Stamping device for metal base plate production

A stamping device and metal substrate technology, applied in the field of metal substrate stamping, can solve the problems of increasing the labor intensity of workers to clean up scraps, reducing the environmental sanitation of the workplace, and the scraps are easy to hurt workers, etc., to reduce the cleaning workload, It is easy to clamp and disassemble the lower mold and avoid the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

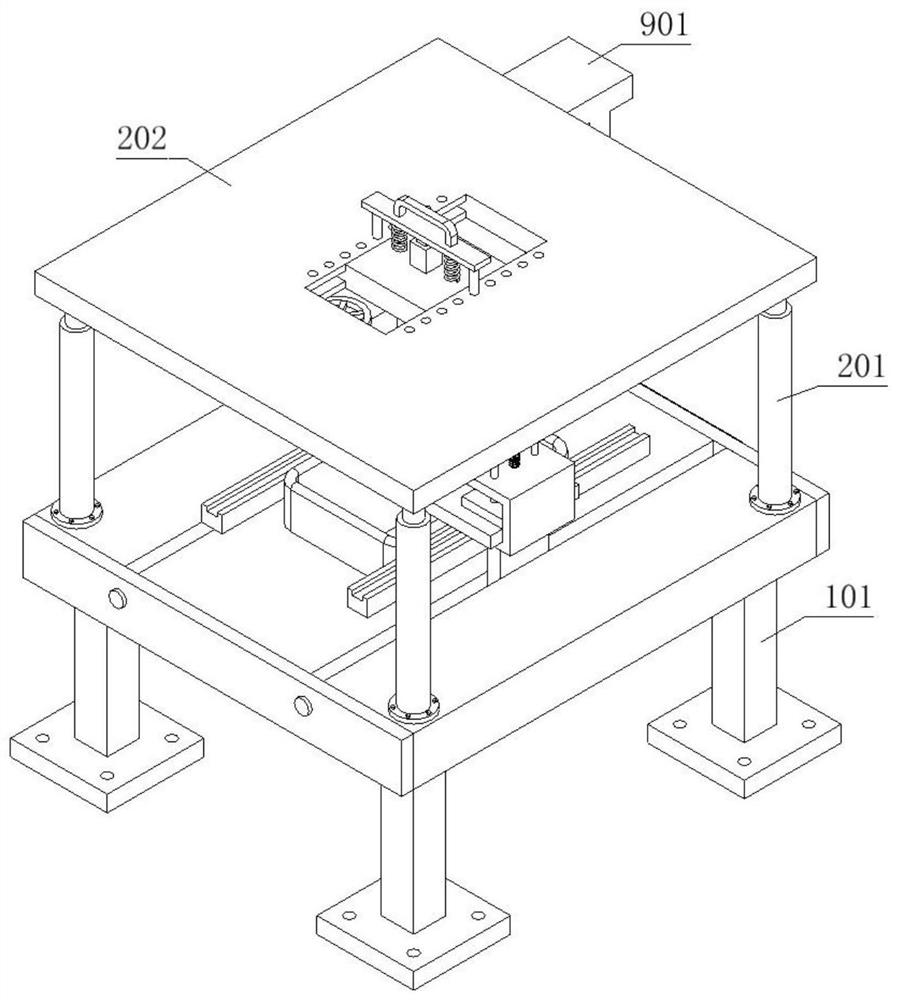

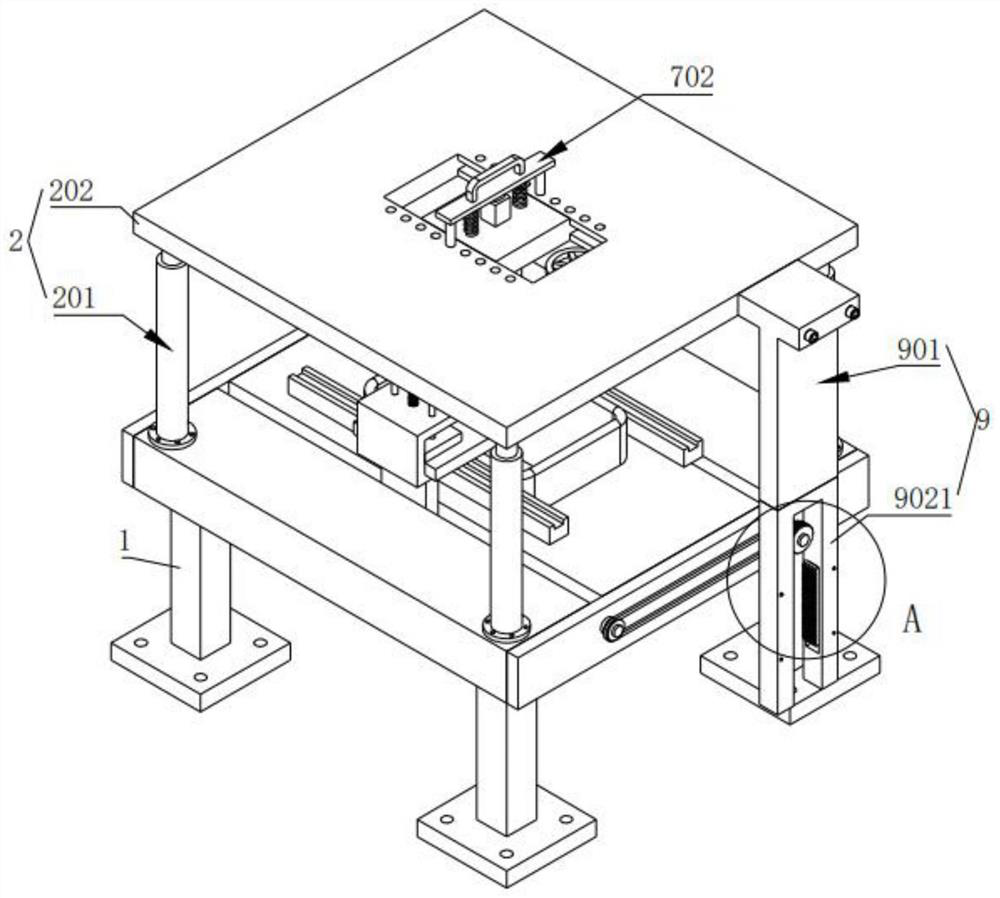

[0034] as attached figure 1 to attach Figure 14 Shown:

[0035] The present invention provides a stamping device for metal substrate production, including an installation mechanism 1;

[0036] A lifting part 2 is installed on the top of the installation mechanism 1;

[0037] There are two groups of clamping parts 3, and the two groups of clamping parts 3 are symmetrically installed on the top of the installation mechanism 1, and a lower mold 4 is arranged between the two groups of clamping parts 3, and the two groups of clamping parts A fixing part 5 is installed inside the tightening part 3;

[0038] The connecting part 6, the connecting part 6 is installed inside the installation mechanism 1;

[0039] The stamping part 7, the stamping part 7 is installed on the lifting part 2;

[0040] The collecting part 8, the collecting part 8 is installed on the bottom of the installation mechanism 1;

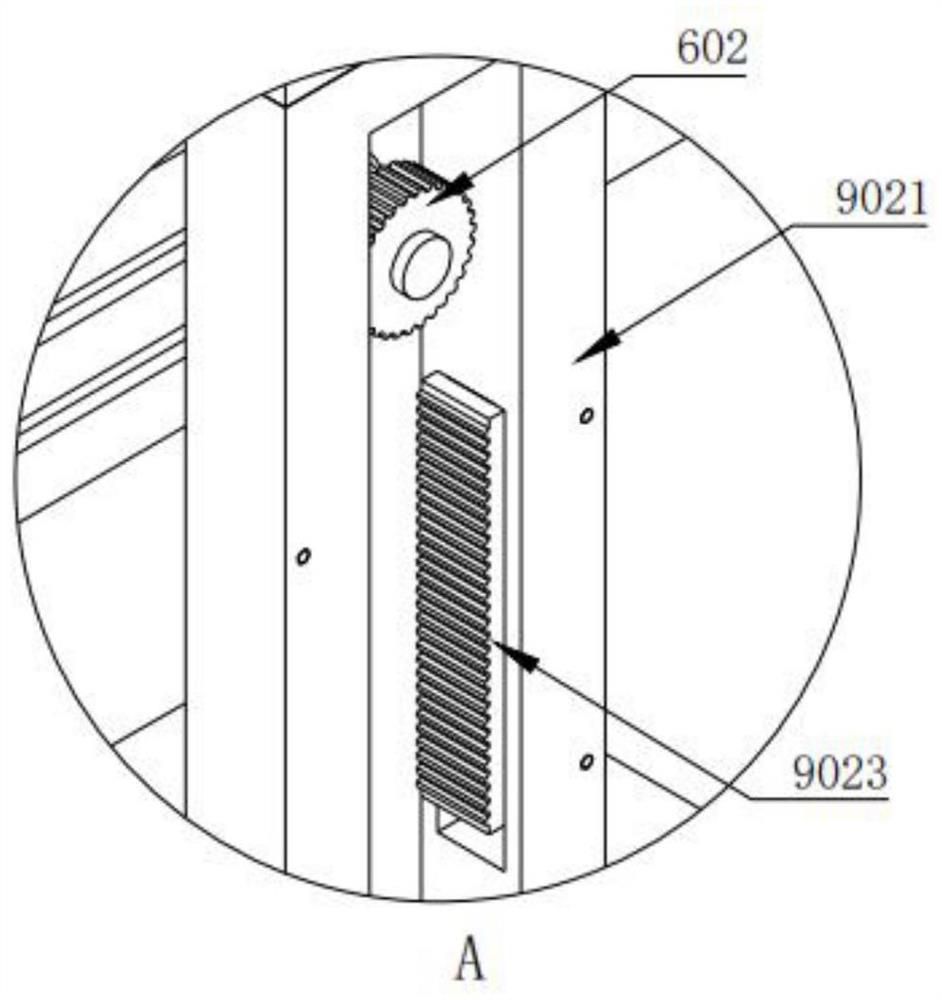

[0041] The moving part 9 is installed on the right side of the lifting part 2 ...

Embodiment 2

[0075] In the actual production and processing of metal substrates, there is a deviation in the thickness of each metal substrate, requiring the operator to manually rotate the locking member 304 to clamp the metal substrate, and the operator cannot accurately judge the clamping force on the metal substrate, there is a certain Potential safety hazards reduce production efficiency at the same time. To improve the above-mentioned problems, control is carried out according to the method described in this embodiment.

[0076] The installation mechanism 1 includes a base 101 and a control unit. A chute is opened on the upper surface of the base 101, and a fixing hole 102 is provided in the chute; the installation mechanism 1 is fixedly connected with the installation plate 202 through an electric push rod 201; A clamping part 3 is provided, and the clamping part 3 includes a slider 301. One end of the slider 301 is slidably connected to the chute, and the other end is fixedly connec...

Embodiment 3

[0080] Since the length of the bump on the stamping head 703 is fixed and the depth of the opening of the lower mold 4 is fixed, when stamping a thicker metal substrate, the stamping head 703 cannot penetrate the lower mold 4 so that there are foreign objects in the hole of the lower mold 4. It will hinder the next stamping, resulting in the failure of normal production of the metal substrate. In order to improve the above problems, control is performed according to the method described in this embodiment.

[0081] The bottom of the installation mechanism 1 is provided with a collection part 8, the collection part 8 includes: a support base 801, the support base 801 is fixedly connected with the installation frame 101, the installation frame 101 is slidingly connected with the storage groove 802, and the storage box 802 and the support base 801 are fixed Springs are installed, and the front and rear sides of the storage box 802 are fixedly equipped with connecting rods 803 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com