Pan coating device

A technology of coating device and air supply chamber, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., which can solve the problems of spraying mist disorder, inability to spray coating liquid or adhesive liquid uniformly, etc. , to achieve stable airflow, reduce the workload of drum cleaning, and reduce the workload of drum cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

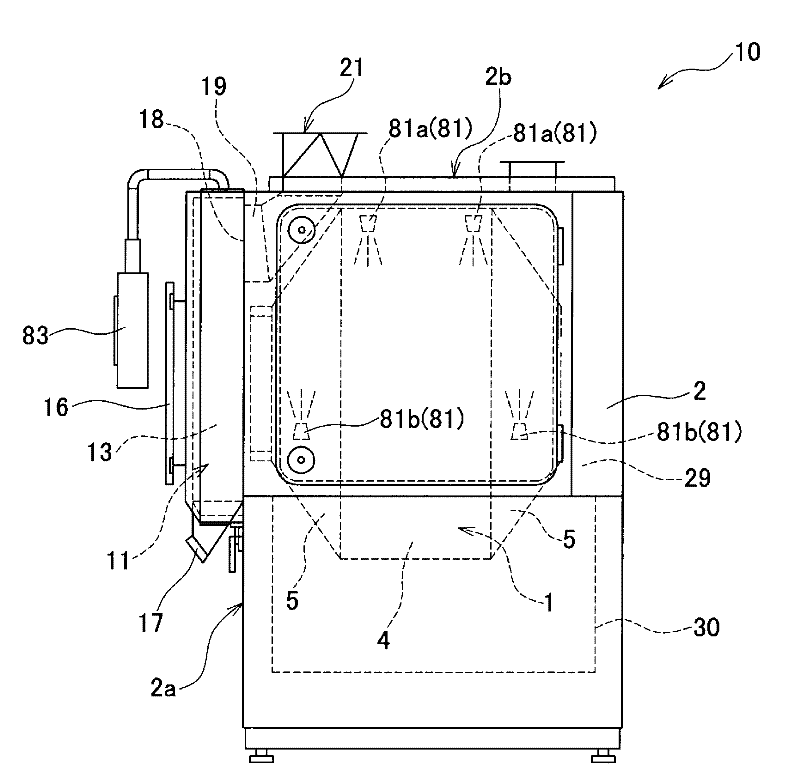

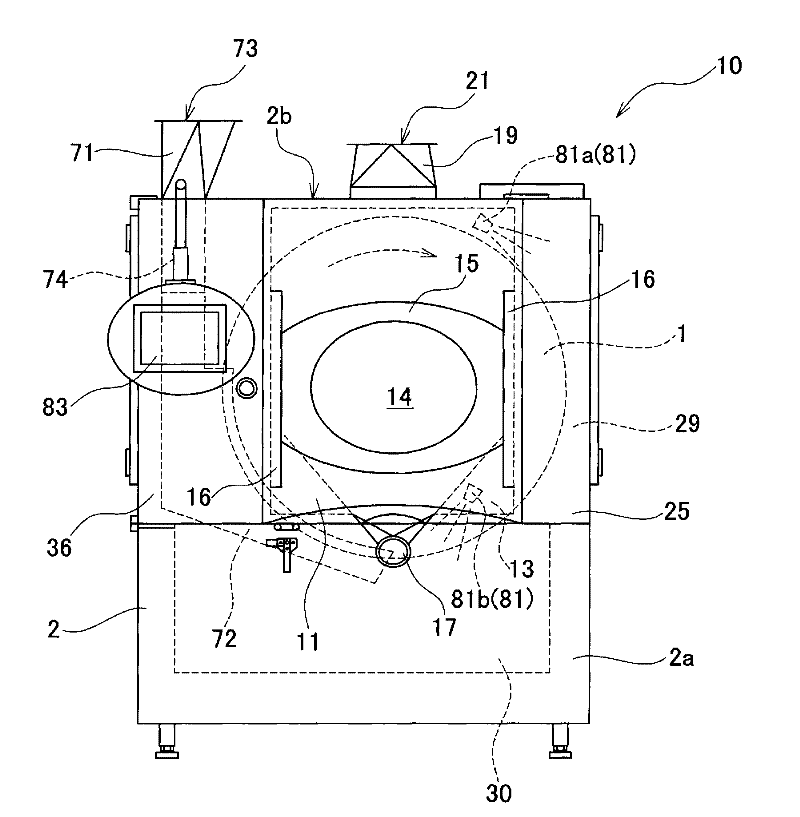

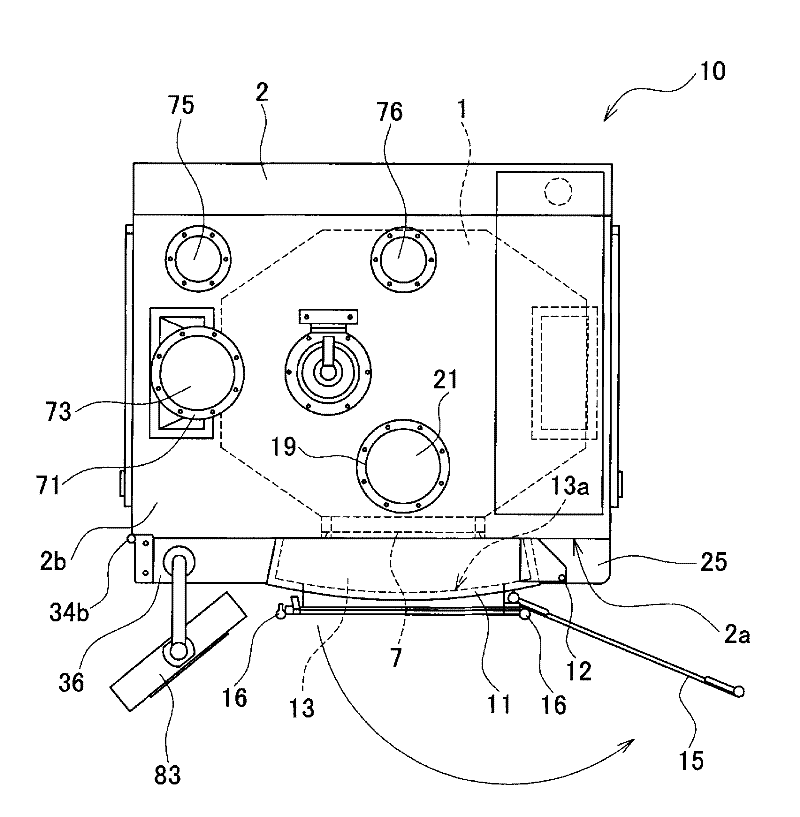

[0035] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. figure 1 It is a right side view showing the structure of a disk coating device 10 (hereinafter abbreviated as coating device 10) as an embodiment of the present invention, figure 2 is its front view, image 3 It is a plan view (top view). figure 1The device is a sleeveless type coating device using a so-called full punch type rotary drum. In the coating device 10 , to-be-processed objects such as tablets are accommodated in a rotating drum (coating pan, hereinafter simply referred to as a drum) 1 . In addition, the coating process of the object to be processed is performed by spraying the coating liquid on the object to be processed in the drum.

[0036] like Figure 1~4 As shown, in the coating device 10 , the drum 1 is provided rotatably at the center of the housing 2 . The drum 1 rotates about a substantially horizontal rotation axis O. As shown in FIG. Object...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com