Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24116results about "Metal-working storage devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent autofill

InactiveUS7254569B2Minimize effortData augmentationData processing applicationsMetal-working feeding devicesData miningData entry

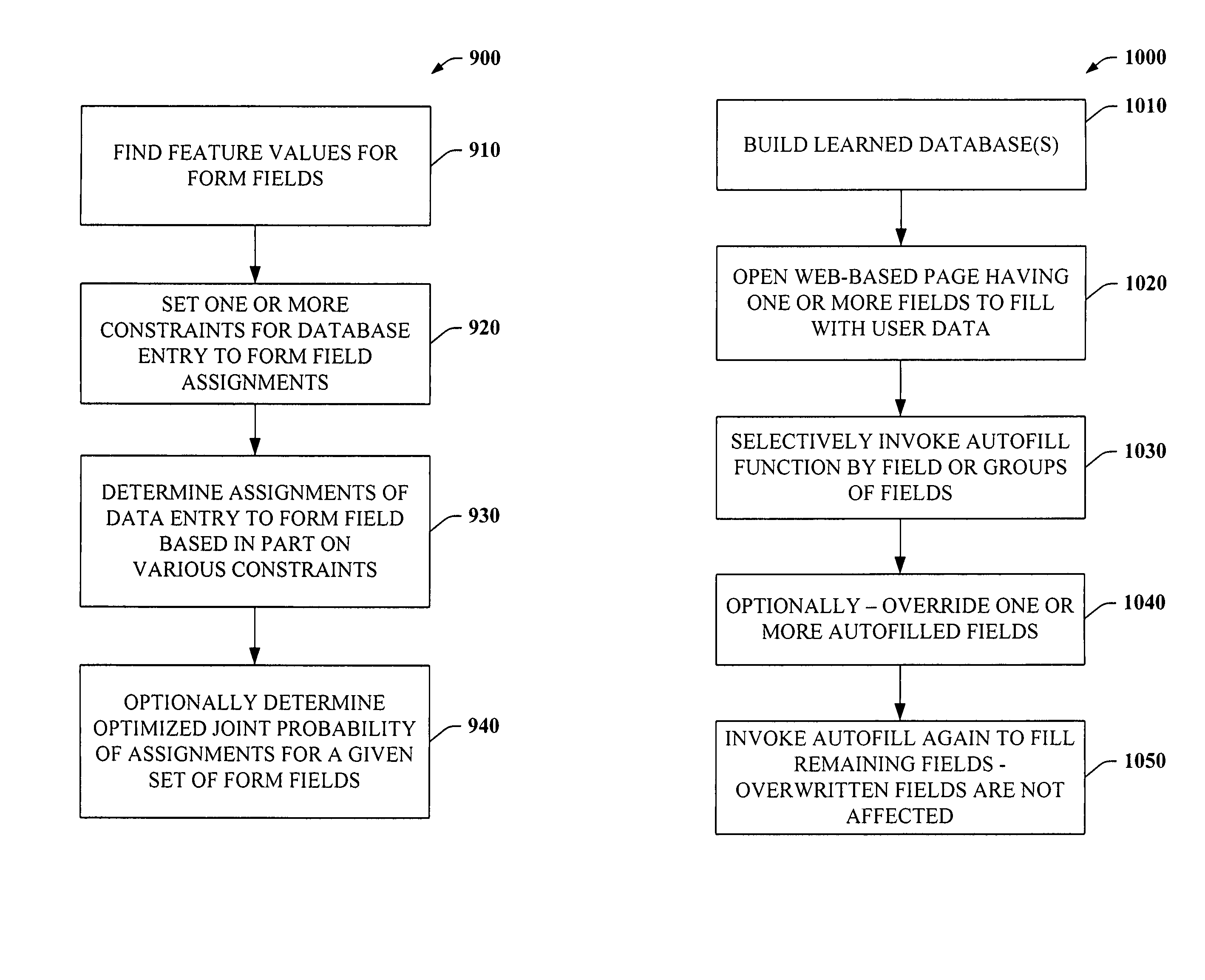

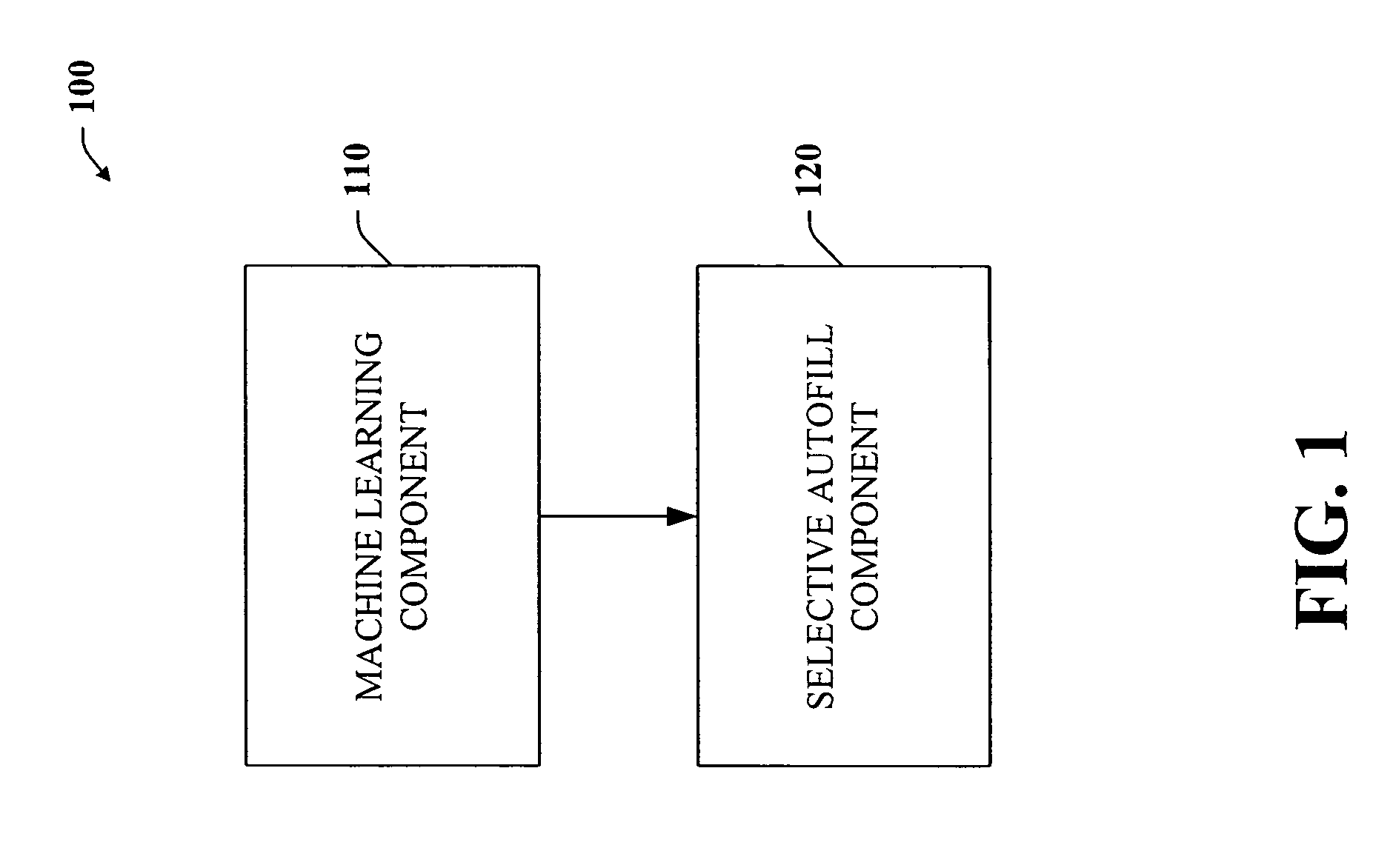

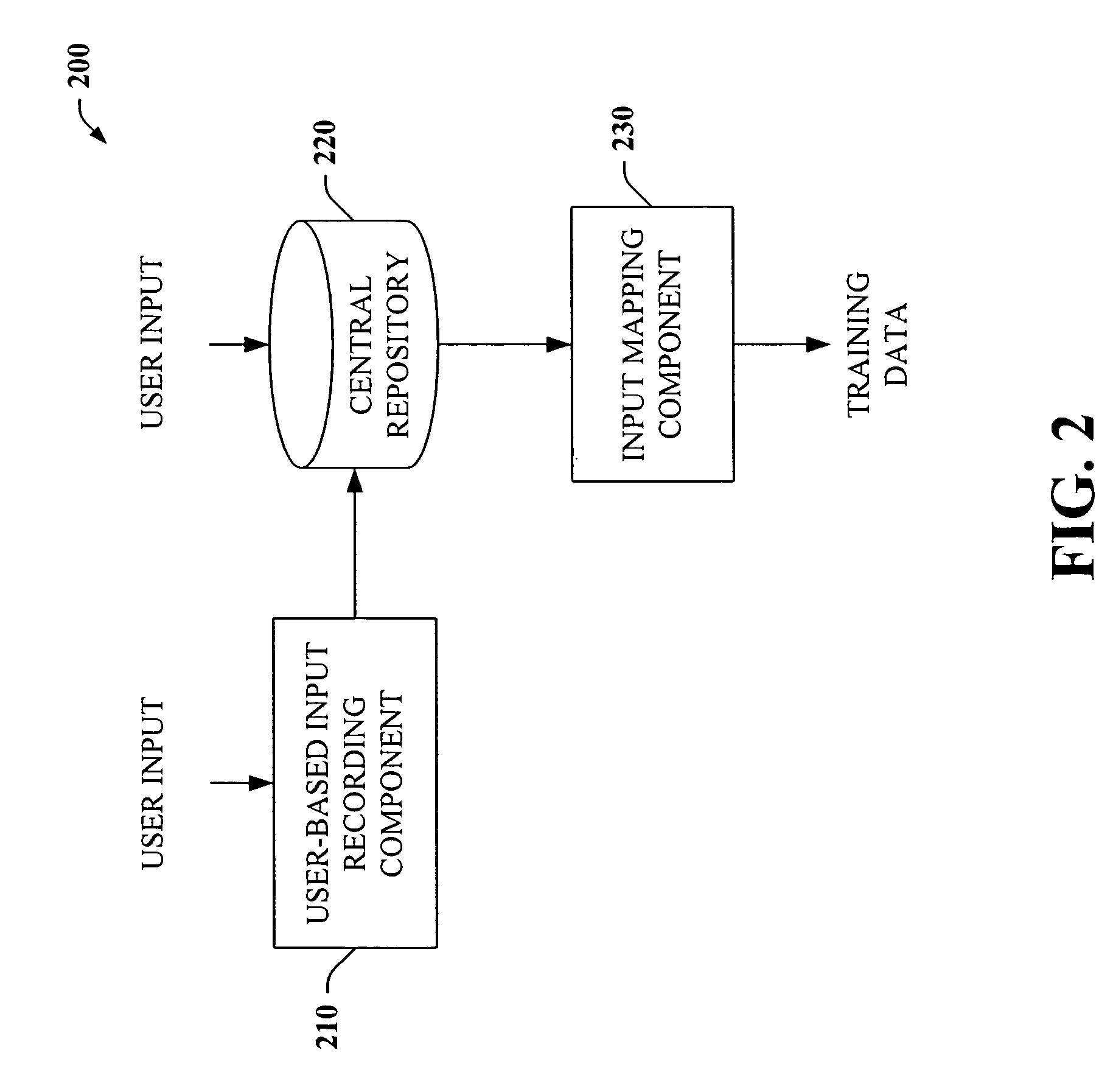

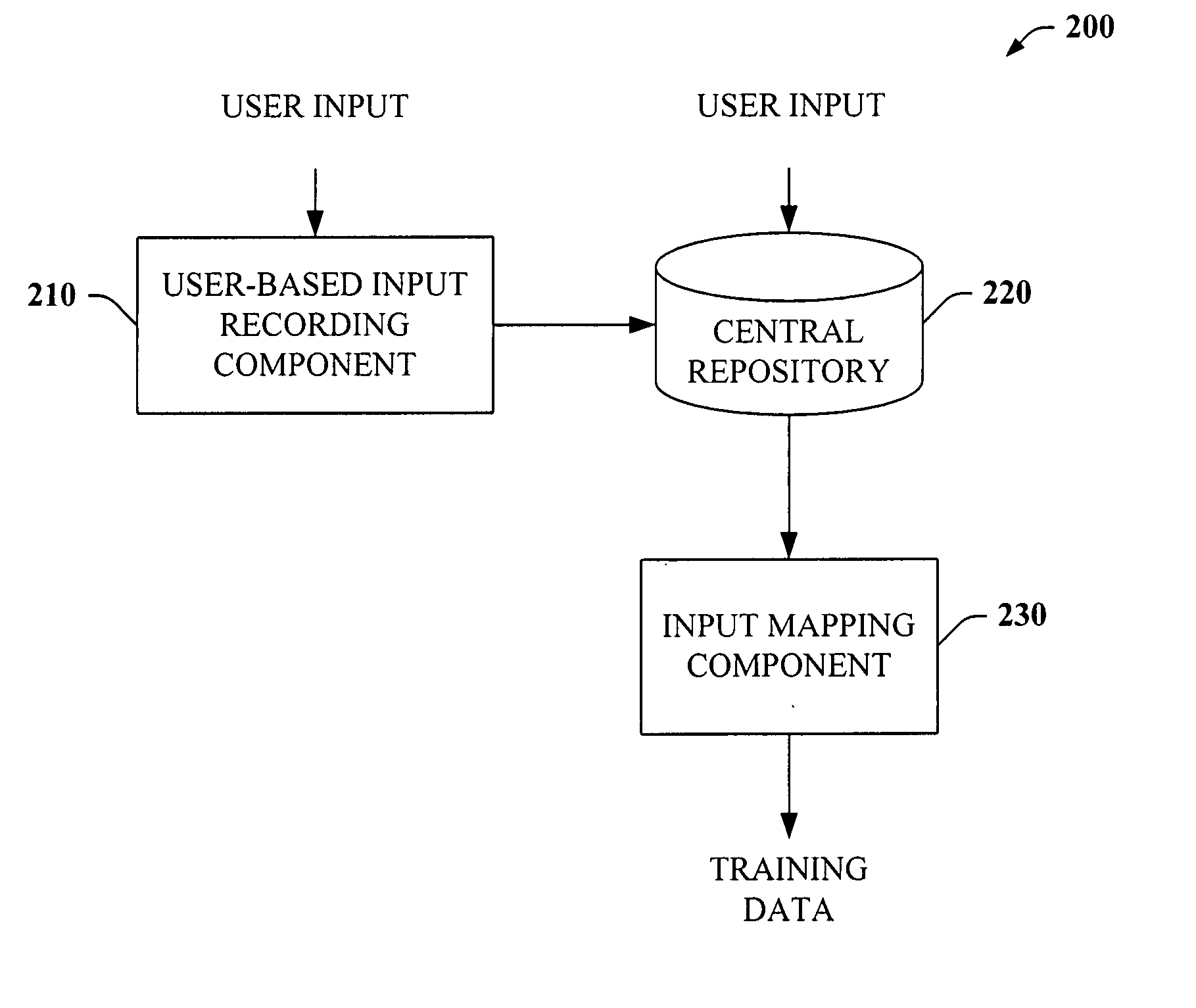

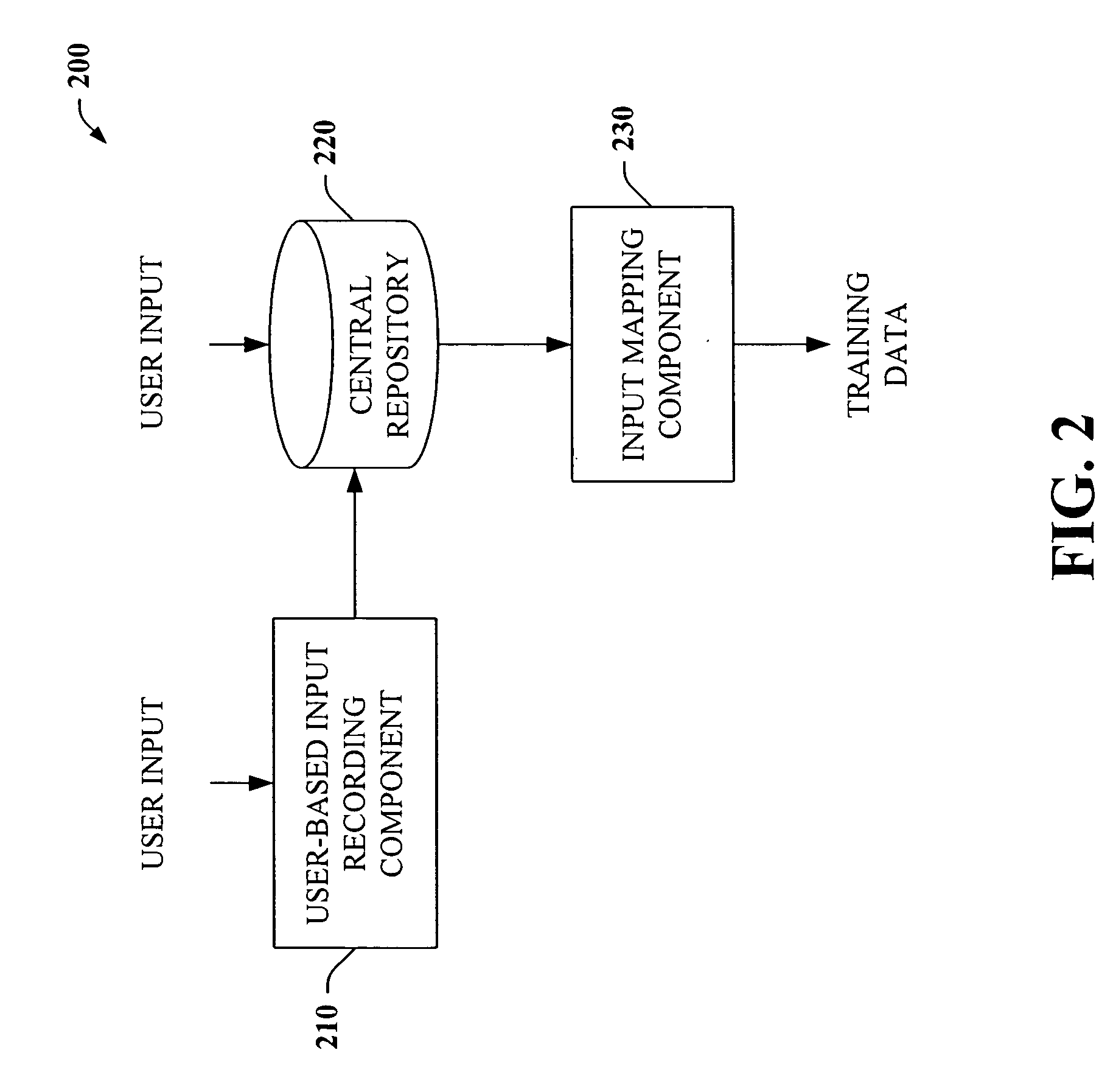

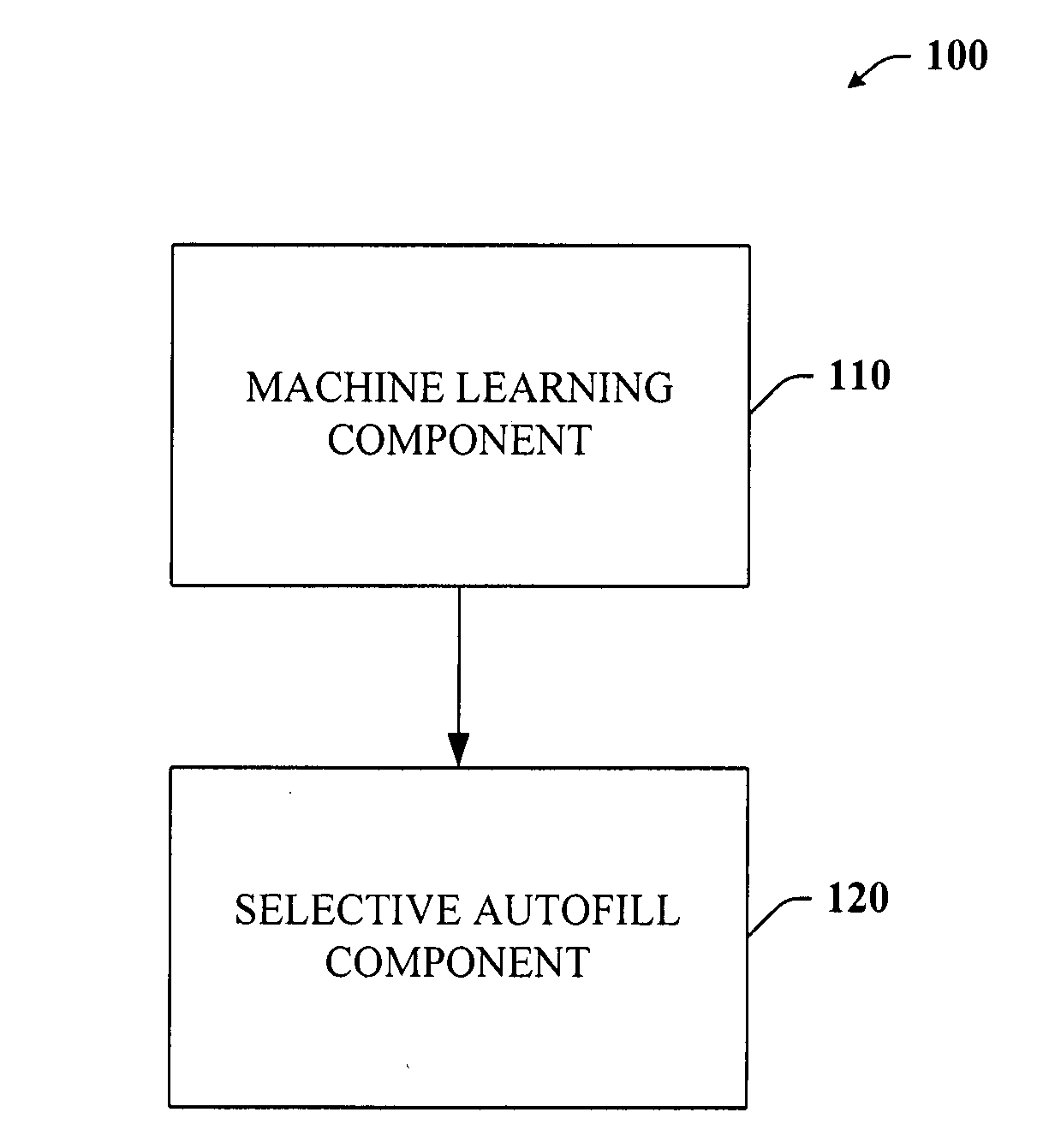

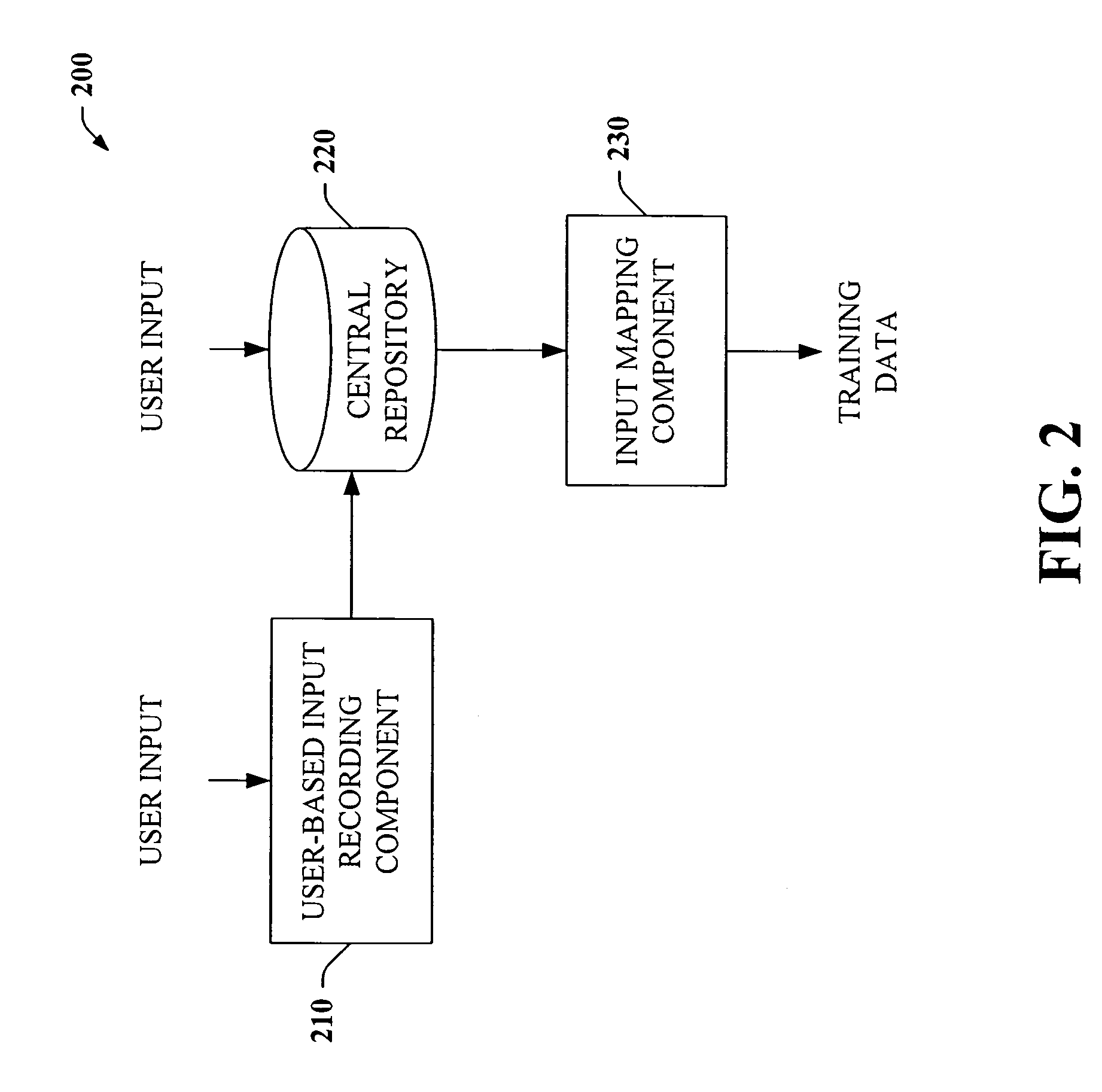

The present invention provides a unique system and method that can employ machine learning techniques to automatically fill one or more fields across a diverse array of web forms. In particular, one or more instrumented tools can collect input or entries of form fields. Machine learning can be used to learn what data corresponds to which fields or types of fields. The input can be sent to a central repository where other databases can be aggregated as well. This input can be provided to a machine learning system to learn how to predict the desired outputs. Alternatively or in addition, learning can be performed in part by observing entries and then adapting the autofill component accordingly. Furthermore, a number of features of database fields as well as constraints can be employed to facilitate assignments of database entries to form values—particularly when the web form has never been seen before by the autofill system.

Owner:MICROSOFT TECH LICENSING LLC

Intelligent autofill

InactiveUS20050257148A1Minimize effortData augmentationData processing applicationsMetal-working feeding devicesDatabaseCentral repository

The present invention provides a unique system and method that can employ machine learning techniques to automatically fill one or more fields across a diverse array of web forms. In particular, one or more instrumented tools can collect input or entries of form fields. Machine learning can be used to learn what data corresponds to which fields or types of fields. The input can be sent to a central repository where other databases can be aggregated as well. This input can be provided to a machine learning system to learn how to predict the desired outputs. Alternatively or in addition, learning can be performed in part by observing entries and then adapting the autofill component accordingly. Furthermore, a number of features of database fields as well as constraints can be employed to facilitate assignments of database entries to form values—particularly when the web form has never been seen before by the autofill system.

Owner:MICROSOFT TECH LICENSING LLC

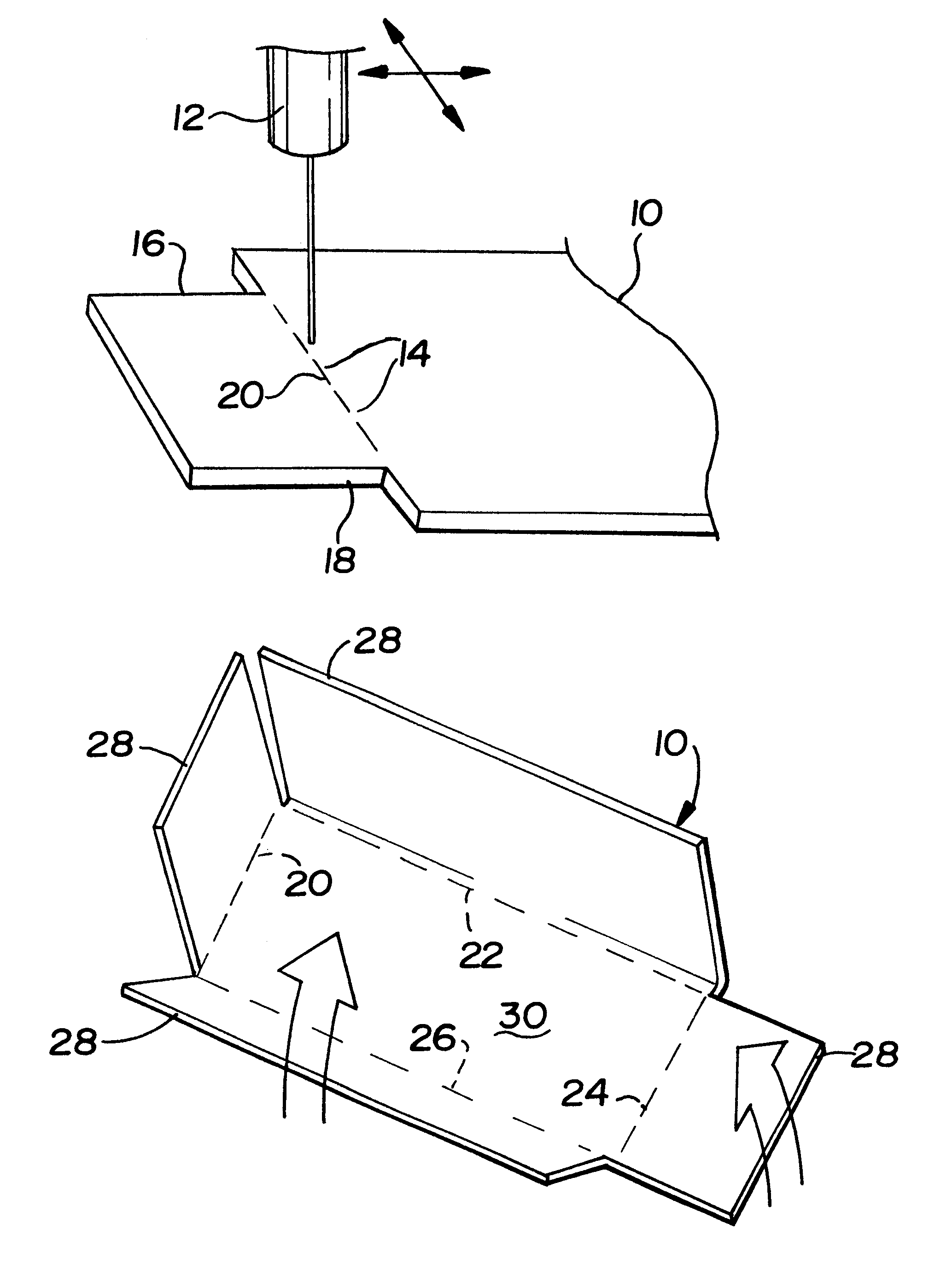

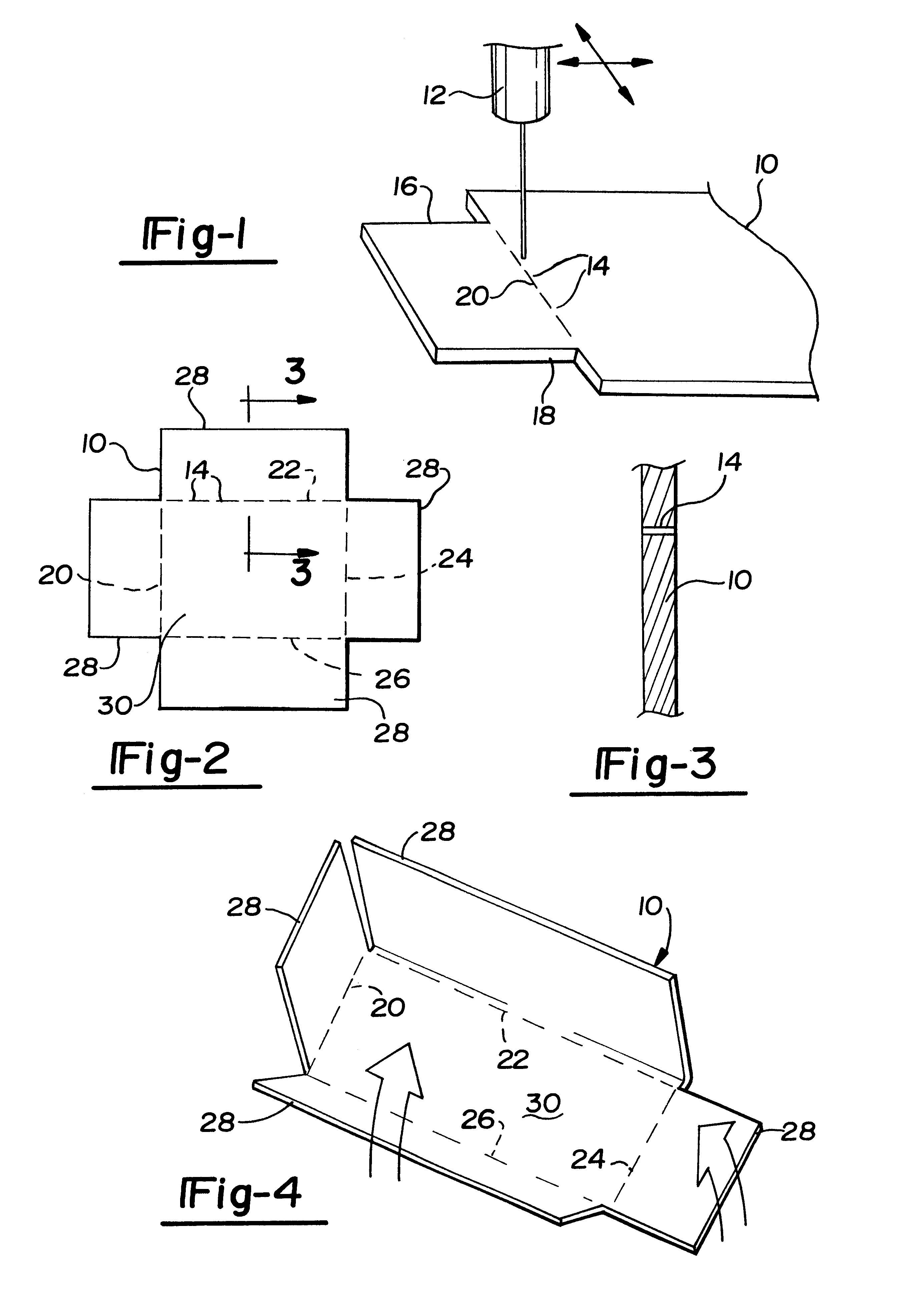

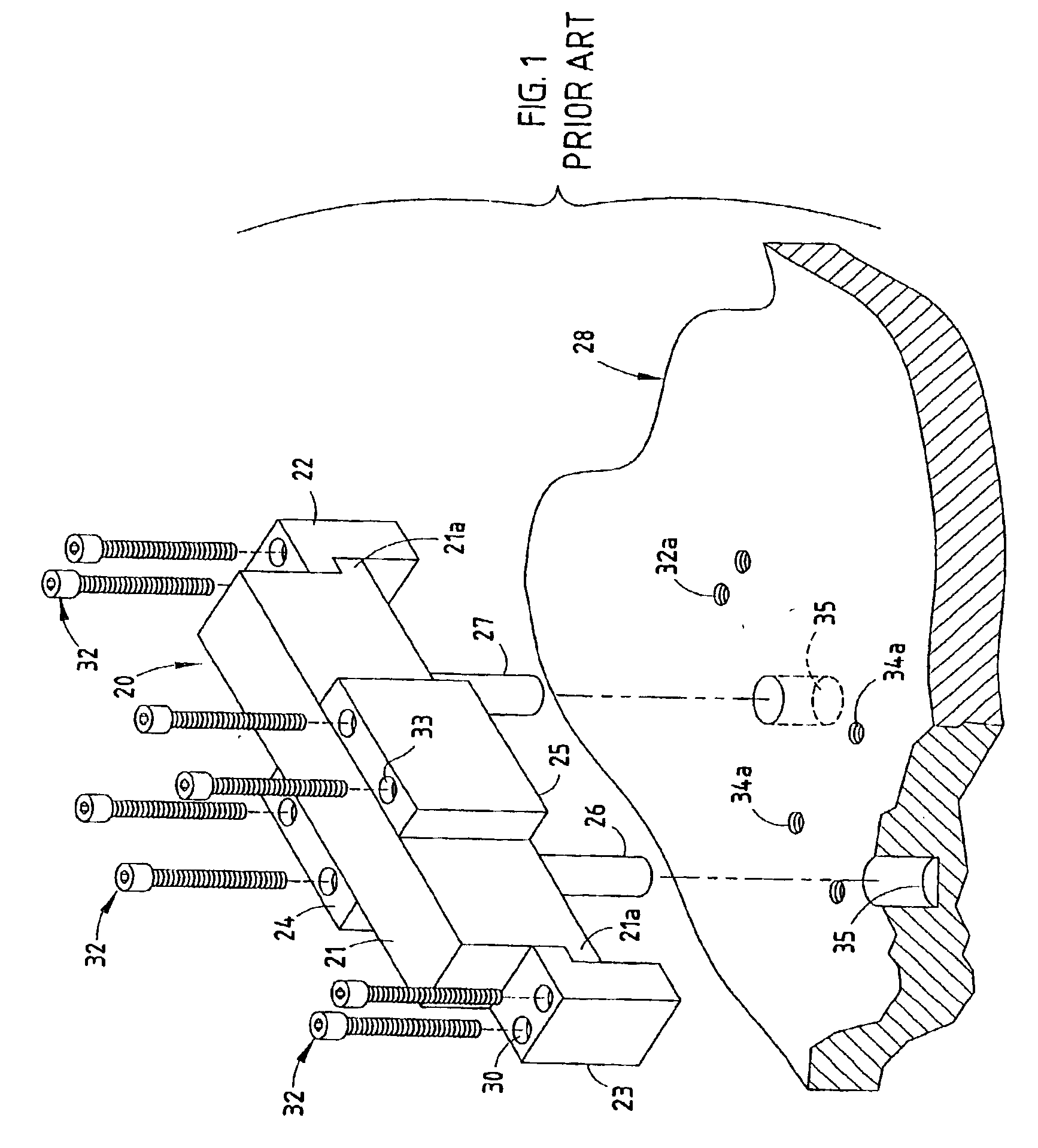

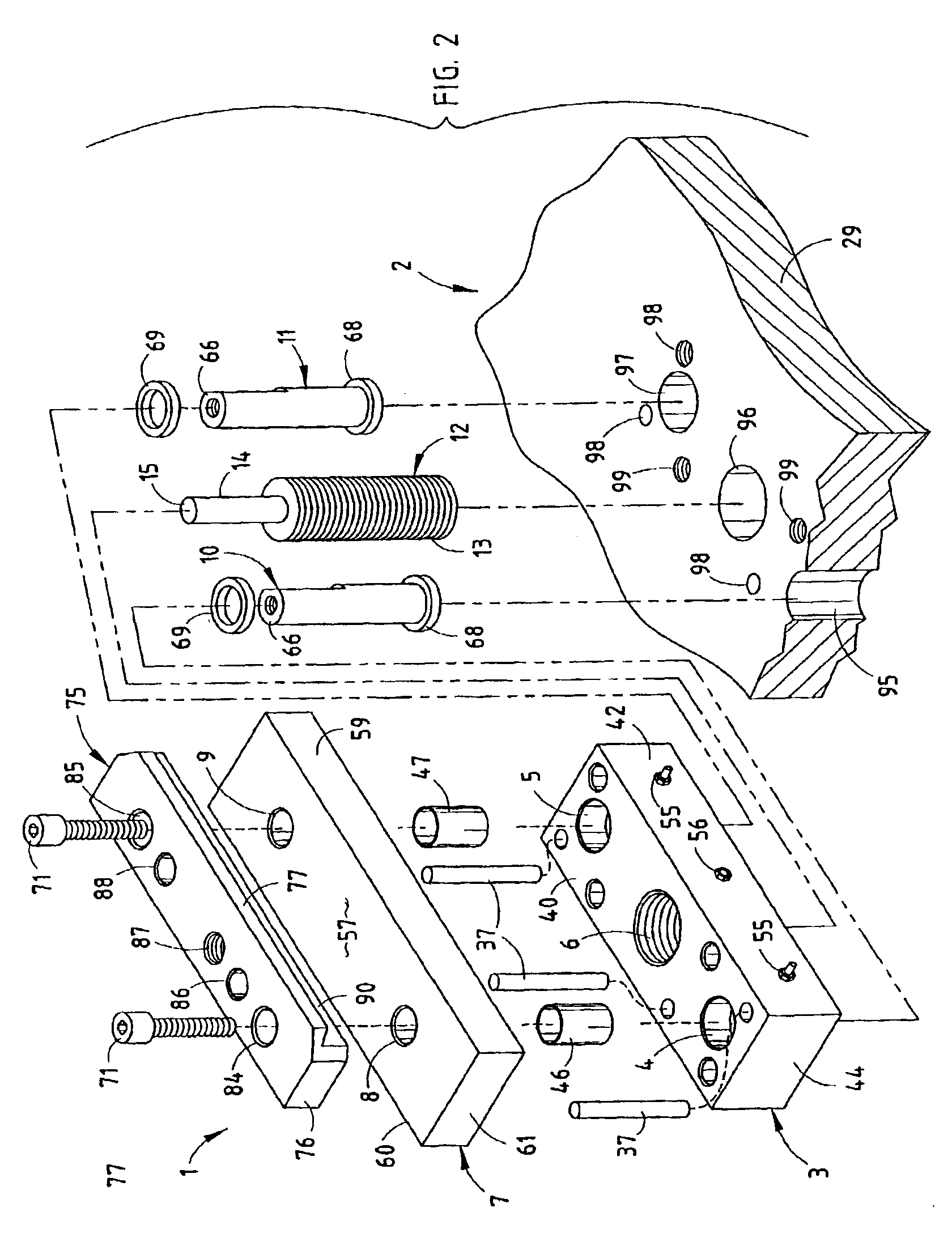

Method for precision bending of a sheet of material and slit sheet therefor

InactiveUS6481259B1Reduce stress concentrationPrecise positioningConstruction materialMetal-working feeding devicesEngineeringSheet material

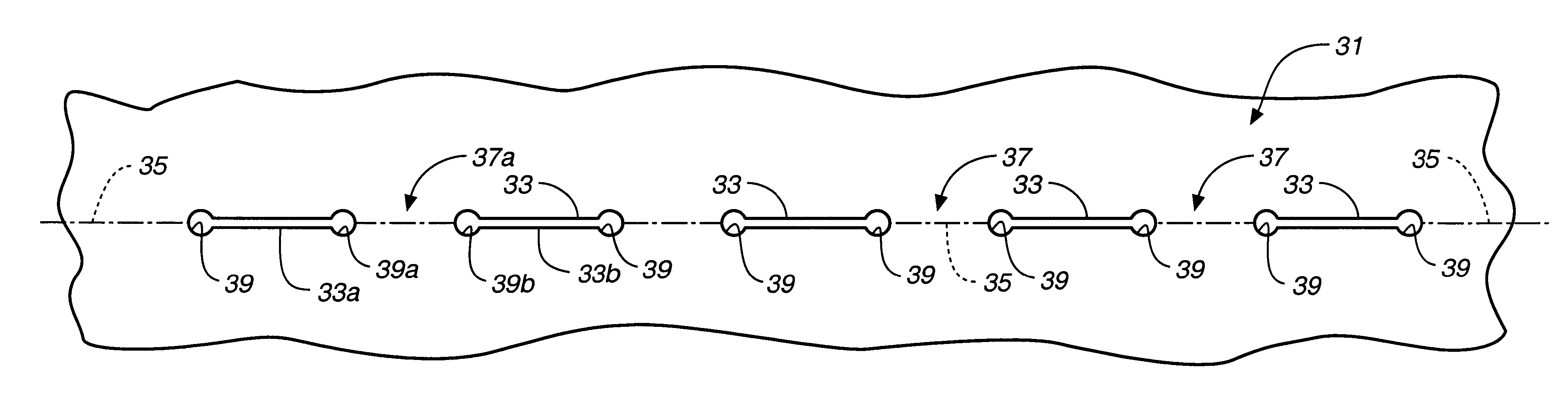

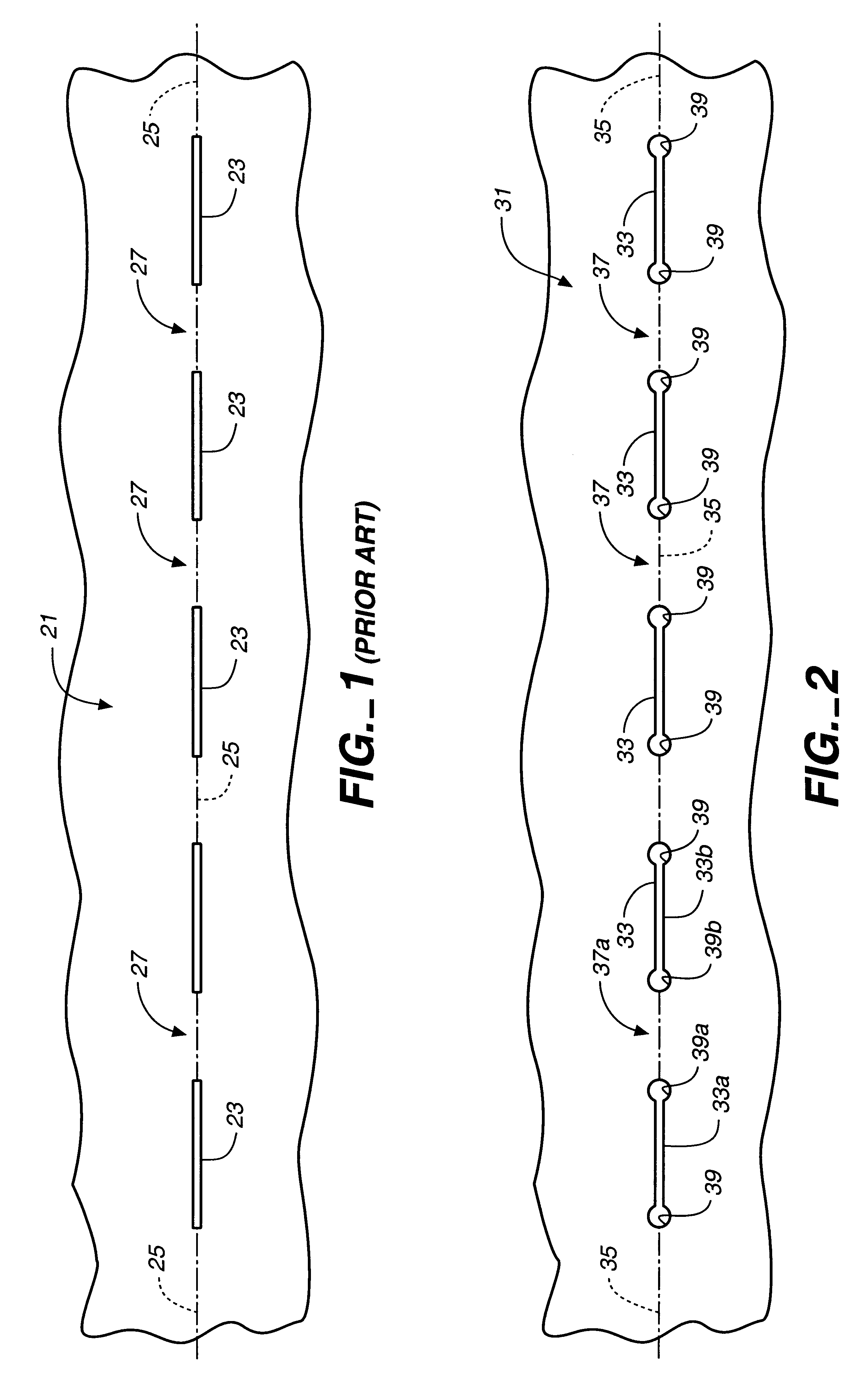

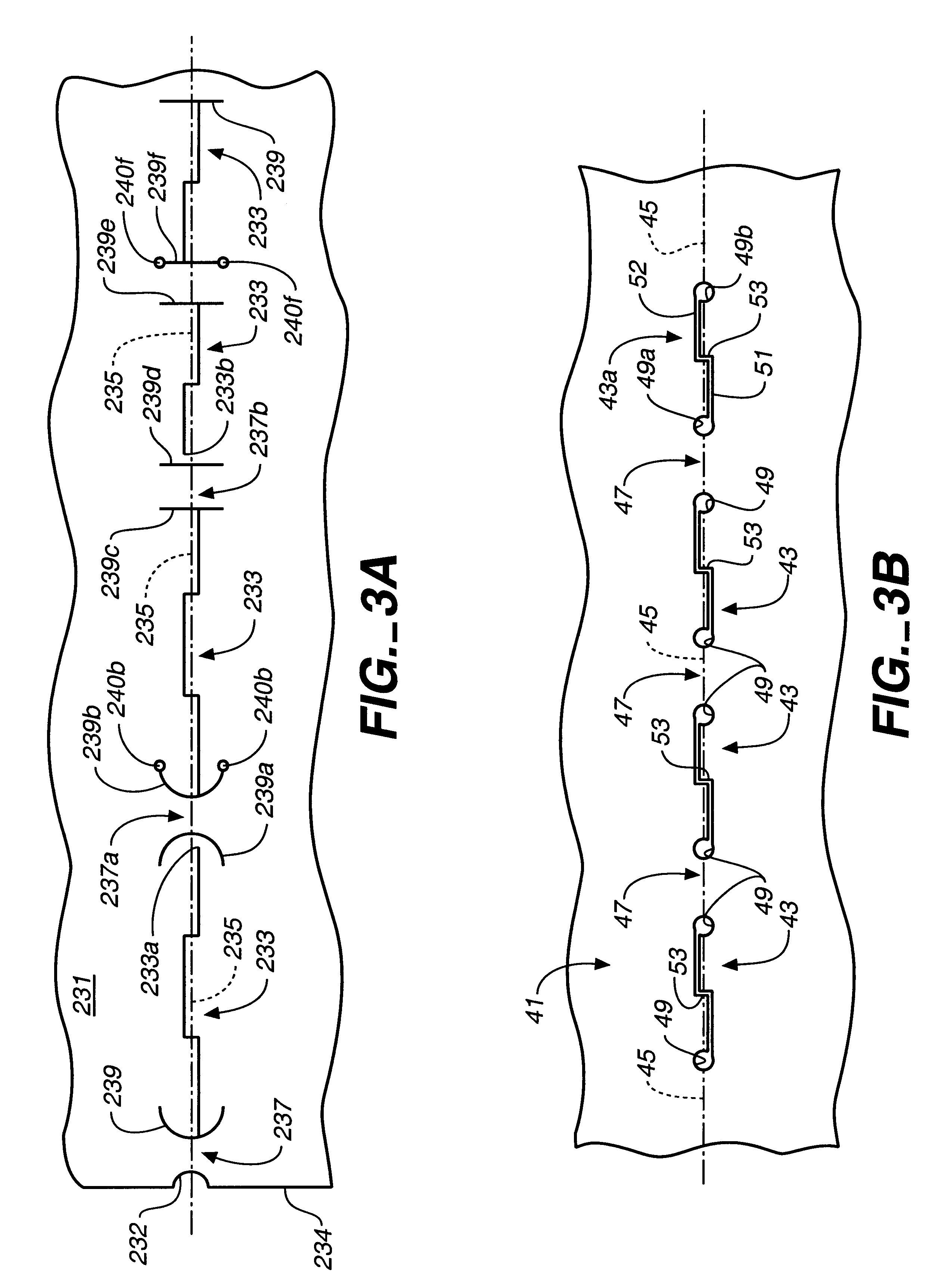

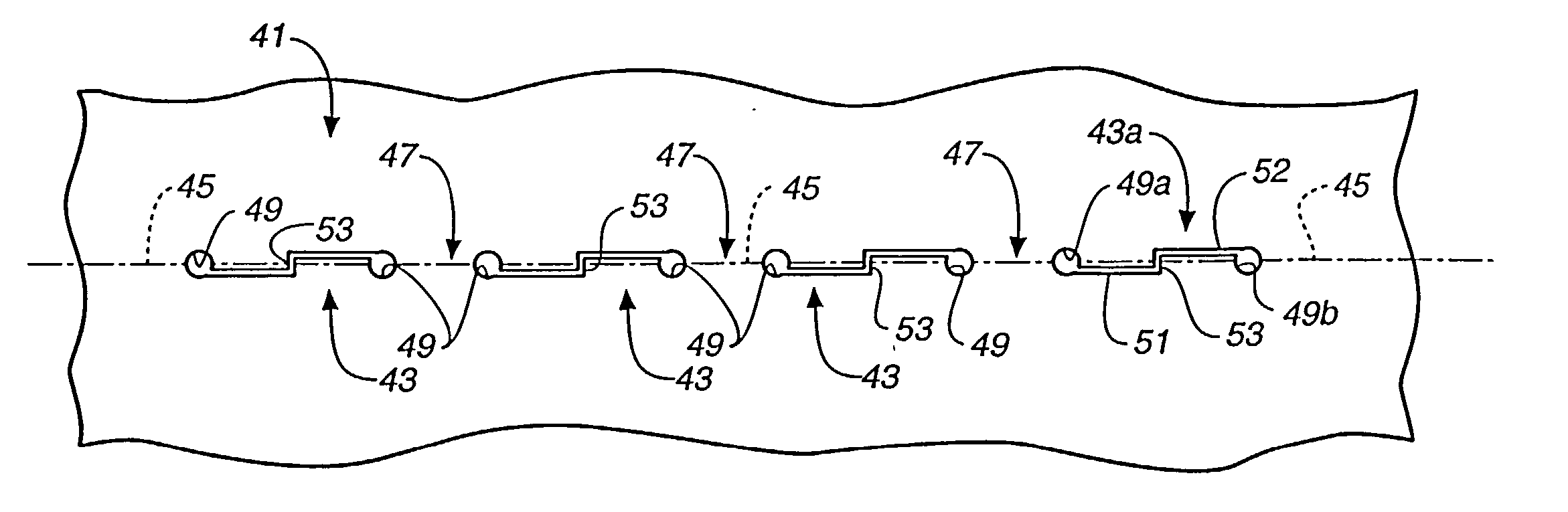

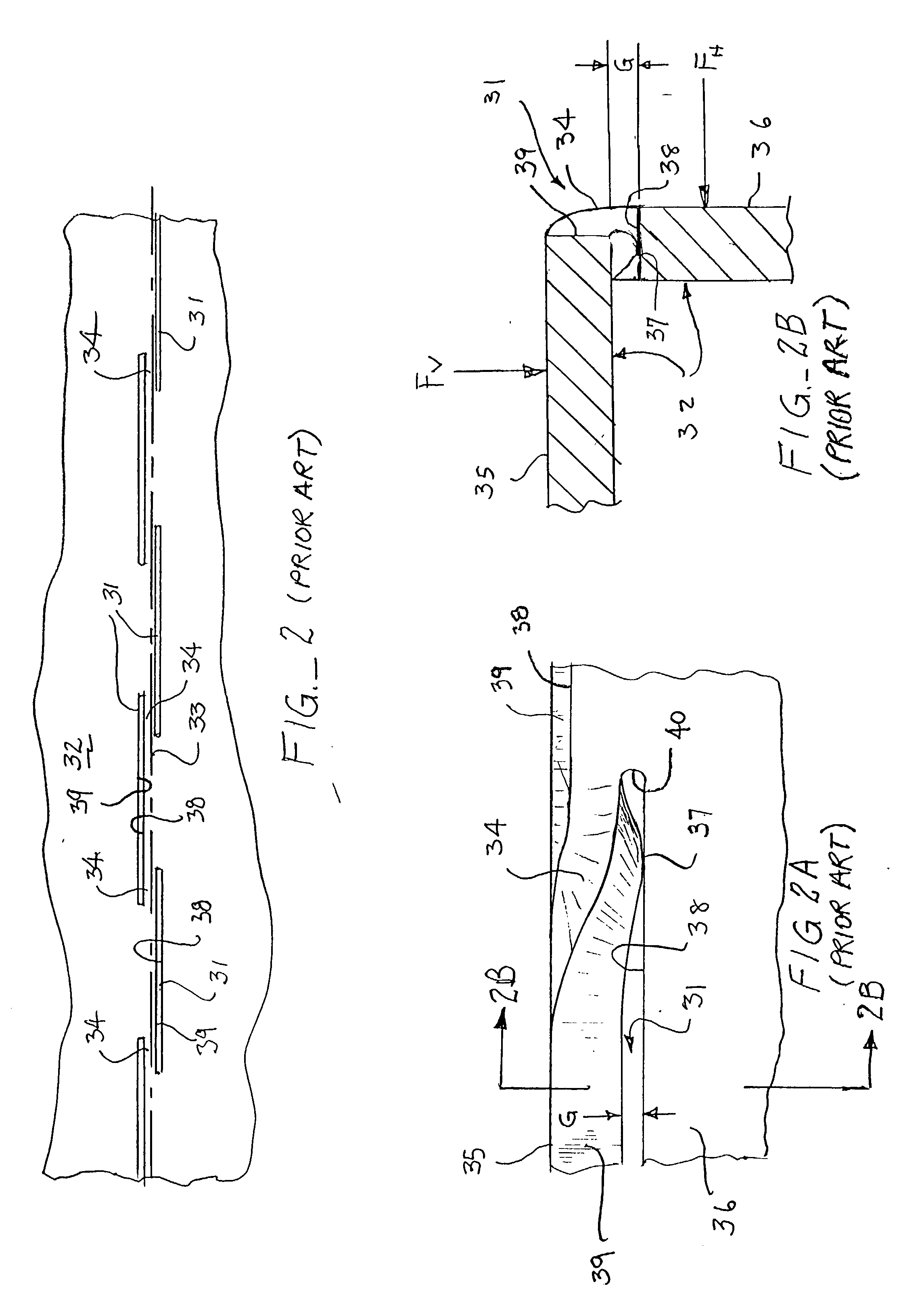

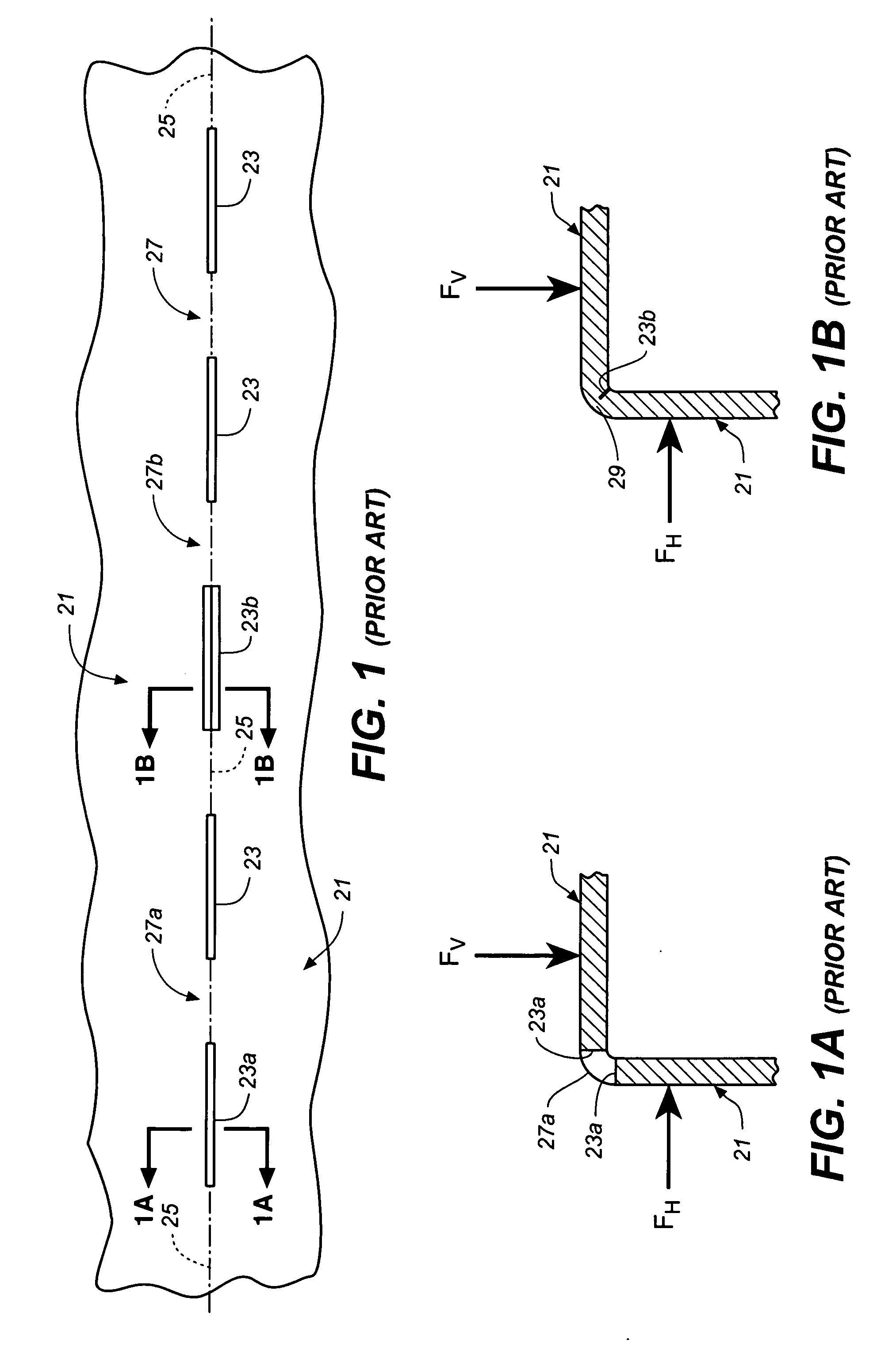

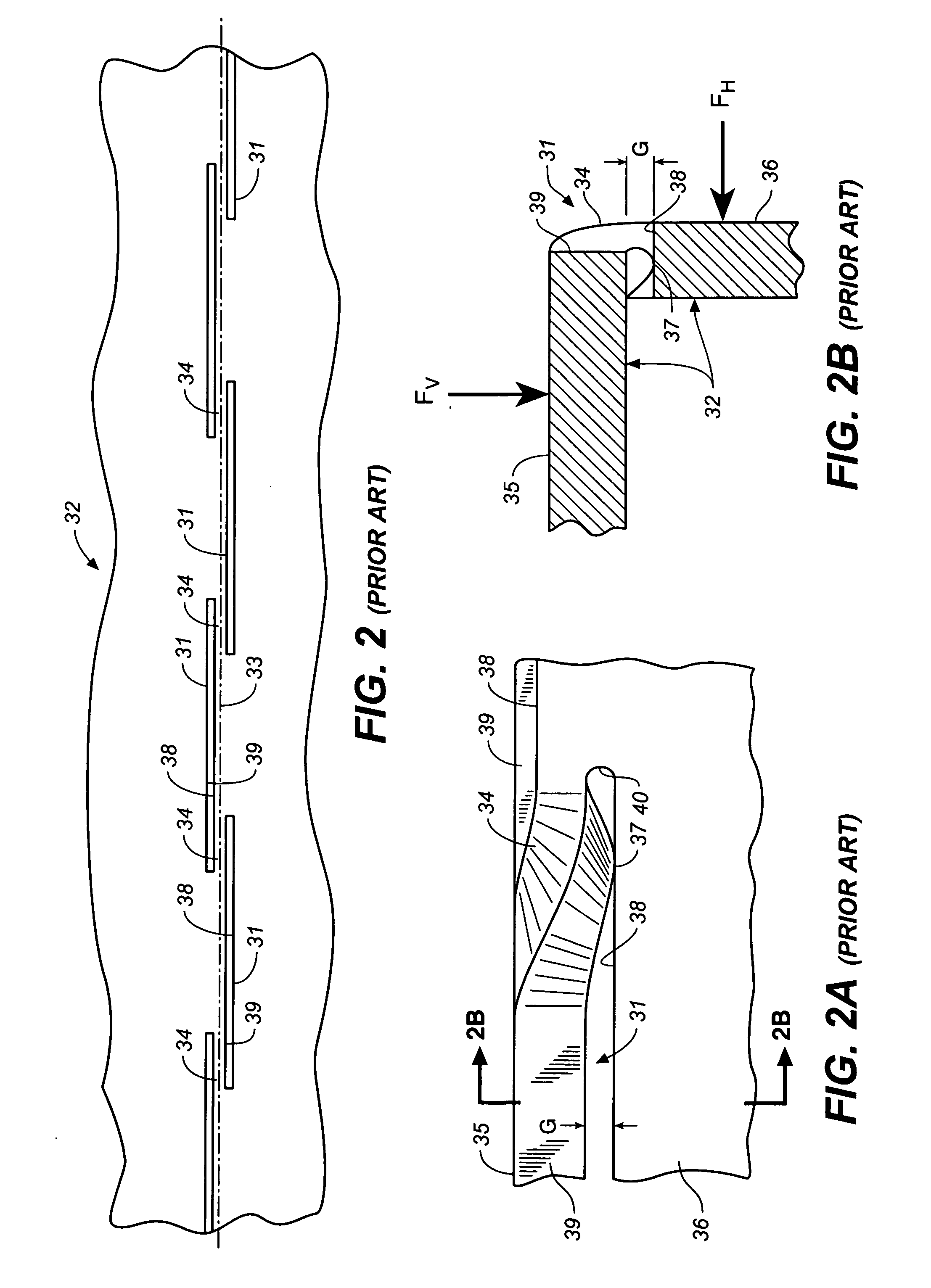

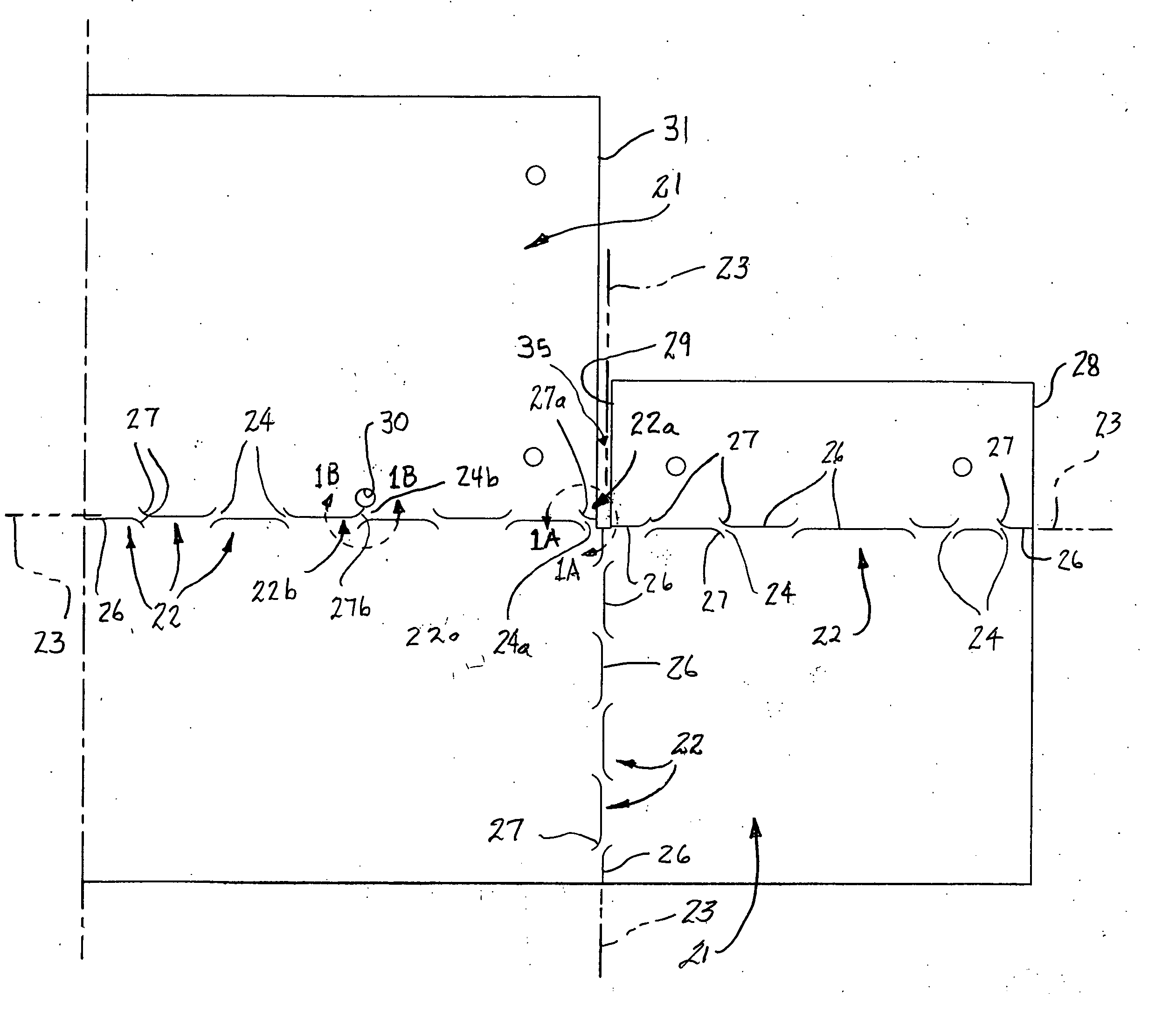

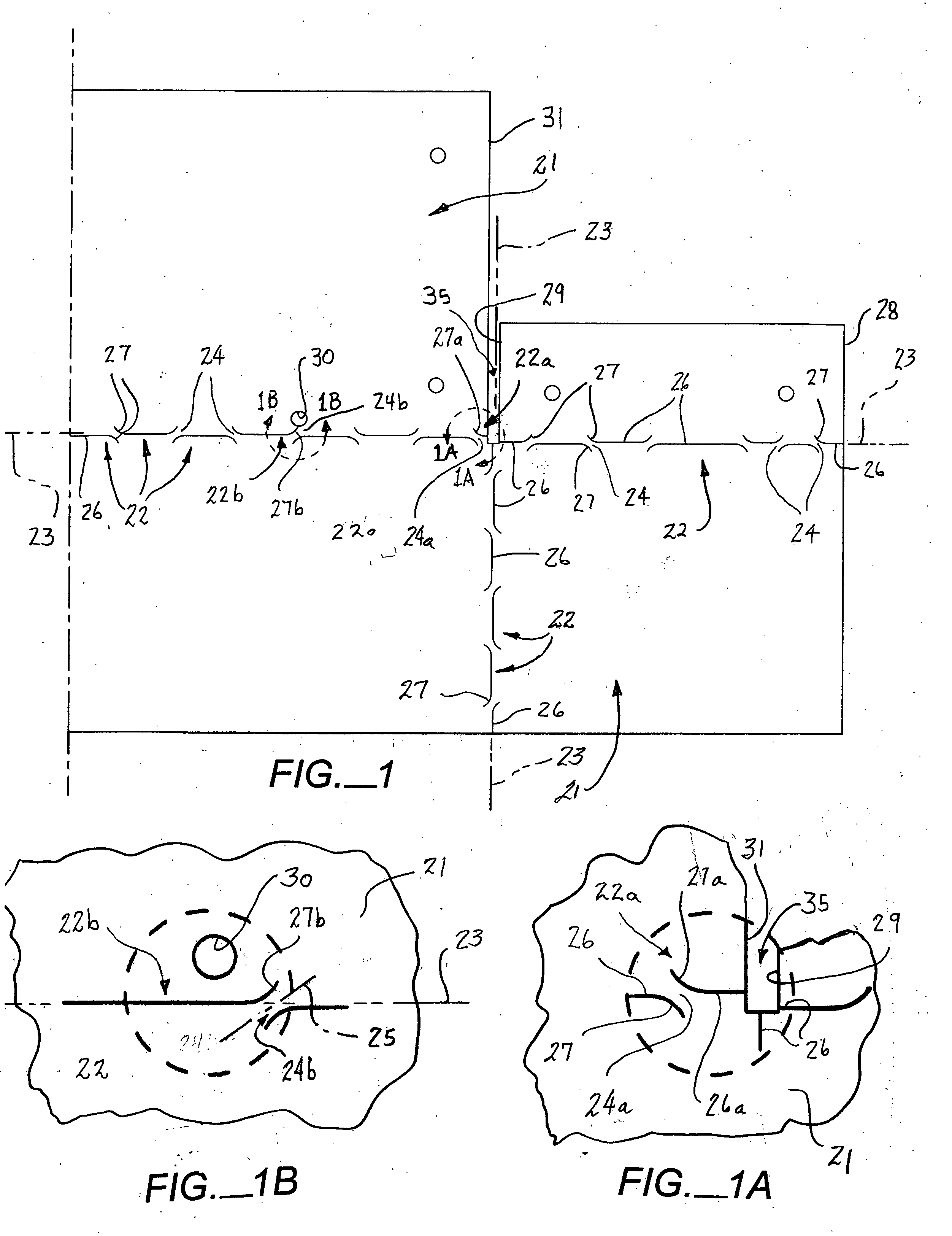

A method for precision bending of a sheet of material (31,41,61,91,231) along a bend line (35,45,62-66,96,235) and the resulting sheet are disclosed. A method includes a step of forming and longitudinally extending slits (33,43,68,92,233) through the sheet of material in axially spaced relation to define bending webs (37,47,71,72,106,237), forming stress reducing structures such as enlarged openings (39,49,69,73) or transversely extending slits (239) at each of adjacent ends of pairs of slits in order to reduce crack propagation across the bending webs. In another aspect, the elongated slits (43,68,92,233) are formed with pairs of longitudinally extending slit segments (51,52;74,76;98,99;127) proximate to and on opposite sides of and substantially parallel to the desired bend line. Longitudinally extending slit segments further are connected by at least one intermediate transversely extending slit segment (53,77,101,128). Sheets of slit material suitable for bending also are disclosed.

Owner:IND ORIGAMI INC CA US

Intelligent autofill

ActiveUS20050257134A1Minimize effortData augmentationData processing applicationsMetal-working feeding devicesDatabaseCentral repository

The present invention provides a unique system and method that can employ machine learning techniques to automatically fill one or more fields across a diverse array of web forms. In particular, one or more instrumented tools can collect input or entries of form fields. Machine learning can be used to learn what data corresponds to which fields or types of fields. The input can be sent to a central repository where other databases can be aggregated as well. This input can be provided to a machine learning system to learn how to predict the desired outputs. Alternatively or in addition, learning can be performed in part by observing entries and then adapting the autofill component accordingly. Furthermore, a number of features of database fields as well as constraints can be employed to facilitate assignments of database entries to form values—particularly when the web form has never been seen before by the autofill system.

Owner:MICROSOFT TECH LICENSING LLC

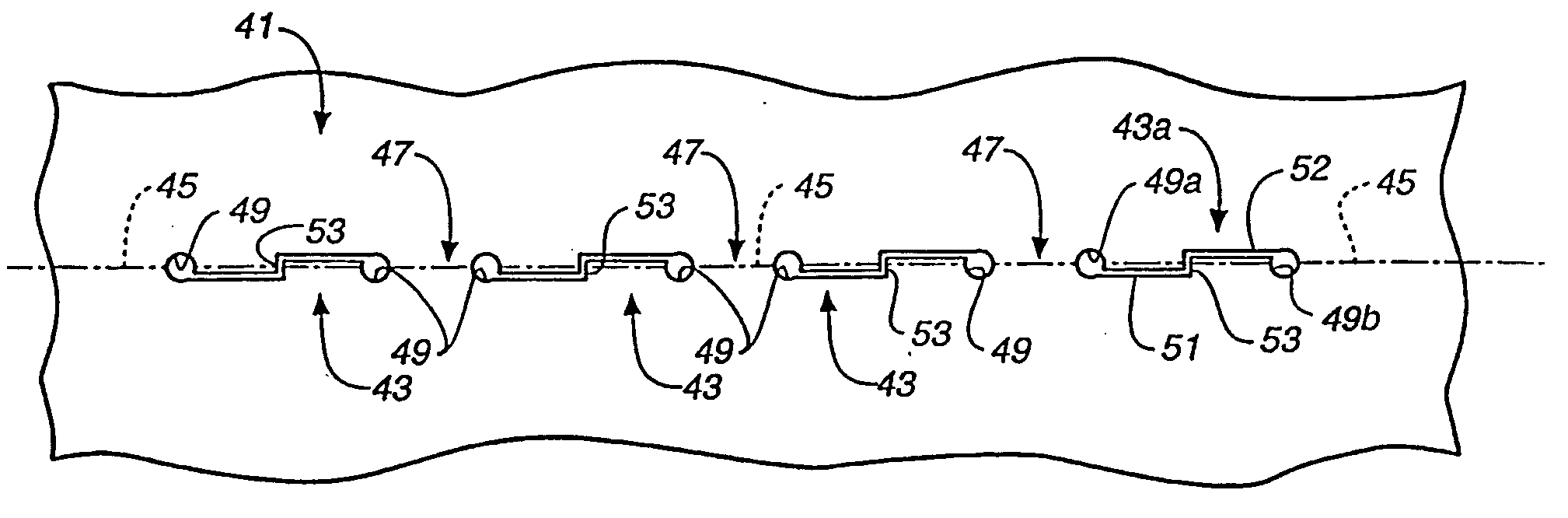

Method for precision bending of sheet of materials, slit sheets fabrication process

InactiveUS20030037586A1Reduce stress concentrationImprove accuracyAdditive manufacturing apparatusConstruction materialSheet materialEngineering

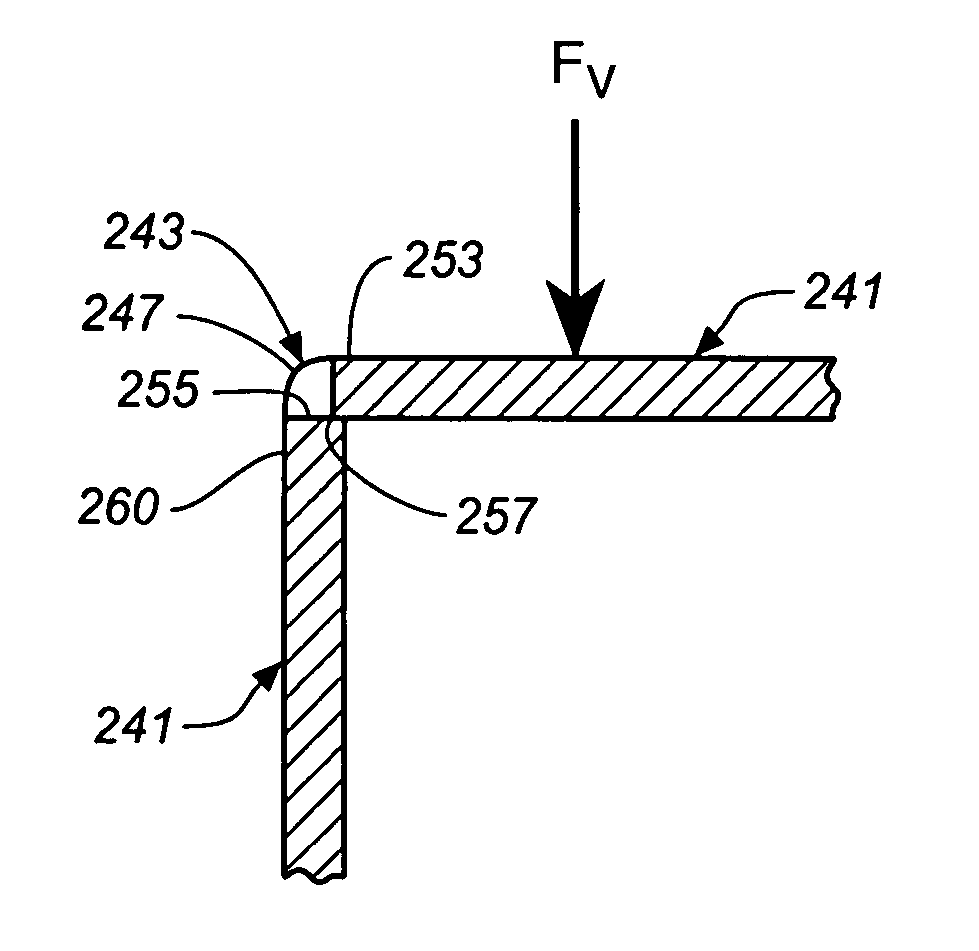

A method for precision bending of a sheet of material (41, 241, 341, 441) along a bend line (45, 245, 345, 445) and the resulting sheet are disclosed. A method includes a step of forming longitudinally extending slits (43, 243, 343, 443) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441) along the bend line (45, 245, 345, 445) with edges (257, 457) engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445). Several slit embodiments (43, 243, 343, 443) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to enhance various fabrication techniques.

Owner:IND ORIGAMI INC CA US

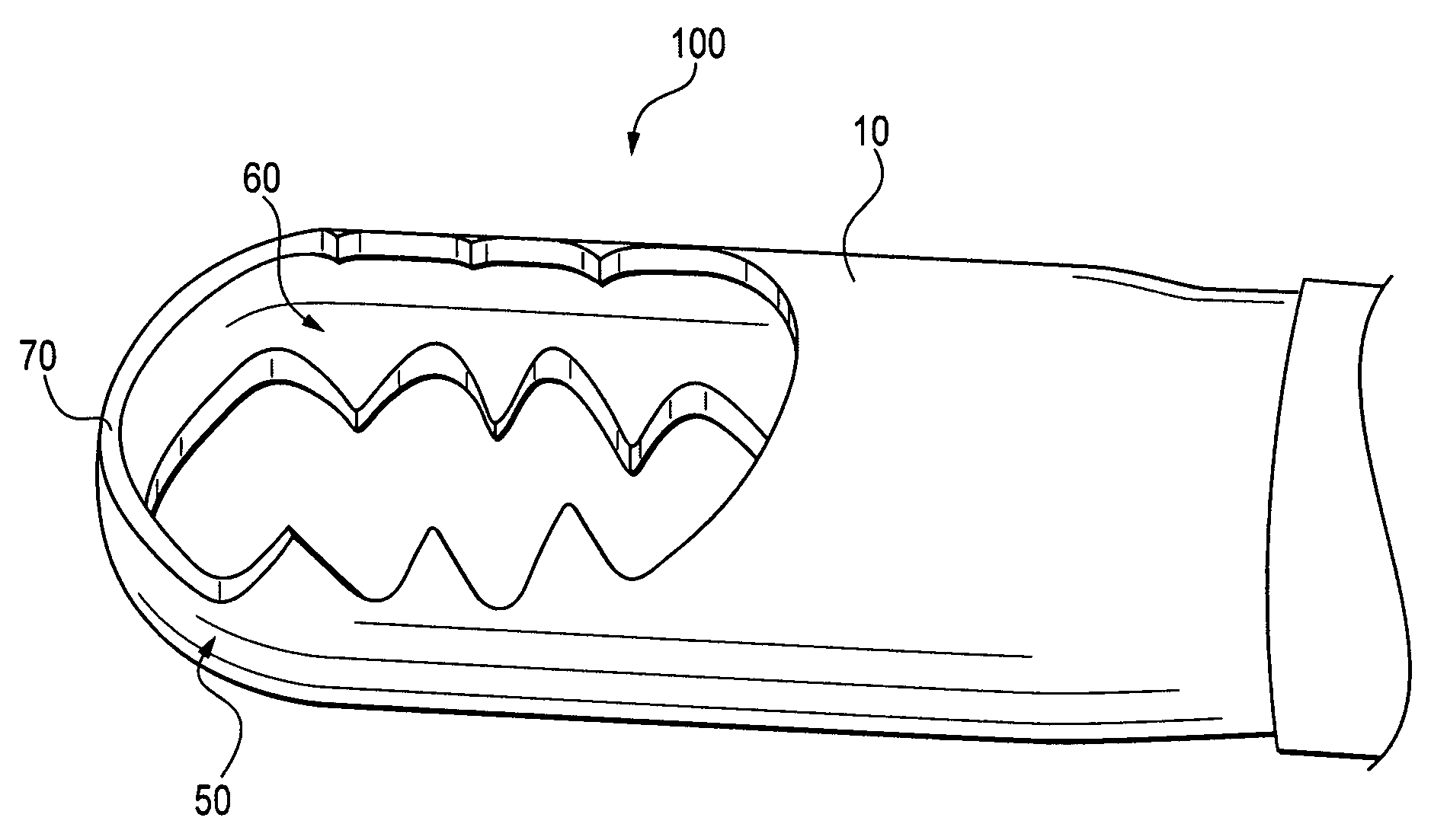

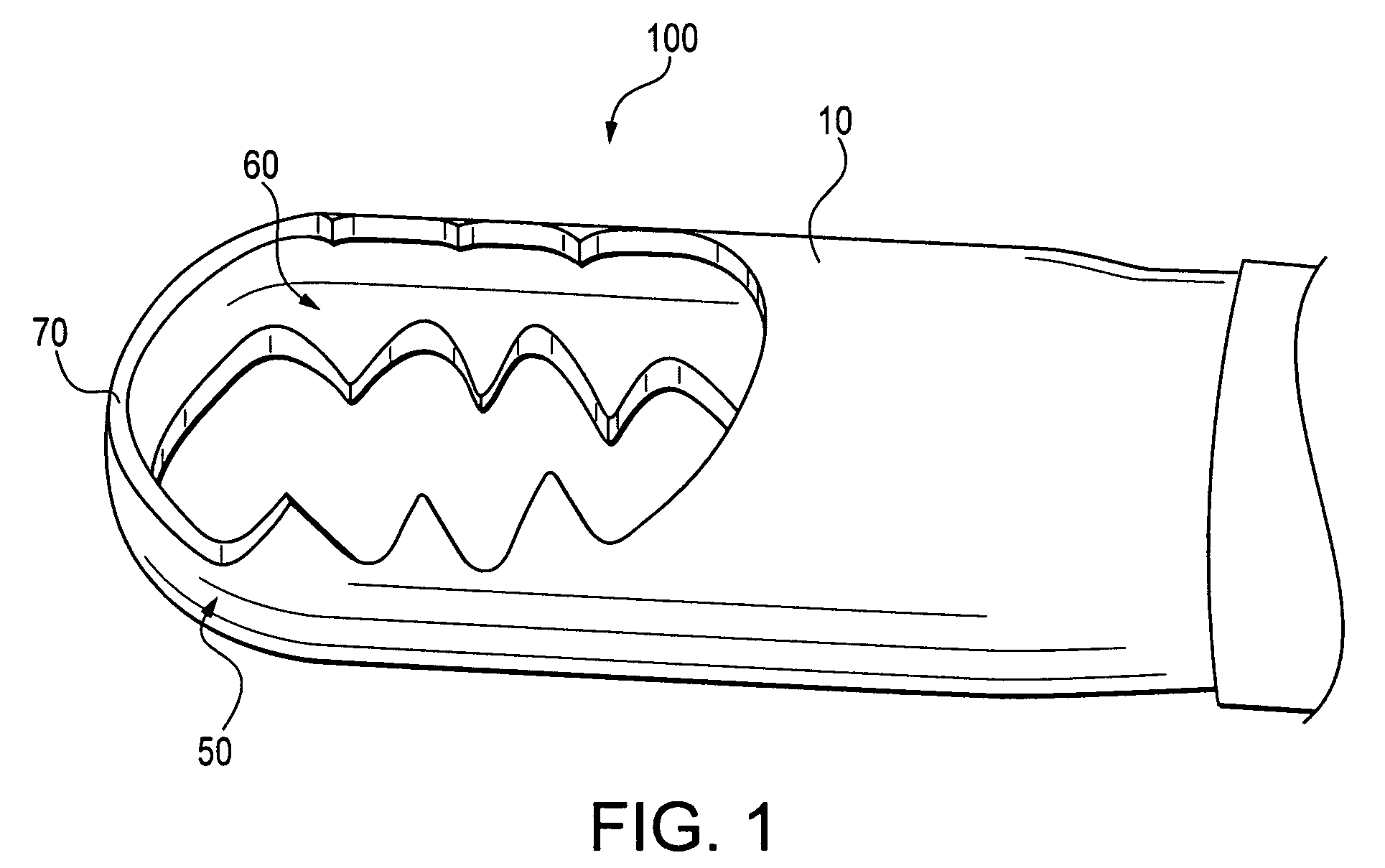

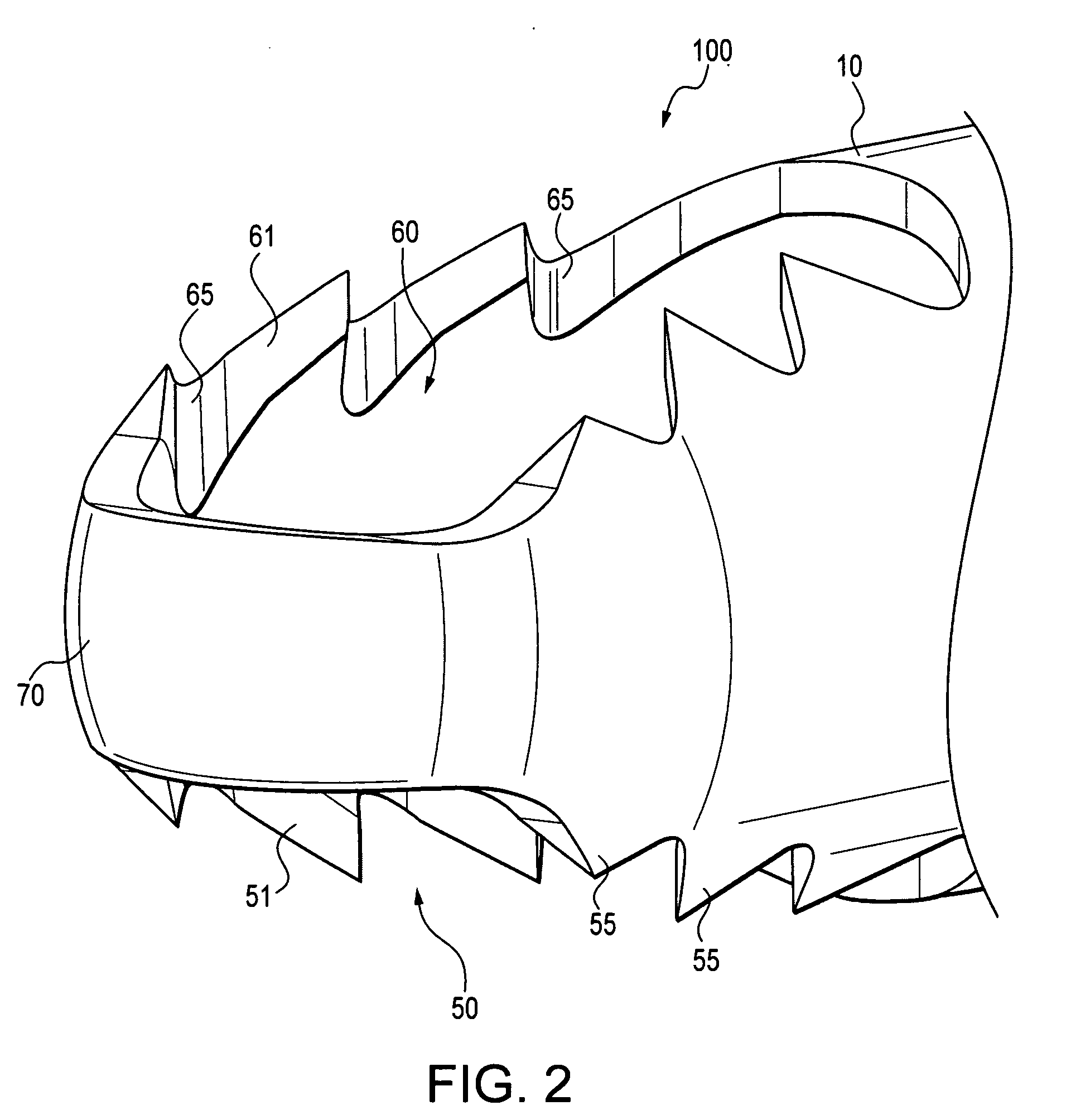

Double cut shaver

InactiveUS20080208194A1Improve resection efficiencySharp teethMetal-working feeding devicesEndoscopic cutting instrumentsEngineeringRazor Blade

Owner:ARTHREX

Techniques for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and sheet therefor

InactiveUS20040134250A1High precisionImprove bending strengthAdditive manufacturing apparatusConstruction materialManufacturing technologyEngineering

A process for designing and manufacturing precision-folded, high strength, fatigue-resistant structures and a sheet therefore. The techniques include methods for precision bending of a sheet of material (41, 241, 341, 441, 541) along a bend line (45, 245, 345, 445,543) and a sheet of material formed with bending strap-defining structures, such as slits or grooves (43, 243, 343, 443, 542), are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves (43, 243, 343, 443, 542) through the sheet of material in axially spaced relation to produce precise bending of the sheet (41, 241, 341, 441,541) when bent along the bend line (45, 245, 345, 445, 543). The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges (257, 457) to be engaged and supported on faces (255, 455) of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line (45, 245, 345, 445, 543). Several slit embodiments (43, 243, 343, 443, 542) suitable for producing edge-to-face engagement support and precise bending are disclosed, as is the use of the slit sheets to produce various three-dimensional structures and to enhance various design and fabrication techniques.

Owner:IND ORIGAMI INC CA US

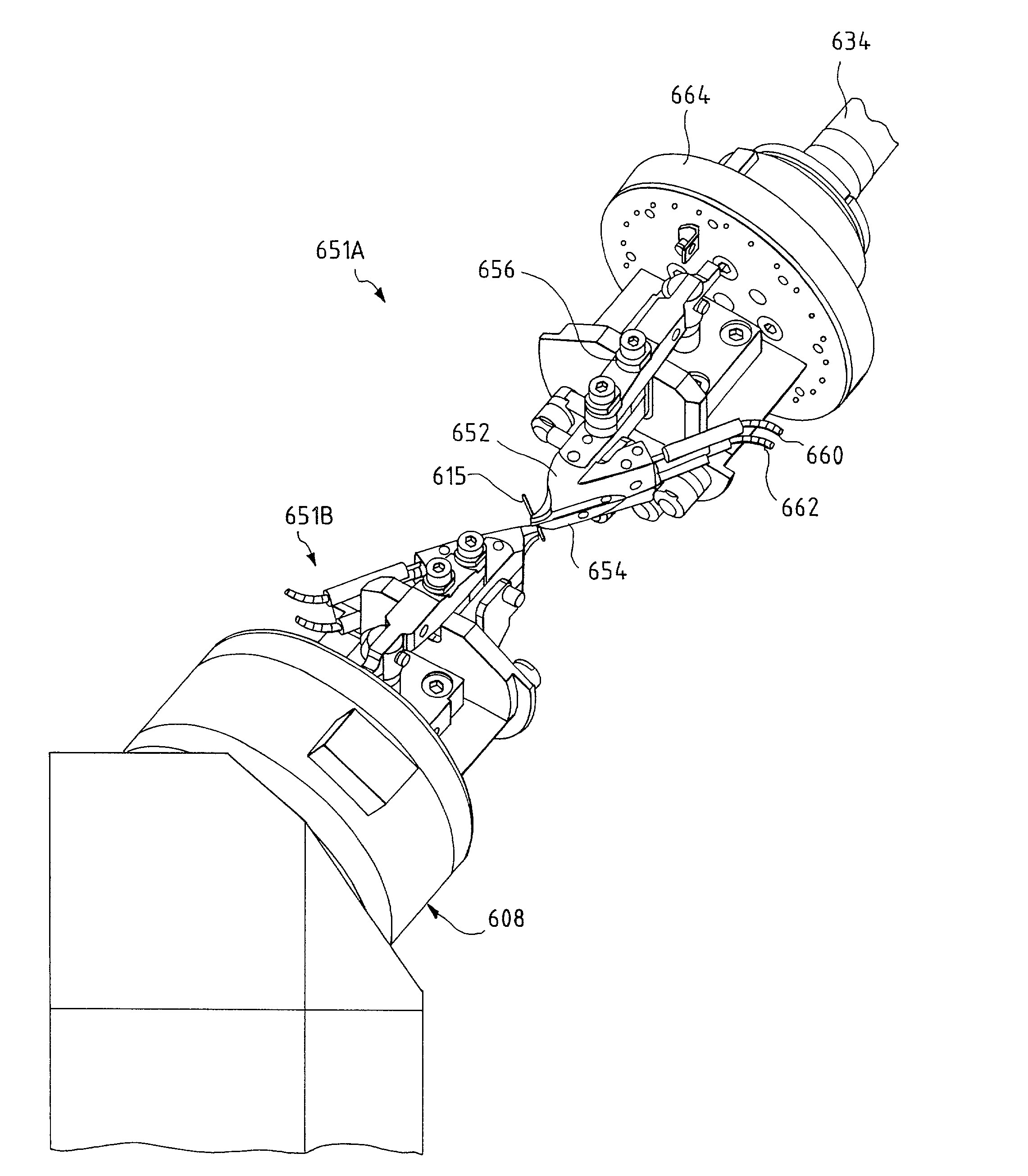

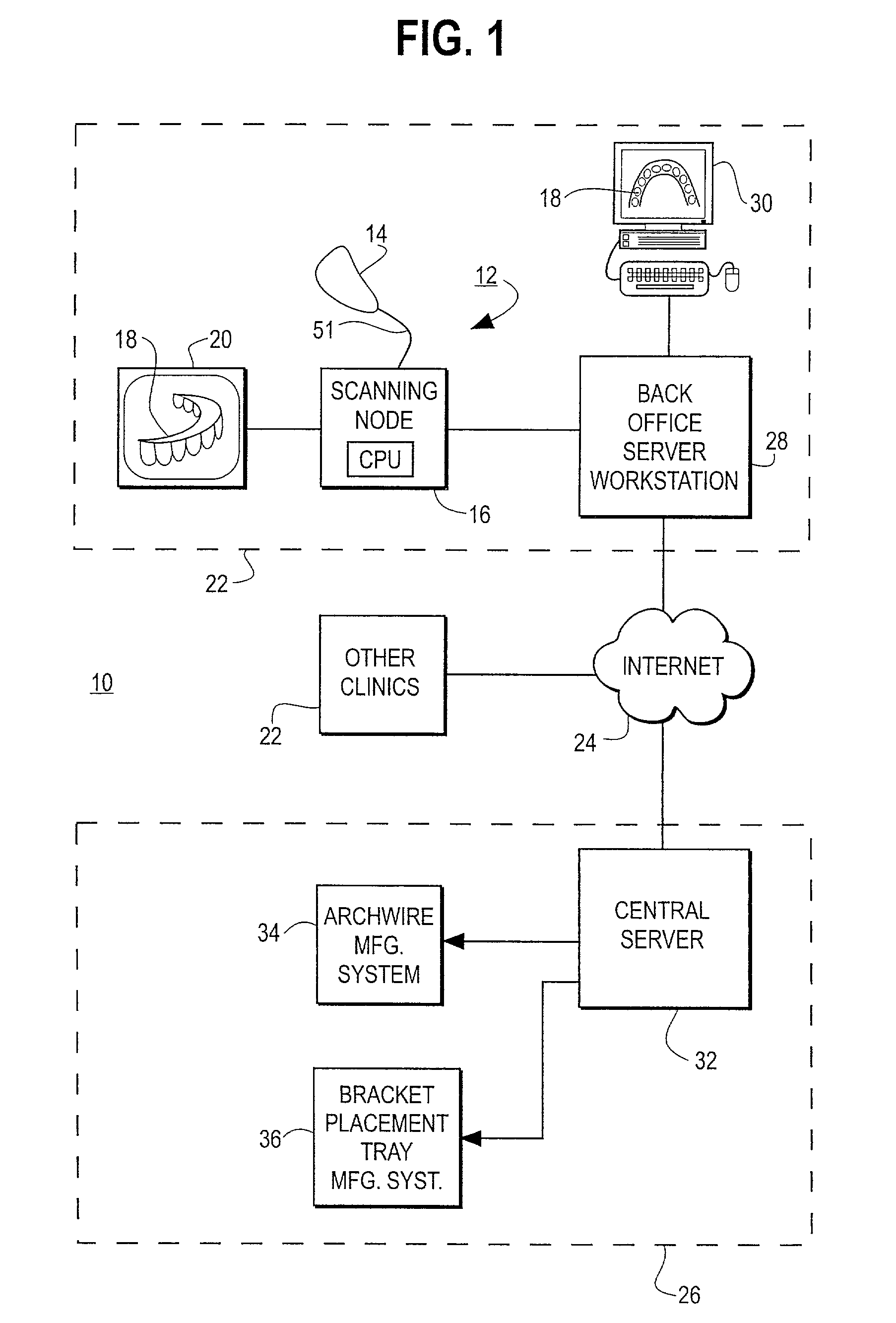

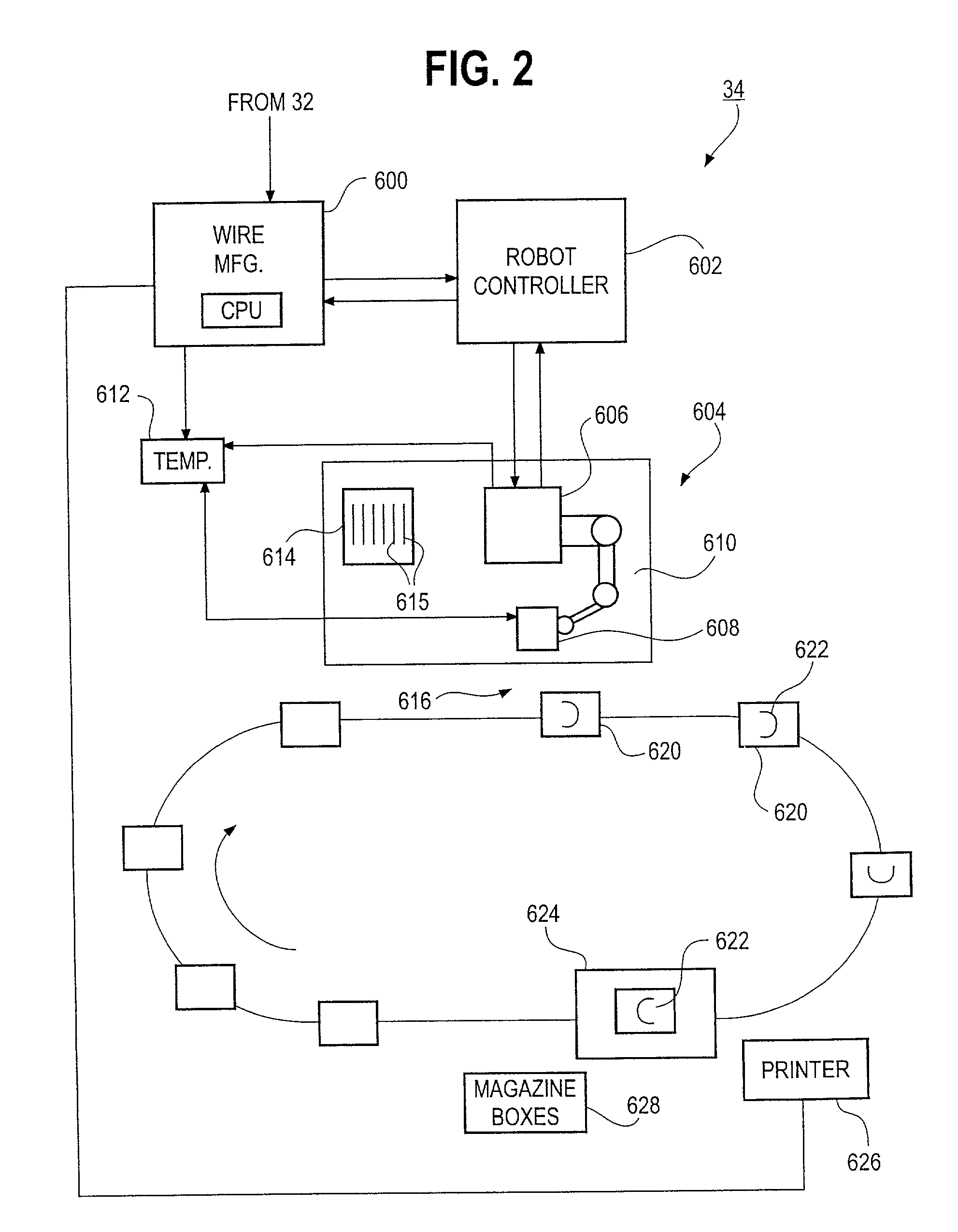

Robot and method for bending orthodontic archwires and other medical devices

A robotic bending apparatus for bending archwires and other types of elongate, bendable medical devices into a desired configuration includes a first gripping tool and a moveable gripping tool. The first gripping tool can be either fixed with respect to a base or table for the robot or positioned at the end of robot am. The moveable gripping tool is mounted to the end of a moveable robot arm having a proximal portion also mounted to the base. The robot preferably comprises a six axis bending robot, in which the distal end of the moveable arm can move relative to the fixed gripping tool about three translational axes and three rotational axes. The gripping tools preferably incorporate force sensors which are used to determine overbends needed to get the desired final shape of the archwire. The robot may also include a resistive heating system in which current flows through the wire while the wire is held in a bent condition to heat the wire and thereby retain the bent shape of the wire. A magazine for holding a plurality of straight archwires needing to be bent and a conveyor system for receiving the wires after the bending process is complete are also described. The robot bending system is able to form archwires with any required second and third order bends quickly and with high precision. As such, it is highly suitable for use in a precision appliance-manufacturing center manufacturing a large number of archwires (or other medical devices or appliances) for a distributed base of clinics.

Owner:ORAMETRIX

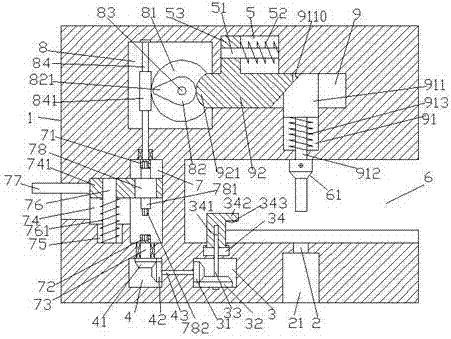

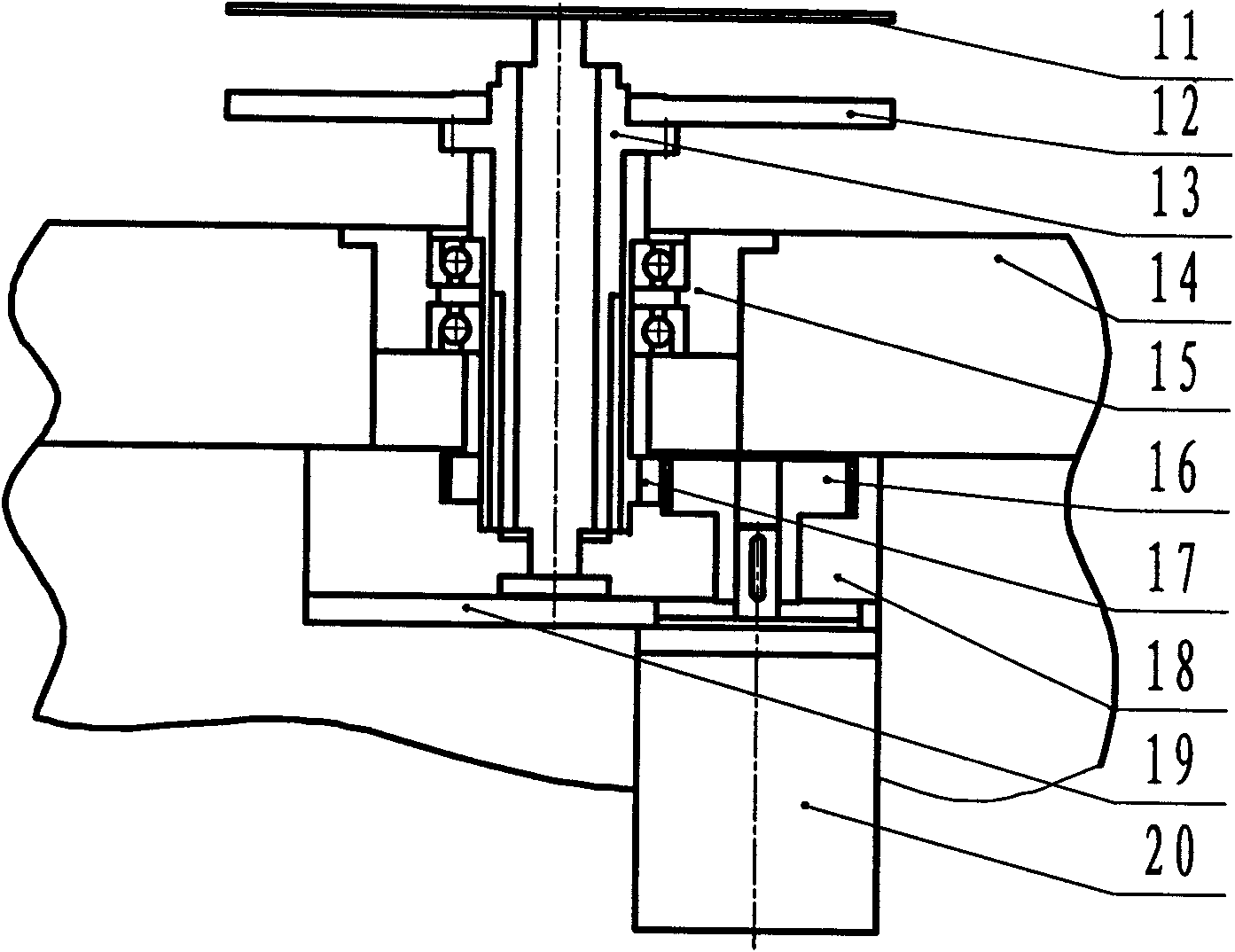

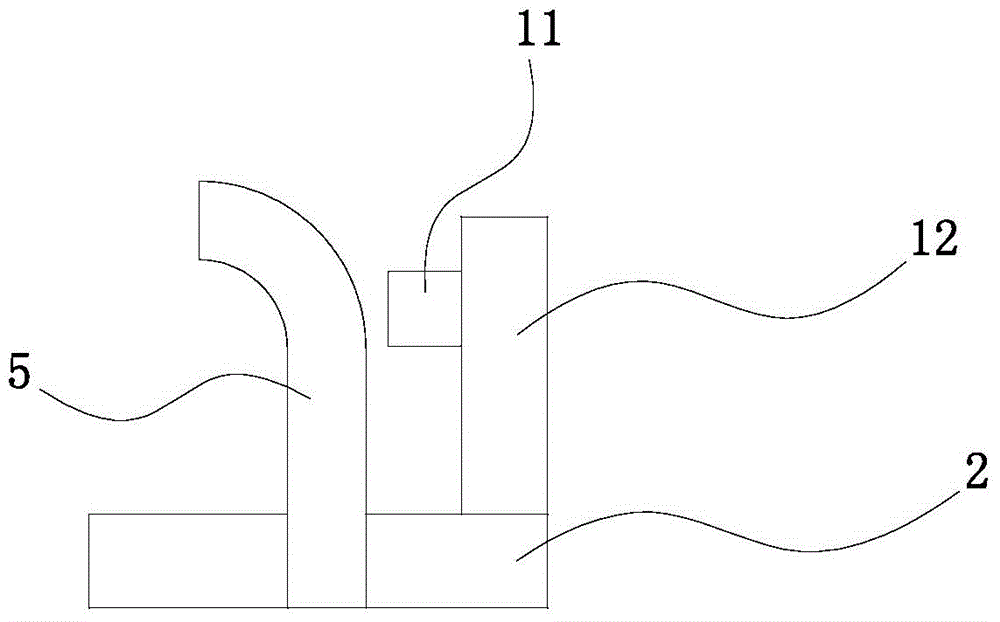

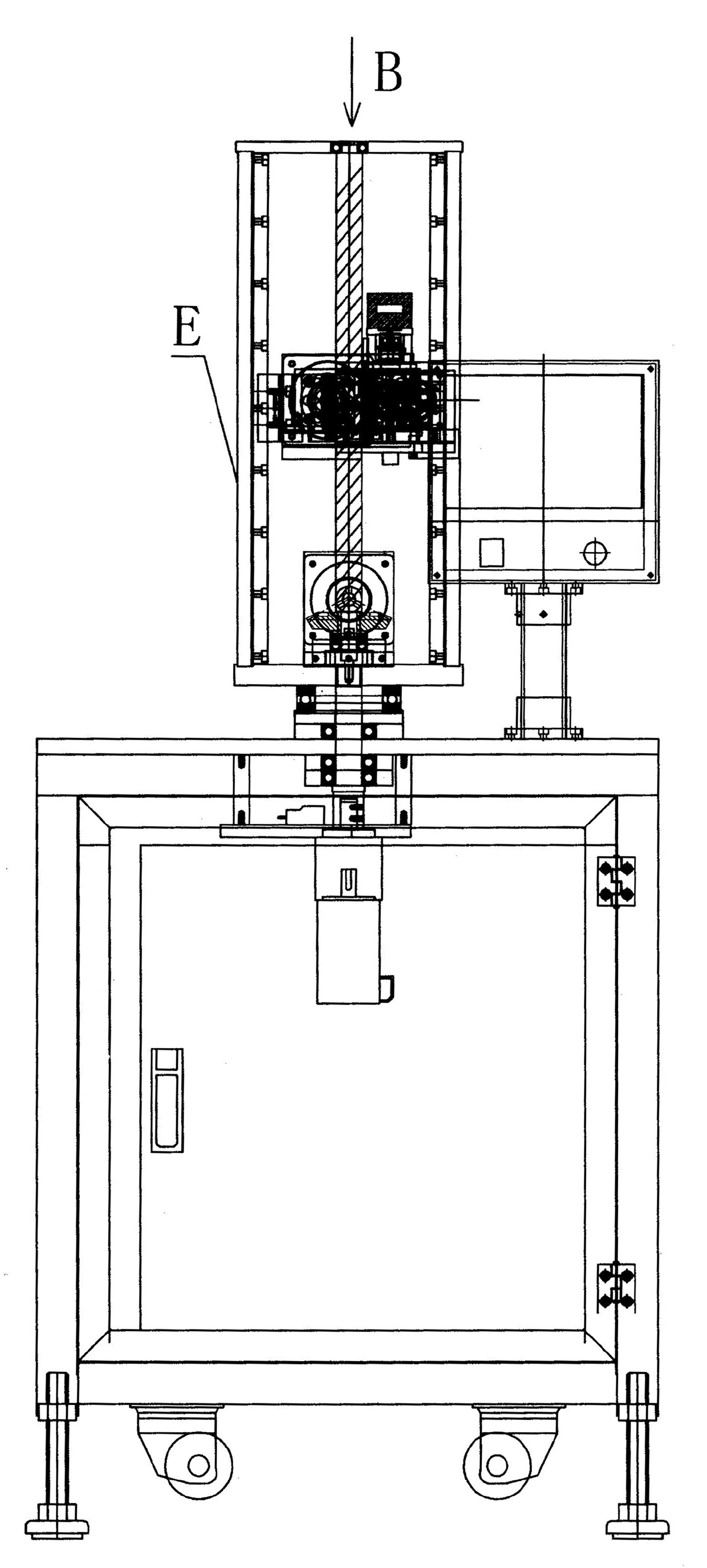

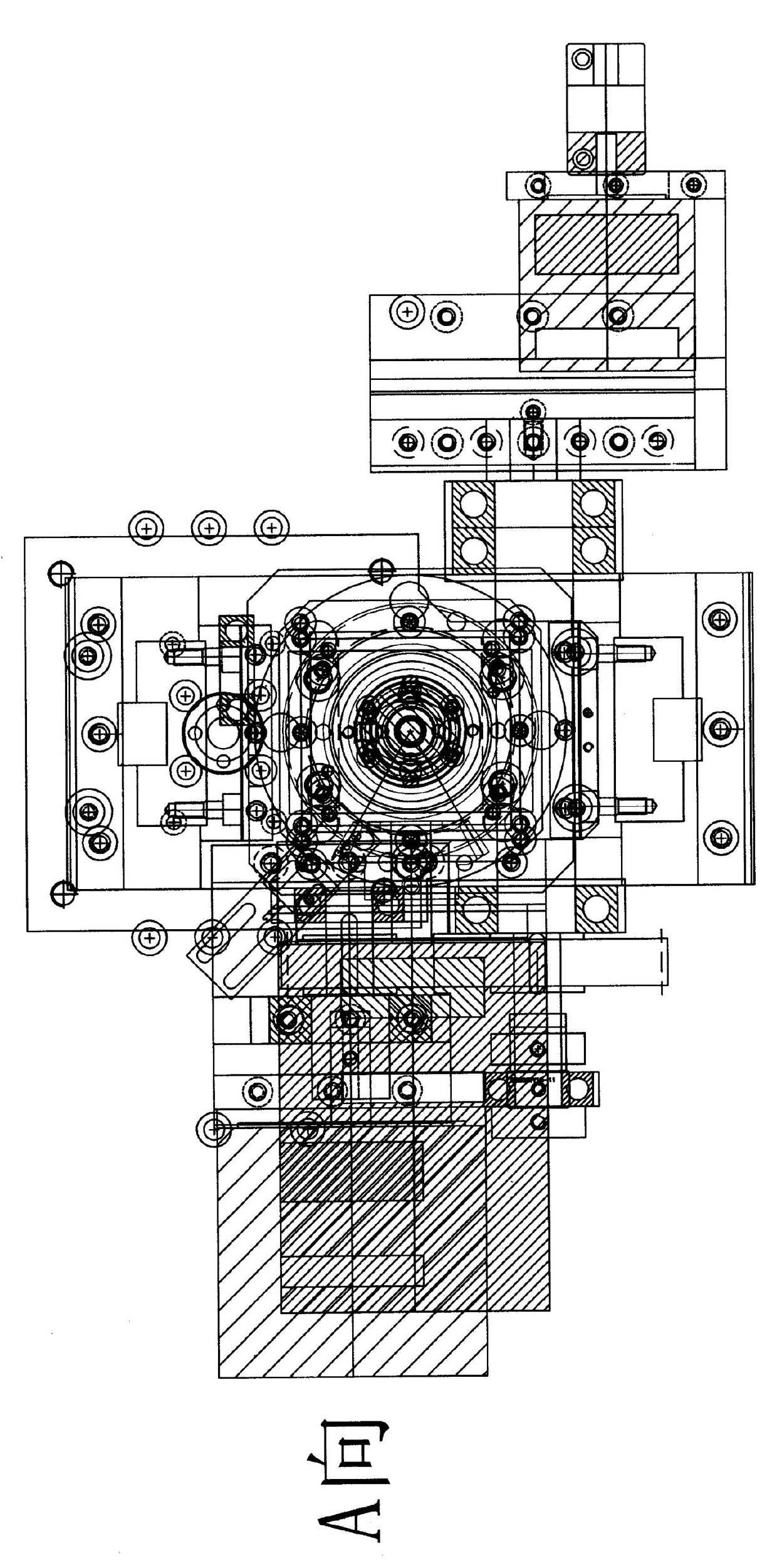

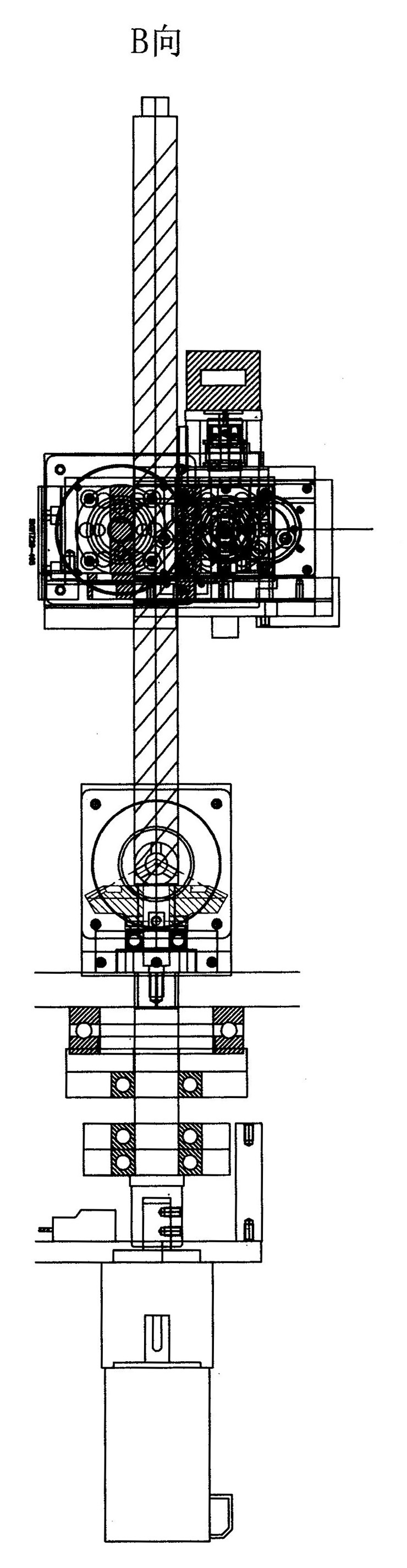

Simple and convenient thin metal sheet drilling machine device

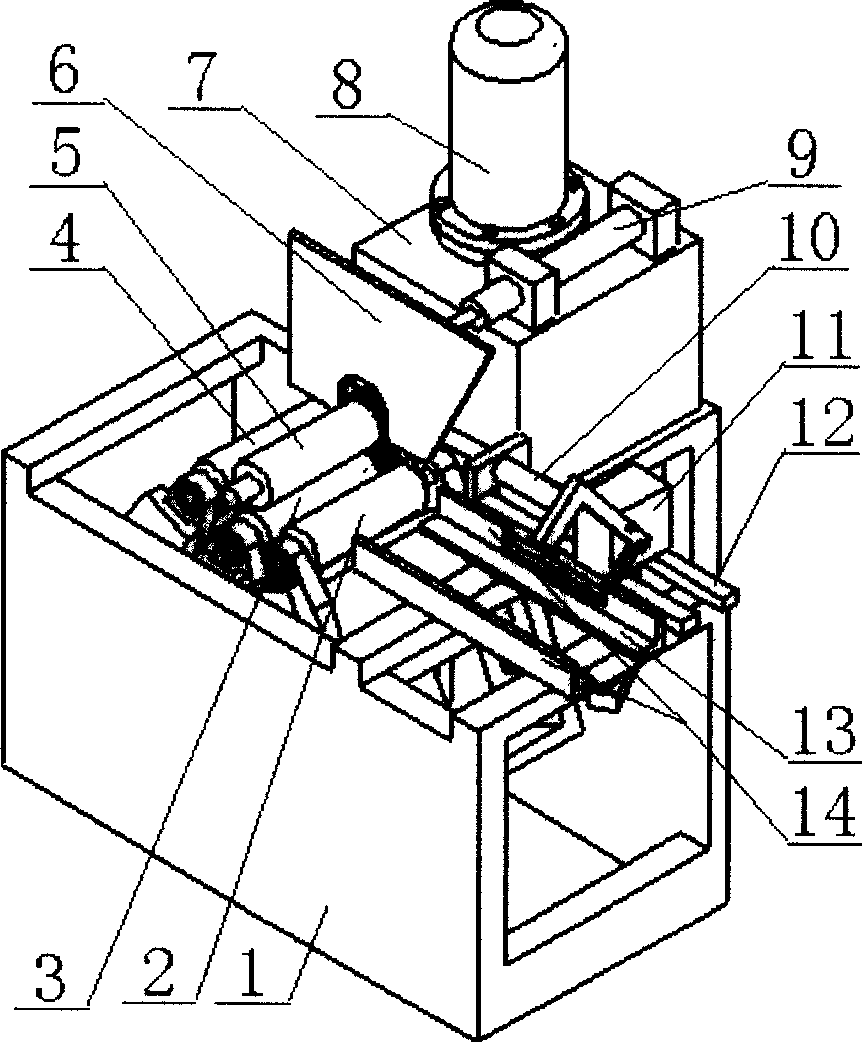

InactiveCN106984698AImplement manual controlRealize manual control up and down switching mobile workMetal-working feeding devicesPositioning devicesThin metalDrive shaft

The invention discloses a simple and convenient thin metal sheet drilling machine device. The device comprises a device body. An operating groove is formed in the end face of the right side of the device body. A switching cavity is formed in the portion, on the left side of the operating groove, of the device body. A first inner spline shaft and a second inner spline shaft are arranged on the inner walls of the upper side and the lower side of the switching cavity correspondingly. A first sliding groove is formed in the inner wall of the left side of the switching cavity. A sediment groove is formed in the inner bottom wall of the first sliding groove. A first guide rod is arranged between the inner bottom wall of the sediment groove and the inner top wall of the first sliding groove. A first sliding block extending rightwards is slidably connected to the first guide rod in a matched mode. A first spring is arranged on the outer surface of the first guide rod located at the bottom of the first sliding block in a surrounding mode. A right extending section of the first sliding block extends into the switching cavity and abuts against the inner wall of the right side of the switching cavity in a sliding fit mode. A motor is arranged in the first sliding block in the switching cavity. Driving shafts are arranged at the ends of the upper side and the lower side of the motor. A transmission cavity is formed in the portion, above the switching cavity, in the device body. The device is simple in structure, convenient to operate, low in manufacturing and maintaining cost, high in drilling speed and stability and good in drilling quality.

Owner:衢州市洼帝尔数控设备有限公司

Method for phototyping parts from sheet metal

InactiveUS6412325B1Easy to bendShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

A method for prototyping parts from a sheet metal blank in which the sheet metal has at least two spaced edges. The method includes the step of forming a plurality of longitudinally aligned slots through the sheet metal blank to form a bend line extending between two spaced edges on the sheet metal blank. The slots are preferably formed by laser cutting. The sheet metal blank is then bent along the bend line to form the prototype.

Owner:3 DIMENSIONAL SERVICES

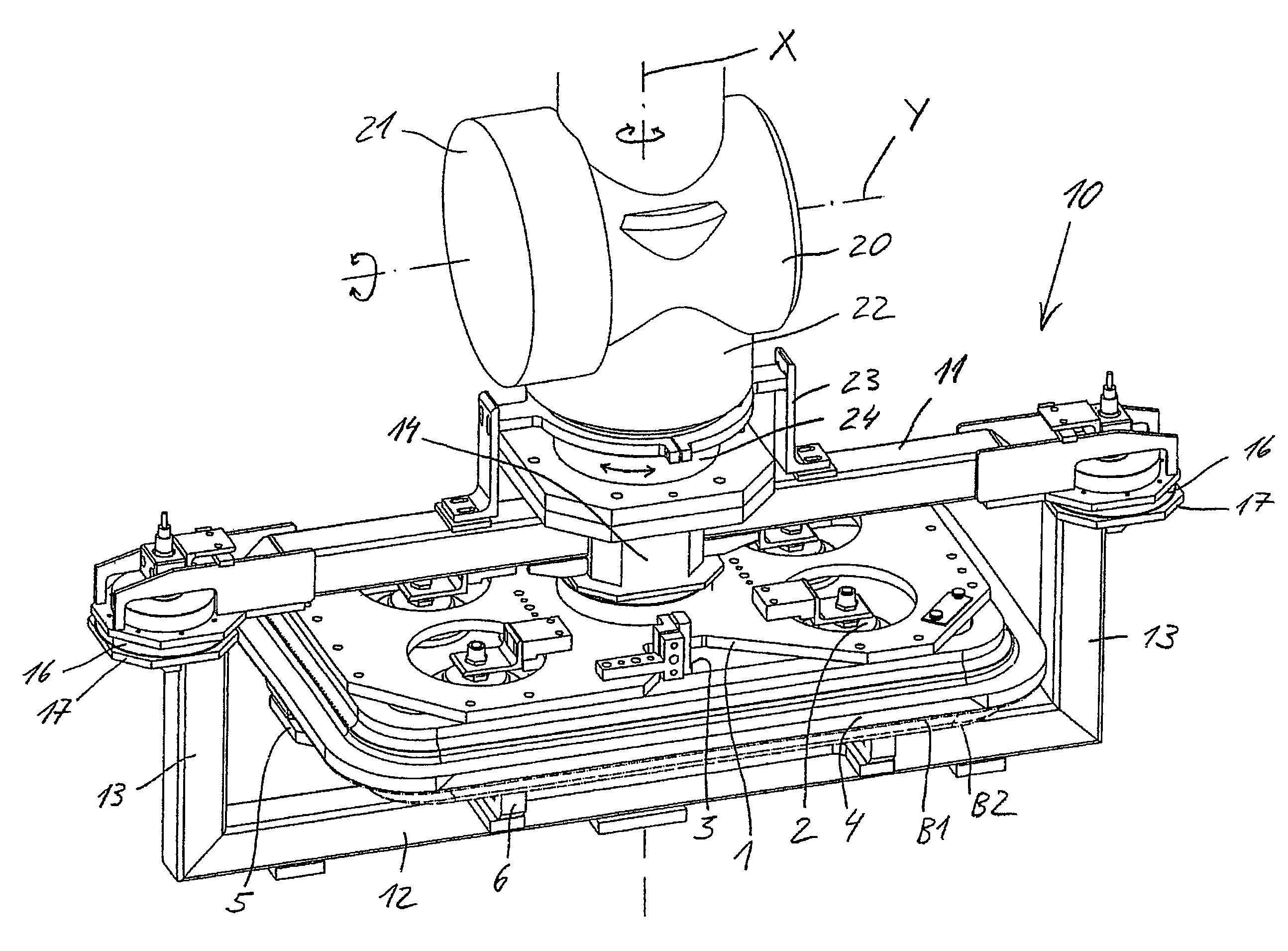

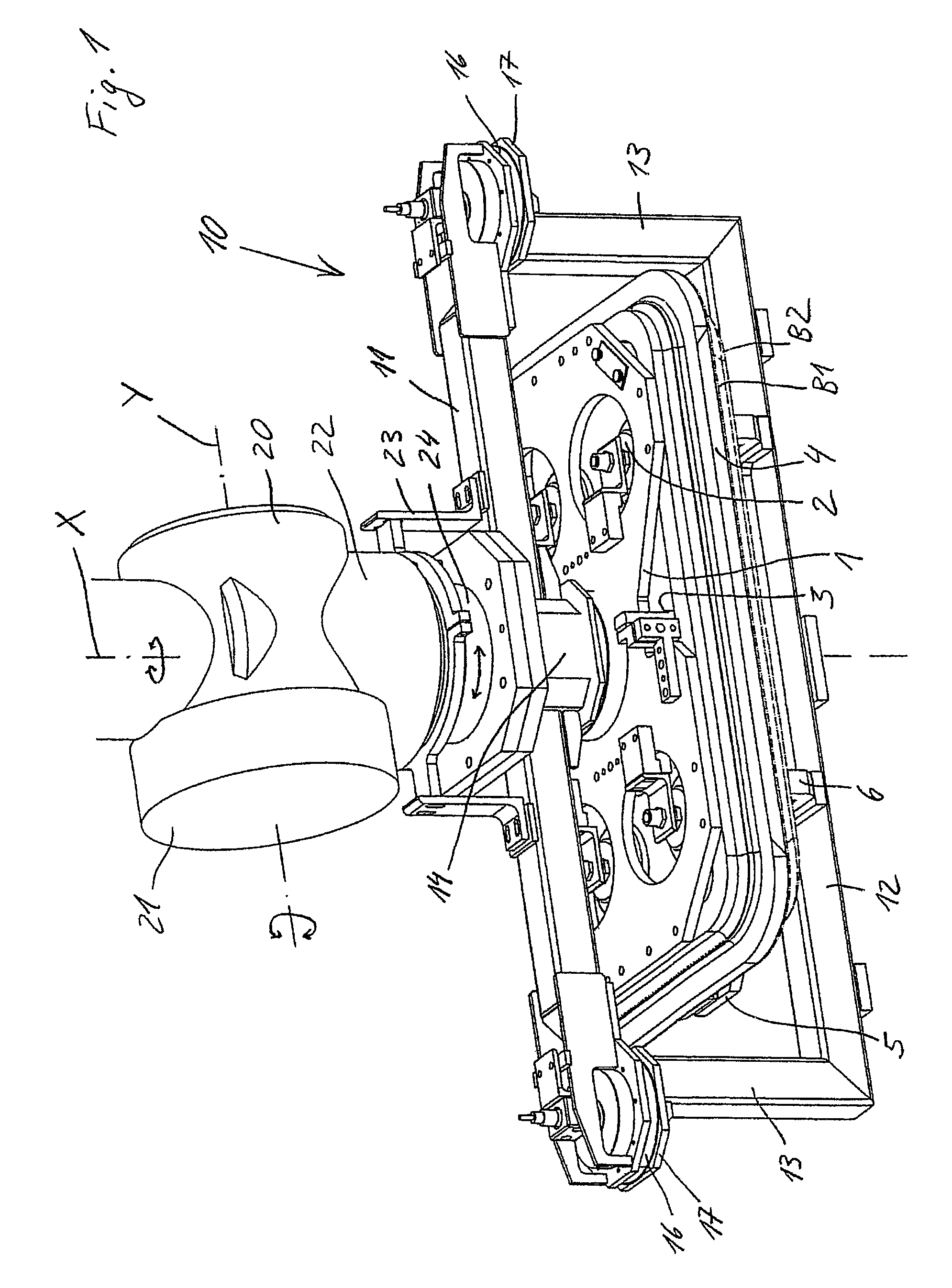

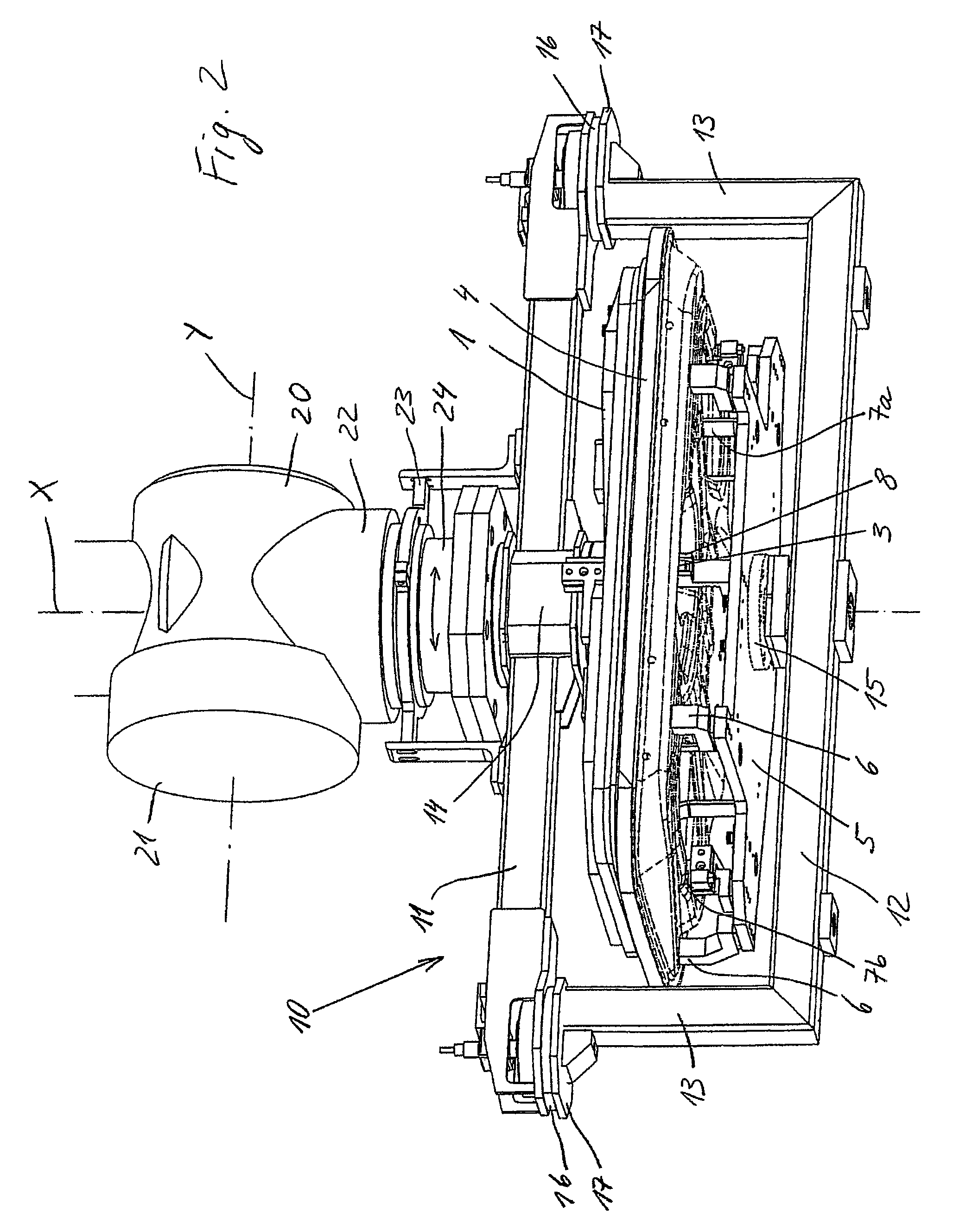

Clamping device for holding and clamping components

ActiveUS8720876B2Avoid that disruptive contoursHigh mechanical strengthMetal-working feeding devicesGripping headsMechanical engineering

A clamping device for components to be joined, which clamping device comprises: a first component holder for a first component, a second component holder for a second component, and a clamping structure which secures the component holders relative to one another in a joining position, and when the component holders are in the joining position, the clamping structure extends from an external face of the first component holder to an external face of the second component holder facing away from the external face of the first component holder and extends respectively around a peripheral edge of the component holders.

Owner:FFT PRODIONSSYST

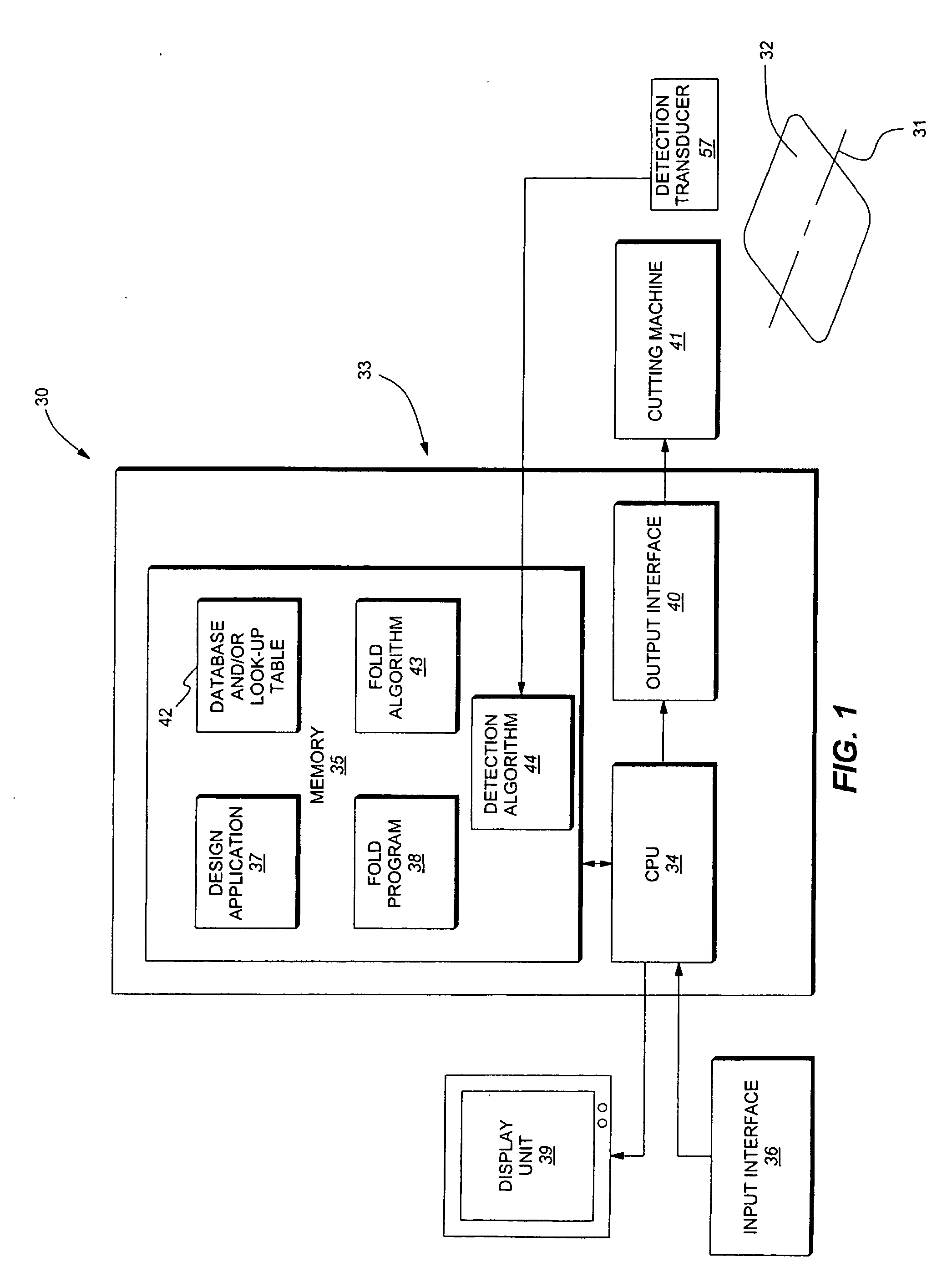

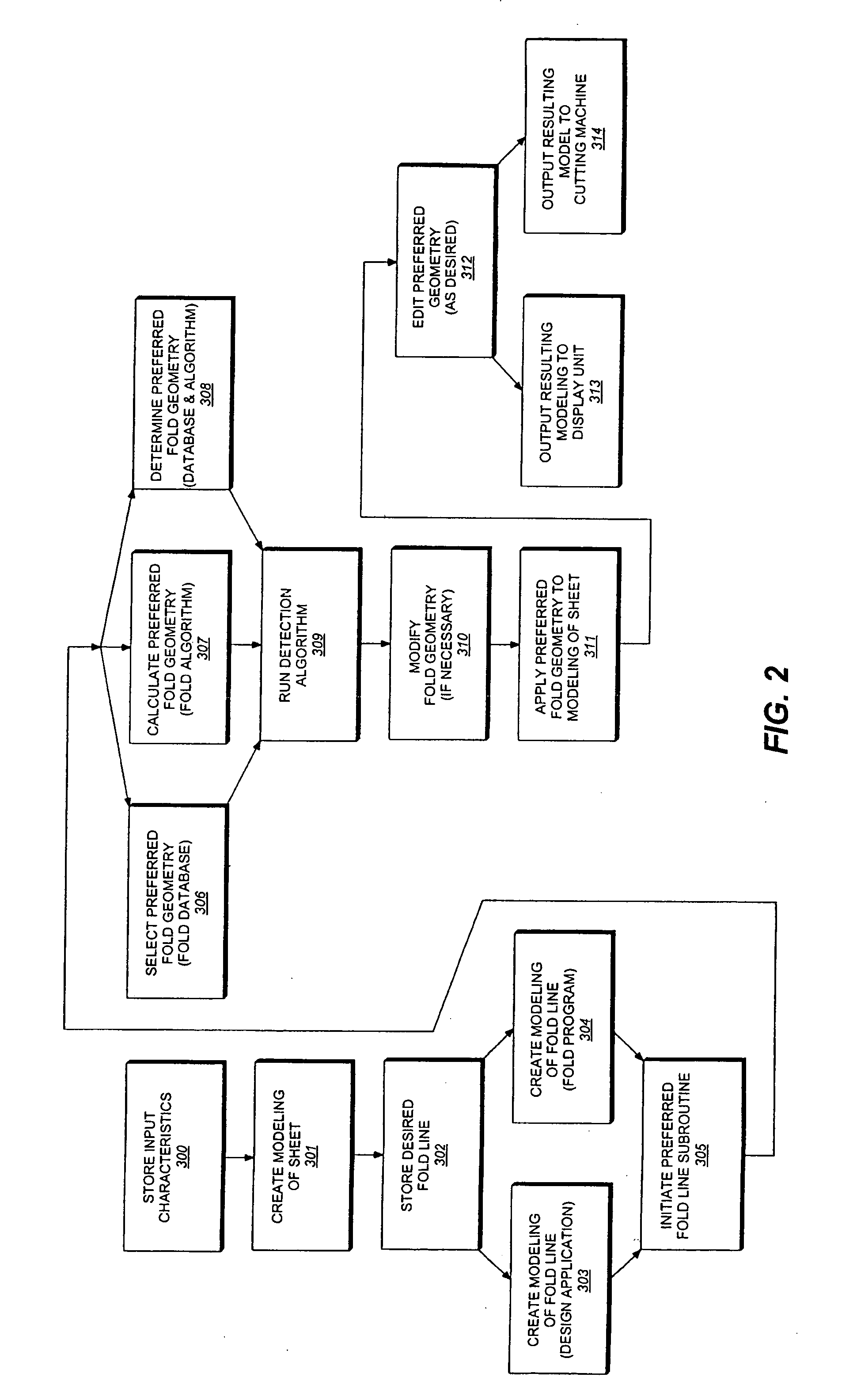

Method of designing fold lines in sheet material

InactiveUS20050005670A1Metal-working feeding devicesComputation using non-denominational number representationEngineeringComputer program

A method of designing fold lines in sheet material includes the steps defining the desired fold line in a parent plane on a drawing system, and populating the fold line with a fold geometry including a series of cut zones that define a series of connected zones configured and positioned relative to the fold line whereby upon folding the material along the fold line produces edge-to-face engagement of the material on opposite sides of the cut zones. Alternatively, the method may include the steps storing a plurality of cut zone configurations and connected zone configurations having differing dimensions and / or shapes, defining a desired fold line in a parent plane on a drawing system, selecting a preferred cut zone and / or a preferred connected zone which have a desired shape and scale, locating a preferred fold geometry along the fold line, the preferred fold geometry including the selected cut zone and the selected connected zone, and relocating, resealing and / or reshaping the preferred fold geometry to displace, add and / or subtract at least one of the connected zones, whereby upon folding the material along the fold line produces edge-to-face engagement of the material on opposite sides of the cut zones. A computer program product and a system configured for implementing the method of designing fold lines in sheet material is also disclosed.

Owner:IND ORIGAMI INC CA US

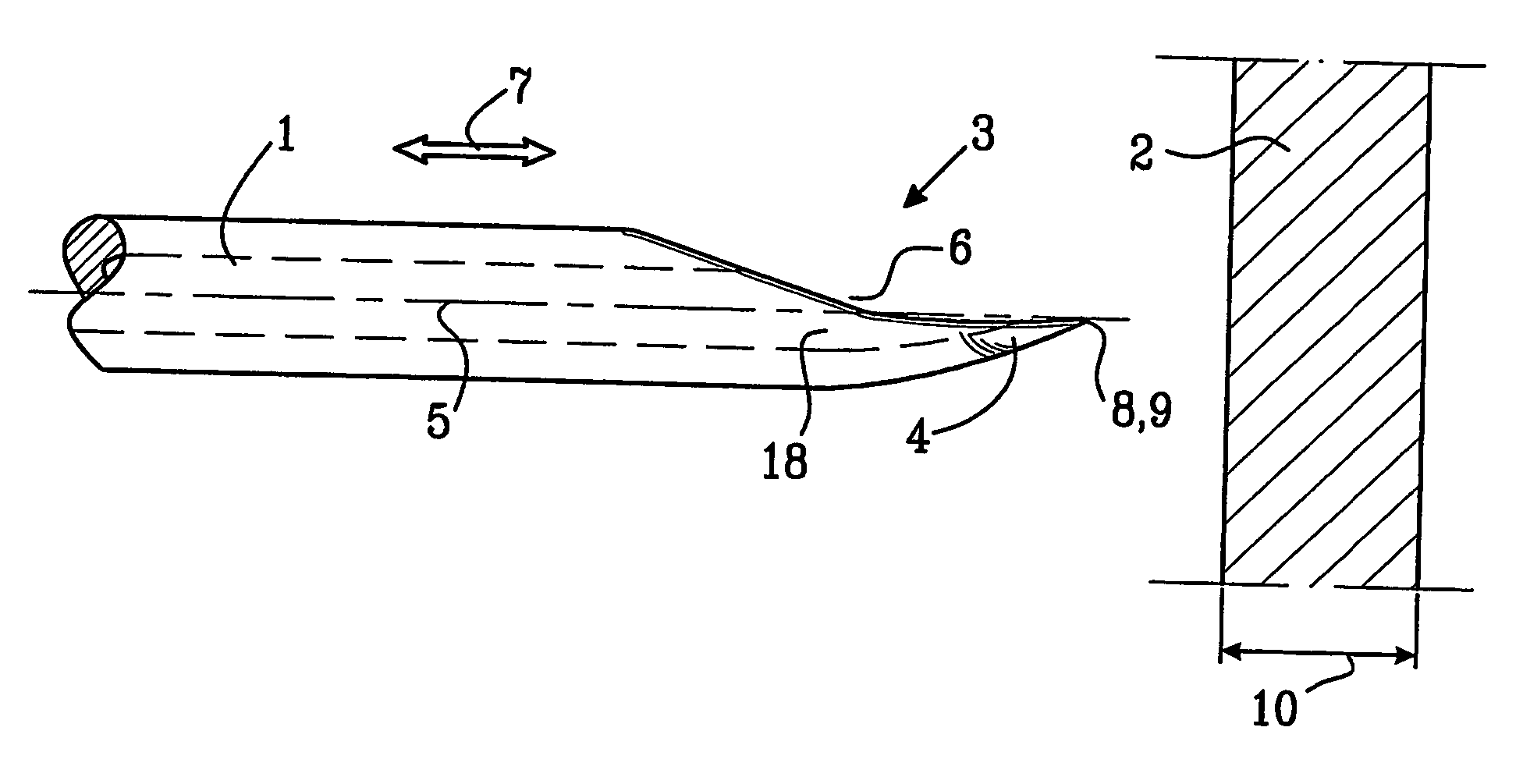

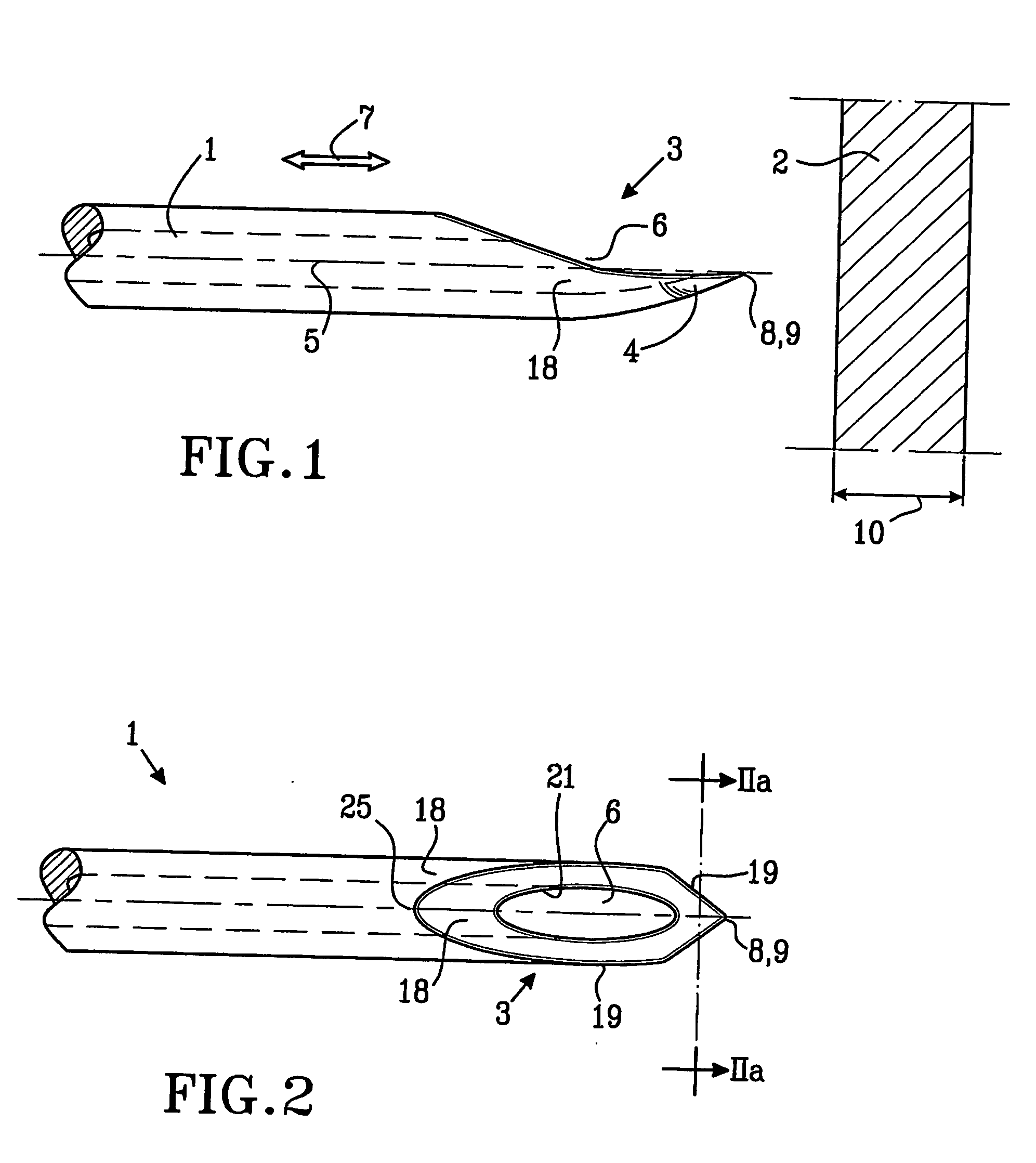

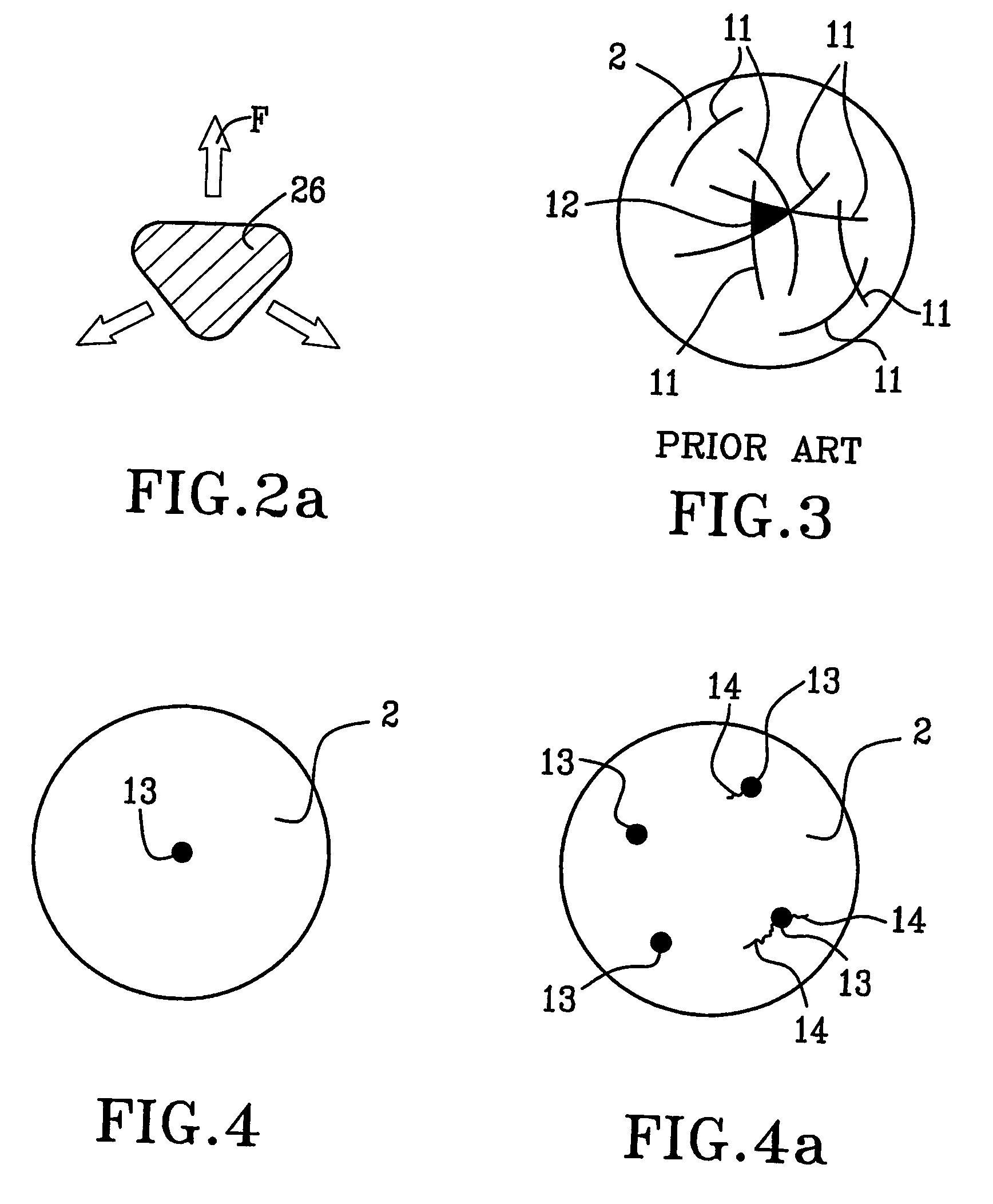

Needle for penetrating a membrane

ActiveUS20060276759A1Reduce riskMitigate such drawbackMetal-working feeding devicesMedical devicesEngineeringMechanical engineering

A needle 1 for penetrating a membrane 2, having a pointed end 3 provided with a penetrating tip 4 and with an opening 6 for letting a liquid in and / or out in a main direction 7 which is substantially parallel to the longitudinal extension of the needle 1. The penetrating tip 4 is designed with a substantially point-shaped edge 8 to initially prick the membrane when the membrane is penetrated. The outer edges 19 present on the pointed end 3 in the area from the point-shaped edge 8 to a position beyond the opening 6 are rounded so that after the initial penetration the pointed end 3 will push the membrane material away rather than cutting the membrane material.

Owner:CARMEL PHARMA

Method and apparatus for forming sheet metal

InactiveUS7536892B2Improve accuracyShort timeMetal-working feeding devicesPositioning devicesMechanical engineeringMetal

In order to provide a method and apparatus for forming a sheet metal, in which a three-dimensional product such as a prototype for commercialized press-forming can be formed in short time without limitations as to the shape and with high accuracy, preventing body wrinkles or reduction of the sheet thickness,a process of: performing drawing-forming to a predetermine height by pushing the forming punch having a desired shape in the sheet thickness direction with the edges of the blank workpiece being clamped; performing shape-forming with the shaping tool in the opposite side to the forming punch by increasing a clamping pressure to lock movement of a material with the forming punch being pushed; performing drawing-forming again by decreasing the clamping pressure and raising the forming punch by a desired height; and performing shape-forming with the shaping tool by increasing the clamping pressure to lock movement of a material, is repeated at least once.

Owner:AMINO CORP (JP)

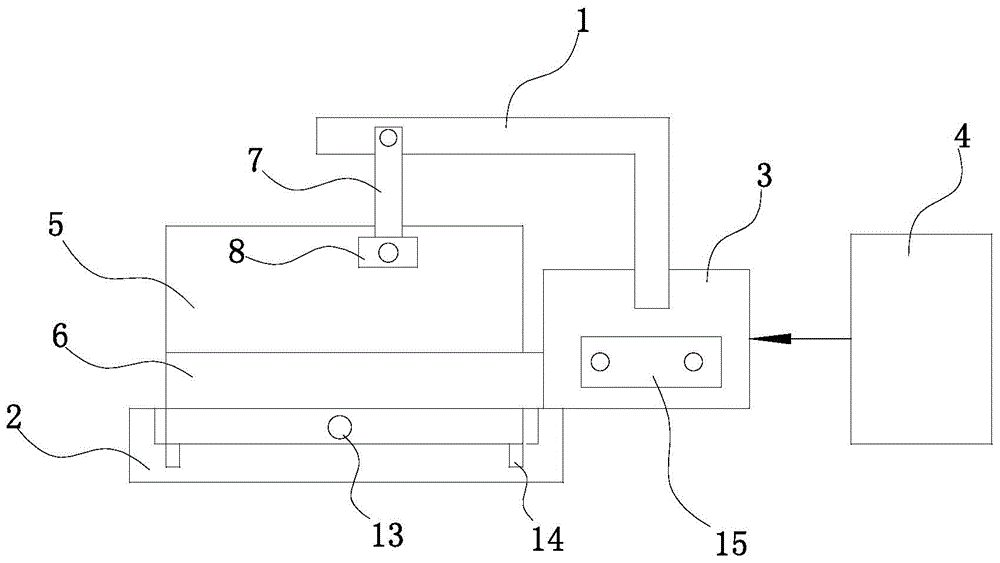

Full-automatic fixed-length cutting device of metallic hose

InactiveCN101623780ARealize fixed-length automatic cuttingIncrease productivityMetal-working feeding devicesTube shearing machinesFixed lengthMetal hose

The invention relates to a full-automatic fixed-length cutting device of a metallic hose, comprising a base, a strip conveyer and a conveying chute. The strip conveyer is used for conveying the metallic hose and is erected on the base; the conveying chute vertically penetrates through the strip conveyer which is provided with a positioning mechanism, a conveying mechanism and a clamp, wherein the conveying mechanism sends the metallic hose into the clamp and pulls the metallic hose away for a certain distance, and then, the metallic hose is cut by a cutting mechanism which is arranged on the base. The invention realizes the automatic fixed-length cutting of the metallic hose, greatly improves the production efficiency, and achieves higher consistency degree of a cut product.

Owner:严光辉

Precision-folded, high strength, fatigue-resistant structures and sheet therefor

Precision-folded, high strength, fatigue-resistant structures and a sheet therefore are disclosed. To form the structures, methods for precision bending of a sheet of material along a bend line and a sheet of material formed with bending strap-defining structures, such as slits or grooves, are disclosed. Methods include steps of designing and then separately forming longitudinally extending slits or grooves through the sheet of material in axially spaced relation to produce precise bending of the sheet when bent along the bend line. The bending straps have a configuration and orientation which increases their strength and fatigue resistance, and most preferably slits or arcs are used which causes edges to be engaged and supported on faces of the sheet material on opposite sides of the slits or arcs. The edge-to-face contact produces bending along a virtual fulcrum position in superimposed relation to the bend line. Several slit embodiments suitable for producing edge-to-face engagement support and precise bending are disclosed. With these teachings, forming numerous three-dimensional load-bearing structures from a two dimensional sheet are enabled. Examples of straight and curved beams, chassis, and exoskeletons are disclosed.

Owner:IND ORIGAMI INC CA US

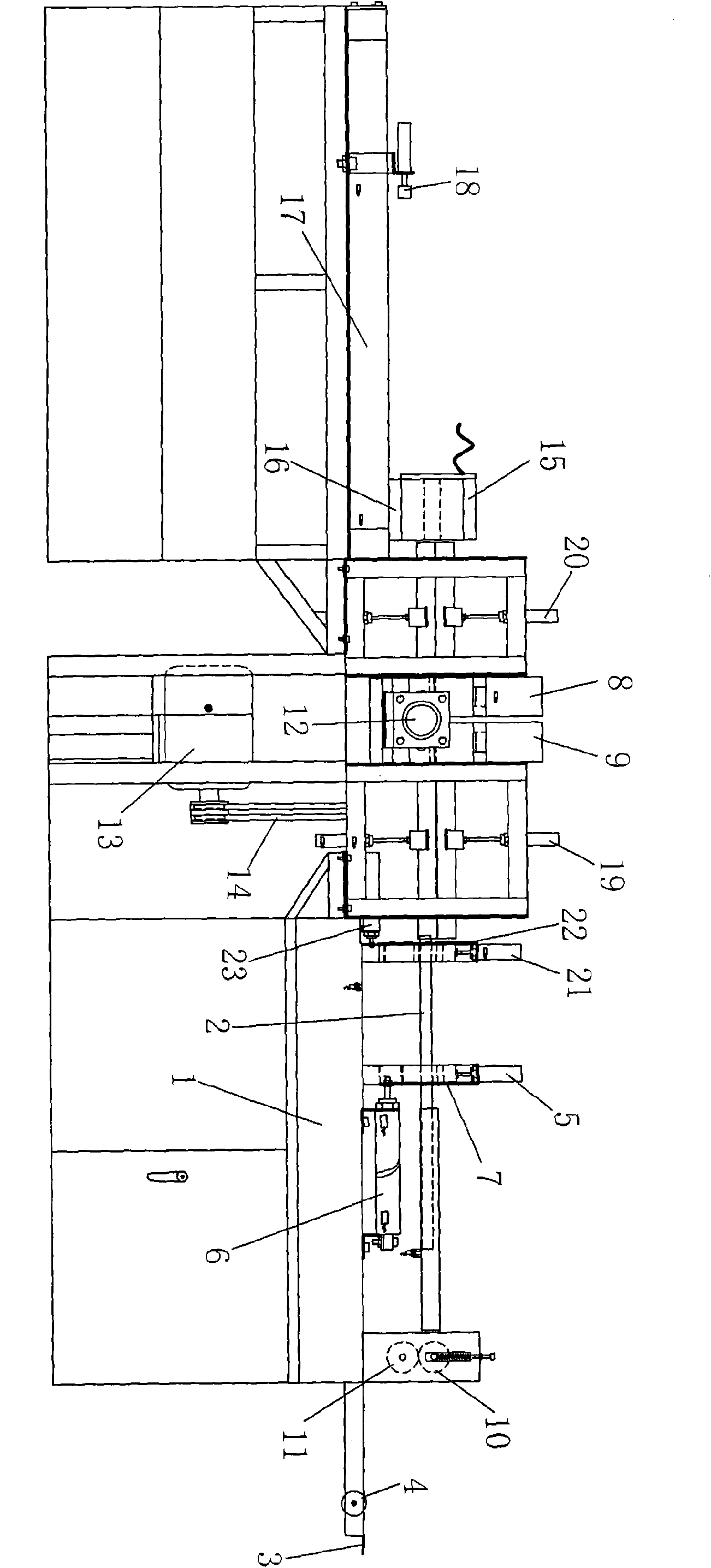

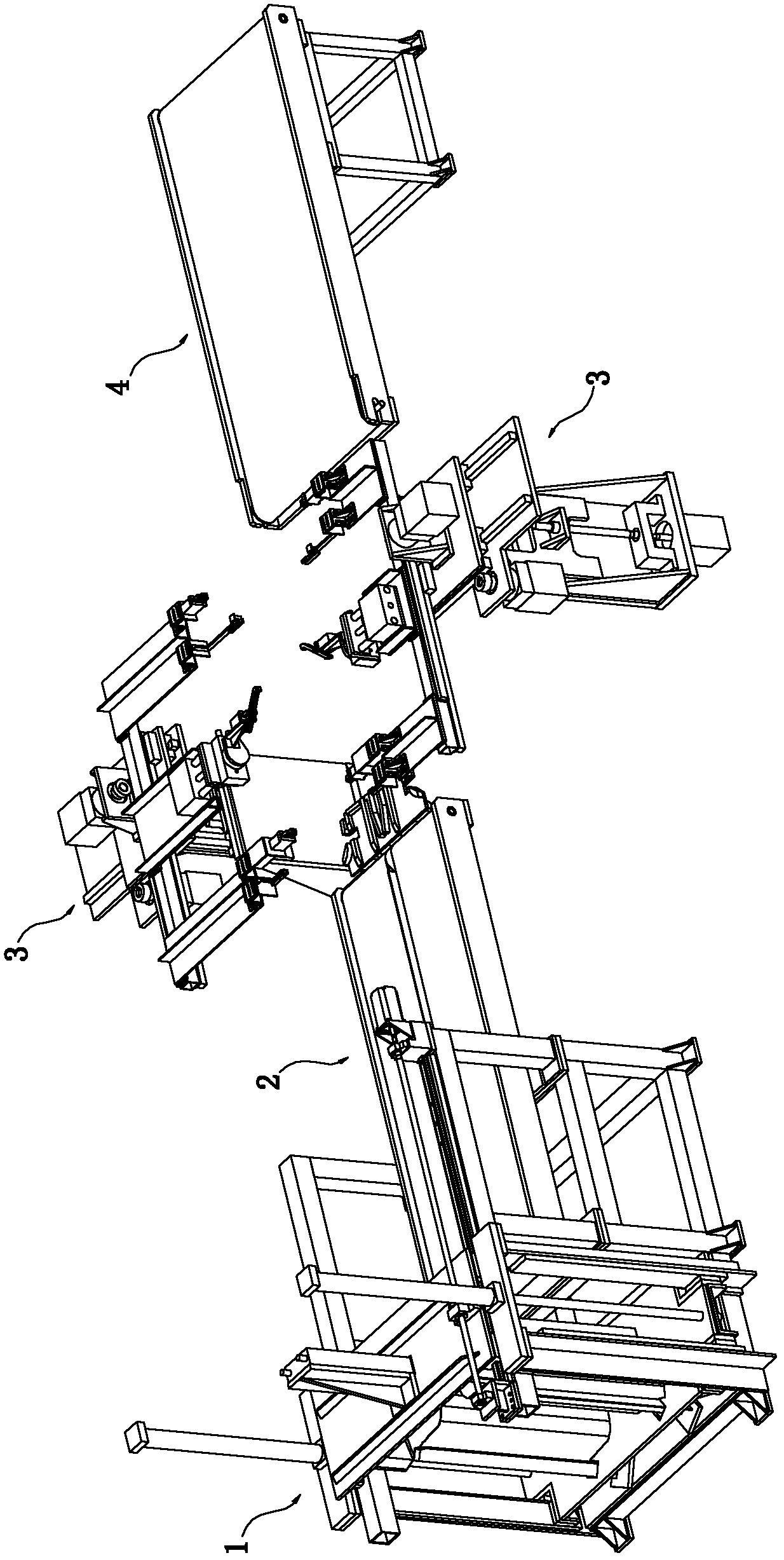

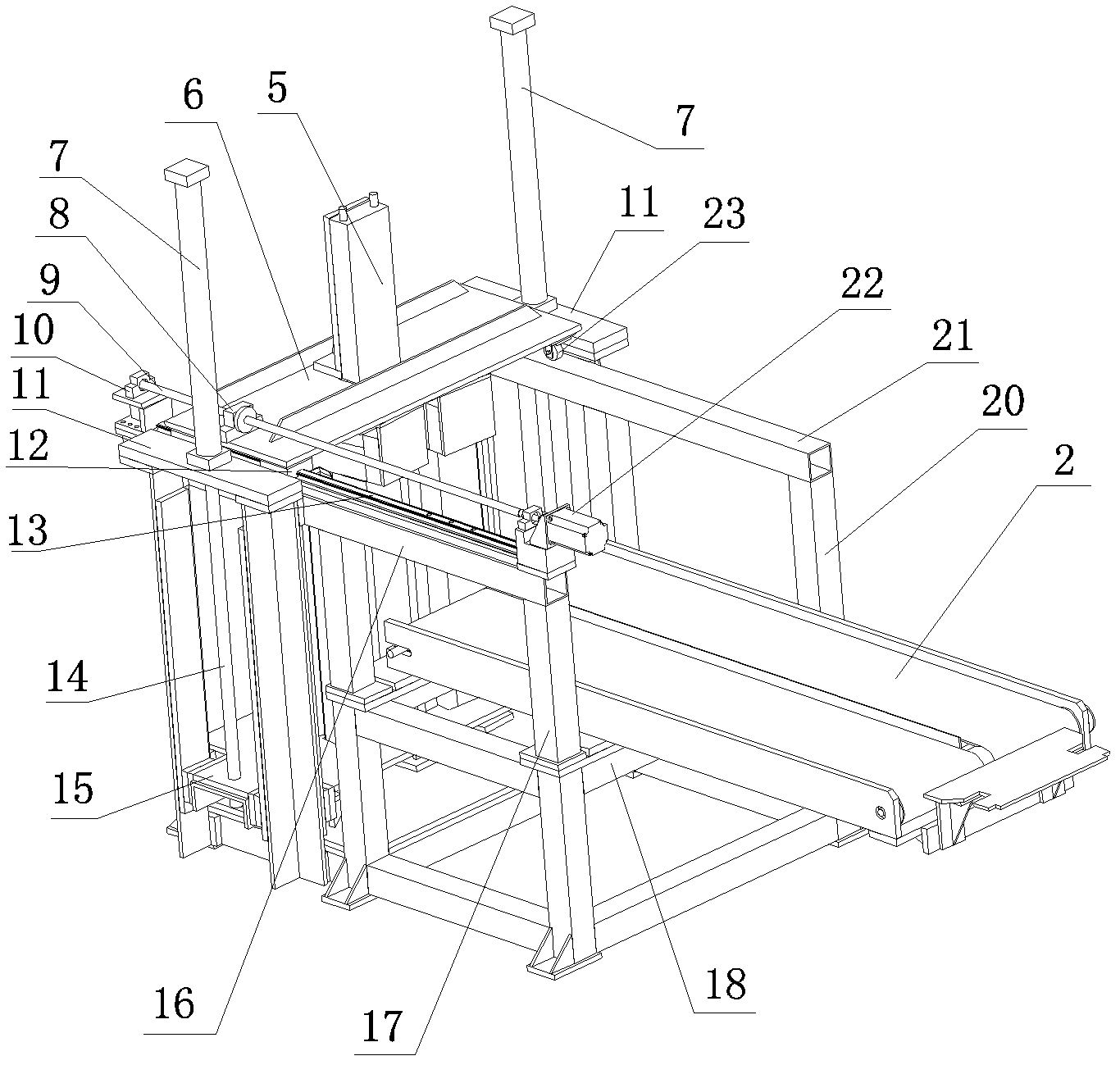

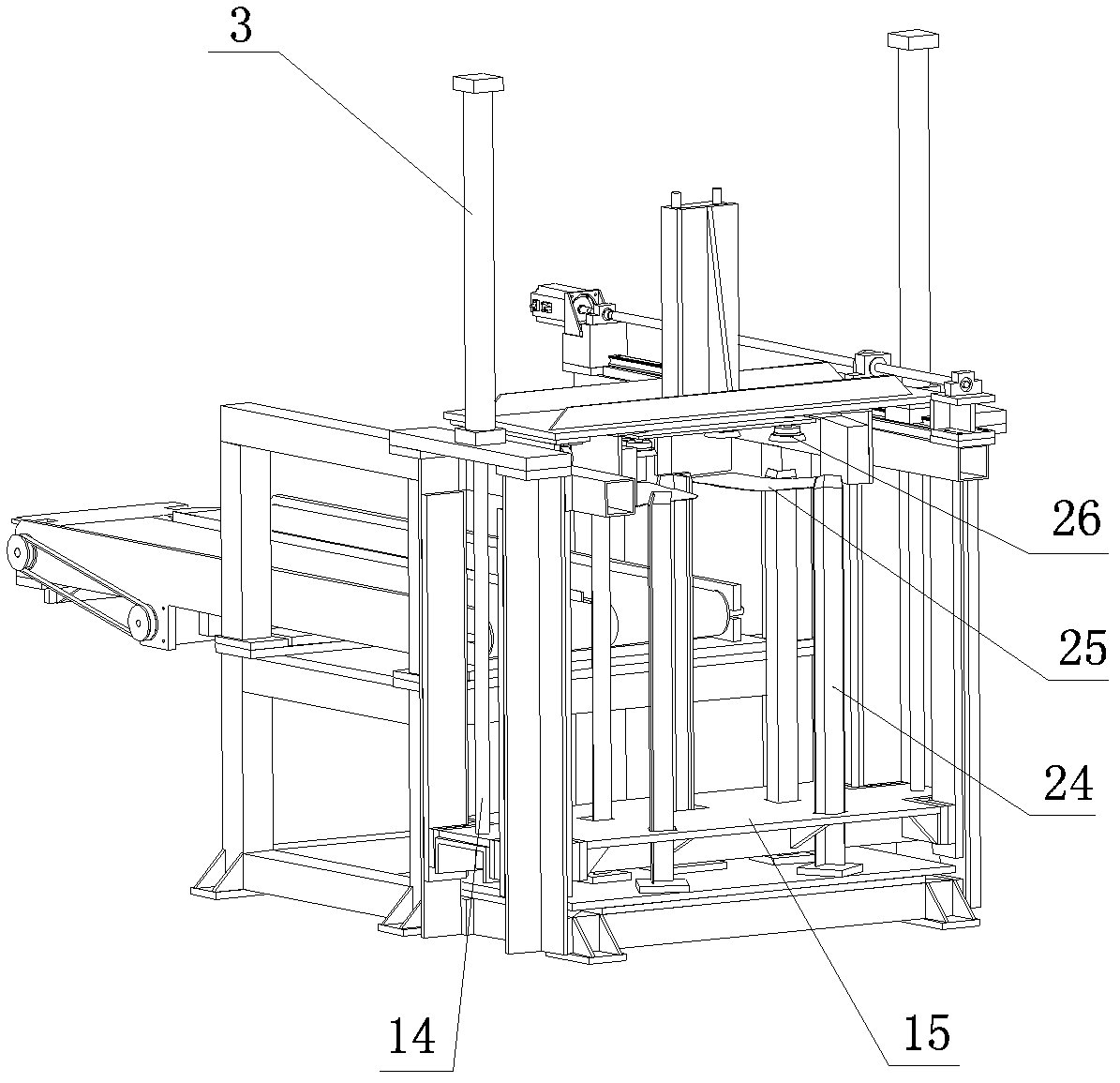

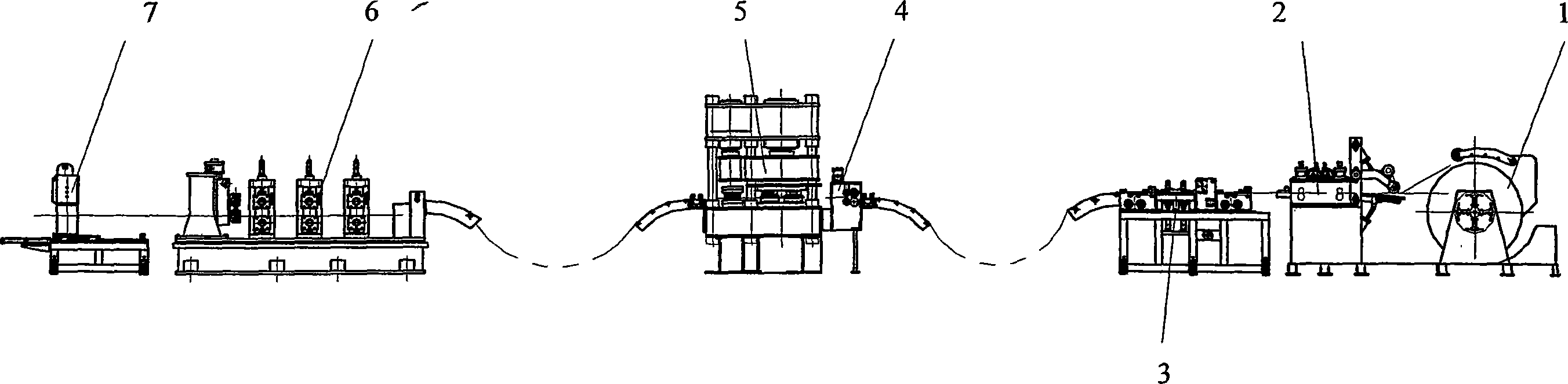

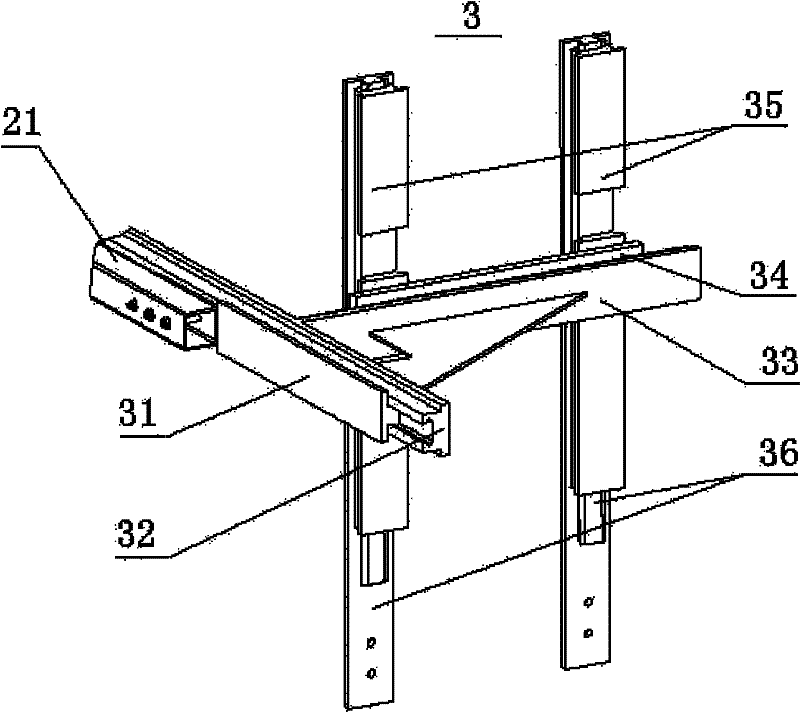

Automatic stamping production line

InactiveCN102554062AReduce labor intensityReduce riskMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention relates to a stamping production line, in particular to an automatic stamping production line which comprises an electromagnetic feeding device and manipulators. A feeding conveying belt is arranged between the electromagnetic feeding device and the manipulators; the manipulators are arranged on one or two sides of a stamping mold which is arranged behind the feeding conveying belt; the electromagnetic feeding device comprises two rows of supporting brackets, a supporting beam I, a supporting beam II and a feeding moving platform; the feeding moving platform is connected with a feeding air cylinder I; the bottom of a piston rod of the feeding air cylinder I is connected with an electromagnet through a feeding connecting plate; each manipulator comprises a base, a servo motor I, a ball screw and a vertical supporting plate; the top of the vertical supporting plate is connected with a movable platform I which can slide relative to the vertical supporting plate; the movable platform I is provided with a movable platform II which can slide relative to the movable platform I; one side of the movable platform II is provided with a movable platform III which can slide relative to the movable platform II; and the movable platform III is connected with a feeding grabbing device, a grabbing rotating device and a discharging grabbing device which are made to extend outwards and arranged juxtaposedly.

Owner:LIUZHOU GAOHUA MACHINE

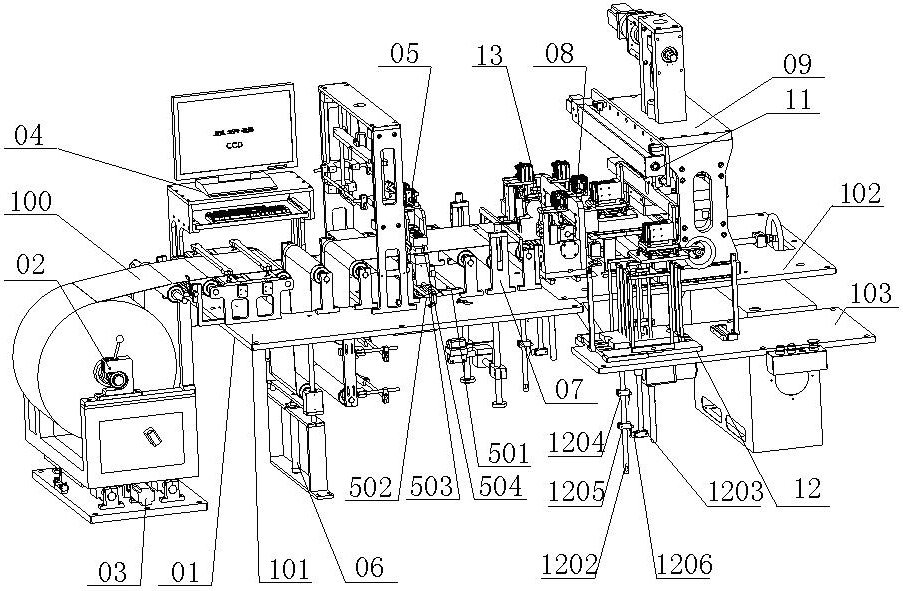

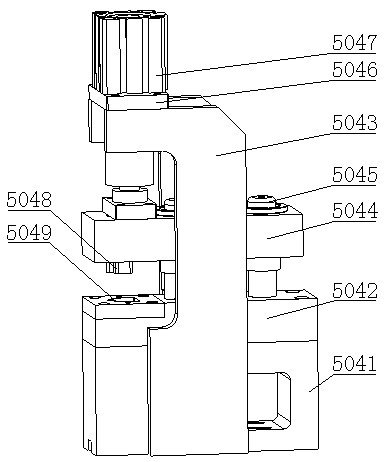

Electrode sheet forming machine

ActiveCN102306744AReduce manufacturing costExpanded range of specificationsElectrode manufacturing processesMetal-working feeding devicesPunchingAgricultural engineering

The present invention discloses an electrode sheet forming machine. The electrode sheet forming machine comprises a support mechanism, an unwinding mechanism, an unwinding rectification mechanism, an unwinding traction mechanism, a tension mechanism, a forming mechanism and a material collecting mechanism. The electrode sheet forming machine is characterized in that: the forming mechanism comprises a chamfer clipping mechanism, a constant length cutting mechanism and an electrode lug punching mechanism, wherein the chamfer clipping mechanism, the constant length cutting mechanism and the electrode lug punching mechanism are sequentially arranged on an electrode sheet belt in an unwinding direction; the chamfer clipping mechanism is provided for carrying out clipping for both sides of the electrode sheet belt to form the chamfer of each single electrode sheet, the constant length cutting mechanism is provided for carrying out constant length cutting for the electrode sheet belt to formthe single electrode sheet, the electrode lug punching mechanism is provided for punching the electrode lug of the single electrode sheet. Compare to the prior art, with the present invention, the die cost is saved.

Owner:深圳市和合自动化有限公司

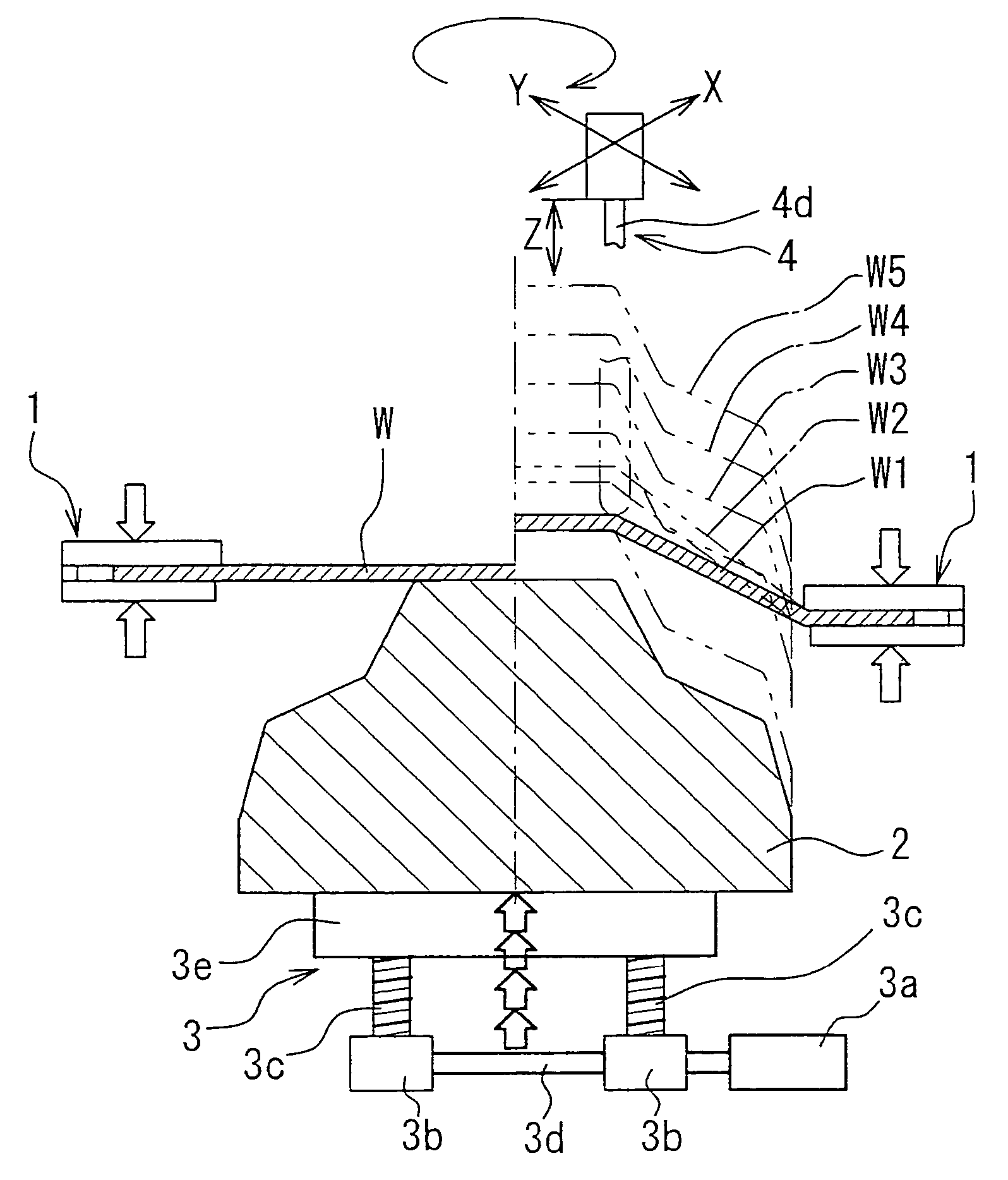

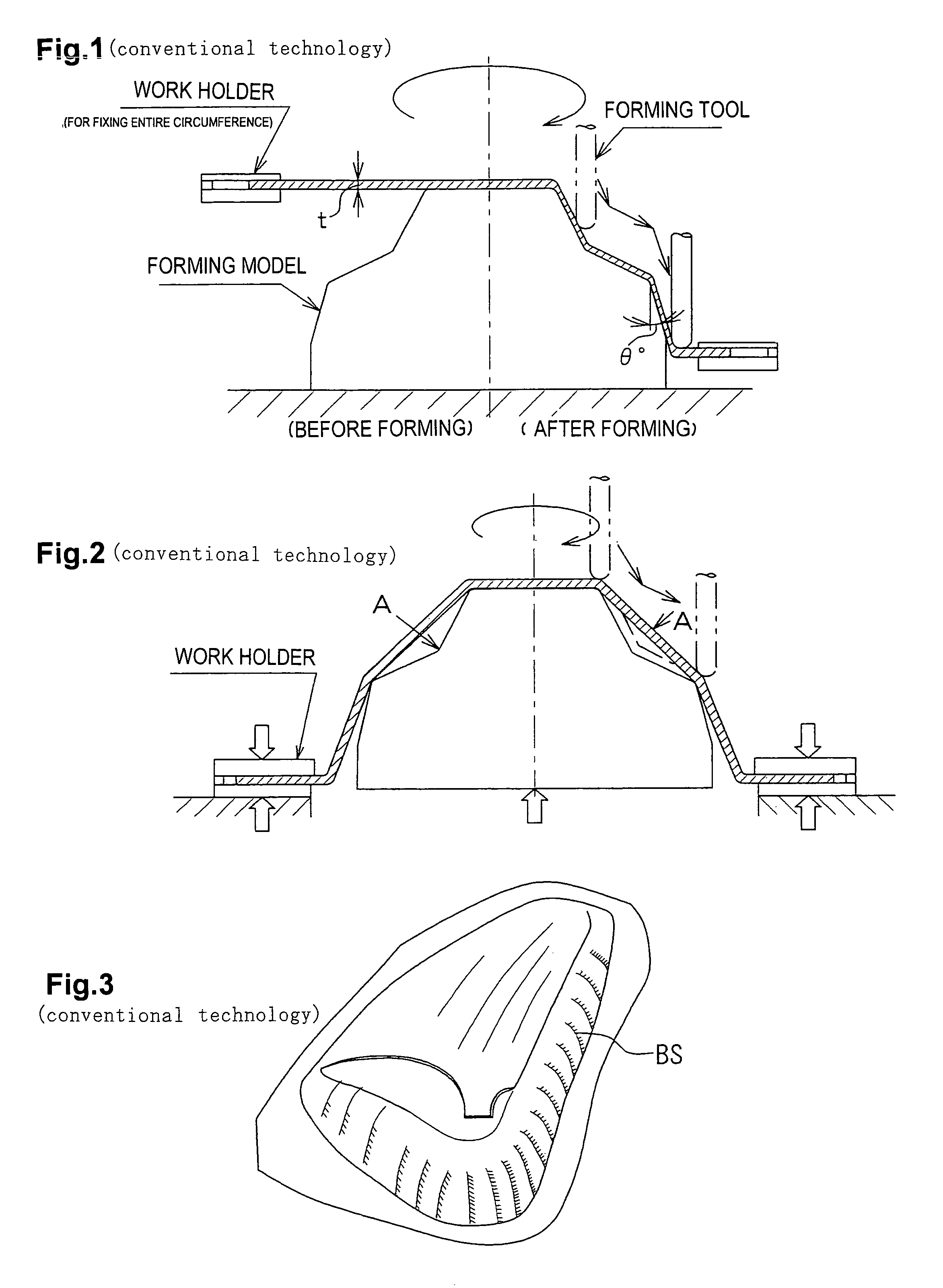

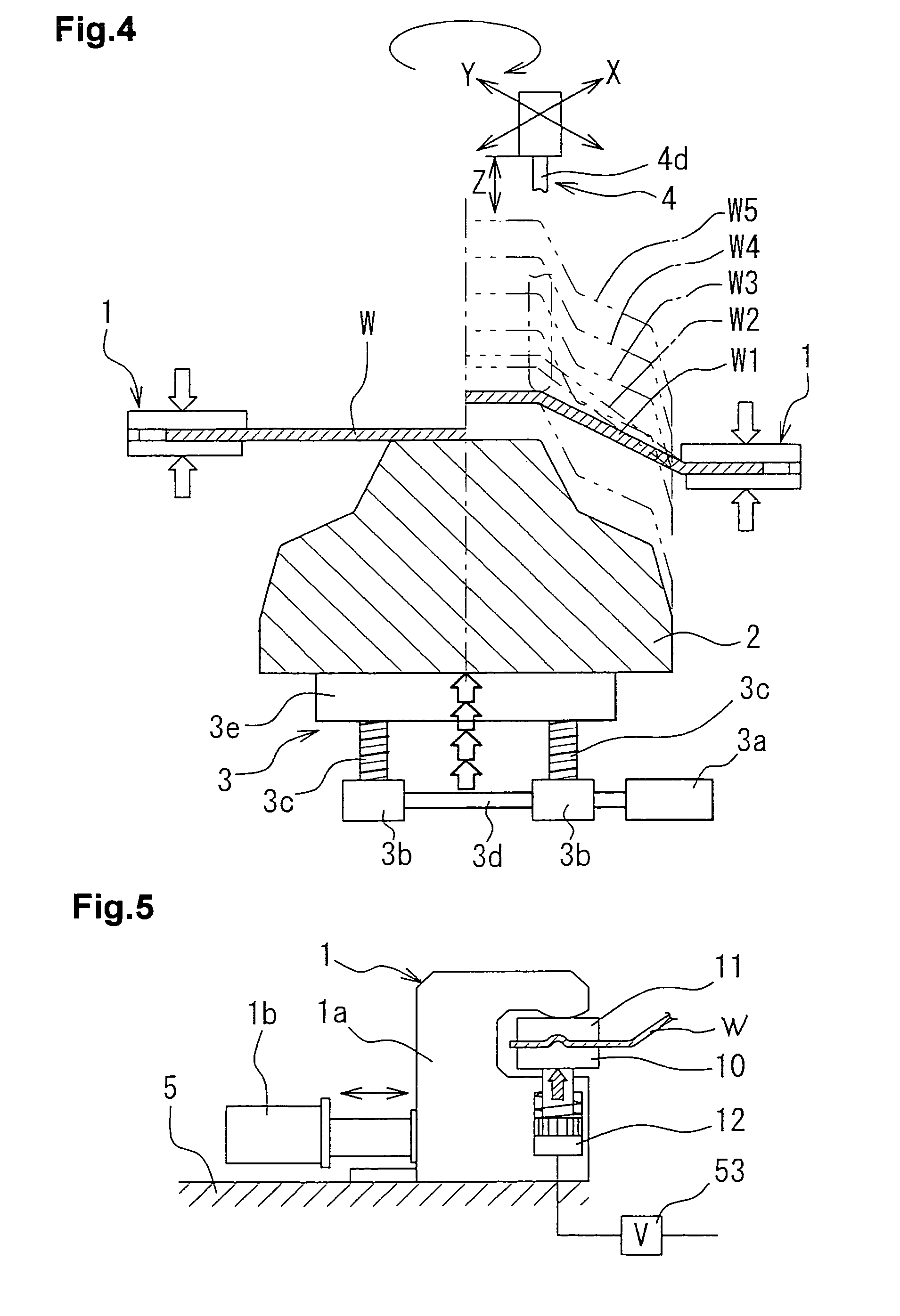

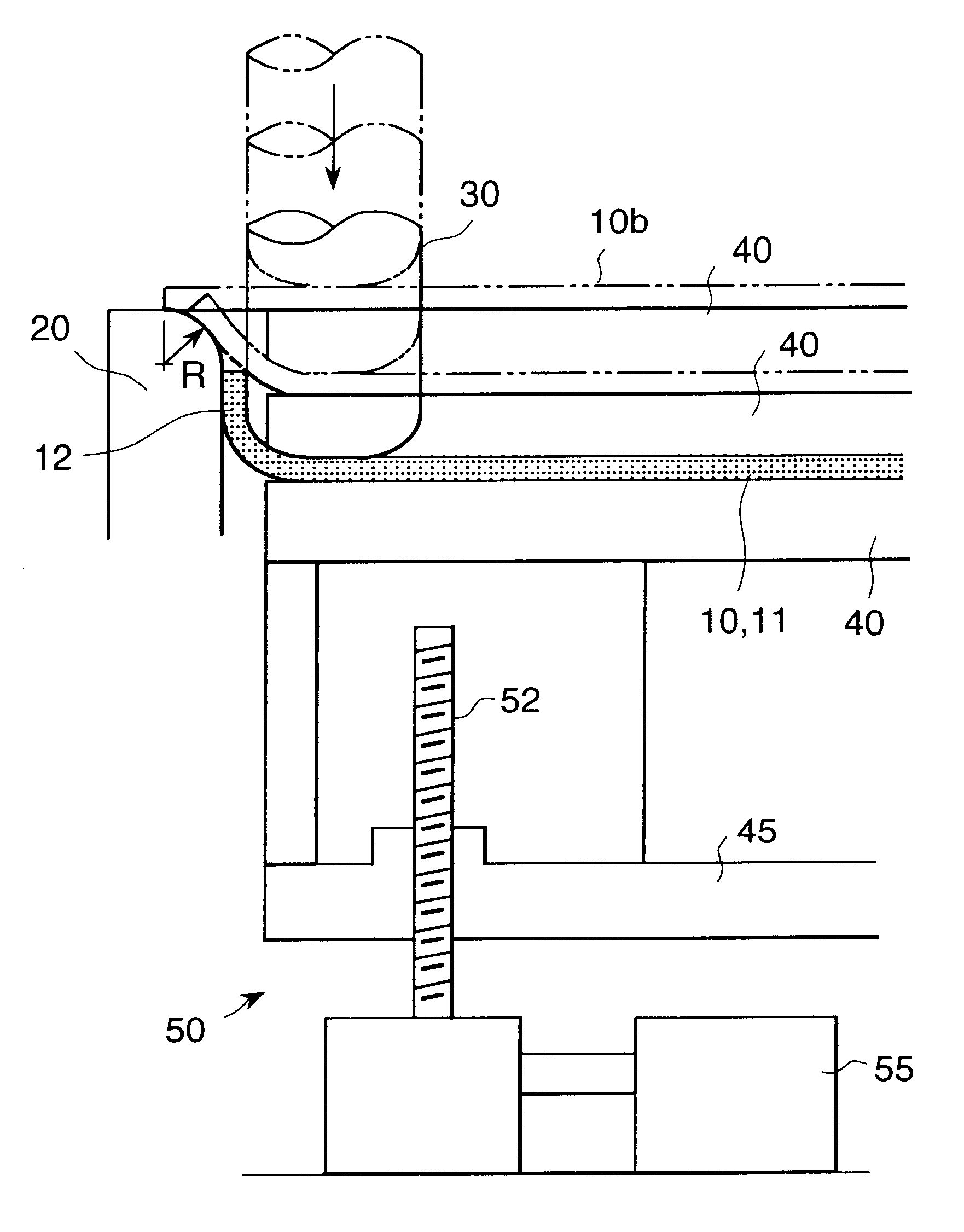

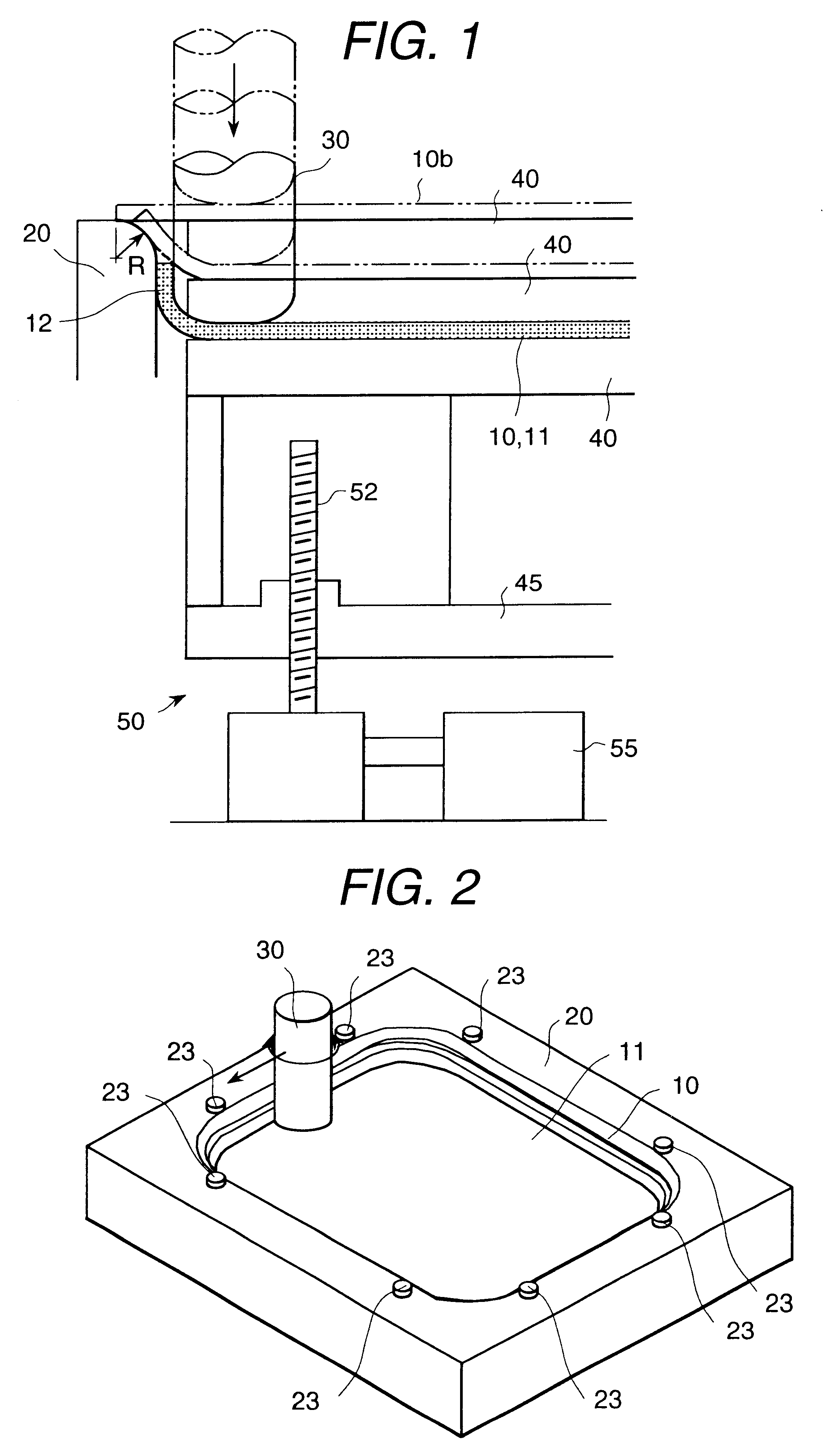

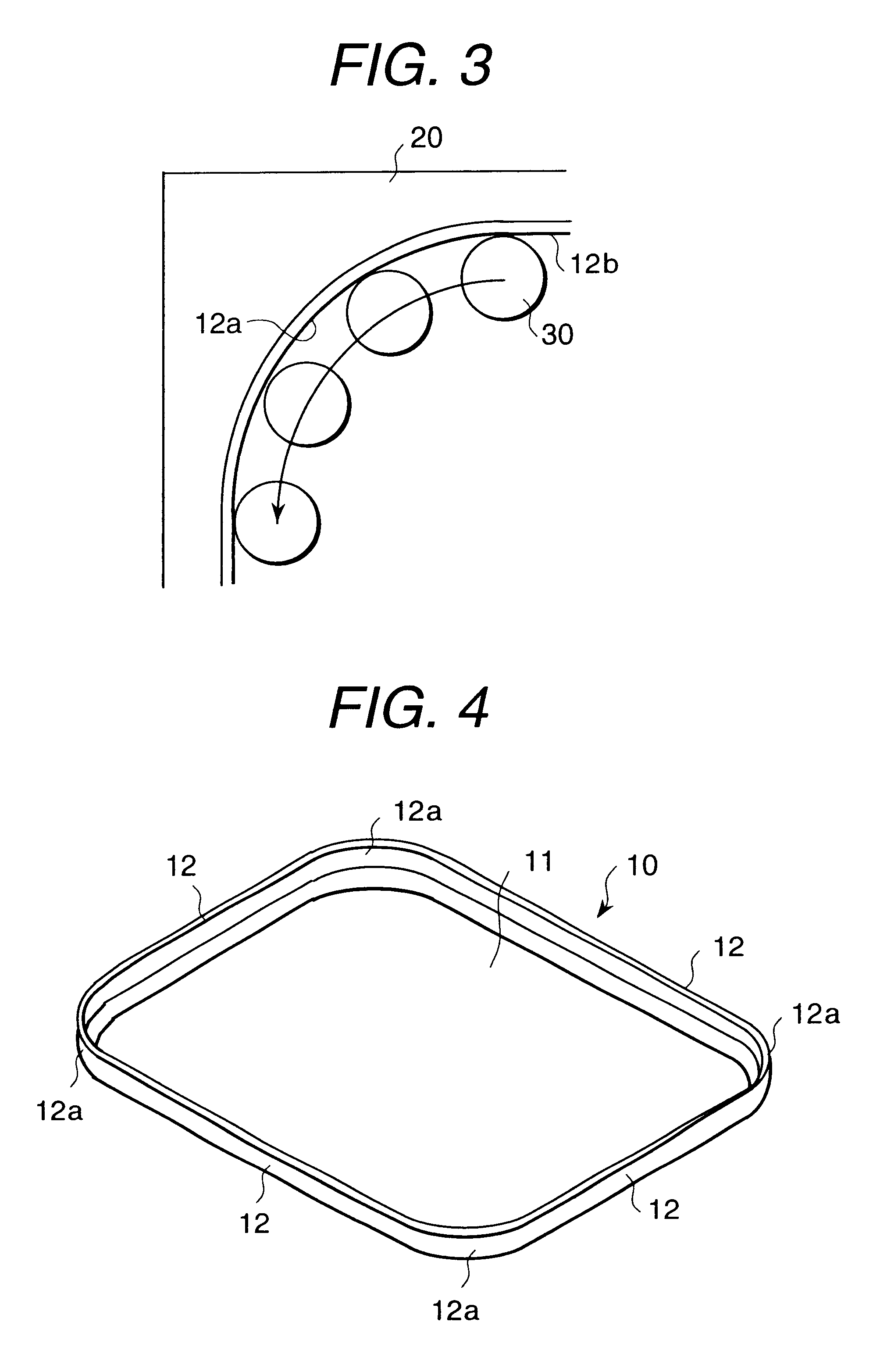

Incremental forming method and apparatus for the same

In a state in which a material (blank) cut in a predetermined shape is mounted on a die and the bottom of the material is supported by a seat, the material is pressed by a tool from above and the tool is moved along the die so that the material is incrementally formed. The bottom of the material is fixed, so that the material is not inclined and can be formed in a predetermined shape. A circular arc portion of a flange is processed in a state in which it is clamped by the female die and the tool, so that the circular arc portion of the flange is not spread outside and the perpendicularity between the flange of the circular arc portion and the bottom can be increased.

Owner:HITACHI LTD

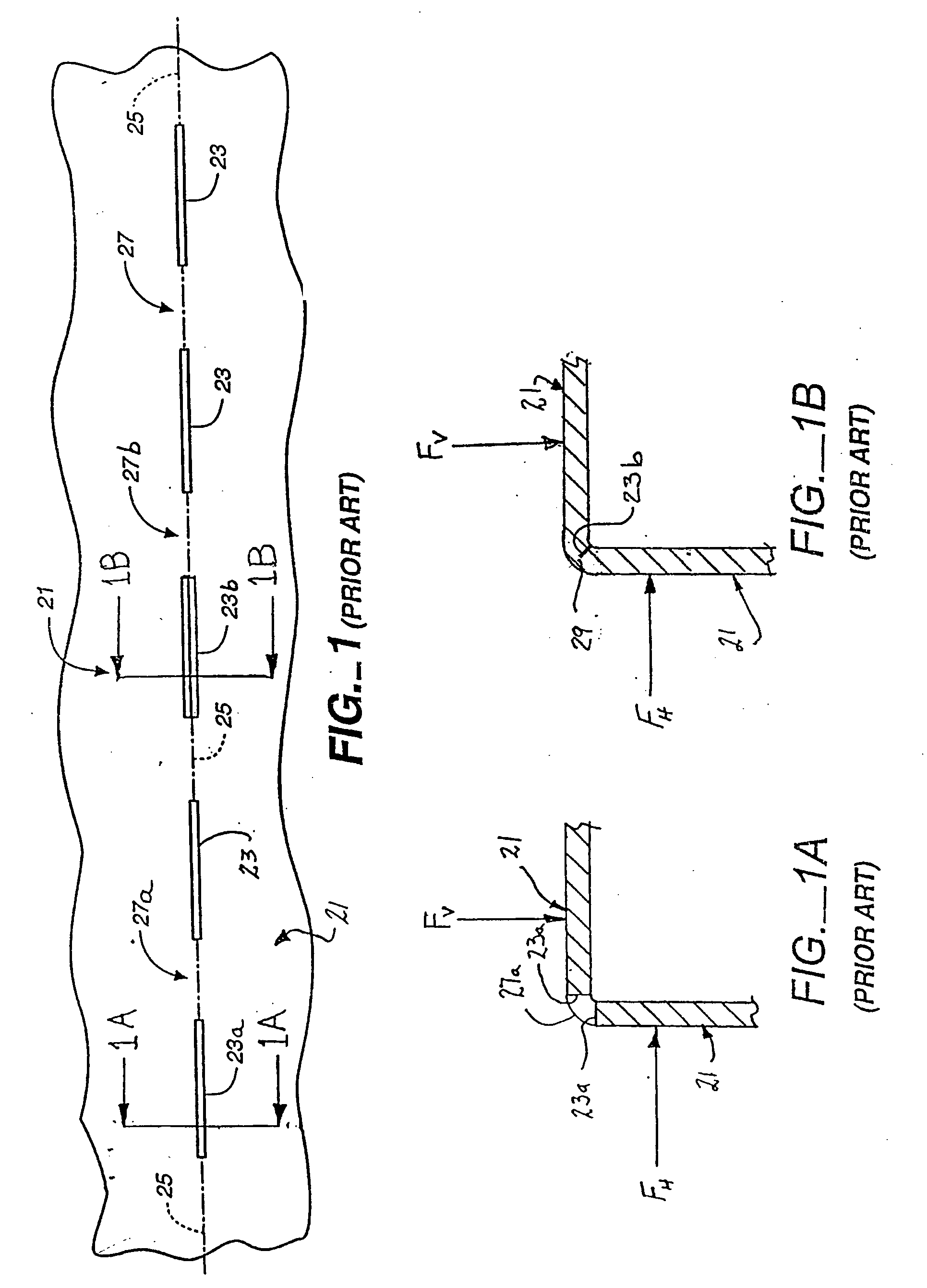

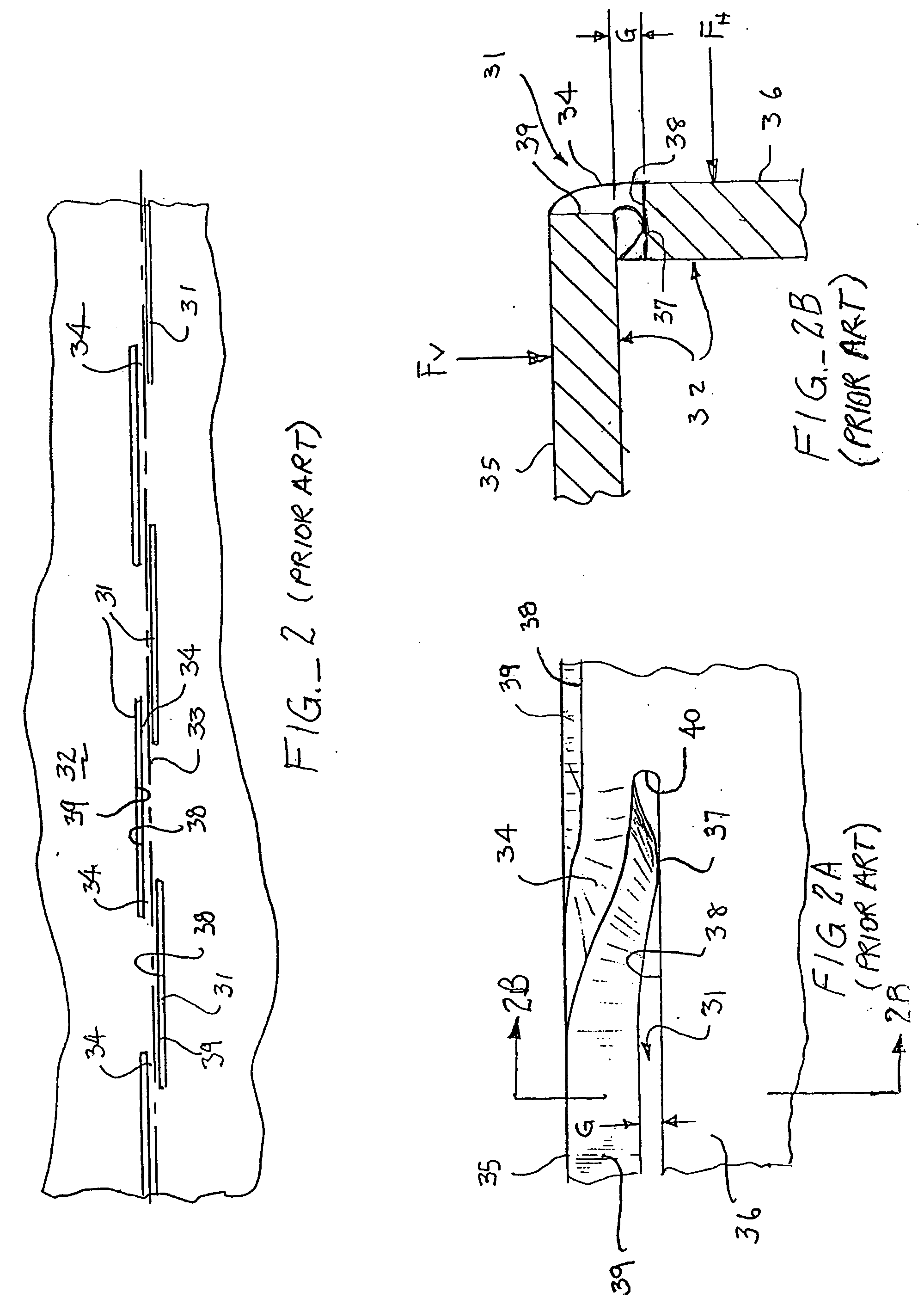

Process of forming bend-controlling structures in a sheet of material, the resulting sheet and die sets therefor

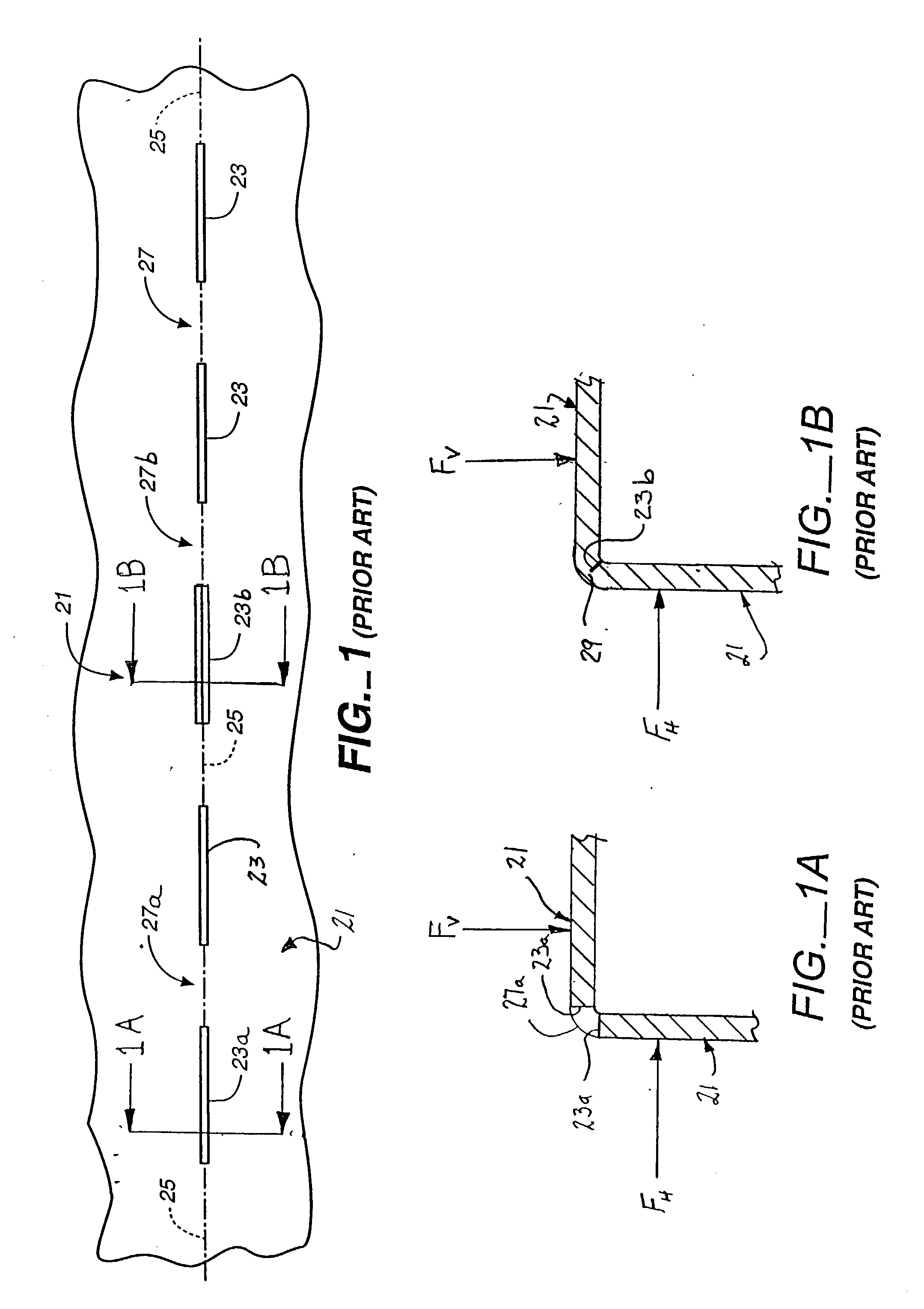

InactiveUS20050061049A1Optimize locationAchieved economicallyShaping toolsPerforating toolsMirror imageExtremity Part

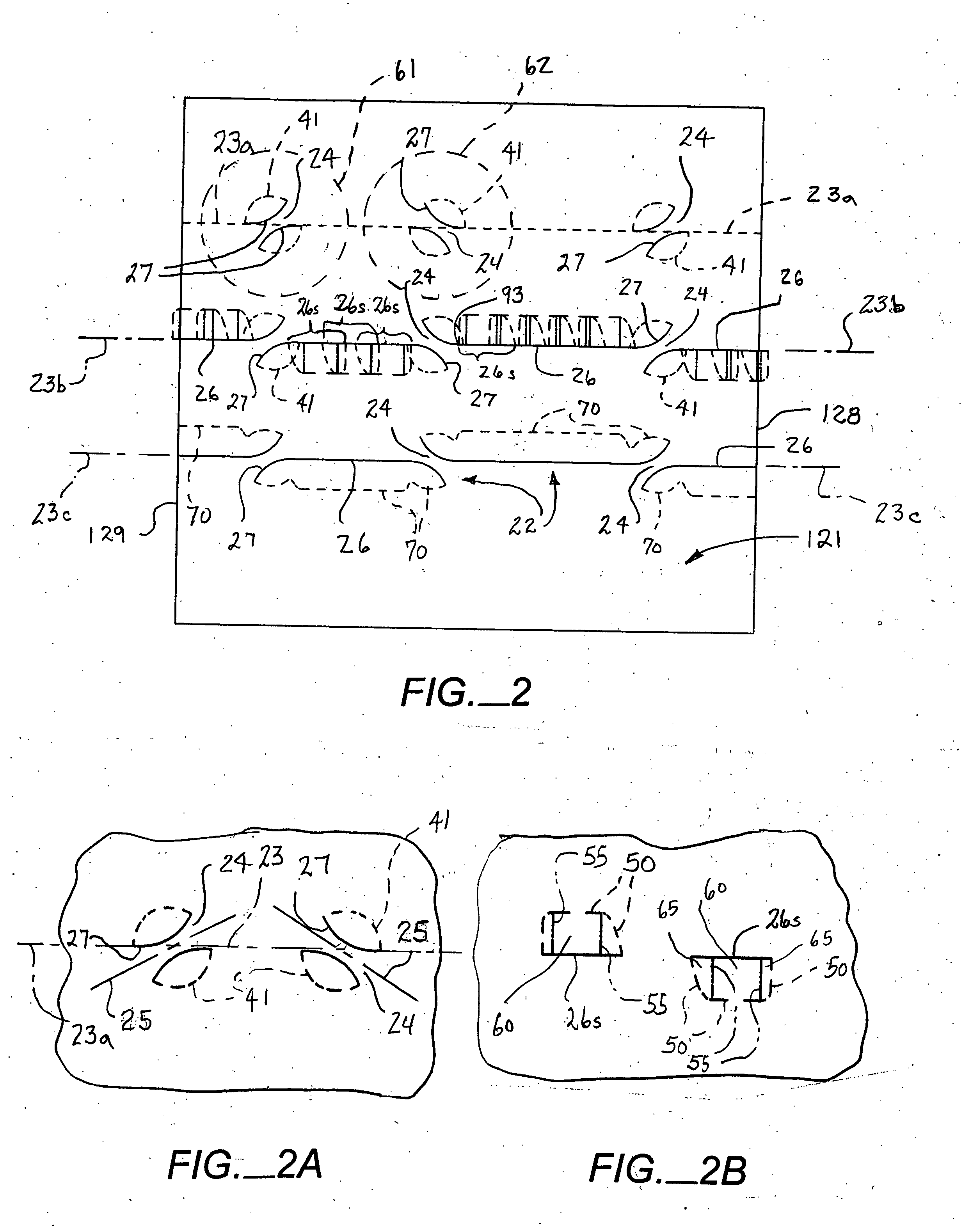

A process of forming bend-controlling structures, such as slits, grooves or displacements (22), in a sheet of material (21, 121, 221, 321, 421, 521, 621,721). The bend-controlling structures (22) have central portions (26) extending substantially parallel to a desired bend line (23) on the sheet and end portions (27) which diverge away from the bend line (23). In one embodiment the process includes the step of forming the bending straps (24) between pairs of slit end portions (27) at a desired spaced apart distances along the bend line (23) with the straps (24) having a desired configuration, and the step of forming central portions (26) which connect the end portions (27) to complete the slits (22) using a separate die set. A plurality of end portion dies (51 / 54) can be used to produce end portions (27) of various shapes and straps (24) of various widths, and a single set of central portion forming dies (71 / 74) are used to connect the end portions (27). In other embodiments die sets producing a single end portion (27) or mirror image impressions (A,B) are used and preferably overlapped to produce the complete bend-controlling structure (22). A modular die assembly (500) also is disclosed in which the bend-controlling structures can be produced by modular die inserts (511-514, 611-614). Finally, a selection of die sets (722a, 722b, 722c) of differing length from a group of die sets can be made to position the bending straps (24) at desired locations along the bend line.

Owner:IND ORIGAMI INC CA US

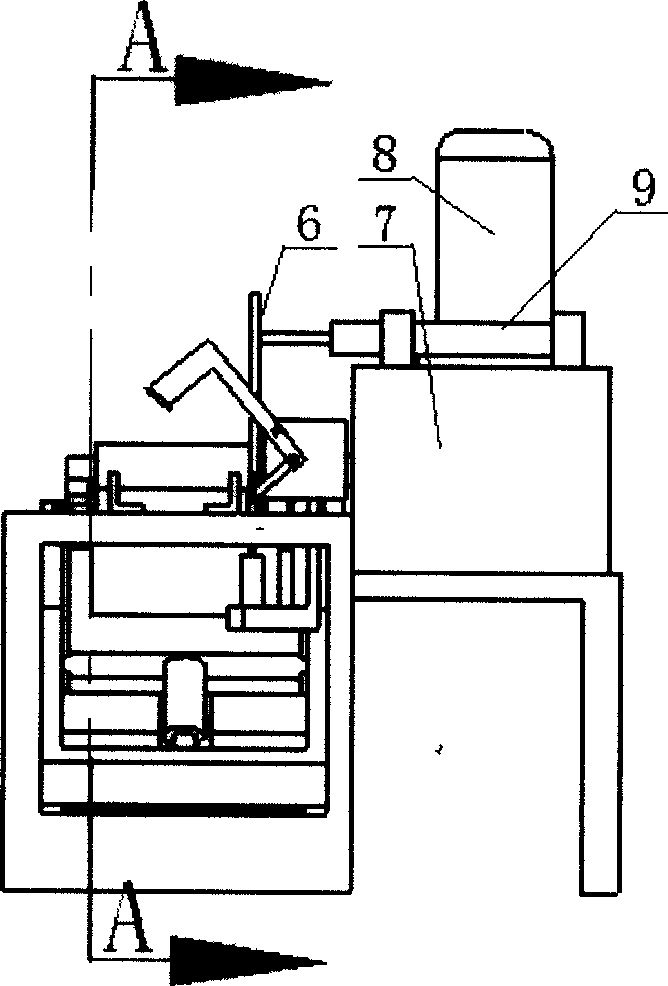

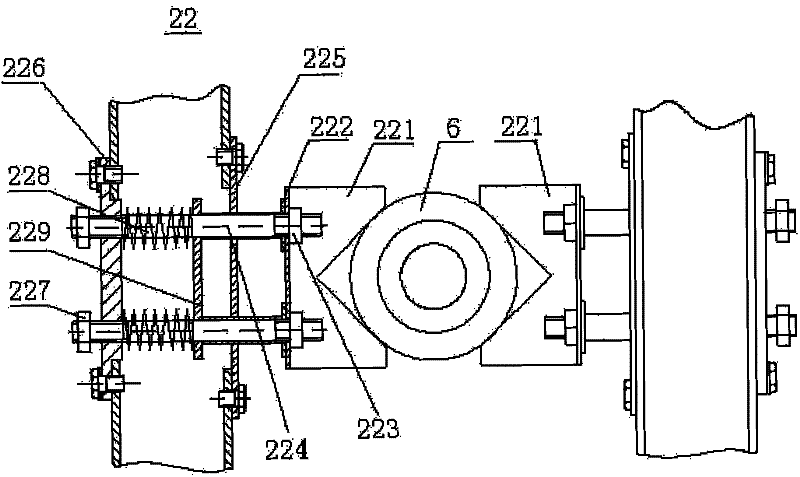

Four rollers automatic reeling mechanism in product line of manufacturing ternary cleaner for tail gas of cars

InactiveCN1759949AMeet the needs of automated productionAdjustable radiusMetal-working feeding devicesPositioning devicesProduction lineBarrel Shaped

An automatic 4-roller barrel shaping unit for the production line of three-element cleaner used to treat the tail gas of car is composed of machine frame, feeding track with both side barrier plates, feeding manipulator with its guide track and cylinder, blanking cylinder with push plate, the upper, lower, front and back rollers, AC motor and speed reducer. Its advantages are high automation level and productivity, and simple structure.

Owner:SHANGHAI JIAO TONG UNIV

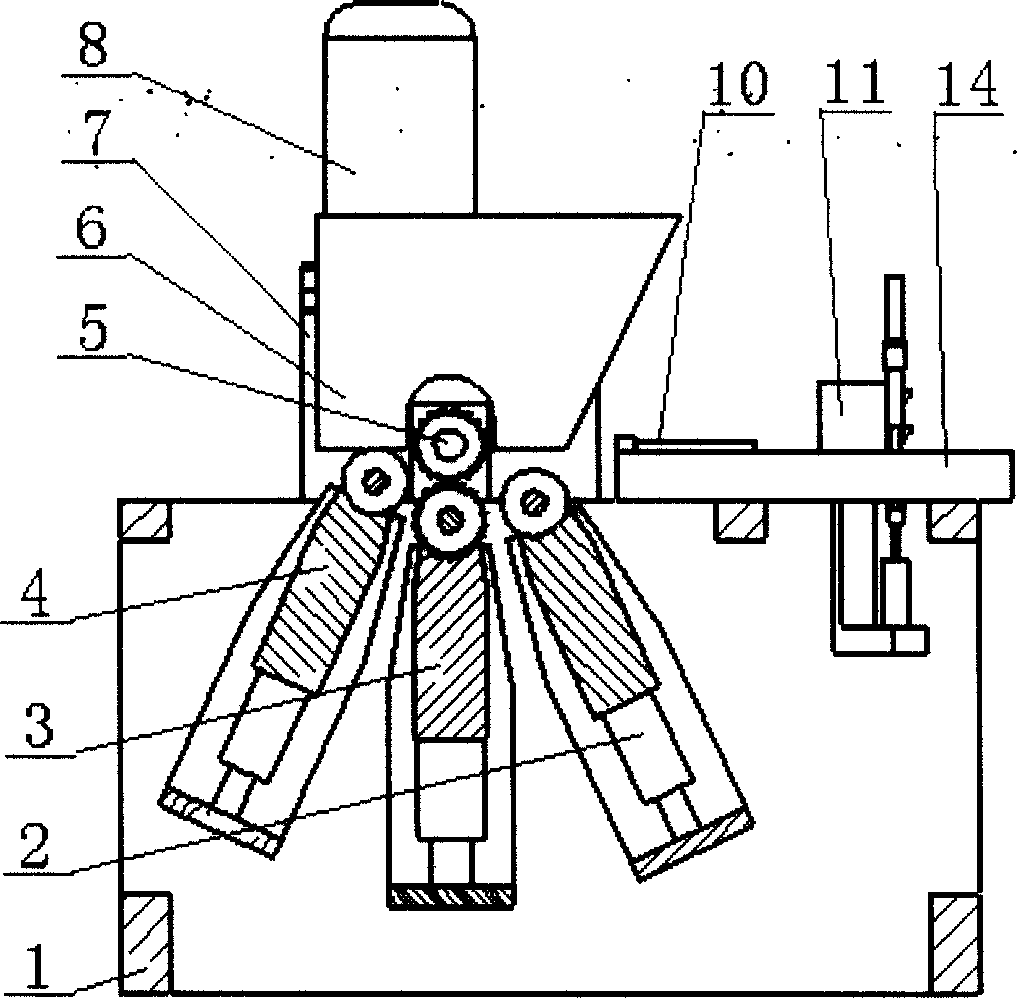

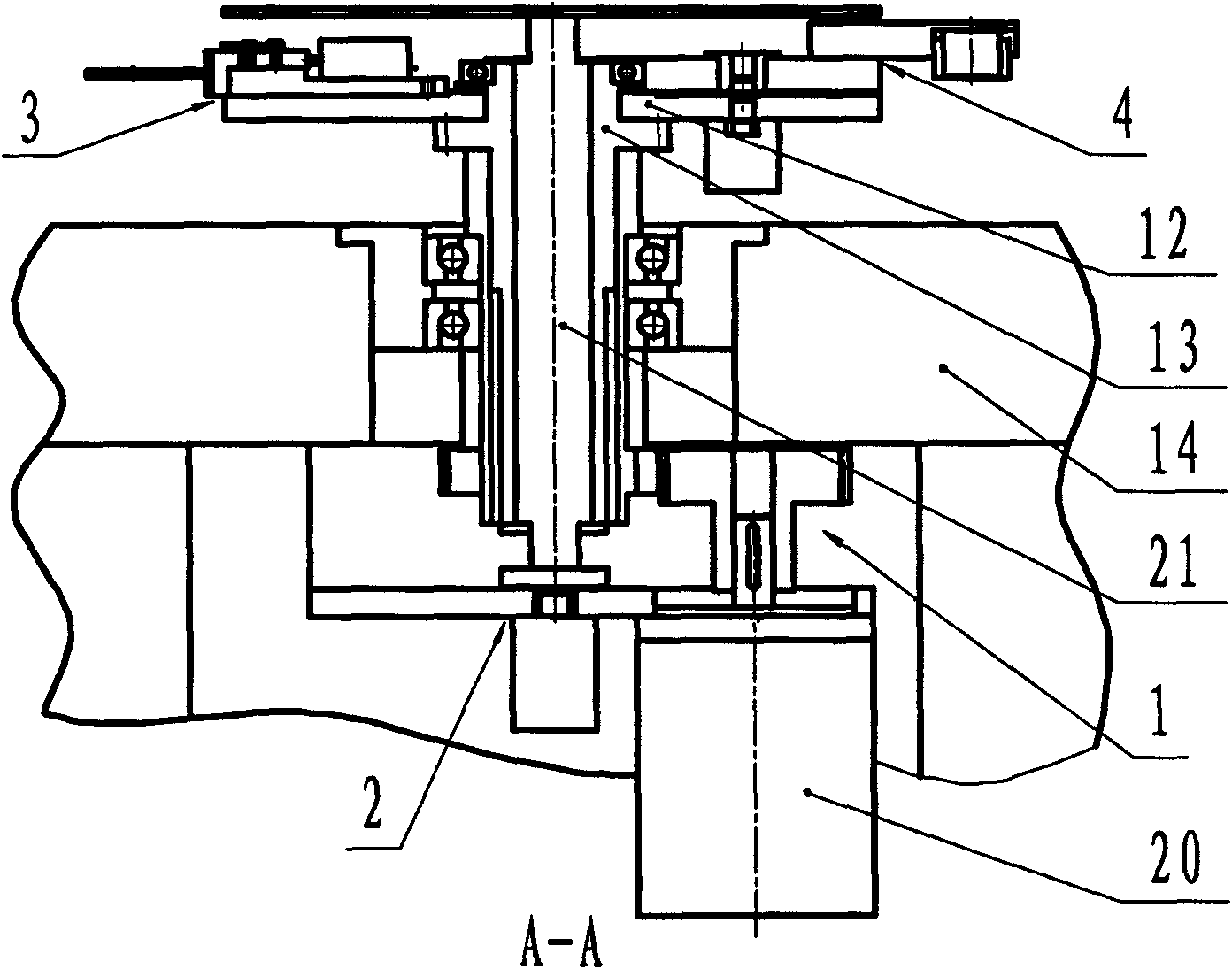

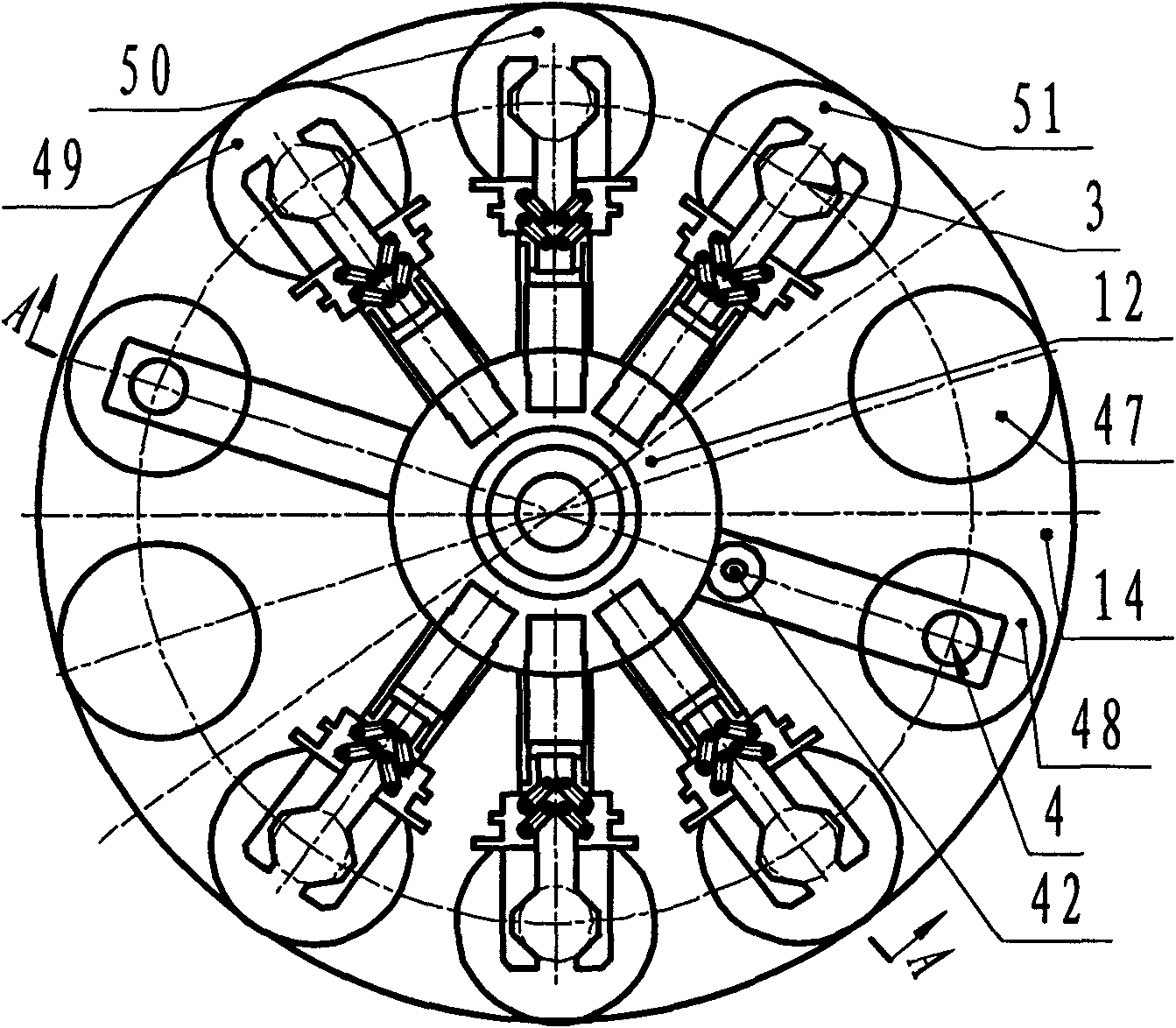

Multistation material transmission manipulator

InactiveCN101633023AImprove efficiencyQuality improvementProgramme-controlled manipulatorMetal-working feeding devicesPunchingManipulator

The invention relates to a multistation material transmission manipulator which is characterized in that the manipulator is used for a rotary sealing ring framework punching forming technique and mainly comprises a big template, a swing mechanism, a lifting mechanism, six finger mechanisms and two electromagnetic chucks, wherein the big template is round; the swing mechanism and the lifting mechanism are arranged at the center of the big template; 10 positioning slots are distributed on the periphery of the big template; the six finger mechanisms and the two electromagnetic chucks are divided into two groups, uniformly arranged on the swing mechanism in a radial shape and central symmetrical mode and are corresponding to the position of the positioning slot; and the finger mechanisms and the electromagnetic chucks are all arranged on the top of a rotary disc of the swing mechanism. The manipulator can automatically and continously finish the material transmission and carrying operation (among three working stations of stretching, reverse-drawing and punching) in the punching forming process of the rotary sealing ring framework.

Owner:HEBEI UNIV OF TECH

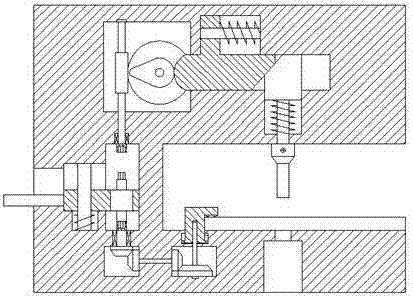

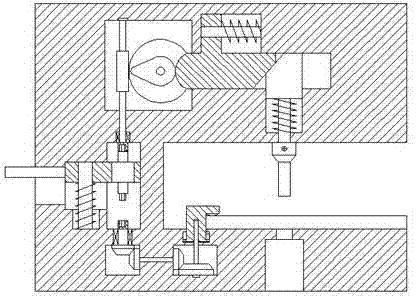

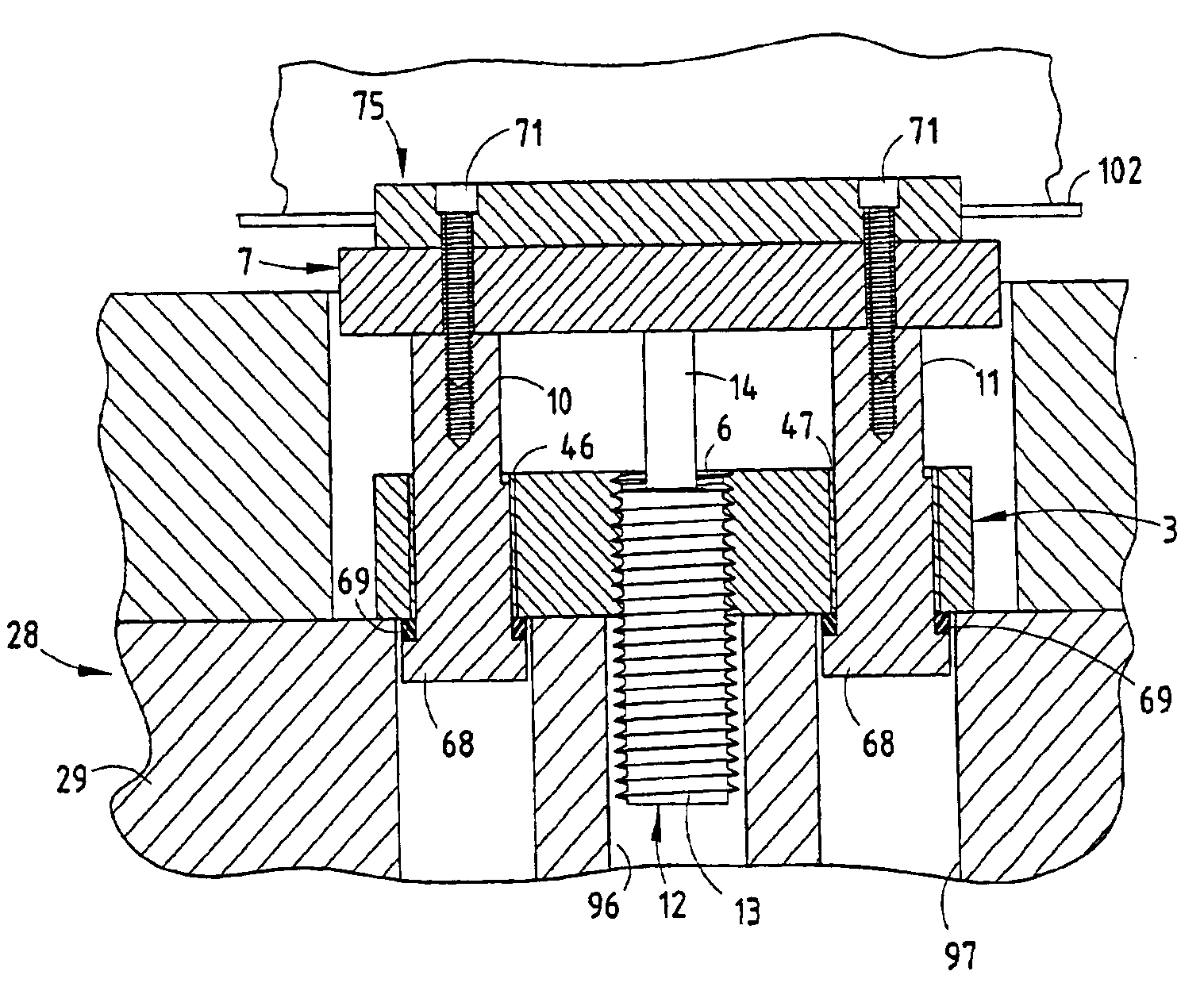

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

Stainless-steel band special apparatus for steel-aluminum composite contact rail

InactiveCN101028685AImprove performanceQuality improvementMetal-working feeding devicesOther manufacturing equipments/toolsButt weldingControl theory

Owner:南京赛彤铁路电气化有限公司

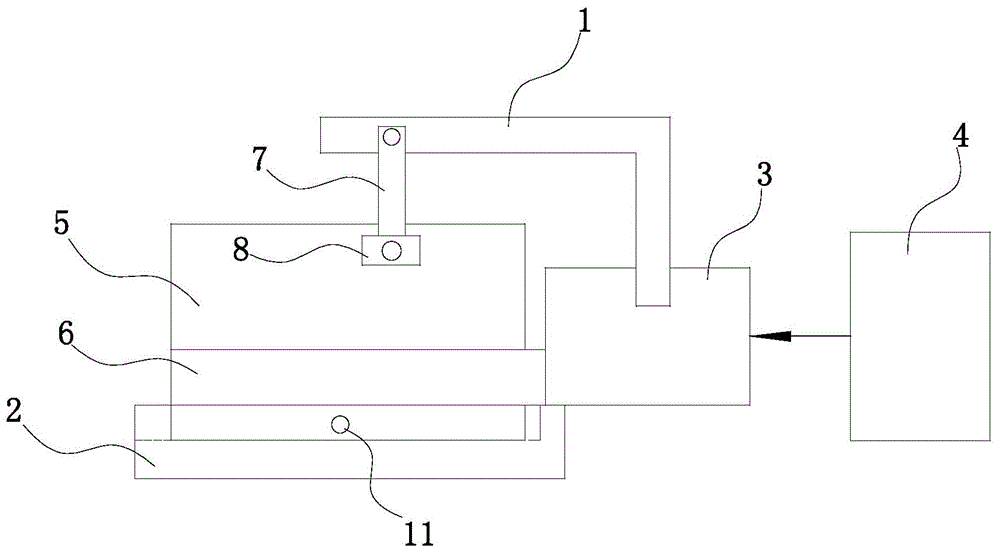

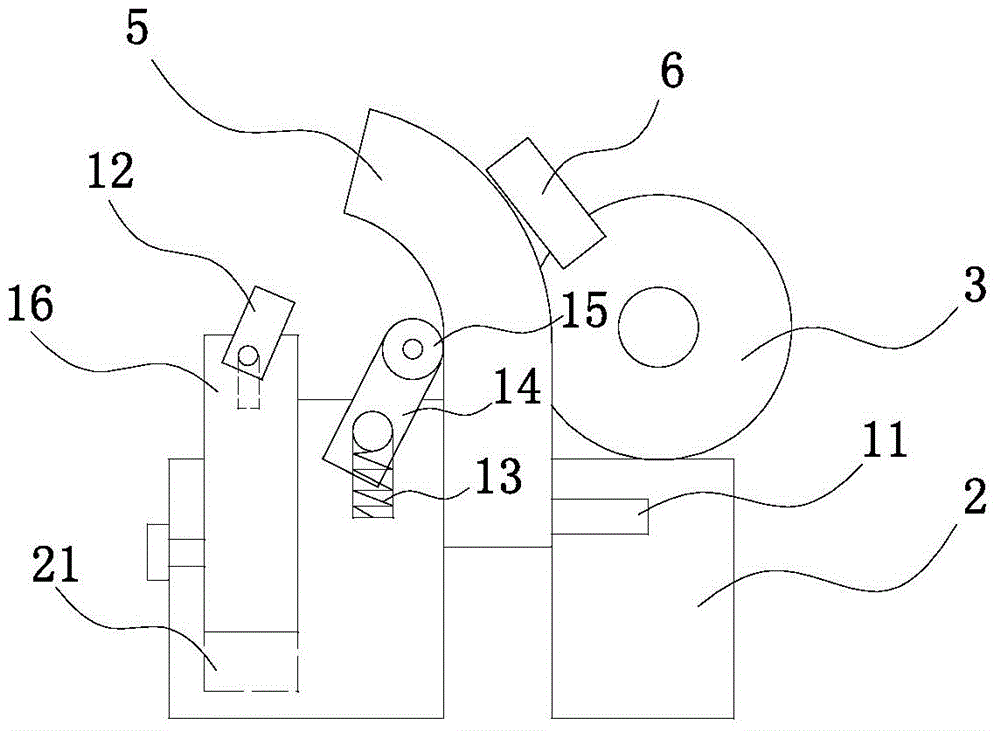

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

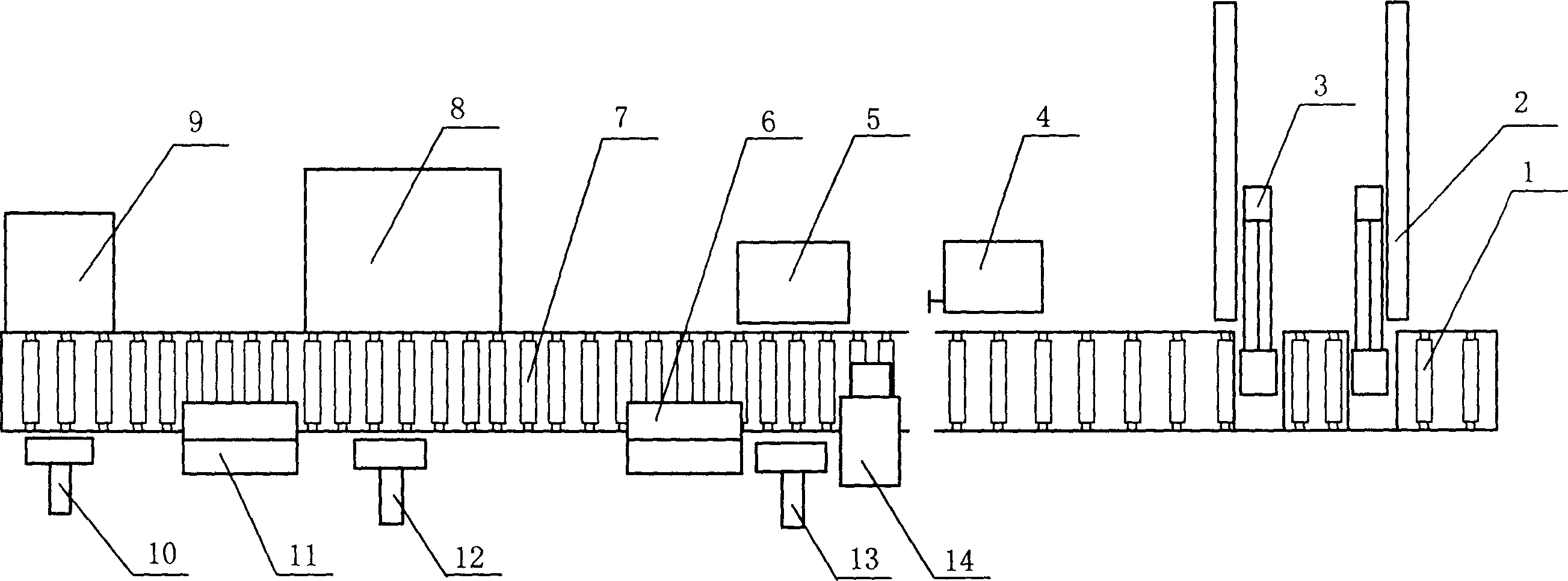

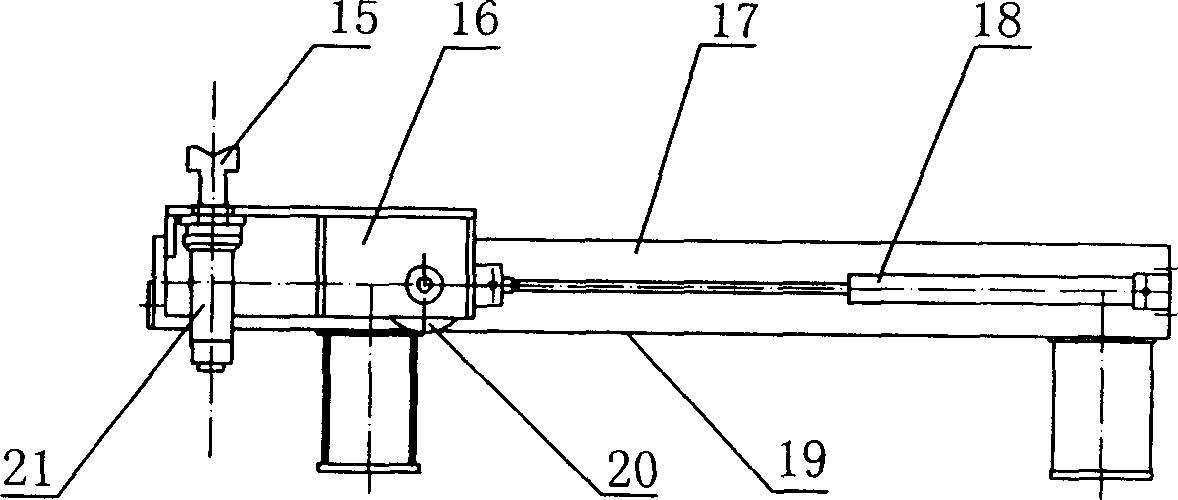

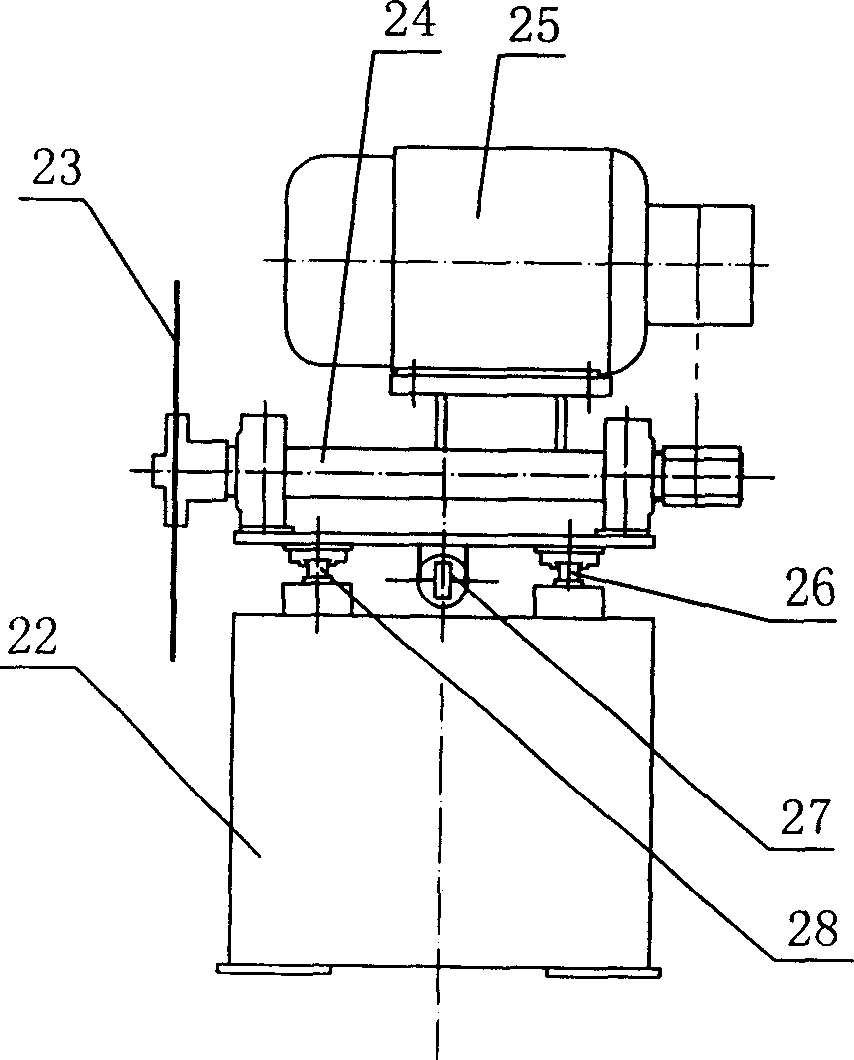

Automatic sawing, cutting and stacking machine for aluminum alloy bar

ActiveCN1899719ARealize automatic controlFree laborMetal-working feeding devicesPositioning devicesAutomatic controlStack machine

The automatic sawing, cutting and stacking machine for aluminum alloy bars includes conveying roller bed comprising conveying rollers and chain wheel driving mechanism, operating stations set along the conveying roller bed, material feeding mechanism, material setting mechanism, cutting mechanism, sizing mechanism, stacking mechanism, side aluminum bar pushing mechanism, power mechanism and control mechanism. The present invention has power mechanism and control mechanism, and can realize PLC automatic control and automatic operation of feeding, sizing, cutting and stacking aluminum alloy bars, and possesses high production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

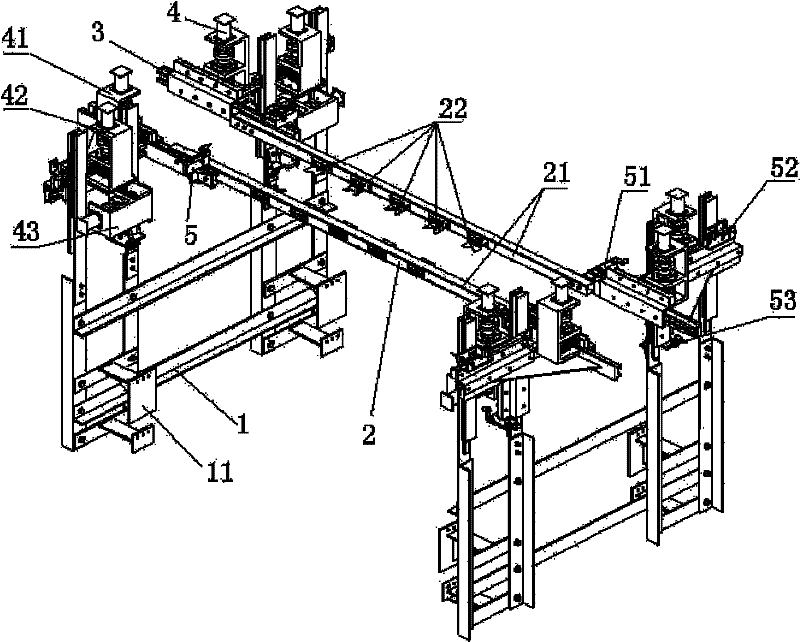

Multi-station automatic feeding method and device

InactiveCN102173097ARealize continuous automatic feedingAccurate clamping forceMetal-working feeding devicesForging/hammering/pressing machinesControl systemFeed drive

The invention relates to a multi-station automatic feeding method and device. The feeding device is characterized by comprising an execution mechanism, a guiding mechanism, a driving device, a sensing limiting device and a control system, wherein the execution mechanism, the guiding mechanism, the driving device and the sensing limiting device are arranged on a frame; the execution mechanism comprises two walking beams which are arranged in parallel; a plurality of pairs of clamping devices are alternately arranged on the two walking beams; the guiding mechanism comprises feeding guide rails and feeding guide grooves, which are respectively arranged at two ends of the walking beams; a clamping guide groove which slides along one clamping guiderail is vertically fixedly arranged in the middle of each feeding guide groove; two ends of the clamping guide rails are respectively fixedly arranged on lifting guide grooves which slide along lifting guide rails; the bottom ends of the two lifting guide rails are respectively fixedly arranged on the frame; the driving device comprises a feeding driving device, a clamping driving device and a lifting driving device; the sensing limiting device comprises a feeding sensing limiting device, a clamping sensing limiting device and a lifting sensing limiting device; and the output end of the control system is connected with the sensing limiting device while the output end is connected with the driving device.

Owner:CHINA AGRI UNIV

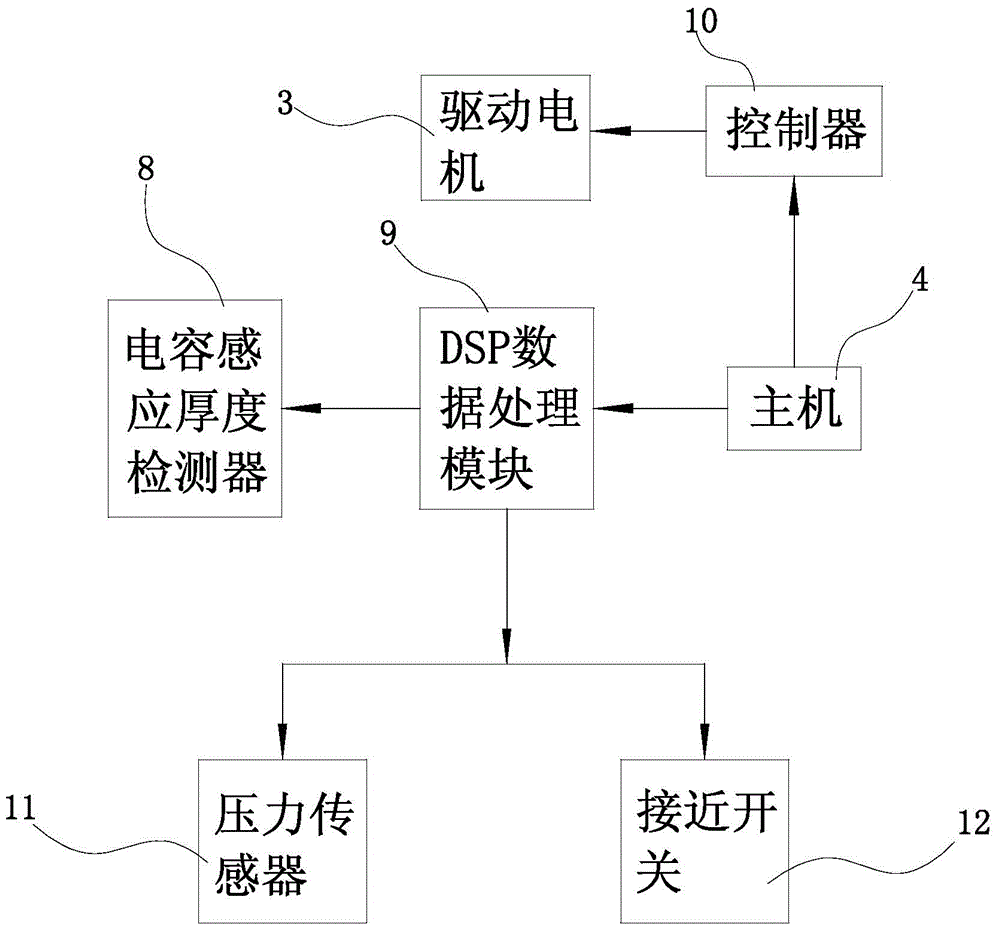

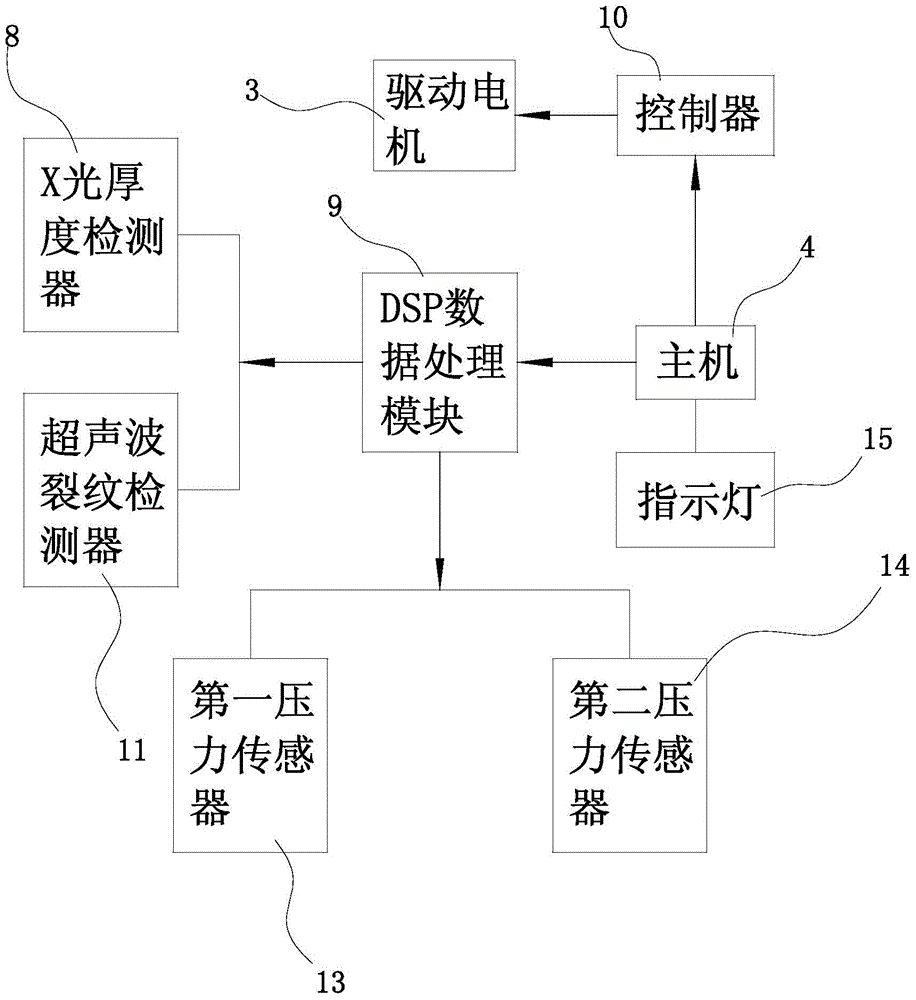

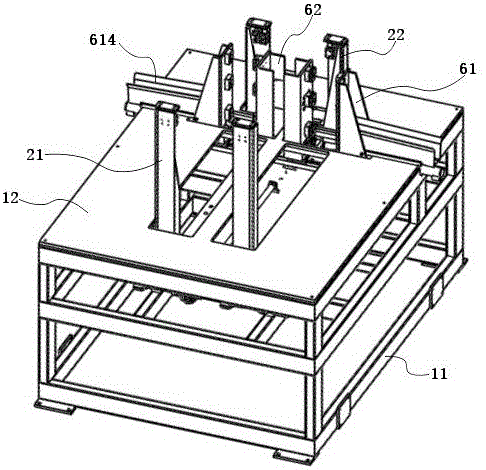

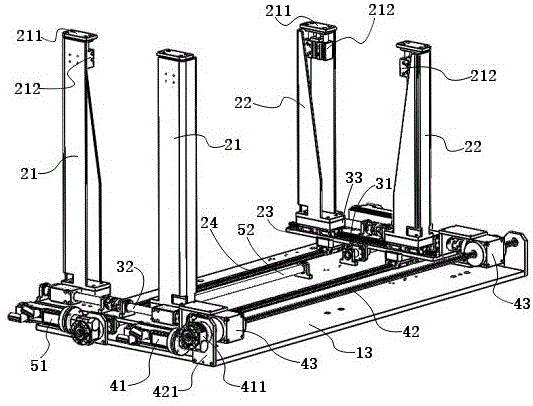

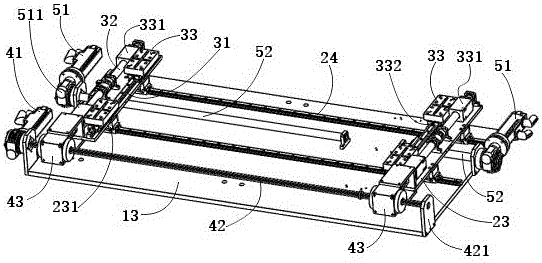

X-ray thickness detection and bending speed adjusting bending machine based on PLC

ActiveCN104624726AAvoid bendingAvoid empty foldsMetal-working feeding devicesShaping safety devicesX-rayDrive motor

The invention relates to an X-ray thickness detection and bending speed adjusting bending machine based on a PLC. The X-ray thickness detection and bending speed adjusting bending machine comprises a driving motor, a clamping fixing base, a main machine as well as an X-ray thickness detector, a first pressure sensor, a second pressure sensor and a detection feedback device, wherein the driving motor is arranged on a rack; the main machine is used for controlling the driving motor; a bending shaft is mounted on a motor shaft of the driving motor; a processed workpiece is arranged on the clamping fixing base; the X-ray thickness detector is mounted on the rack through a first bracket; the first pressure sensor and the second pressure sensor are arranged on the clamping fixing base; the detection feedback device comprises an ultrasonic crack detector which is arranged on the clamping fixing base through a second bracket. The invention further provides a bending processing method adopting the bending machine. Due to PLC controlled sectional processing and positioning detection, the phenomenon of bending deviation or bending omission can be avoided, and the processing reliability can be improved; the processed workpiece can be bent according to most appropriate torque, so that the processed workpiece is prevented from being affected by too large or too small torque, bending cracks can be reduced, and the processing quality can be improved.

Owner:南京比泰数控机械设备有限公司

Shell riveting device

InactiveCN105798180ASolve the problem of insufficient shock travelDoes not affect the rotation transmission effectMetal-working feeding devicesPositioning devicesEngineeringRisk stroke

The invention discloses a shell riveting device. The shell riveting device comprises a machine frame, a shell four-corner inner supporting mechanism and a shell riveting mechanism. The shell four-corner inner supporting mechanism and the shell riveting mechanism are installed on the machine frame. The shell four-corner inner supporting mechanism is used for supporting a shell when the shell is riveted. The shell four-corner inner supporting mechanism comprises four vertically-arranged inner supporting columns used for supporting the four corners of the shell. The shell riveting mechanism is used for riveting the shell and comprises two symmetrical and vertically-arranged outer supporting frames, two symmetrical and vertically-arranged inner supporting frames, two shell attachment adjustment mechanisms, plate type slide rails and a double-stroke oil cylinder. Riveting bases are arranged inside the outer supporting frames. Riveting heads are arranged outside the inner supporting frames. The outer supporting frames and the inner supporting frames are erected on the plate type slide rails. The shell attachment adjustment mechanism is connected with the outer supporting frames and used for driving the outer supporting frames to move along the plate type slide rails so that the riveting bases can get close to the outer side of the shell. The double-stroke oil cylinder is arranged between the two inner supporting frames and provides impact force for shell riveting.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Intelligent mechanical arm of punch press

InactiveCN101947607AWork fasterOperating speed and power savingProgramme-controlled manipulatorMetal-working feeding devicesPunch pressGear wheel

The invention relates to an intelligent mechanical arm of a punch press. In the invention, a horizontal movement mechanism of the mechanical arm is transmitted by adopting a stepper motor and a linear ball screw; a mechanical arm rolling-over mechanism is transmitted by adopting a stepper motor and a gear, connected by a rolling-over spindle and rolled over by a driving arm, and the driving arm is provided with the mechanical horizontal movement mechanism which rolls over together; the mechanical horizontal movement mechanism is transmitted by adopting a servo motor and a planetary reducer; an executing end rotating movement mechanism is transmitted by a stepper motor and a synchronizing wheel, an executing part is a vacuum sucking disc, and the executing end rotating movement mechanism is arranged on the arm of the horizontal movement mechanism; a vertical movement mechanism is transmitted by adopting a stepper motor, a pair of bevel gears, a ball screw and a screw nut sleeve; and the horizontal movement mechanism, the rolling movement mechanism and the executing end rotating movement mechanism are all arranged on the screw nut sleeve of the vertical movement mechanism. The invention adopts a servo system in the aspect of electrical control to ensure that the running speed of the machine is improved, electricity is saved, and the effects of energy saving and environmental protection are achieved.

Owner:FOSHAN DINGFENG ROBOT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com