Zircon power alternative coating for casting and preparation method thereof

A zircon powder and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of high radioactivity, physical injury of workshop employees, poor high temperature stability, etc., achieve good thixotropy and leveling, reduce The effect of cleaning workload and reducing porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

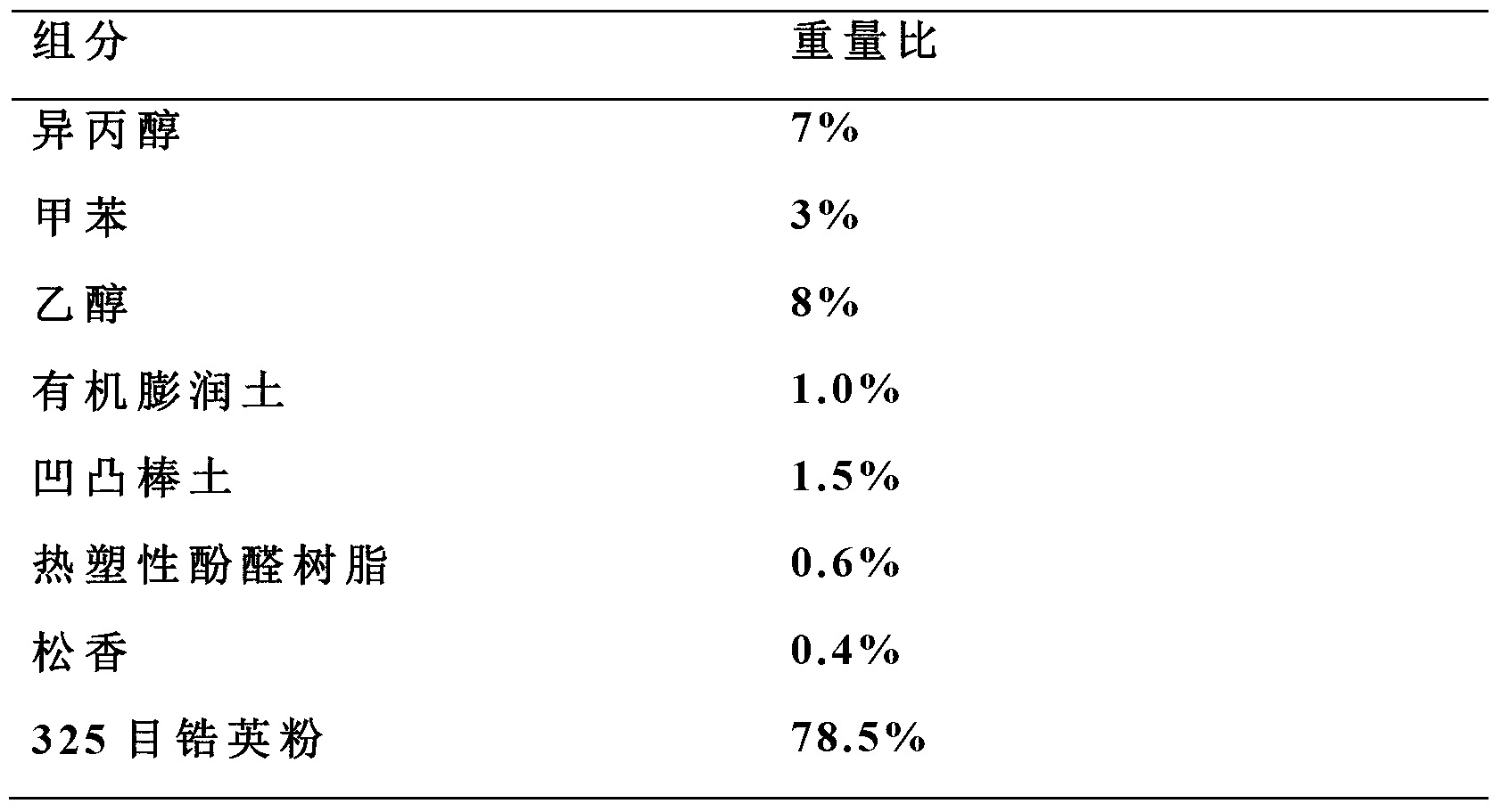

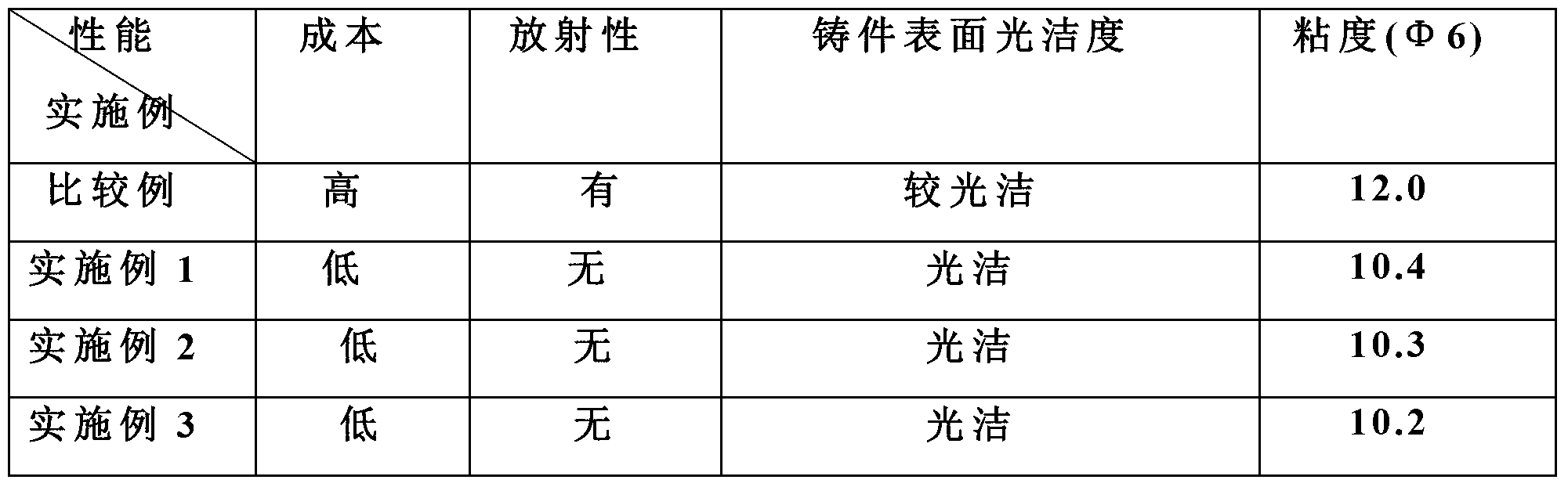

[0054] Example 1 Preparation of zircon powder substitute coating for foundry

[0055]

[0056] The preparation method is as follows:

[0057] (1) Add organic bentonite to toluene to make a paste to form a semi-finished product A.

[0058] (2) Add semi-finished product A, attapulgite, thermoplastic phenolic resin, rosin, 325 mesh white corundum powder, and 325 mesh andalusite powder into the kneader in this order, and knead for 1 hour to form semi-finished product B.

[0059] (3) Add isopropanol and ethanol to the high-speed disperser, then add semi-finished product B, stir at 1000 rpm, and stir for 1 hour to form semi-finished product C.

[0060] (4) Pass the semi-finished product C through a colloid mill, and the glue is ground into a slurry, and then packed in barrels.

[0061] The new cast steel coating has high refractoriness and good sintering peeling performance, and the surface quality of cast steel parts is greatly improved.

Embodiment 2

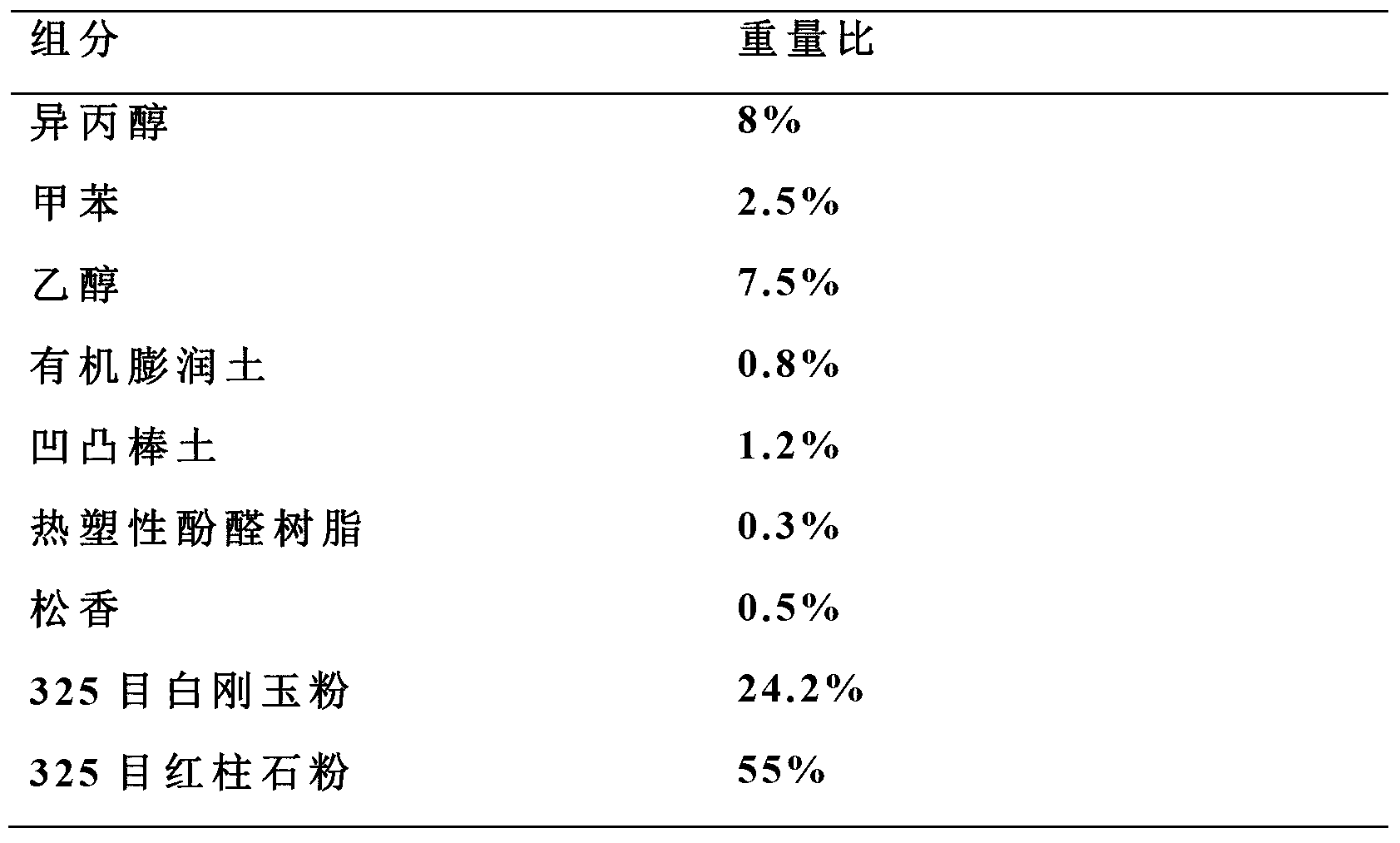

[0062] Example 2 Preparation of Zircon Powder Substitute Coating for Casting

[0063] The composition of the new cast steel coating: isopropanol 10%, toluene 3%, ethanol 6.0%, organic bentonite 1.3%, attapulgite 1.0%, thermoplastic phenolic resin 0.8%, rosin 0.3%, 325 mesh white corundum powder 40%, 325 mesh Andalusite powder 37.6%.

[0064] The new cast steel coating has high refractoriness and good sintering peeling performance, and the surface quality of cast steel parts is greatly improved.

Embodiment 3

[0065] Example 3 Preparation of Zircon Powder Substitute Coating for Casting

[0066] The composition of the new cast steel coating: isopropanol 6%, toluene 3.5%, ethanol 9%, organic bentonite 1.5%, attapulgite 1.1%, thermoplastic phenolic resin 0.7%, rosin 0.4%, 325 mesh white corundum powder 55%, 325 mesh Andalusite powder 22.8%.

[0067] The new cast steel coating has low cost, no radioactivity, good fluidity and good sintering peeling performance, and the surface quality of the steel casting is greatly improved.

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com