Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4850 results about "Stepper motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed.

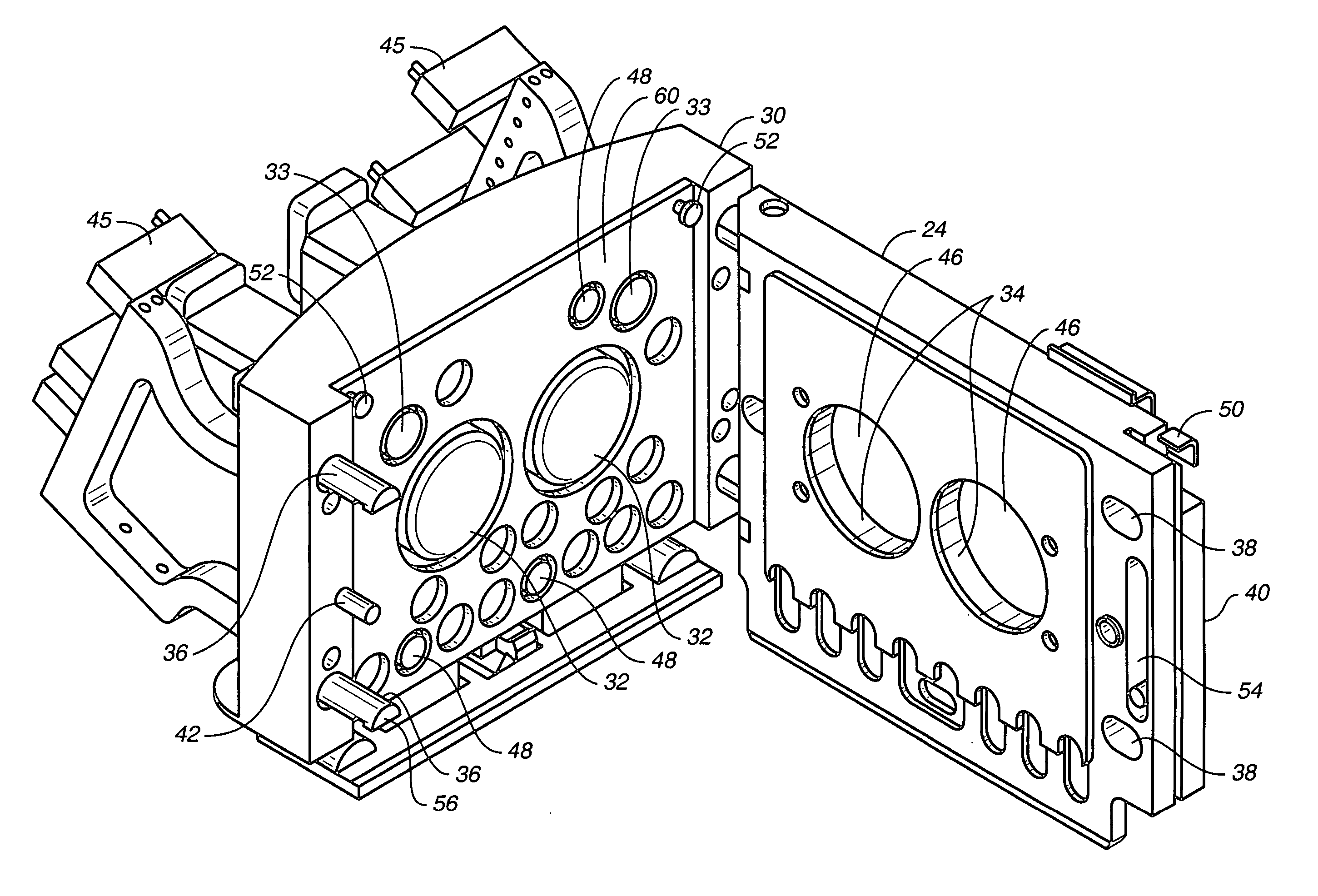

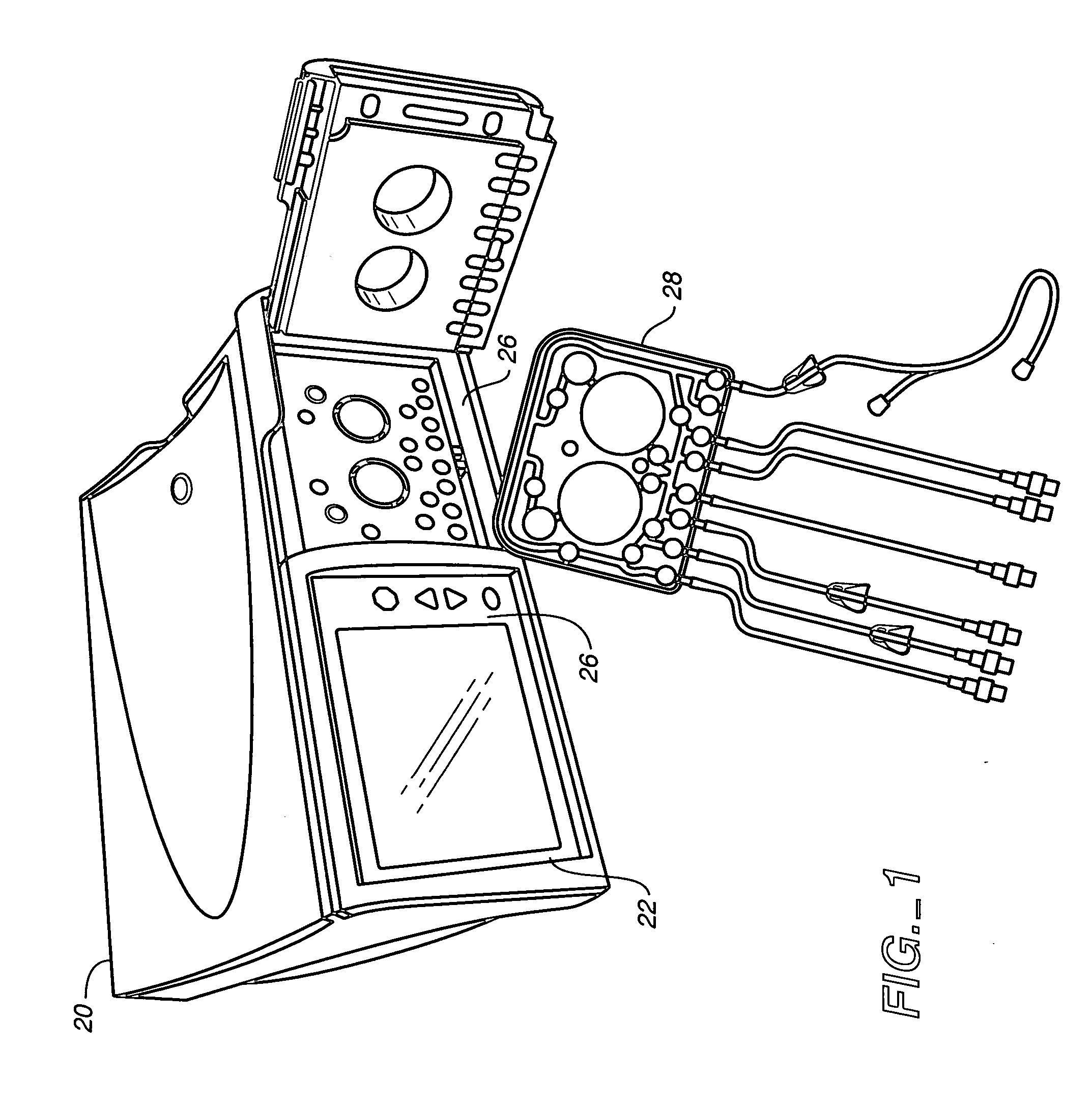

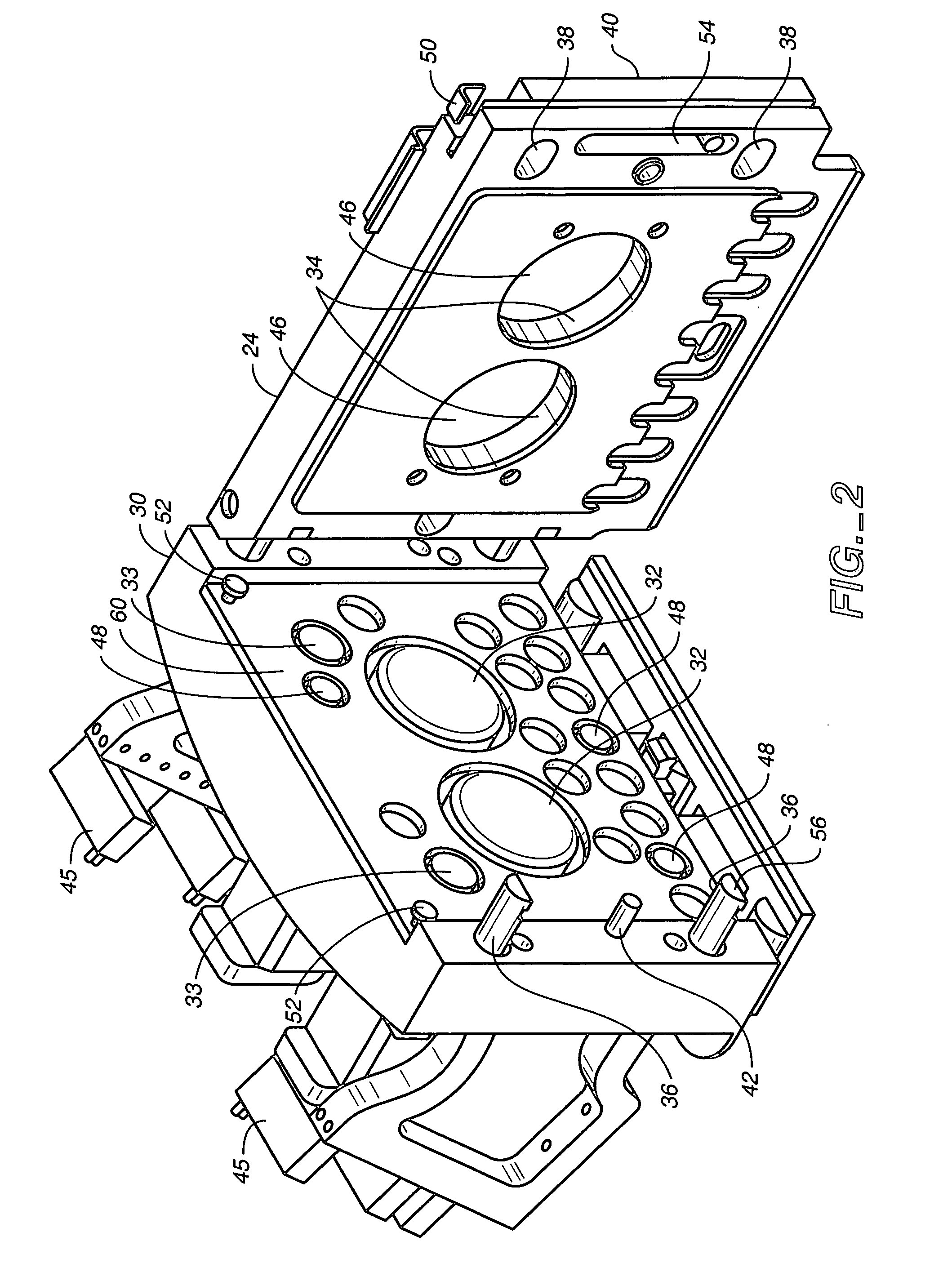

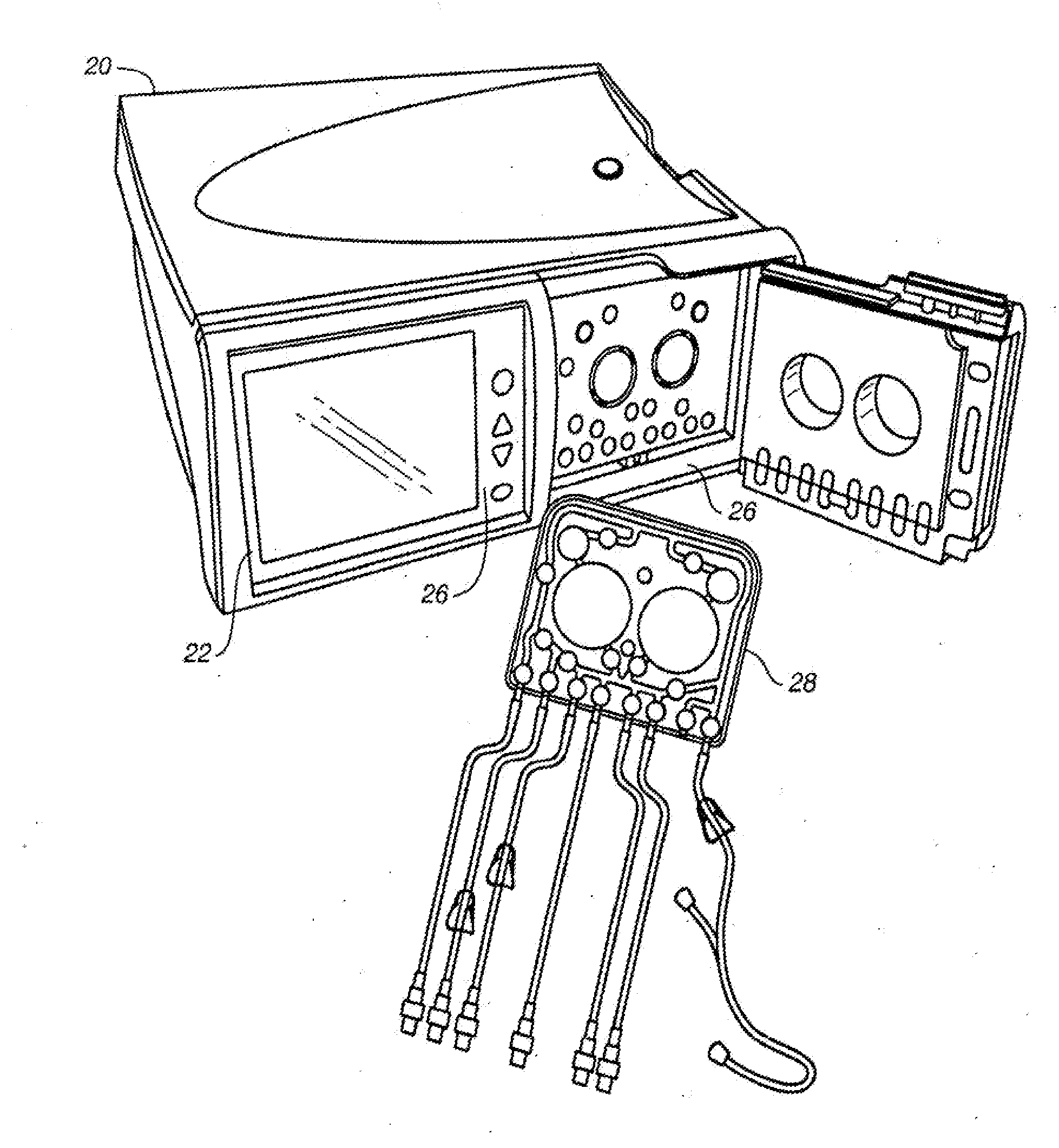

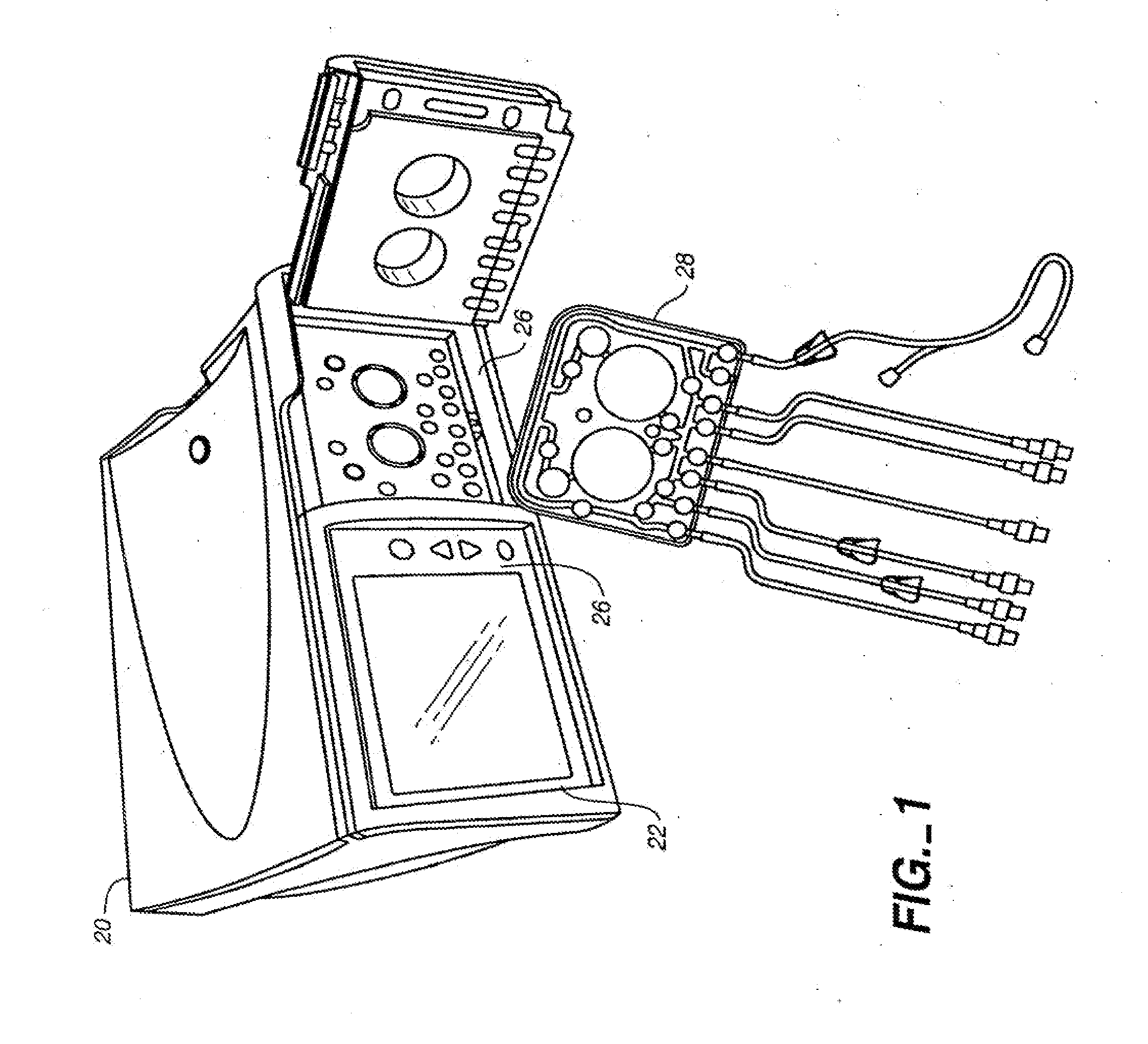

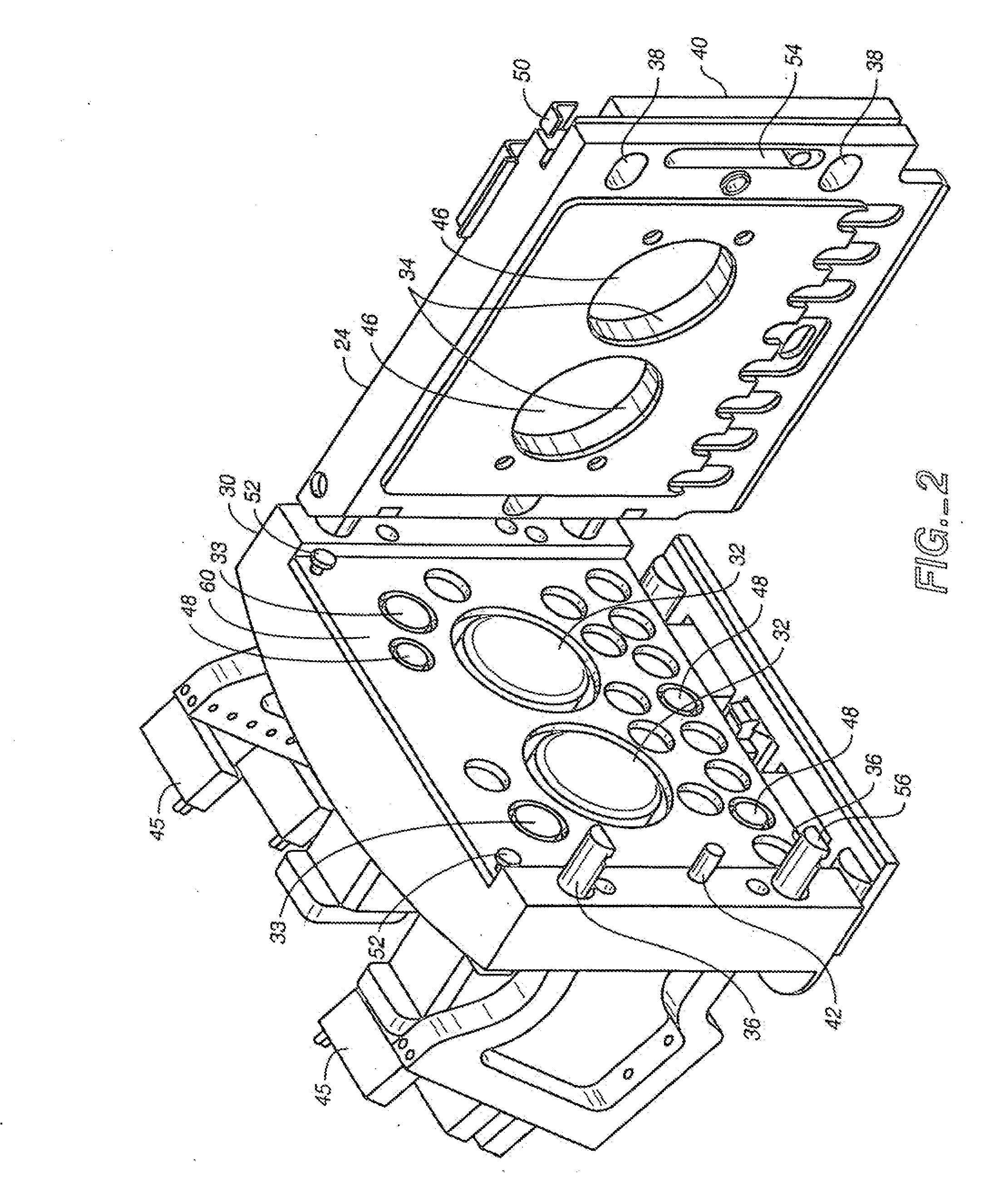

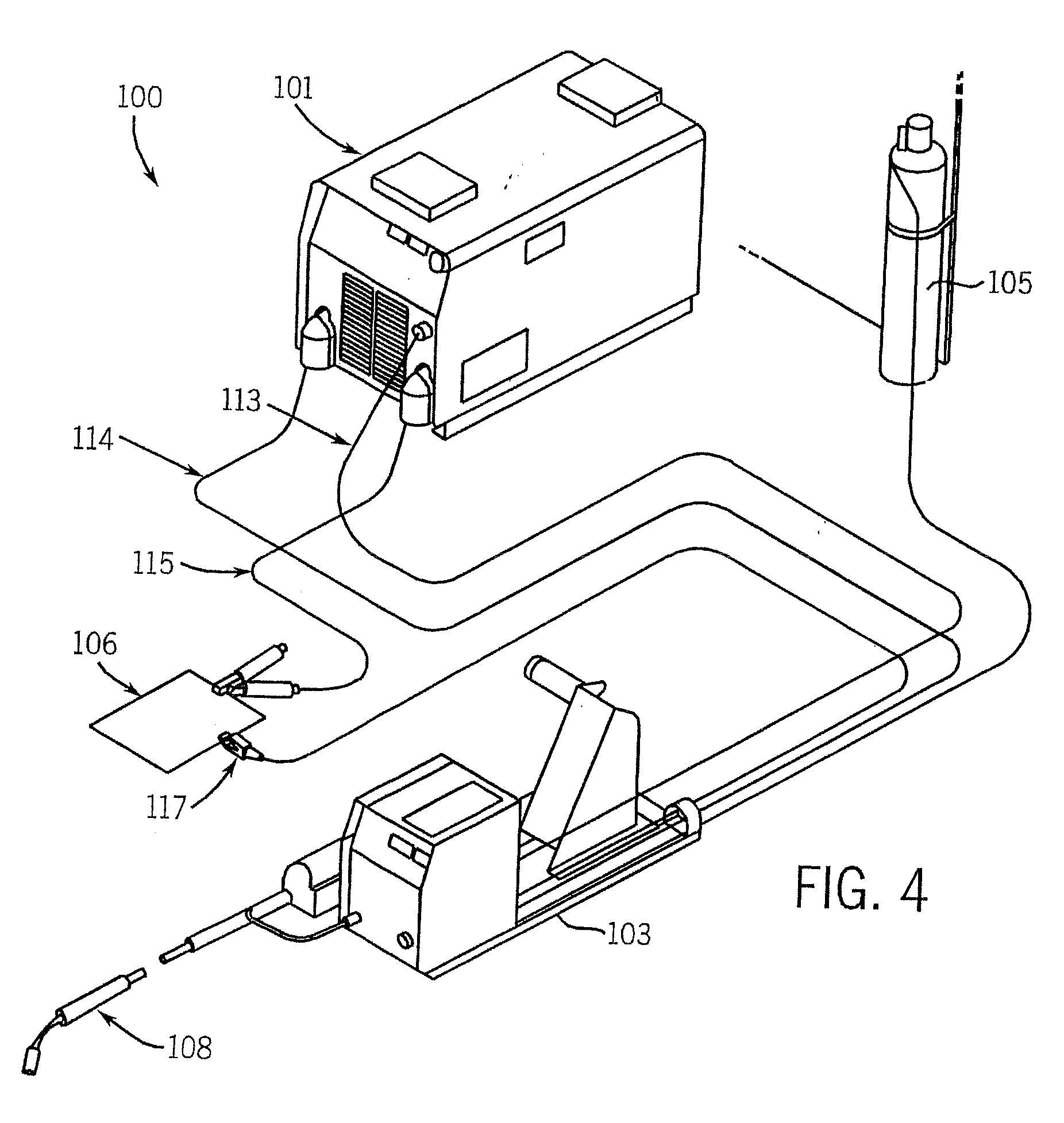

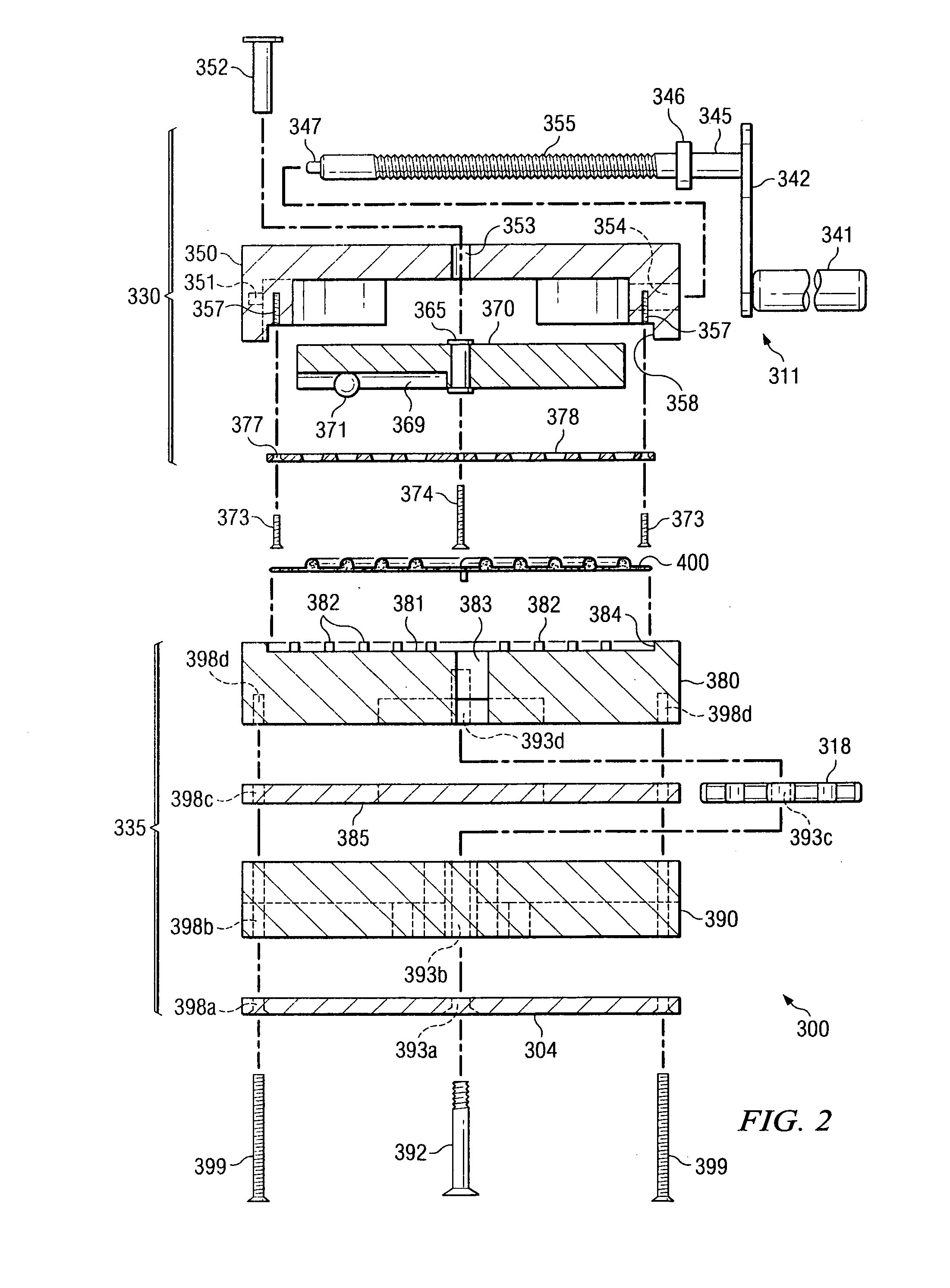

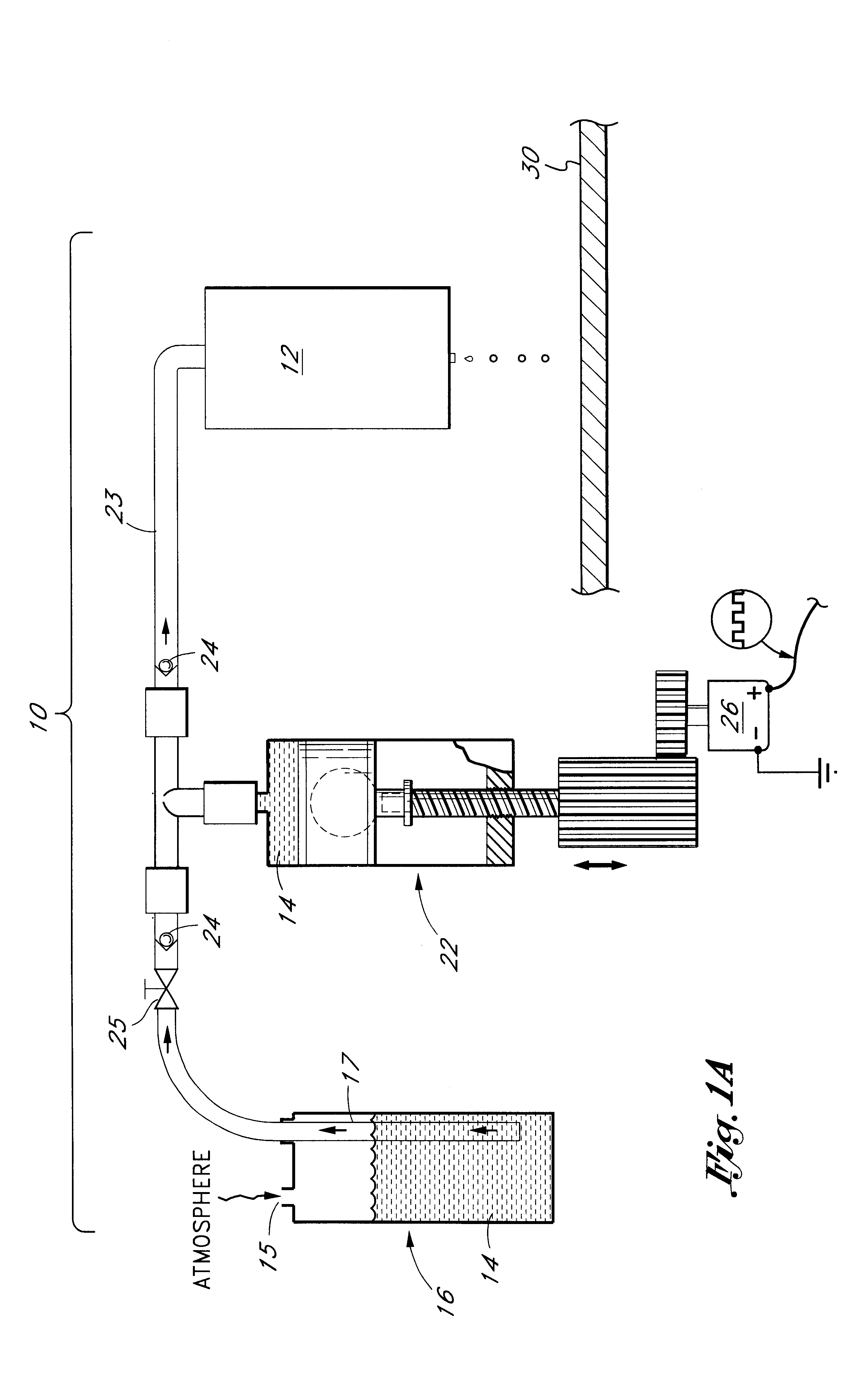

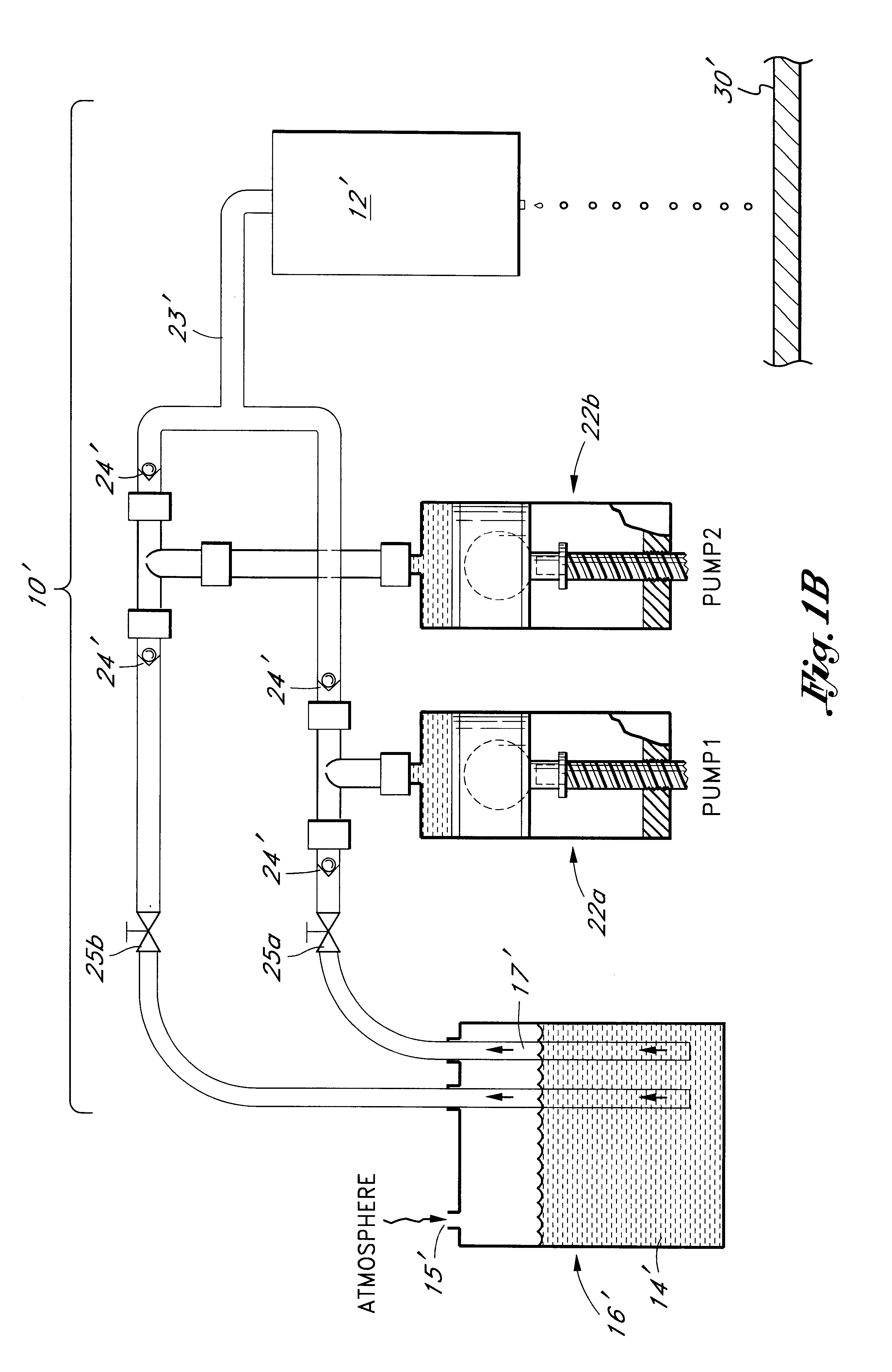

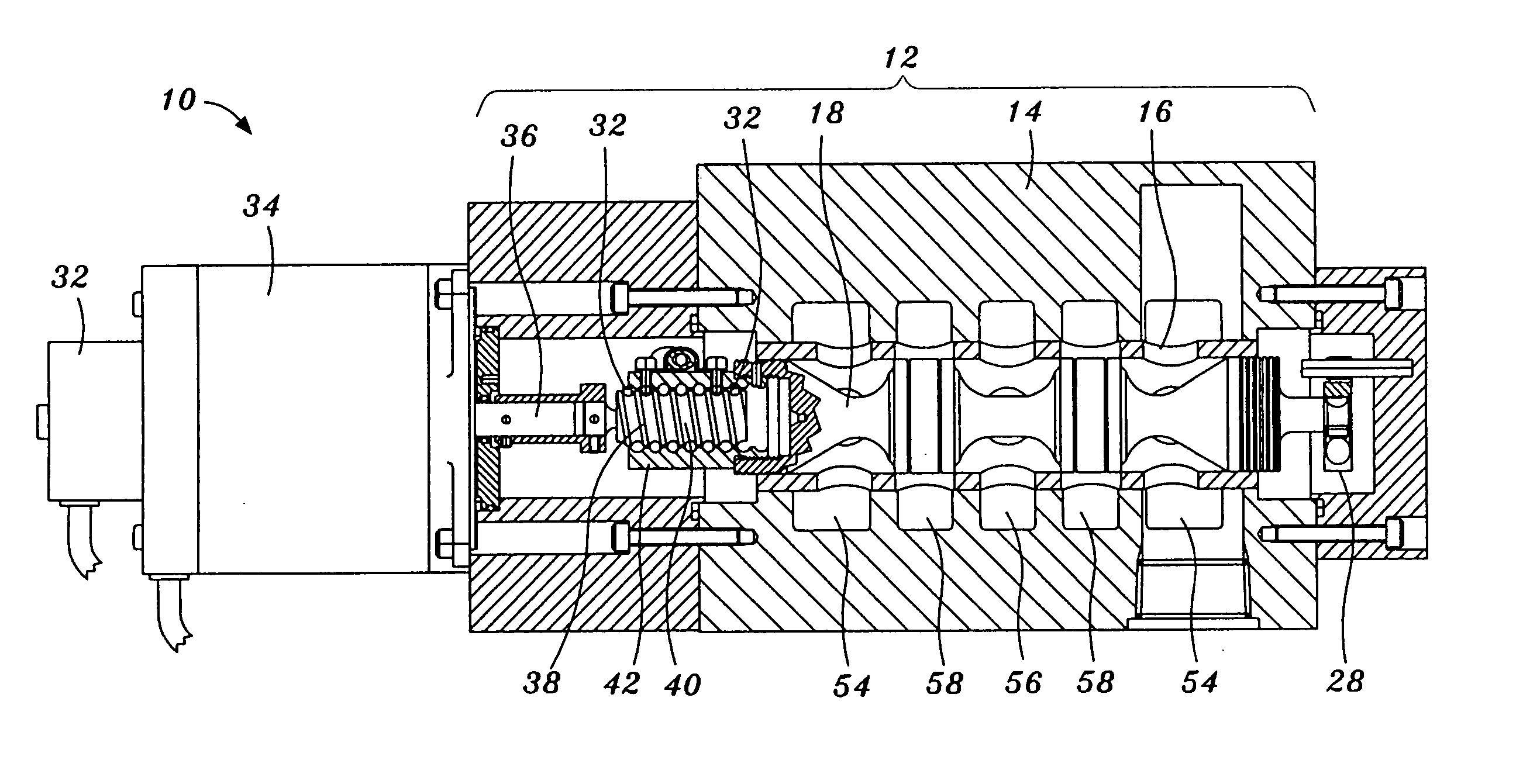

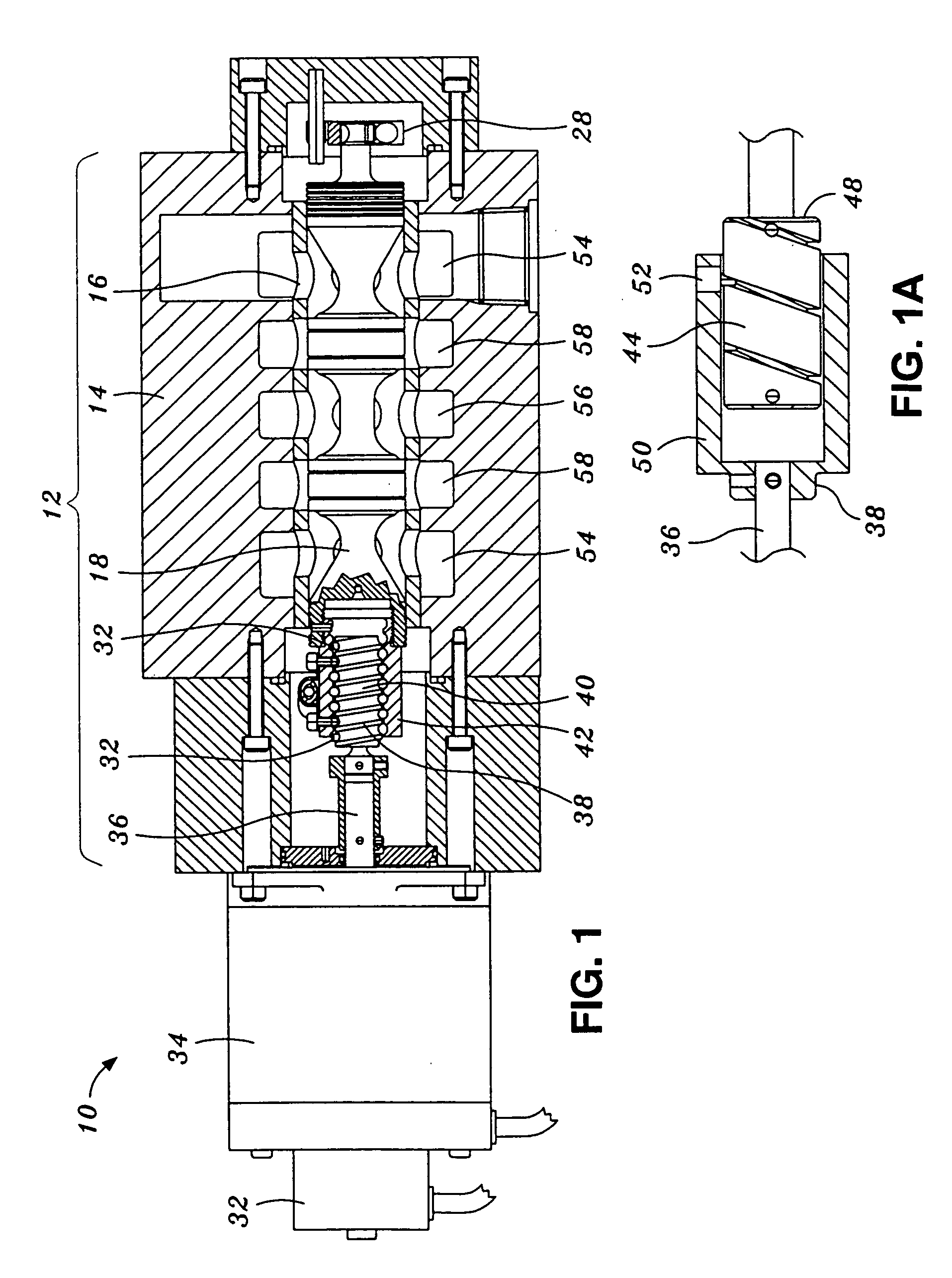

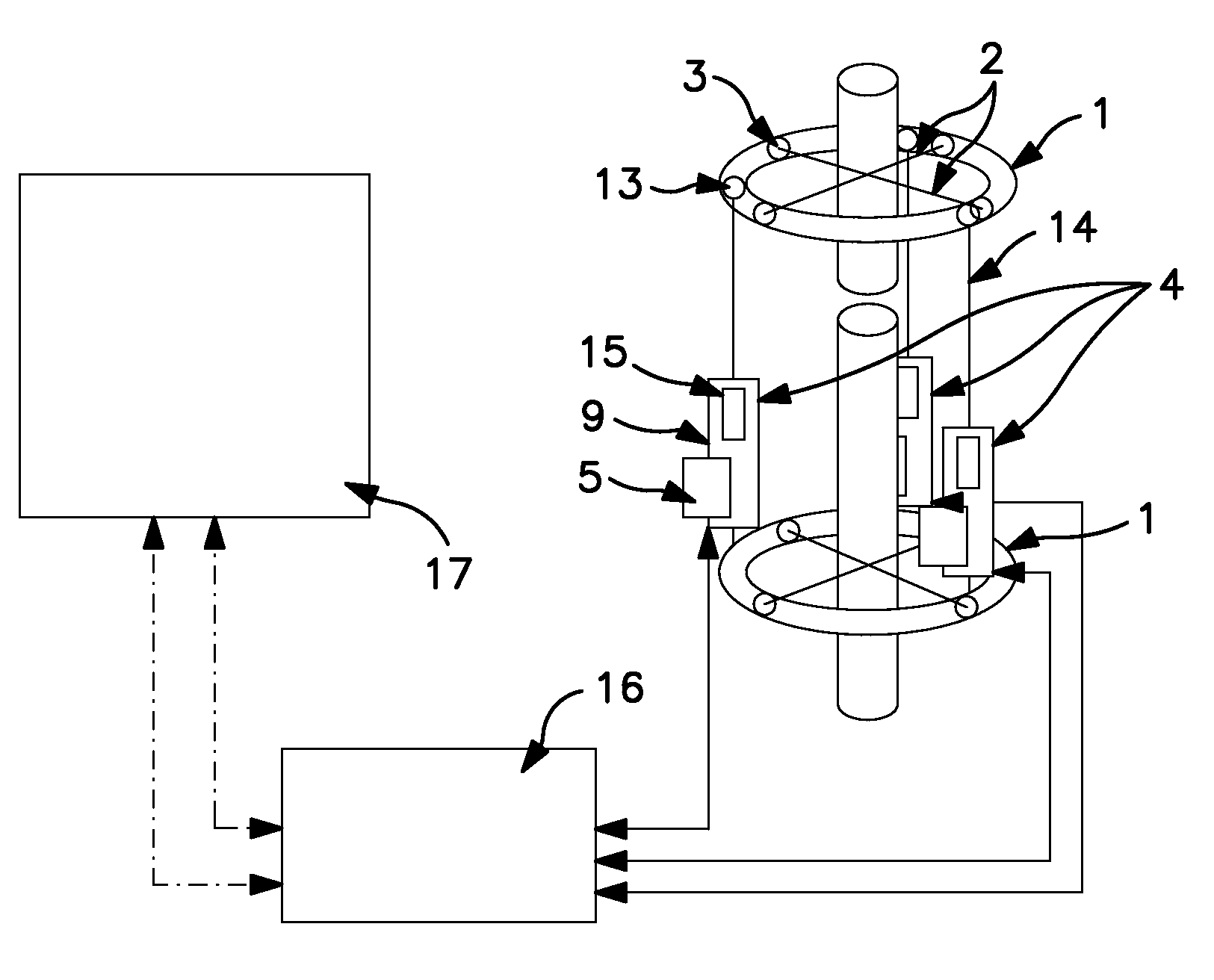

Portable apparatus for peritoneal dialysis therapy

A portable peritoneal dialysis apparatus having (1) a hinged door for enclosing a disposable cassette that seals tightly shut using air pressure; (2) accurate pressure sensing of pressures applied to the patient through an enclosure in the disposable cassette; (3) two pumps that can operate separately or in tandem actuated by two separate stepper motors; and (4) a touch screen user interface where indicia of the operating mode is always visible along with indicia for the other possible operating modes and the mode can be changed by touching one of these indicia.

Owner:FRESENIUS MEDICAL CARE HLDG INC

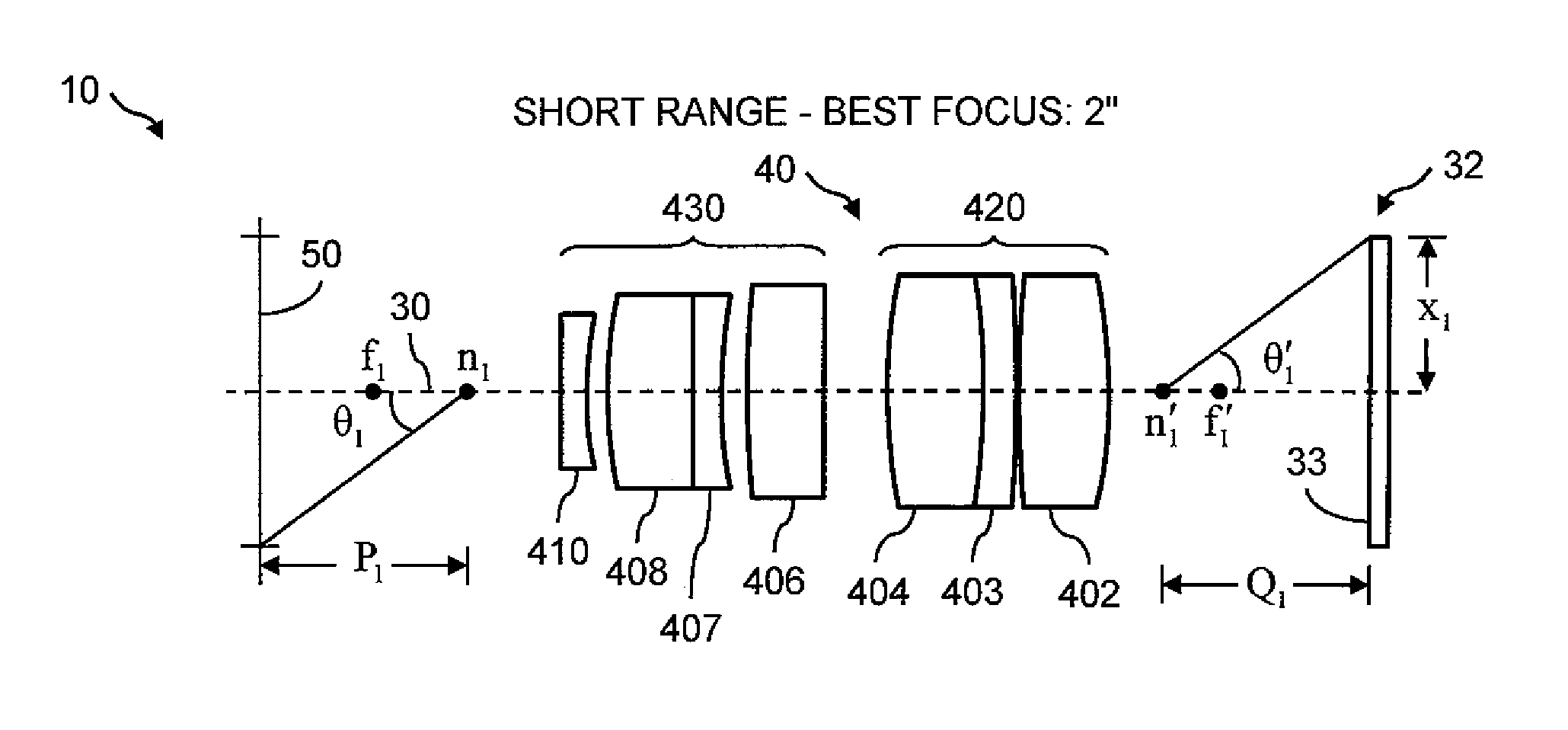

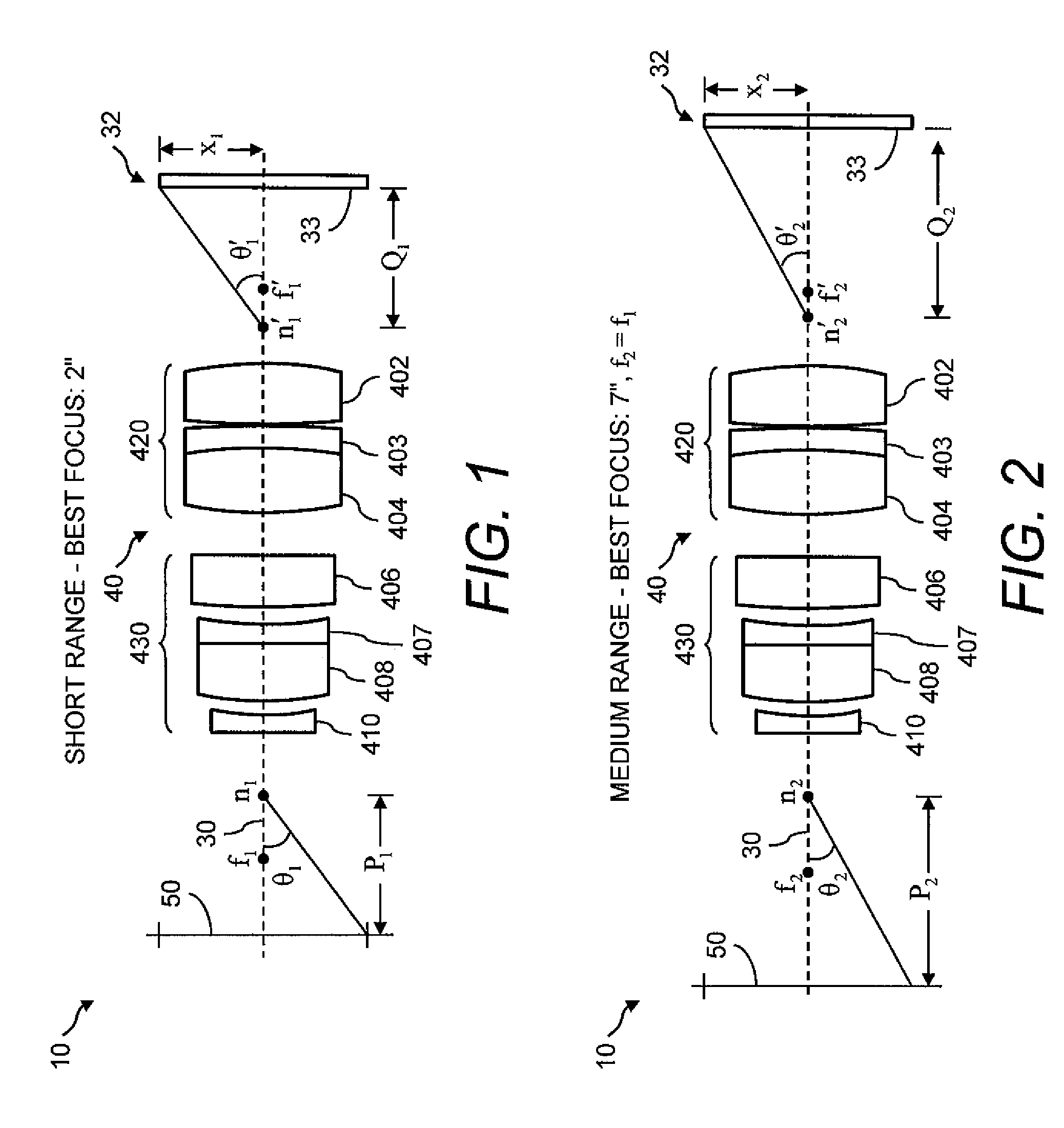

Indicia reading terminal having multiple setting imaging lens

ActiveUS7918398B2Visual representatino by photographic printingExposure controlSensor arrayCamera lens

An indicia reading terminal can include a multiple setting imaging lens assembly and an image sensor having an image sensor array. In one embodiment, an indicia reading terminal in an active reading state can cycle through a set of different lens settings, expose pixels of an image sensor array during an exposure period when each new lens setting is achieved, and attempt to decode decodable indicia represented in frames of image data captured corresponding to each exposure period. In one embodiment, movement of an imaging lens assembly lens element can be provided with use of a hollow stepper motor.

Owner:HAND HELD PRODS

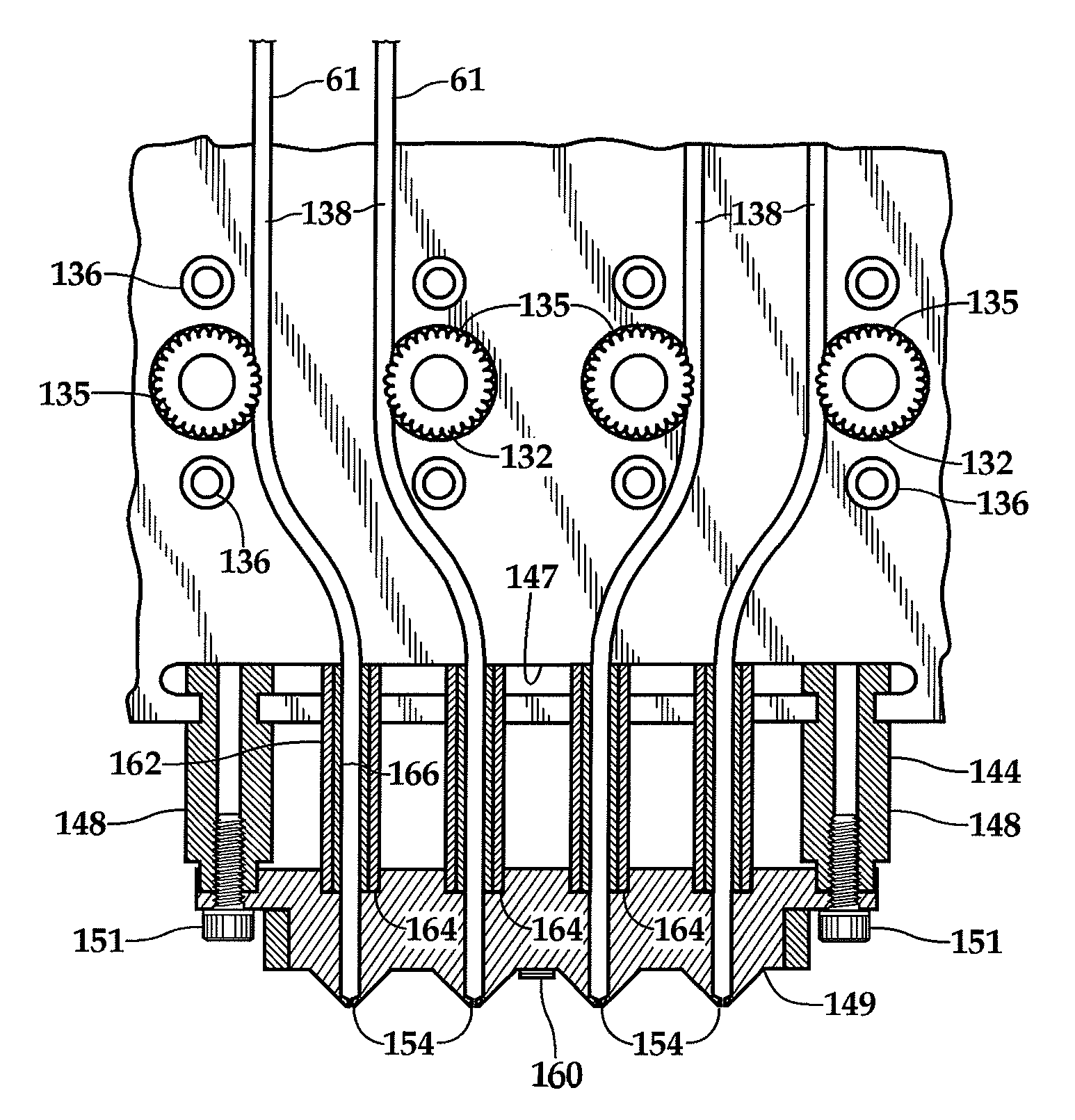

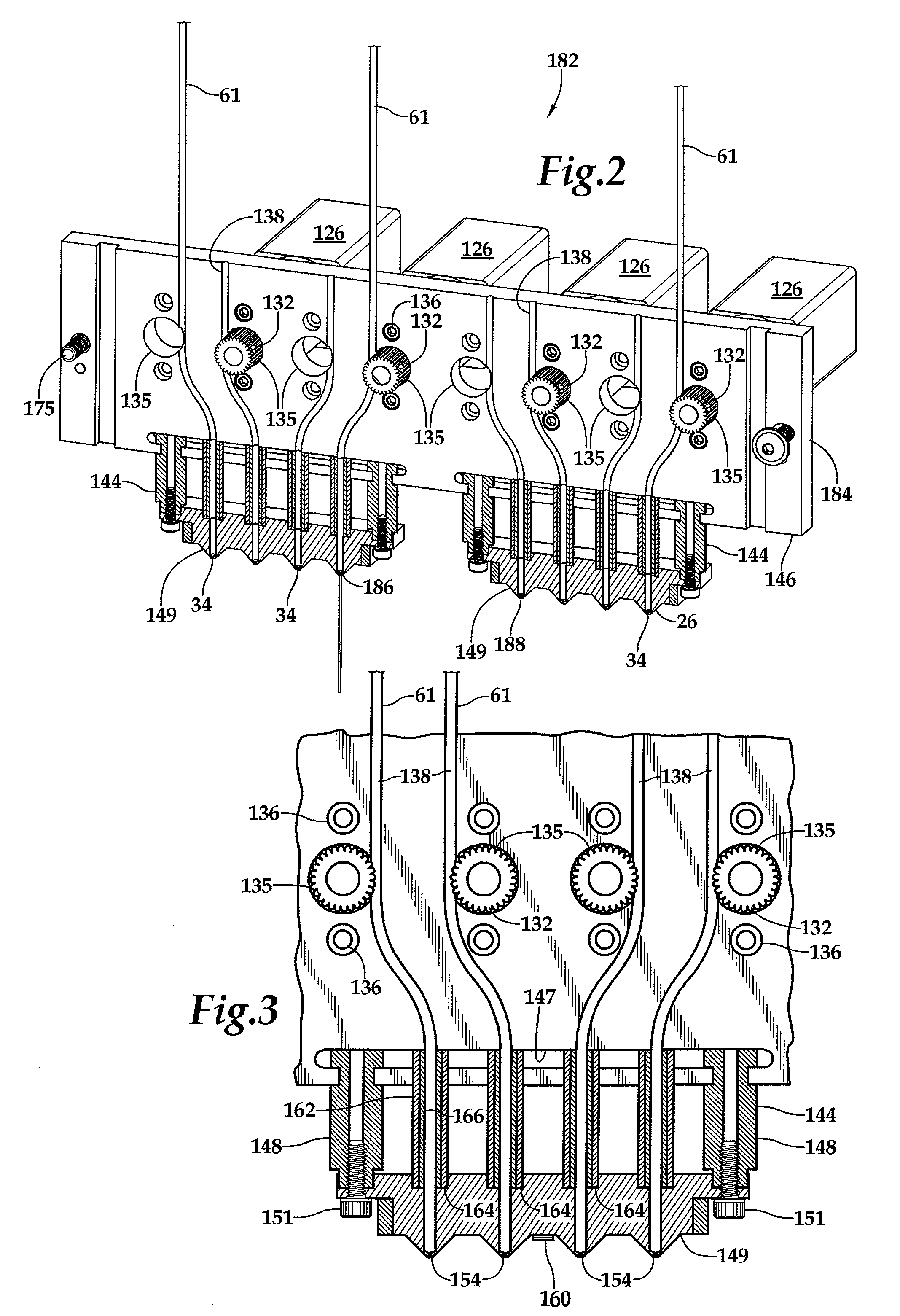

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

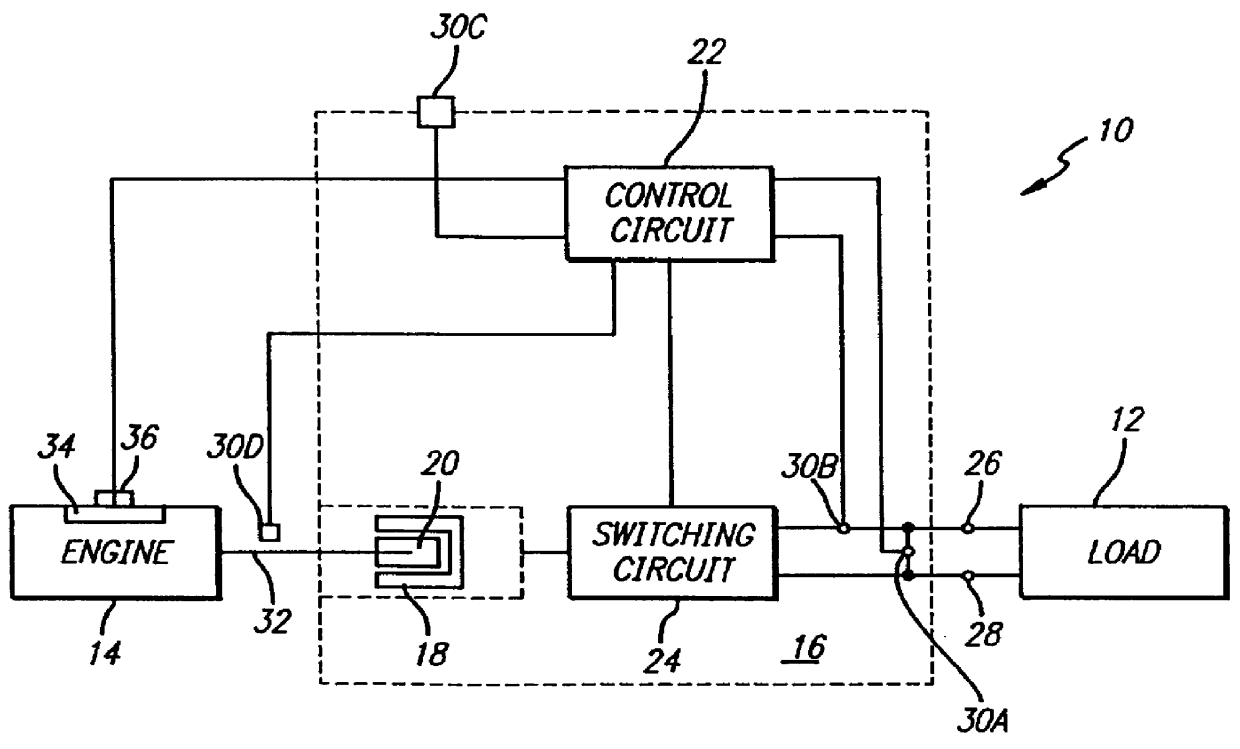

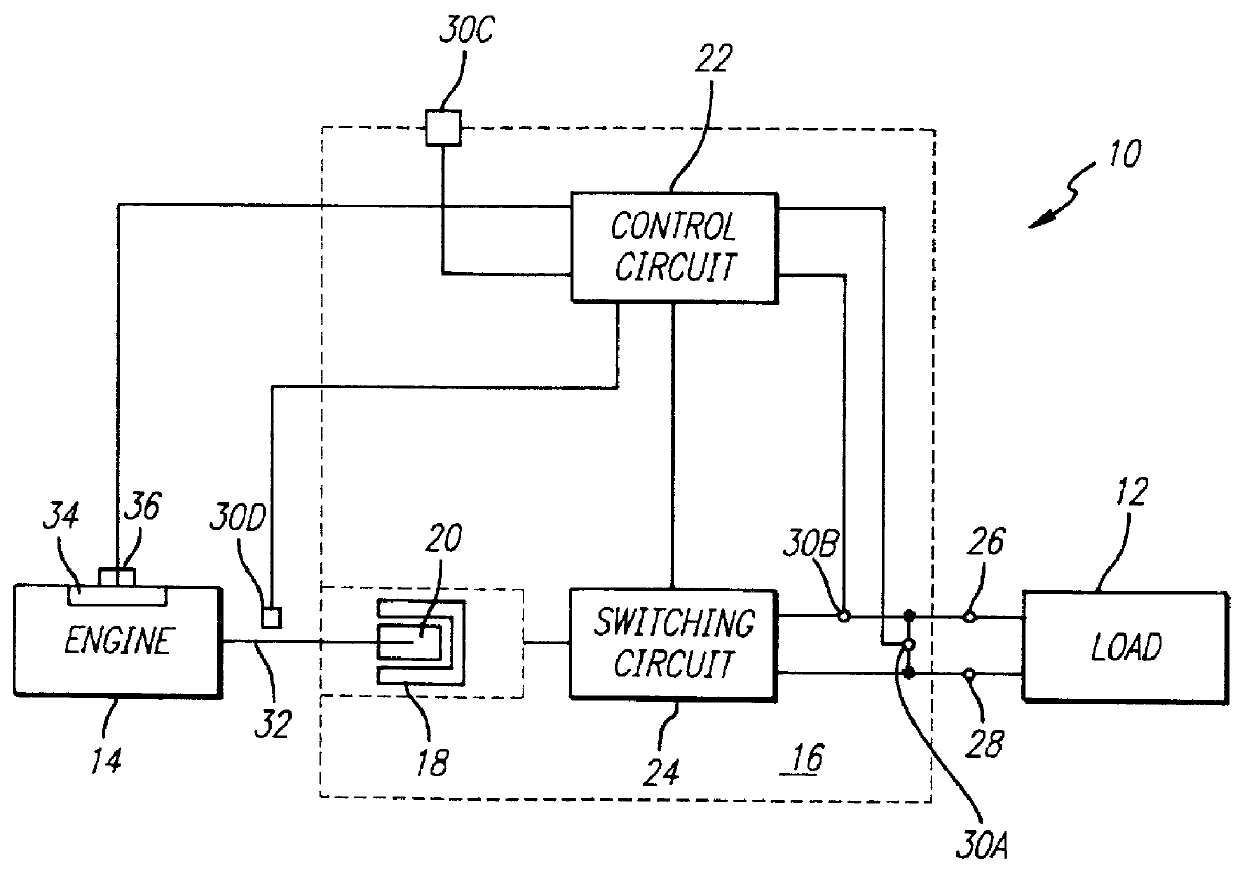

Throttle control for small engines and other applications

InactiveUS6118186AInhibit currentElectric motor startersEngine controllersThrottle controlSufficient time

The throttle of an engine in an engine driven generator system operating under an intermittently heavy load, as in supplying current to a welder, is controlled such that successive control signals sent to a throttle actuator for adjusting the engine throttle position are inhibited until at least a predetermined time has elapsed since the last preceding adjustment to the throttle. This procedure ensures that, as to each incremental adjustment to the throttle, the engine has sufficient time to respond, thereby preventing over-speeding or stalling the engine. The throttle actuator may be a stepper motor which is stepped by throttle position change signals from a processor which monitors engine speed and generator load to determine whether the throttle should be adjusted and, if so, in which direct. Alternatively, the throttle actuator may be a solenoid pulling against a spring in accordance with the average current through the solenoid coil. In this embodiment, the processor causes pulse width modulated signals to be applied across the solenoid coil with throttle position changes being reflected in changes to the width of the pulses, such changes in the pulse width being delayed for at least the predetermined time since the last preceding adjustment to the throttle.

Owner:PRAMAC AMERICA

Load demand throttle control for portable generator and other applications

The throttle of an engine in an engine driven generator system operating subject to a wide and rapidly variable load, as in supplying current to a welder, is operated such that control signals are sent to a throttle actuator for adjusting the engine throttle position in response to load changes. The throttle actuator may be a solenoid pulling against a spring in accordance with the average current through the solenoid coil. In this embodiment, the processor causes pulse width modulated signals to be applied across the solenoid coil with throttle position changes being reflected in changes to the width of the pulses, such changes in the pulse width being delayed for at least the predetermined time since the last preceding adjustment to the throttle. Alternatively, the throttle actuator may be a stepper motor which is stepped by throttle position change signals from a processor which monitors engine speed and generator load to determine whether the throttle should be adjusted and, if so, in which direction and to what extent for optimum response.

Owner:PRAMAC AMERICA

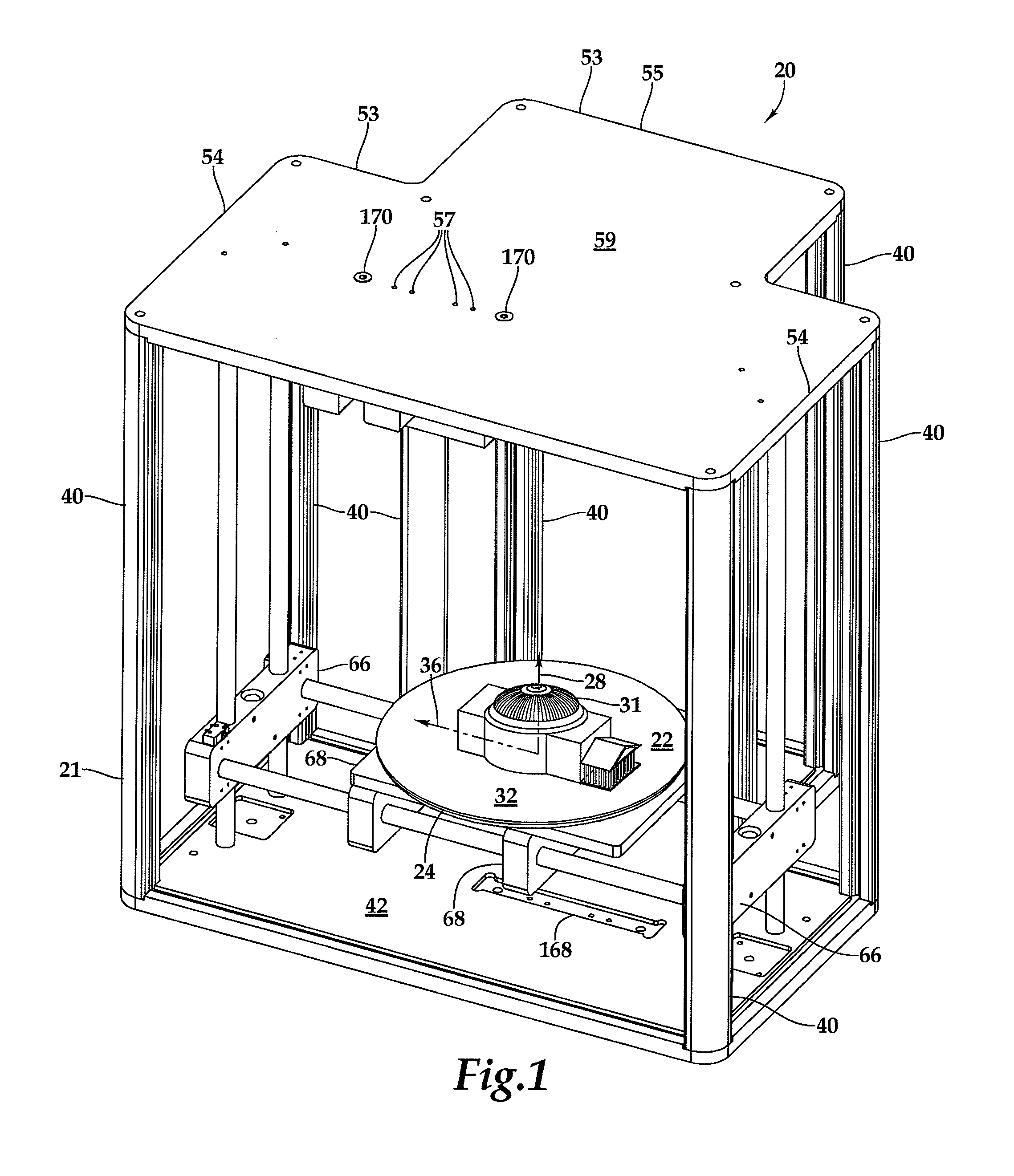

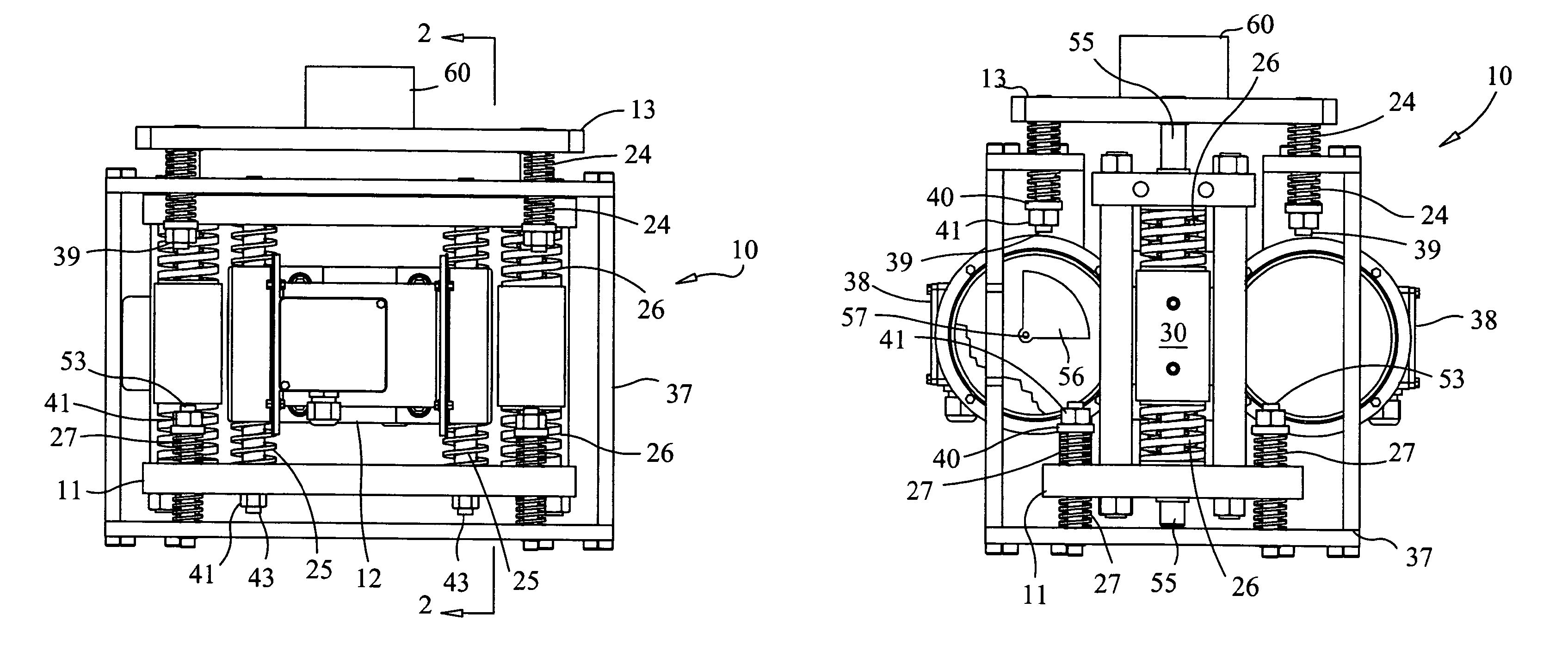

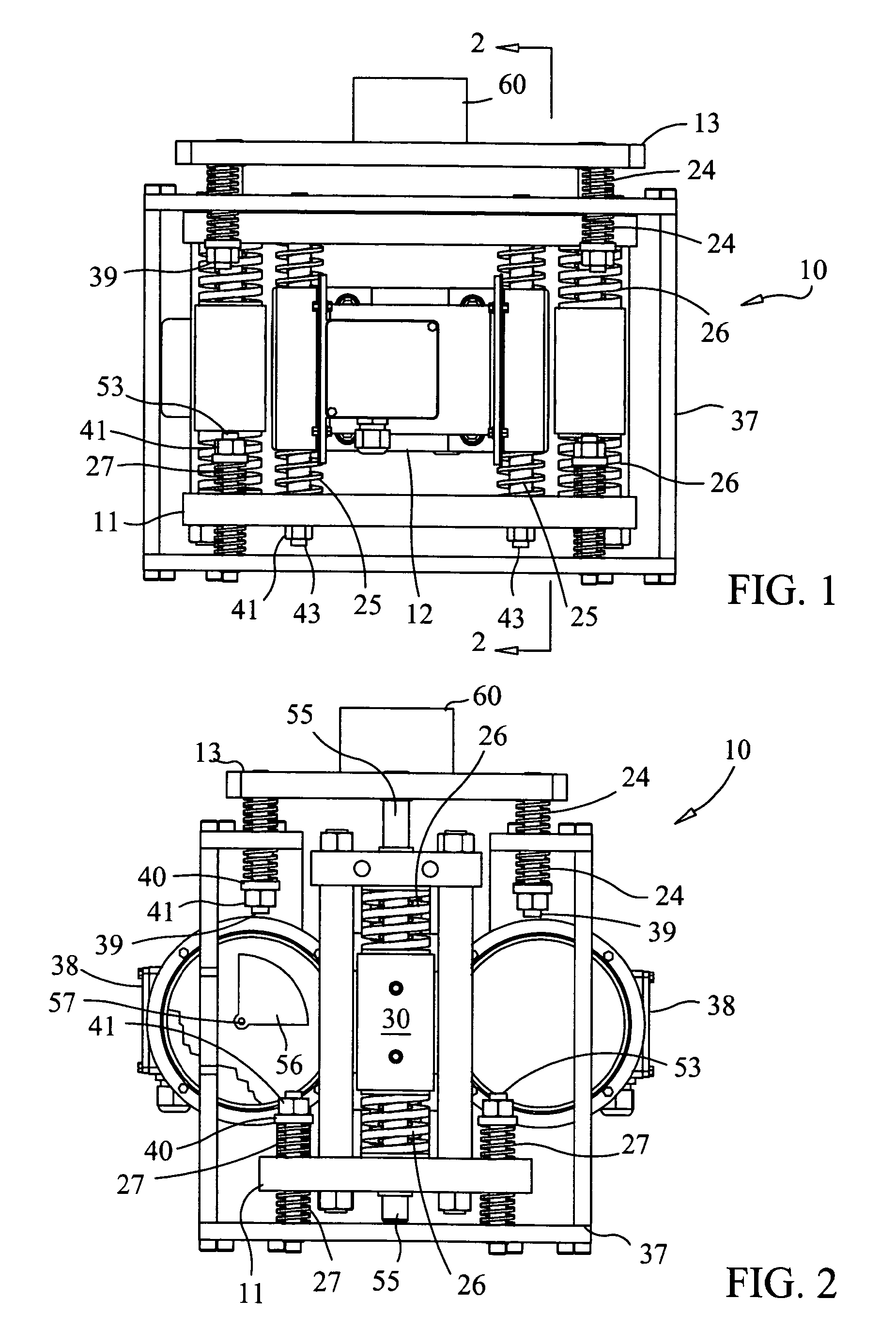

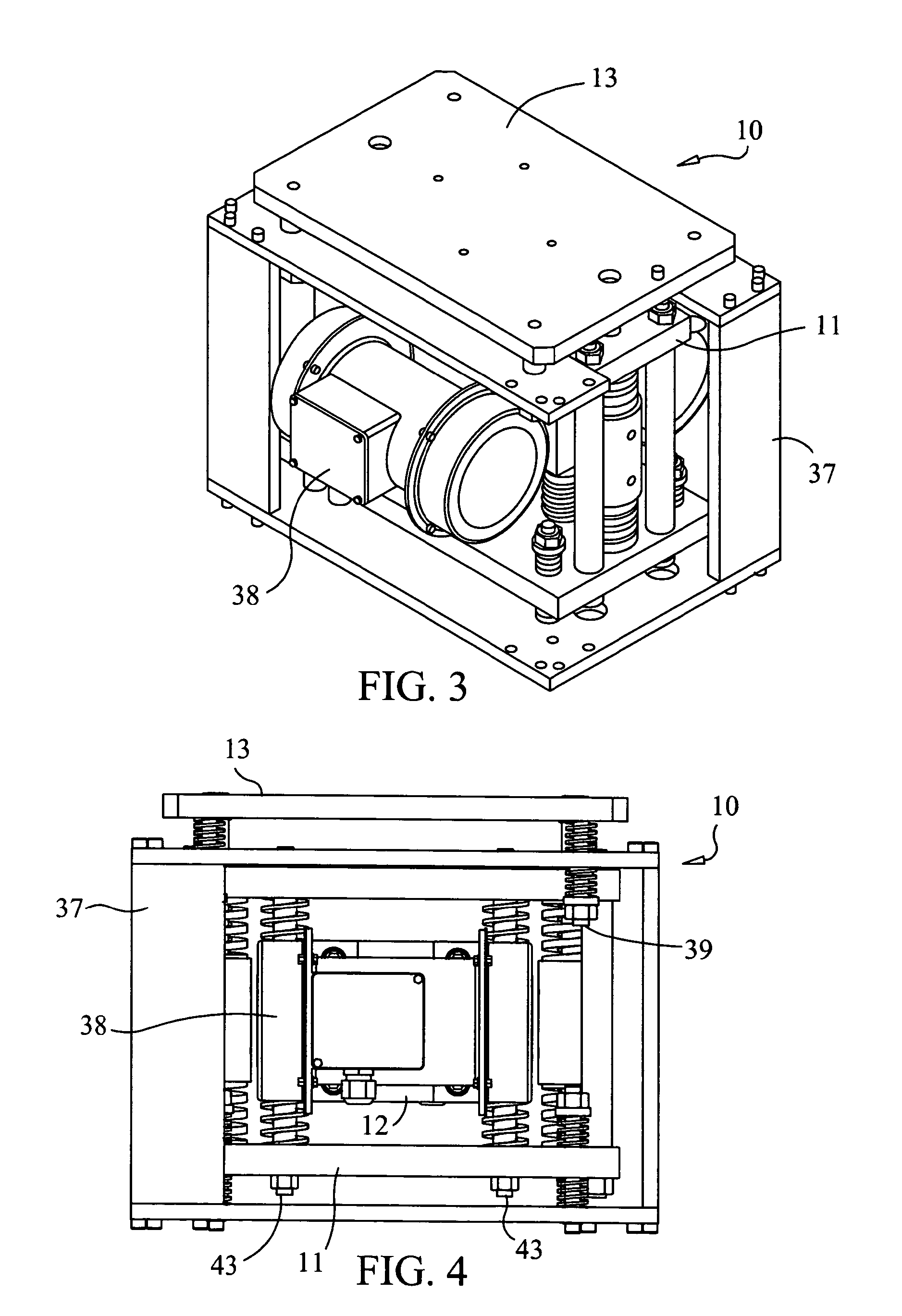

Apparatus and method for resonant-vibratory mixing

ActiveUS7188993B1Reduce the overall heightImprove bearing lifeShaking/oscillating/vibrating mixersTransportation and packagingLinear motionElectronic controller

An apparatus and method for mixing fluids and / or solids in a manner that can be varied from maintaining the integrity of fragile molecular and biological materials in the mixing vessel to homogenizing heavy aggregate material by supplying large amounts of energy. Variation in the manner of mixing is accomplished using an electronic controller to generate signals to control the frequency and amplitude of the motor(s), which drive an unbalanced shaft assembly to produce a linear vibratory motion. The motor may be a stepper motors a linear motor or a DC continuous motor. By placing a sensor on the mixing vessel platform to provide feedback control of the mixing motor, the characteristics of agitation in the fluid or solid can be adjusted to optimize the degree of mixing and produce a high quality mixant.

Owner:RESODYN ACOUSTIC MIXERS

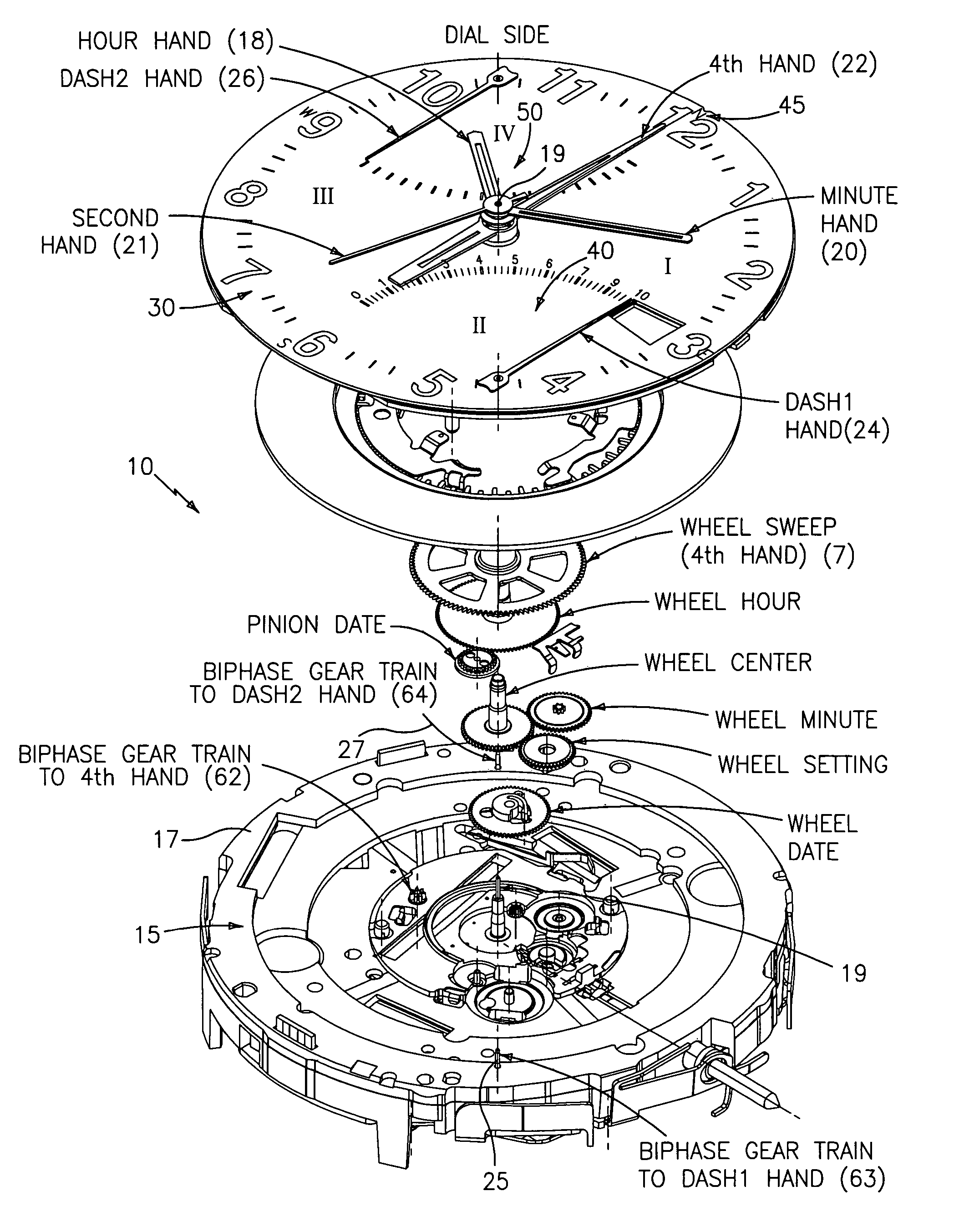

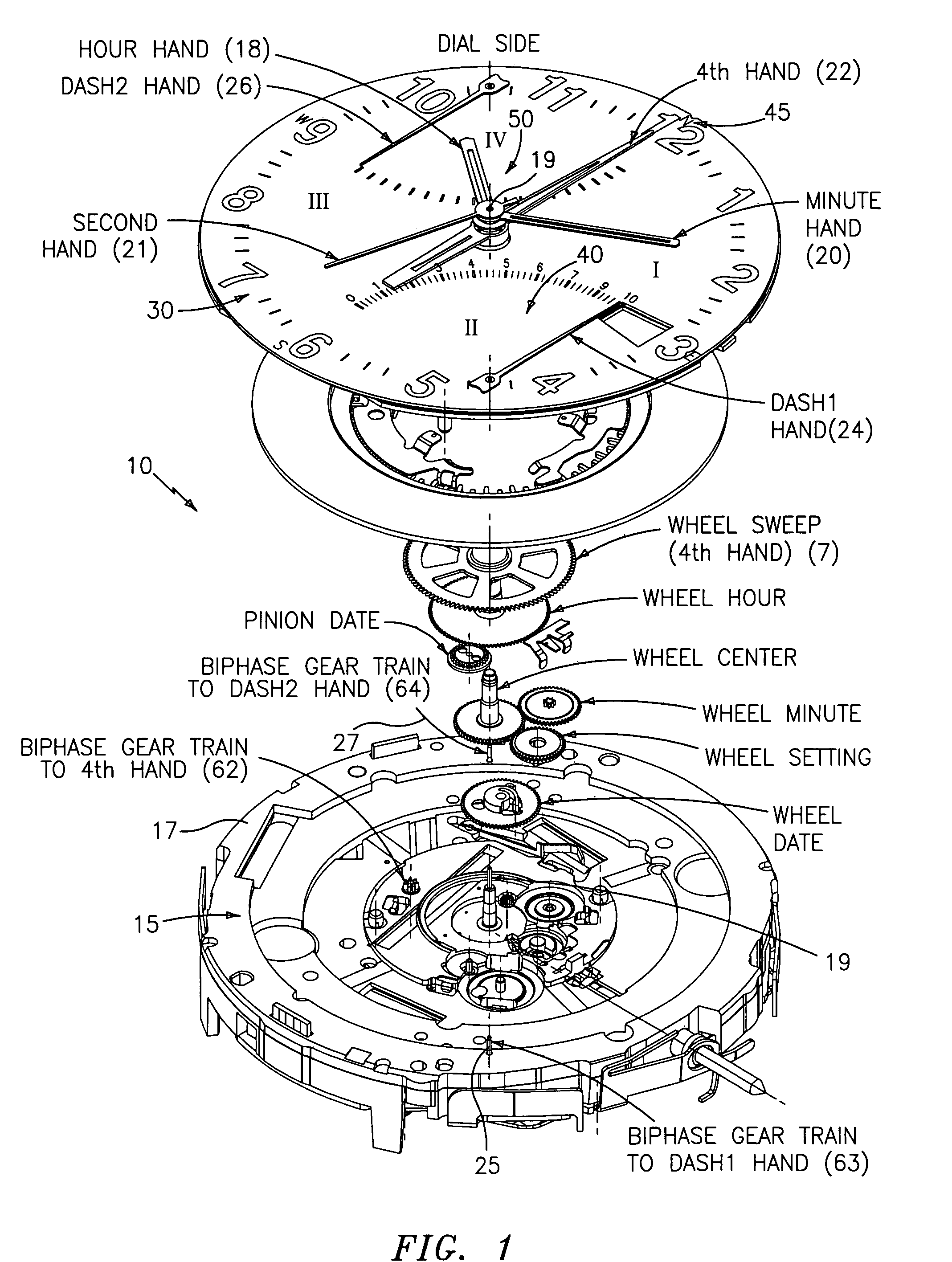

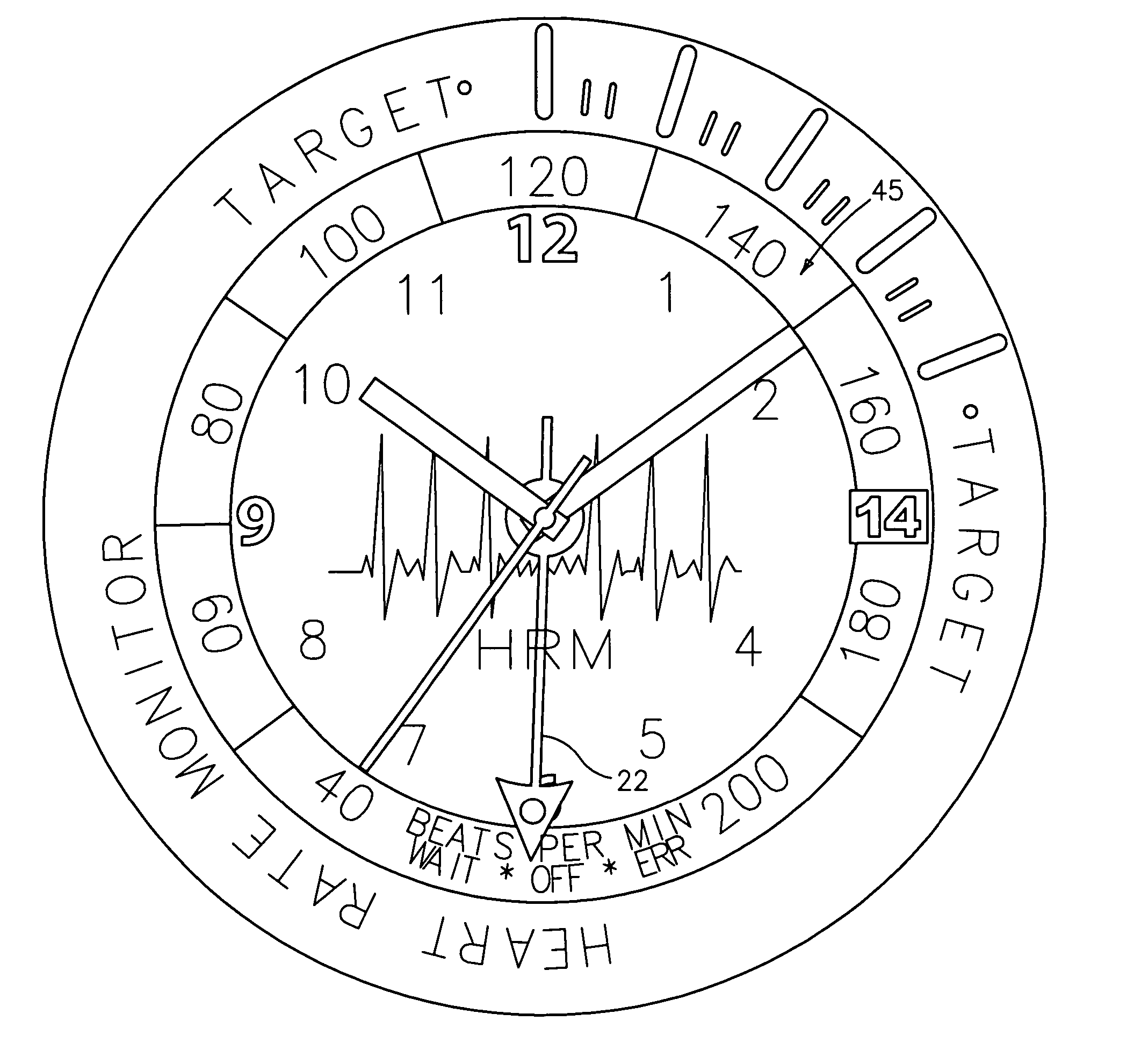

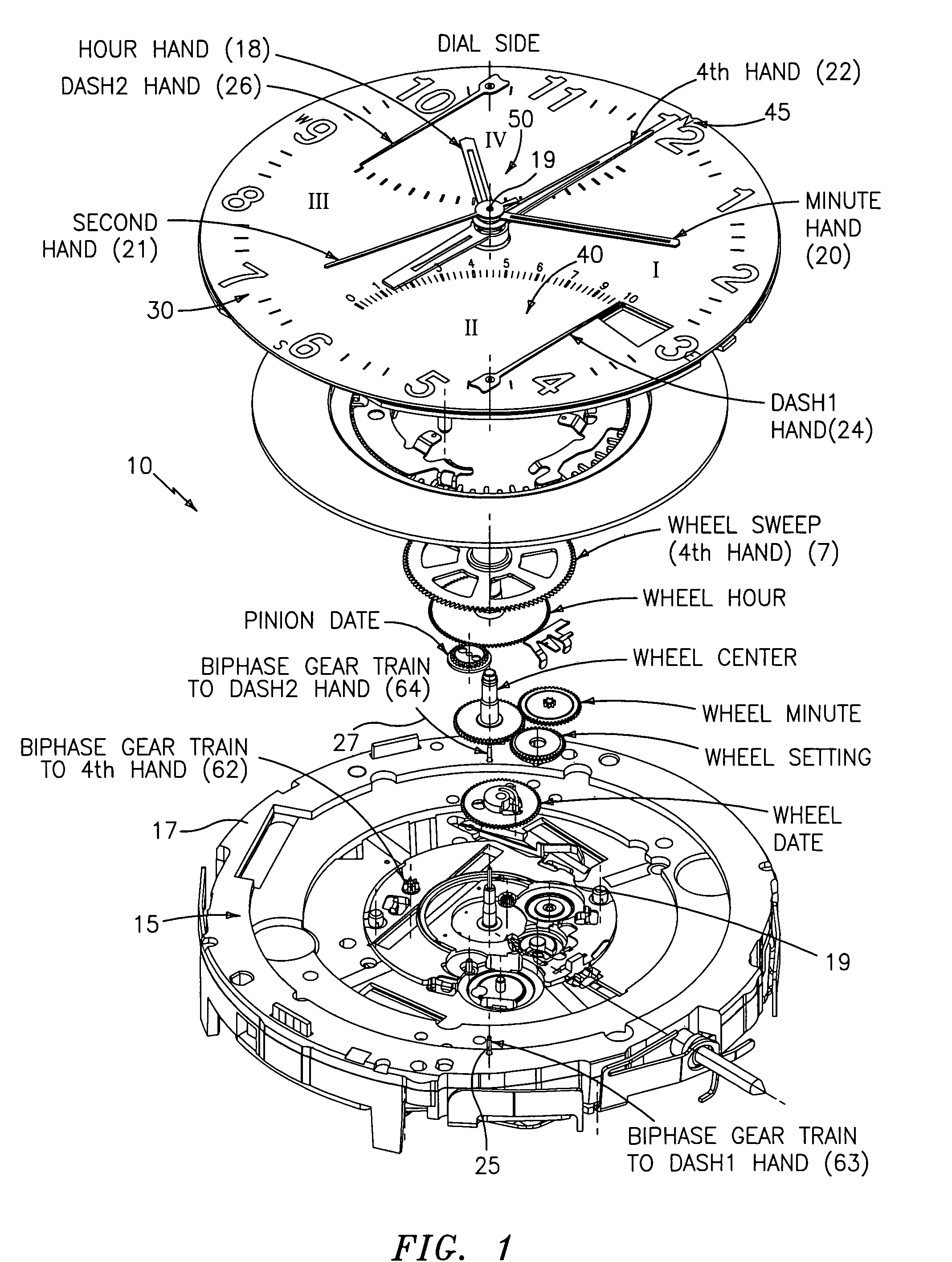

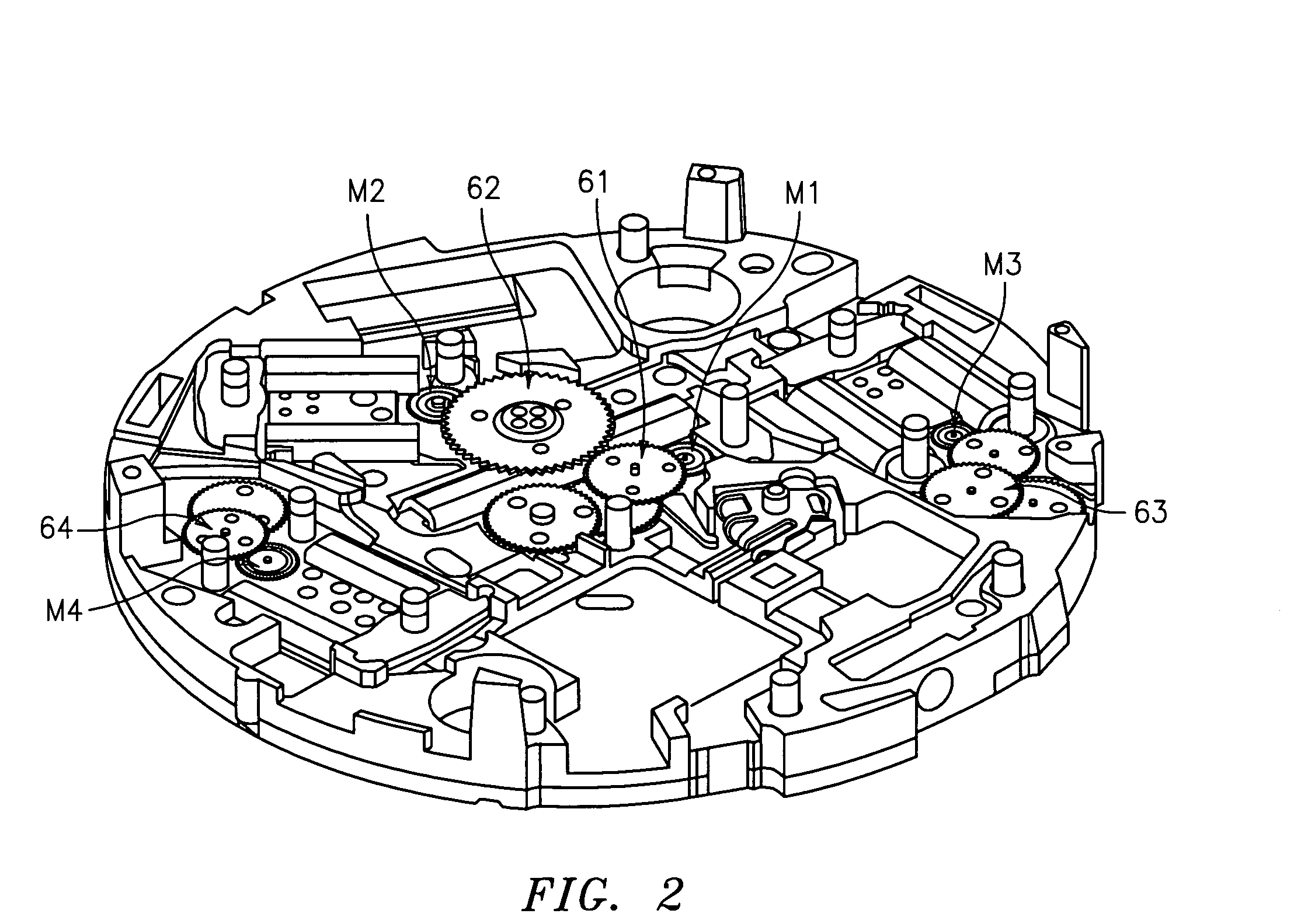

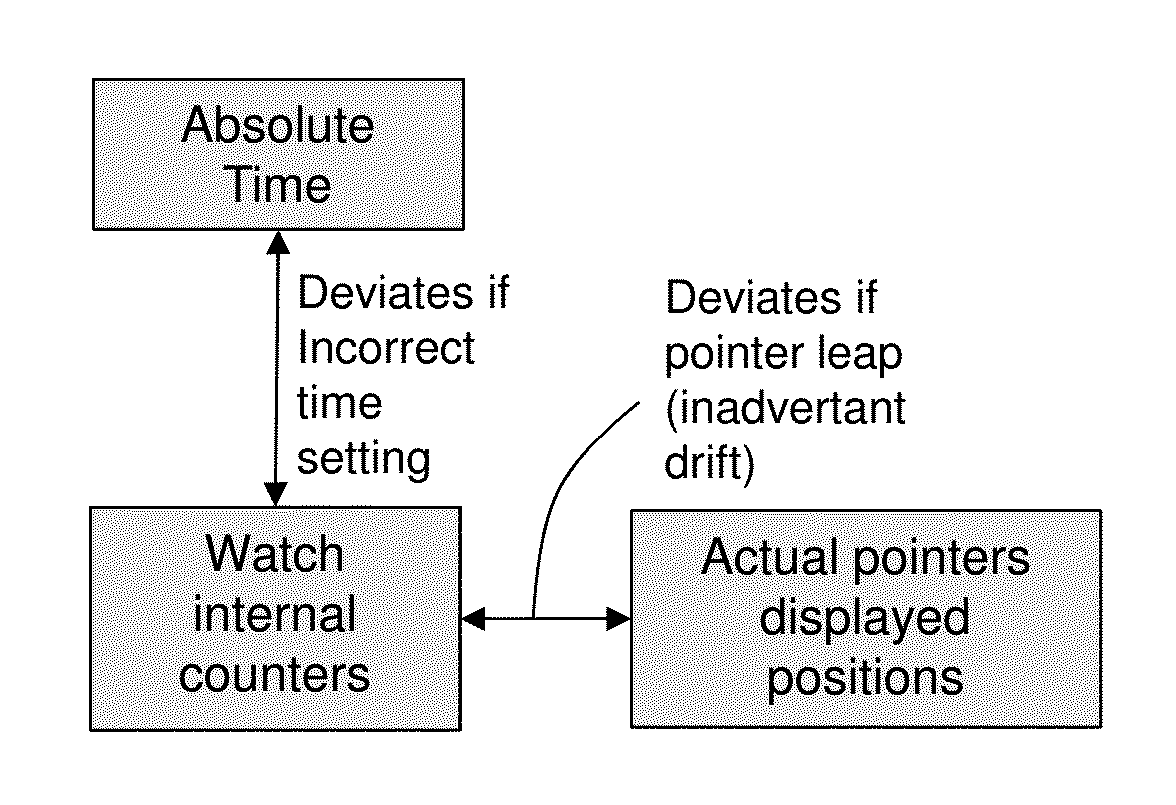

Wearable electronic device with multiple display functionality

InactiveUS20040233788A1Clearly displayableEasy to understandVisual indicationElectric indicationWearable Electronic DeviceEmbedded system

A wearable electronic device for conveying information in an analog manner at least in part by the use of at least one display hand positioned on the dial side of a dial, wherein the wearable electronic device uses the display hand(s) to convey information that is stored in the controller of the device and / or provided by sensors and / or an external transmitter. An actuation mechanism, preferably a stepper motor, is used to rotate the display hands in the clockwise and / or counterclockwise directions in predefined increments to convey the information.

Owner:TIMEX CORP

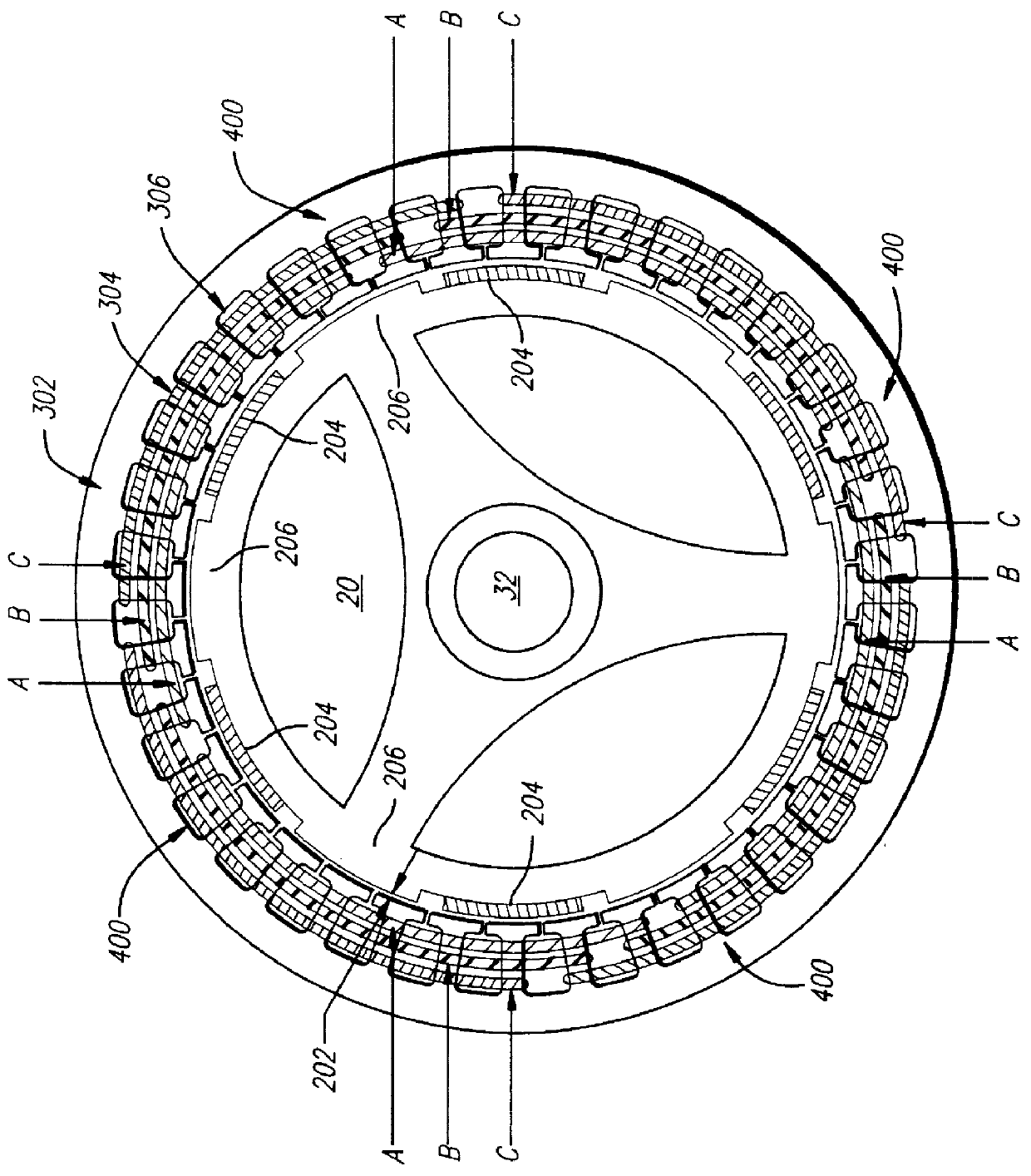

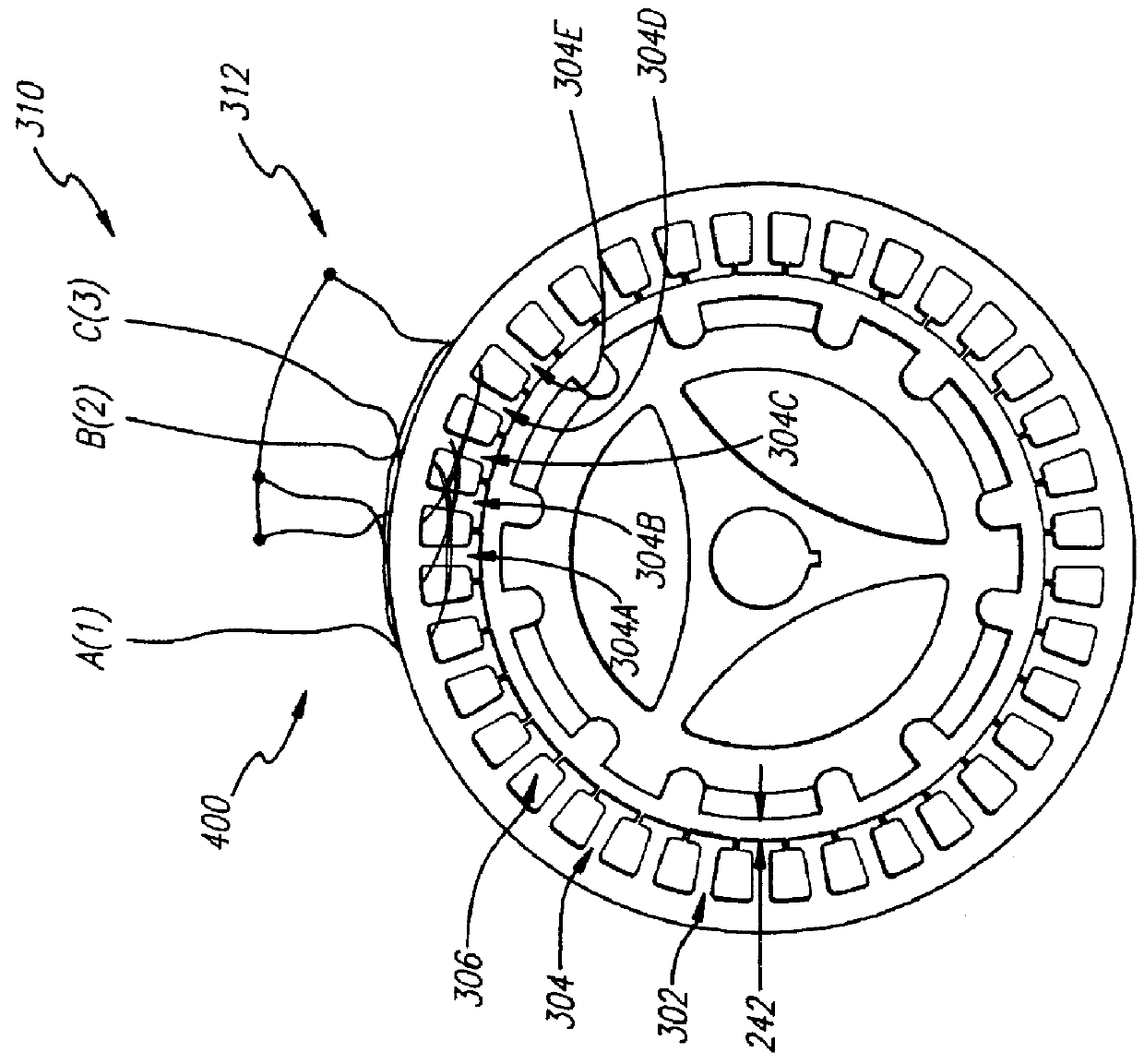

Portable apparatus for peritoneal dialysis therapy

A portable peritoneal dialysis apparatus having (1) a hinged door for enclosing a disposable cassette that seals tightly shut using air pressure; (2) accurate pressure sensing of pressures applied to the patient through an enclosure in the disposable cassette; (3) two pumps that can operate separately or in tandem actuated by two separate stepper motors; and (4) a touch screen user interface where indicia of the operating mode is always visible along with indicia for the other possible operating modes and the mode can be changed by touching one of these indicia.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Wearable electronic device with multiple display functionality

InactiveUS7113450B2Display clearEasy to understandVisual indicationElectric indicationWearable Electronic DeviceEmbedded system

A wearable electronic device for conveying information in an analog manner at least in part by the use of at least one display hand positioned on the dial side of a dial, wherein the wearable electronic device uses the display hand(s) to convey information that is stored in the controller of the device and / or provided by sensors and / or an external transmitter. An actuation mechanism, preferably a stepper motor, is used to rotate the display hands in the clockwise and / or counterclockwise directions in predefined increments to convey the information.

Owner:TIMEX CORP

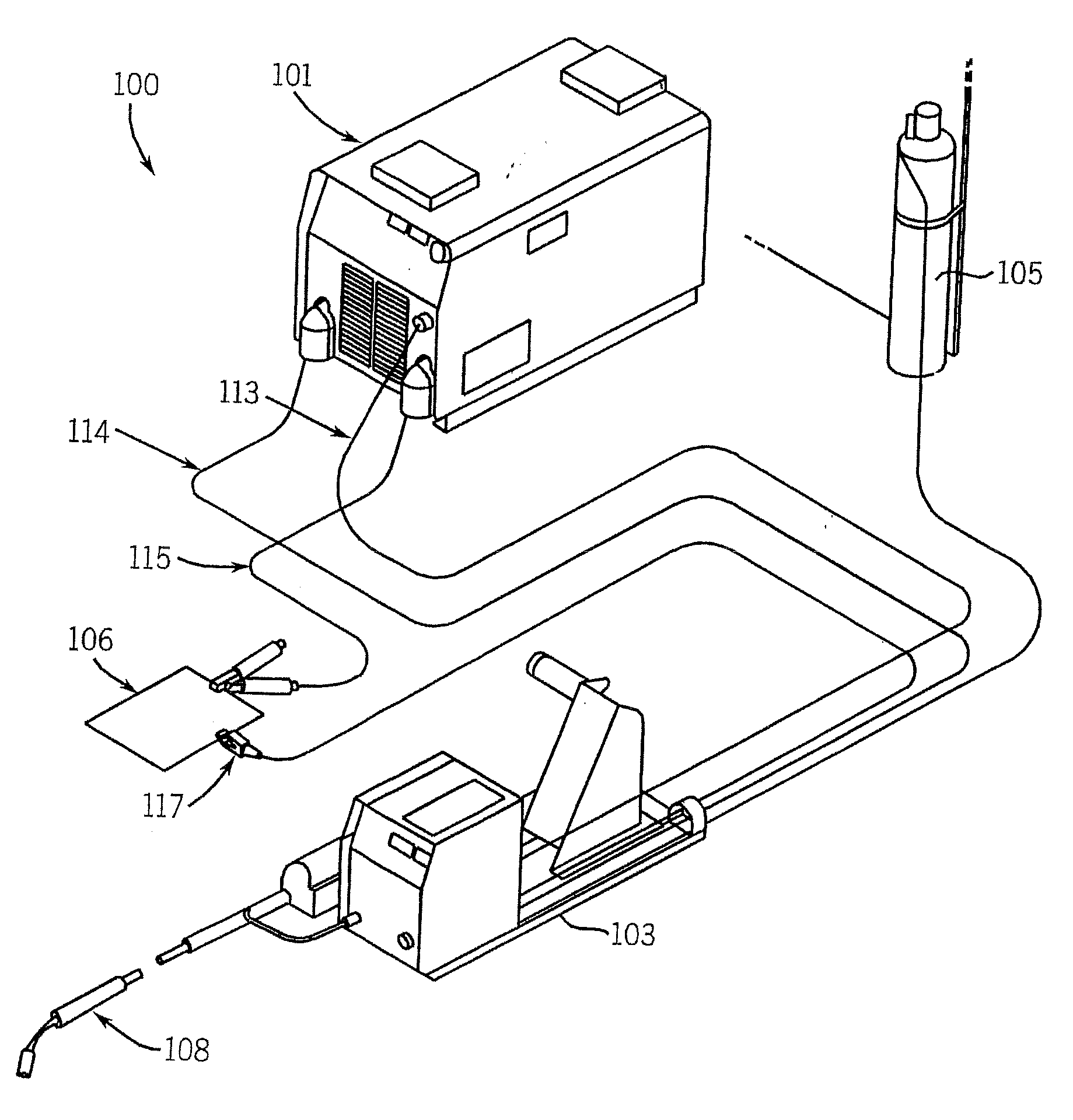

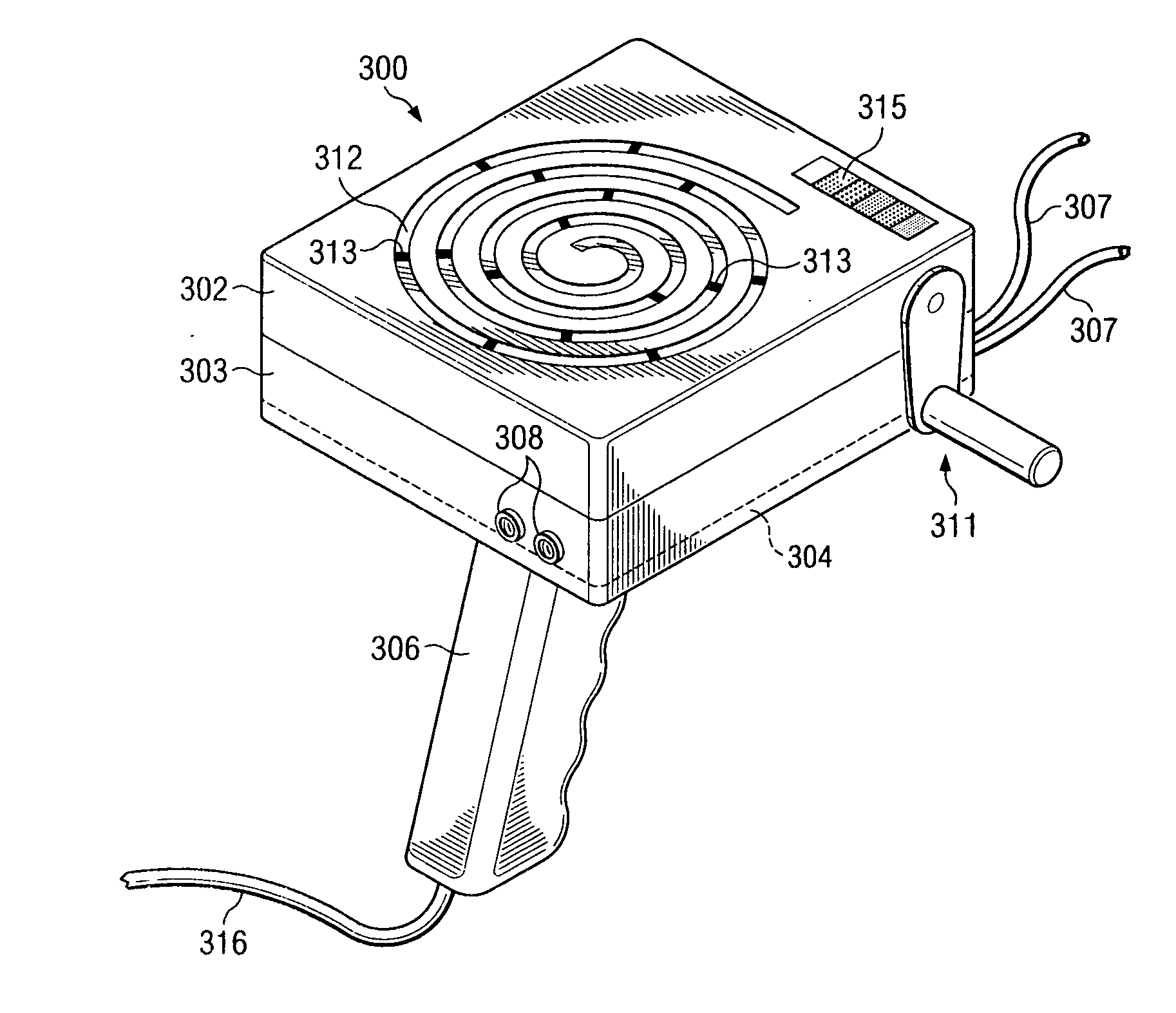

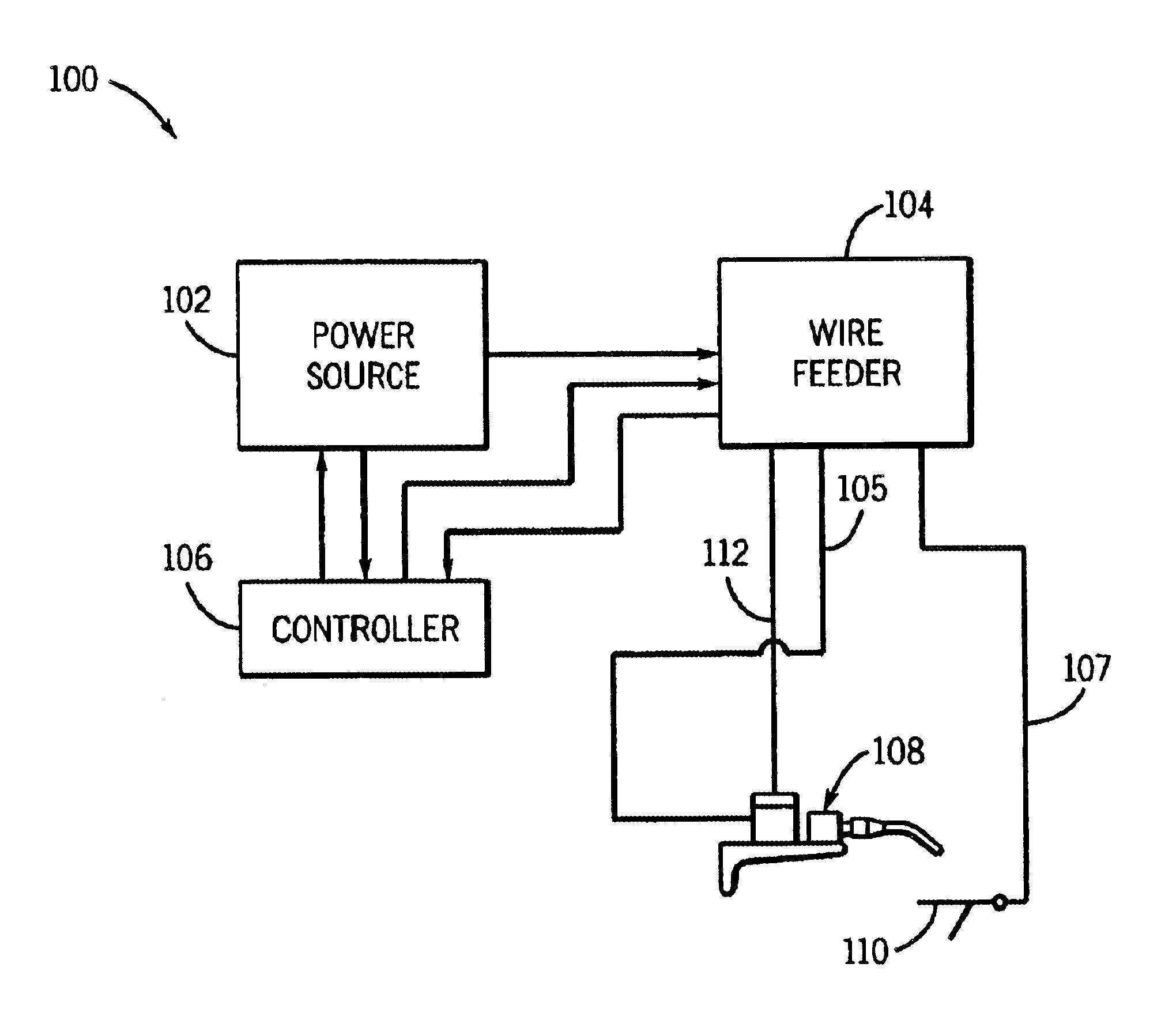

Method and Apparatus For Feeding Wire to a Welding Arc

A method and apparatus for feeding wire in a welding system include one or more motors disposed adjacent the wire to drive it. A wire feed motor is also disposed along the wire path, and is closer to the source of wire than the torch, and closer to the source than the one or more motors. The motors may be a pair motors disposed on opposite sides of the wire and move the wire to and away from an arc end of a torch. They preferably reversing the direction of the wire within one process cycle. The or more motors may be a stepper motor, a servo motor, a zero backlash motor, a gearless motor, a planetary drive motor, or a linear actuator (such as a piston), in various embodiments.

Owner:ILLINOIS TOOL WORKS INC

Improvements to Electrically Operable Resuscitators

InactiveUS20100170512A1Avoid flowShorten speedTracheal tubesOperating means/releasing devices for valvesLinear motorPiston

The present invention relates to an electrically operable resuscitation device comprising a pump including a rigid cylinder including at least one gas inlet and at least one gas outlet, a piston to travel in said cylinder, and at least one valve, the or each valve configured to allow gas to be displaced into said cylinder through said at least one gas inlet during at least one of a first stroke direction and second stroke direction of said piston in said cylinder, and for allowing gas to displaced through said at least one gas outlet during an opposite of said at least one of the first stroke direction and second stroke direction of said piston in said cylinder; a motor, selected from one of a stepper motor and feedback motor and stepper motor with feedback and linear motor, operatively connected to said piston to move said piston in said cylinder; a patient interface in ducted fluid connection with said pump to receive gas via said at least one gas outlet and to deliver said gas to said patient.

Owner:KUYPERS GILBERT JACOBUS +1

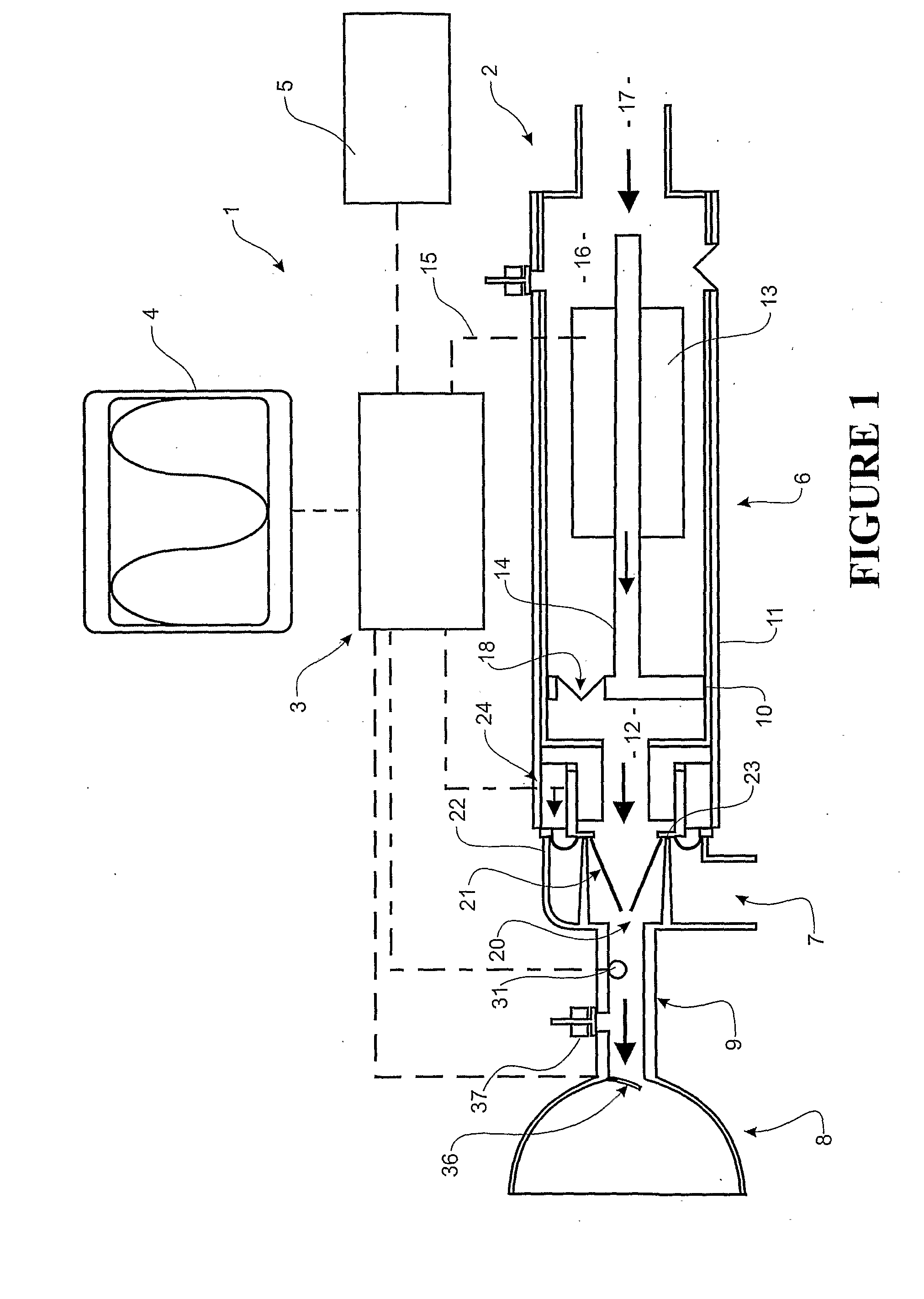

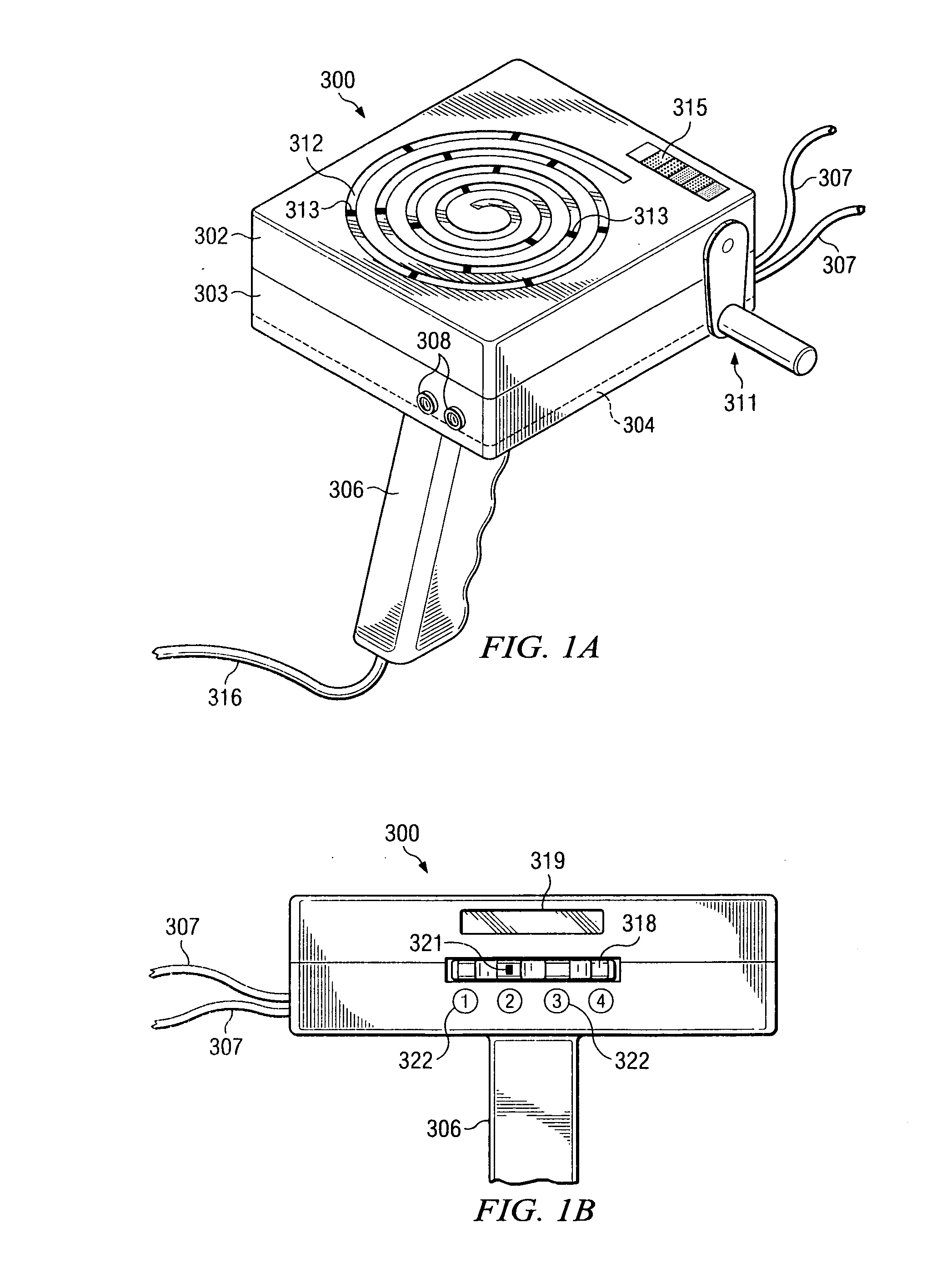

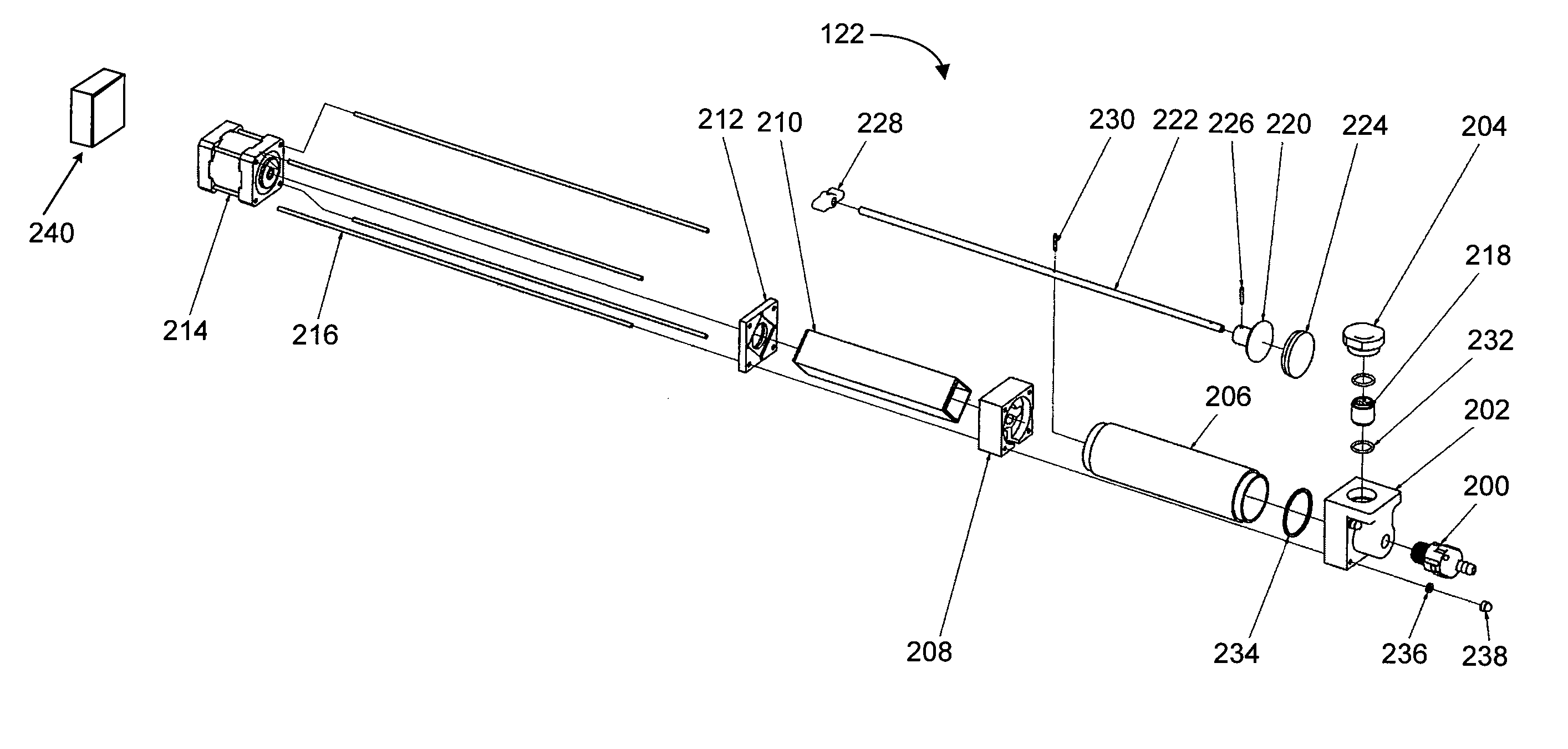

Apparatus and method for the dispensing of bone cement

Apparatus and method to dispense PMMA bone cement including a temperature controller, a disposable cement cartridge and a means for extracting cement from the cement cartridge so that the temperature of the extracted cement is first cooled to discourage polymerization and to prolong working time, then warmed so as to control viscosity of the cement flowing into the desired bone repair location. A first embodiment includes a spiral cement cartridge along with a means for extracting cement therefrom. A second embodiment includes a linear disposable cement cartridge along with a means for extracting cement therefrom. A color matching mechanism identifies cement temperature and viscosity during dispensation. A manual cement dispensing method includes a calibrated hand crank mechanism for causing calibrated delivery of cement. An automatic cement dispensing method uses a stepper motor and computer programmed means for causing calibrated flow of cement.

Owner:WOLF II ERICH W

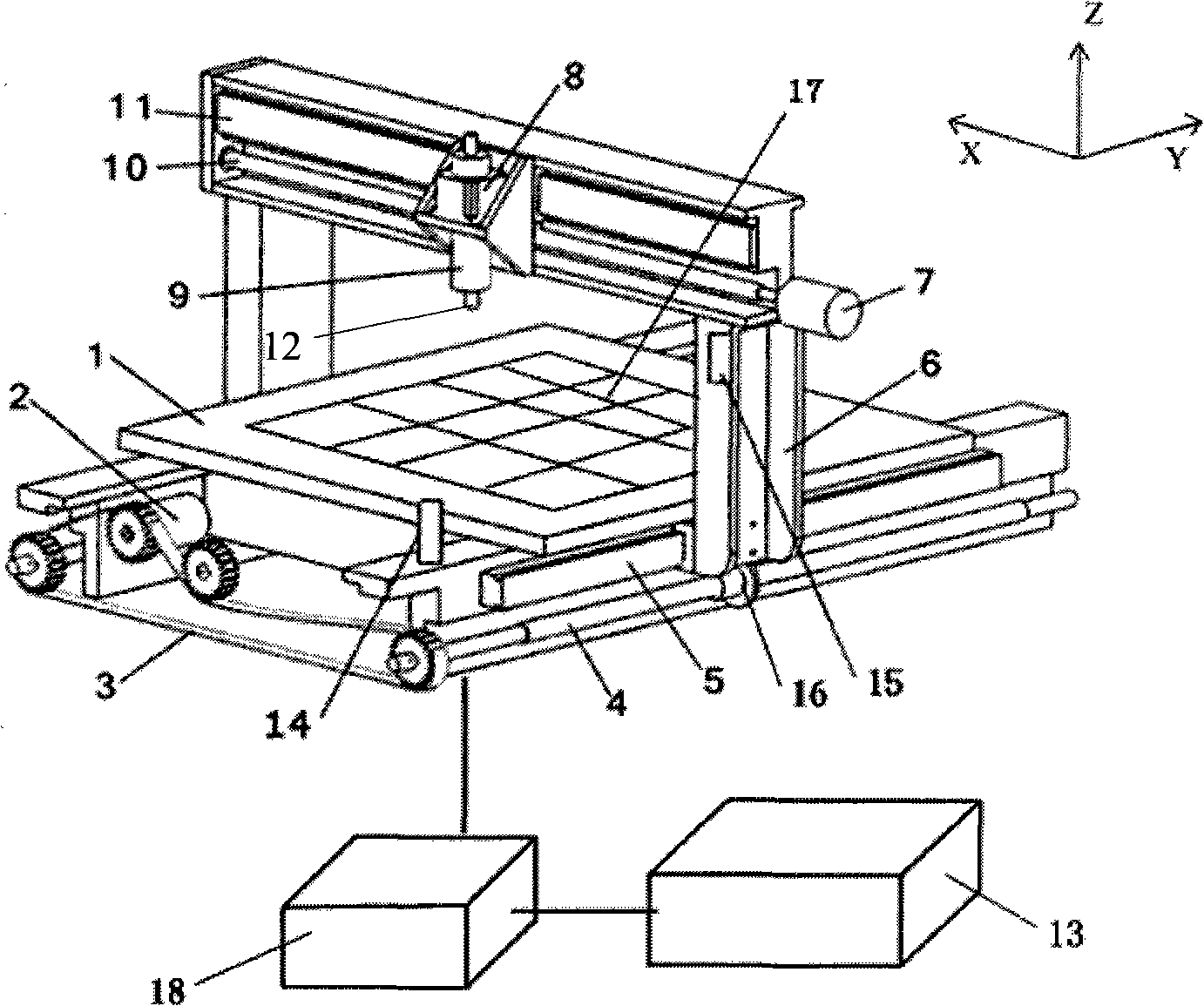

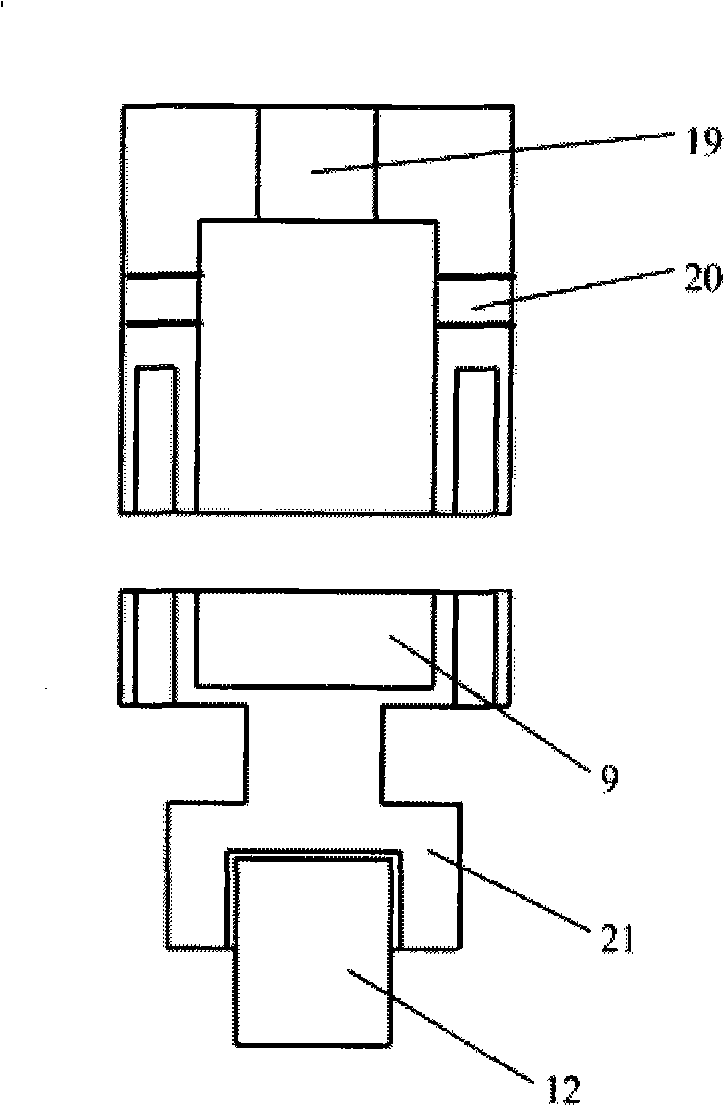

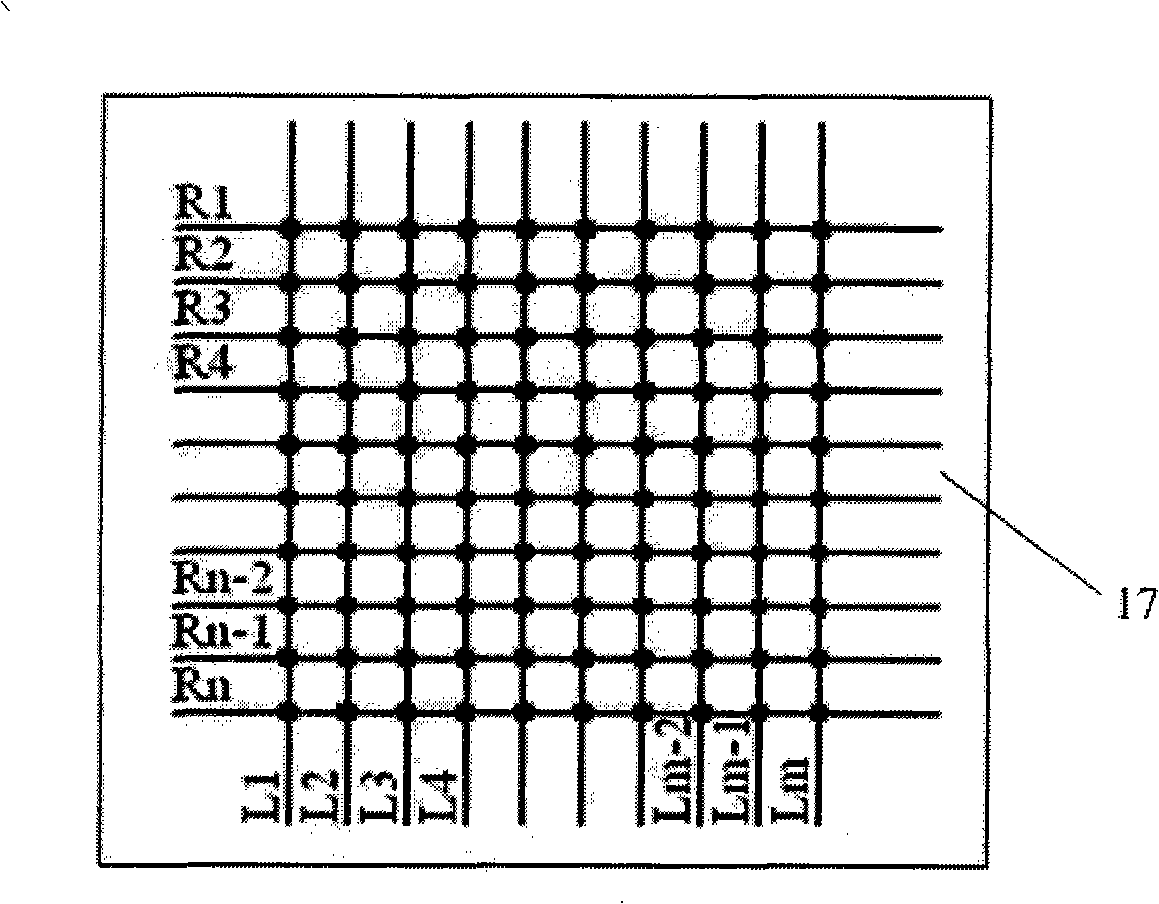

Mechanics sensor array calibrating apparatus and working method thereof

ActiveCN101281073APrecision mechanical designQuick start and stopForce/torque/work measurement apparatus calibration/testingSensor arrayElectricity

The present invention discloses a mechanical sensor array calibration device and the working method thereof. The device comprises locating transmission part and control part which is electrically connected with the locating transmission part; wherein, the locating transmission part comprises calibrated working platform and pressure head testing part; the pressure head testing part is connected with a force sensor through an extension head of a Z-directional linear stepper motor. Using the working method of the device adopts three stepper motors as the driving source; two stepper motors drive the coordinate motion of the slides on the guide rail to finish the location of coordinate point on the working platform; an extension of a linear stepper motor drives the pressure head to exert force on the tested sensor; when the force exerted by the pressure head achieves the set pressure valve, the singlechip collects the output of the tested sensor and the force sensor and the position coordinate of the tested sensor. The present invention is able to execute the choose and configuration of the calibrating mode and process according to the specific sensor array and the specific calibrating demand so as to enlarge the using range of the device.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

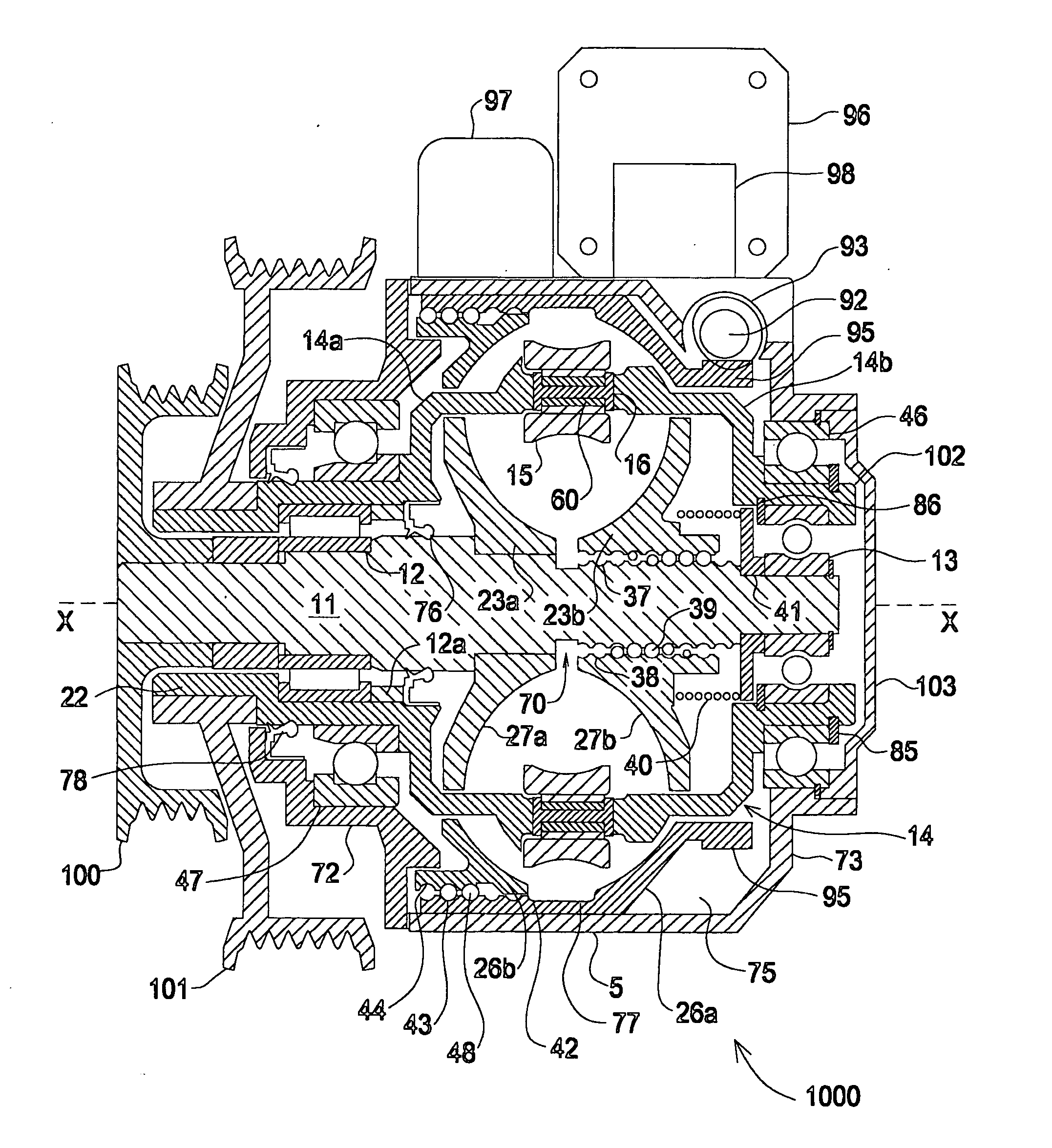

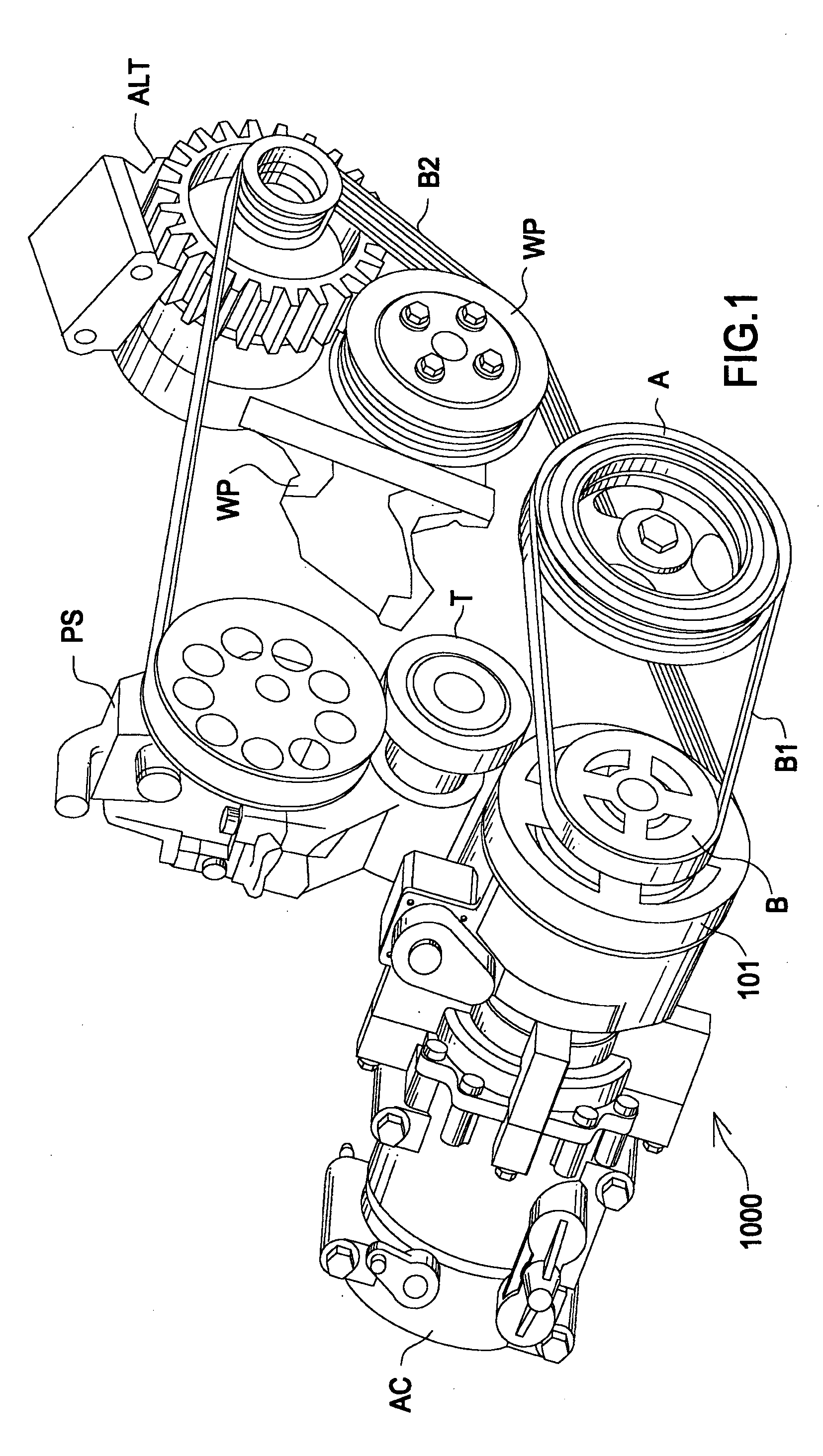

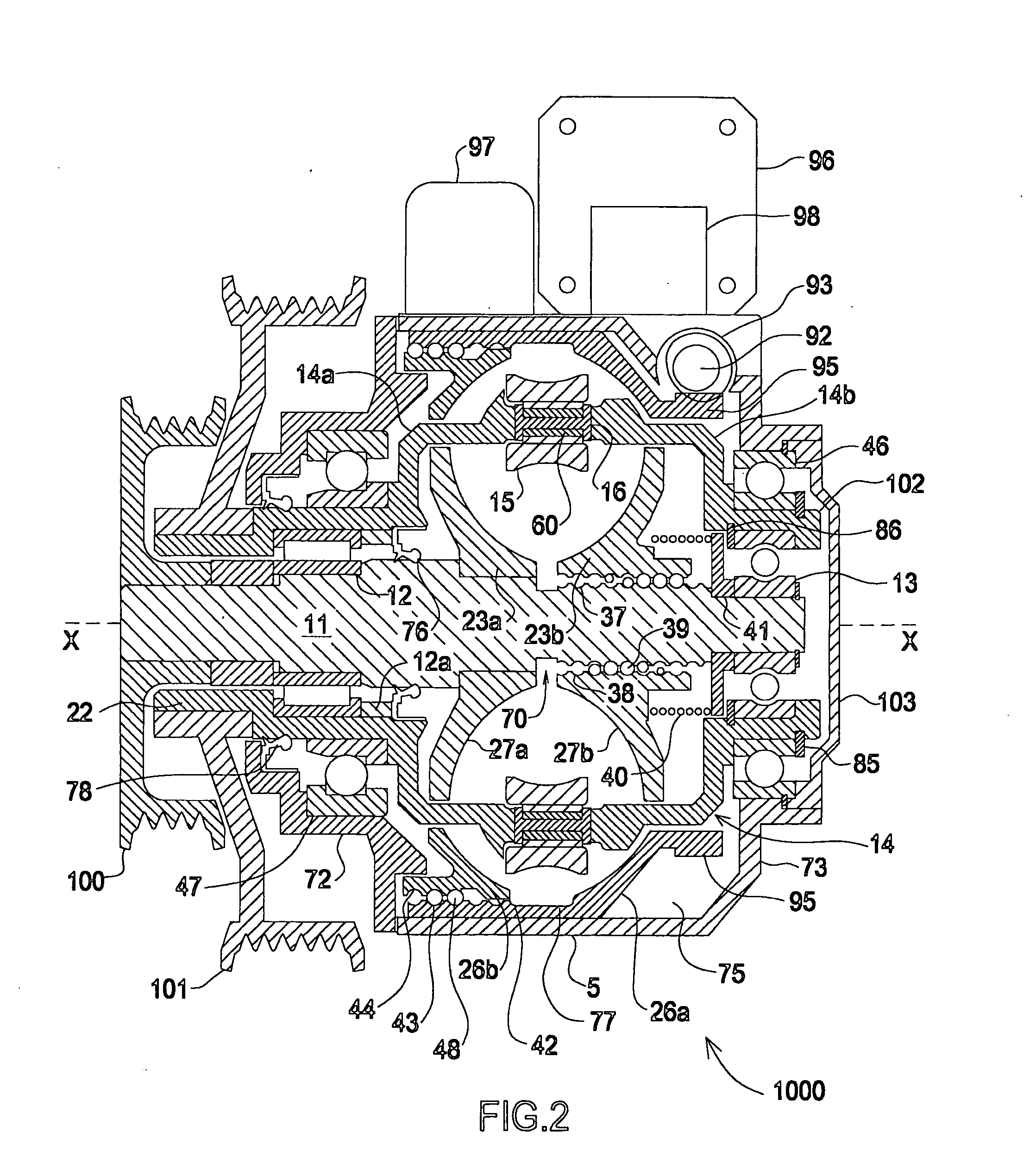

Transmission and constant speed accessory drive

InactiveUS20050181905A1Constant output speedGearing controlFriction clutchesControl systemDirect coupling

An infinitely variable speed ratio planetary ball transmission comprising planetary members in rolling contact with moveable inner and outer races and a constant speed accessory drive system utilizing the transmission. The transmission is infinitely variable between ratios of approximately 0.3 and 1.0. A transmission input shaft is connected to a prime mover such as a vehicle engine crankshaft by a drive belt. The transmission comprises at least one output shaft that is coaxial with the input shaft. An output pulley is attached to the output shaft. A belt is engaged between the output pulley and various engine accessories. A second end of the transmission output shaft may be directly coupled to an engine accessory mounted on the transmission. An included control system senses a crankshaft speed. A processor analyses the crankshaft speed and accordingly adjusts the transmission ratio using a stepper motor connected to a worm drive to maintain a constant output speed regardless of crankshaft speed.

Owner:THE GATES CORP

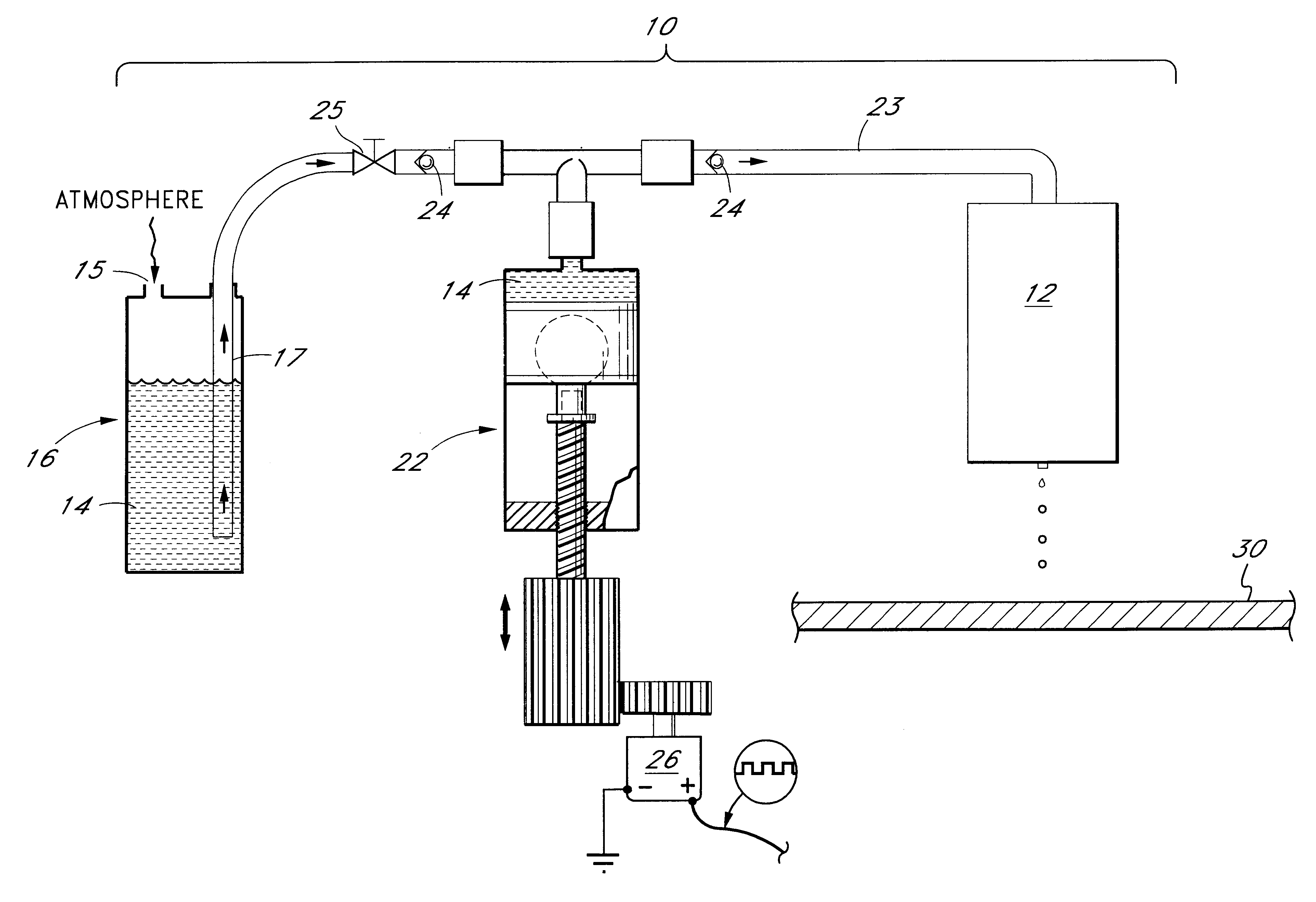

Dispensing apparatus having improved dynamic range

InactiveUSRE38281E1Improve performanceIncrease rangeLiquid surface applicatorsWithdrawing sample devicesSolenoid valveContinuous flow

A method and apparatus for dispensing precise quantities of reagents is disclosed including a positive displacement syringe pump in series with a dispenser, such as an aerosol dispenser or solenoid valve dispenser. The pump is controlled by a stepper motor or the like to provide an incremental quantity or continuous flow of reagent to the dispenser. The pump and dispenser are operated in cooperation with one another such that the quantity and / or flow rate of liquid dispensed by the dispenser can be precisely metered substantially independently of the particular operating parameters of said dispenser to attain a desired flow rate, droplet size or mist quality, droplet frequency and / or droplet velocity.

Owner:BIODOT

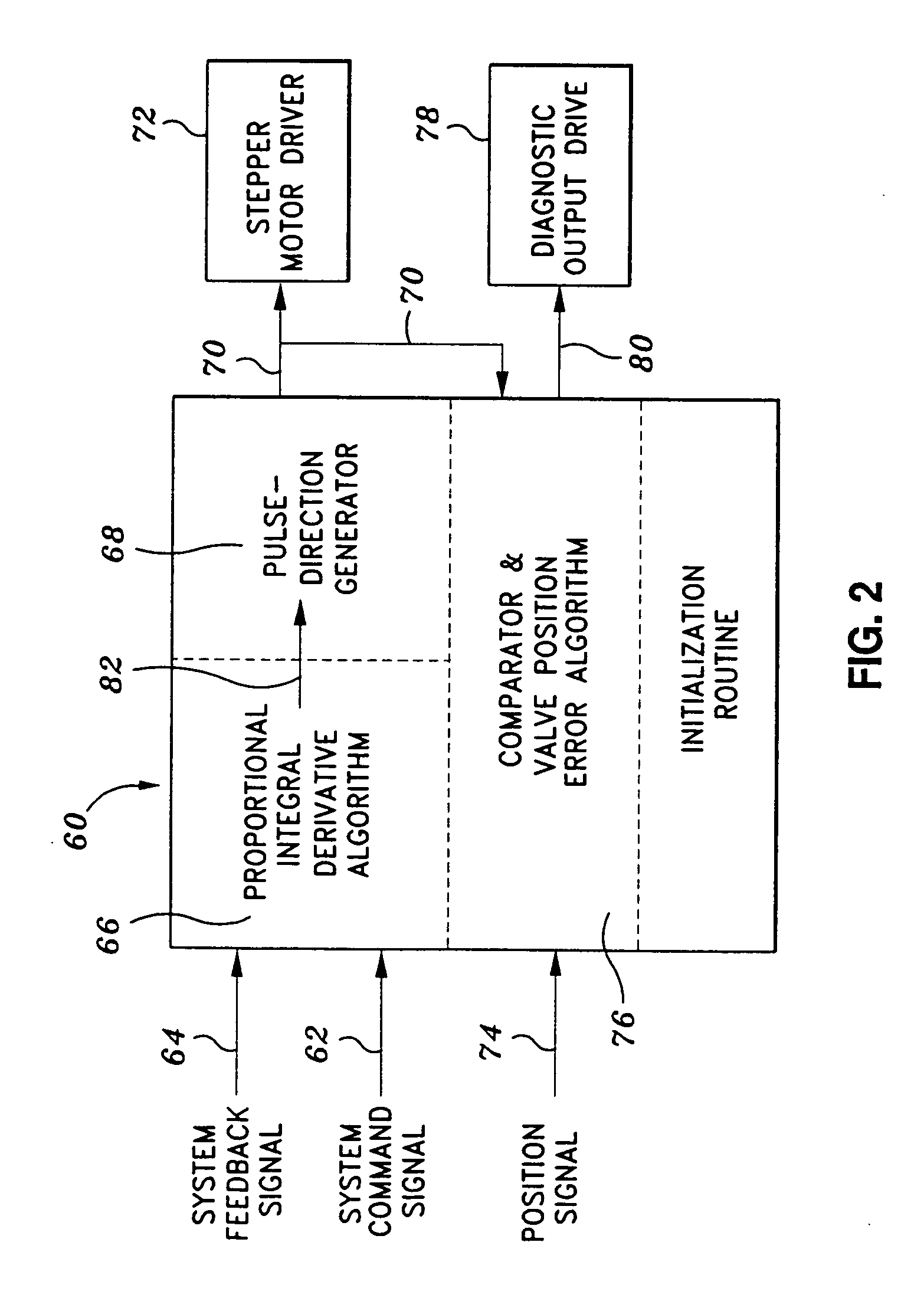

Predictive maintenance and initialization system for a digital servovalve

ActiveUS20050000580A1Simple and reliable initializationReduced referenceFluid-pressure actuator testingOperating means/releasing devices for valvesMechanical resistanceEngineering

Provided is a servovalve system for regulating fluid flowing within a fluid circuit. The servovalve system comprises a housing, a spool slidably disposed within the housing, a stepper motor operatively connected to the spool, and a controller and a position sensor electronically connected to the stepper motor. The controller generates driver signals representative of a desired amount of stepper motor rotation in order to cause the stepper motor to effectuate spool motion relative to the housing. The position sensor senses an actual amount of stepper motor rotation and generates a quantity of position signals representative thereof. The controller determines a signal ratio of the quantity of the position signals to the quantity of the driver signals and generates a diagnostic signal when the signal ratio reaches a threshold value representative of a predetermined level of mechanical resistance of spool motion relative to the housing.

Owner:CONTROL COMPONENTS INC

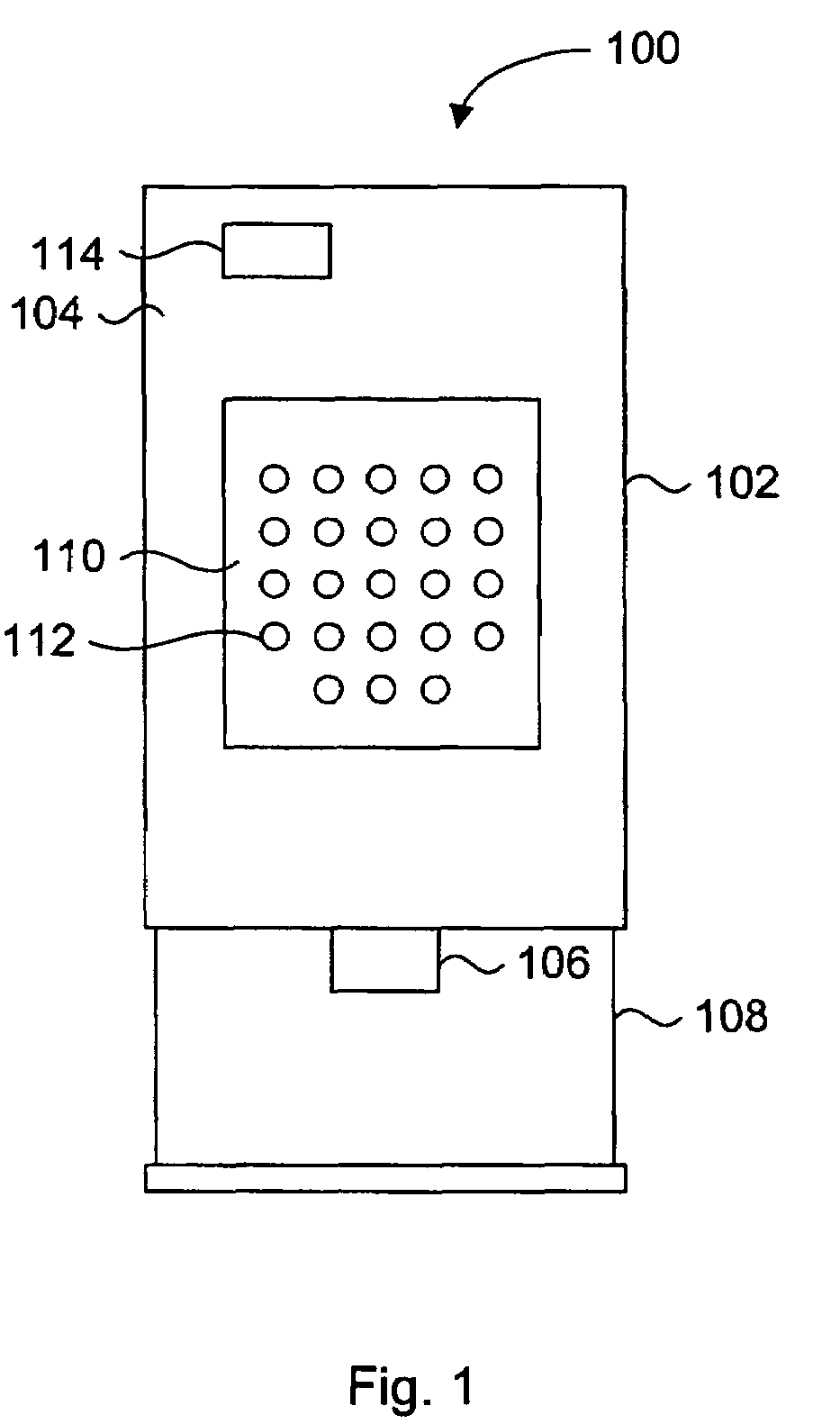

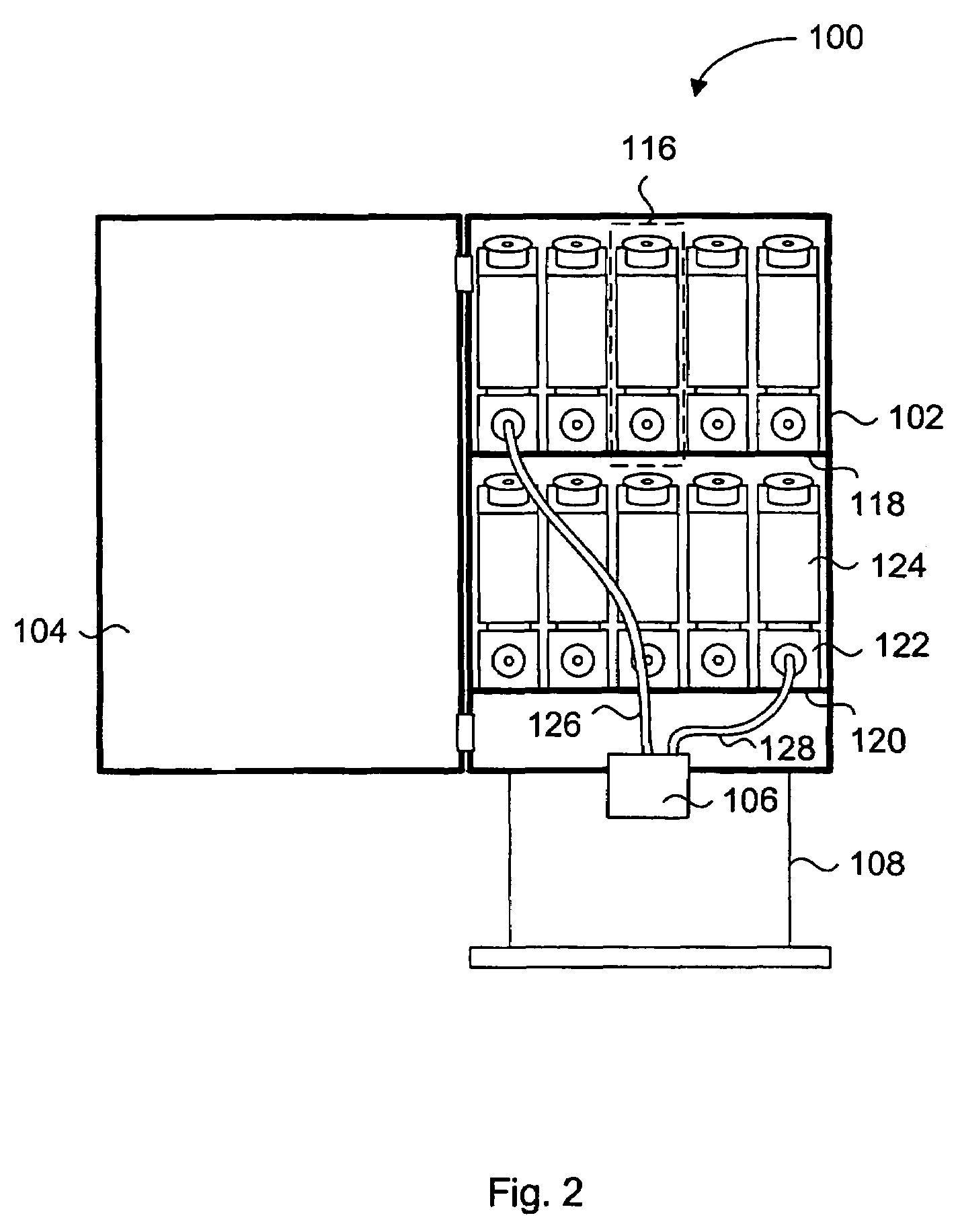

Fluid dispensing apparatus

ActiveUS7337920B2Wide viscosity rangePrevent exitContracting/expanding measuring chambersLiquid flow controllersViscosityMechanical engineering

A concentrated flavour dispensing machine having displacement pumps for delivering between a few millilitres and few ounces of fluids having a viscosity value between 1 to 4000 centepoise is described. The dispensing machine includes a cabinet for containing a multitude of displacement pumps, where each displacement pump is in direct fluid communication with a respective storage tank, and a control panel having a programmable microprocessor mounted to the cabinet for receiving user selections and controlling each individual pump. Each displacement pump includes a stepper motor in engagement with a threaded drive rod for advancing a piston by any one of several predetermined distances to dispense a corresponding volume of fluid. The control panel receives a valid user selection for actuating one or more pumps to dispense the appropriate volume of a concentrated flavouring fluid. The microprocessor tracks the amount of fluid dispensed from each storage tank and alerts users and / or prevents further operation when reservoirs are close to empty to avoid null dispenses to customers. Various maintenance routines can be executed through the user interface, and dispense volumes and combination dispenses can be re-programmed manually or automatically.

Owner:A C DISPENSING EQUIP

Method and apparatus for retracting and advancing a welding wire

A method and apparatus for providing welding-type power include a wire feeder that provides wire to an arc and a power supply that provides power to the arc. A reversible wire feed motor moves the wire to and away from the arc. A controller controls the reversible wire feeder motor to reverse at least once per process cycle, and / or controls the power source to provide a desired mean arc current, and / or controls the reversible motor in response to short detection and short clearing, and / or controls the reversal frequency in response to pool oscillation frequency. A wire feed motor output is slaved to an average of the reversible motor output. The controller may include various control modules, such as a mean arc current control module, and / or a short detection feedback circuit. The reversible motor is a stepper motor, that incrementally turns in a series of steps having a given angle in another embodiment. The controller includes a step size output and the given angle is varied in response to the step size output.

Owner:ILLINOIS TOOL WORKS INC

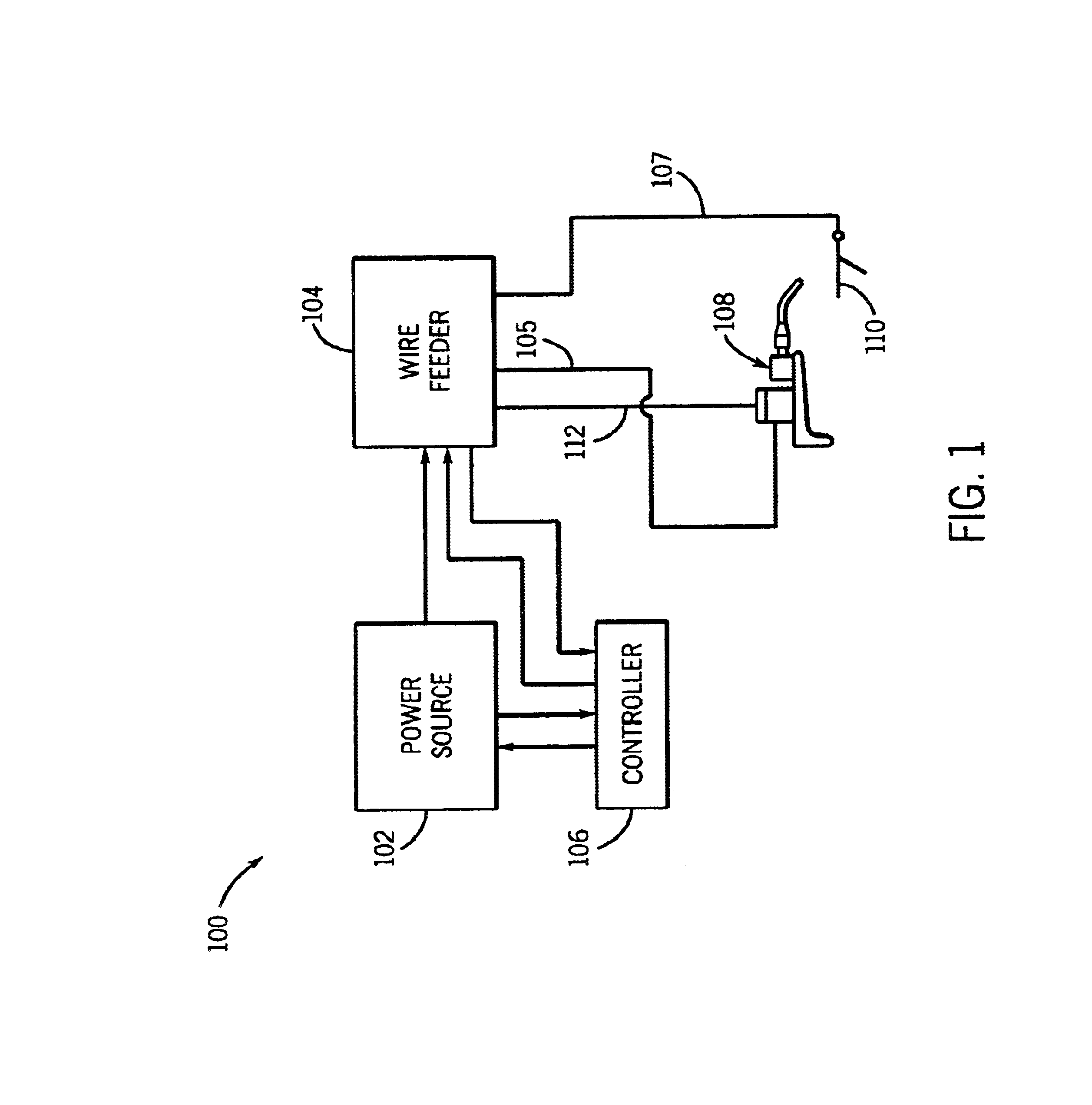

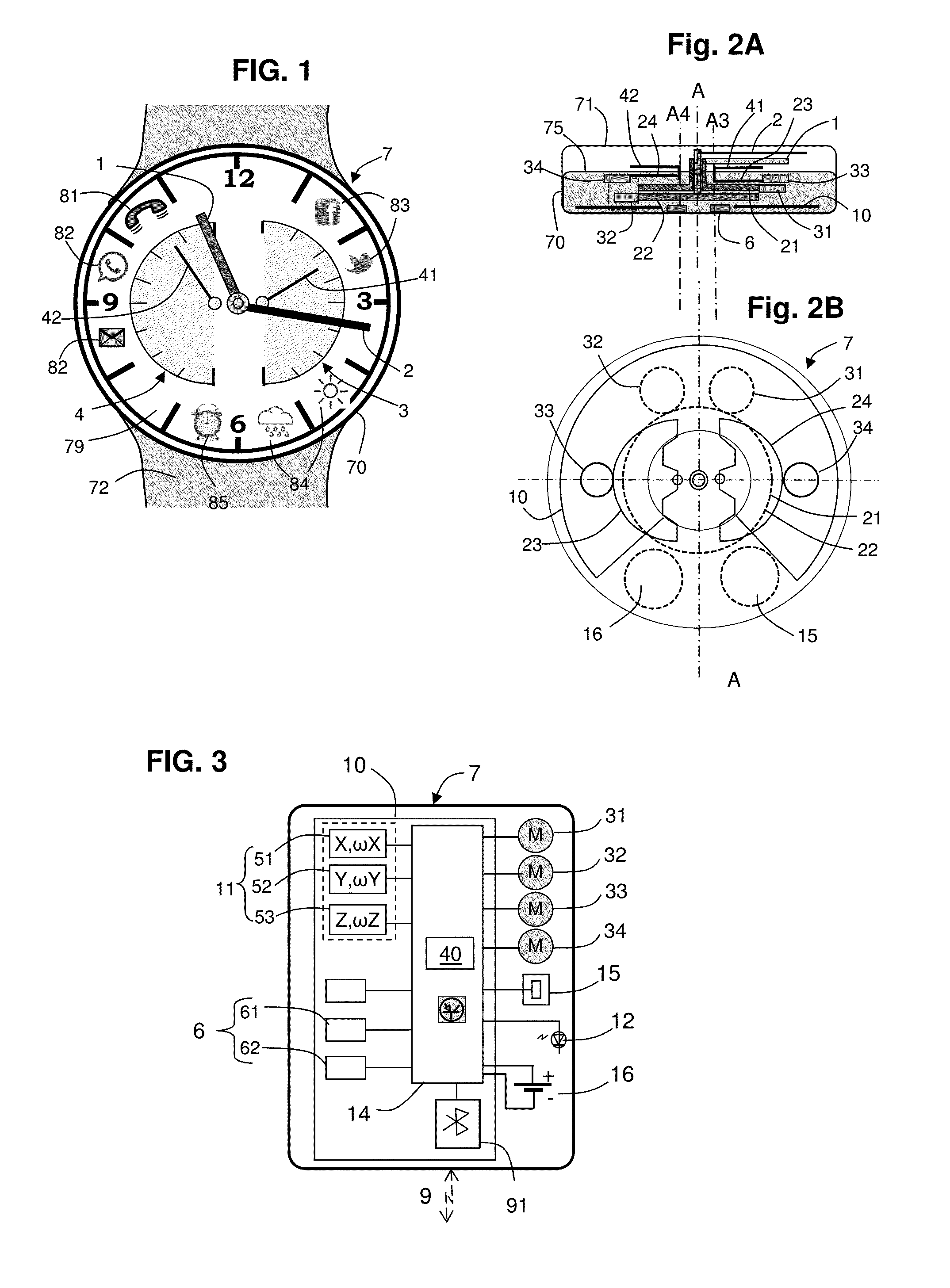

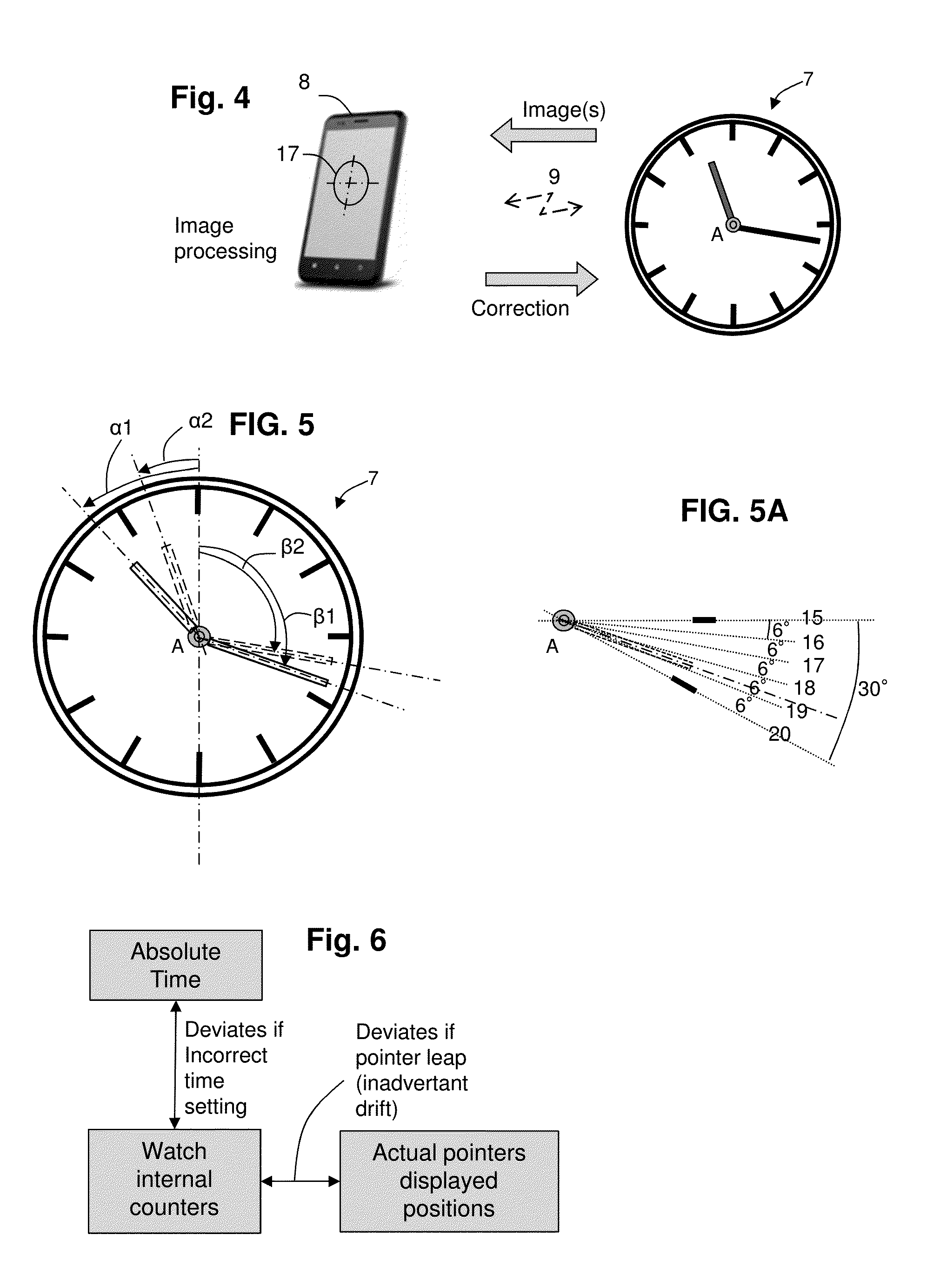

Analog Type Watch and Time Set Method

ActiveUS20150362893A1Simple mechanical structureLow costElectromechanical unknown time interval measurementElectric unknown time interval measurementCommunication linkComputer science

Interaction methods between a smartphone and a timepiece having two analog-type pointers, each of the pointers being controlled independently by a stepper motor, the timepiece and the smartphone being able to be in communication through a wireless remote short-range communication link, the calibration method comprising the steps of S1—capturing image(s) of the watch with the smartphone, S2—processing the image(s) to determine accurately the displayed angular positions of the pointers, S3—send correction data from the smartphone to the watch, S4—carry out, at the watch, an appropriate correction so that the pointers are caused to display the current absolute time, the absolute time set method comprising the steps of S11—send absolute time reference from the smartphone to the watch, S12—carry out, at the watch, an appropriate correction, to update the internal counters and positions of the pointers so that the pointers display the current absolute time.

Owner:WITHINGS SAS

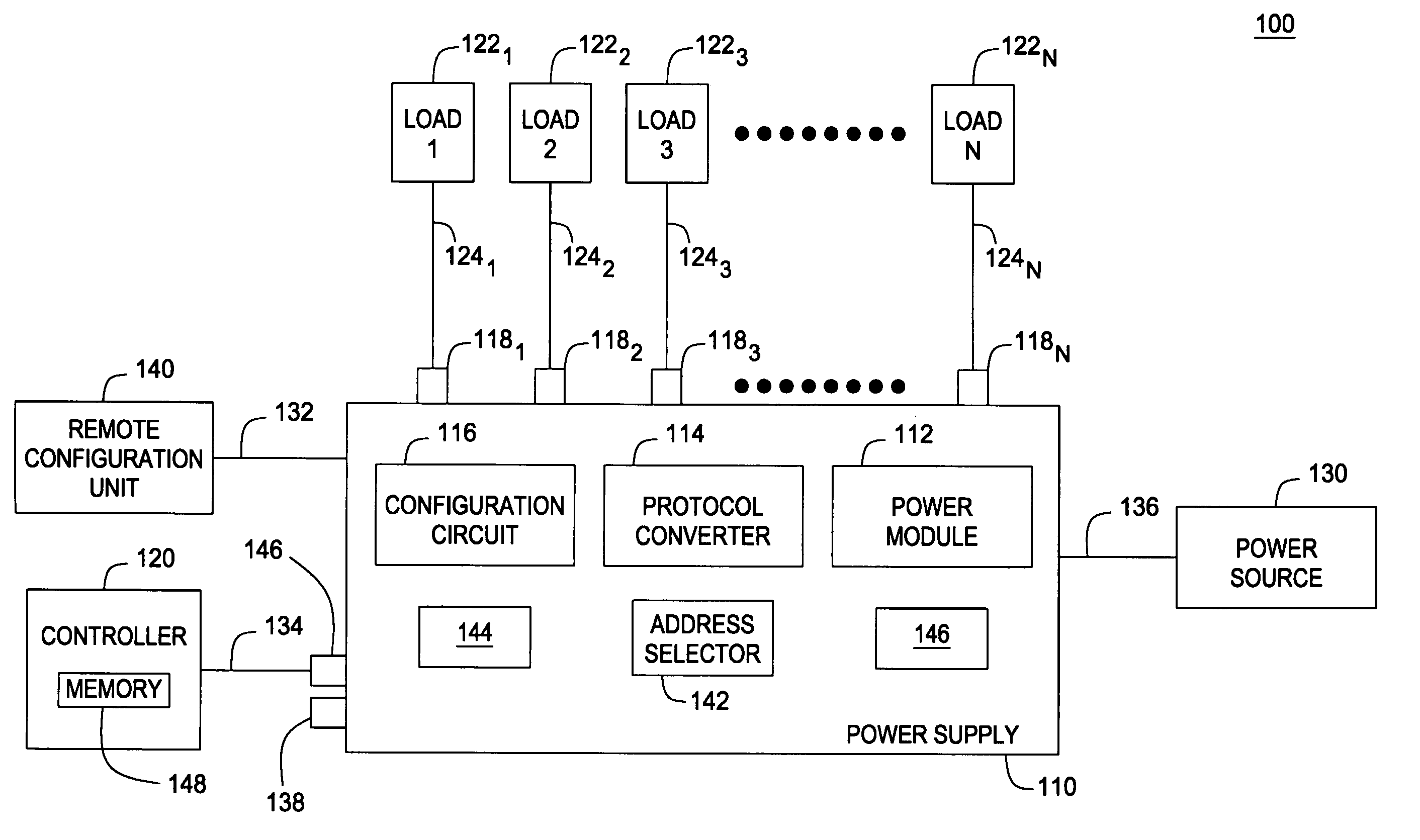

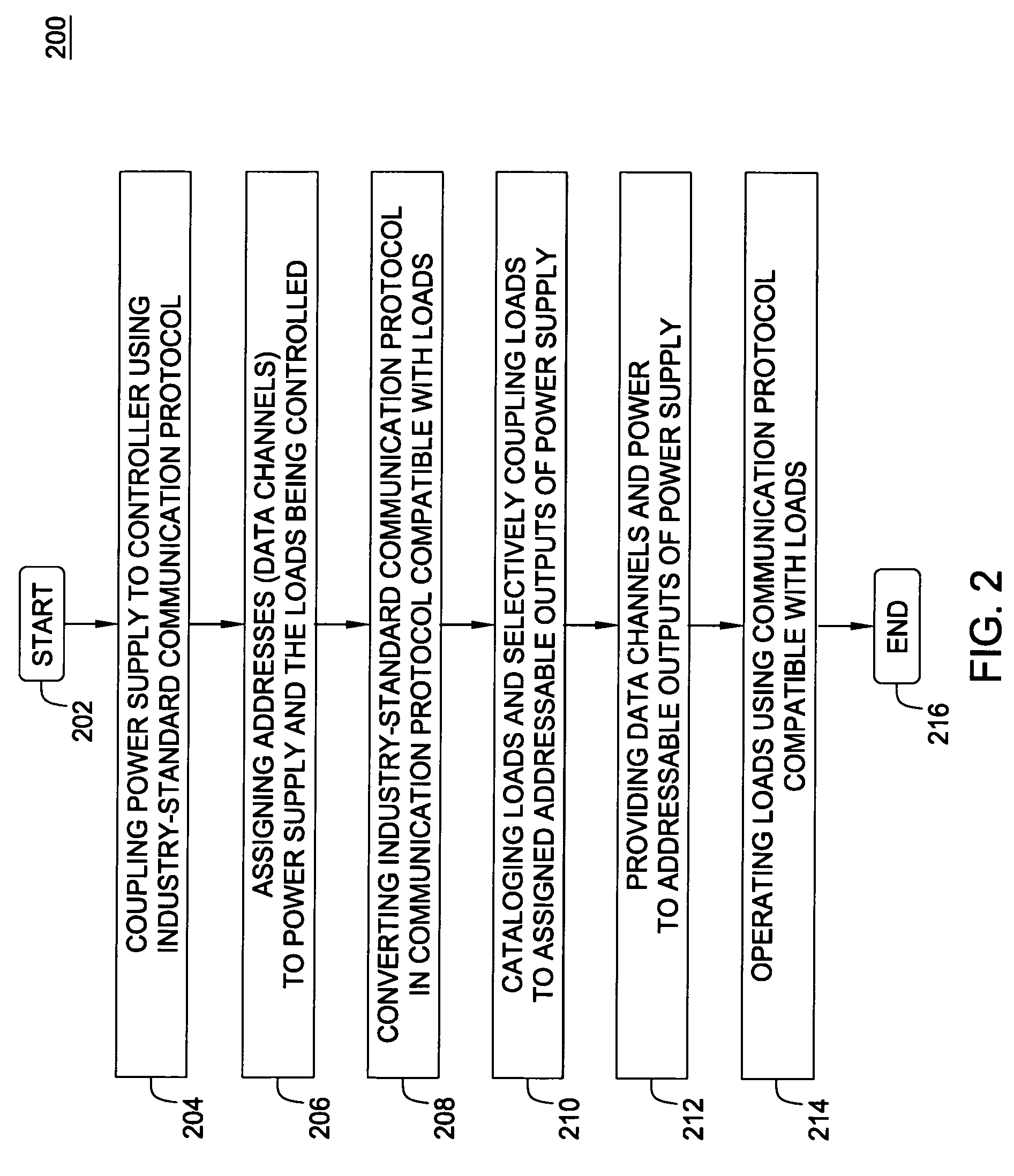

Power supply system and method thereof

A system and a method for operating devices (e.g., luminaries, light dimmers, effect devices, stepper motors, and the like) used in entertainment lighting applications is disclosed. Embodiments include a power supply operating a plurality of such devices coupled to selectively addressable outputs and having a converter of an industry-standard communication protocol (e.g., DMX512, RDM, or ACN protocol) in a communication protocol compatible with such devices.

Owner:CITY THEATRICAL

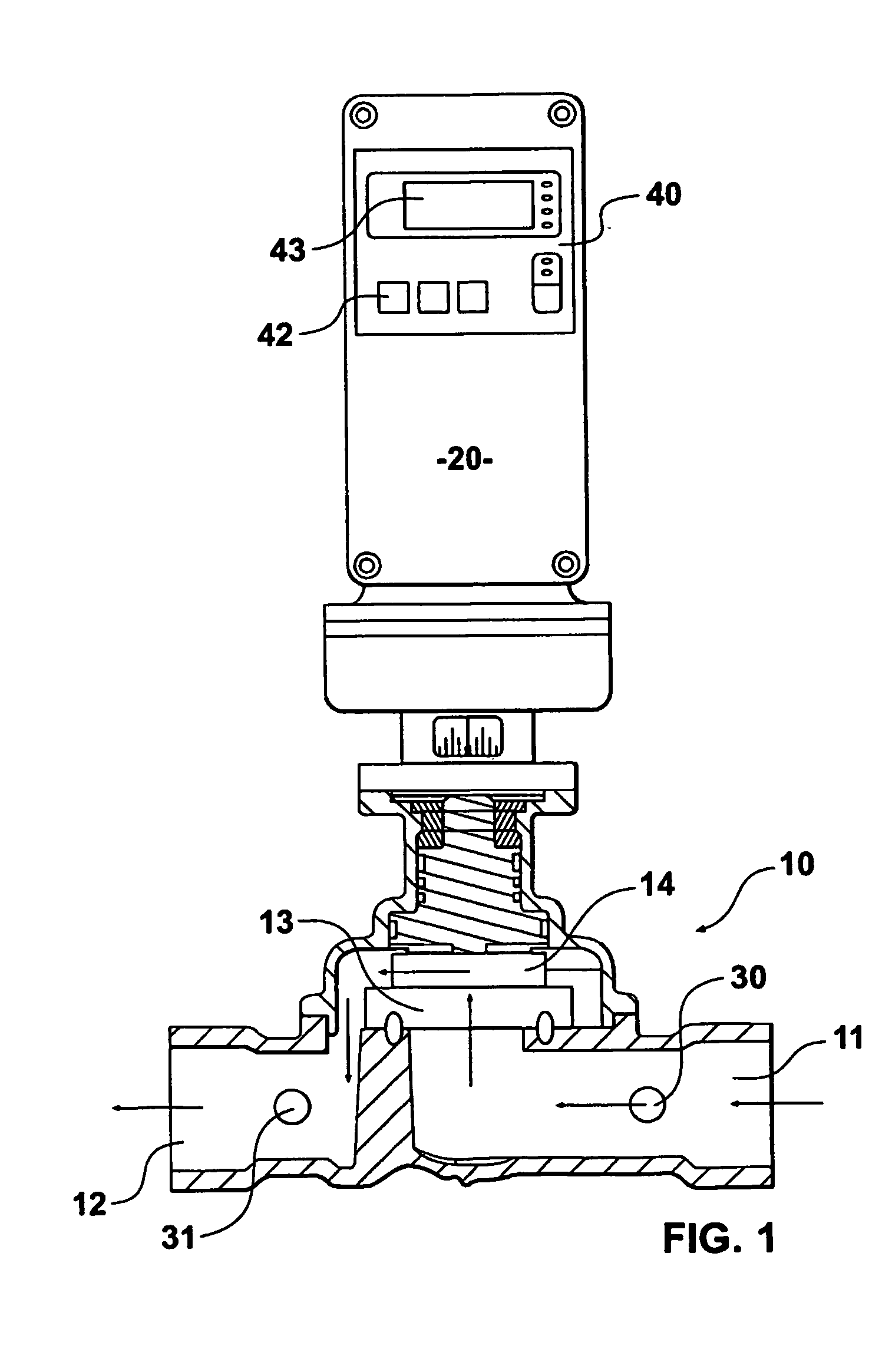

Process control valve

InactiveUS20050016592A1Provide controlOperating means/releasing devices for valvesFlow control using electric meansClosed loop feedbackEngineering

A “plug and play” process control valve 10 providing closed loop feedback control has a built in microprocessor 40, stepper-motor 20, a position encoder, a valve body having an inlet 11 and an outlet 12, and pressure sensors 30, 31 positioned within the inlet 11 and the outlet 12 of the valve body, the pressure sensors being connected to the microprocessor 20, which is in turn connected to an input from the position encoder, and provided with outputs to the step-per-motor 40. Within the valve body there are a pair of apertured ceramic shear action discs 13, 14. The stepper-motor rotates the upper disc 14 relative to the apertured stator disc 13 to control pressure or flow in the pipeline.

Owner:JEROMSON PETER JAMES +1

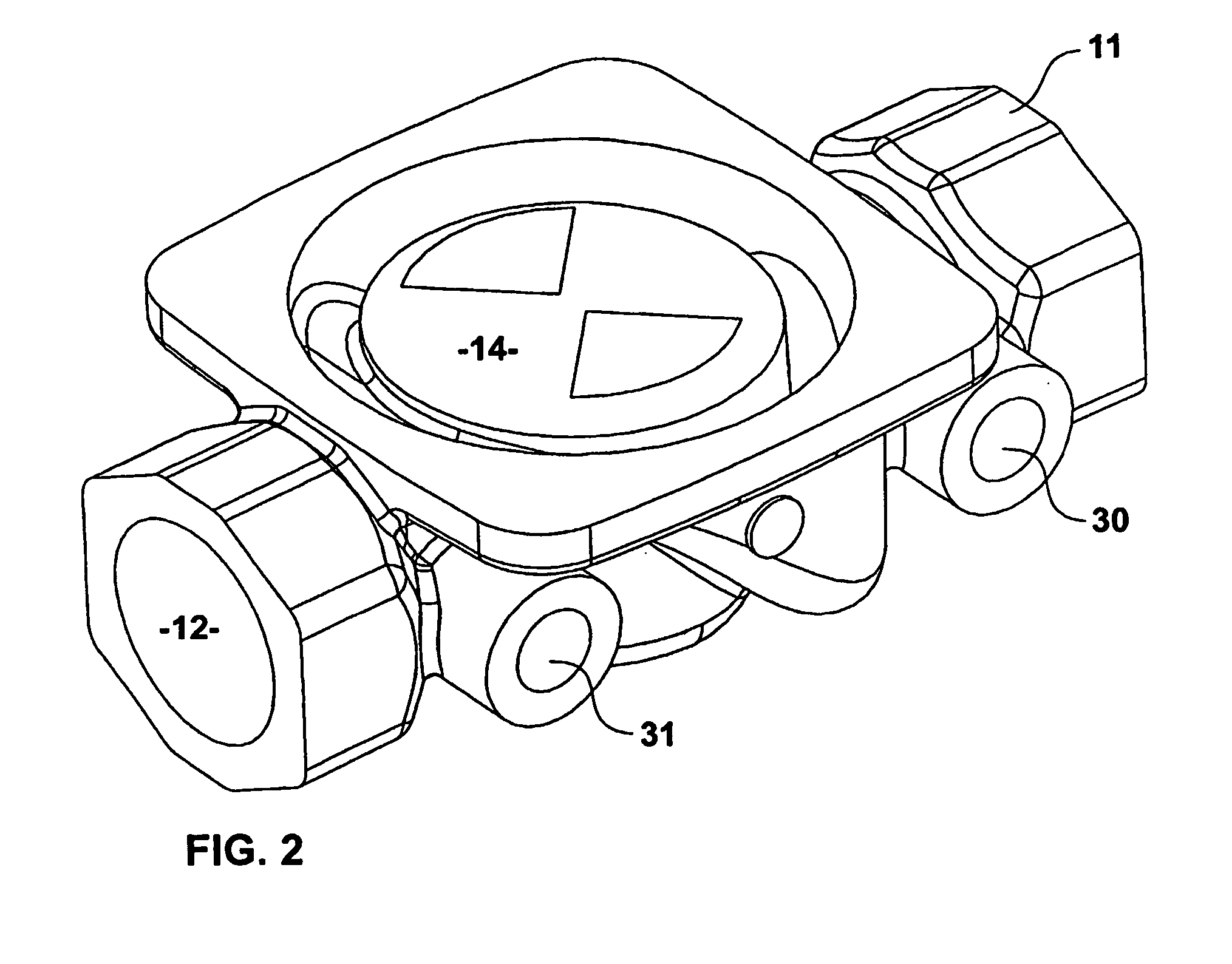

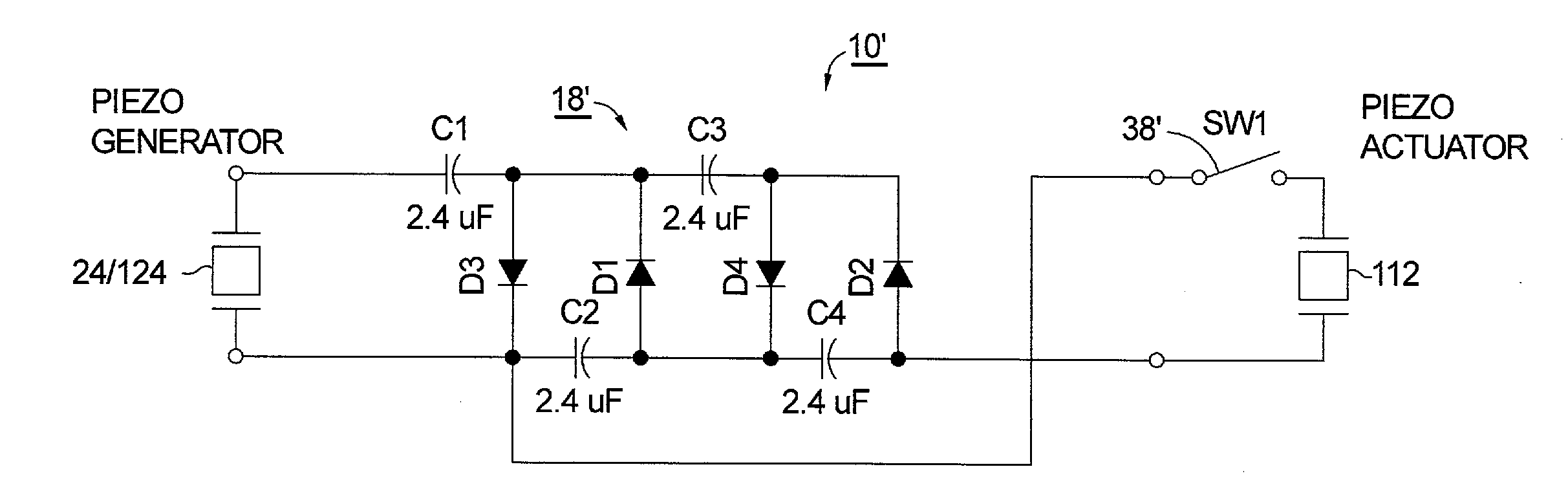

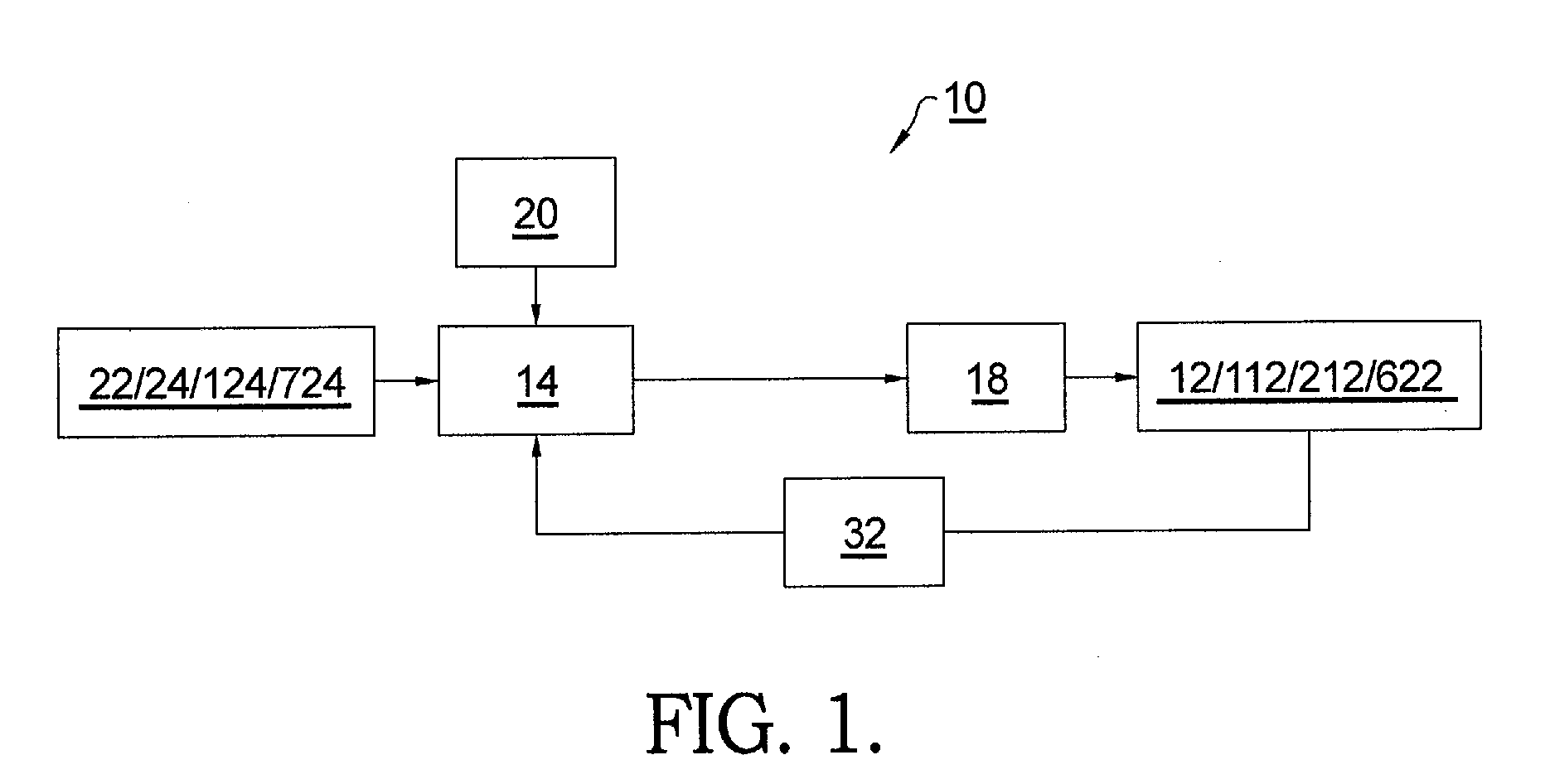

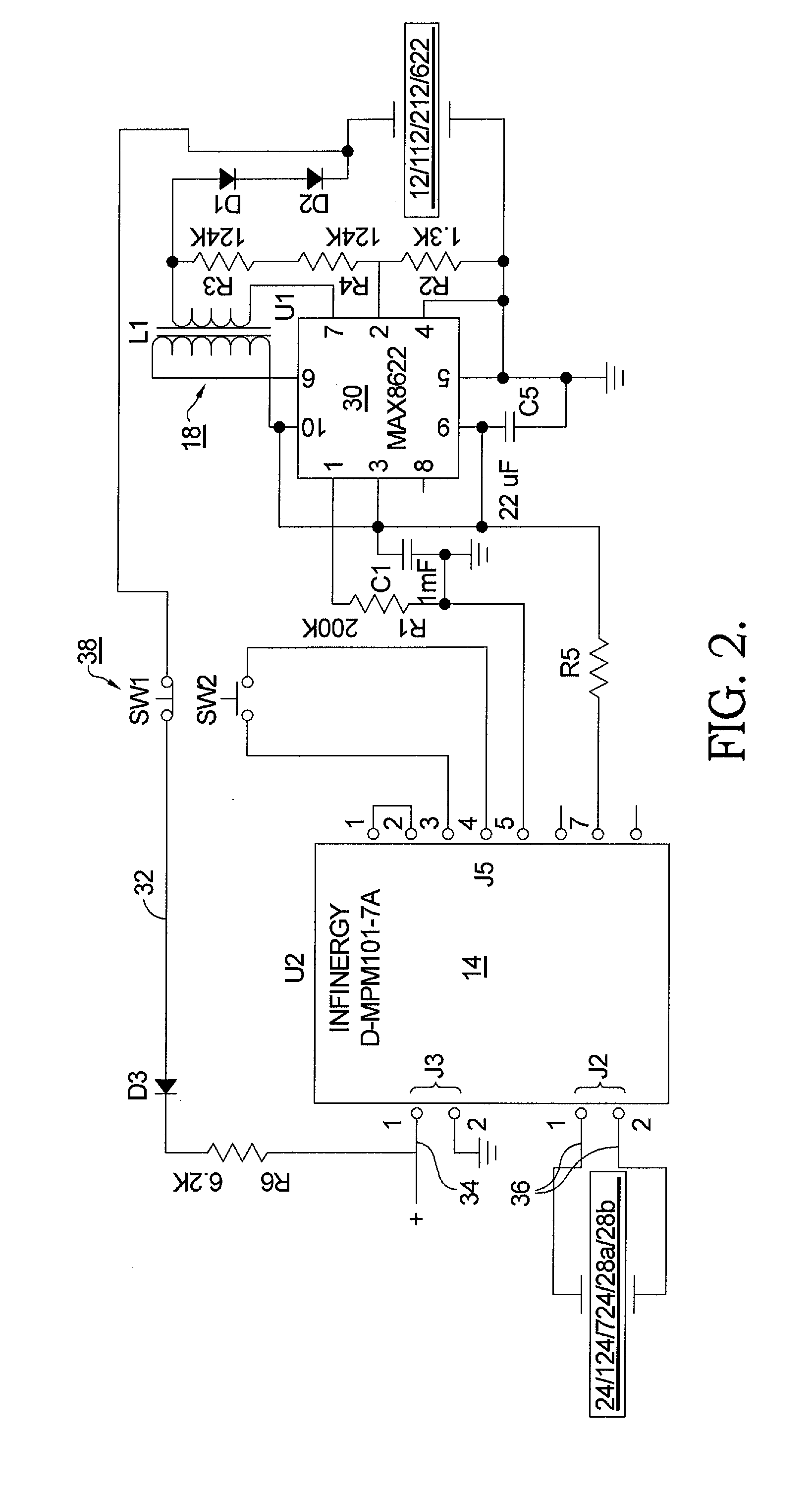

Electric Door Release Powered by Energy Harvester

ActiveUS20110252845A1Piezoelectric/electrostriction/magnetostriction machinesWing handlesElectricityEnergy harvester

A system for operating an electric door release having an actuator powered by an energy harvester. The actuator may be a piezoelectric actuator and the harvester may be a piezo harvester. The system may further include a power module, a rechargeable battery and a voltage boost circuit disposed between the energy harvester and the actuator. When a piezoelectric actuator is used, a recycle actuator discharge circuit may be disposed between the piezoelectric actuator and the power module battery for recapturing a portion of the energy delivered to the piezoelectric actuator. The piezoelectric harvester may include an energy input portion whereby the piezo electric harvester is excited by the energy input portion. The energy input portion may include a circular or linear driving gear for exciting the piezoelectric harvester or a stepper motor generator, driven by movement of a door. The harvester may also be a stepper motor / generator.

Owner:HANCHETT ENTRY SYST

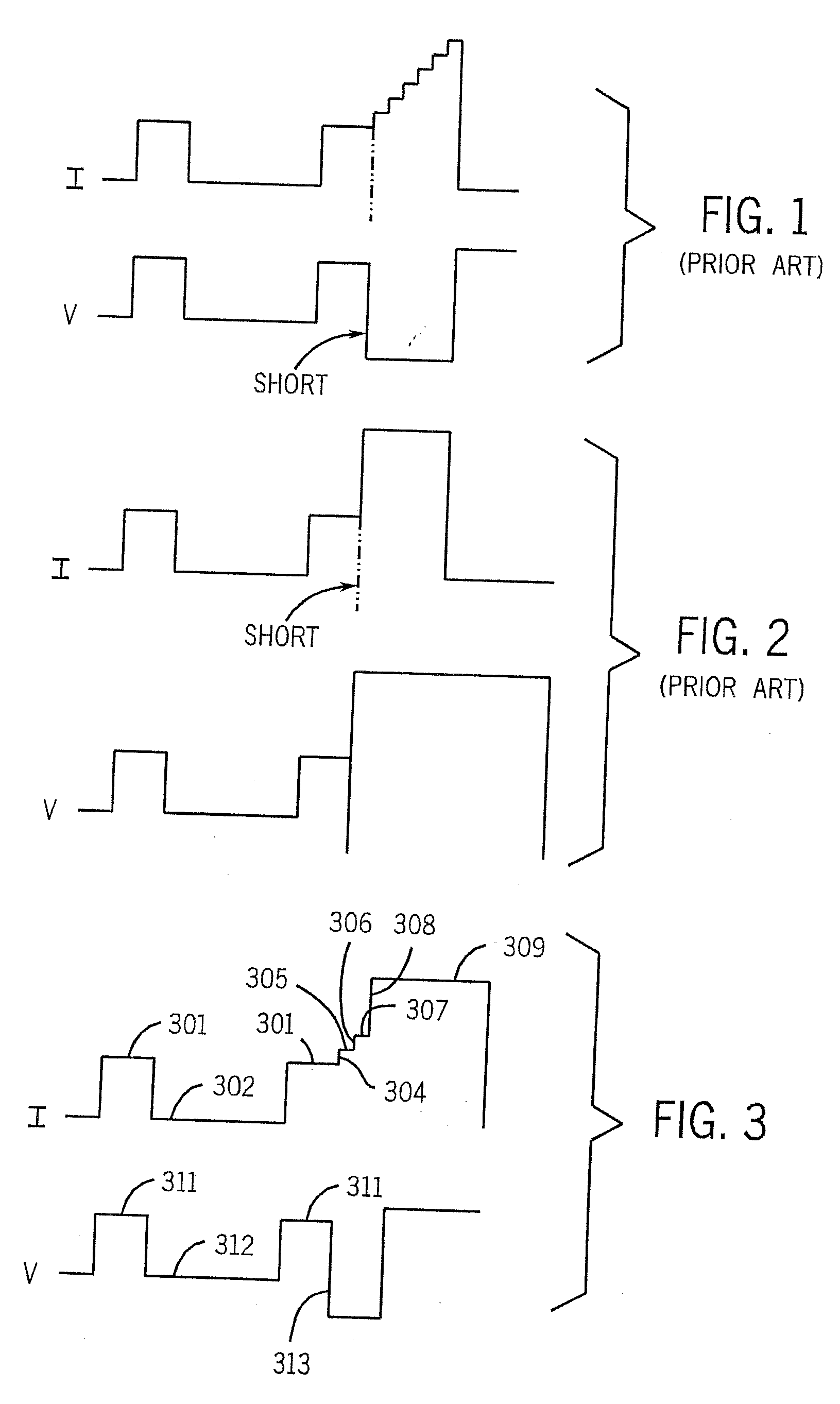

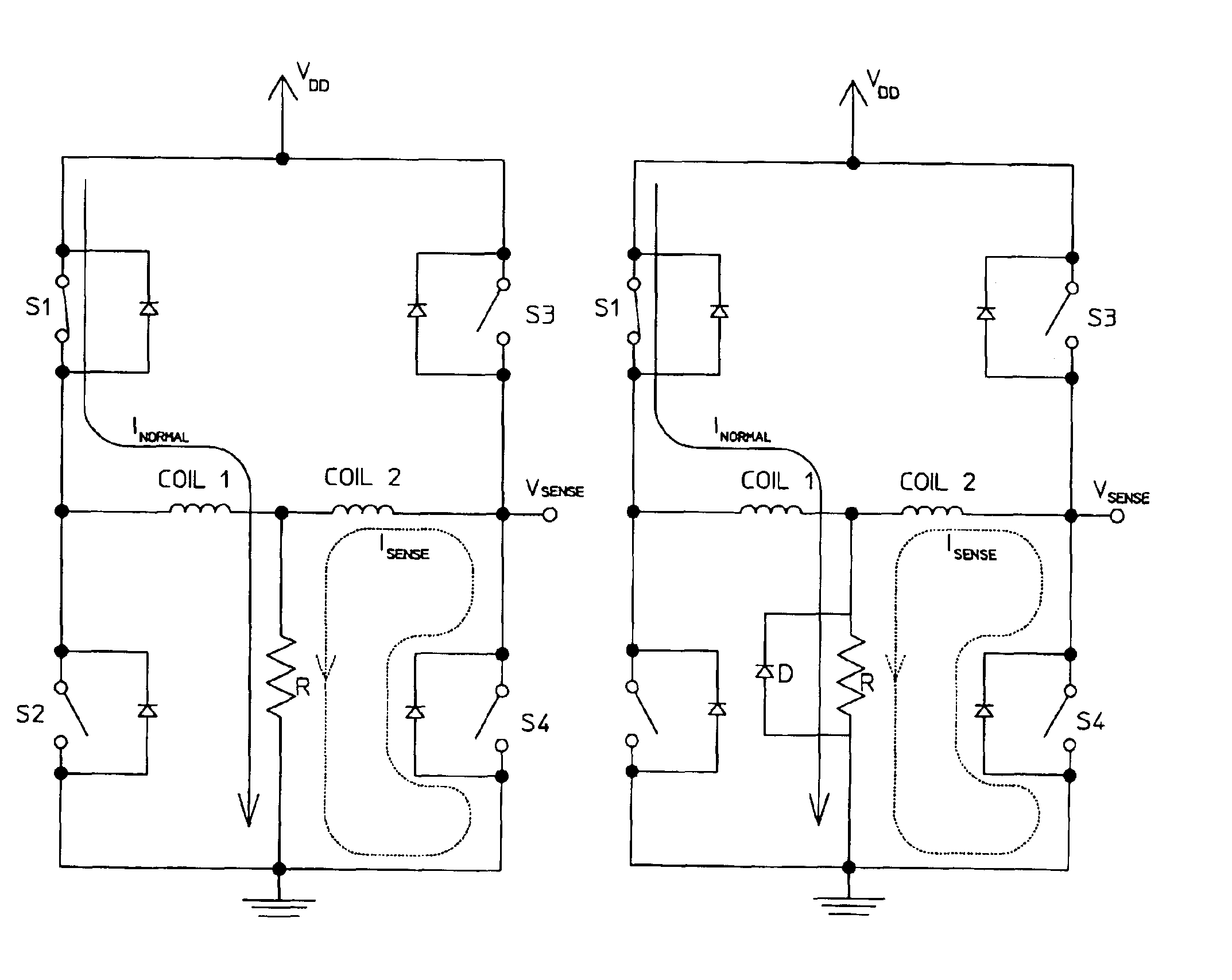

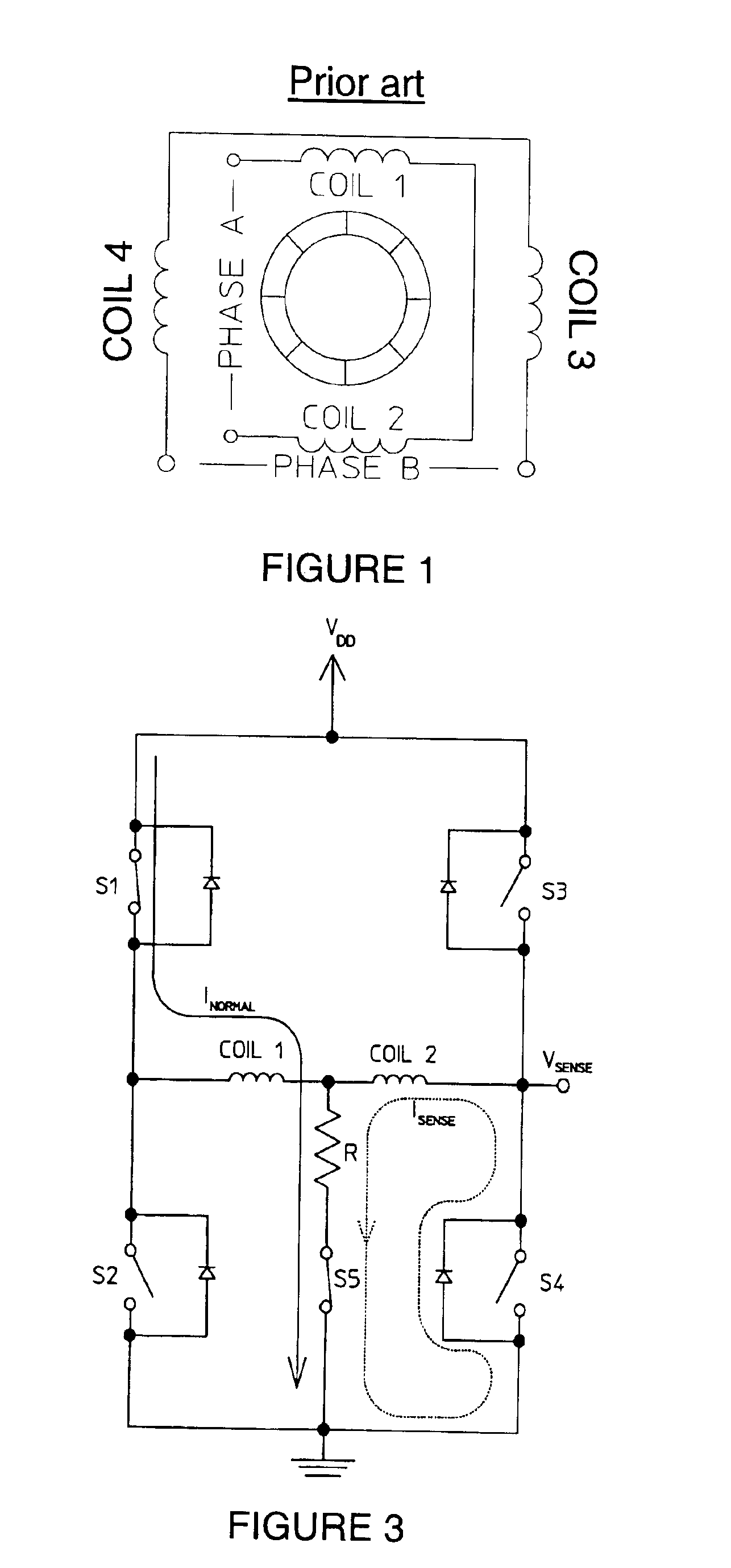

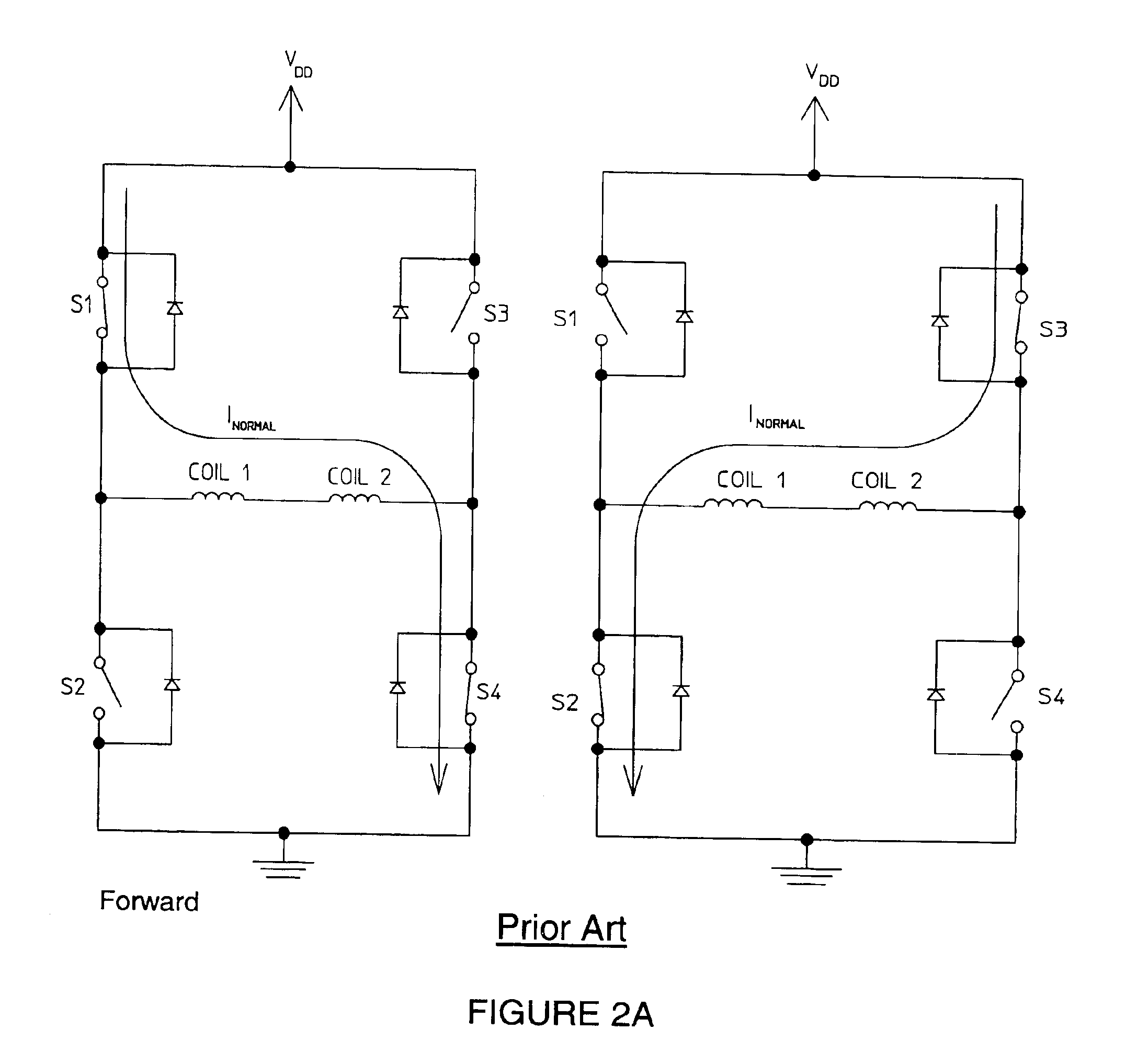

Stall detection circuit and method

InactiveUS6900657B2Avoid difficultyDetect changeDynamo-electric converter controlDynamo-electric machine testingCounter-electromotive forceConductor Coil

A stall detection circuit and method for a stepper motor. The circuit has an H-bridge configuration with an additional circuit pathway to ground being connected at a point between two center windings. During the transition between step sequences, the circuit employs a monitoring phase in which the previously active low side driver is turned off such that current passes through only the first winding and then is diverted to ground via the additional pathway. While the phase voltage is thus momentarily extinguished, the second coil is used to monitor the motor's back EMF, from which it can be determined whether the rotor is in a normal running mode, a stall, or a reverse condition.

Owner:SAIA BURGESS AUTOMOTIVE

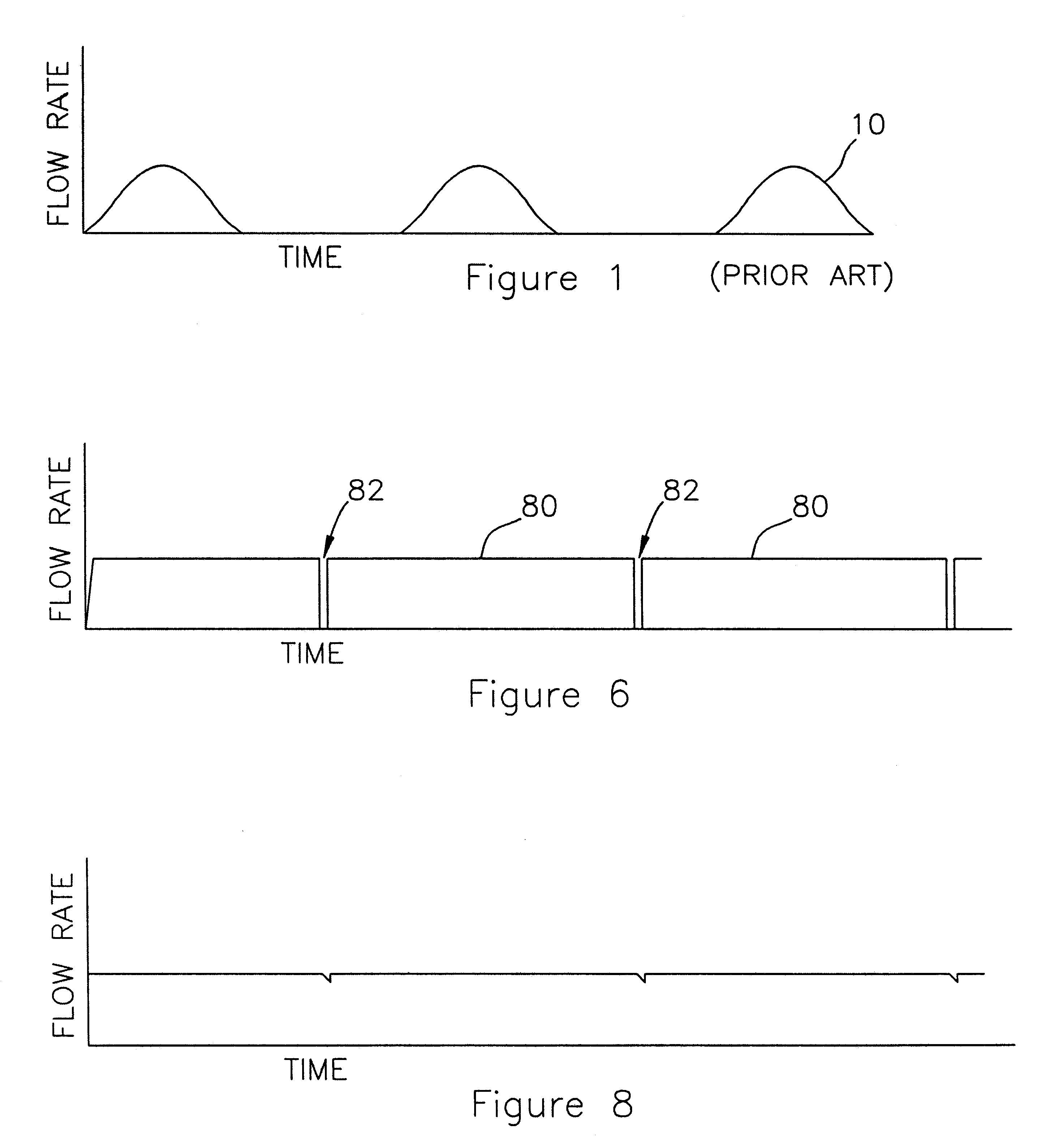

Constant flow fluid pump

InactiveUS6227807B1Water/sewage treatment bu osmosis/dialysisLiquid solutions solvent extractionControl theoryStreamflow

The present invention is a means and method for providing constant output flow from a fluid pump. The invention does this by controlling the radial speed of the pump motor during discreet segments of the motor's 360° angular / radial path through a revolution of the pump. The electric pump motor is controlled throughout the 360° radial path by employing a control means for controlling the speed of actuation of the radial steps of a stepper motor throughout the 360° path of rotation of the stepper motor. Control means for controlling the speed of the discreet steps of the stepper motor comprises at least a memory means, a counting means and an amplification means.

Owner:BECTON DICKINSON & CO

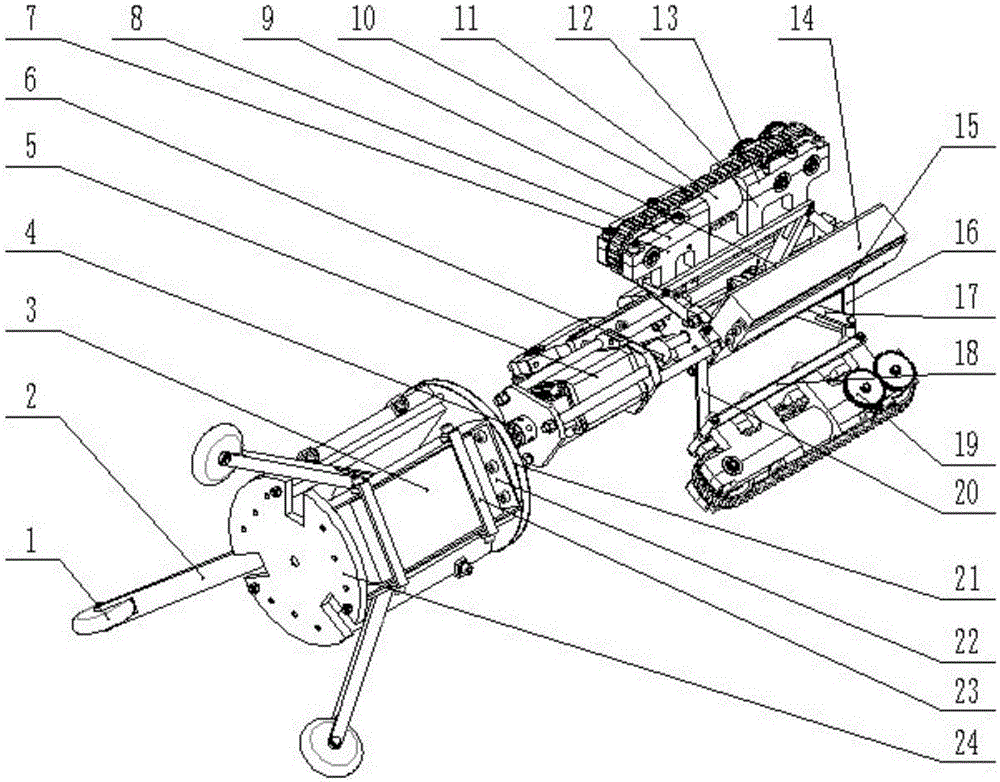

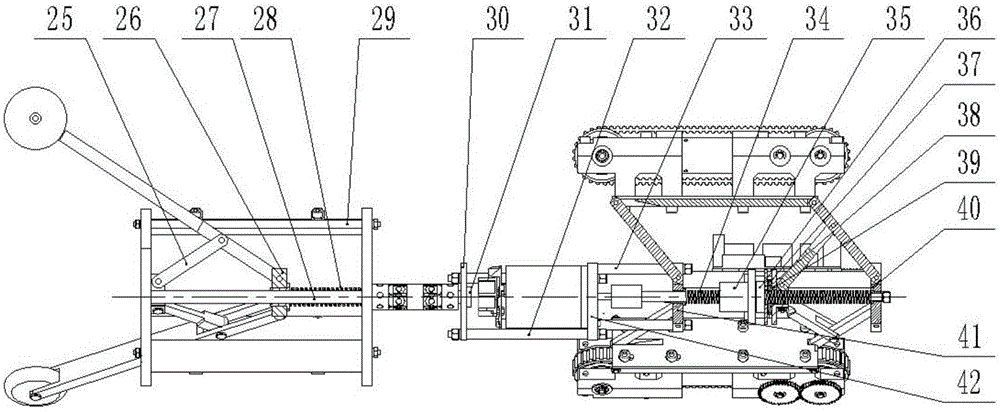

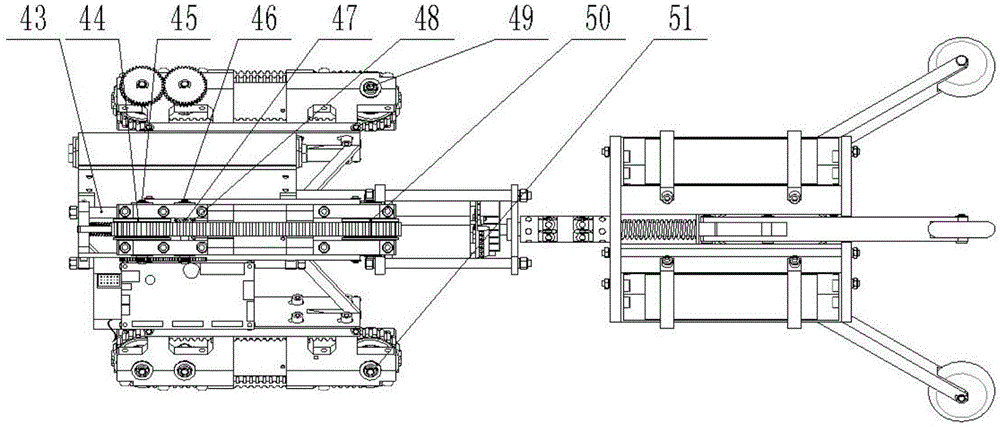

Crawler-type pipeline robot with active adaptation and self-adaptation functions

InactiveCN105135151ARealize driving functionRealize active adaptive driving functionPigs/molesSimulationServomotor

The invention belongs to the technical field of robots, and relates to a crawler-type pipeline robot with active adaptation and self-adaptation functions. A series combination mechanism, which is composed of a screw mechanism, a rocker slider mechanism and a parallelogram mechanism and driven by a stepper motor, is utilized to actively adapt to different pipeline diameters and keep a certain pressure between the crawler and pipeline inner wall. A set of butterfly springs arranged between the screw nut and slider are stressed to generate deformation to automatically adapt to the working conditions of pipeline joints, uneven-surface partial obstacles and the like in the pipeline. Three servomotors drive three sets of synchronous belt wheels to rotate through the transmission of a bevel gear and a cylindrical gear, thereby driving the three bifacial synchronous notched belts used as pipeline robot crawlers to move, and implementing the running function of the pipeline robot. The crawler-type pipeline robot has the simple structure, high operation and running safety, high environmental adaptability and wide application range, is convenient to use, and can work in pipelines with different diameters.

Owner:QINGDAO UNIV

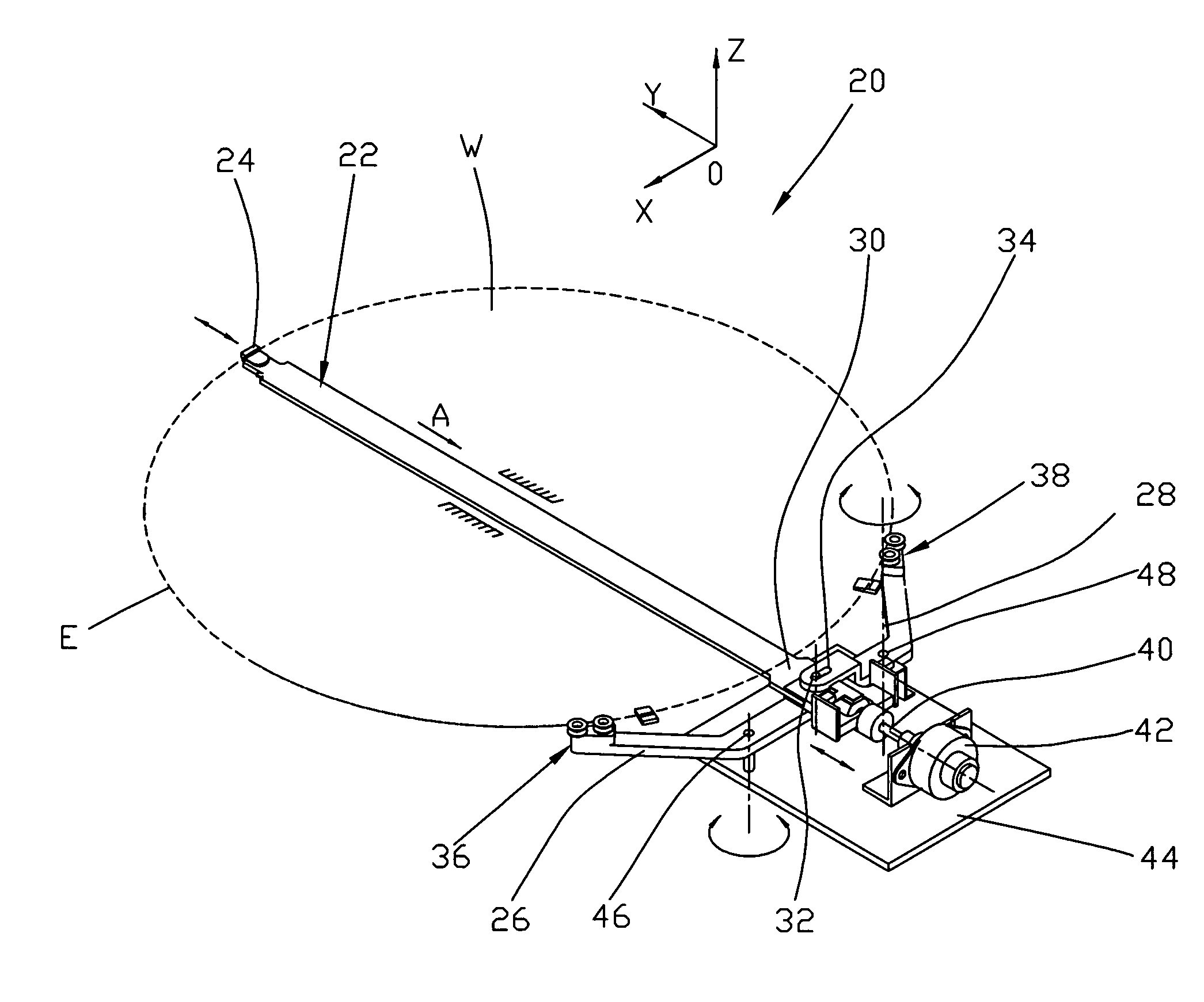

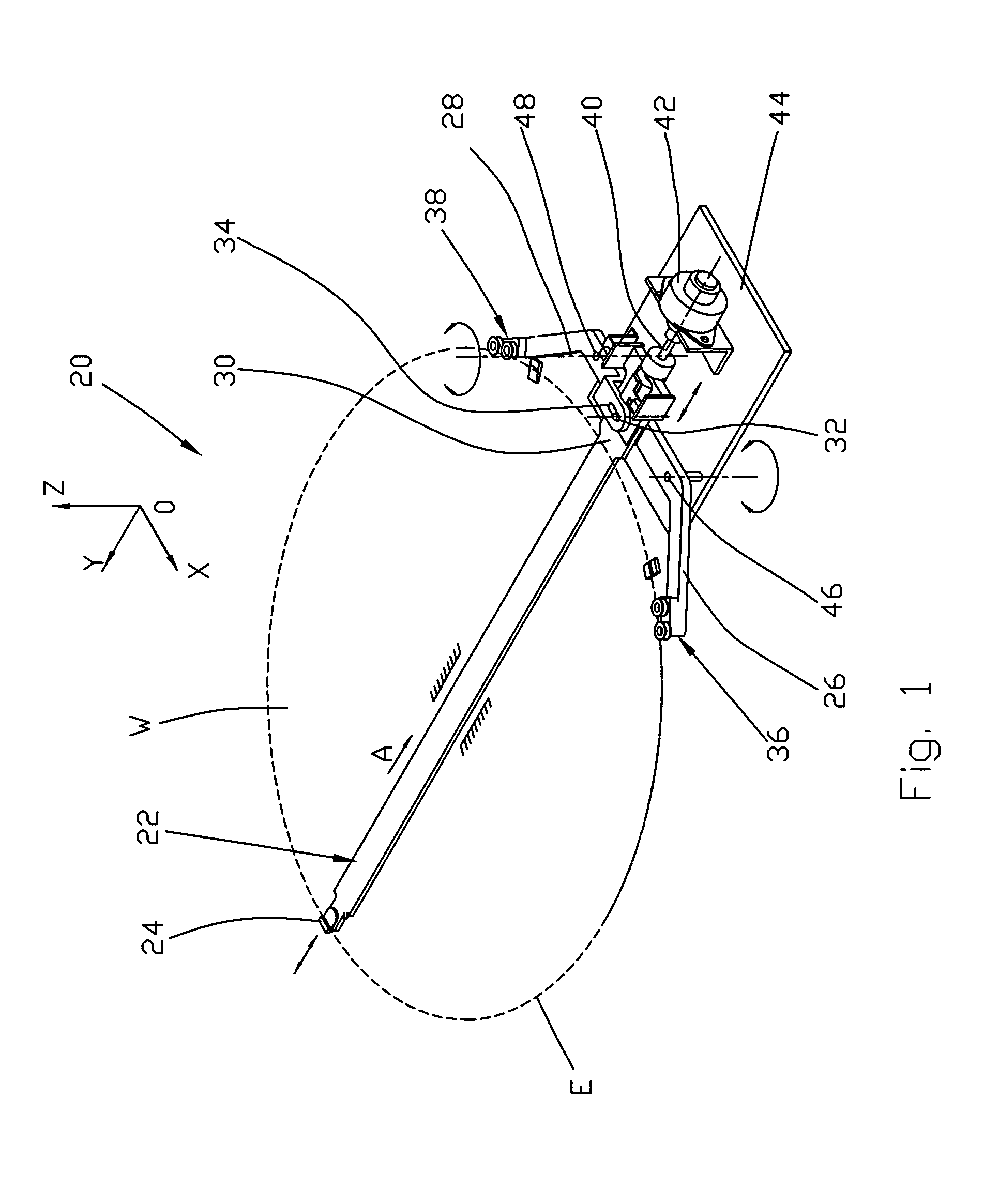

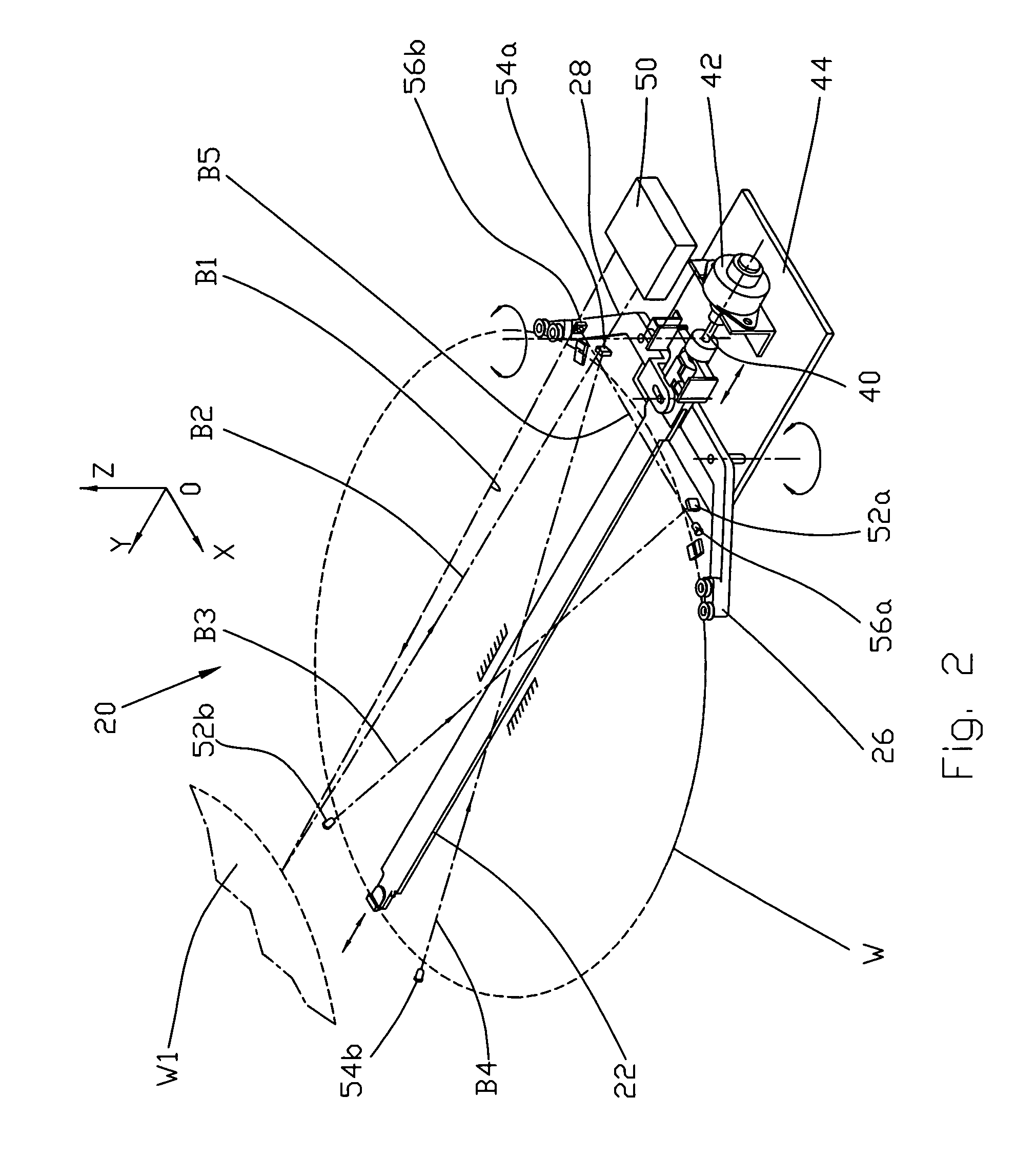

Computer-aided system for limb lengthening

ActiveUS8157800B2Safe and optimal for patientDiagnostic recording/measuringSensorsComputer moduleEngineering

An apparatus for lengthening of extremities includes at least two supporting rings, a plurality of spikes mounted in each of the at least two supporting rings by spike-fixating elements, the at least two supporting rings connected with one another by threaded rods, which are displaced into rectilinear movement by automated drives connected with a portable block for power supply and control. Each automated drive includes a screw pair composed of a threaded rod and a threaded insert mounted via two bearings that are spaced from one another, and movable through a reducer with a stepper motor. The portable block is provided with elements for controlling a speed and a direction of movement of each of the automated drives, and a unit is provided for calculation and indication of displacement supplied by each of the automated drives.

Owner:VVEDENSKY PYOTR S +1

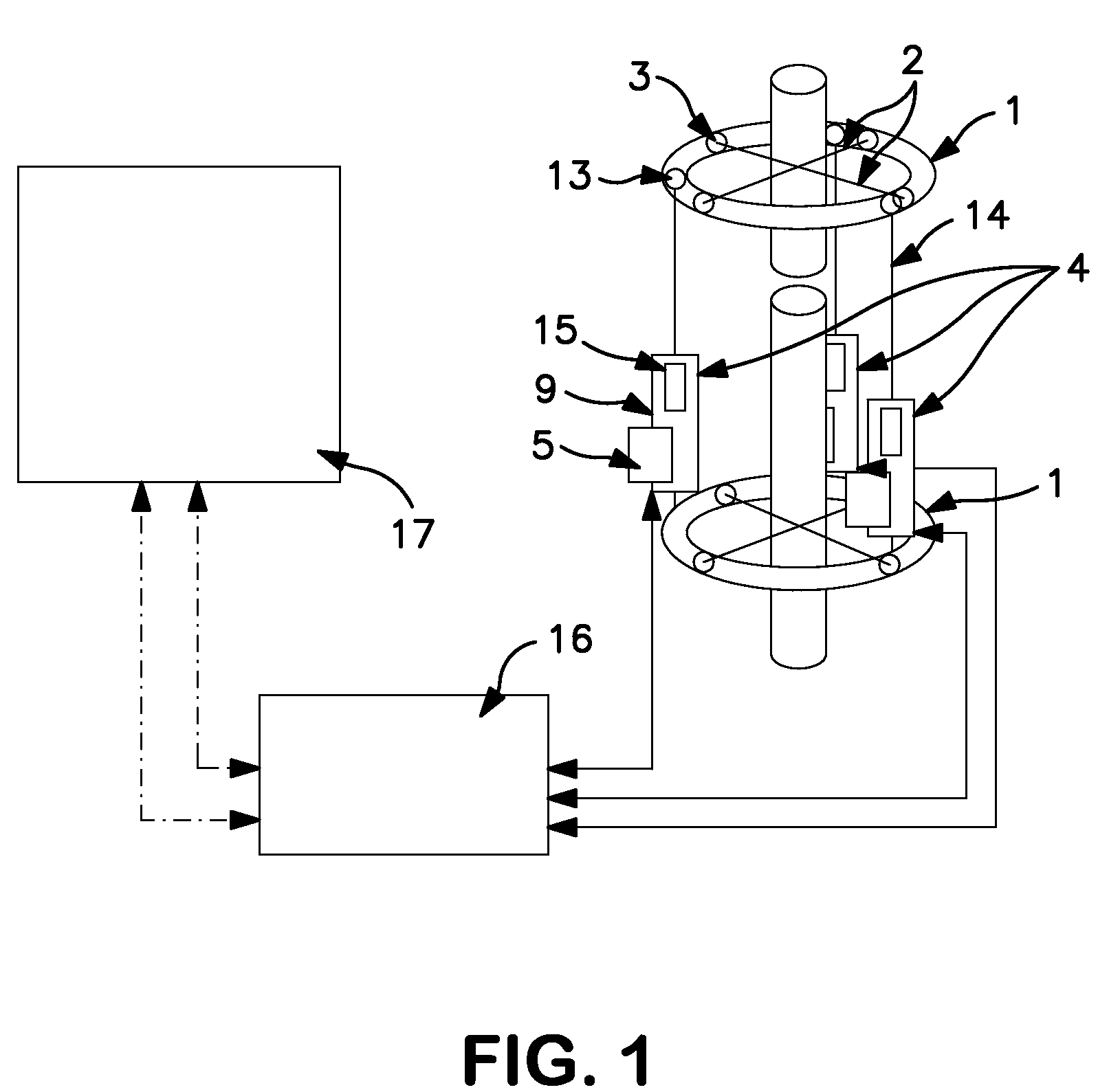

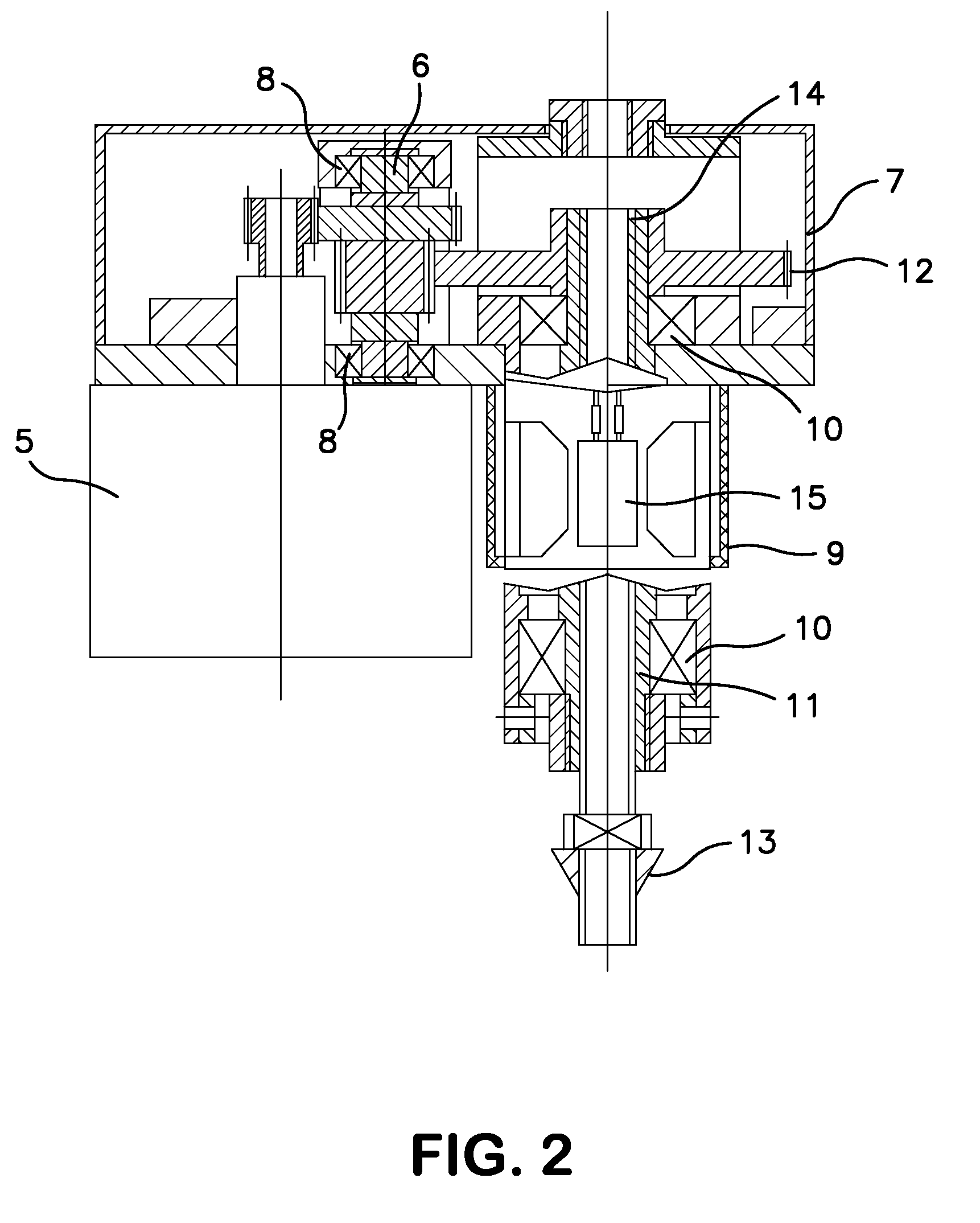

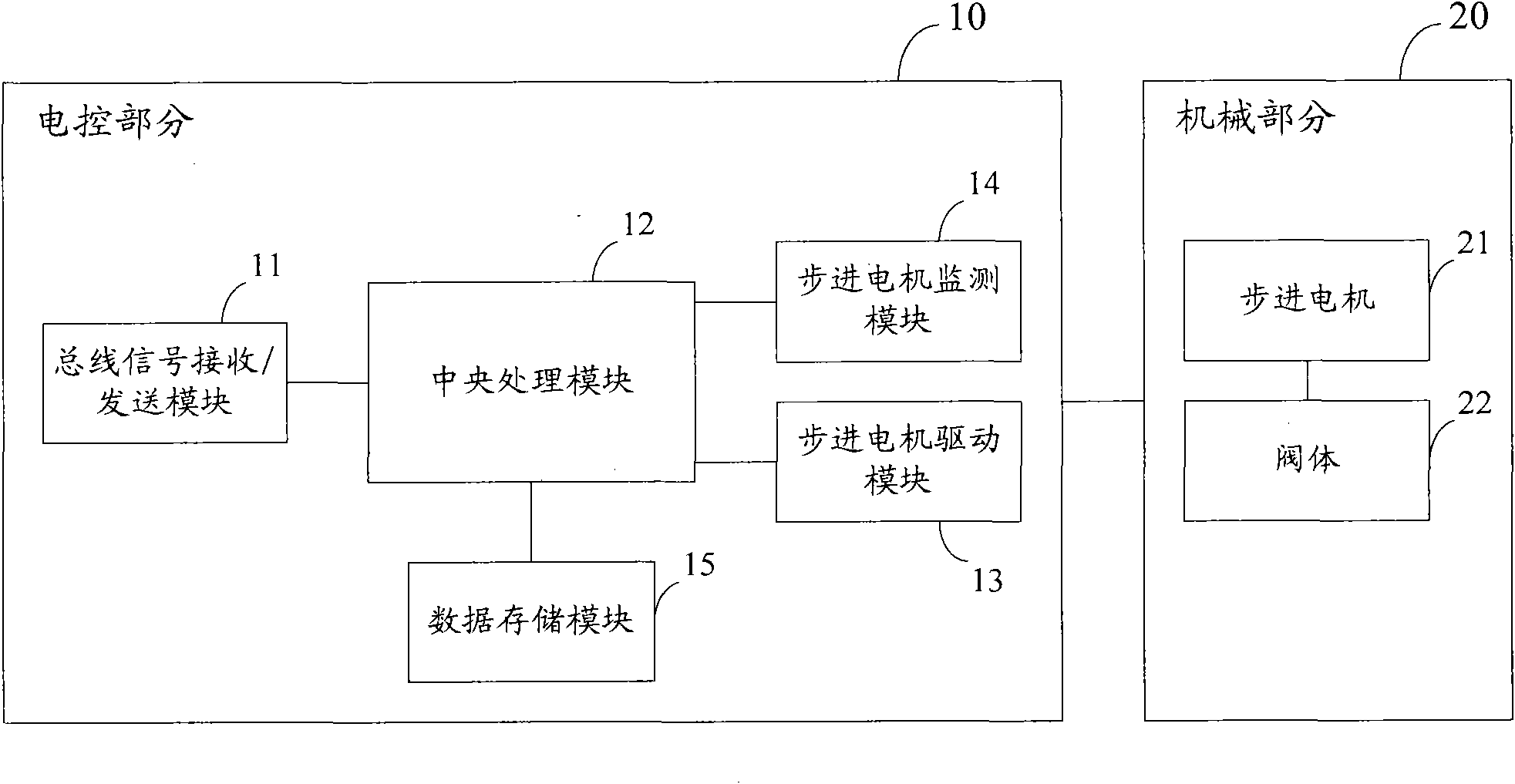

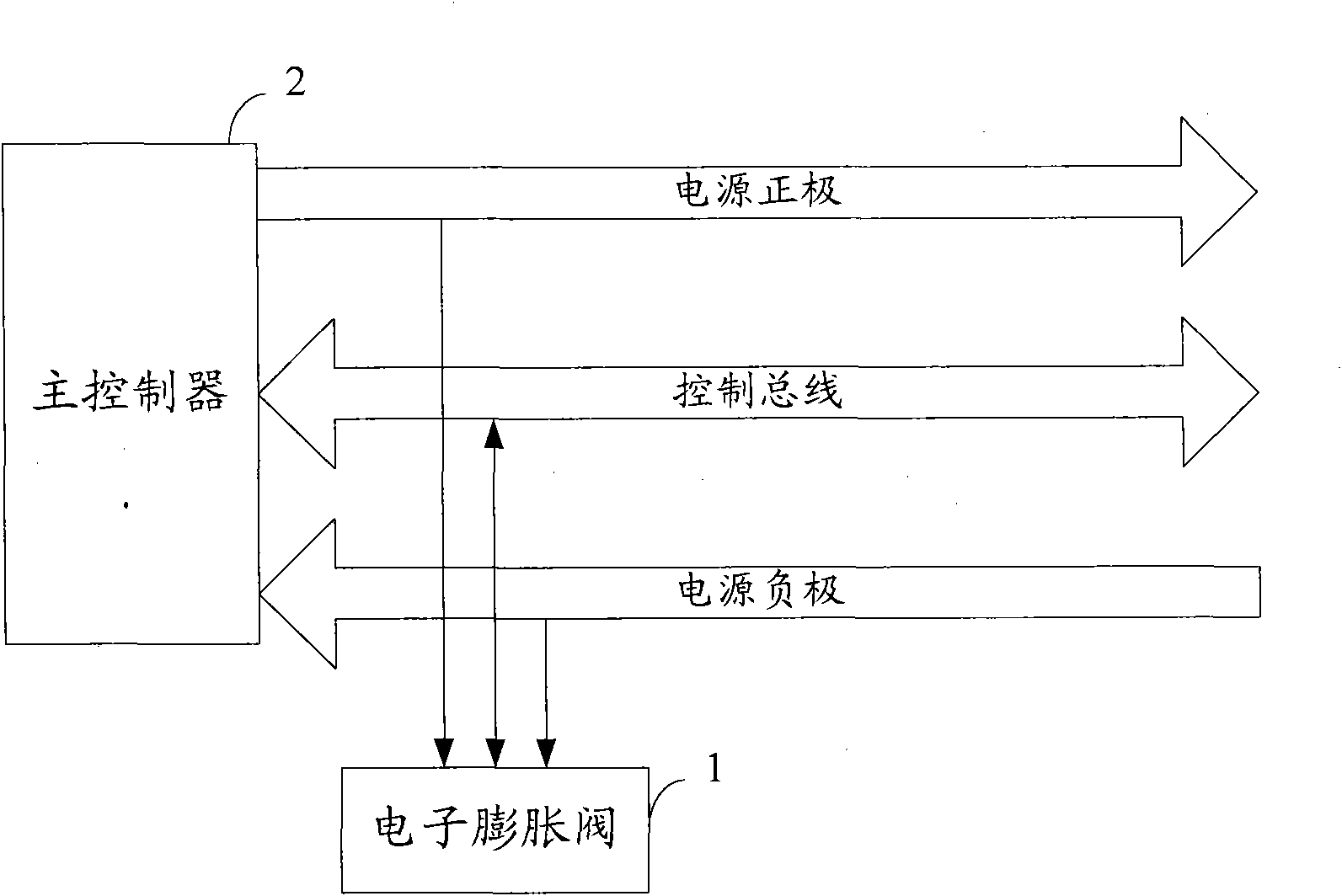

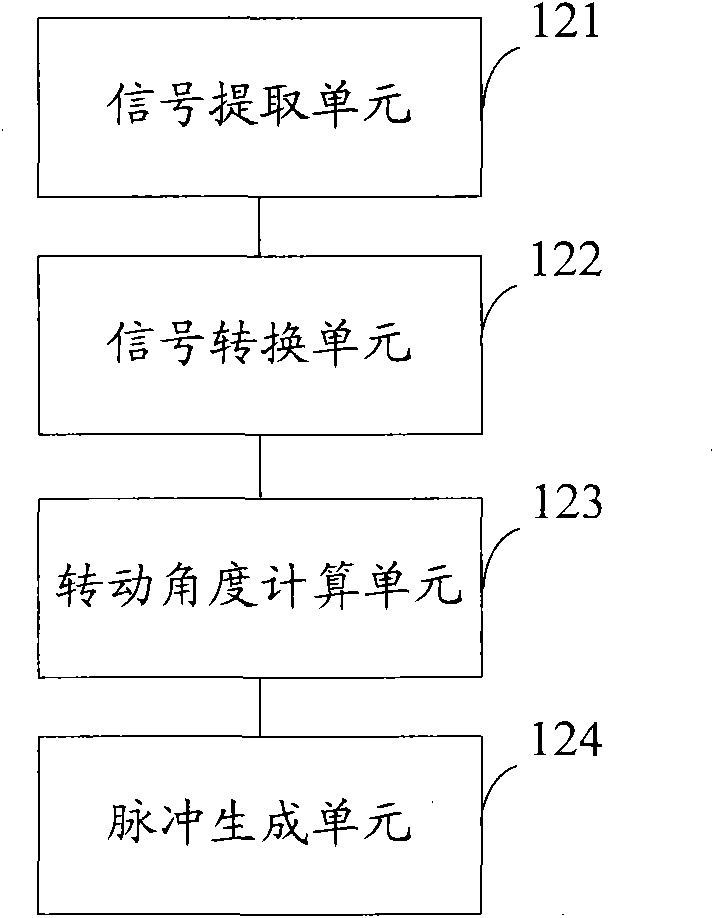

Electronic expansion valve, stepper motor and reversing valve

ActiveCN102374328AReduce in quantitySimple structureOperating means/releasing devices for valvesDynamo-electric converter controlPulse controlControl signal

The invention discloses an electronic expansion valve, which comprises an electrical control part and a mechanical part. The electrical control part comprises a bus signal reception / transmission module, a central processing module and a stepper motor driving module; wherein the bus signal reception / transmission module is used for receiving a bus control signal and transmitting the bus control signal to the central processing module; the central processing module is used for extracting valve opening information included in the bus control signal, generating a corresponding pulse control signalin combination with current position information of a stepper motor read from a data storage module, and outputting the pulse control signal to the stepper motor driving module; and the stepper motordriving module is used for driving the stepper motor to adjust the valve opening according to the pulse control signal. The invention also discloses a stepper motor and a reversing valve. The number of drive wires directly connected with a main control board can be reduced, the structure of the main control board can be simplified, and the manufacturing cost can be saved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Precision soft-touch gripping mechanism for flat objects

InactiveUS7140655B2Improve reliabilityImprove approachProgramme controlProgramme-controlled manipulatorGrip forceEngineering

A precision soft-touch gripping mechanism has a mounting plate attached to a robot arm. The plate supports a stepper motor. The output shaft of the stepper motor is connected through a spring to an elongated finger that slides in a central longitudinal slot of the plate and supports a first wafer gripping post, while on the end opposite to the first wafer gripping post the mounting plate pivotally supports two L-shaped fingers with a second and third wafer gripping posts on their respective ends. The mounting plate in combination with the first sliding finger and two pivotal fingers forms the end effector of the robot arm which is thin enough for insertion into a wafer-holding slot of a wafer cassette. The end effector is equipped with a mapping sensor for detecting the presence or absence of the preceding wafer, wafer position sensors for determining positions of the wafer with respect to the end effector, and force sensors for controlling the wafer gripping force. Several embodiments relate to different arrangements of gripping rollers and mechanisms for control of the gripping force and speed of gripping required for gripping the wafer with a soft and reliable touch.

Owner:MULTIMETRIXS

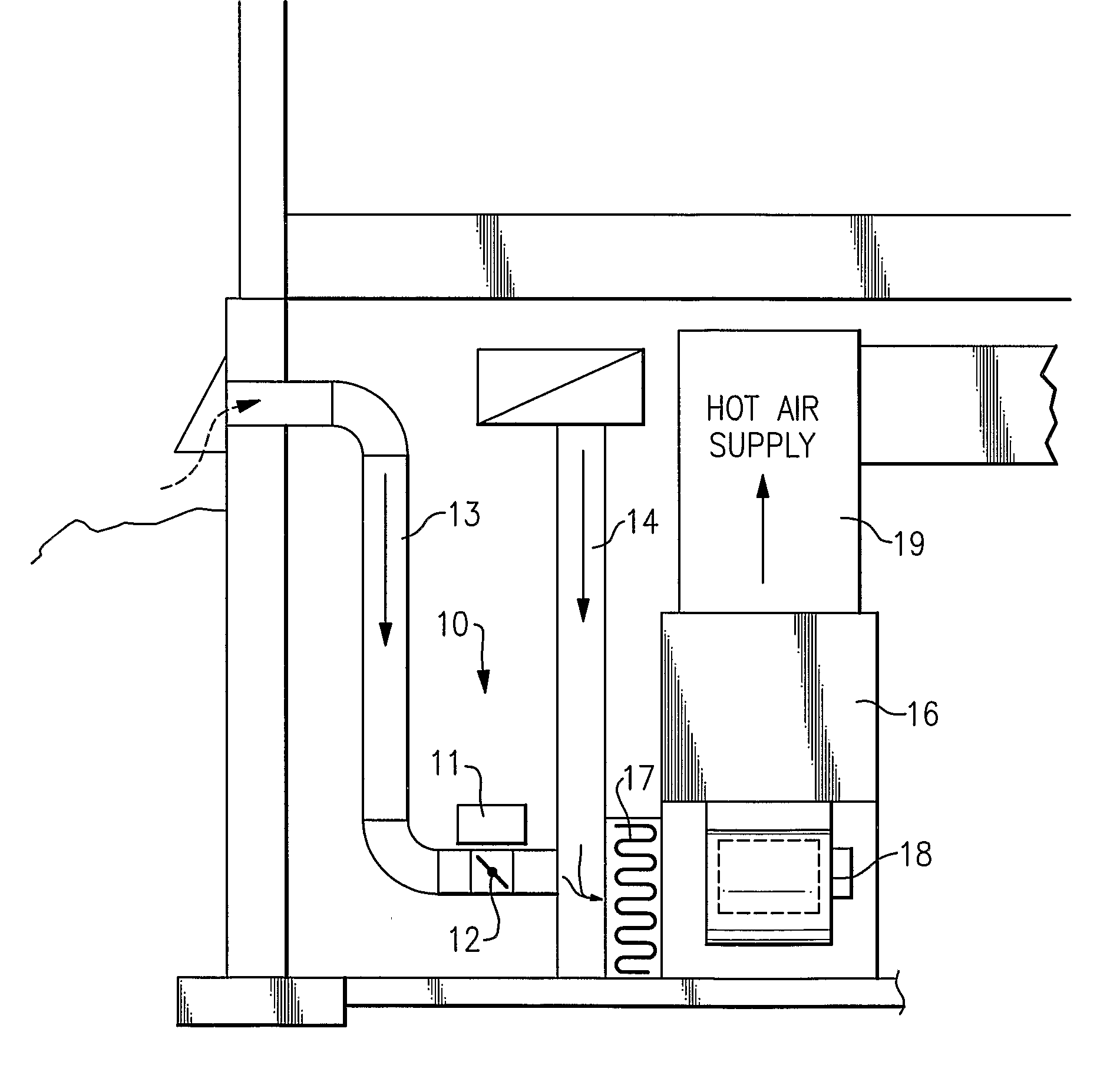

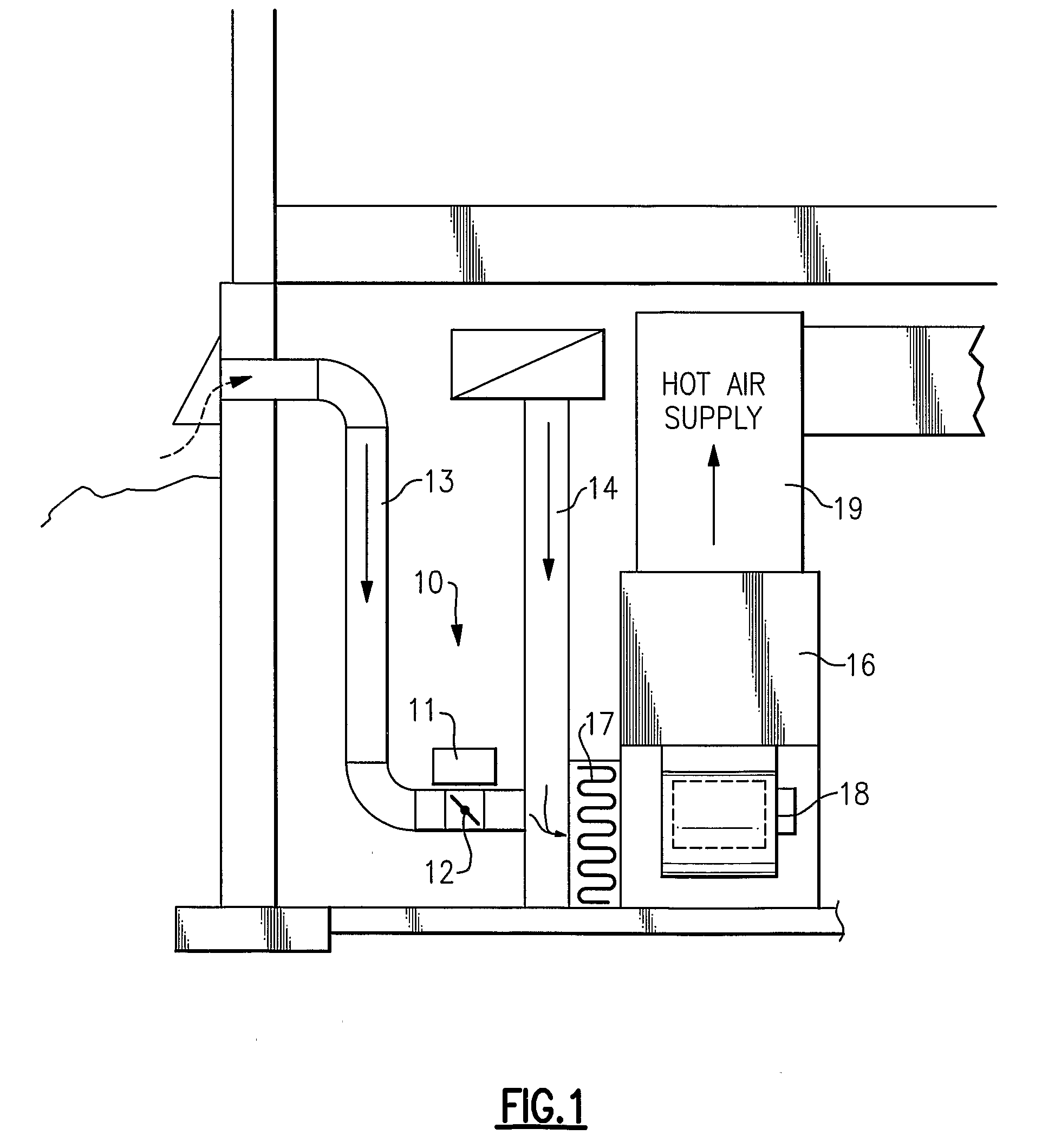

Energy Efficient House Ventilation

InactiveUS20090001179A1Degree of reductionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsNatural ventilationSnubber

A method and apparatus for maintaining an acceptable level of outside air exchange rate in a structure. The natural ventilation rate is determined as a function of the outdoor air temperature, and the amount of mechanically induced ventilation that is used to supplement the natural air ventilation is controlled such that the sum of the natural occurring ventilation and the mechanically induced ventilation is maintained by a substantially constant predetermined level. One approach is to use a stepper motor to modulate the position of the damper, while another approach is to use an on / off motor damper and to close the damper at outdoor temperatures below a threshold level and to otherwise leave the damper open and use the regular on / off cycle of the system blower to control the flow of outdoor air, with provision for allowing the fan to remain on for a calculated period of time after the system is cycled off to thereby maintain the desired level of ventilation. Can also vary the speed of the furnace blower or a separate ventilation fan motor.

Owner:CARRIER CORP

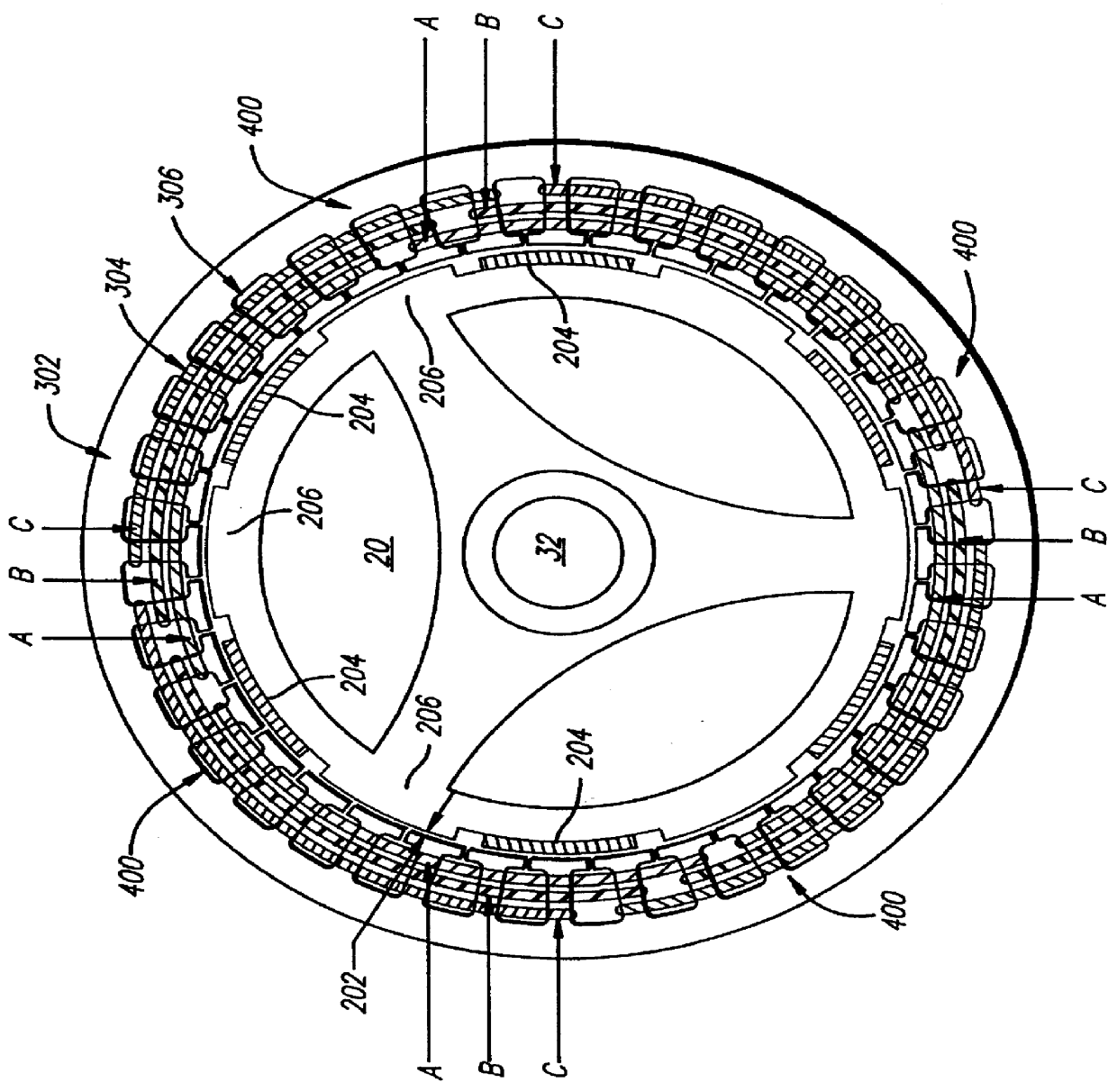

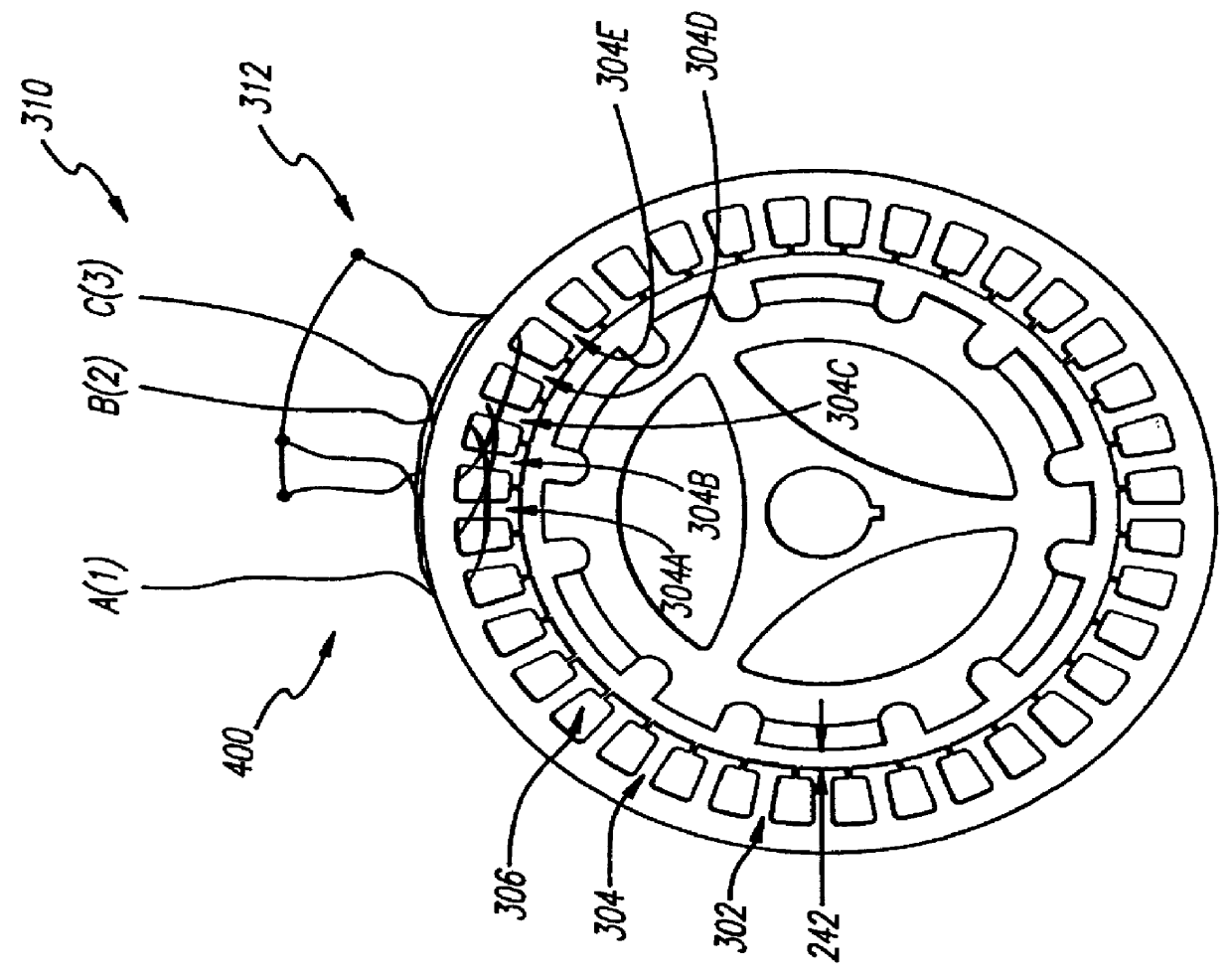

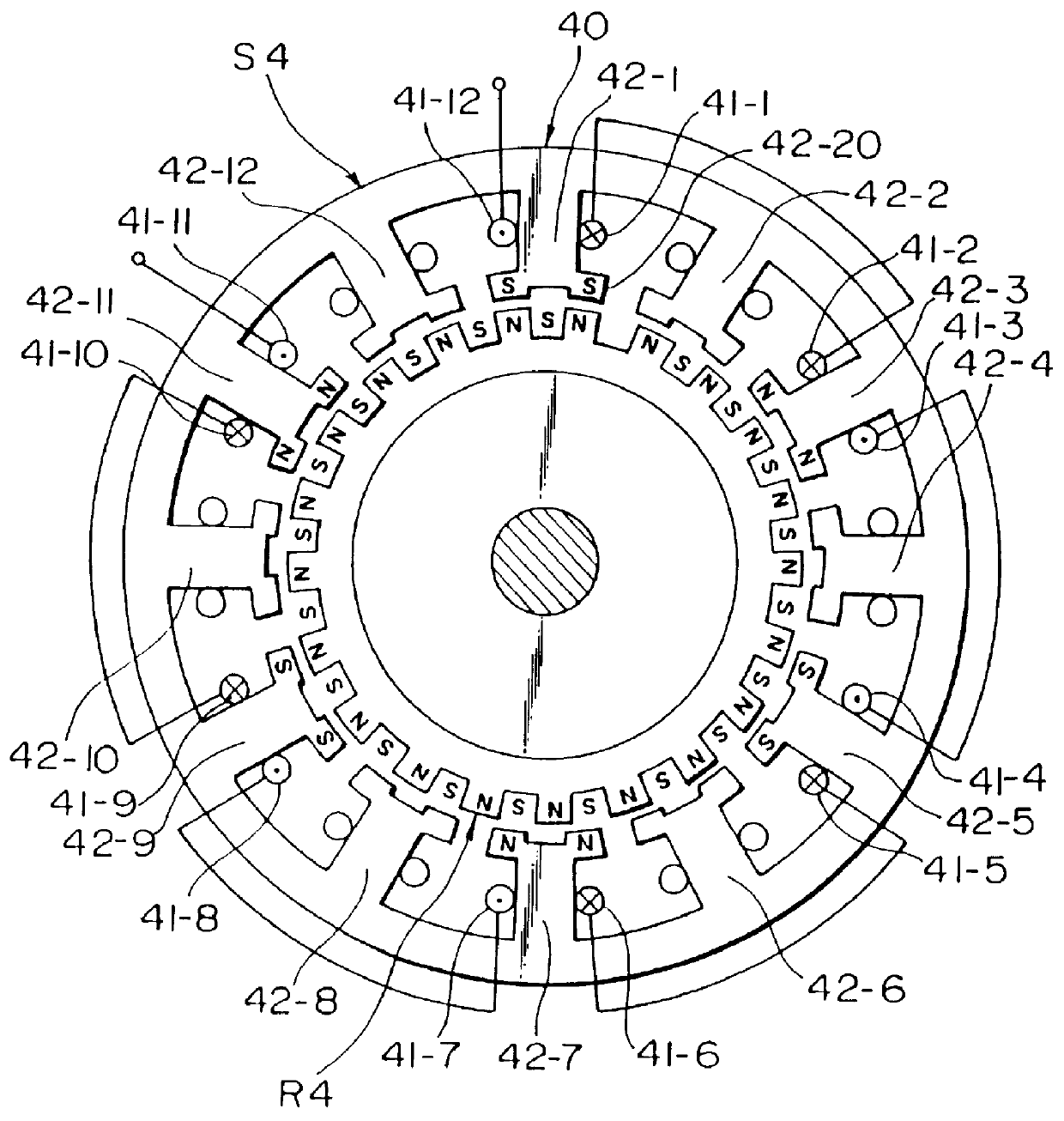

Three-phase permanent magnet cascade claw type stepping motor

InactiveUS6028377ASmall noiseSmall oscillationMagnetic circuit rotating partsMagnetic circuit stationary partsThree-phaseConductor Coil

A magnet type stepping motor which has (1) a stator with three-phase stator windings, and 6 m pieces of stator main pole arranged side by side, where m is an integer and.gtoreq.1, the stator windings of one phase are wound around every two stator main poles among the 6 m pieces of the stator main pole, wherein when the stator windings of one phase are excited with a direct current, m pieces of N pole and M pieces of S pole are formed alternately on the 6 m pieces of stator main pole, and (2) a rotor of a cylindrical permanent magnet magnetized in the circumferential direction to form Z / 2 pieces of N pole and Z / 2 pieces of S pole alternately, where Z is the number of rotor poles.

Owner:JAPAN SERVO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com