Automatic stamping production line

A production line and automatic technology, applied in the field of stamping production lines, can solve the problems of small and medium-sized enterprises that are difficult to afford, difficult to produce in batches, and high system prices, and achieve the effect of reducing the risk of work-related injuries, reducing the labor intensity of workers, and the overall structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

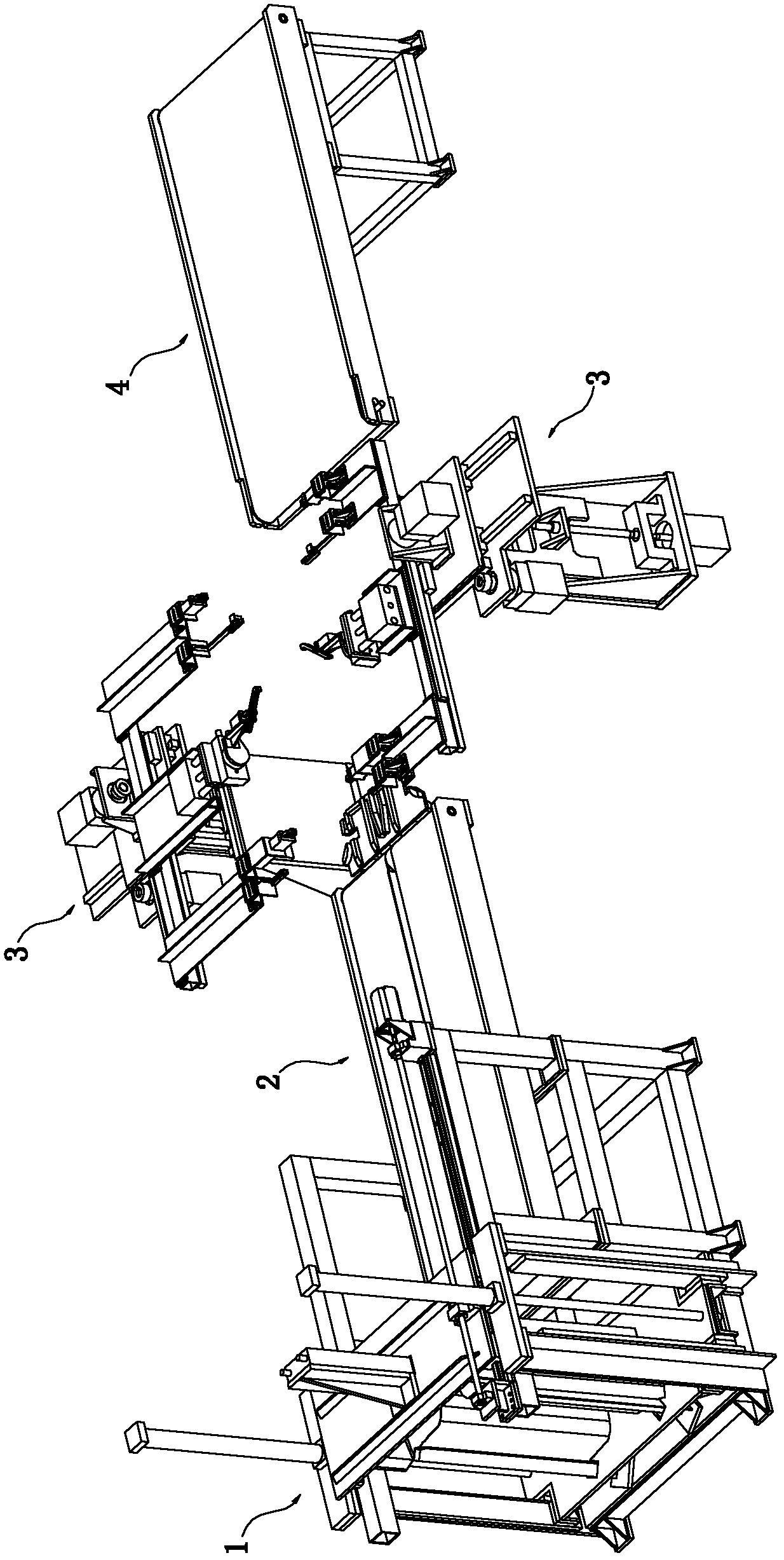

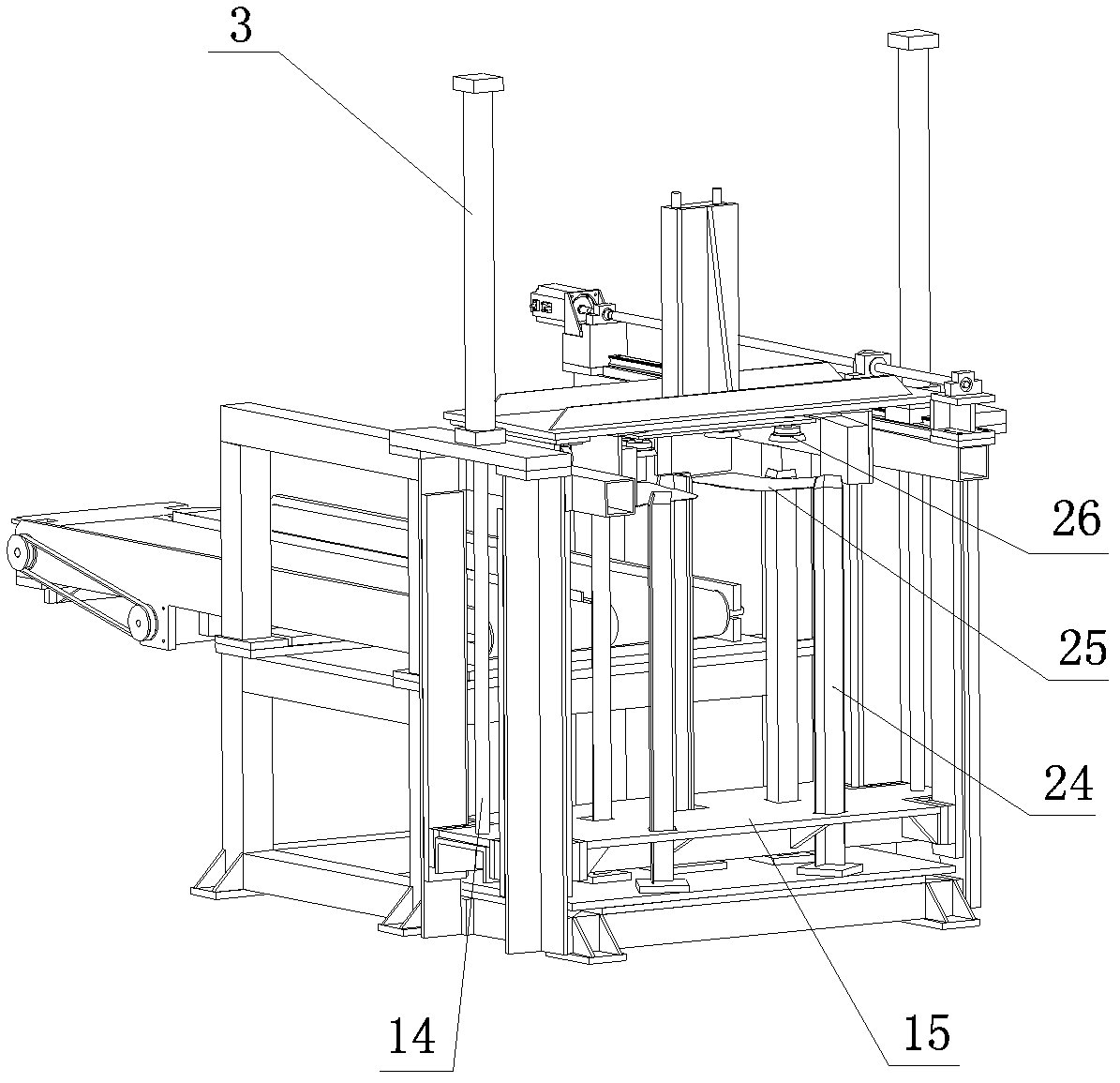

[0027] like figure 1 As shown, the automatic stamping production line of the present invention includes an electromagnetic feeding device 1 for sucking workpieces to be processed and a manipulator 3 for grabbing and turning over workpieces. The conveyor belt 2 and the manipulator 3 are arranged on one side or both sides of the stamping die after the feeding conveyor belt 2. In this embodiment, the manipulator 3 is symmetrically arranged on both sides of the stamping mold behind the feeding conveyor belt 2.

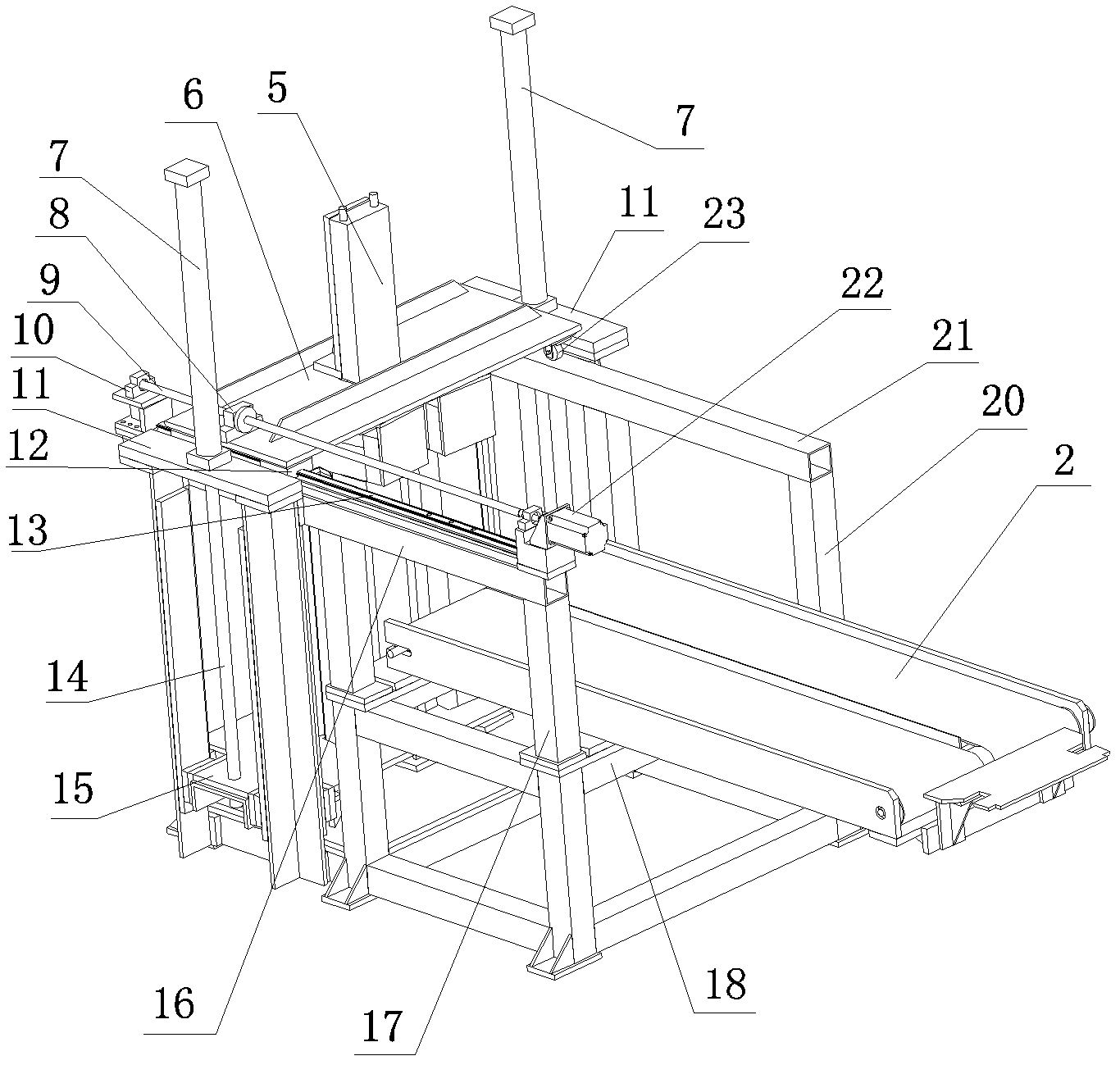

[0028] like Figure 2 to Figure 4As shown, the electromagnetic feeding device 1 includes two rows of support frames 17, 20, support beams I 16 and support beams II 21 that are respectively arranged on the tops of the two rows of support frames 17, 20 and are parallel to each other, and supported on the support beams I 16 and support beams II 21. The feeding mobile platform 6 is connected with the feeding cylinder Ⅰ5 on the feeding moving platform 6, and the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com