Biomass gas burner

A biomass gas and burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as environmental pollution, tar clogging burners, and difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

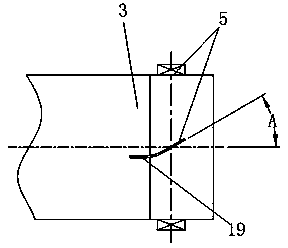

[0020] Such as Figure 1~3 As shown, the present invention includes the pilot gas passage 100 positioned at the axis, the pilot air passage 200 placed outside the pilot gas passage 100, the main combustion gas passage 300 placed outside the pilot air passage and the main combustion gas passage 300 of its outer layer. The fuel air channel 400, in this embodiment, the eternal fire gas channel 100 is the first pipe 1 arranged on the axis, the second pipe 2, the third pipe 3 and the shell 4 are coaxially sleeved outside the first pipe 1 in sequence, An open flame air passage 200 is formed between the first pipe 1 and the second pipe 2 , a main combustion gas passage 300 is formed between the second pipe 2 and the third pipe 3 , and a main combustion air passage is formed between the third pipe 3 and the casing 4 400. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com