Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about "Material granulation and coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

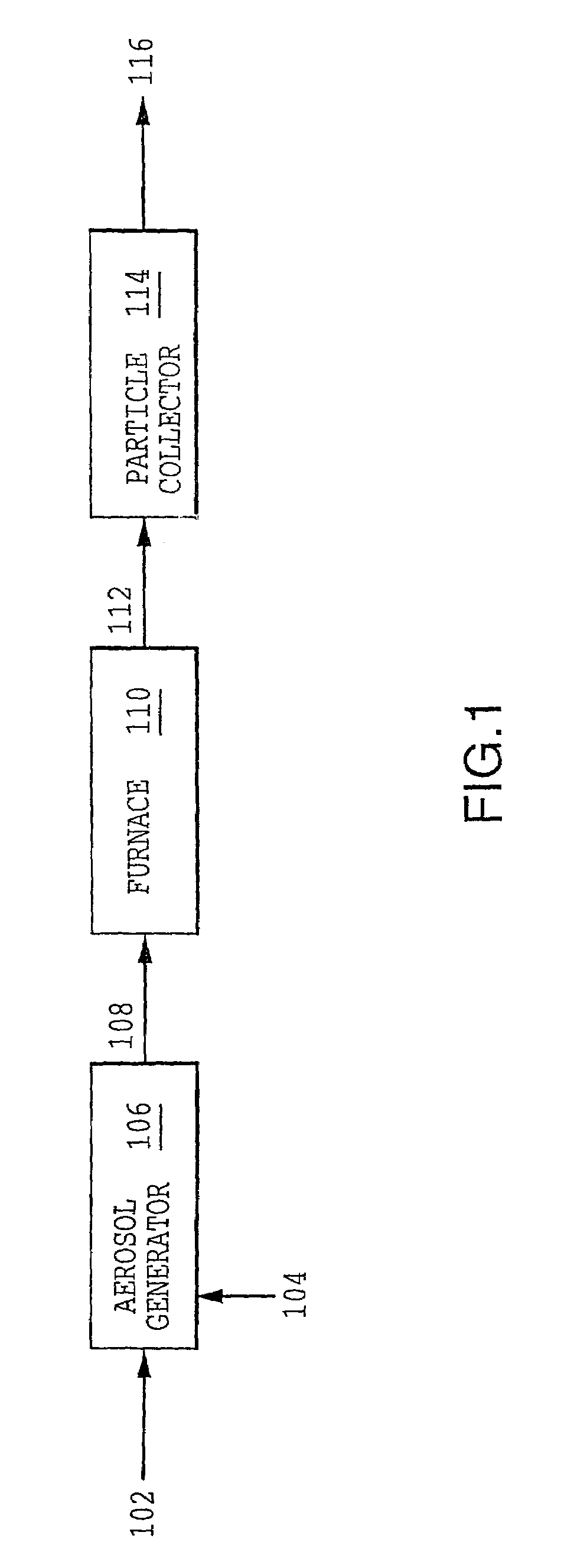

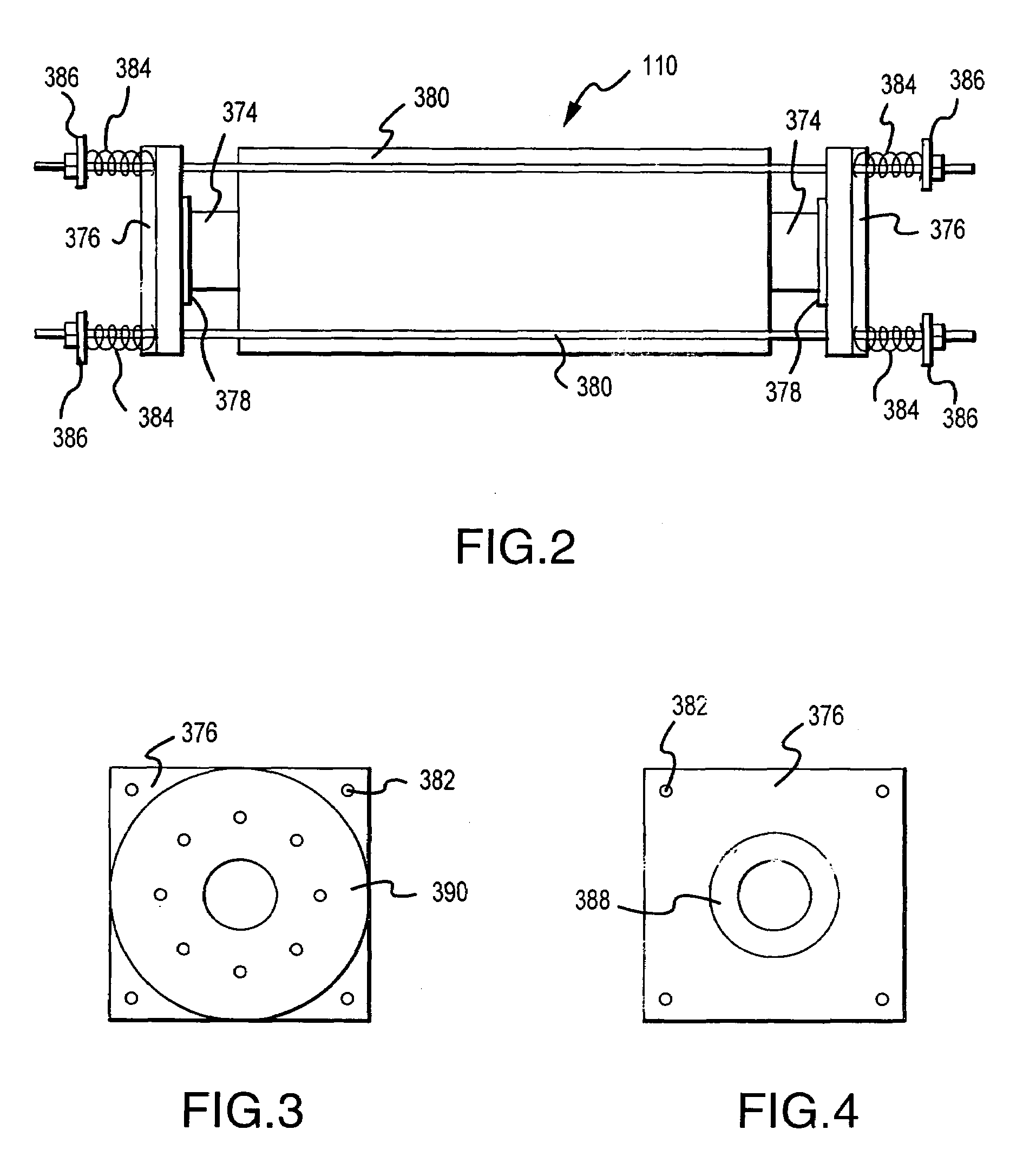

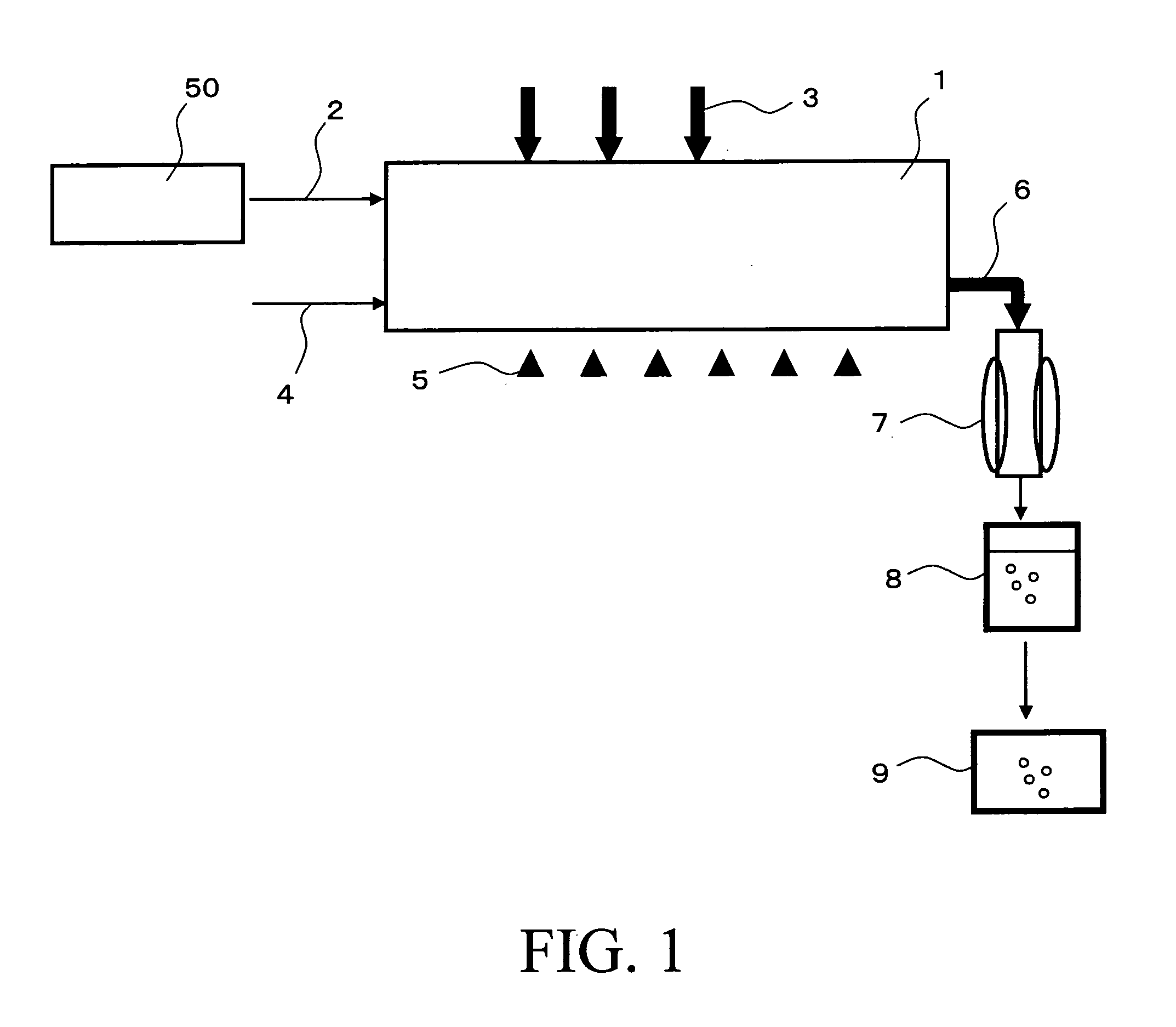

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

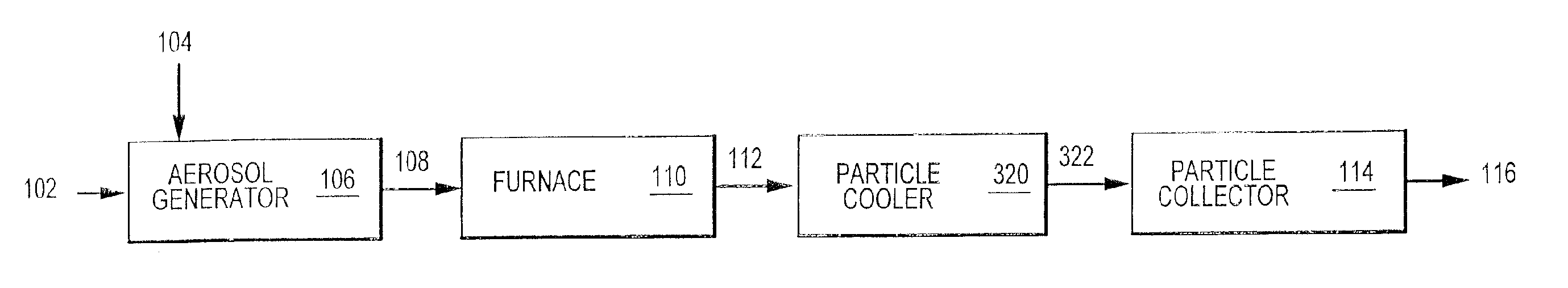

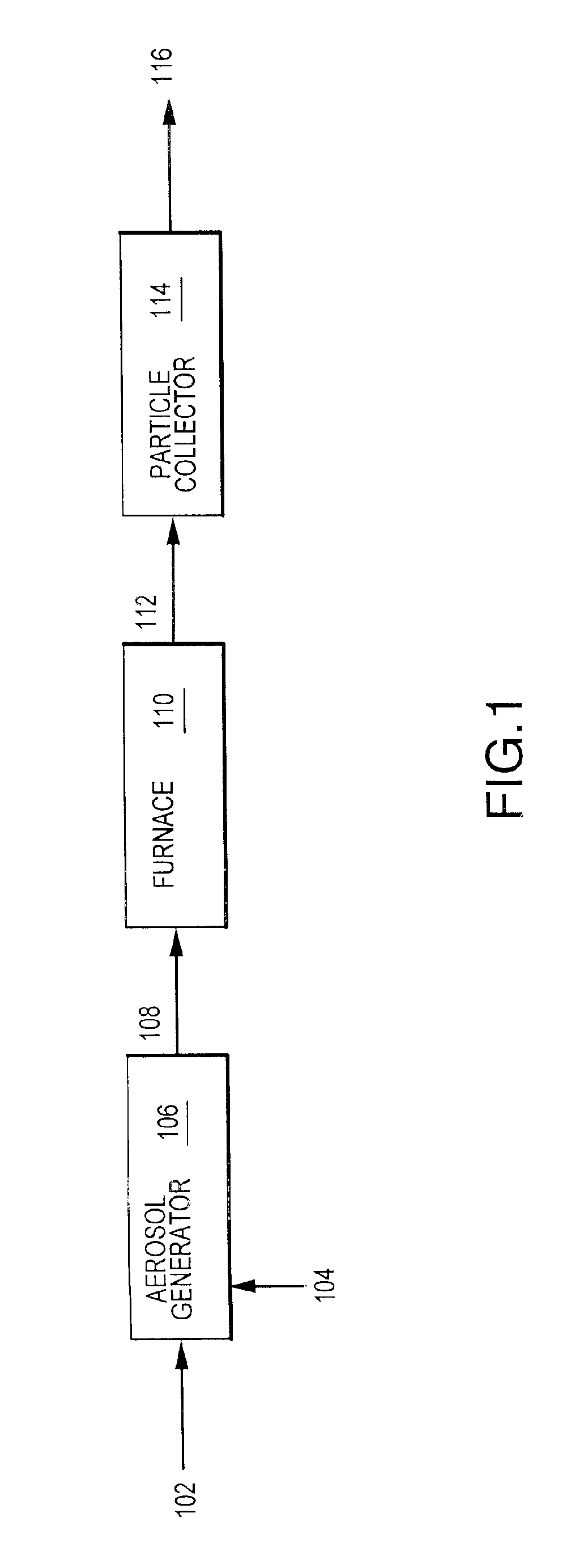

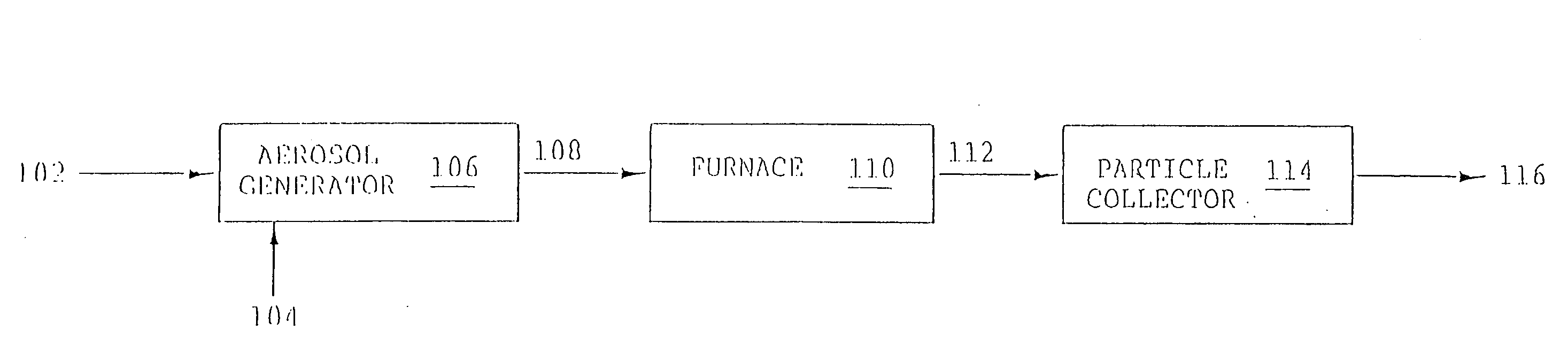

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

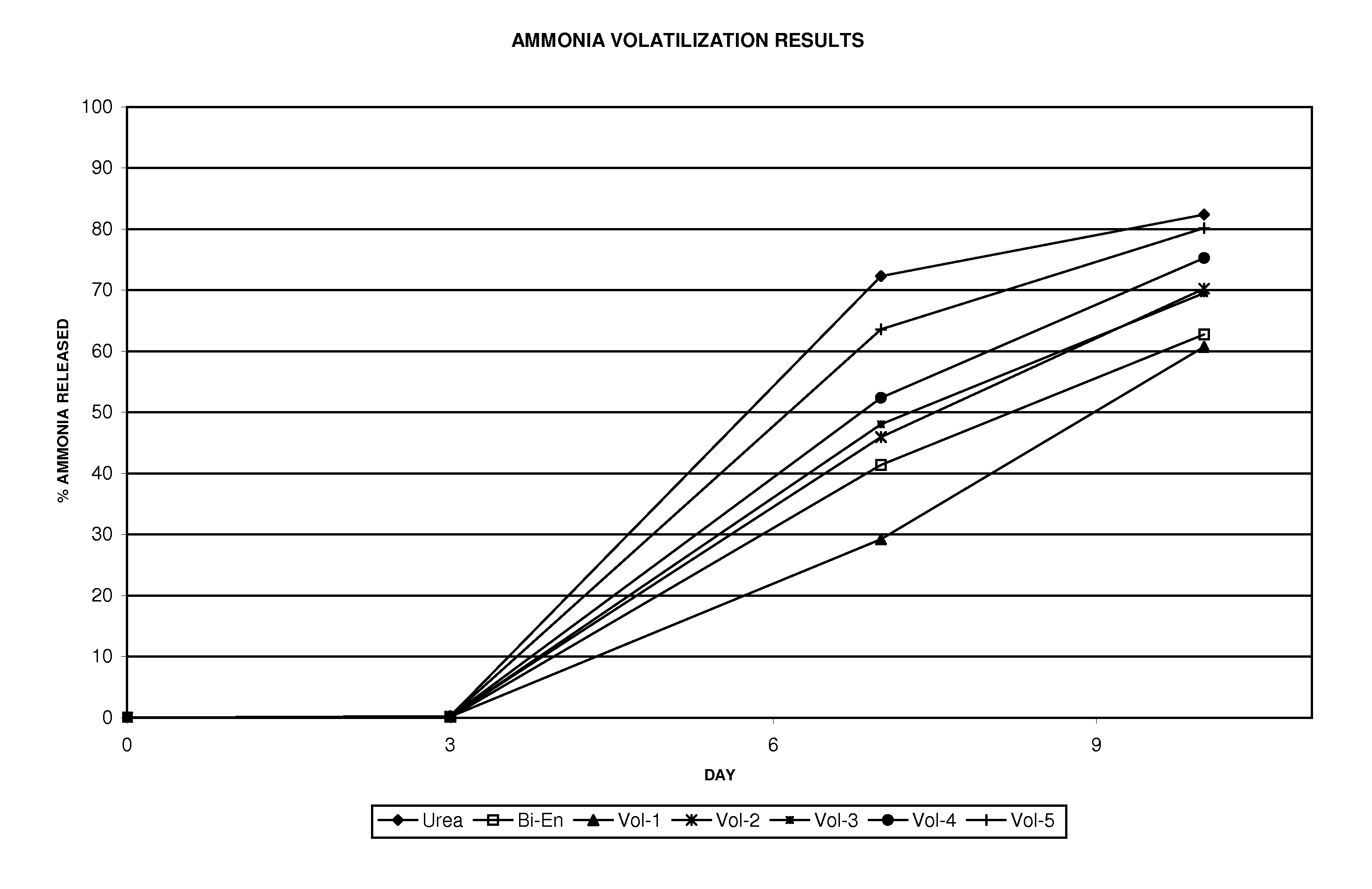

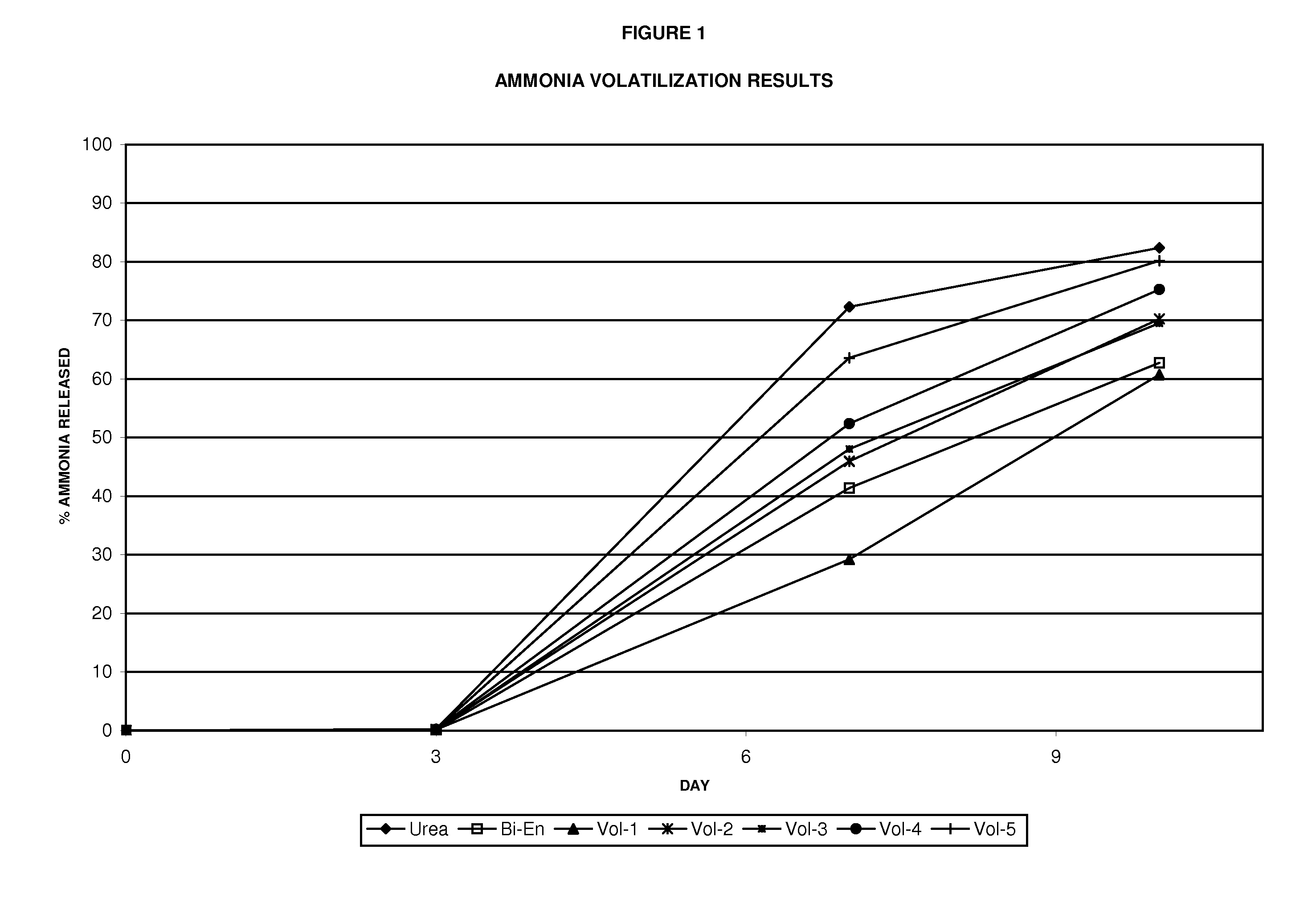

Urea fertilizer containing central volatilization inhibitor particles to reduce release of ammonia and processes for making same

A urea fertilizer having reduced ammonia volatilization upon application to soil including a central particle having an outer surface and comprising ammonia volatilization inhibiting compounds containing one or more of boron and iodine, and a coating of urea on the outer surface of the central particle, and further a process of making the fertilizer including the steps of: granulating ammonia volatilization inhibiting compounds containing one or more of boron and iodine, with a binder to produce volatilization inhibitor particles; screening the inhibitor particles to a preselected particle size; spraying melted urea onto the surface of the inhibitor particles to produce a coating on the inhibitor particles; granulating the coated inhibitor particles with sprayed melted urea to produce granules of urea coated central volatilization particles; and cooling the granules.

Owner:NEW FERTILIZER TECH LLC

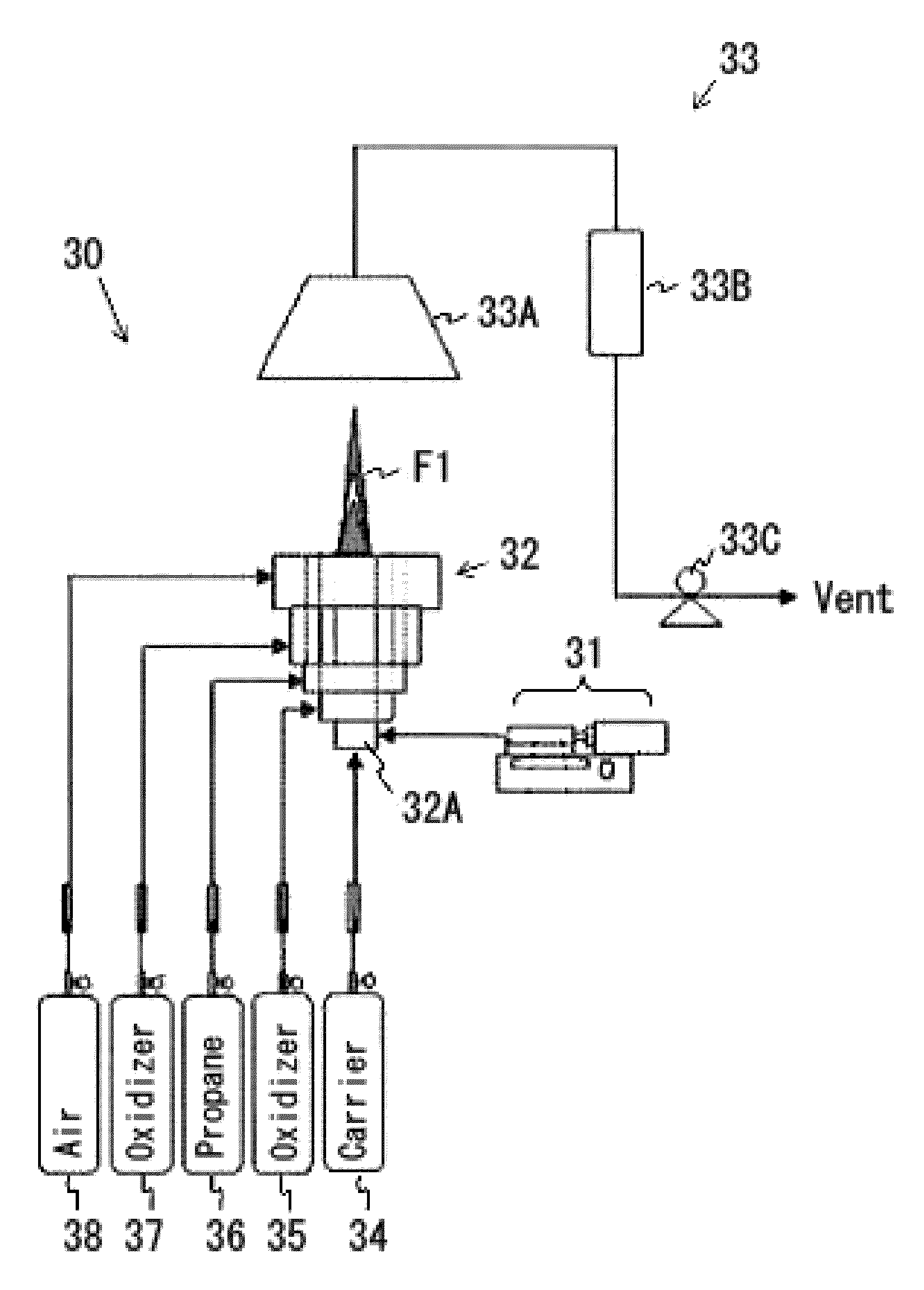

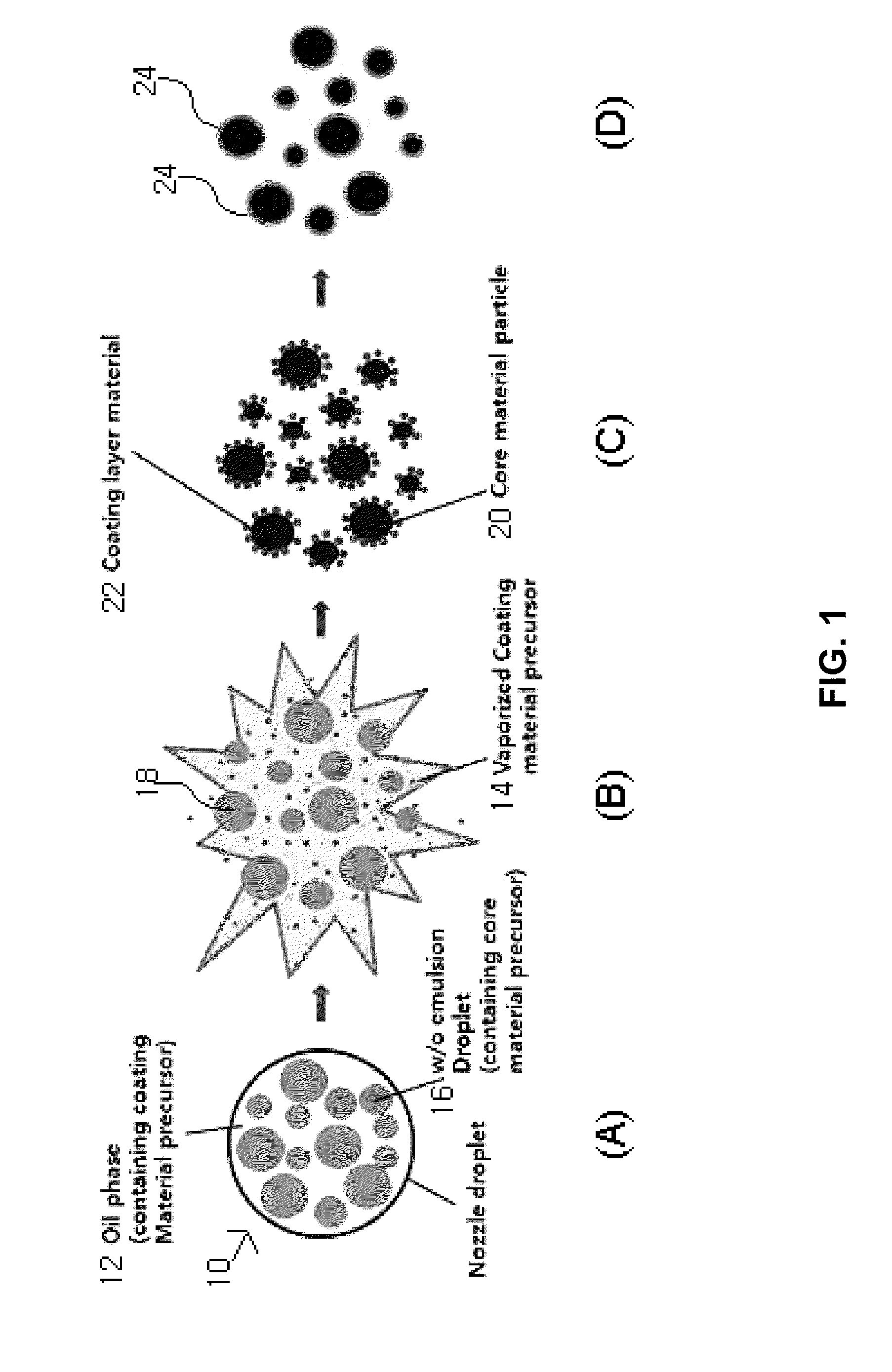

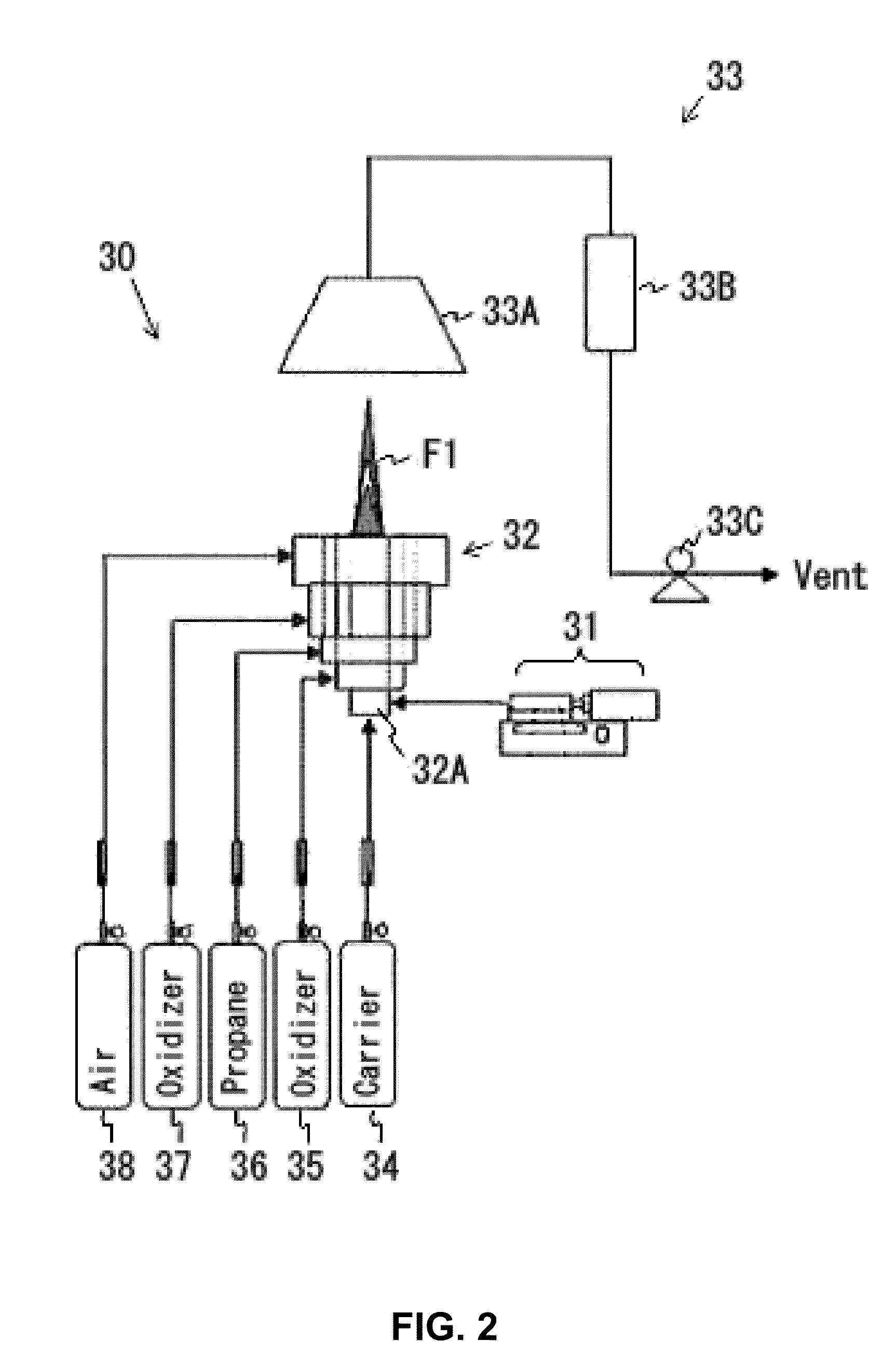

Method for Coating Core Ceramic Particles by Emulsion Flame Spray Pyrolysis

InactiveUS20100055340A1Reduce preparation timeReduce manufacturing costMaterial granulation and coatingLiquid surface applicatorsSingle stageMetallurgy

A method for coating the core ceramic particles by emulsion flame spray is provided. In particular, the method forms a core ceramic particle simultaneously with coating the surface of the formed core ceramic particles by emulsion flame spray pyrolysis. The core ceramic particle may be coated in a single stage by emulsion flame spray pyrolysis conventionally used in the art, through putting coating material precursor into the oil phase of emulsion solution at a stage of preparing emulsion solution in emulsion flame spray pyrolysis process.

Owner:KOREA ADVANCED INST OF SCI & TECH

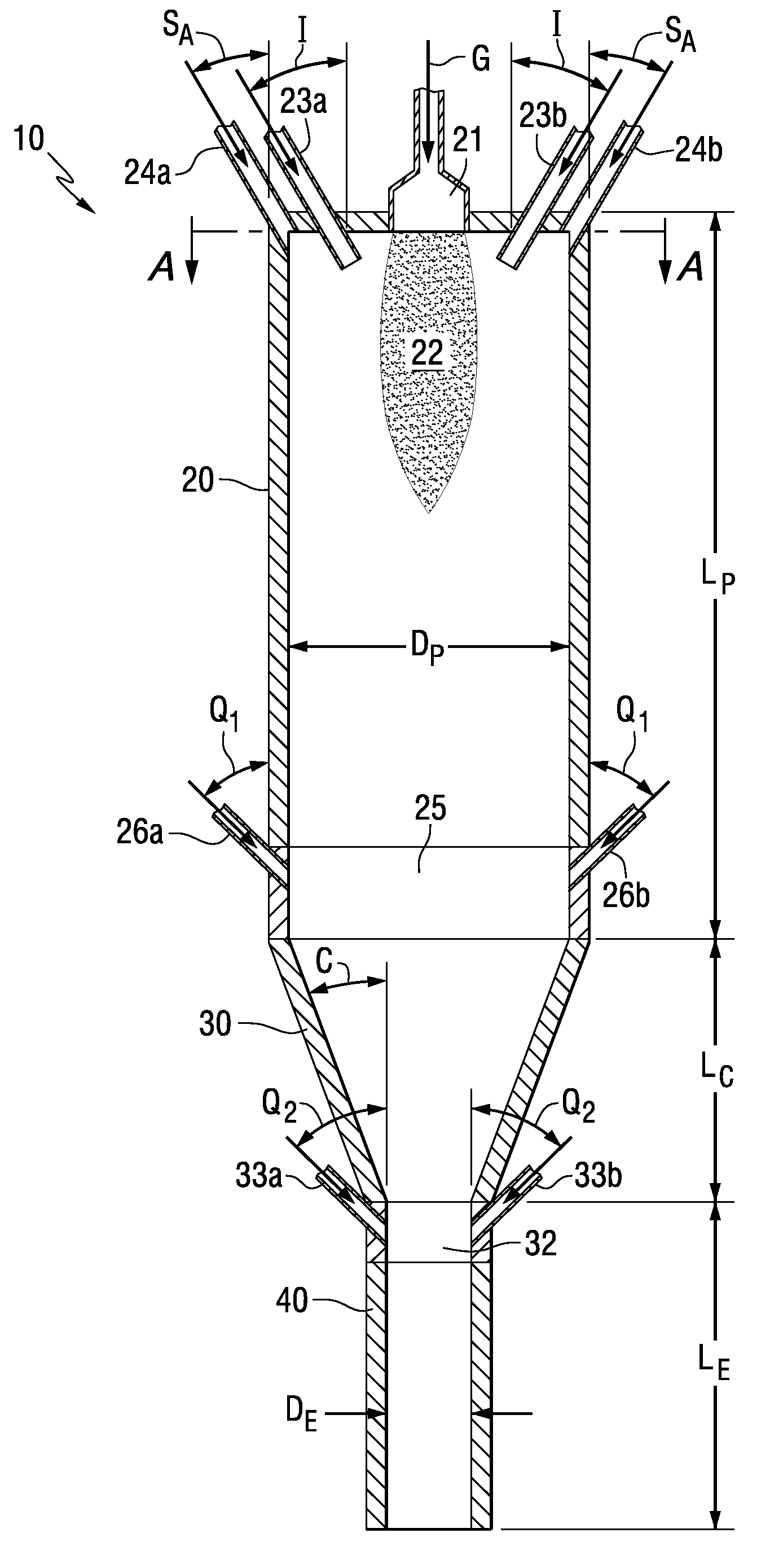

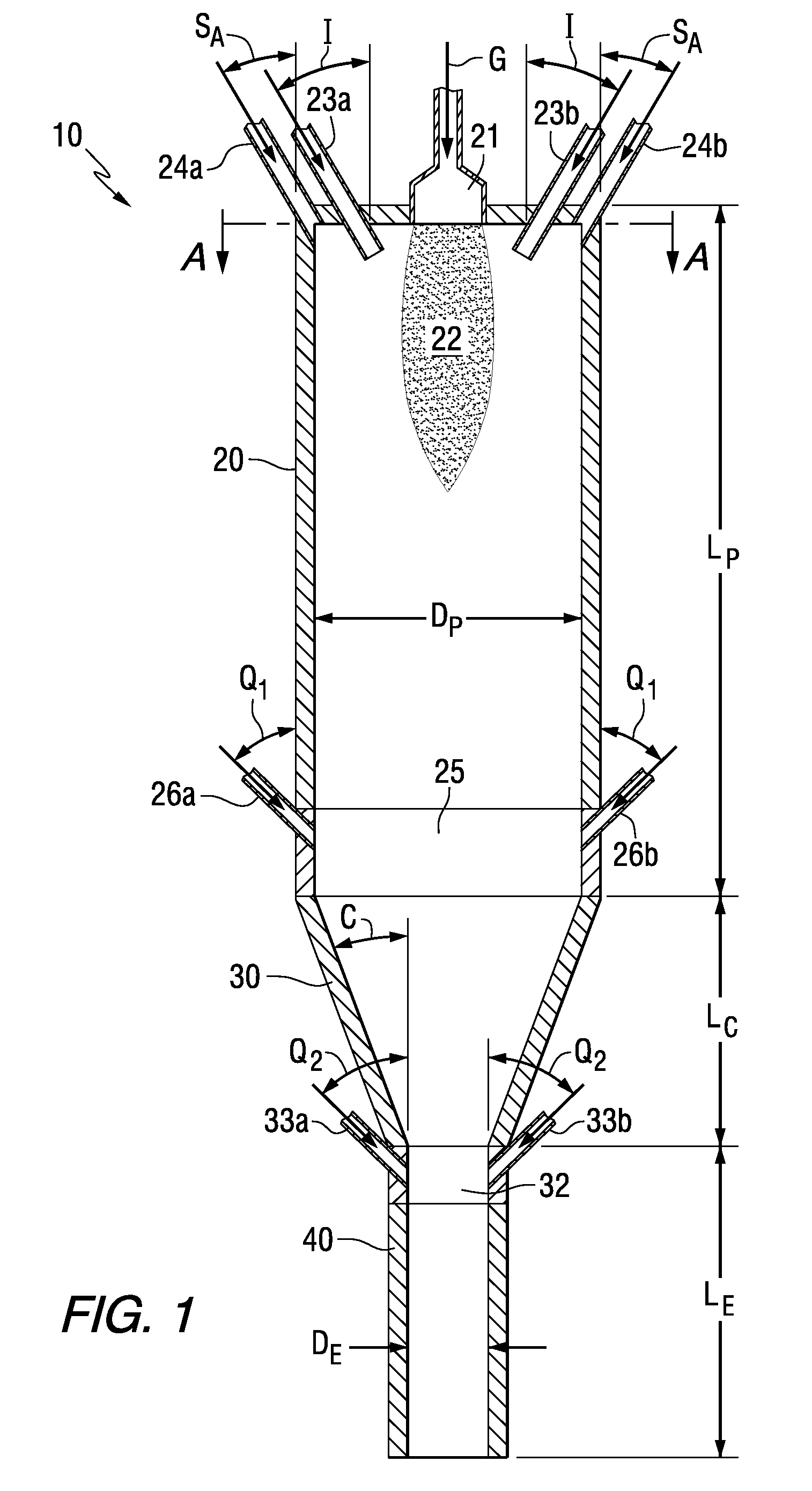

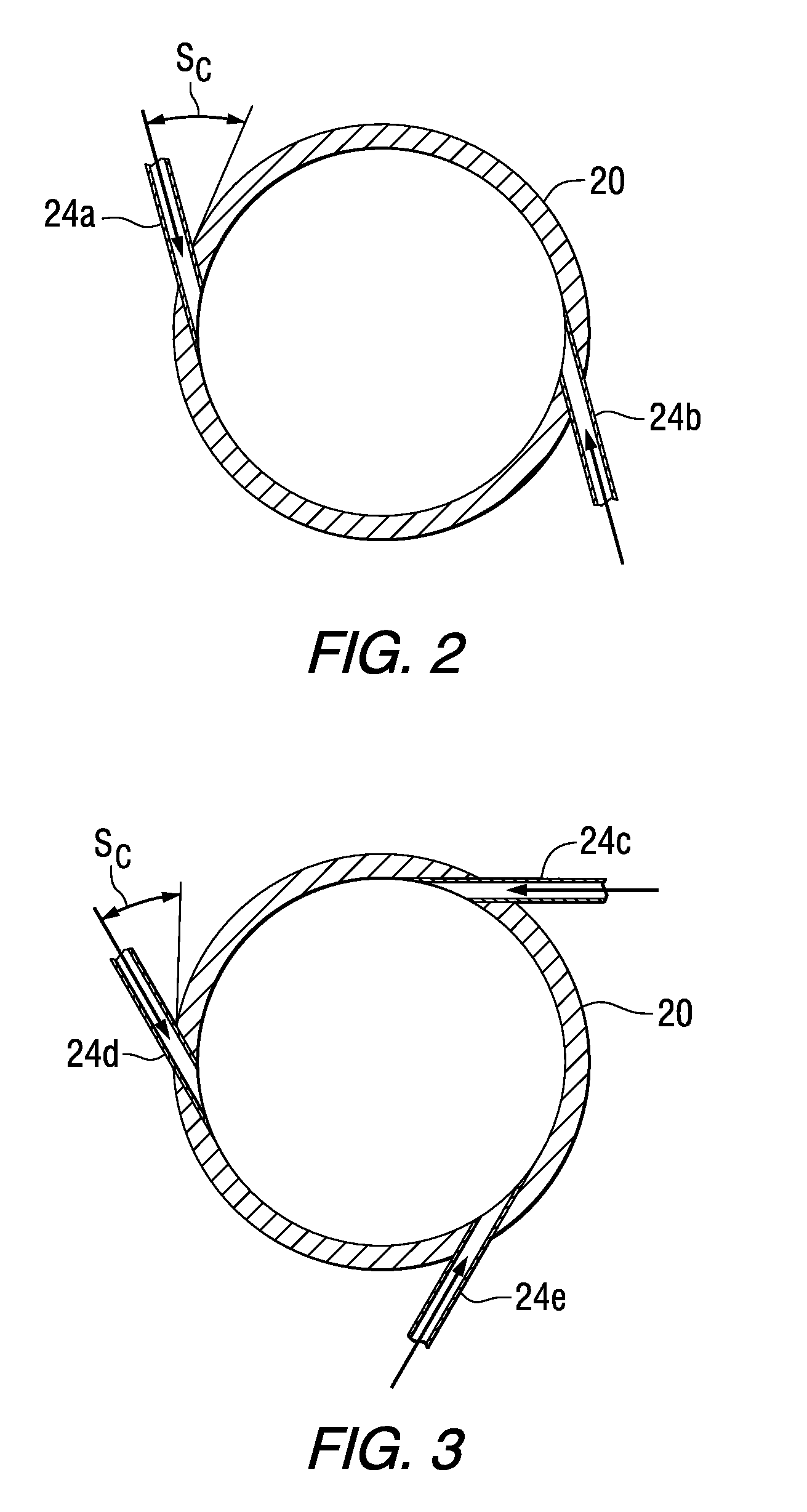

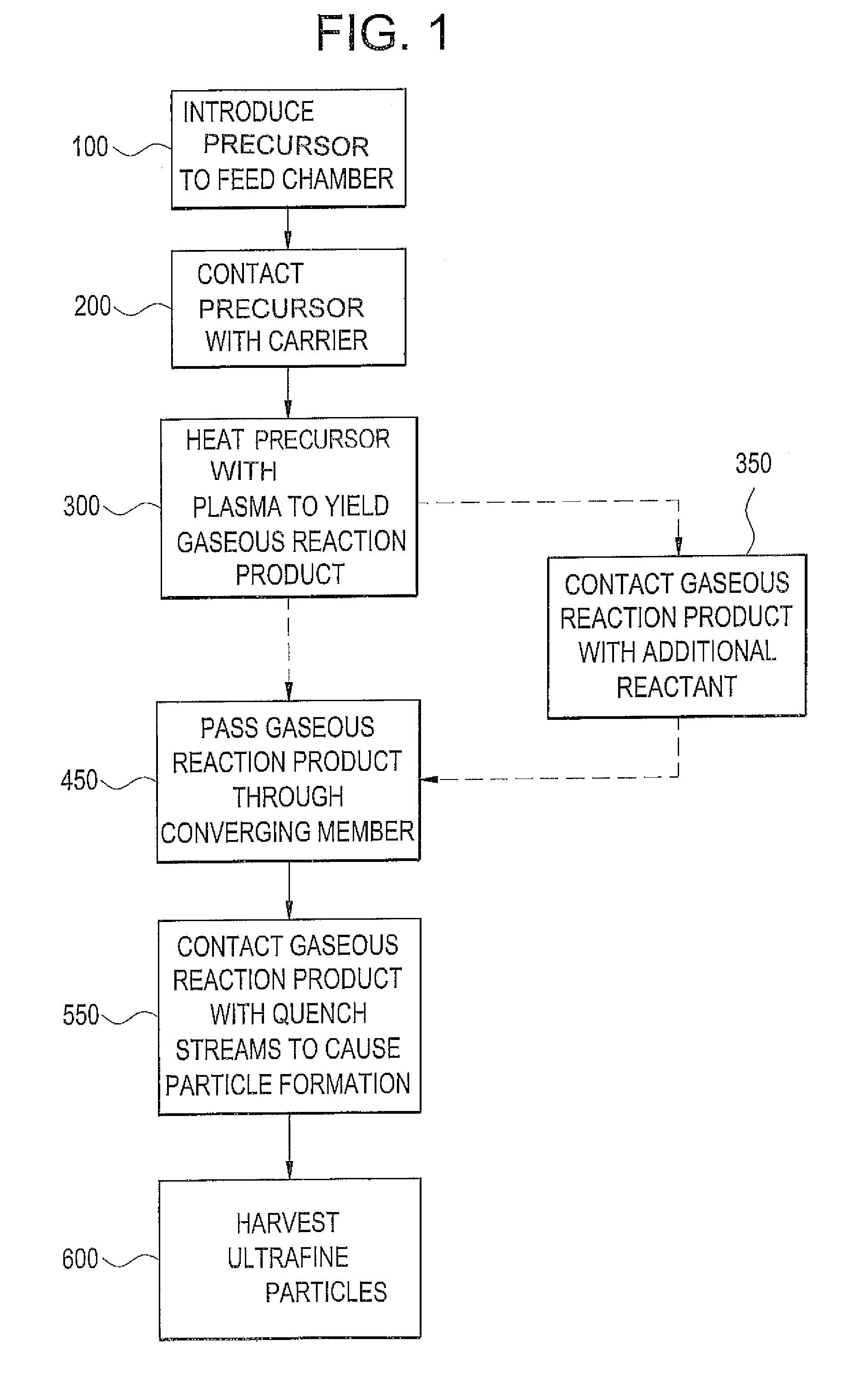

Production of Ultrafine Particles in a Plasma System Having Controlled Pressure Zones

InactiveUS20100314788A1Constant pressureMaterial granulation and coatingMaterial nanotechnologyEngineeringPlasma chamber

A system and method for making ultrafine particles are disclosed. A high temperature plasma is generated at an inlet end of a plasma chamber into which precursor materials are introduced. A converging member is located adjacent an outlet end of the plasma chamber. During operation, a substantially constant pressure and / or material flow pattern is maintained to reduce or eliminate fouling of the system.

Owner:PPG IND OHIO INC

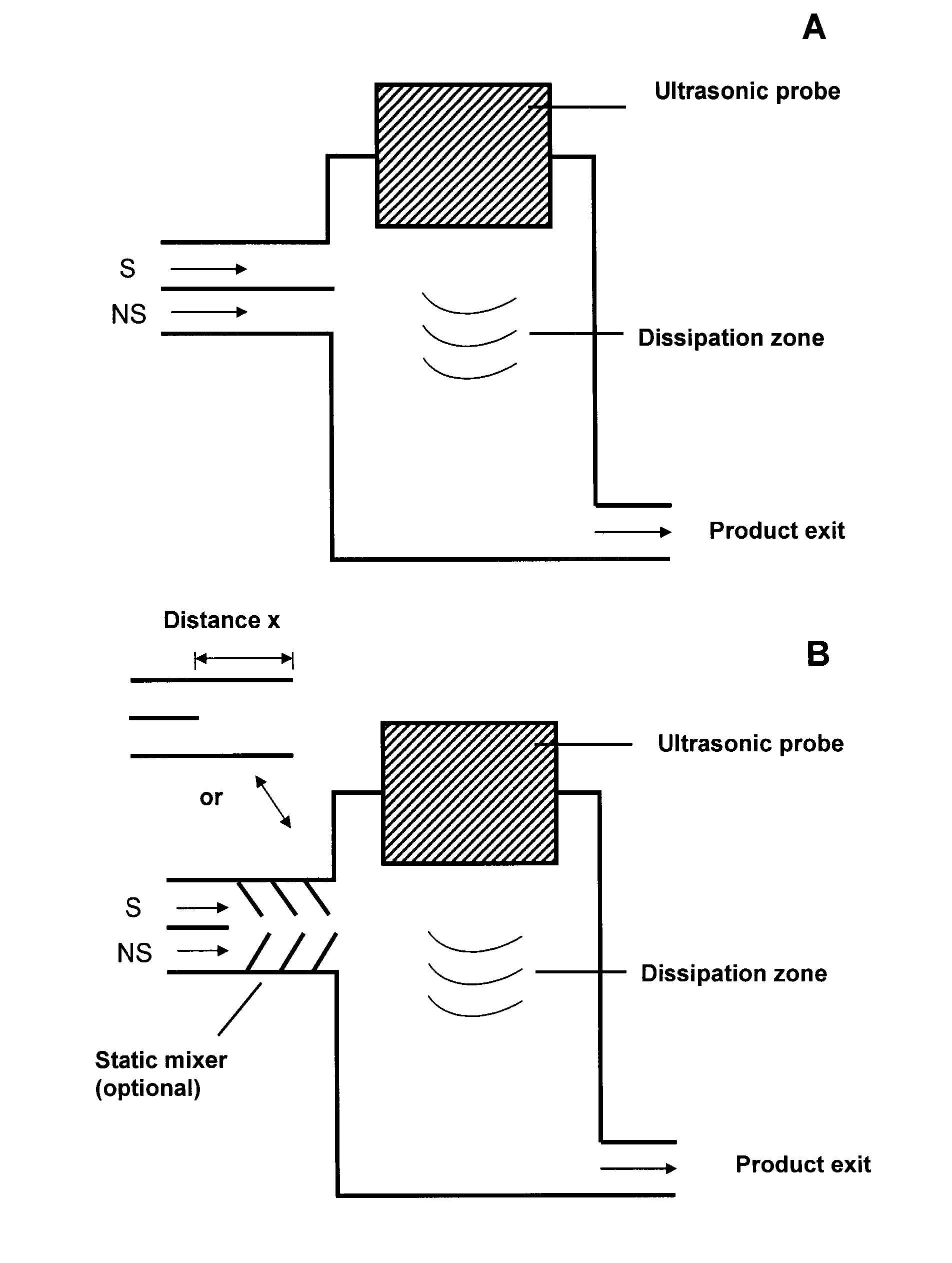

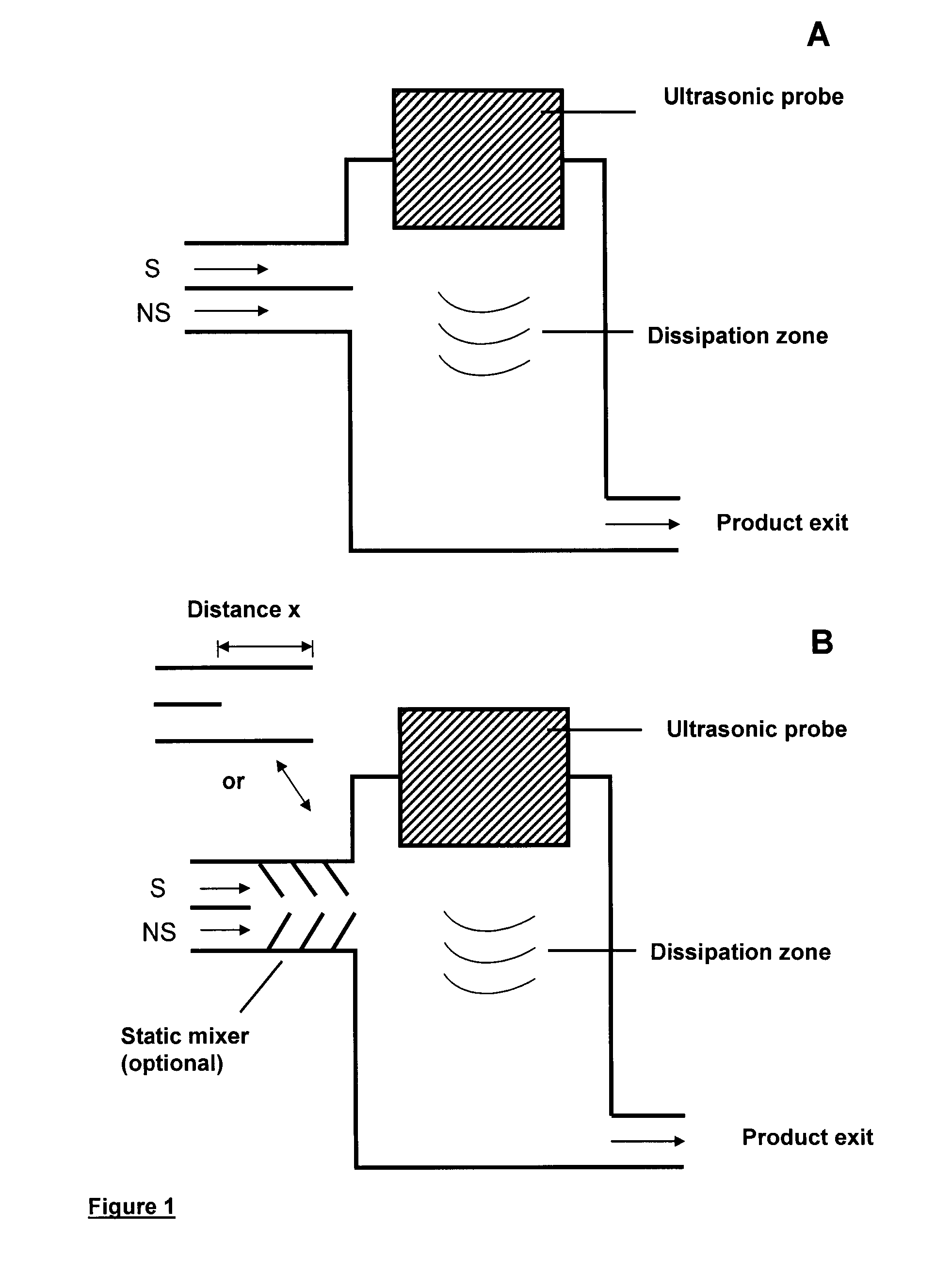

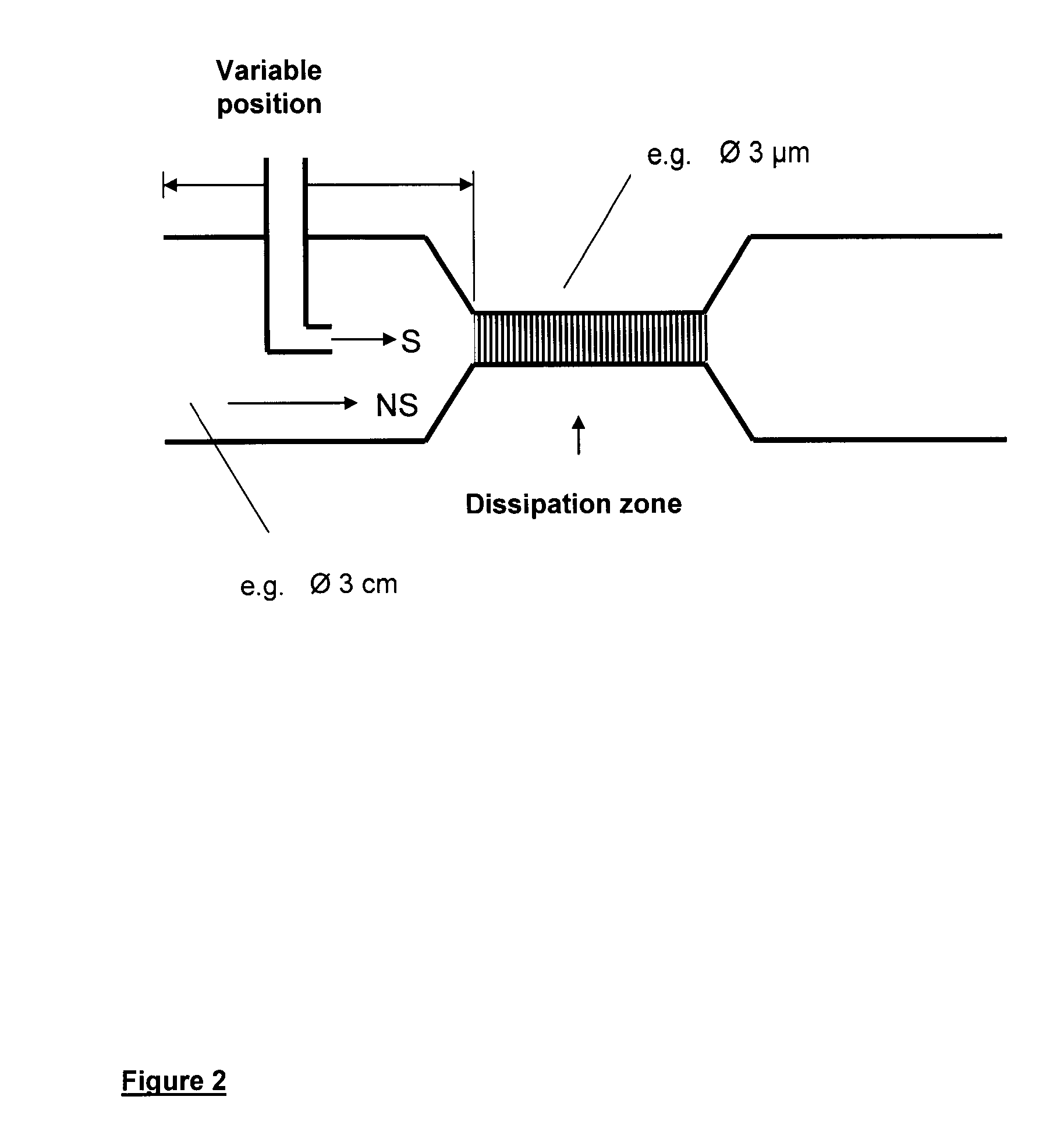

Method and device for producing very fine particles and coating such particles

Disclosed are methods and devices for producing very fine particles which are then coated with protective polymers in another step of the process. The particles are produced using a method in which a liquid flow comprising a particle-free liquid 1 that contains the active substance in a dissolved form is combined with a second liquid flow comprising a liquid 2 in a high-energy zone or no sooner than two seconds before reaching the high-energy zone. Said two liquids can be mixed with each other while the active substance dissolved in liquid 1 is insoluble or more difficult to dissolve in liquid 2 than in liquid 1 and settles in the form of particles in the high-energy zone or within a maximum of 2 seconds before reaching the high-energy zone when the two liquids are mixed. The obtained particles are introduced into an aqueous outer phase which contains the coating materials in a dissolved form and are then subjected to a drying step such that said materials settle on the particles as a closed coating. The coated particles are protected from damaging influences and are provided with modified release kinetics compared to uncoated particles.

Owner:ABBVIE DEUTSHLAND GMBH & CO KG

Method for making a film from silver-containing particles

InactiveUS7004994B2High rateIncrease loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

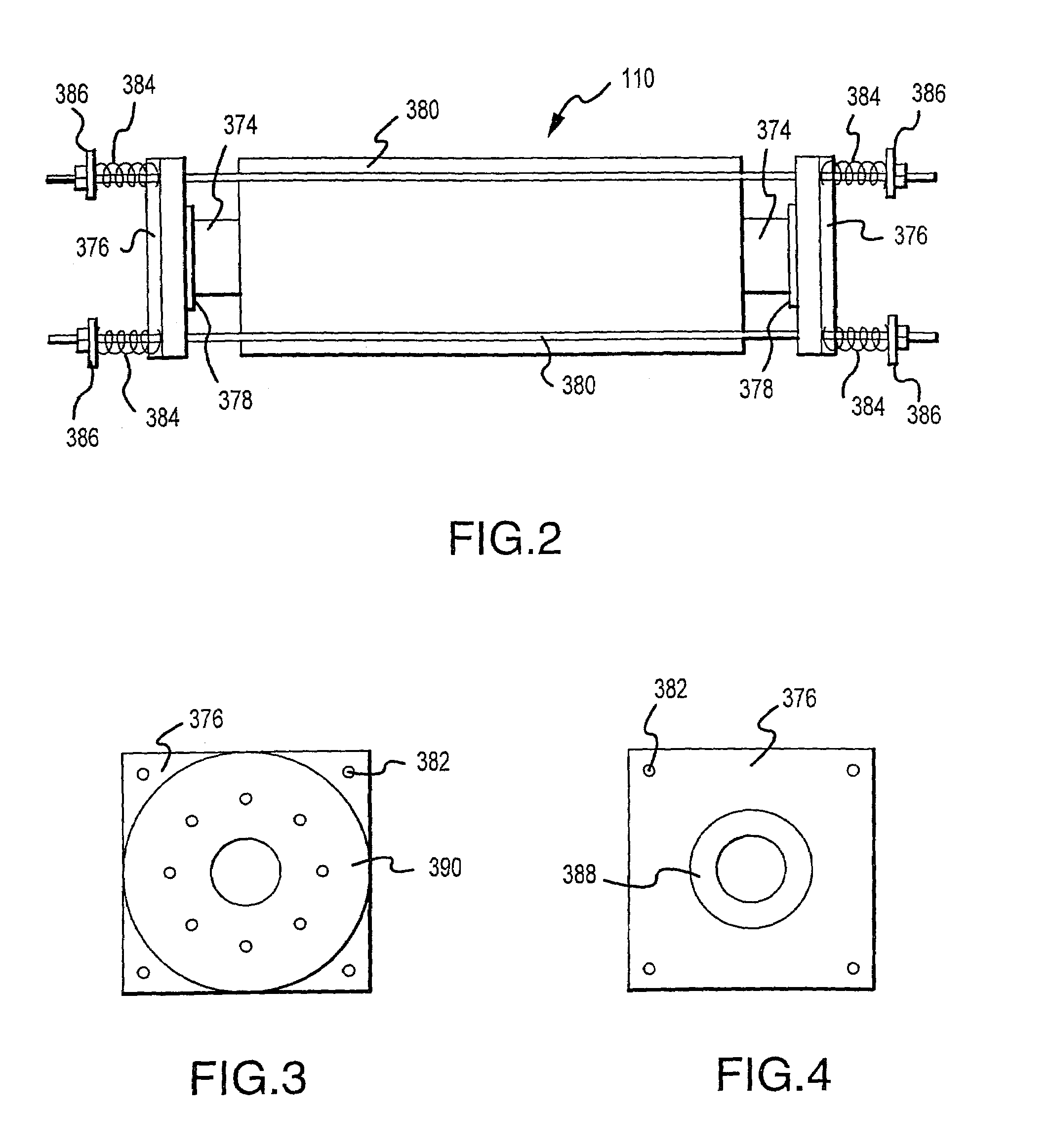

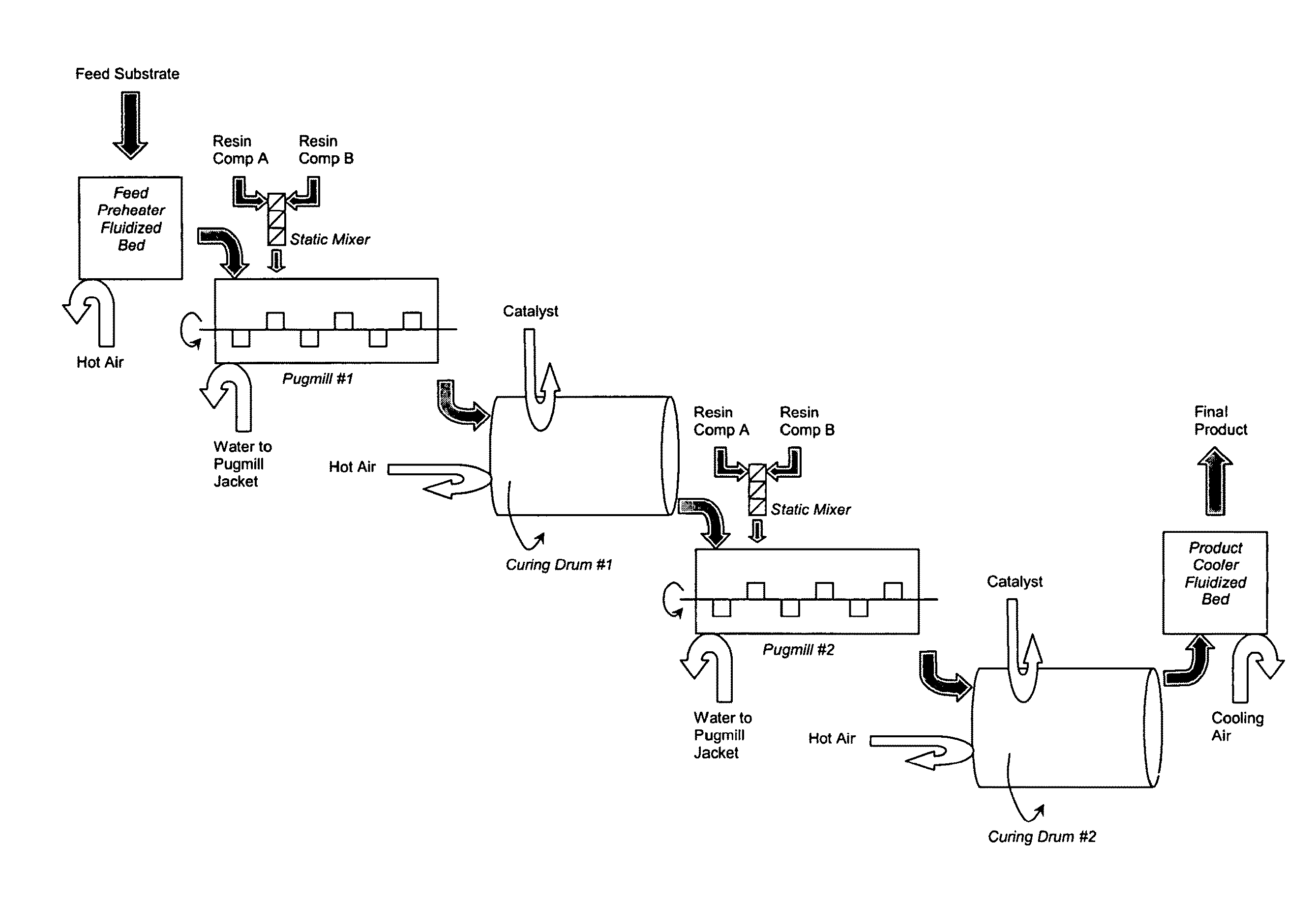

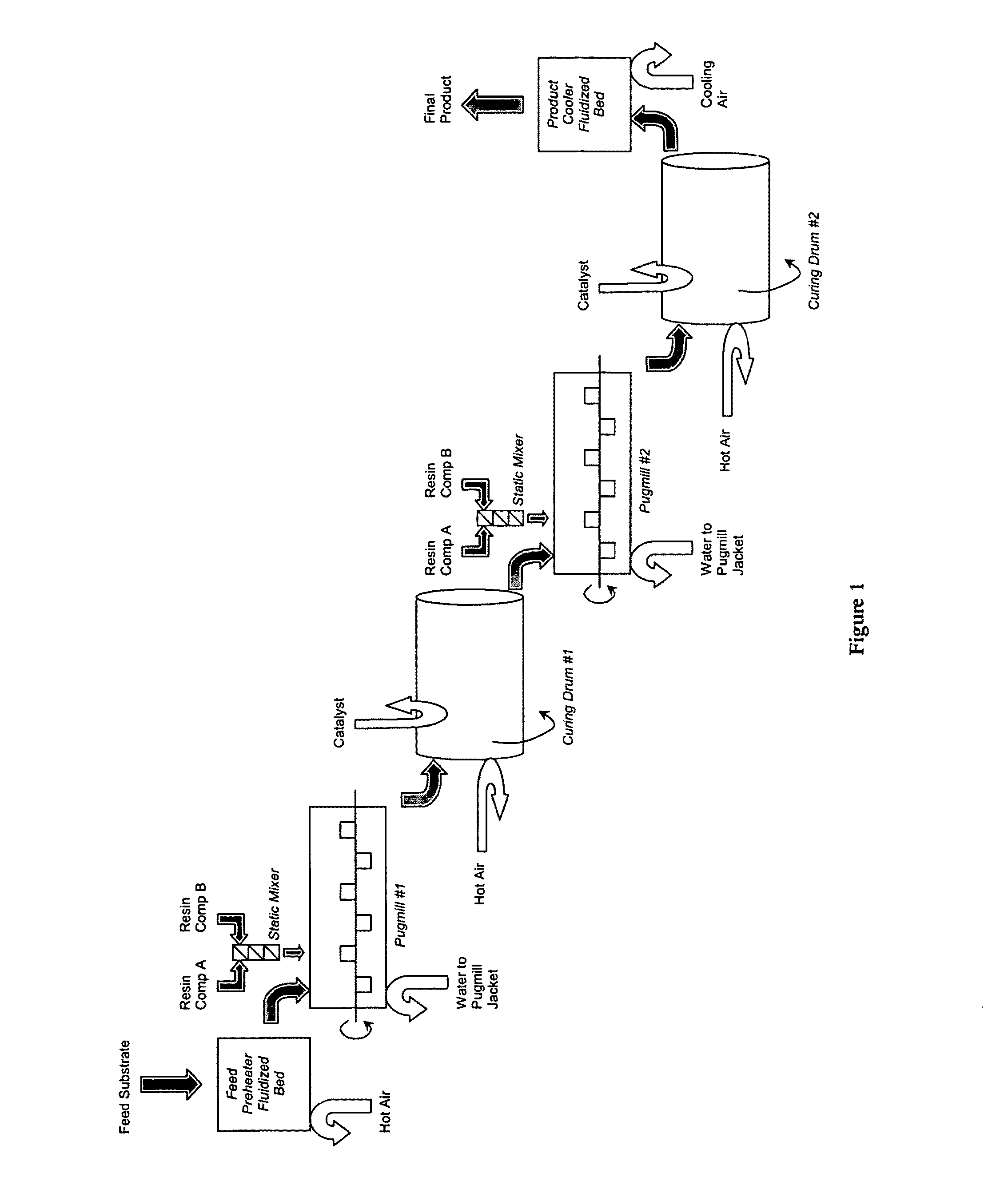

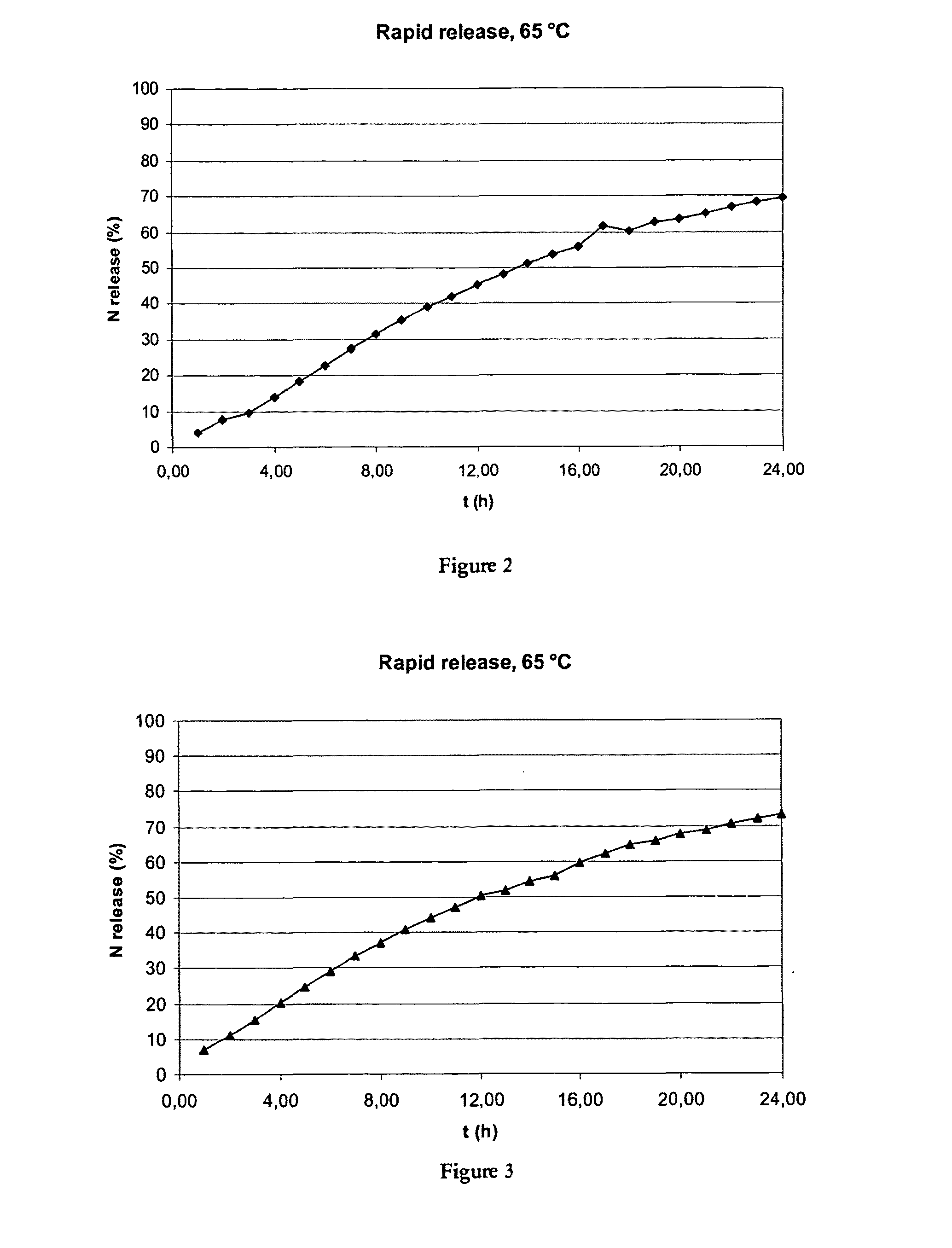

Methods and systems for coating granular substrates

ActiveUS20140033779A1Easy to controlReduce the possibilityBiocideRotating receptacle mixersEngineeringCoating

Owner:EVERRIS INT

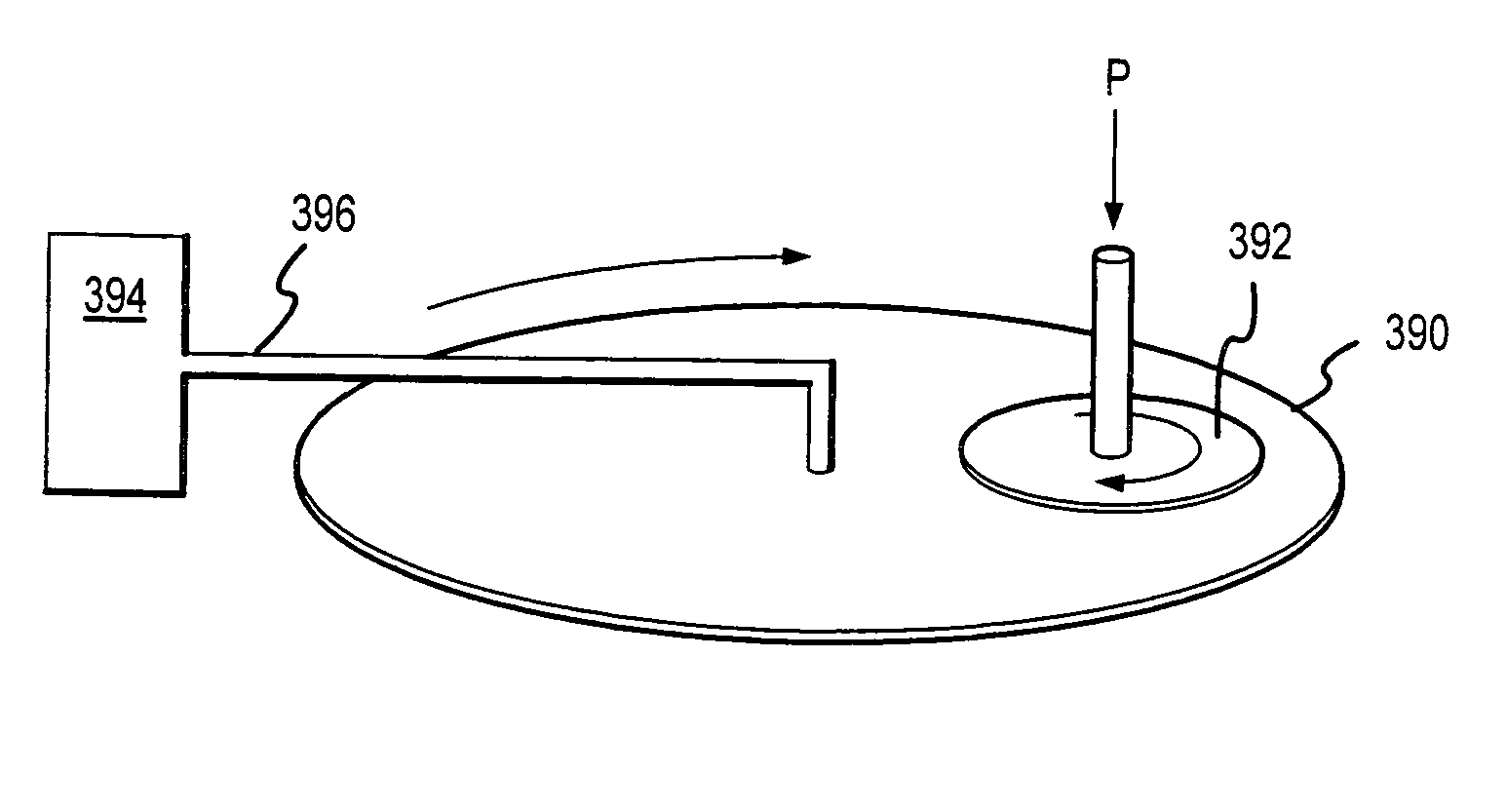

Direct-write deposition of phosphor powders

InactiveUS7476411B1Improve automationHigh resolution displayRare earth metal oxides/hydroxidesMaterial granulation and coatingApparent densityPhosphor

A liquid suspension of phosphor particles and method for depositing the liquid suspension. The suspension advantageously has a low viscosity with a high solids-loading of phosphor particles. The apparent density of the phosphor particles is well-controlled to enable the particles to be dispersed in the liquid vehicle. The suspension is useful in direct-write tools such as ink-jet devices.

Owner:SICPA HLDG SA

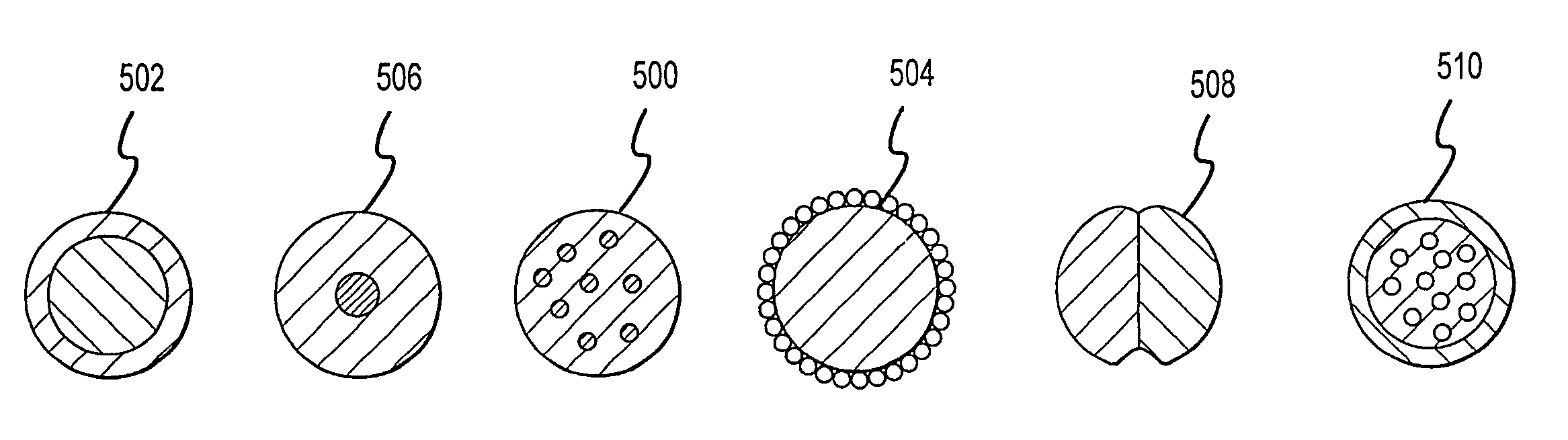

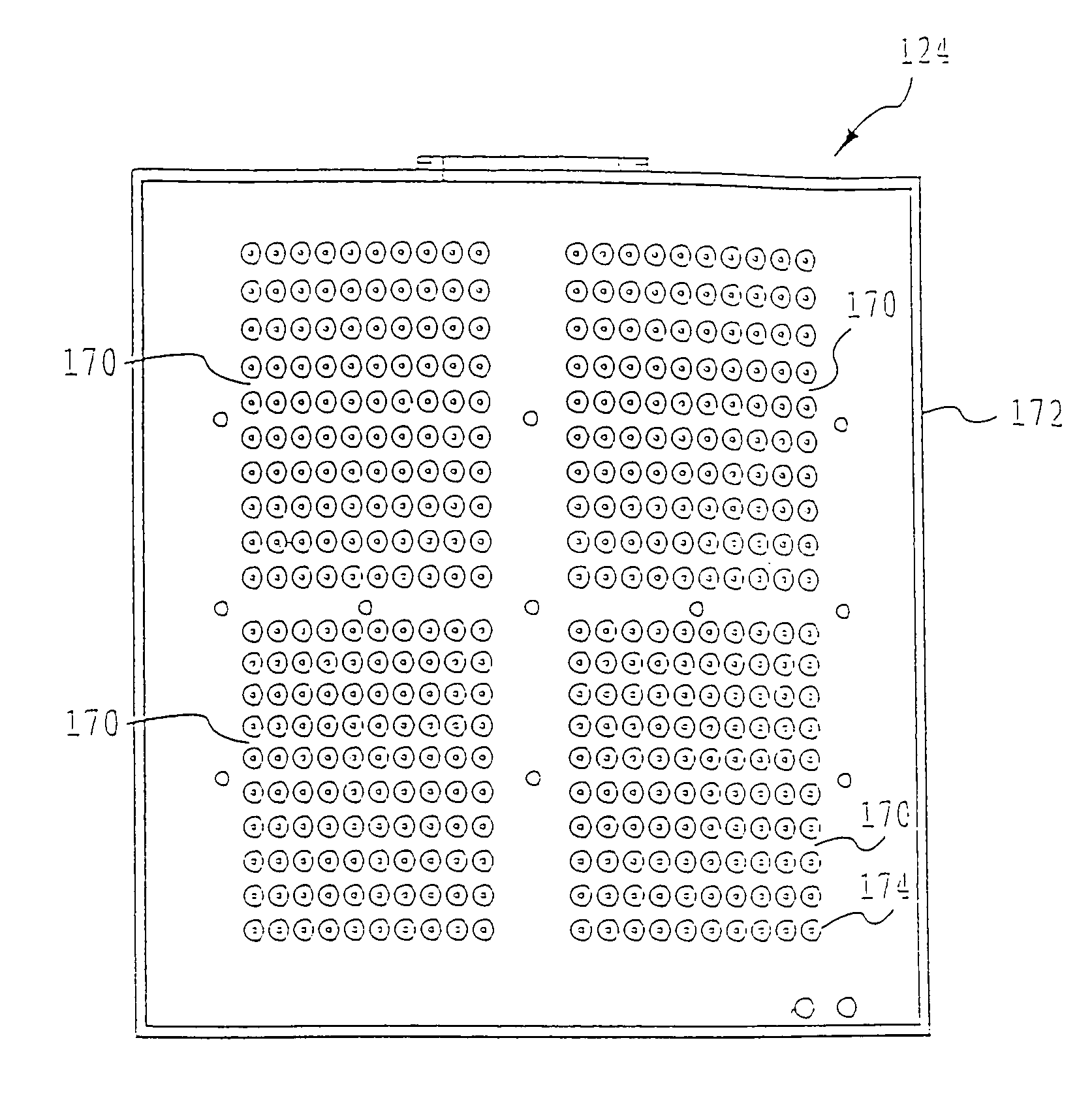

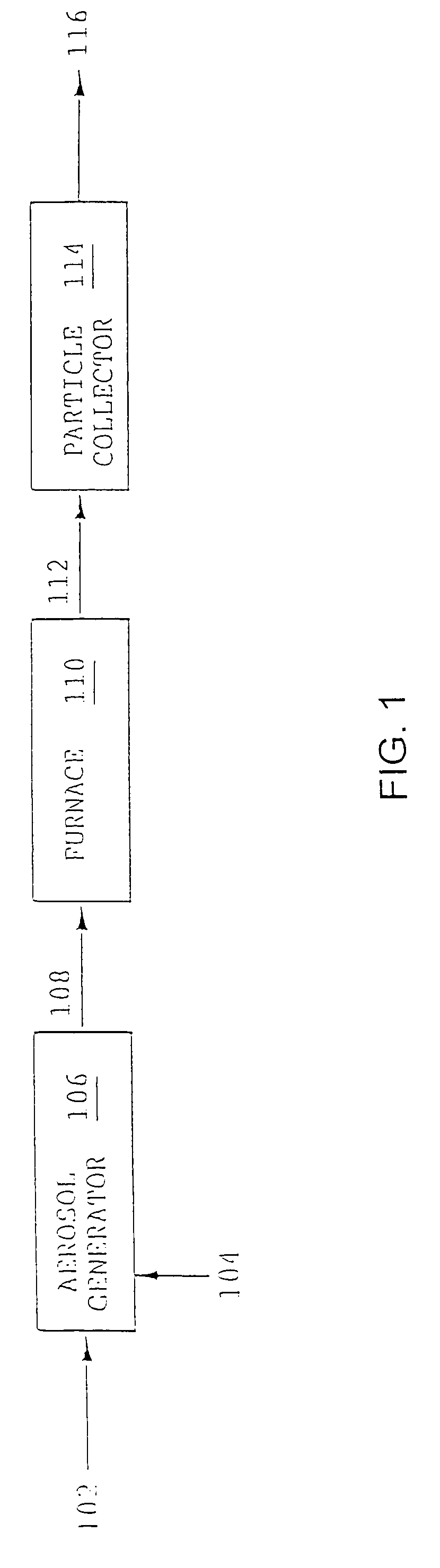

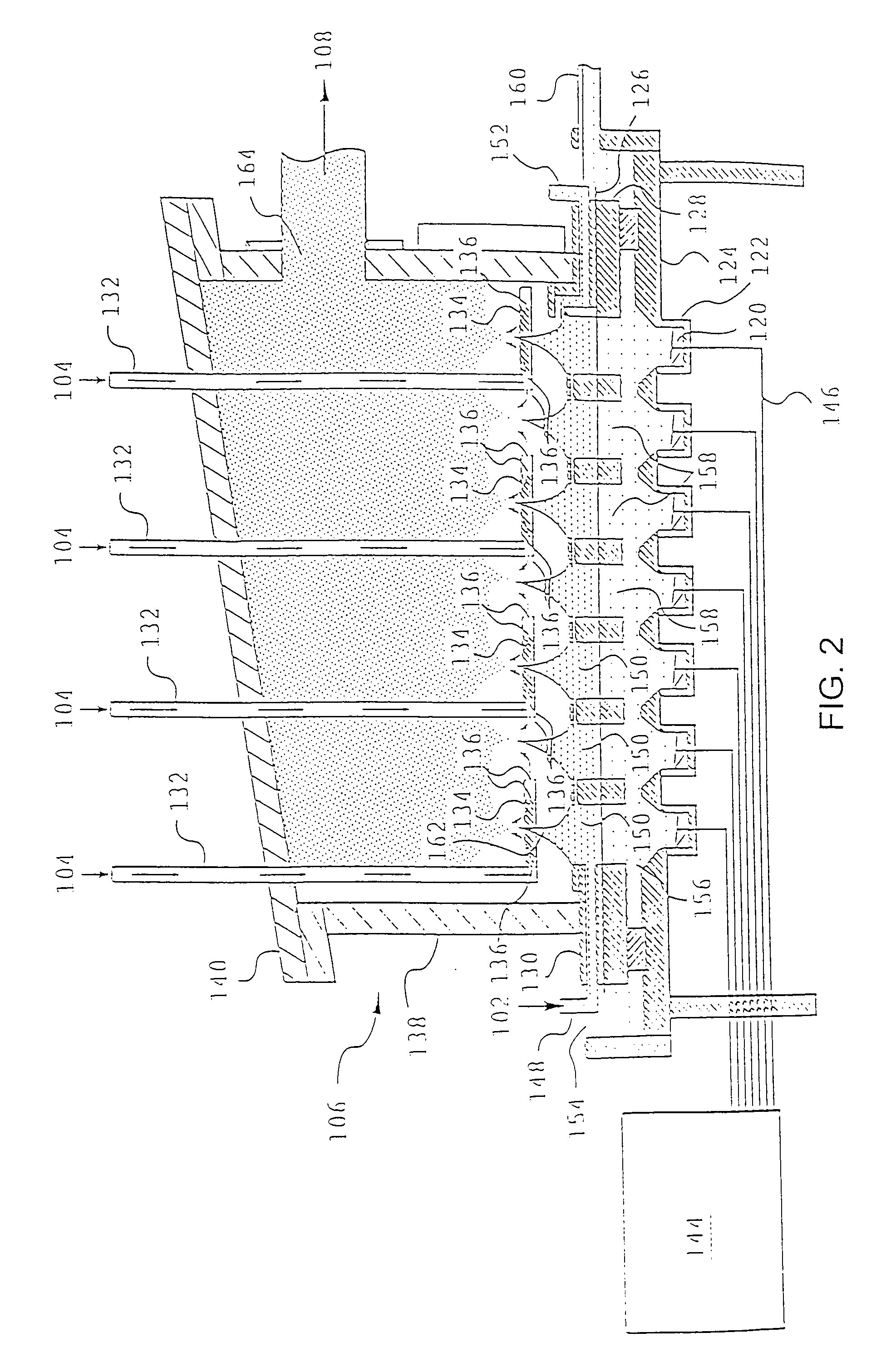

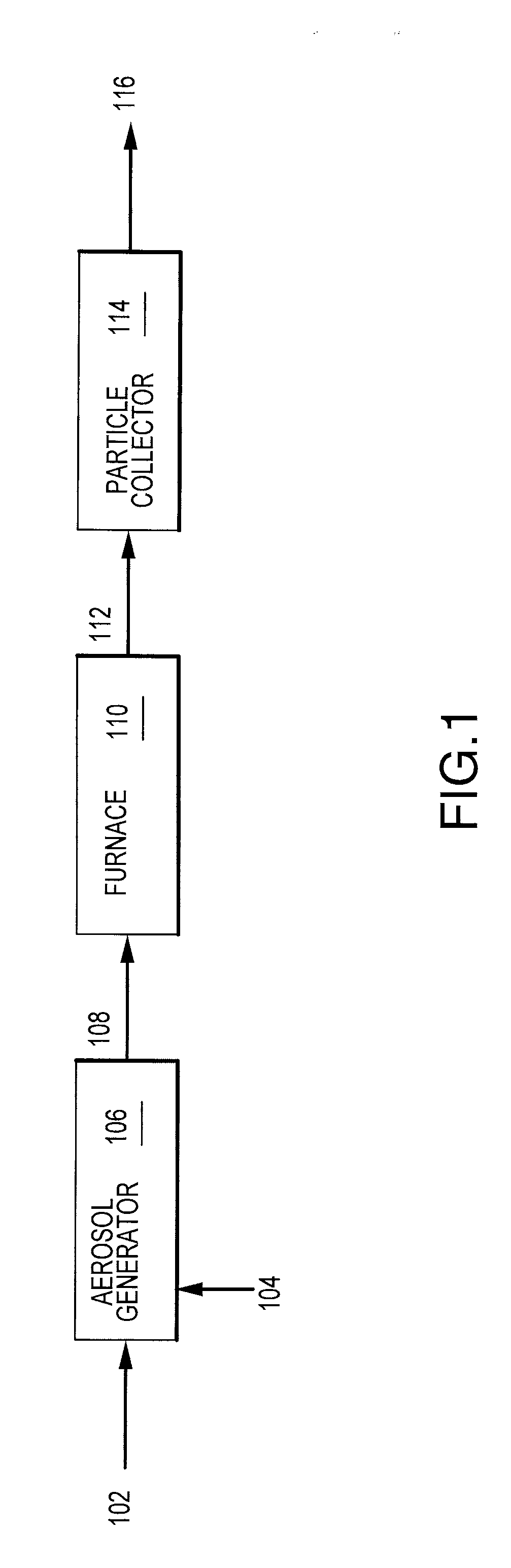

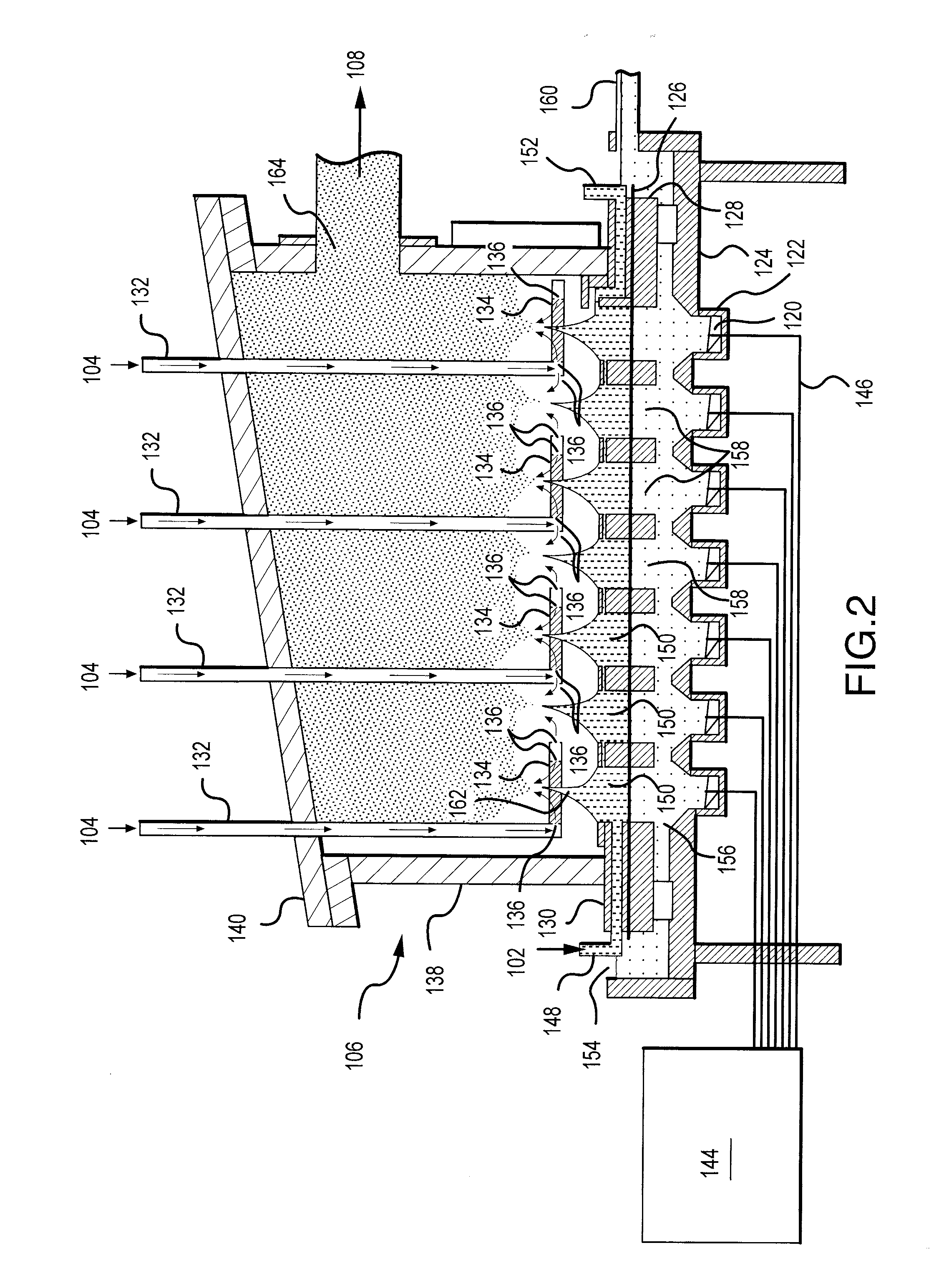

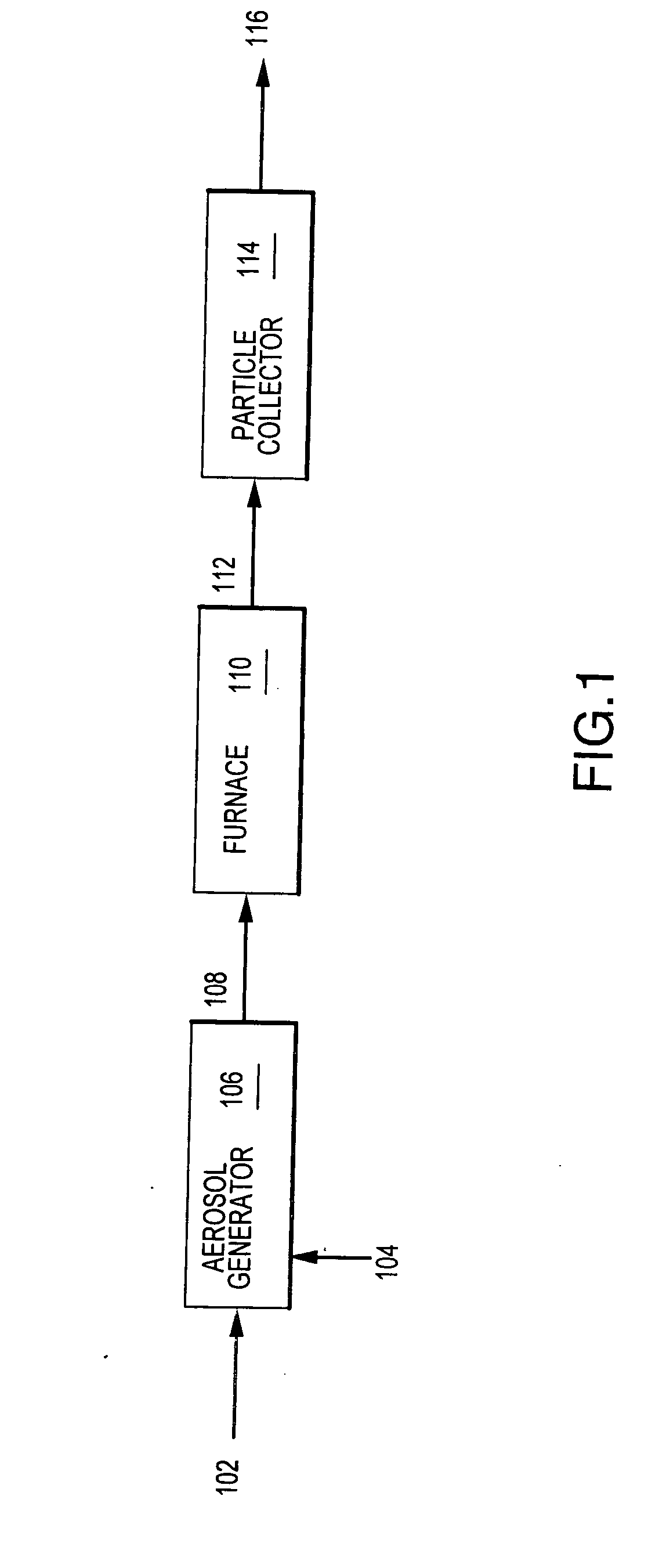

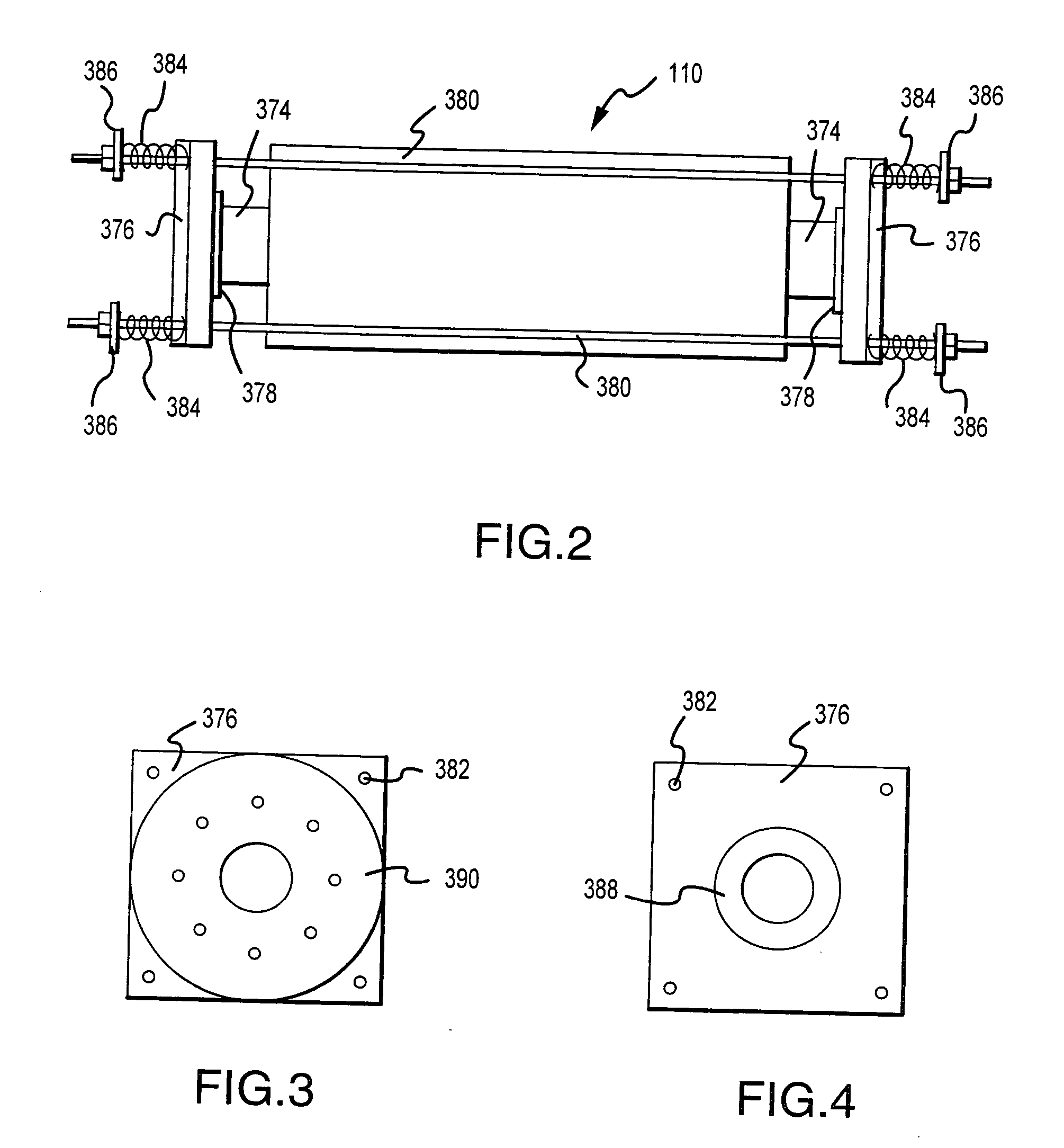

Aerosol method and apparatus, coated particulate products, and electronic devices made therefrom

InactiveUS20050100666A1High rateIncrease loadMaterial granulation and coatingGranule coatingParticulatesUltrasonic sensor

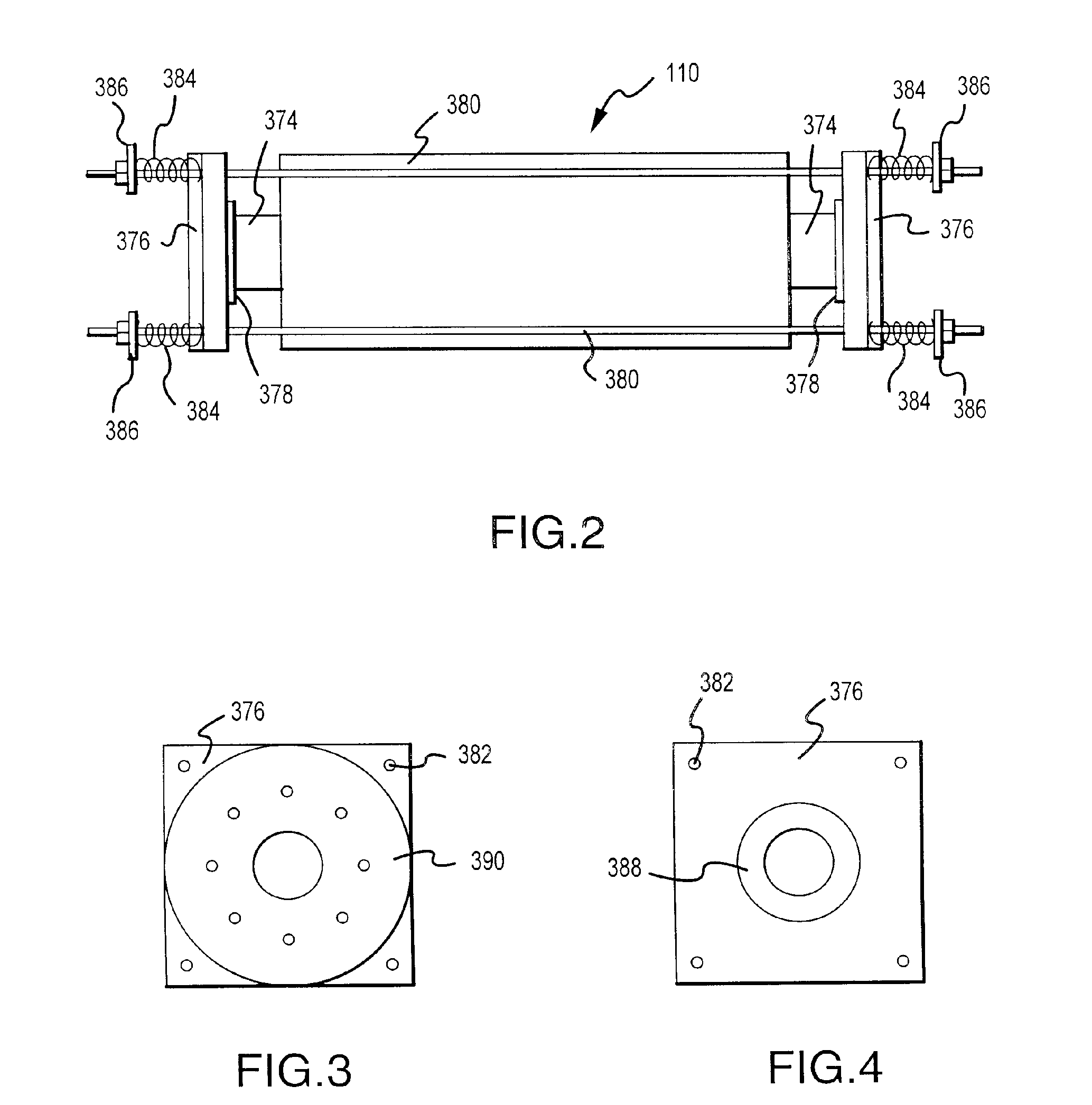

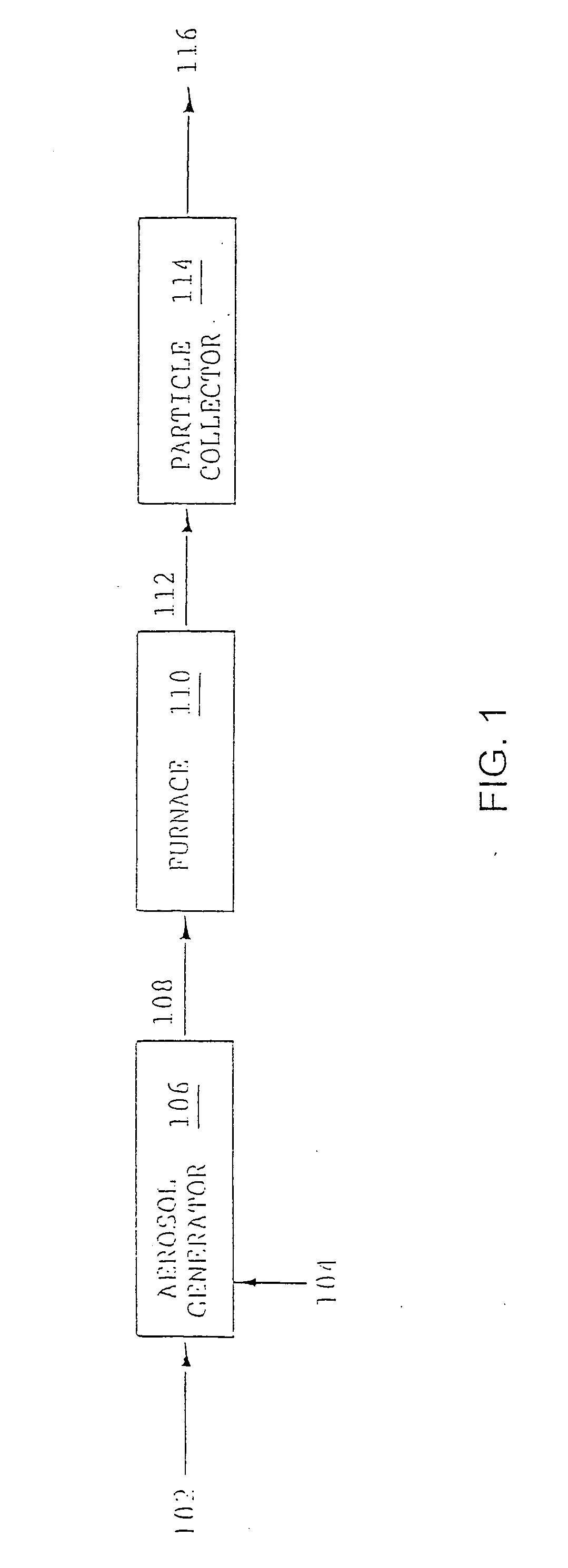

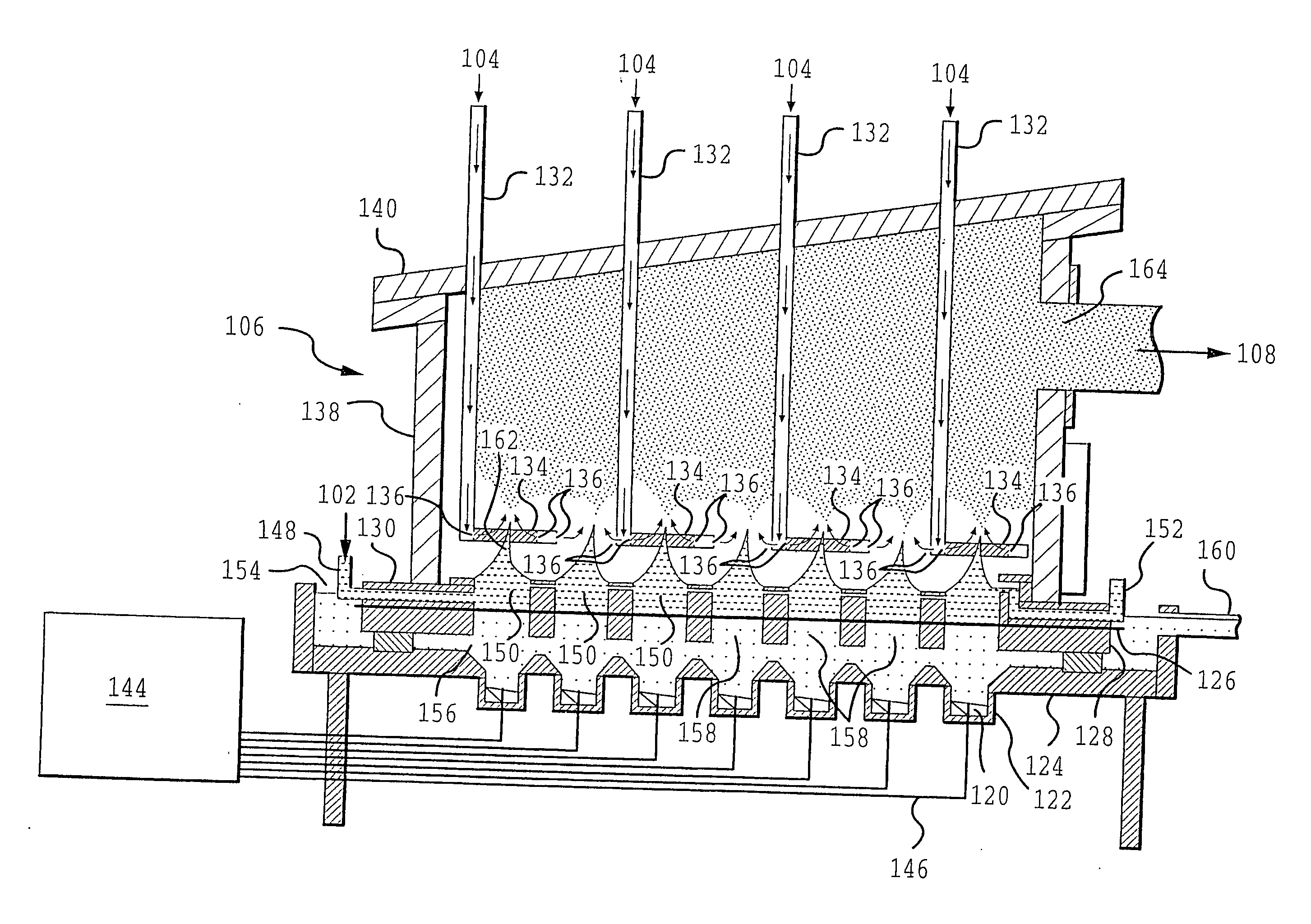

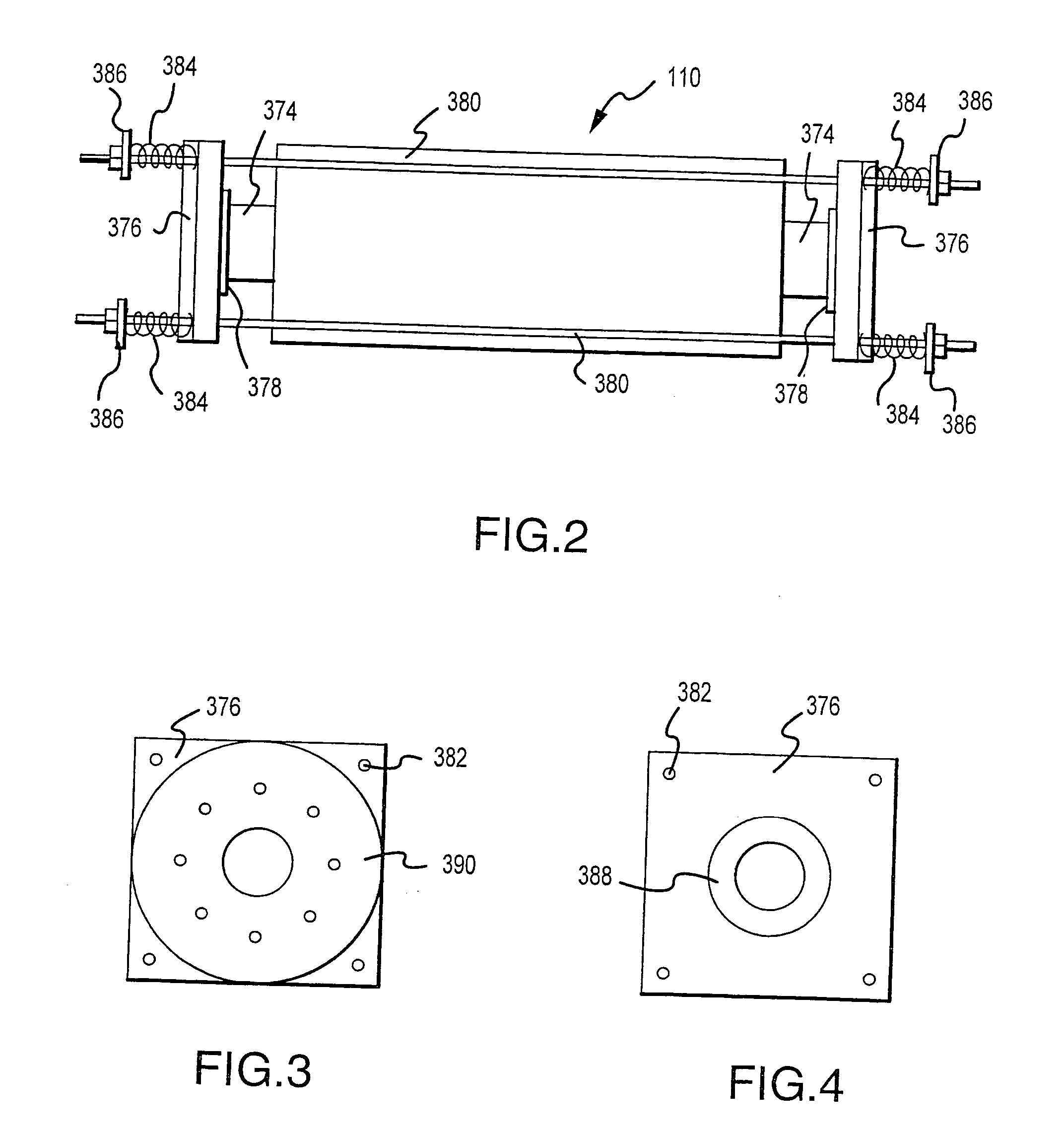

Provided is an aerosol method, and accompanying apparatus, for preparing powdered products of a variety of materials involving the use of an ultrasonic aerosol generator (106) including a plurality of ultrasonic transducers (120) underlying and ultrasonically energizing a reservoir of liquid feed(102) which forms droplets of the aerosol. Carrier gas (104) is delivered to different portions of the reservoir by a plurality of gas delivery ports (136) delivering gas from a gas delivery system. The aerosol is pyrolyzed to form particles, which are then cooled and collected. The invention also provides powders that include coated particles made by the method and devices made using the coated particles.

Owner:CABOT CORP

Cathodoluminescent phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS6875372B1High crystallinitySmall particle sizeMaterial granulation and coatingGranule coatingMetallurgyEconomic production

Cathodoluminescent phosphor powders and a method for making phosphor powders. The phosphor powders have a small particle size, narrow particle size distribution and are substantially spherical. The method of the invention advantageously permits the economic production of such powders. The invention also relates to improved devices, such as cathodoluminescent display devices, incorporating the phosphor powders.

Owner:CABOT CORP

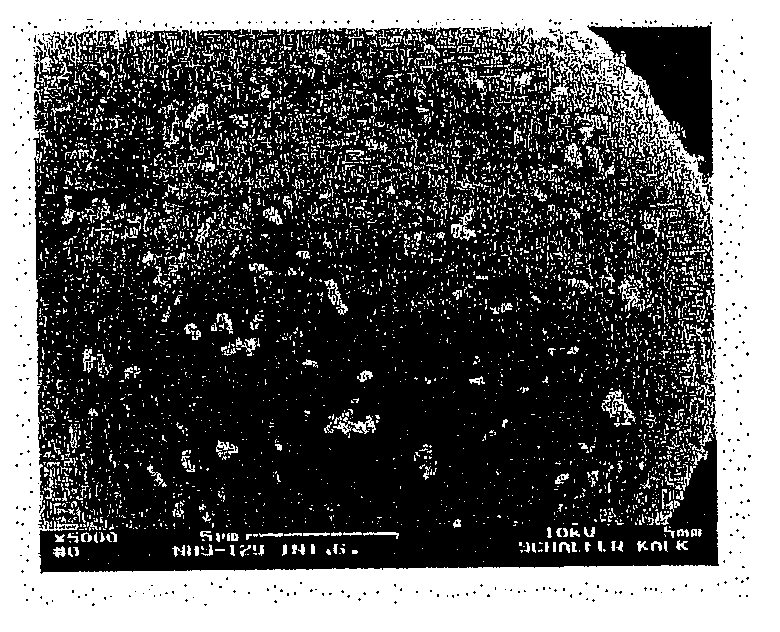

Microstructured Composite Particles

ActiveUS20140004348A1Low costImprove propertiesPigmenting treatmentMaterial granulation and coatingPolymer scienceLarge particle

Microstructured composite particles obtainable by a process in which large particles are bonded to small particles. The composite particles are preferably used as an additive, especially as a polymer additive, as an additive or starting material for the production of components, for applications in medical technology and / or in microtechnology and / or for the production of foamed articles.

Owner:SCHAEFER KALK

Photoluminescent phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS20070138438A1Small particle sizeHigh crystallinityMaterial granulation and coatingGranule coatingPhotoluminescenceEconomic production

Owner:SICPA HLDG SA

Copper powders methods for producing powders and devices fabricated from same

InactiveUS7316725B2High crystallinityHigh rateMaterial nanotechnologyMaterial granulation and coatingPowder methodSpherical morphology

Copper metal powders, methods for producing copper metal powders and products incorporating the powders. The copper metal powders have a small particle size, narrow size distribution and a spherical morphology. The method includes forming the metal particles in a continuous manner.

Owner:CABOT CORP

Chemical-mechanical planarization slurries and powders and methods for using same

InactiveUS20050081998A1High rateIncrease loadRare earth metal oxides/hydroxidesMaterial granulation and coatingSpherical morphologySlurry

Chemical-mechanical planarization slurries and methods for using the slurries wherein the slurry includes abrasive particles. The abrasive particles have a small particle size, narrow size distribution and a spherical morphology and the particles are substantially unagglomerated.

Owner:CABOT CORP

Sulfur-containing phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS20060231795A1High rateIncrease loadMaterial granulation and coatingGranule coatingMetallurgyPhosphor

Sulfur-containing phosphor powders, methods for making phosphor powders and devices incorporating same. The powders have a small particle size, narrow particle size distribution and are substantially spherical. The method of the invention permits the continuous production of such powders. The invention also relates to products such as display devices incorporating such phosphor powders.

Owner:SICPA HLDG SA

Oxygen-containing phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS7005085B2High crystallinitySmall particle sizeMaterial granulation and coatingGranule coatingPhosphorDisplay device

Phosphor powders and a method for making phosphor powders. The powders are oxygen-containing, such as metal oxides, silicates, borates or titanates and have a small particle size, narrow particle size distribution and are substantially spherical. The method of the invention advantageously permits the continuous production of such powders. The invention also relates to improved devices, such as display devices, incorporating the phosphor powders.

Owner:SICPA HLDG SA

Cathodoluminescent phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS20050189517A1Small particle sizeHigh crystallinityMaterial granulation and coatingGranule coatingDisplay deviceEconomic production

Owner:CABOT CORP

Method of forming a particle and apparatus therefor

InactiveUS20050031780A1Material granulation and coatingMaterial nanotechnologyMaterials scienceRaw material

A method of forming a particle comprises the steps of: forming a droplet containing a first material; forming a core portion by heating the droplet to thermally decompose in a reaction vessel; and forming a shell portion which coats the core portion by heating a raw material gas containing a second material which differs from the first material to thermally decompose in the reaction vessel.

Owner:KK TOSHIBA

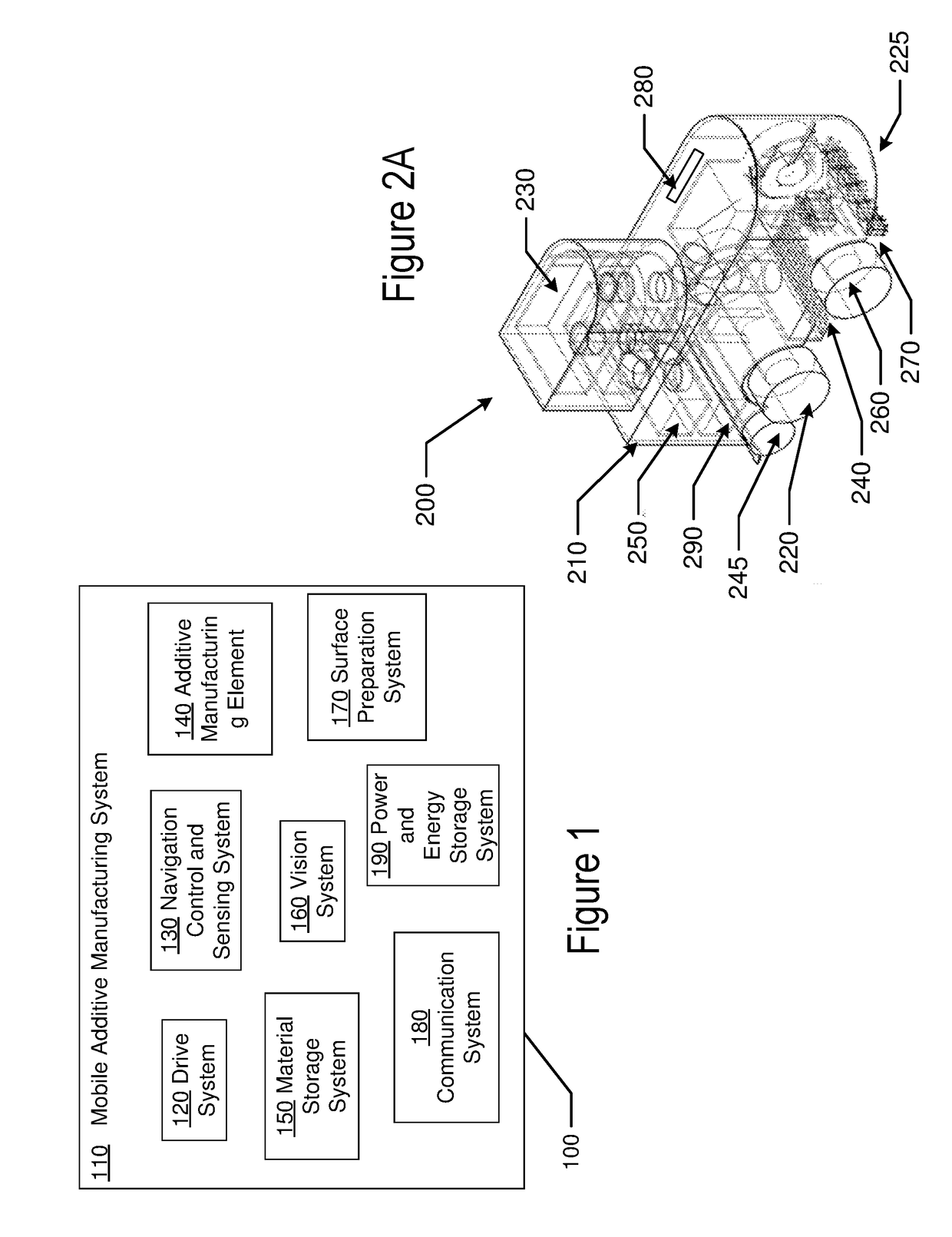

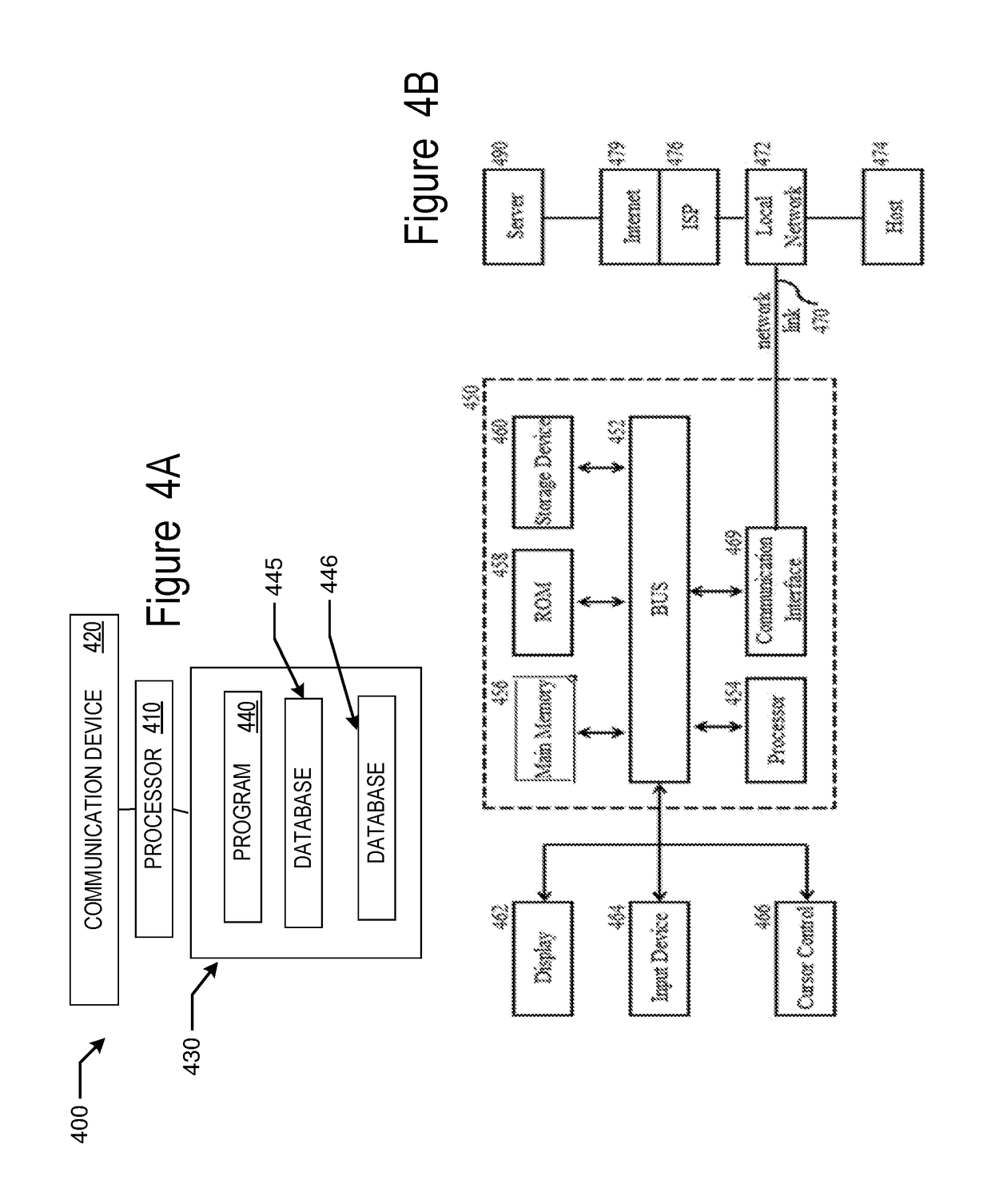

Methods, materials and apparatus for mobile additive manufacturing of advanced structures and roadways

ActiveUS20190055699A1Material granulation and coatingLiquid surface applicatorsAdditive layer manufacturingCoating

The present disclosure provides various aspects for mobile and automated processing utilizing additive manufacturing and the methods for their utilization. In some examples, discrete material formats for use in an Additive Manufacturing Array are disclosed. Methods of using the additive manufacturing robot, discrete materials, and the roadways produced with the additive manufacturing robot are provided. A combined function Addibot, with Additive Manufacturing capabilities, cleaning capabilities, line painting capabilities and seal coating capabilities which may be used in concert with a camera equipped aerial drone for design and characterization function is described.

Owner:FLITSCH ROBERT A +1

Metal Flake Composites and Methods of Making and Using the Same for Additive Manufacturing

InactiveUS20180141119A1Improve mechanical propertiesIncreased durabilityMaterial granulation and coatingAdditive manufacturing apparatusSelective laser sinteringBonding process

This patent describes metal flake composites consisting of metal flakes and thermoplastic resins as printing materials for additive manufacturing of prototypes with metallic appearance, improved mechanical properties and durability. Metal flakes of 5 to 50 microns in average size (D50) and 0.2-2 microns in thickness are made of base metals such as aluminum, chromium, cobalt, copper, iron, nickel, tin, titanium, zinc, and their alloys, e.g., stainless steel, brass and bronze by ball milling metal powder precursors in the presence of a liquid solvent and lubricants. Thermoplastic resins such as Nylon, polystyrene, polycarbonate, acrylonitrile butadiene styrene are coated with metal flakes in a composition ranging from 0.5 to 50% by weight. The composite undergoes a bonding process to improve its adhesion and uniformity. The metal flake-based resin composites are used for additive manufacturing by selective laser sintering or other heating methods such as resistance heating at temperature ranging from 150 to 280° C.

Owner:SHU JUN +2

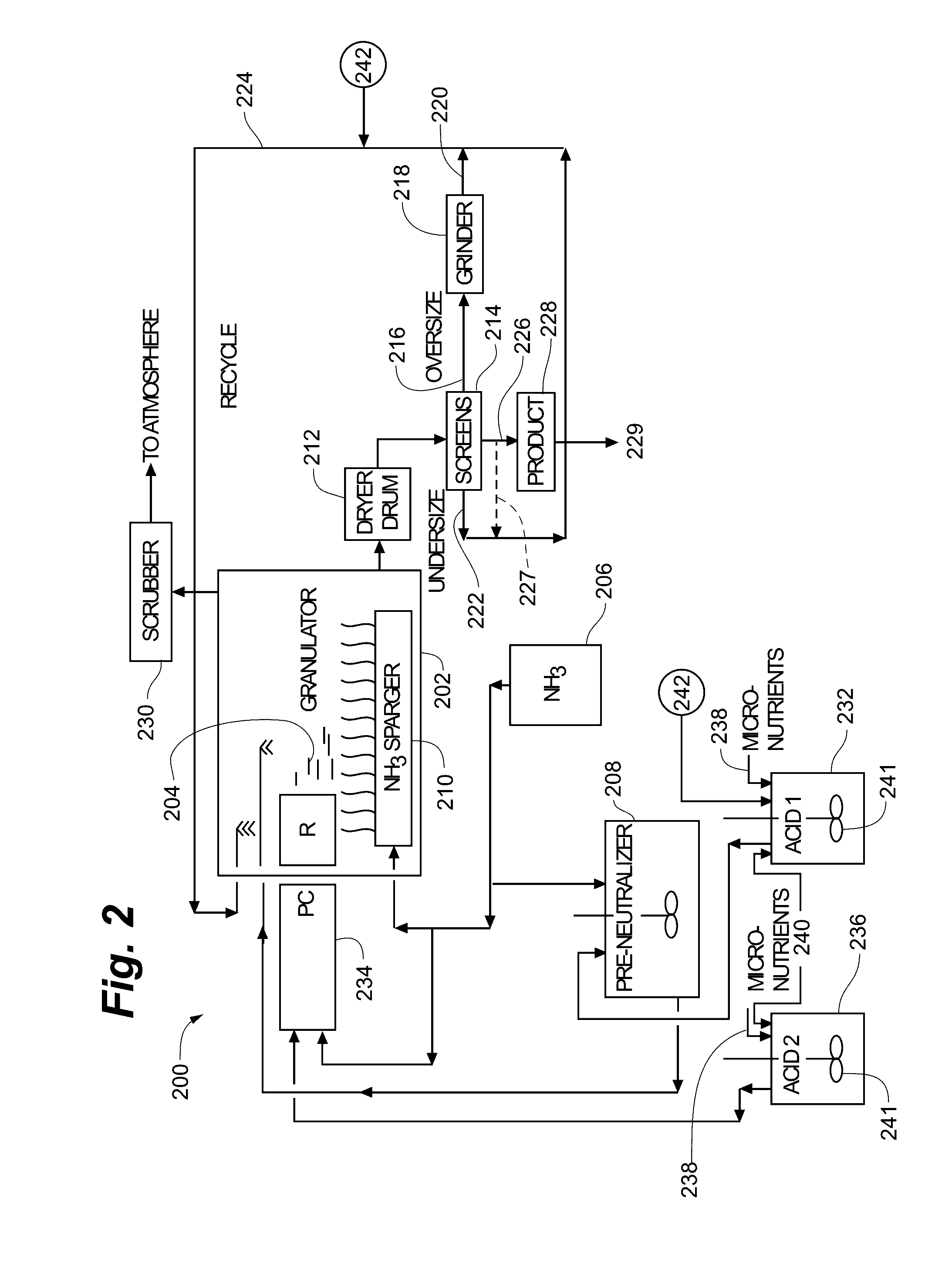

Acid treatment for fertilizers to increase zinc solubility and availability

ActiveUS20170044078A1Improve availabilityGood water solubilityMaterial granulation and coatingAlkali orthophosphate fertiliserSolubilityZinc uptake

Methods and system for increasing the water solubility and availability of zinc in granular fertilizers using acid treatments. The treatment of granular fertilizers with an acidic solution increases an amount of water-soluble zinc, which in turn, increases the efficiency of zinc uptake and reduces the costs and equipment otherwise needed to mitigate zinc deficiencies.

Owner:THE MOSAIC COMPANY

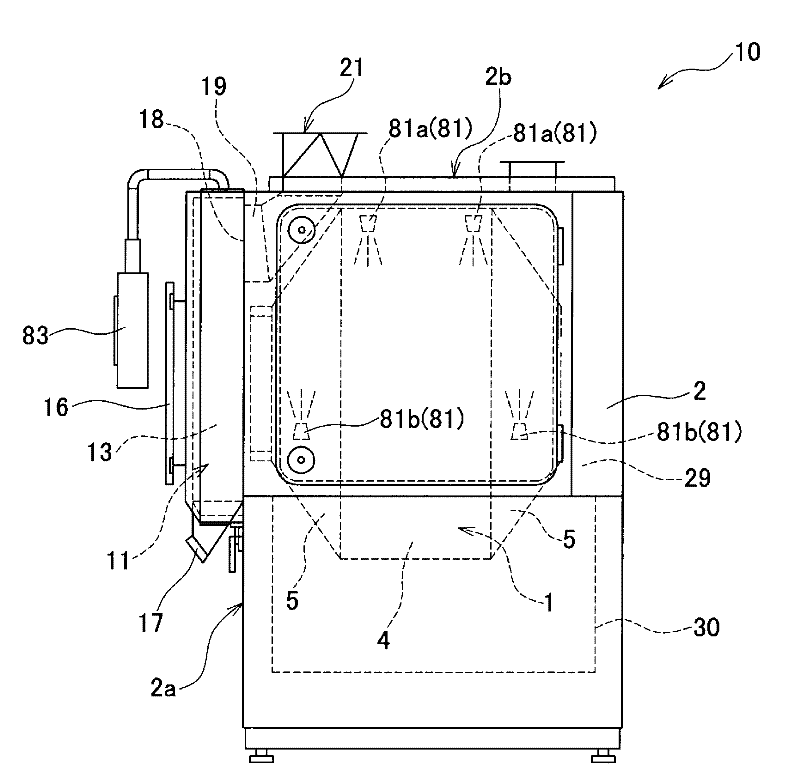

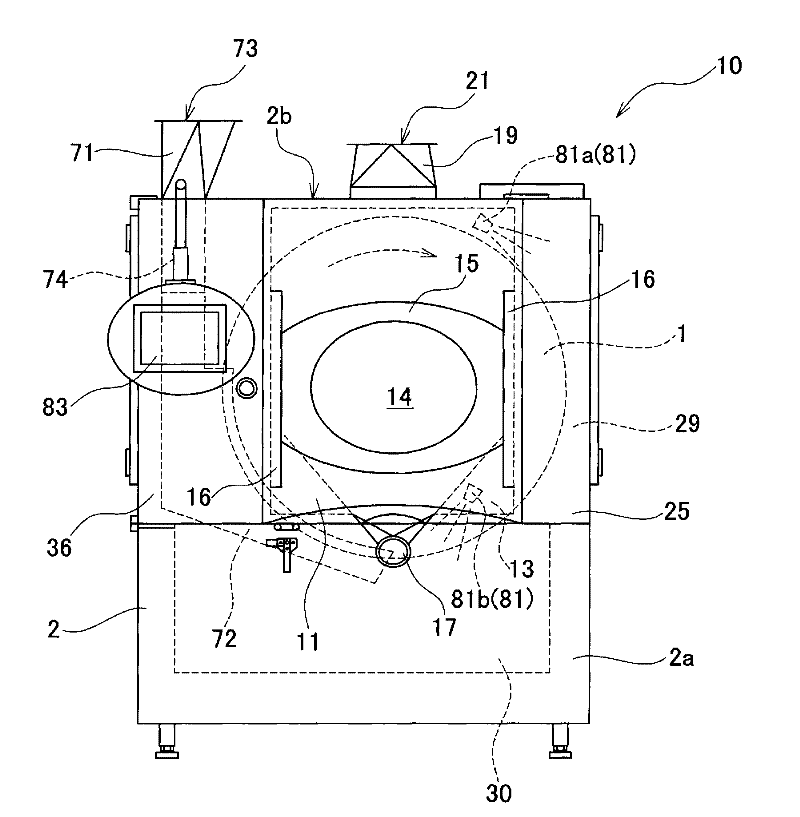

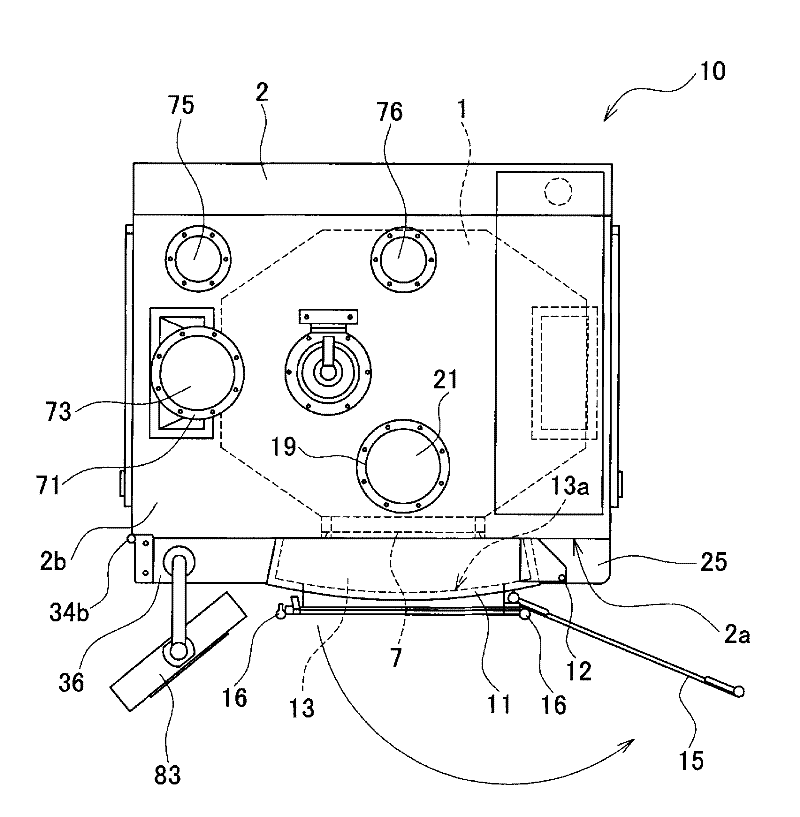

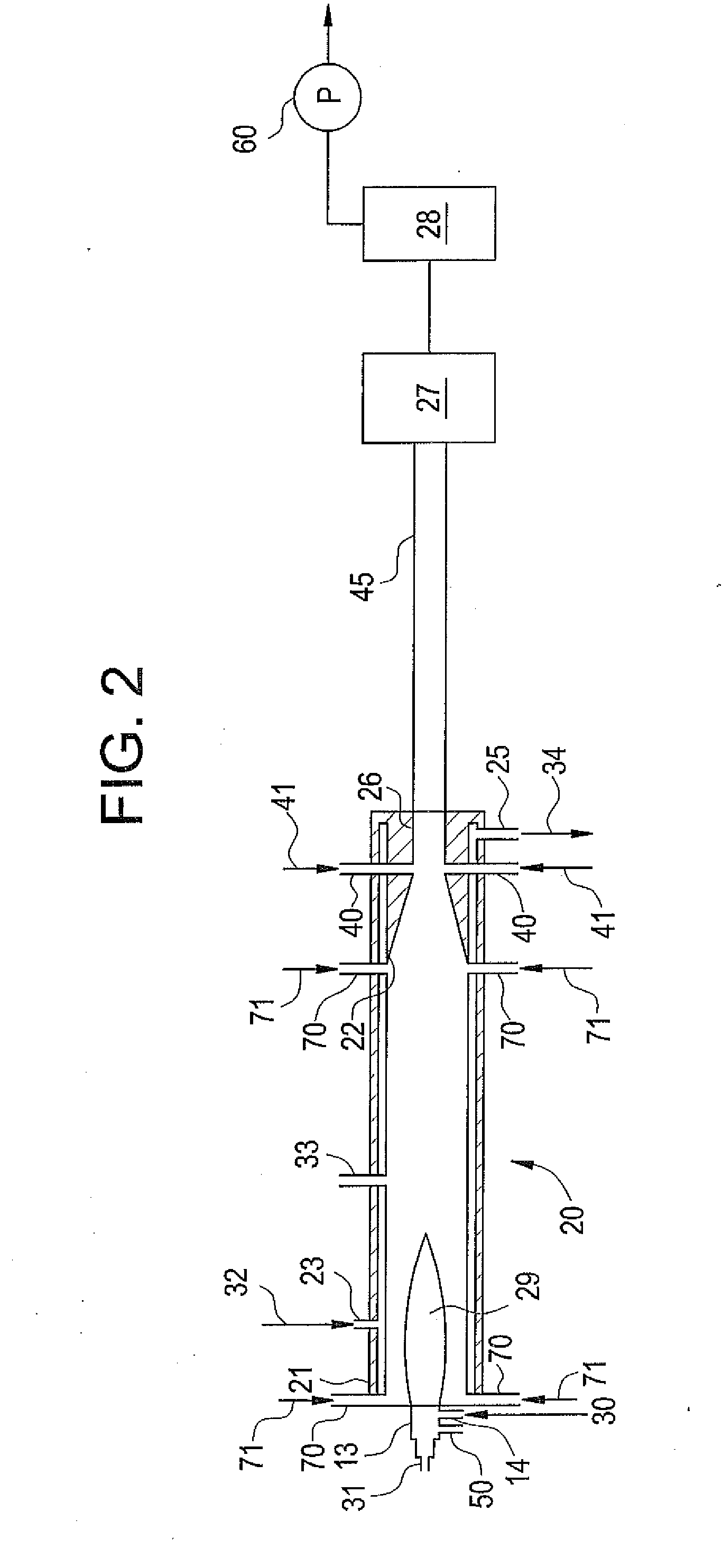

Pan coating device

ActiveCN102202778AReduce cleanup workloadReduce flow rateMaterial granulation and coatingLiquid surface applicatorsStable stateRotational axis

In a pan coating device (10) provided with a rotating drum (1) which rotates about a horizontal rotational axis line (O), an air supply chamber (13) with a larger cross-sectional area than that of an opening (7) in the front surface of the rotating drum is provided at the preceding stage of the opening (7). The air supply chamber (13) is formed inside a chamber door (11) attached to the front of a housing (2) with one end thereof communicating with the opening (7) and the other end thereof connected to an air supply duct (19) via an air supply hole (18). Air flowing into the air supply chamber (13) from the air supply duct (19) is reduced in flow velocity in the air supply chamber (13) and supplied from the opening (7) into the rotating drum (1) with the current thereof in a stable state.

Owner:FREUNT IND

Security features incorporating photoluminescent phosphor powders and methods for making security features

InactiveUS7531108B2Small particle sizeHigh crystallinityMaterial granulation and coatingGranule coatingPhosphorMetallurgy

Photoluminescent phosphor powders and a method for making phosphor powders. The phosphor powders have a small particle size, narrow particle size distribution and are substantially spherical. The method of the invention advantageously permits the economic production of such powders. The invention also relates to improved devices, such as display devices and lighting elements, incorporating the phosphor powders.

Owner:SICPA HLDG SA

Method and apparatus for the production of ultrafine particles and related coating compositions

ActiveUS20080044678A1Material granulation and coatingMaterial nanotechnologyMaterials scienceCoating

Disclosed are methods for making ultrafine particles, apparatus for making ultrafine particles, and coating compositions comprising ultrafine particles made by such methods and / or apparatus.

Owner:PPG IND OHIO INC

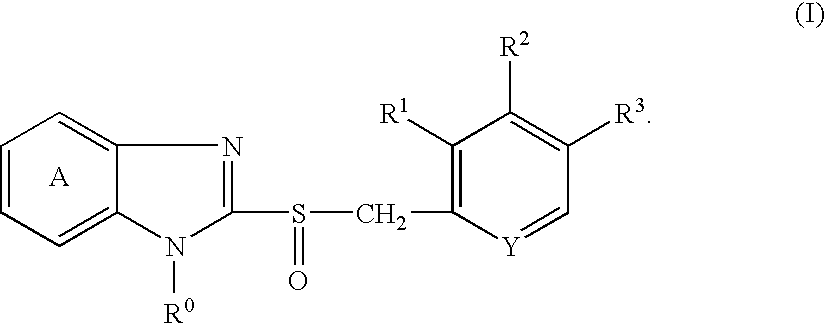

Method for Producing Granules

ActiveUS20080138427A1Improve variationReduce variationMaterial granulation and coatingBiocideFluidized bedElution

In a production process of granules containing a biologically active substance, variation in the elution profile of the biologically active substance is reduced by heating the temperature of granules to about 50° C. or higher and maintaining the temperature for about 1 minute or longer. By setting the spray speed to about 90 mg / min or more per 1 g of cores when a spray agent for a primary agent containing the biologically active substance is sprayed while spraying a binding liquid to the cores and setting the total feeding weight per unit area for a centrifugal fluidized bed coating granulation machine to about 1.5 g / cm2 or more, the variation in the elution profile of the biologically active substance from the granules is reduced.

Owner:TAKEDA PHARMA CO LTD

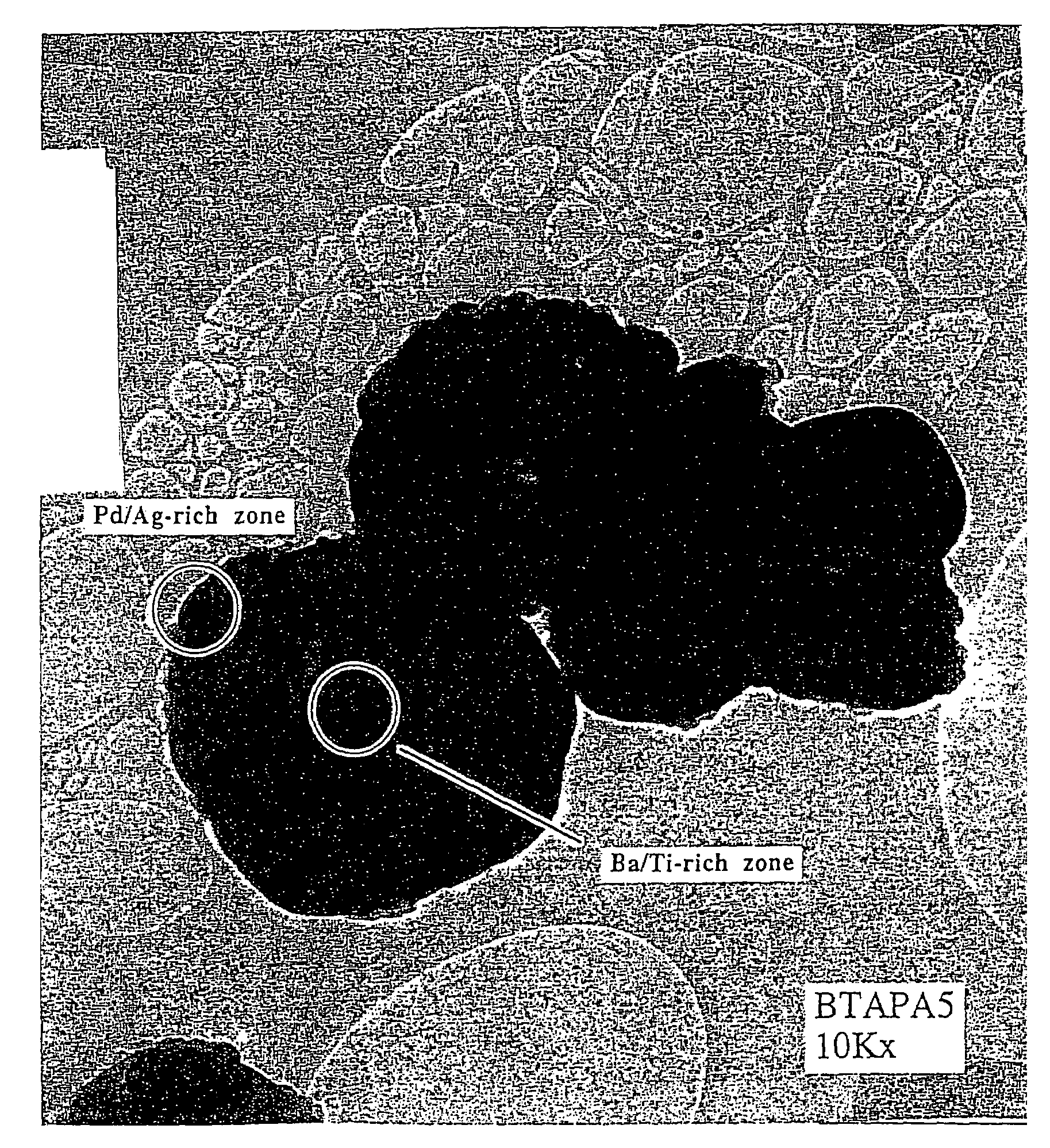

Palladium-containing particles, method and apparatus of manufacture, palladium-containing devices made therefrom

InactiveUS7172663B2Quality improvementHigh rateMaterial granulation and coatingGranule coatingHigh resistancePolymer science

Provided are palladium-containing powders and a method and apparatus for manufacturing the palladium-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications. Powders may have high resistance to oxidation of palladium. Multi-phase particles are provided including a palladium-containing metallic phase and a second phase that is dielectric. Electronic components are provided manufacturable using the powders.

Owner:CABOT CORP

Method and apparatus for the production of ultrafine particles and related coating compositions

Disclosed are methods for making ultrafine particles, apparatus for making ultrafine particles, and coating compositions comprising ultrafine particles made by such methods and / or apparatus.

Owner:PPG IND OHIO INC

Process for the production of titanium oxide coated particles

A process for the production of insulator-coated black particles, which comprises the steps of (1-a) dispersing particles of silica or a metal oxide in an alcohol-based solvent consisting mainly of an intermediate alcohol to obtain a dispersion of the above particles, (1-c) forming a titanium oxide coating of TiO2 on the surface of each of the particles whose surfaces have been activated in the above step, to obtain titanium oxide-coated particles, (1-d) calcining the titanium oxide-coated particles obtained in the above step in a reducing and / or nitriding atmosphere and thereby blackening the above titanium oxide coatings to obtain black particles, and (1-e) forming an electrical insulator coating on a surface of each of the black particles obtained in the above step, to obtain insulator-coated black particles; characterized in that the process includes a step of (1-b) adding an alkaline aqueous solution to the dispersion obtained in step (1-a) to activate a surface of each of the particles of a metal oxide.

Owner:UBE NITTO KASEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com