. The invention also discloses a high temperature sticking resistant agent, and its application in the vanadium-titanium molten iron desulphurization. The high temperature sticking resistant agent can substantially reduce the sticking strength of vanadium and titanium-containing molten iron and the surface of a desulphurization apparatus in order to reduce the cleaning workload in steel smelting engineering and reduce the production cost of a whole process.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Recycling process and system for wooden activated carbon industrial wastewater

ActiveCN103086542AAchieve reasonable disposalEasy to arrange for productionMultistage water/sewage treatmentWater/sewage treatment by neutralisationActivated carbonWastewater

The invention discloses a recycling process and a system for wooden activated carbon industrial wastewater. The method comprises the following steps of: uniformly mixing activated carbon rinsing wastewater, industrial wastewater in an activated carbon workshop and washing water of a scrubber tower and adding lime to neutralize; then, sequentially precipitating, pressure-filtering and precipitating neutralized wastewater and sending the wastewater to a production workshop for water consuming facilities to use; or sequentially precipitating, pressure-filtering, precipitating bio-chemically aerating and precipitating the wastewater and sending the wastewater to the production workshop for water consuming facilities to use or discharge outside so as to recycle the industrial wastewater or reach the standard to discharge the industrial wastewater. Filter mud after pressure filter can be additionally used as fertilizers or building materials and the like, so that product is conveniently arranged, the production cost is lowered and the economic benefit of enterprises is improved. As the wastewater after pressure filter is substantially free from sediments, the phenomenon that sediments in the settling pond is avoided, so that the sedimentation efficiency is improved, the sediment cleaning workload is greatly reduced, and technical reference for expanding the capacity of enterprises can be provided.

Owner:FUJIAN XINSEN CARBON +1

Interception storage adjustment system for intensively transferring initial rainwater by sewage interception pipe

InactiveCN102808447ARealize the storage functionConducive to drainage regulation and storageFatty/oily/floating substances removal devicesSewage drainingSewageEngineering

The invention discloses an interception storage adjustment system for intensively transferring initial rainwater by a sewage interception pipe. The interception storage adjustment system is arranged on multiple different confluence pipes and comprises an interception well arranged on each confluence pipe; the interception well is provided with a sewage interception pipe extending into a sewage plant, a water outlet communicated with a river channel, and a water inlet communicated with the confluence pipe; the storage adjusting system further comprises a storage adjustment pipe, an initial rainwater interception pipe and a filter layer arranged in the interception well; the filter layer is arranged between the water inlet and the water outlet so as to form a water inlet region adjacent to one side of the water inlet and a water outlet region close to one side of the water outlet in the interception well; one end of the initial rainwater interception pipe is communicated to the water outlet region; and the other end of the initial rainwater interception pipe is communicated into the storage adjustment pipe. According to the interception storage adjustment system, the interception effect is greatly improved, the intercepting dry weather flow is led into the sewage treatment plant, the rainwater is led into the storage adjustment pipe, the pollution of the river channel is reduced and the municipal drainage and storage adjustment capability is enhanced at the same time.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

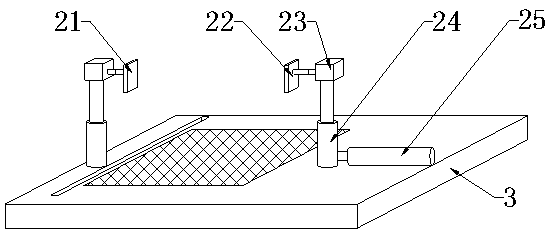

Sand mould casting technology using filter screens instead of washburn cores

The invention relates to a sand mould casting technology using filter screens instead of washburn cores. The sand mould casting technology comprises the following steps: manufacturing an upper sand mould and a lower sand mould of a hammer pattern, and reserving an inner gate position; arranging a filter screen between a riser and the hammer pattern and integrating the filter screen and the hammer pattern; arranging a filter screen at a position close to a pouring cup on a sprue; brushing coating on the upper sand mould and the lower sand mould until sand is not exposed; clamping the upper sand mould and the lower sand mould, arranging clips or fully pressing weights, and blocking a parting surface by using a fire-proof mud strip; and adding a pouring system, smelting pouring liquid, and then pouring. By the sand mould casting technology using the filter screens instead of washburn cores, the riser can be removed easily, sometimes, the riser can drop naturally after a box is opened, so that the labor intensity is reduced, the production efficiency is improved, the riser is broken along the filter screens, misrun is avoided, and reject rate is reduced; and by the filter screen placed at a sprue gate, steel slag can be stopped from entering a casting mould cavity, molten steel is purified, and metallurgical quality is improved, so that the performance of castings is improved.

Owner:LUOYANG ZHILI NEW MATERIALS CO LTD

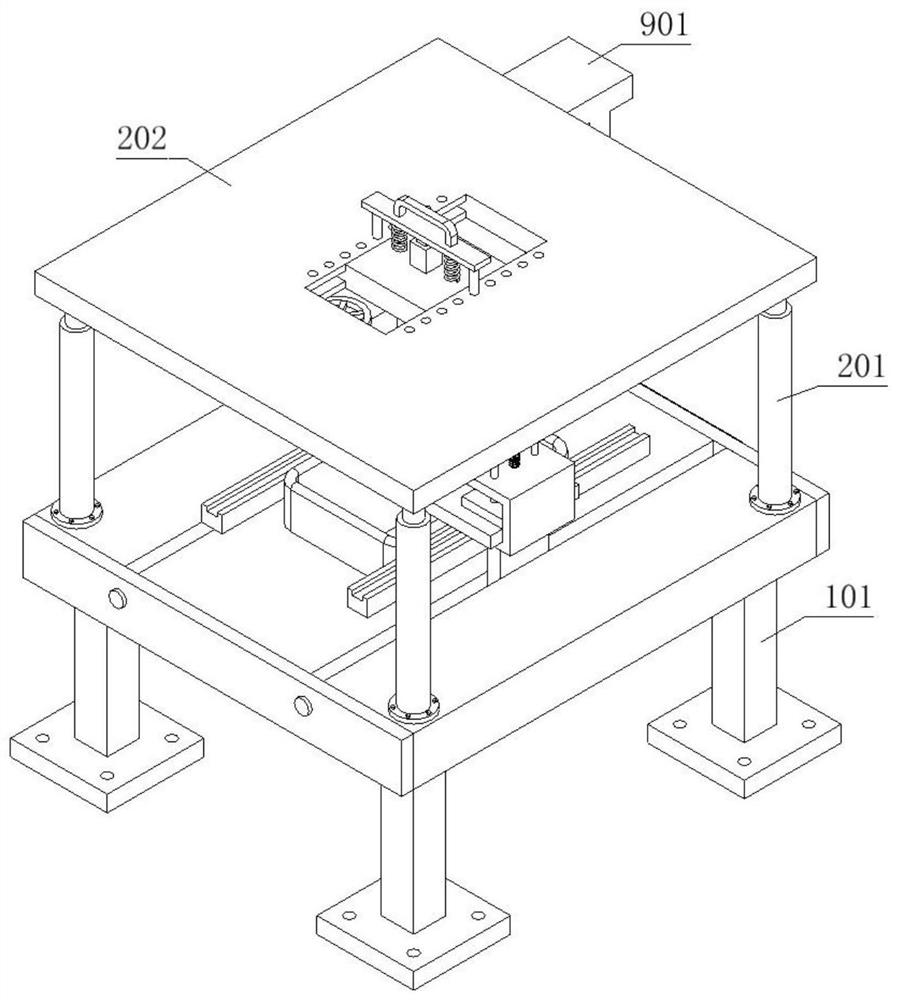

Stamping device for metal base plate production

InactiveCN113560420AAchieve fixationRealize automatic unloadingPerforating toolsMetal-working feeding devicesStructural engineeringMetal

The invention provides a stamping device for metal base plate production. The stamping device comprises a mounting mechanism, two sets of clamping parts, a connecting part, a collecting part, a stamping part and a moving part; a lifting part is mounted at the top of the mounting mechanism; the two sets of clamping parts are symmetrically mounted at the top of the mounting mechanism, a lower mold is arranged between the two sets of clamping parts, and fixing parts are mounted in the two sets of clamping parts; the connecting part is mounted in the mounting mechanism; the stamping part is mounted on the lifting part; the collecting part is mounted at the bottom of the mounting mechanism; and the moving part is mounted on the right side of the lifting part. Two limiting blocks are slidably connected into two guide grooves, so that when two fixing columns are located in two fixing holes in the middle, the top of a storage box is tightly attached to the bottom of the lower mold, splashing of crushed materials after stamping is avoided, on the one hand, the sanitary environment of a working area is improved, and the cleaning time of workers is shortened; and on the other hand, the workers are prevented from being hurt by the splashed crushed materials.

Owner:深圳市建宏达照明电路有限公司

Wood processing dust removal device

InactiveCN111002406AEfficient removalIncrease profitDispersed particle filtrationTransportation and packagingDust controlEnvironmental engineering

The invention discloses a wood processing dust removal device and relates to the technical field of wood processing. A box body is included. A supporting bottom plate is fixedly mounted on a lower surface of the box body, a purifying chamber is arranged in the box body, a compressing part is arranged below the purifying chamber, a dust filtering net is arranged at one end of the purifying chamber,an air outlet pipeline is arranged on one side of the dust filtering net, a drainage fan is arranged at one end of the air outlet pipeline, and a dust removing part is arranged in the purifying chamber. In the invention, through an overall design, wind power generated by the drainage fan is cooperated, and fan blades are driven to rotate so that a cleaning brush on a rotating frame sweeps and brushes the dust filtering net all the time, blocked dust on an upper surface is effectively removed, a good purification effect is guaranteed, and a cleaning workload of people is reduced; and meanwhile, a gear is used for driving a rack to move, then the accumulated dust is subjected to briquetting treatment through a movable plate, secondary utilization can be performed, and an utilization rate ofresources is increased.

Owner:湖州汇德集团有限公司

Coalless environmental-friendly casting molding sand additive and application thereof in molding sand

The invention provides a coalless environmental-friendly casting molding sand additive which comprises the following components in parts by weight: 60-70 parts of silicon oxide, 20-30 parts of a metaloxide and 5-15 parts of aluminosilicate. Coalless environmental-friendly casting molding sand comprises the following components: sand, bentonite, iron, the additive and an anti-sticking agent in a weight ratio of (90-95):(2.5-5):(2-5):(1.5-4):(1-6); and the anti-sticking agent is a mixture of quartz sand, modified lime powder, modified dolomite, an organic silicon modified epoxy phenolic resin and modified gum. By adopting the coalless environmental-friendly casting molding sand provided by the invention, the problem of black pollution which cannot be avoided in the production process of a conventional method can be solved, the energy consumption of a production process can be greatly reduced, the environment protection burden can be alleviated, waste sand, which is a byproduct of a conventional process, can be reduced, and the surface control capability of a casting can be finally improved.

Owner:杭州洁铸科技有限公司

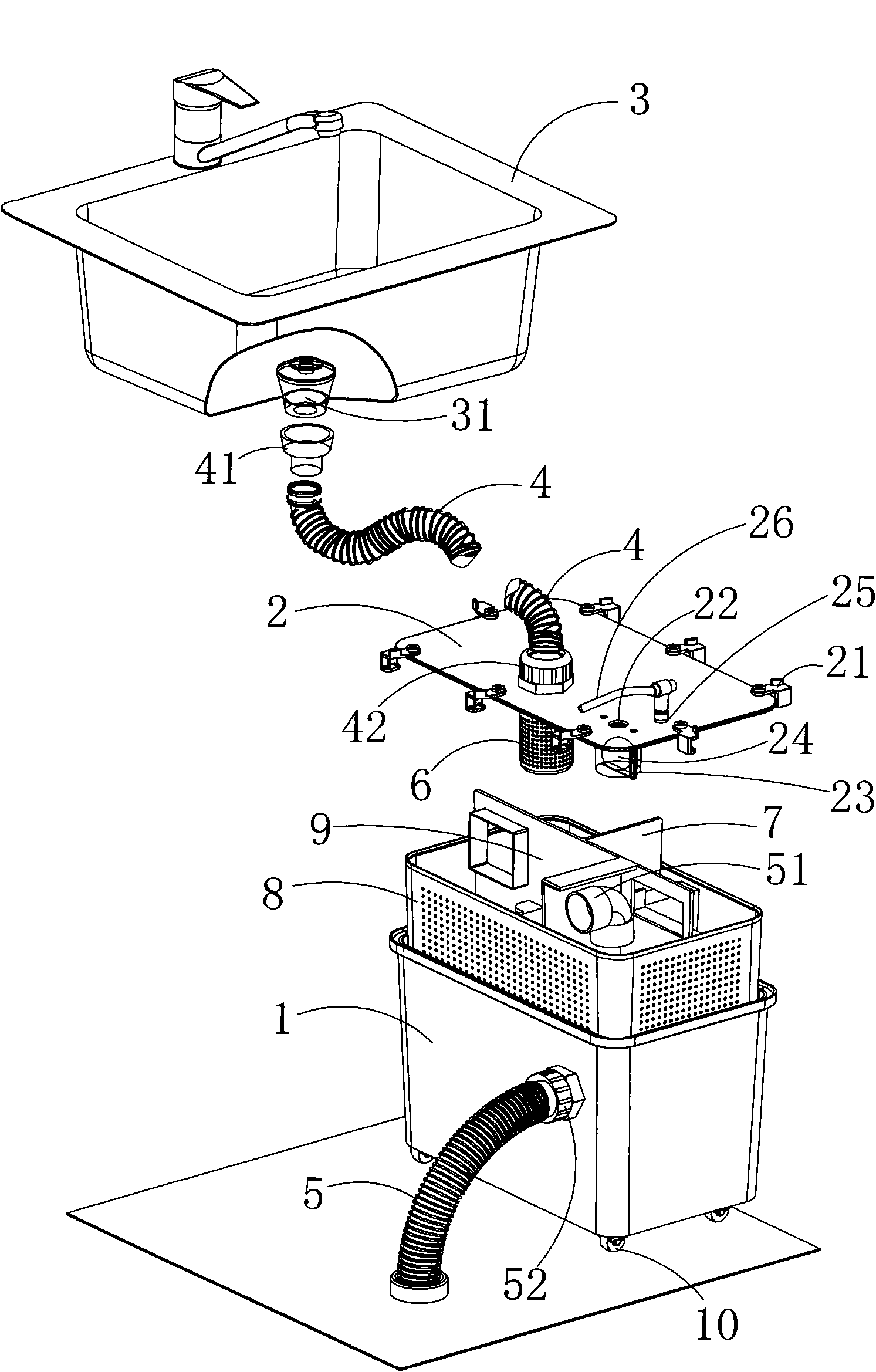

Sediment filter box

InactiveCN103100258ANo accidental water leakageEasy to moveFiltration circuitsWater leakageSediment Filter

The invention discloses a sediment filter box. The sediment filter box is provided with a box body, a box cover, a water inlet and a drain port, wherein the box is internally provided with a plurality of partition plates, the plurality of partition plates can divide the inner space of the box body into a plurality of sedimentation tanks, and waste water successively flows through the all sedimentation tanks. The waste water is subsided when flowing through the plurality of sedimentation tanks, the heights of the partition plates gradually increase, and gypsum, the density of which is higher than that of water, is easy to subside, so that gypsum in the waste water passing through the final sedimentation tank is almost completely filtered; a floating ball assembly and an overflow hole can guarantee that the sediment filter box is free of an unexpected water leakage phenomenon; first and second filter screen bags are convenient to be rapidly assembled and disassembled, and thus the cleaning workload of users can be greatly lightened; and the bottom of the box body is provided with roller wheels, and thus the sediment filter box is convenient to move.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

Precipitation and filtration tank

InactiveCN102336480ANo accidental water leakageEasy to moveMultistage water/sewage treatmentWaxLeaking water

The invention discloses a precipitation and filtration tank, which comprises a tank body, a tank cover, a water inlet and a drainage port; a plurality of partition plates are arranged in the tank body; the plurality of partition plates partition the internal space into a plurality of precipitation tanks; waste water sequentially flows through the precipitation tanks; the waste water is precipitated in the plurality of precipitation tanks, the partition plates are gradually heightened, and the density of gypsum is higher than that of water, so the gypsum is easily precipitated; after the wastewater flows through the final precipitation tank, the gypsum in the waste water is nearly totally filtered; a wax baffle plate is arranged in the tank body; the density of wax oil in the waste water is lower than that of the water, and the wax baffle plate can intercept the wax oil floating on the water surface, so that the precipitation and filtration tank not only can precipitate and filter thegypsum mud, but also can filter the wax oil; the precipitation and filtration tank does not accidently leak water due to the design of a floating ball assembly and an overflow water hole; first and second filtration net slings are conveniently and fast assembled and disassembled, so that the clearing workload of a user is greatly lightened; and rollers are arranged at the bottom of the tank body,so that the precipitation and filtration tank is convenient to move.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

Trench integrated mine collecting and mining method of inclined ore body

ActiveCN107654232AStable supportImprove concentrationUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a trench integrated mine collecting and mining method of an inclined ore body. A trench construction area is arranged in an empty area formed after mining. Trench constructionof the trench construction area specifically includes the steps that a trench slope used for guiding falling ore to move downward and / or protect the upper disc surface of the ore body is constructed at the corner of the upper disc surface and a bottom plate surface of the trench construction area; a mine collecting channel is reserved in the bottom plate surface when the trench slope is constructed, and the constructed trench slope, the reserved mine collecting channel and the lower disc slope of the ore body form a trench used for gathering the falling ore extracted from the upper portion ofthe trench to the mine collecting channel; the ore body on the upper portion of the trench is extracted and output from the upper portion and / or the side face of the mine collecting channel. The method easily improves the ore recovery rate, ore output efficiency, productivity, recovery safety and comprehensive economic benefits, and is suitable for exploitation of inclined ore bodies with medium stability from thin to medium thick and construction of a trench type mine output bottom structure.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Biomass gas burner

The invention relates to a biomass gas burner. The biomass gas burner is characterized in that a long burning fire fuel gas channel, a long burning fire air channel, a main burning fuel gas channel and a main burning air channel are included; an ignition device penetrates through the long burning fire air channel and extends to the front end of the long burning fire fuel gas channel; the front portion of the long burning fire air channel, the front portion of the main burning fuel gas channel and the front portion of the main burning air channel are respectively provided with a whirlcone; the long burning fire air channel and the main burning air channel are respectively provided with a flow regulation device. According to the biomass gas burner, the long burning fire fuel gas channel and the long burning fire air channel are arranged so that a long burning fire standby function can be achieved, the consumption of liquefied gas or the consumption of natural gas is lowered, ignition burning waste is avoided, and boiler starting time is shortened; mixing of the air and biomass gas is reasonably controlled, the biomass gas can be made to be fully reacted with oxygen in a boiler, tar is burnt up, burning efficiency is improved, the tar can be prevented from being coked in the burner and the boiler, cleaning workloads are reduced, and meanwhile pollution to the environment can be reduced.

Owner:ZHEJIANG TUFF BOILER

Glass bottle die casting piece manufacturing process cyclically using molding sand

ActiveCN103817287AHigh strengthImprove impact resistanceFoundry mouldsMould handling/dressing devicesDie castingBreakage rate

The invention discloses a glass bottle die casting piece manufacturing process cyclically using molding sand. According to the invention, a manufactured glass bottle die casting piece has an accurate size and no subcutaneous blowholes; sand discharging of castings is convenient after molding, used sand can be regenerated and reused and has a low breakage rate and small loss in the process of regeneration of the used sand, and the reuse rate of the used sand is high; the process produces little dust, little pollution and no phenol and formaldehyde.

Owner:CHANGSHU WEIHENG MOLD MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com