Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2126 results about "Worm drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm wheel. The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit.

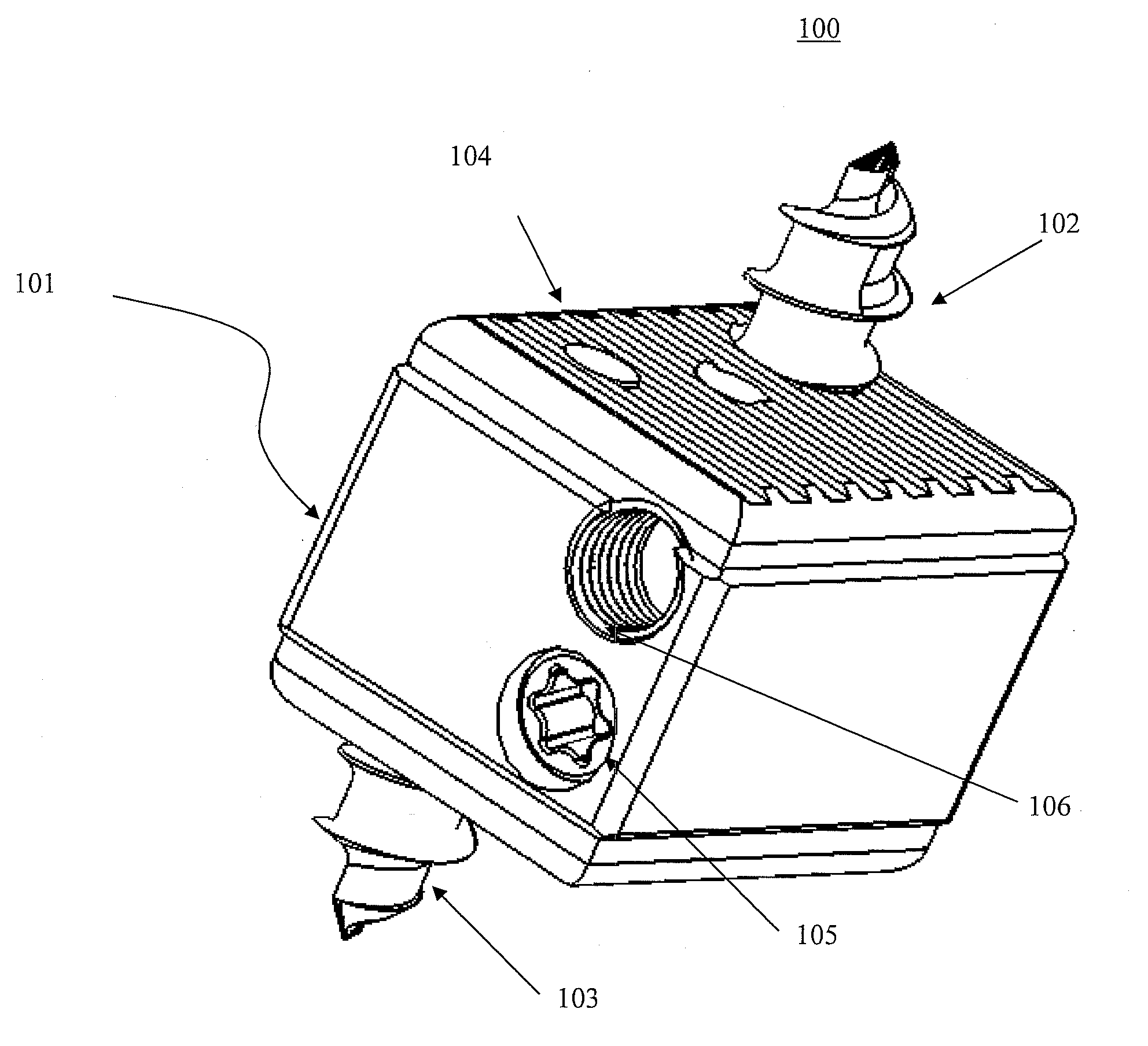

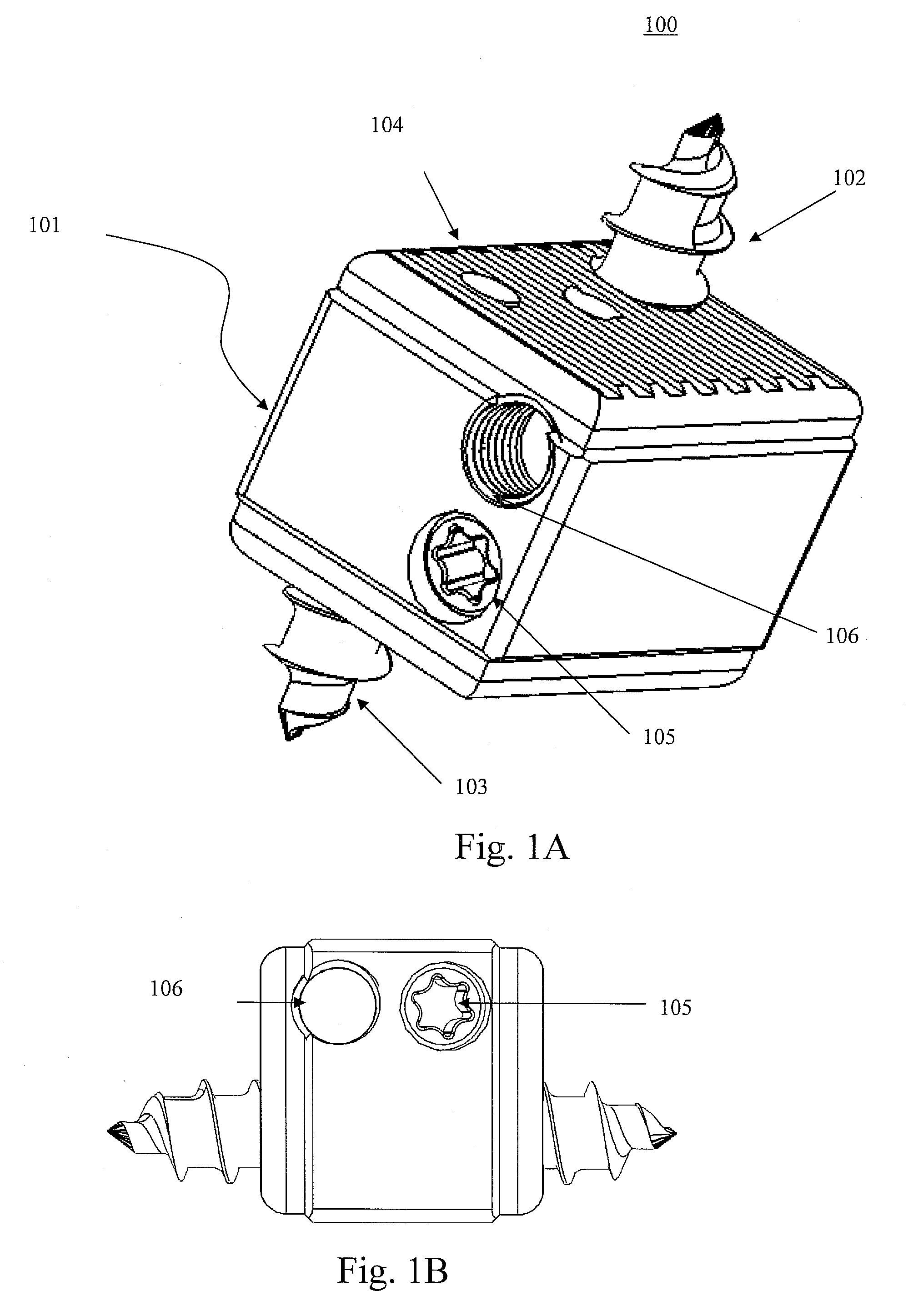

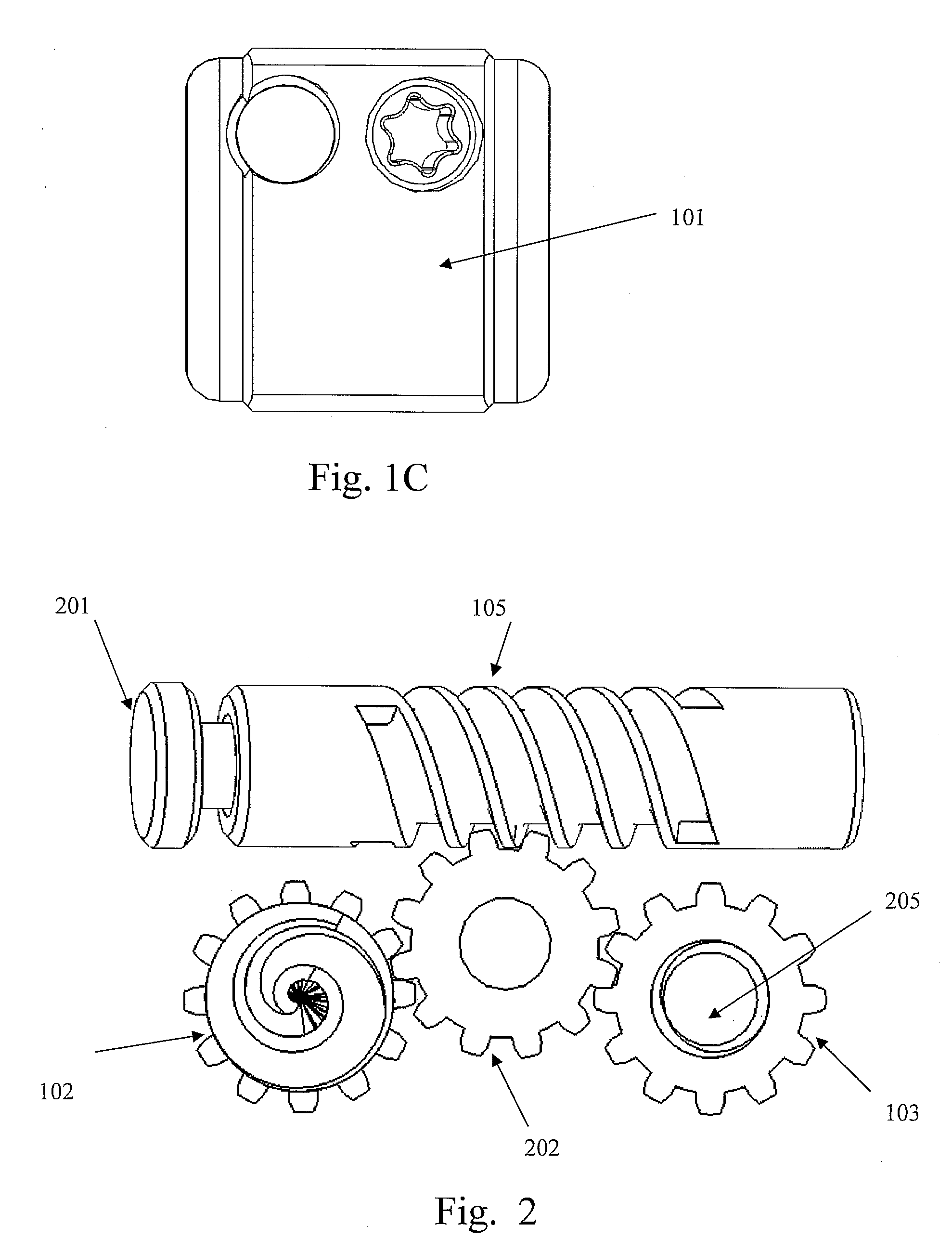

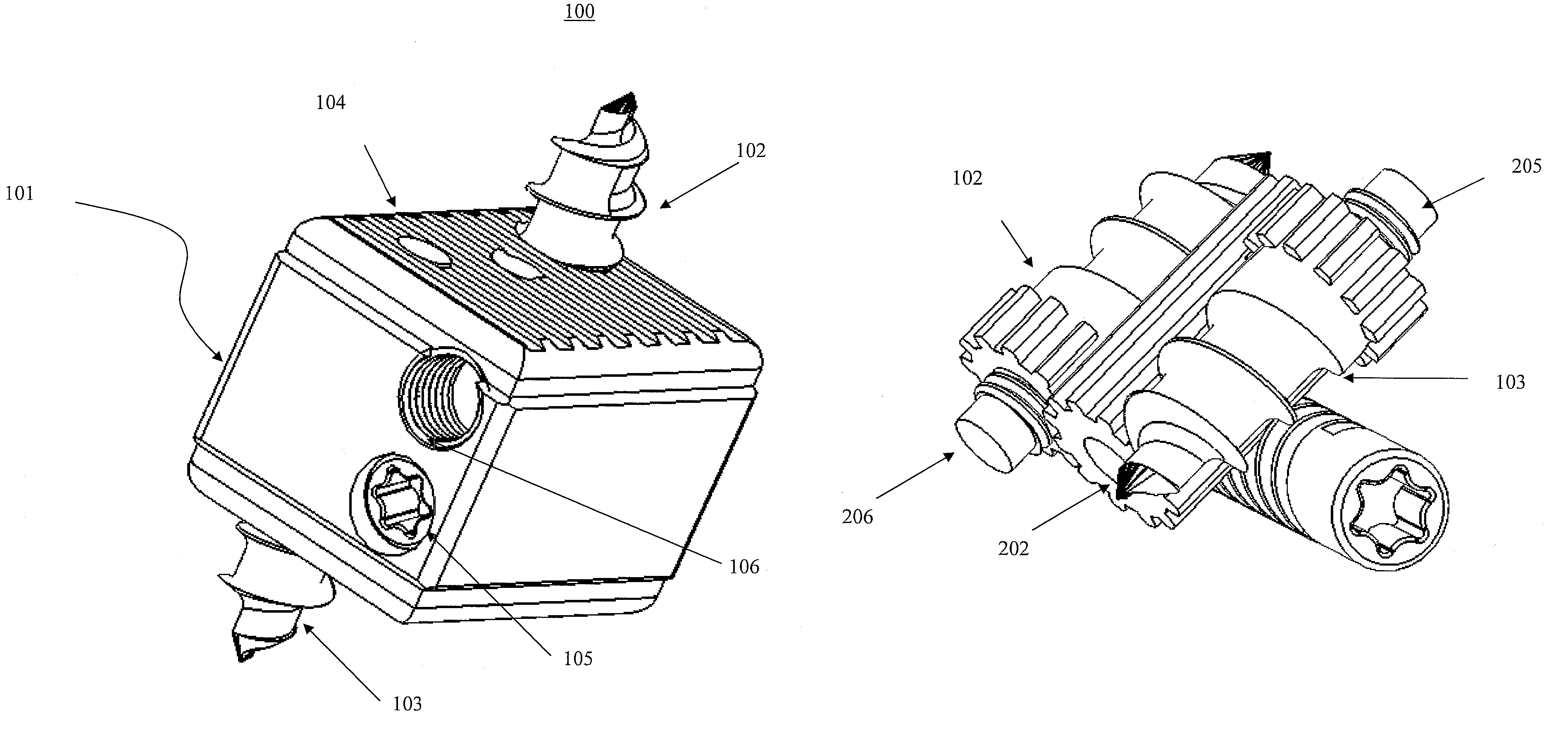

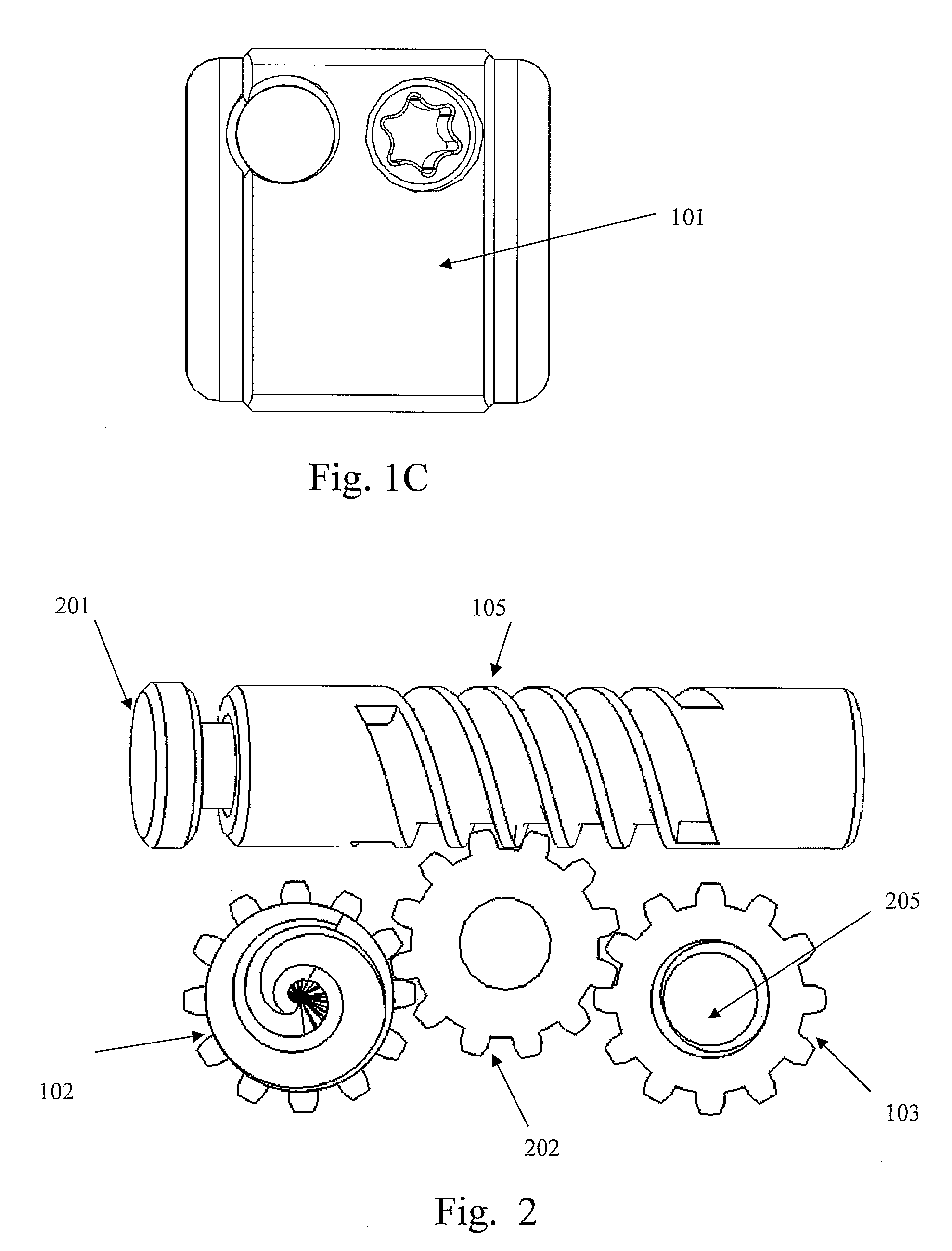

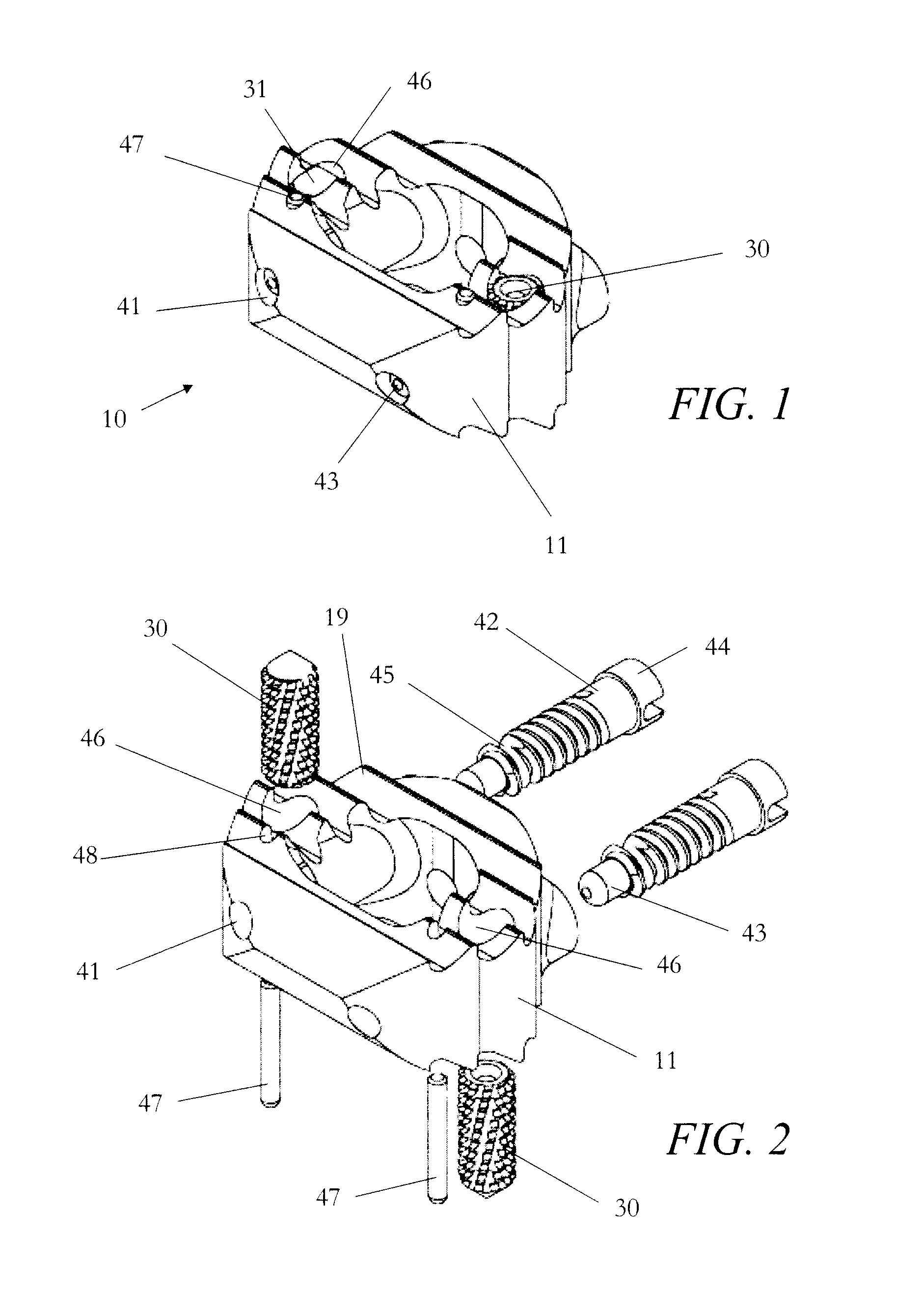

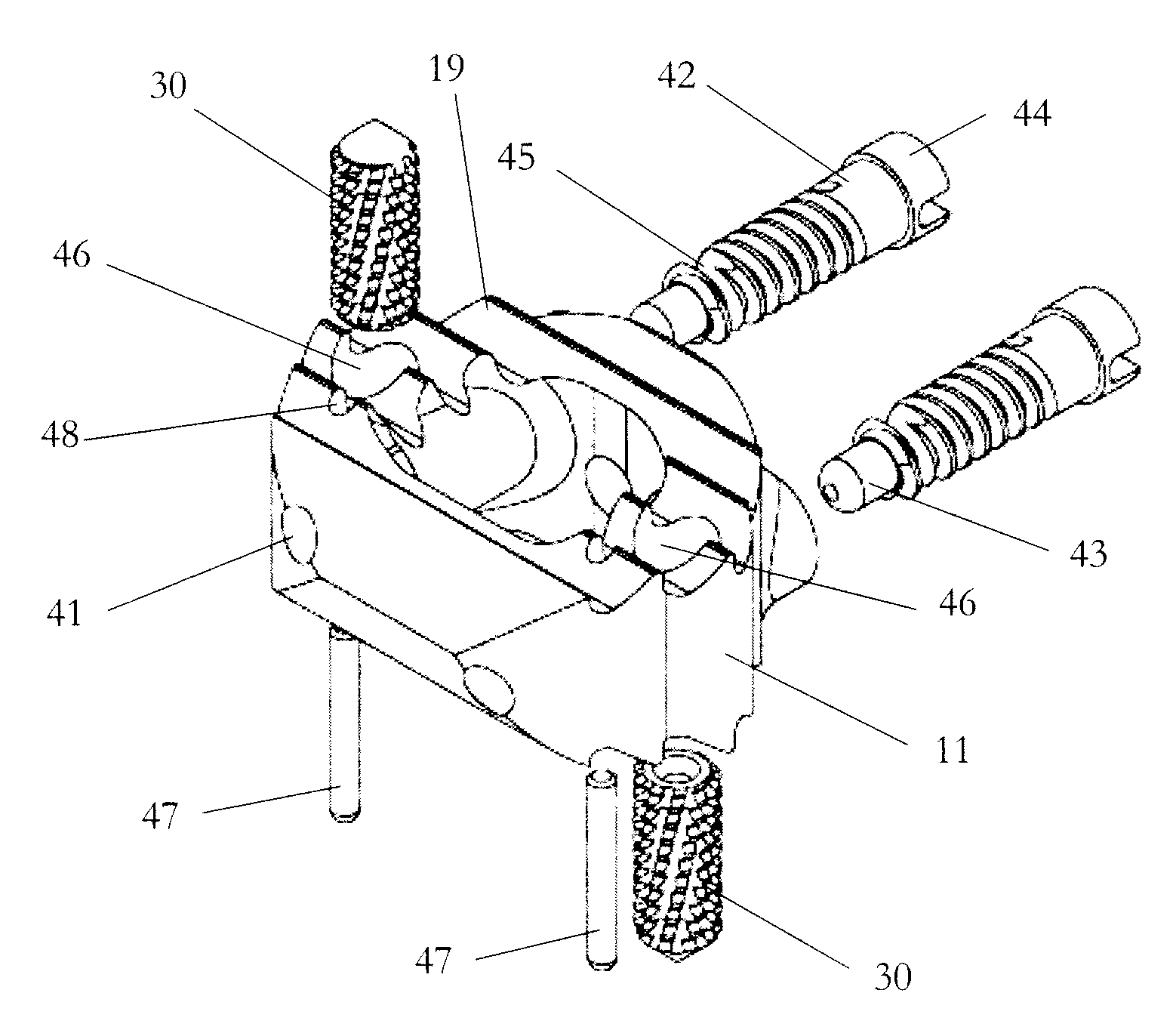

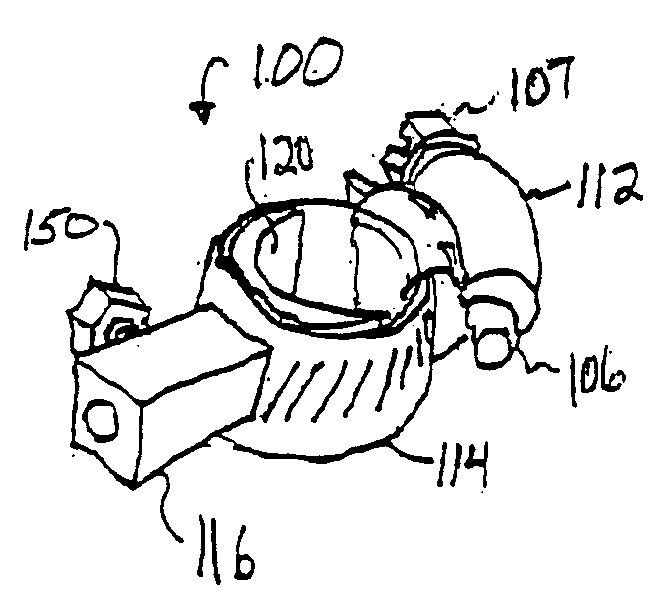

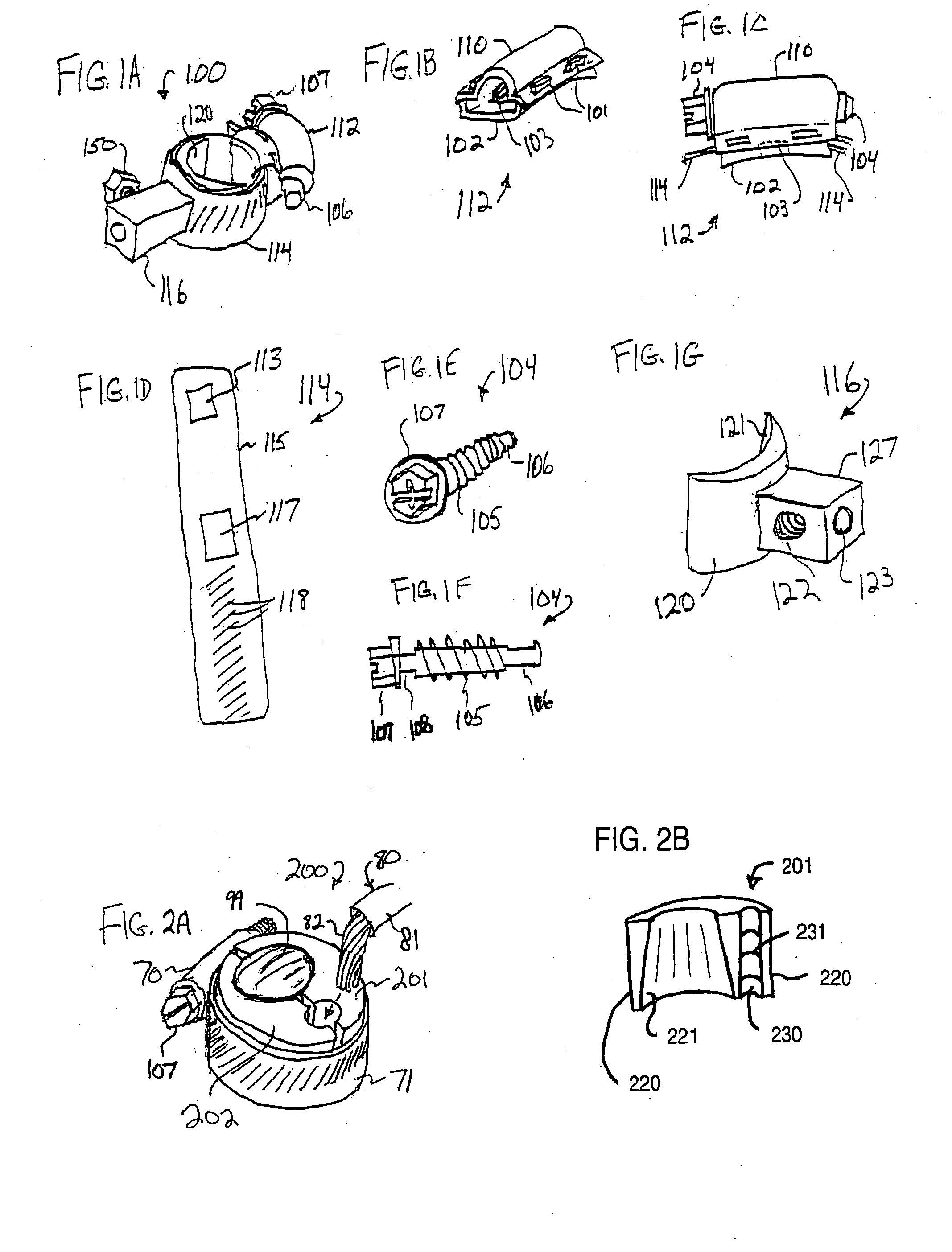

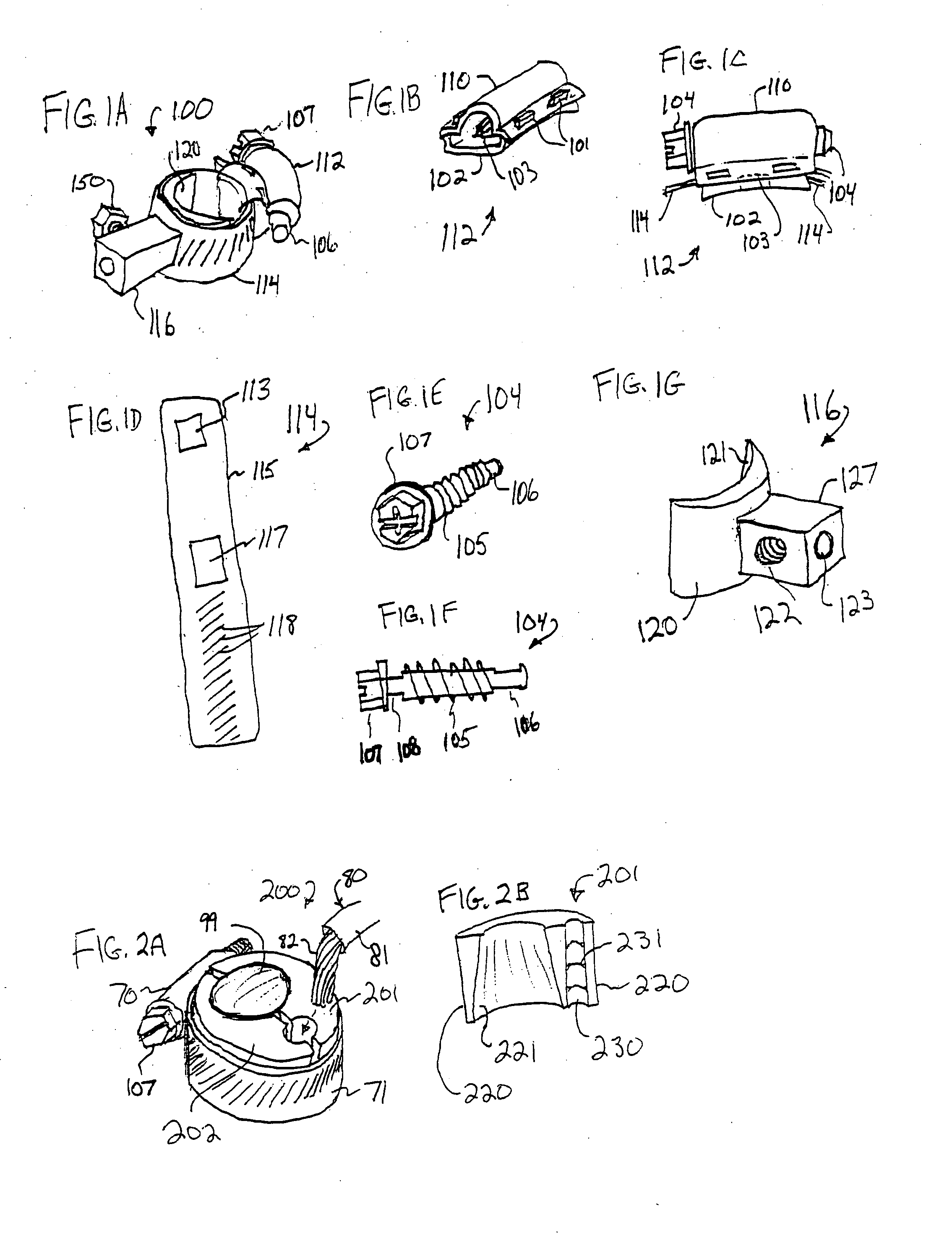

Bi-directional fixating transvertebral body screws, zero-profile horizontal intervertebral miniplates, total intervertebral body fusion devices, and posterior motion-calibrating interarticulating joint stapling device for spinal fusion

InactiveUS20070049943A1Increase pressureIncrease probabilityInternal osteosythesisJoint implantsSpinal columnLocking mechanism

An apparatus and method for joining members together using a self-drilling screw apparatus or stapling apparatus are disclosed. The screw apparatus includes a worm drive screw, a spur gear and superior and inferior screws which turn simultaneously in a bi-directional manner. A rotating mechanism drives the first and second screw members in opposite directions and causes the screw members to embed themselves in the members to be joined. The screw apparatus can be used to join members such as bones, portions of the spinal column, vertebral bodies, wood, building materials, metals, masonry, or plastics. A device employing two screws (two-in-one) can be combined with a capping horizontal mini-plate. A device employing three screws can be combined in enclosures (three-in-one). The stapling apparatus includes grip handles, transmission linkages, a drive rod a fulcrum and a cylinder. The staple has superior and inferior segments with serrated interfaces, a teethed unidirectional locking mechanism and four facet piercing elements. The staples can be also be used to join members such as bones, portions of the spinal column, or vertebral bodies.

Owner:MOSKOWITZ FAMILY LLC

Bi-directional fixating transvertebral body screws, zero-profile horizontal intervertebral miniplates, total intervertebral body fusion devices, and posterior motion-calibrating interarticulating joint stapling device for spinal fusion

InactiveUS7846188B2Increase pressureFacilitate a strong solid fusionInternal osteosythesisJoint implantsSpinal columnLocking mechanism

Owner:MOSKOWITZ FAMILY LLC

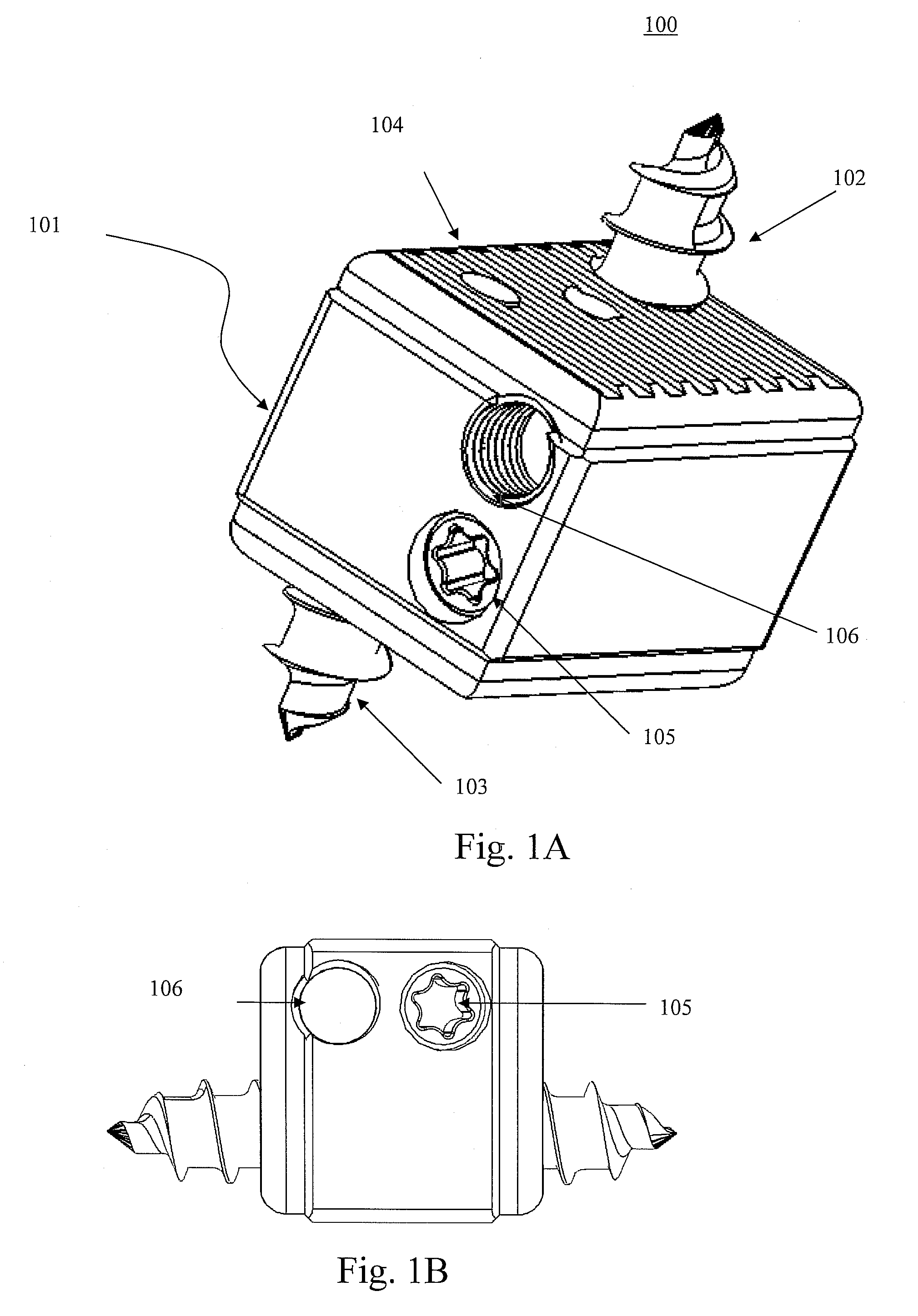

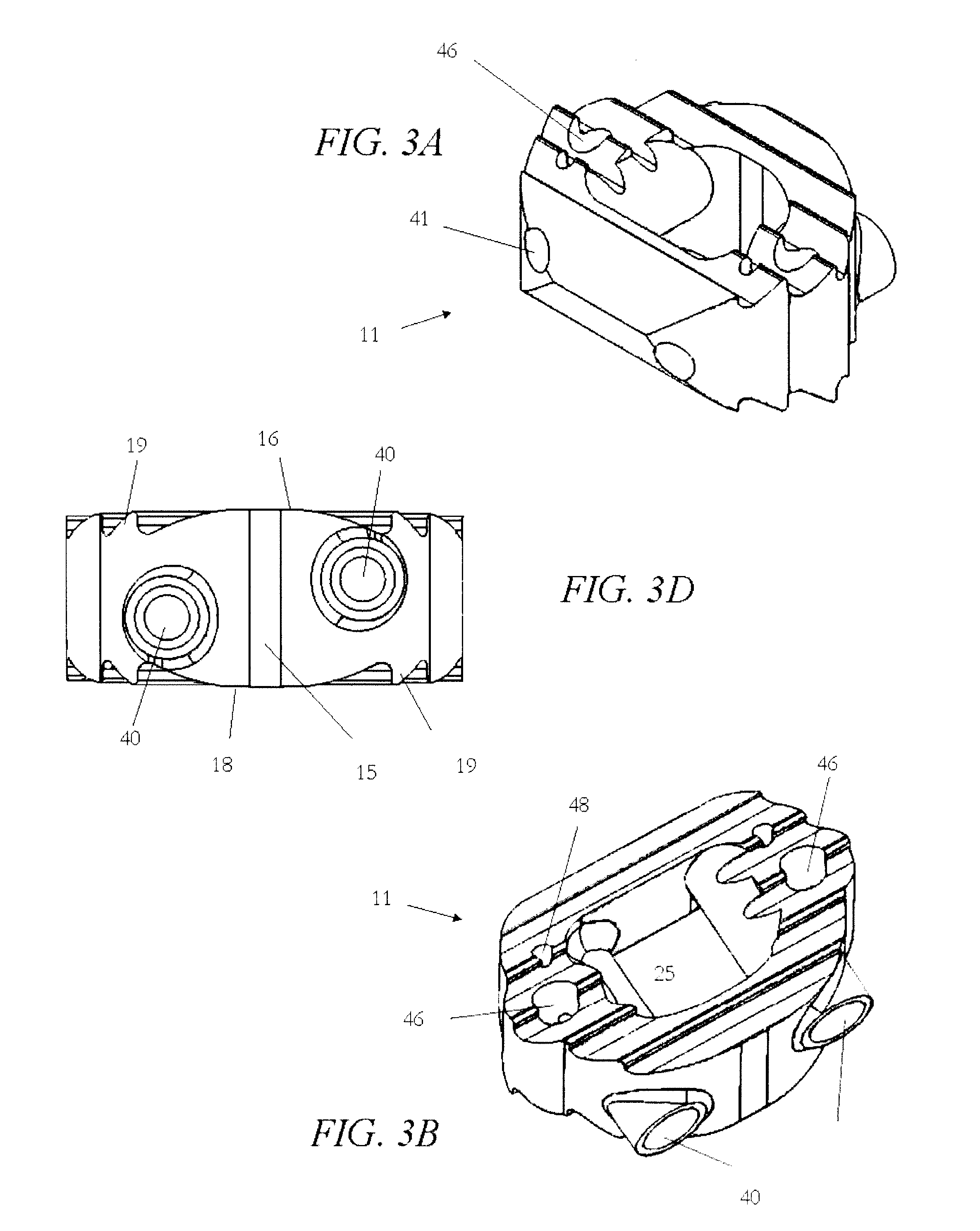

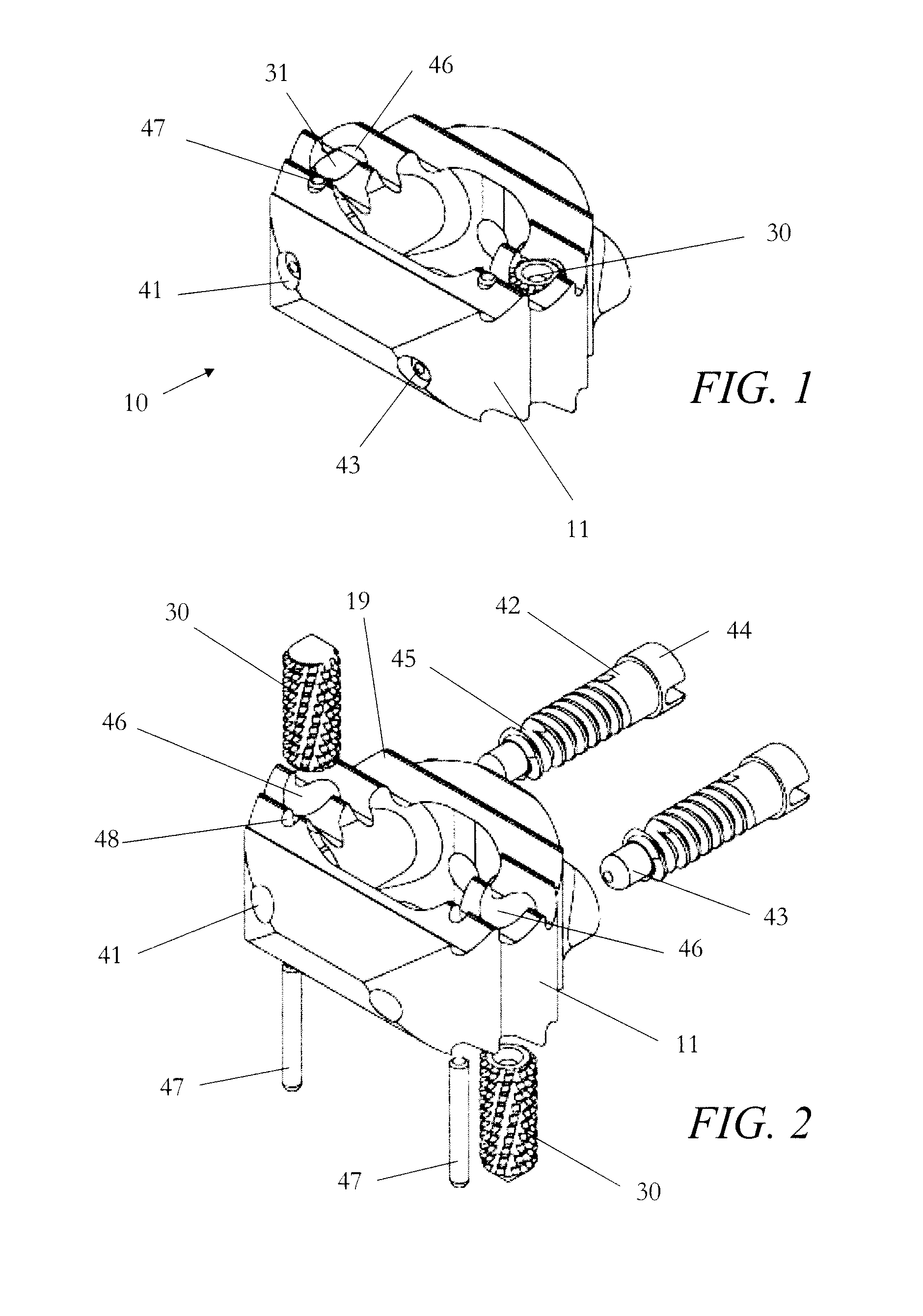

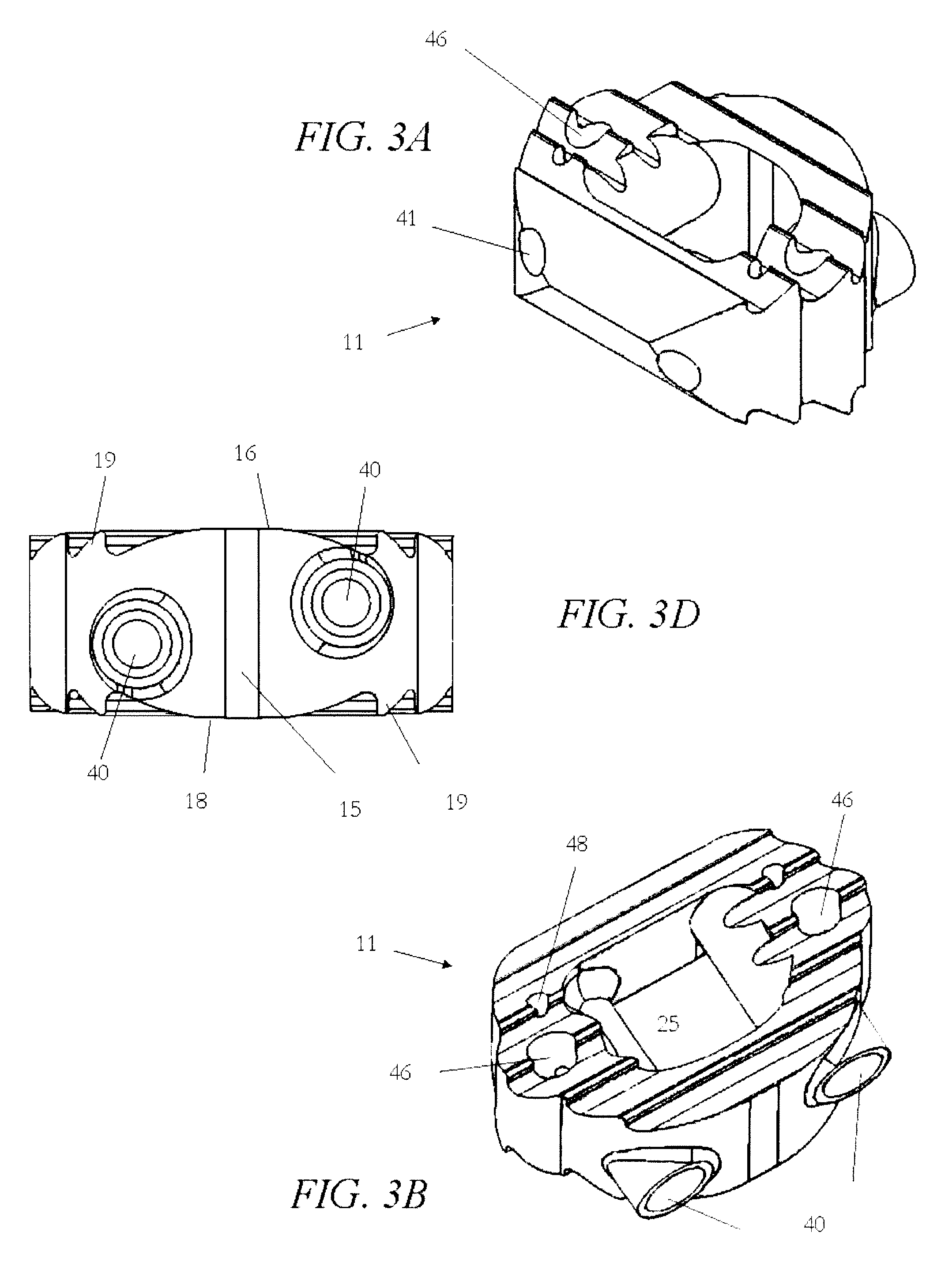

Open body box form interbody fusion cage

An interbody fusion cage having a generally symmetric, annular cage body surrounding a central void extending from a lower surface to an upper surface in which to retain graft material in contact with adjacent vertebra. A lateral channel extending into each half from the cage perimeter contains a worm drive screw. One or more longitudinal channels extending from the upper surface to the lower surface intersect each lateral channel and house a pin which is provided with a series of helically cut worm gear teeth on its external surface for engaging the worm drive screw. The pins are simultaneously externally threaded and engaged to the cooperatively threaded internal surface of the longitudinal channel such that rotation of the drive screw by the surgeon after implantation causes the pins to rotate with the longitudinal channel and advance into the adjacent bone.

Owner:KAMRAN AFLATOON +1

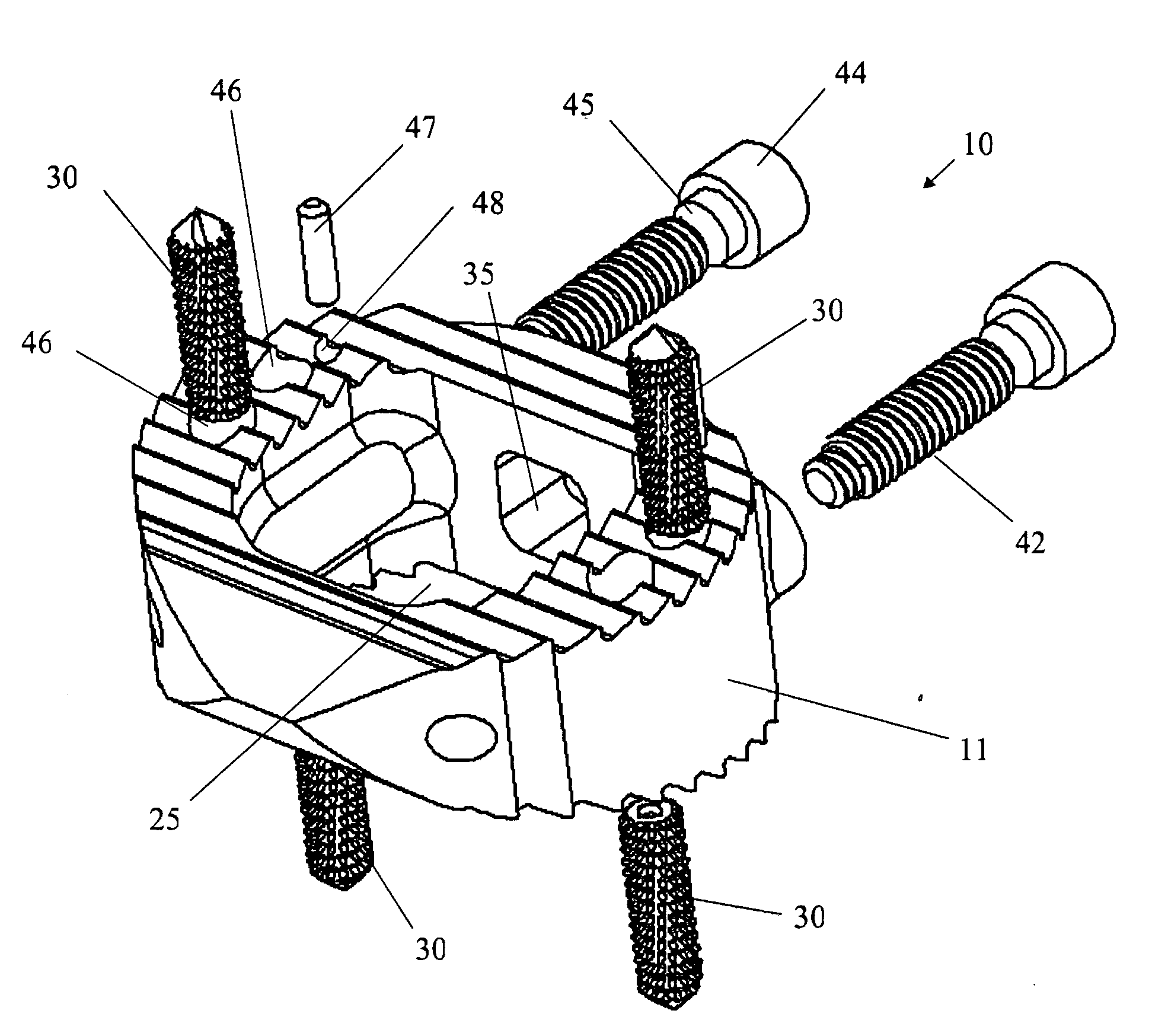

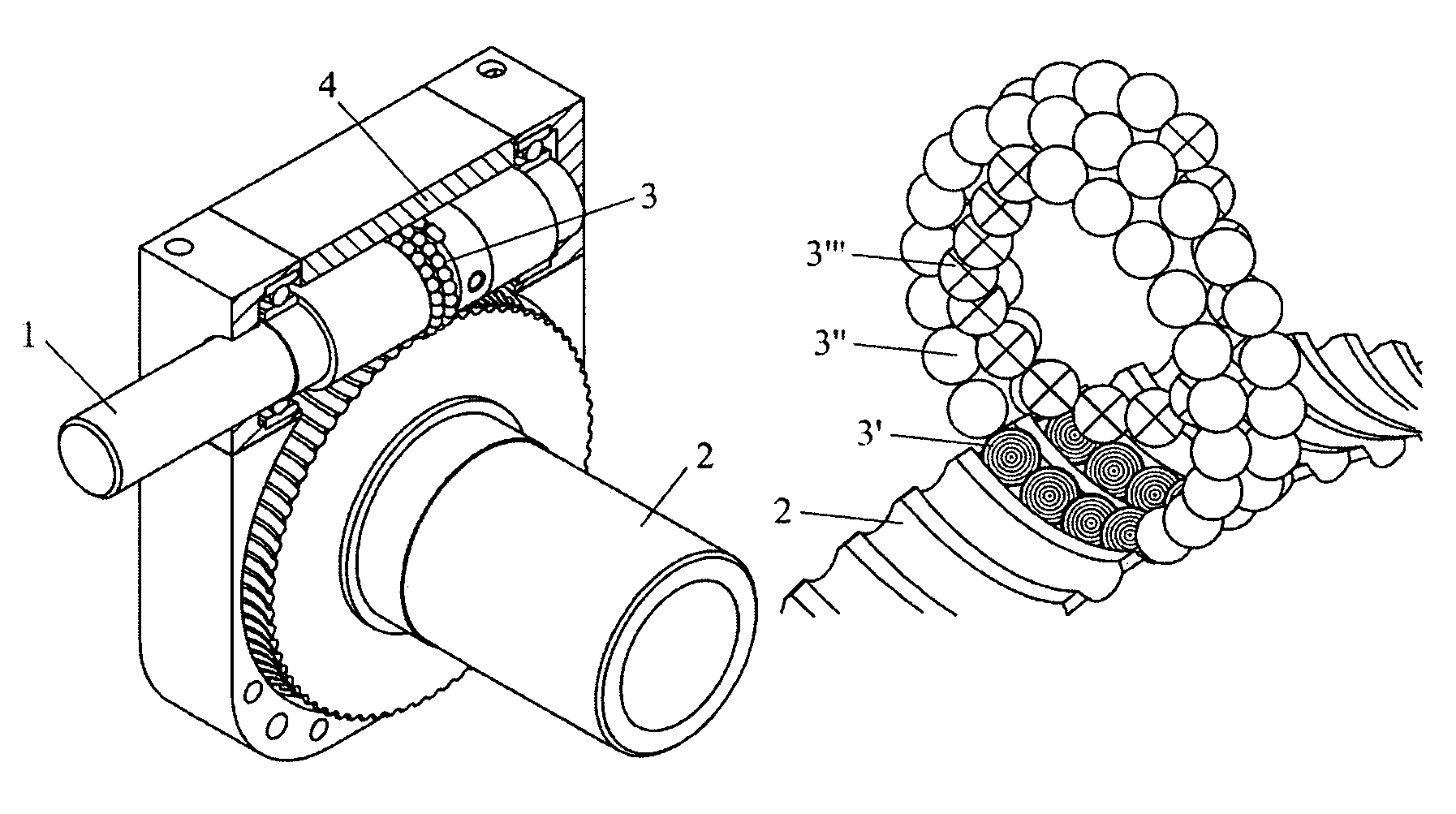

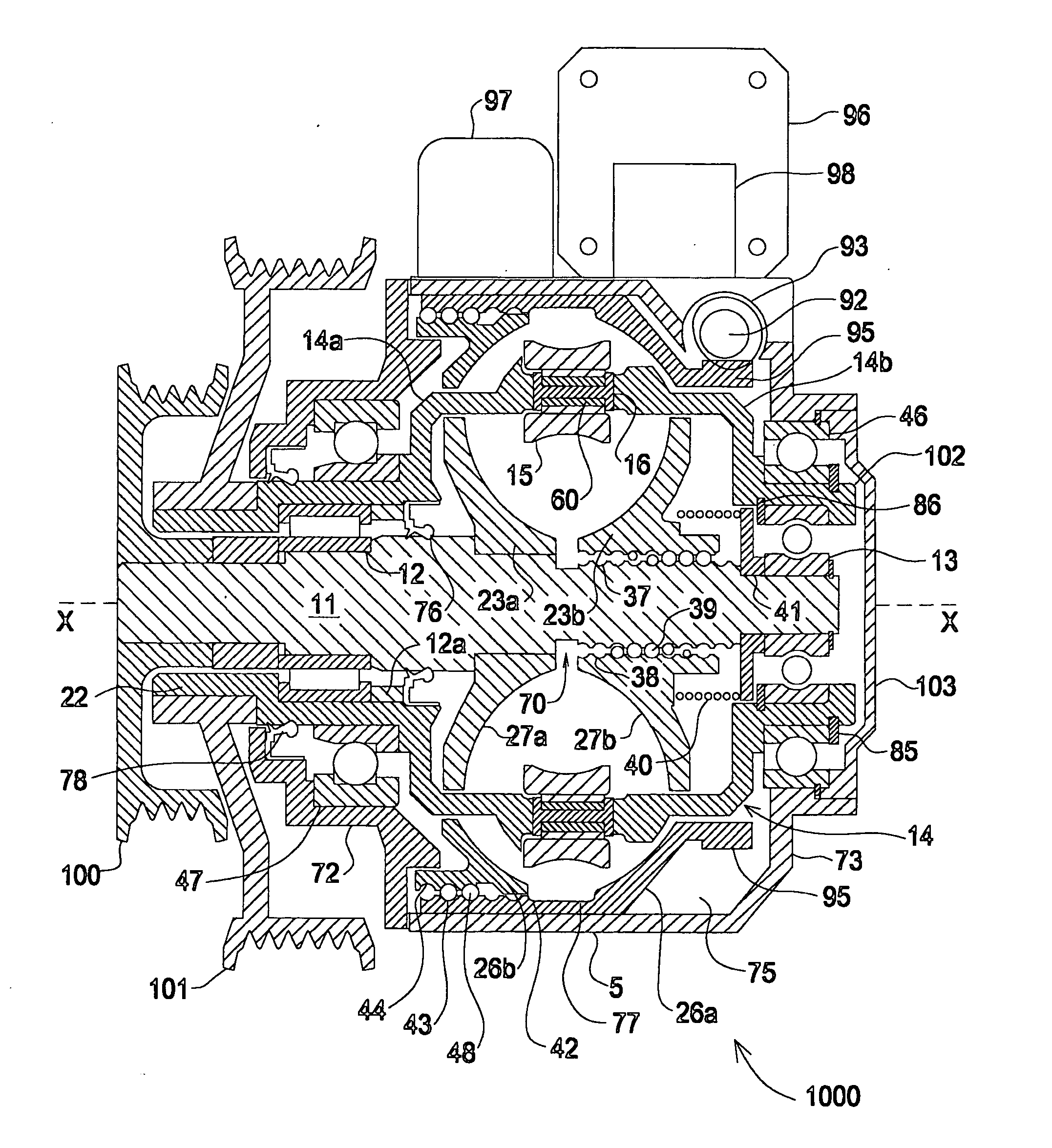

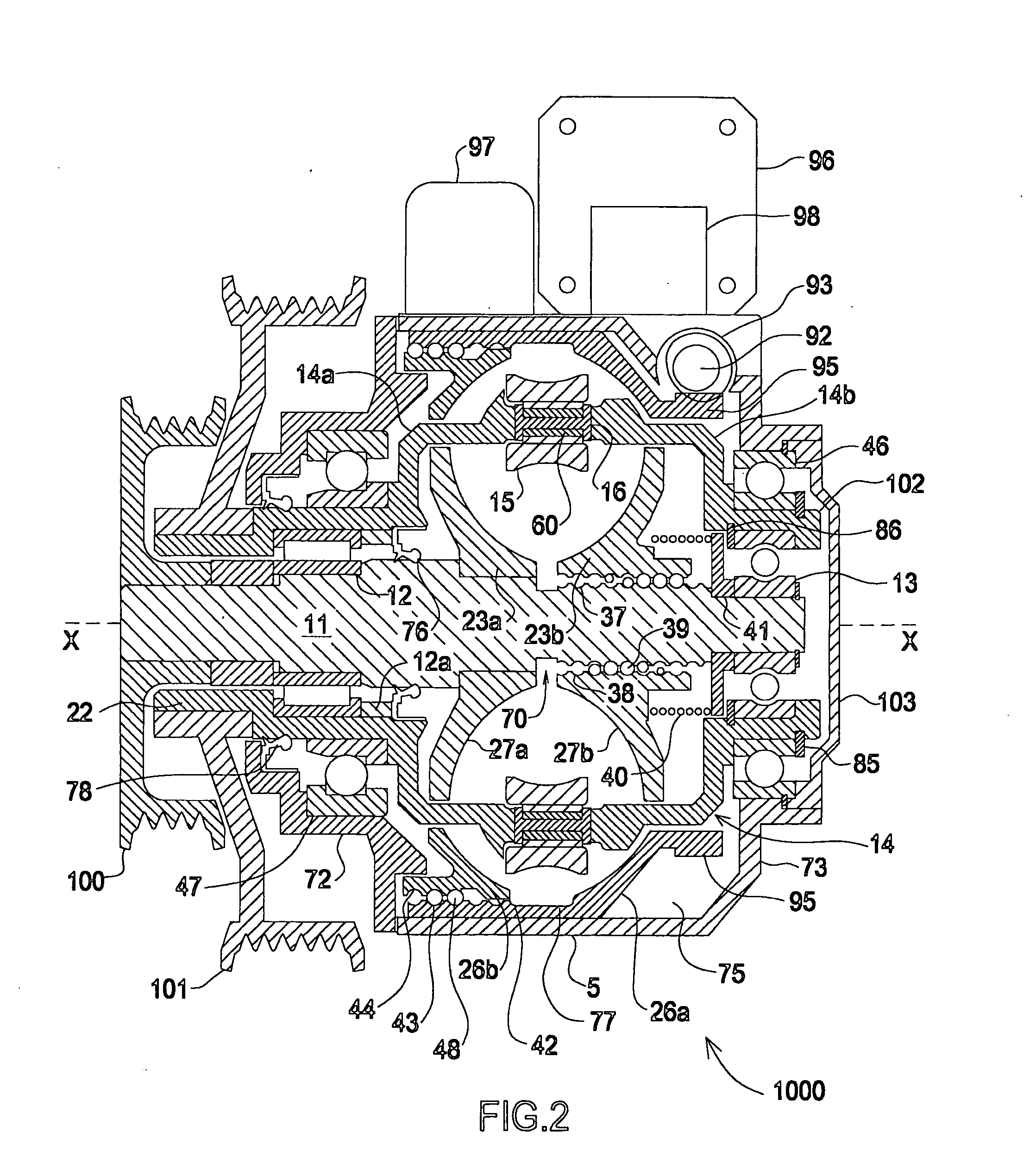

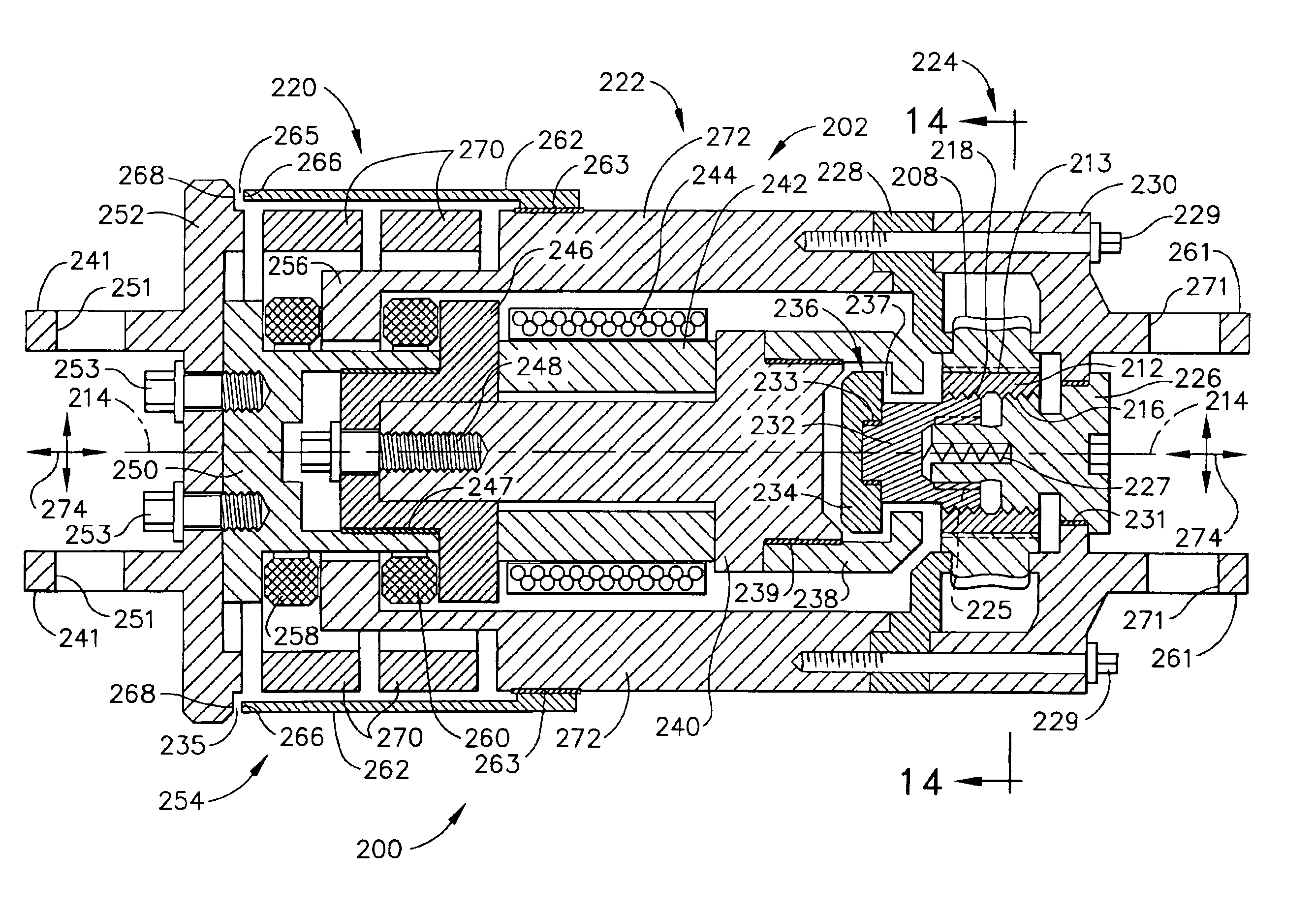

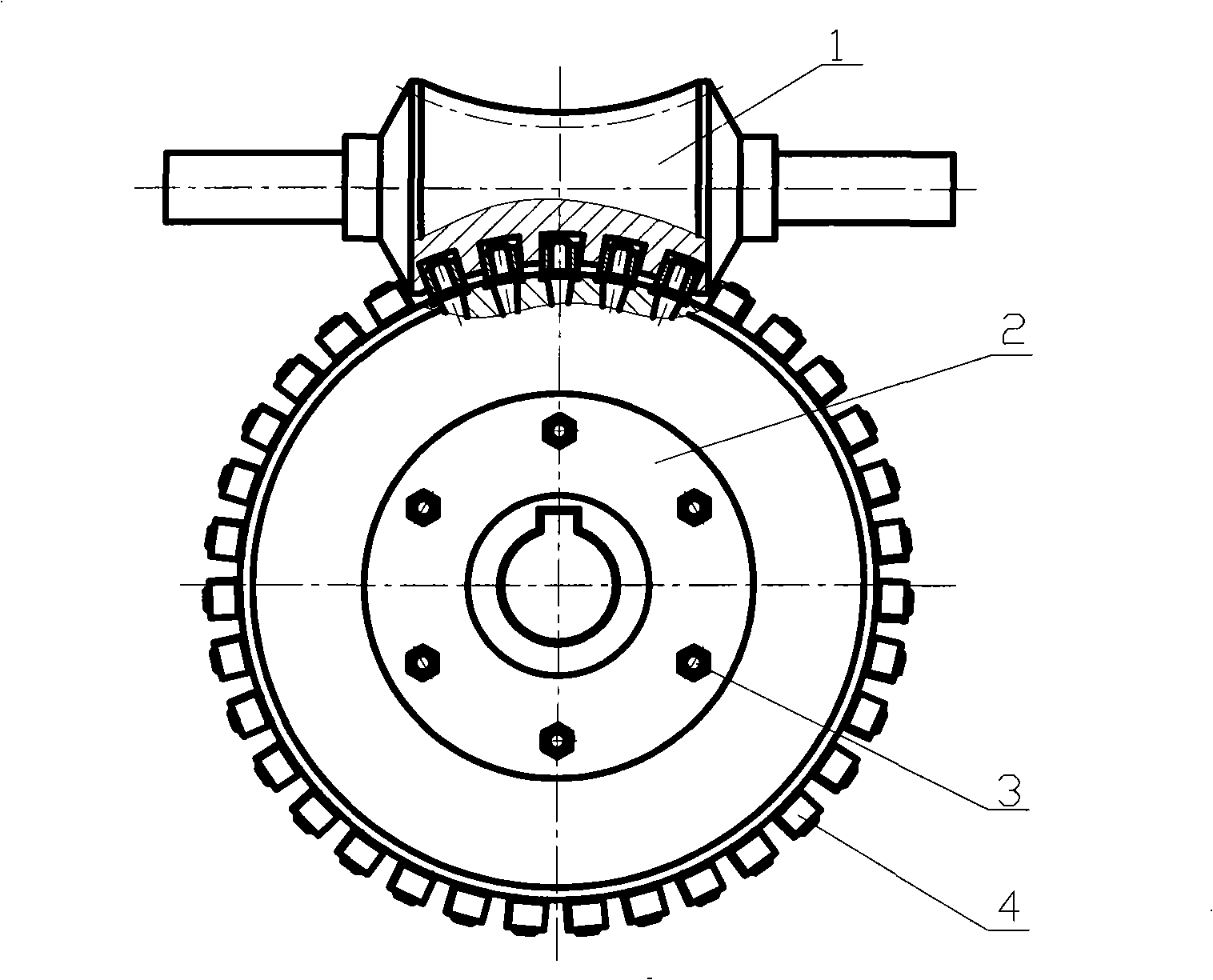

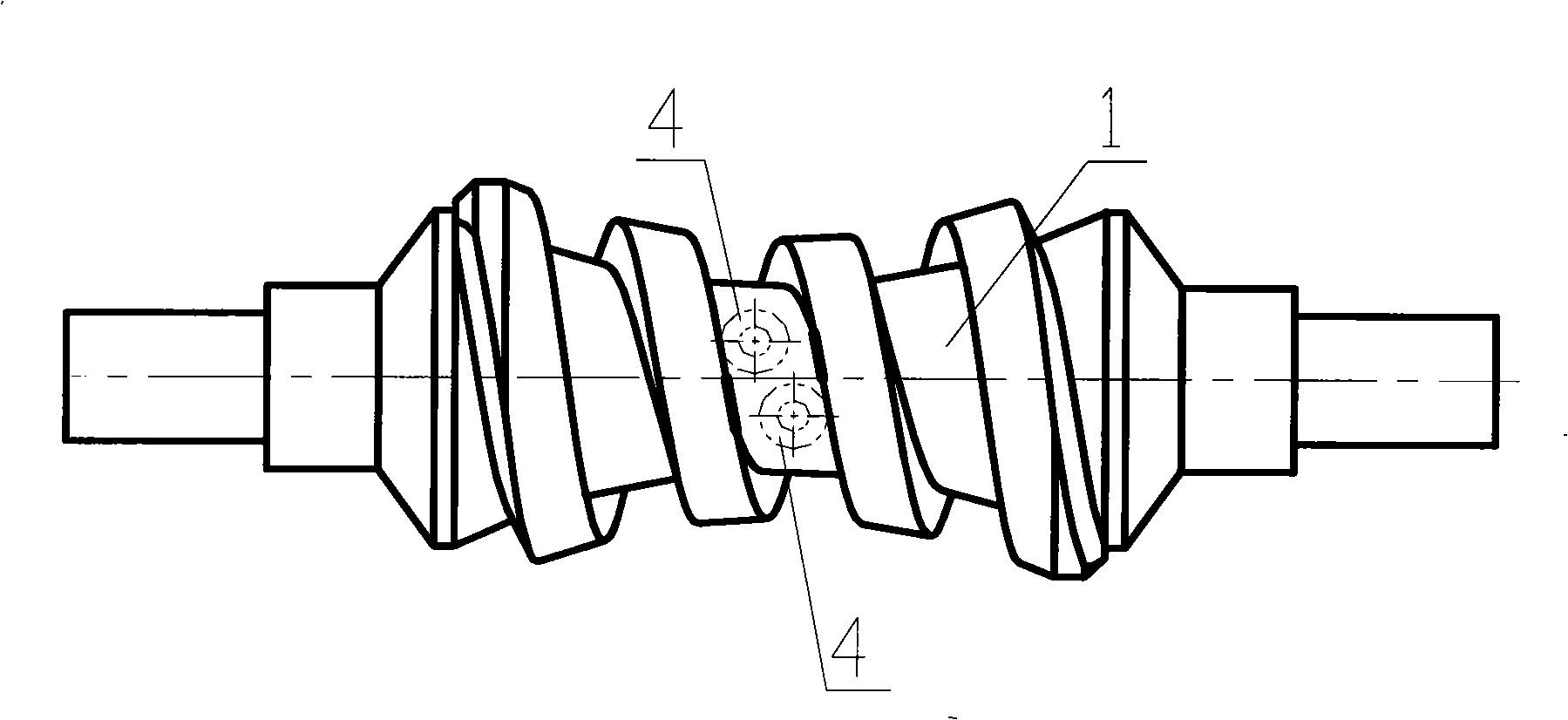

Ball-worm transmission

InactiveUS7051610B2Improve performanceAugments a number of ballsLinear bearingsToothed gearingsGear wheelEngineering

A ball-worm transmission is provided which replaces the sliding friction of the classic worm mechanism with the rolling friction of spherical balls. The ball-worm transmission assembly includes a worm which defines a recirculation path, and a gear coupled to the worm via a plurality of spherical balls. The gear includes a plurality of teeth each having a thickness in a central plane of the gear and a lesser thickness towards both sides of the gear, so that a gap is defined between the teeth is larger towards both sides of the gear than in the central plane of the gear.

Owner:HOLTZ DOUGLAS

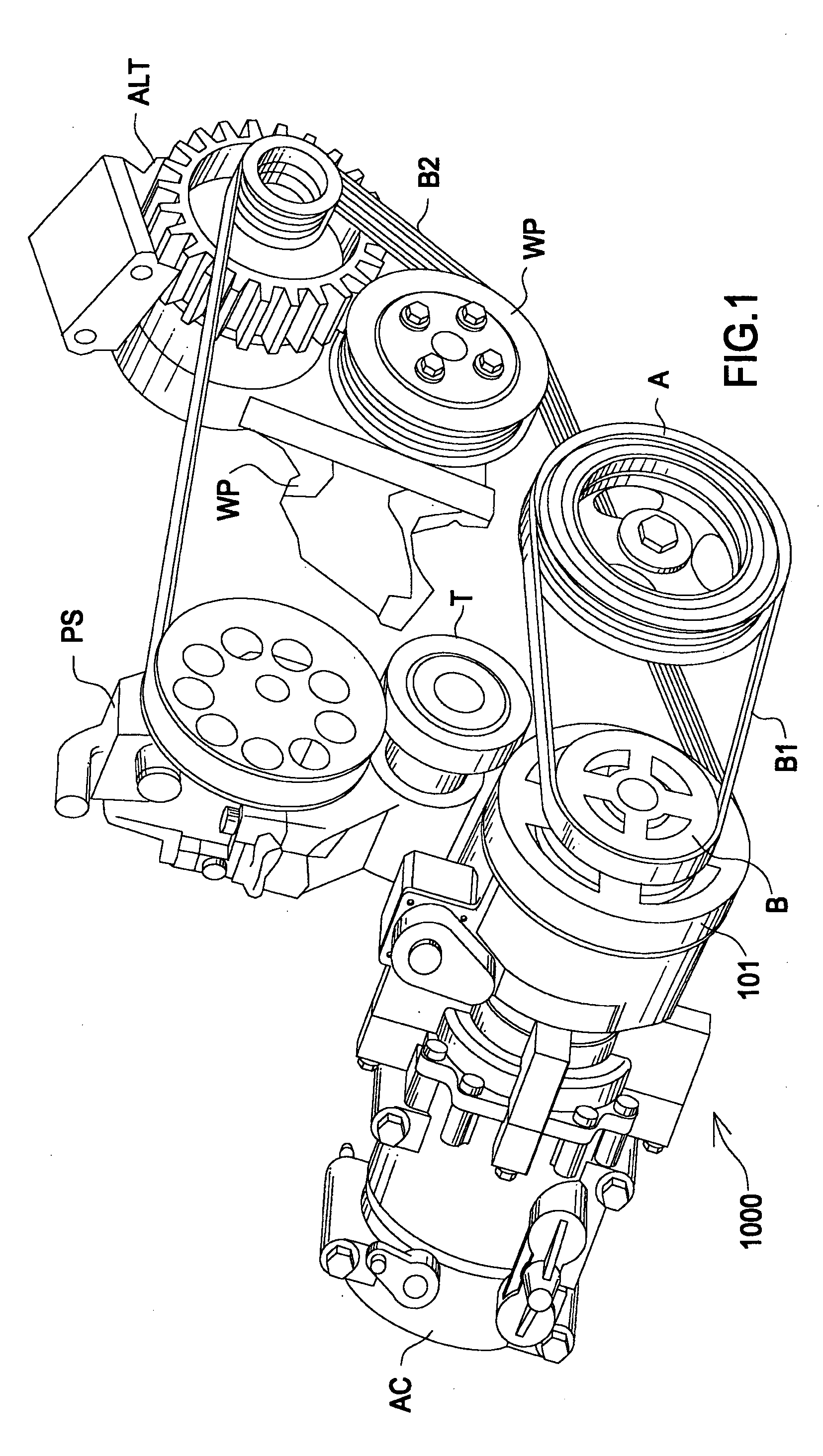

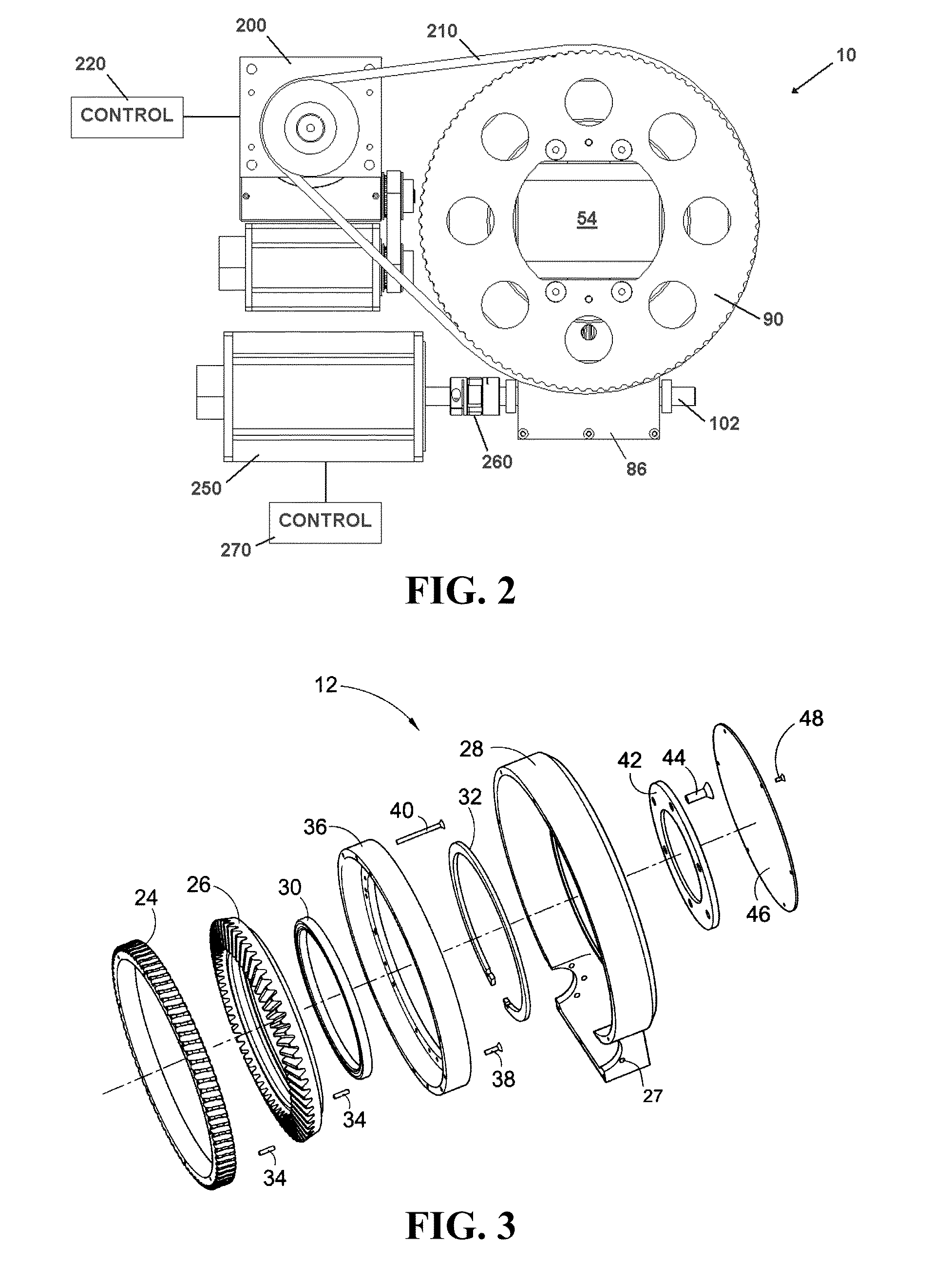

Transmission and constant speed accessory drive

InactiveUS20050181905A1Constant output speedGearing controlFriction clutchesControl systemDirect coupling

An infinitely variable speed ratio planetary ball transmission comprising planetary members in rolling contact with moveable inner and outer races and a constant speed accessory drive system utilizing the transmission. The transmission is infinitely variable between ratios of approximately 0.3 and 1.0. A transmission input shaft is connected to a prime mover such as a vehicle engine crankshaft by a drive belt. The transmission comprises at least one output shaft that is coaxial with the input shaft. An output pulley is attached to the output shaft. A belt is engaged between the output pulley and various engine accessories. A second end of the transmission output shaft may be directly coupled to an engine accessory mounted on the transmission. An included control system senses a crankshaft speed. A processor analyses the crankshaft speed and accordingly adjusts the transmission ratio using a stepper motor connected to a worm drive to maintain a constant output speed regardless of crankshaft speed.

Owner:THE GATES CORP

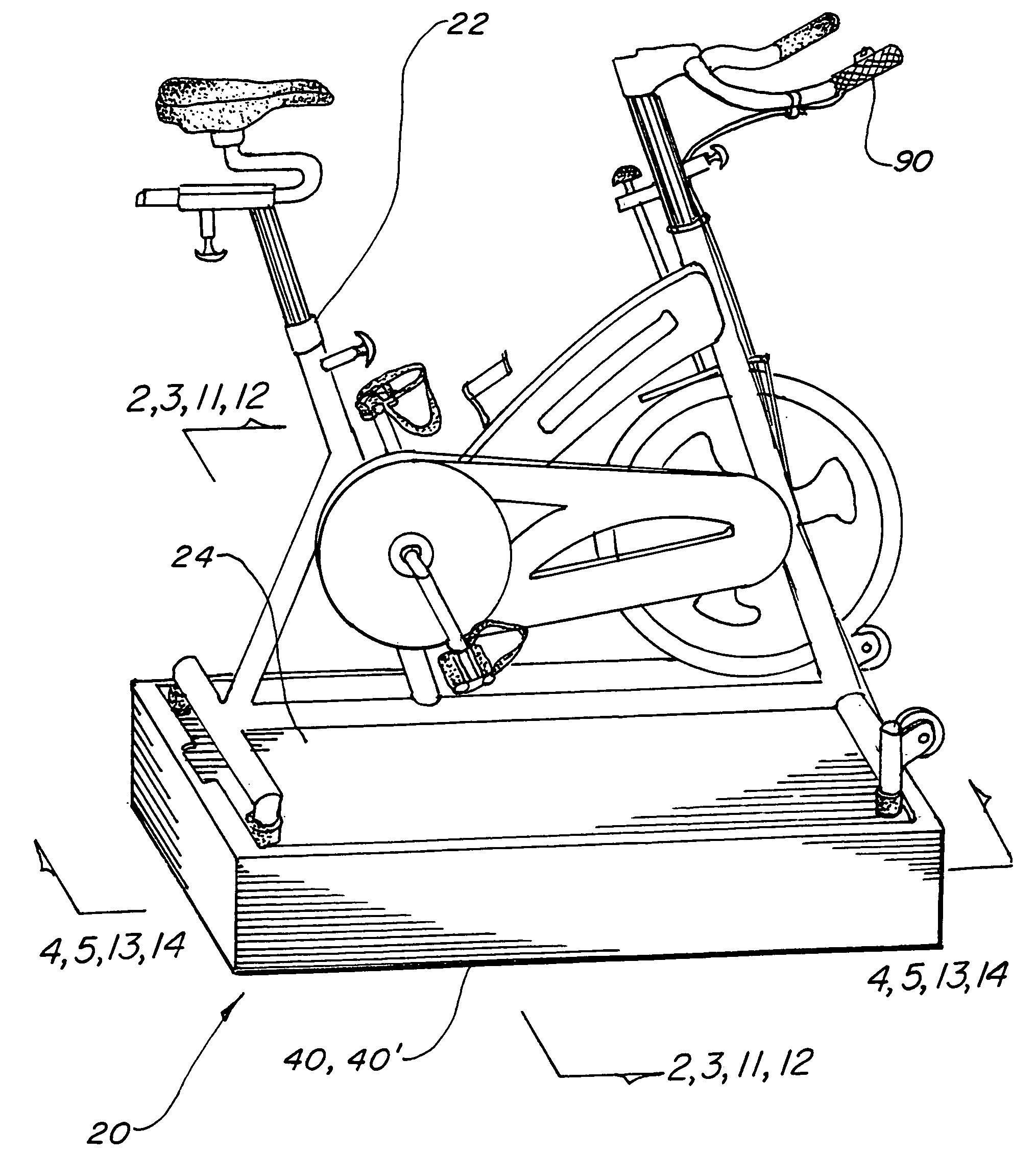

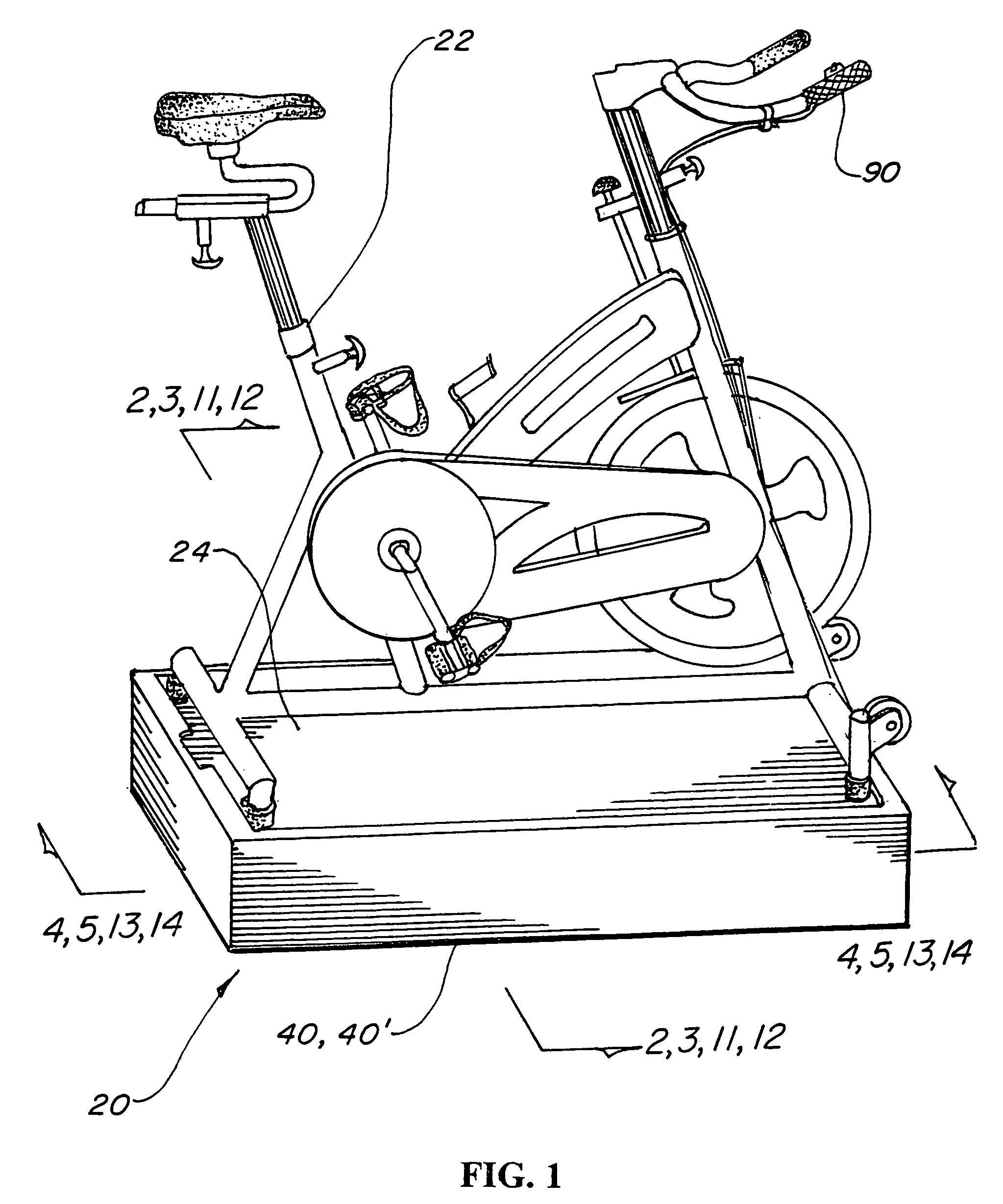

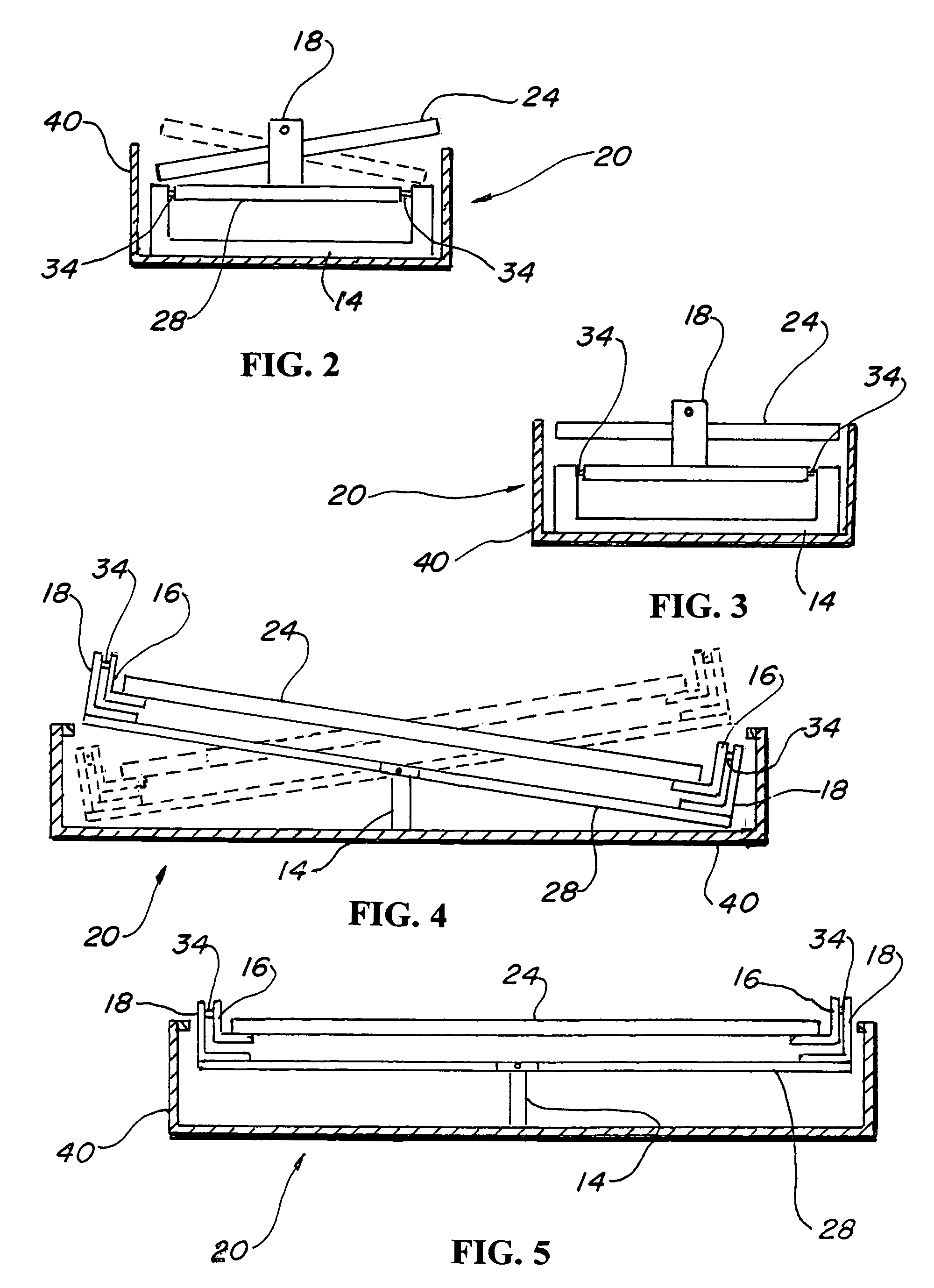

Articulating exercise bicycle platform

InactiveUS7081070B1Add dimensionSimple designCosmonautic condition simulationsSimulatorsMotor driveGear wheel

An articulating platform (20) that is used to vary the longitudinal and lateral angular displacement of an exercise bicycle (22) mounted thereon. The platform includes a bicycle mounting base (24) configured to accept the footprint of a conventionally dimensioned exercise bicycle. The base (24) pivots in both a longitudinal axis and a lateral axis, thereby simulating uphill and downhill bicycle riding and turning when leaning sideways in a turning direction. The base (24) is preferably articulated by a D.C. motor drive system or optionally by a gear motor, pneumatic, hydraulic and worm drive systems each having controls for initiating directional articulation. A platform enclosure (40) supports the base and the drive system to provide a safety barrier for protecting moving components of the platform.

Owner:WASHINGTON KENNETH R

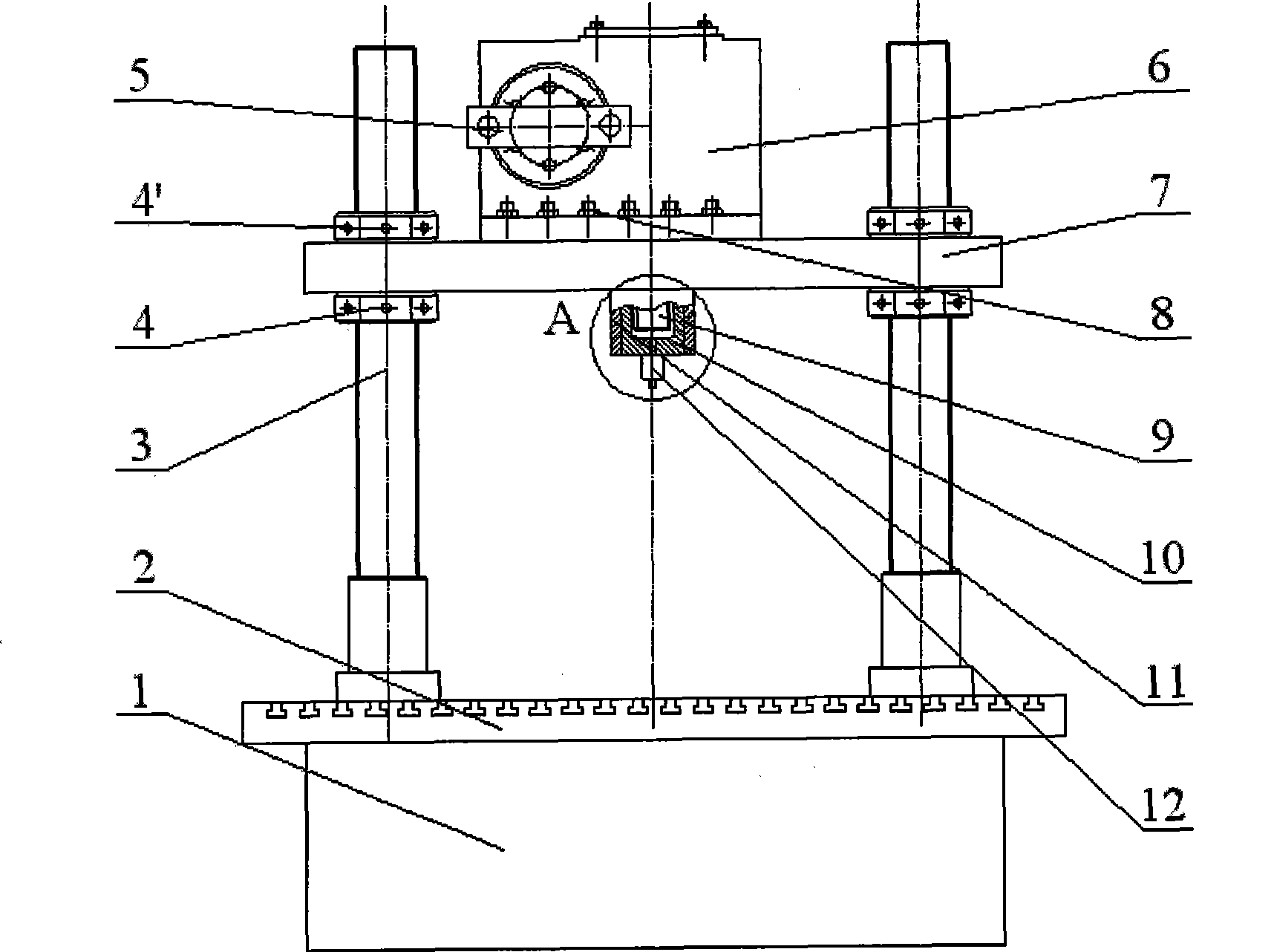

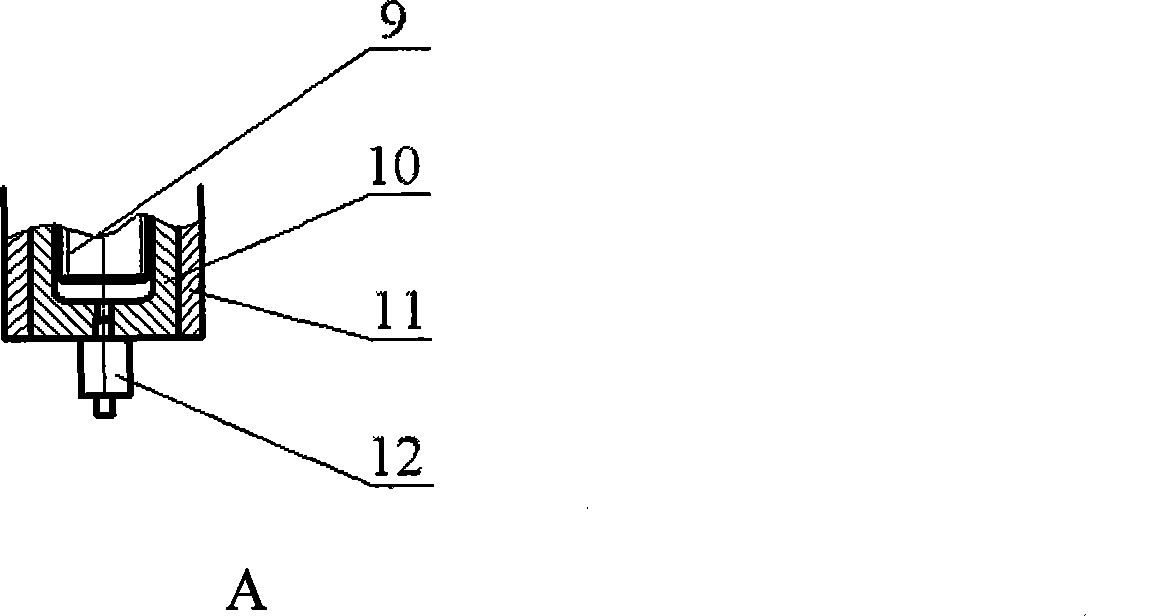

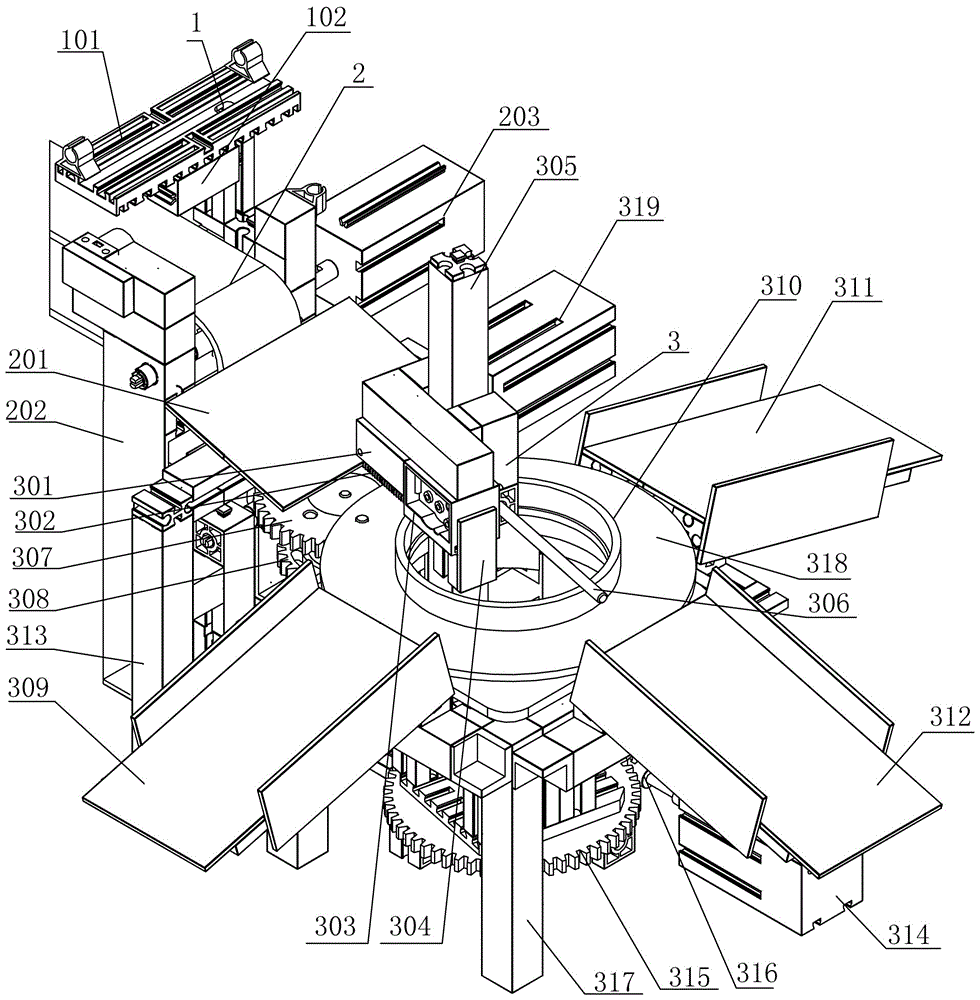

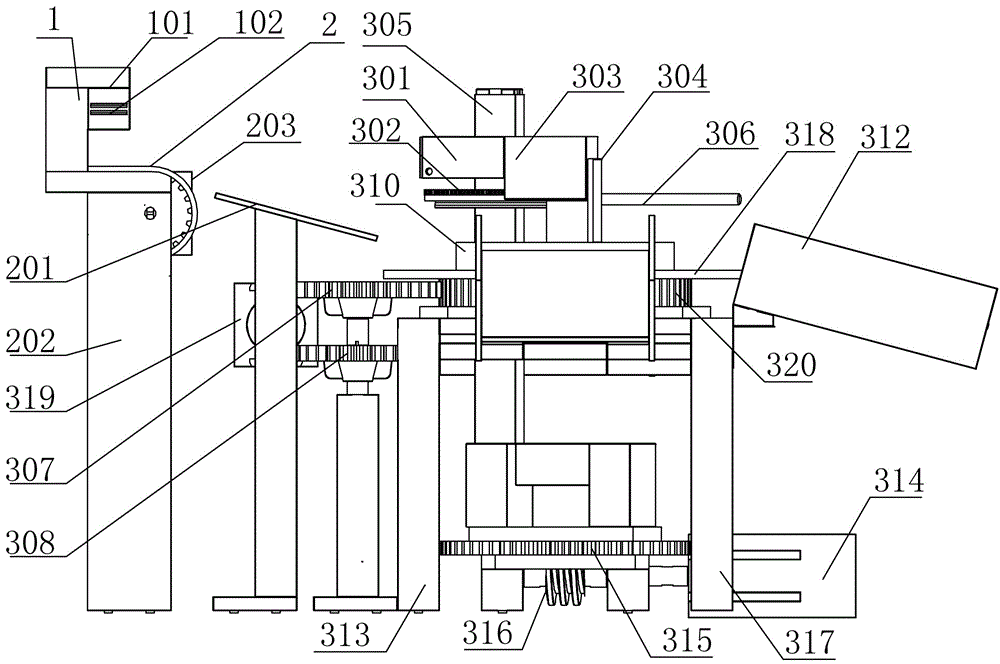

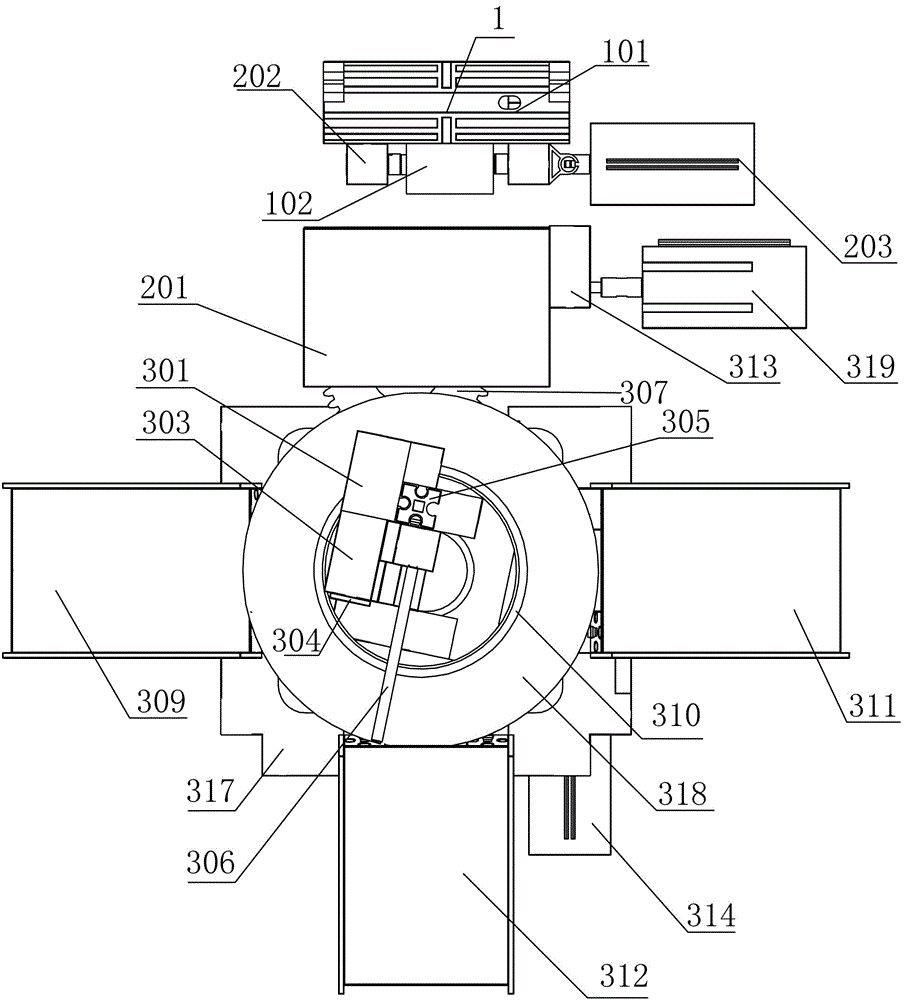

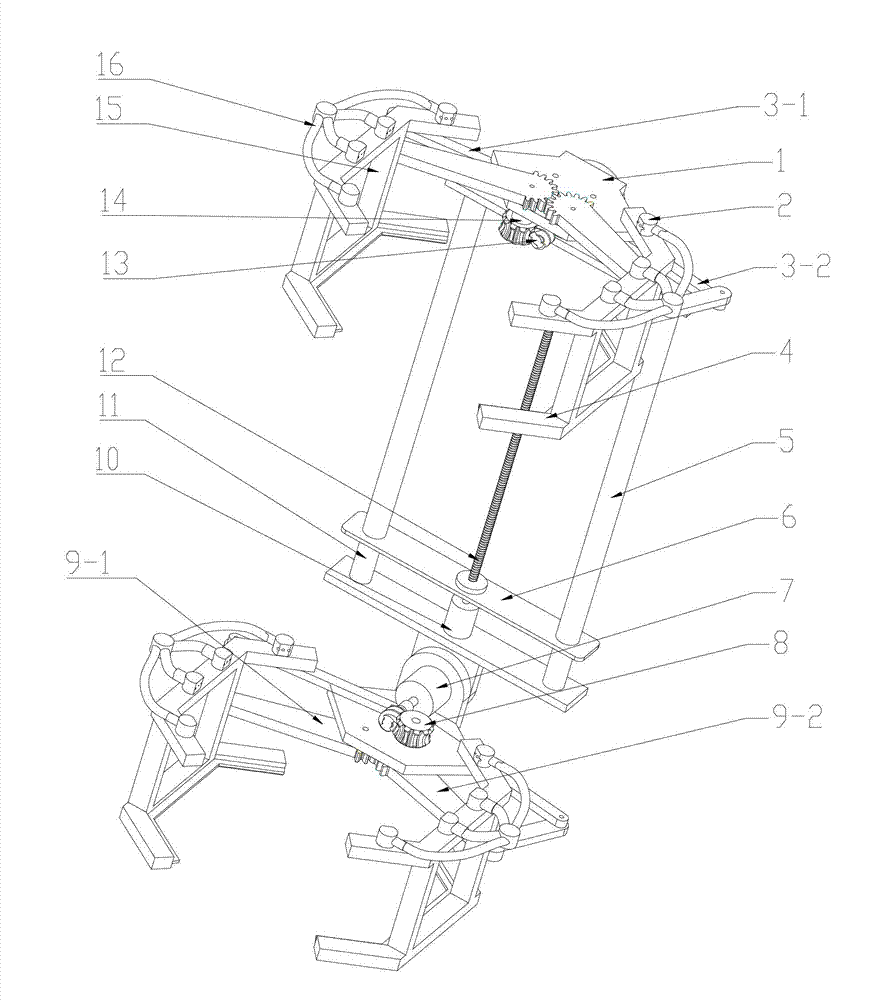

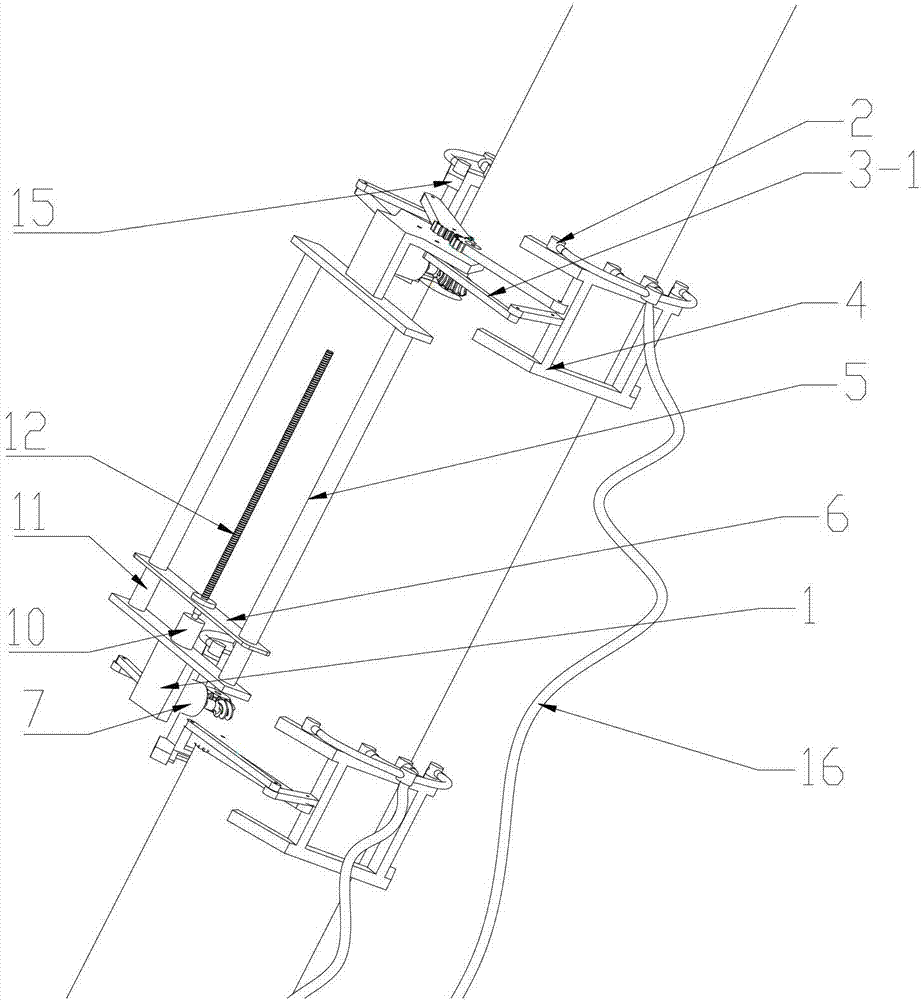

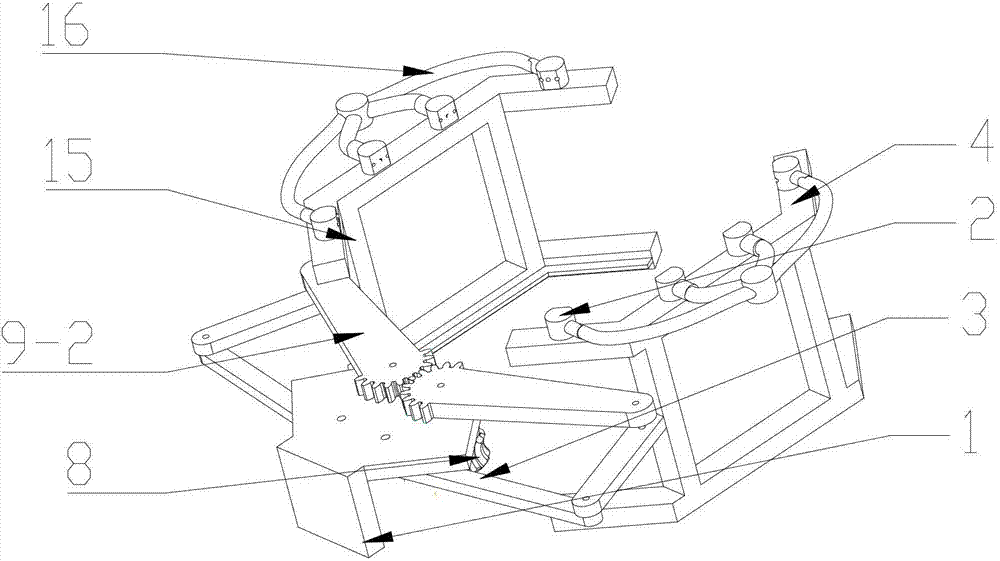

Calibration apparatus for six-dimension heavy force sensor

ActiveCN101464201ARealize Load CalibrationAchieve precise outputForce/torque/work measurement apparatus calibration/testingEngineeringForce sensor

The invention provides a calibration device of a six-dimensional heavy force sensor, and belongs to the field of sensors as well as the measurement and the control thereof. By adopting a single force source, the calibration device is capable of calibrating the six-dimensional force of a force sensor. The calibration device comprises a base, a calibration workbench, an upright post, a lifting nut, a handle, a large force value loading mechanism adopting a worm wheel and a worm for transmission, an upper support tablet, a lead screw, a nut, a sleeve, a standard uni-directional force sensor, a ranging rod, a bolt, a connection block, an L-shaped plate, a sensor to be calibrated, a working shaft, a positioning pin, a base plate, a T-shaped bolt and a signal wire; and a mechanism to be calibrated consists of the ranging rod, the bolt, the connection block, the L-shaped plate, the sensor to be calibrated, the working shaft, the positioning pin and the base plate. The device is capable of loading the six-dimensional heavy force sensor and carrying out systematic calibration. The device has the characteristics of compact structure, simplicity, high rigidity and high precision, and can achieve precise calibration of the six-dimensional heavy force sensor.

Owner:DALIAN UNIV OF TECH

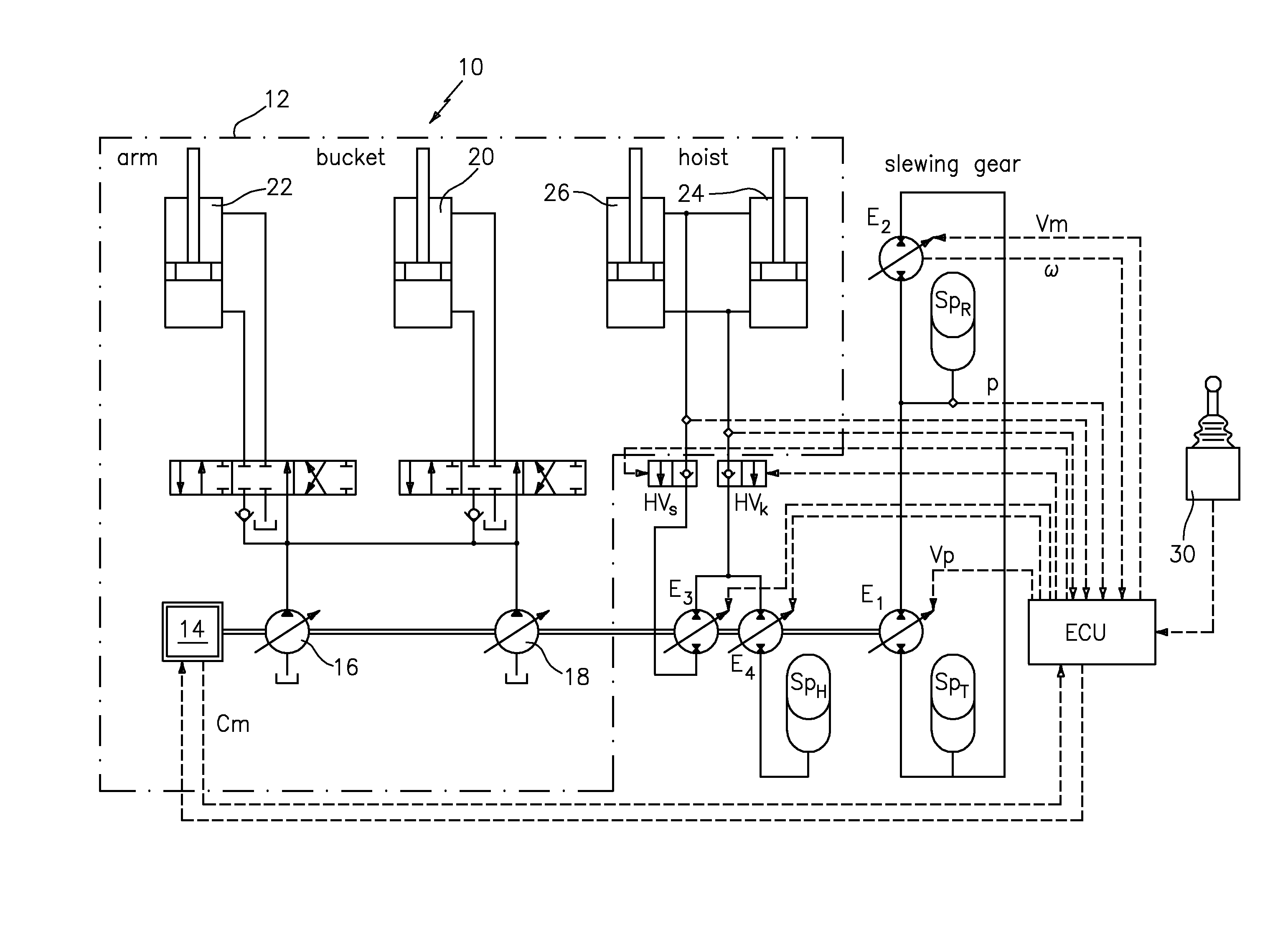

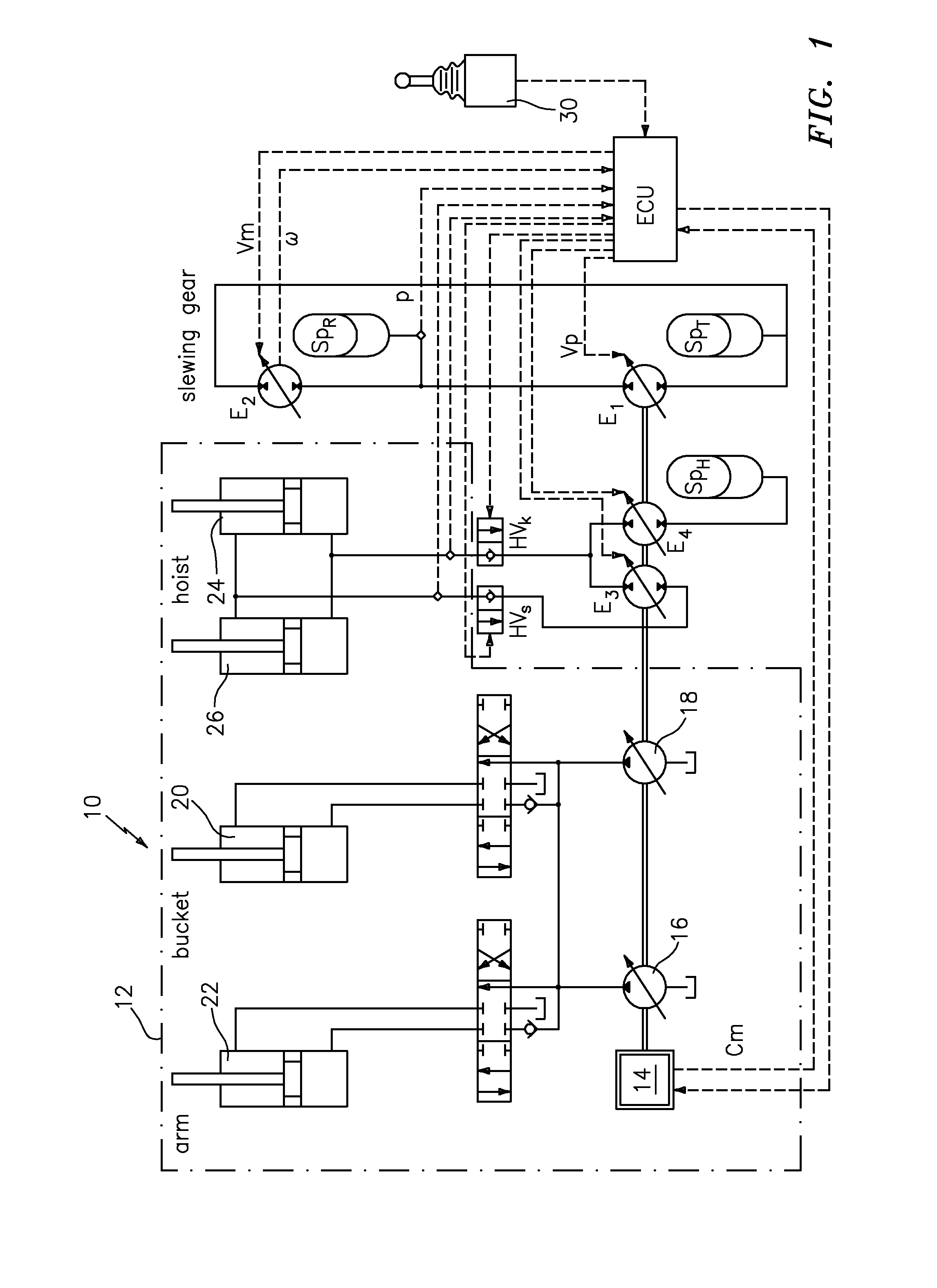

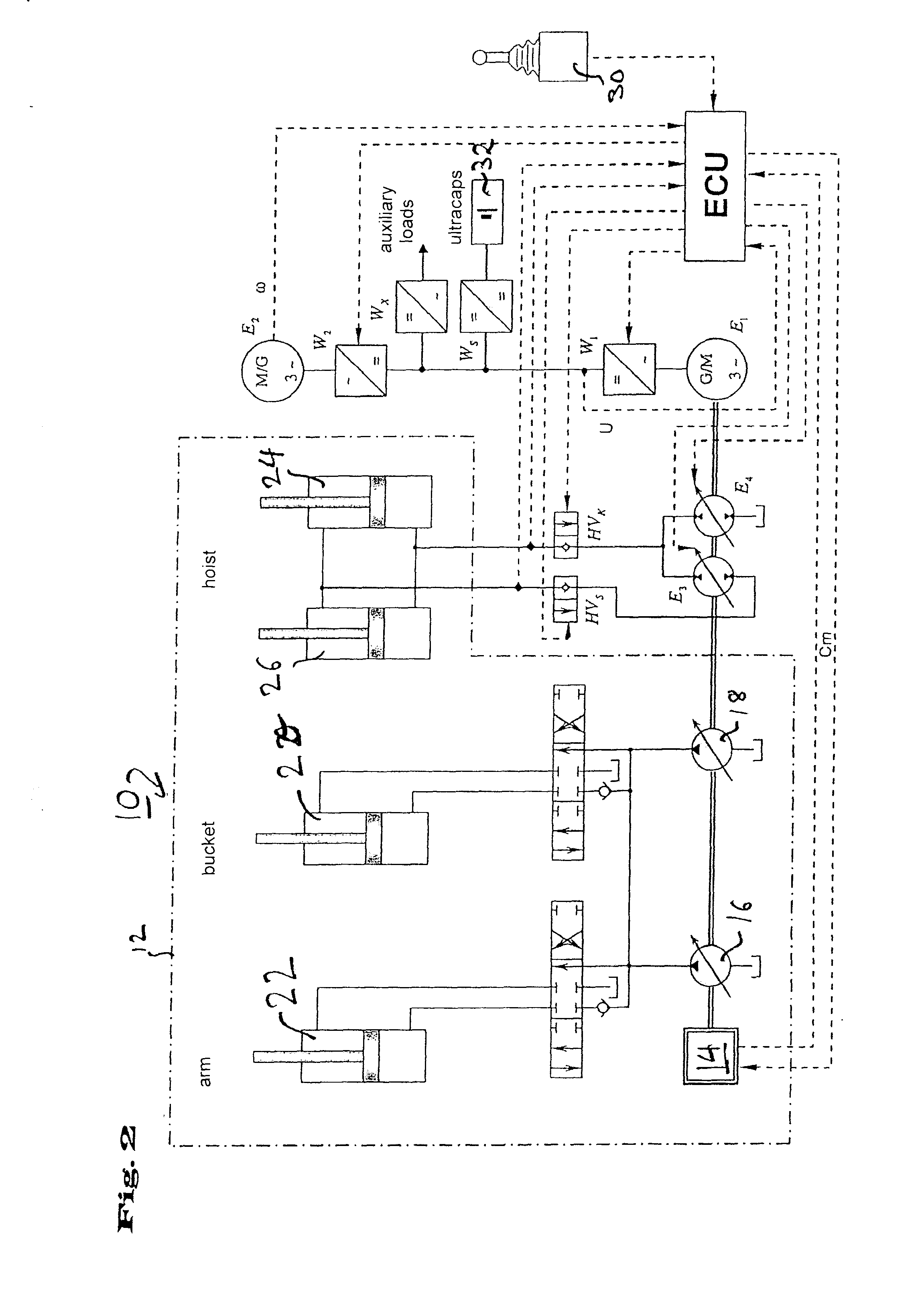

Drive for a Hydraulic Excavator

The present invention relates to a drive for an excavator with a number of individual drives, such as a slewing gear drive, a hoist drive, a bucket drive and an arm drive, wherein for the slewing gear drive two reversible adjusting units are provided, which are at least coupled with an energy accumulator.

Owner:LIEBHERR FRANCE

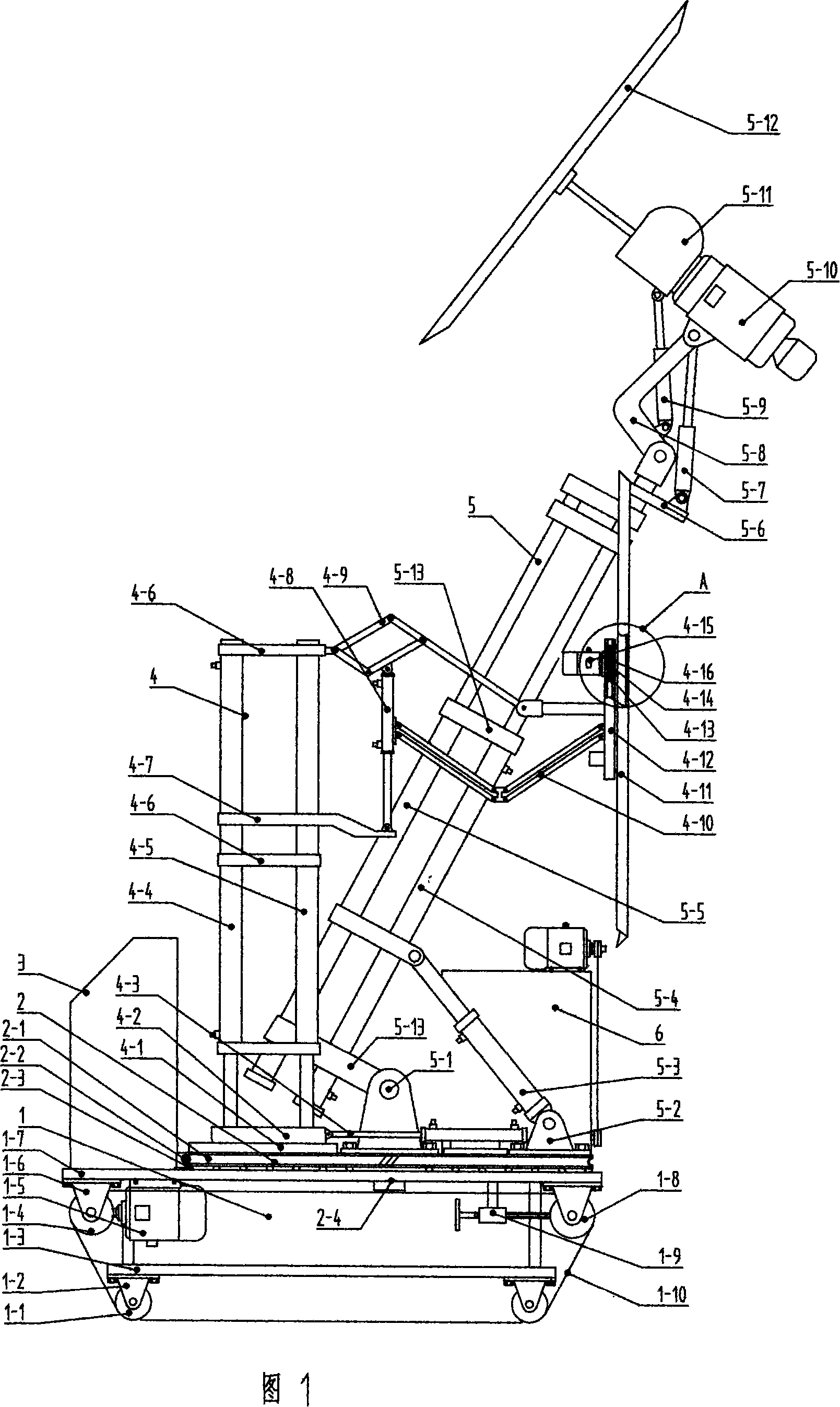

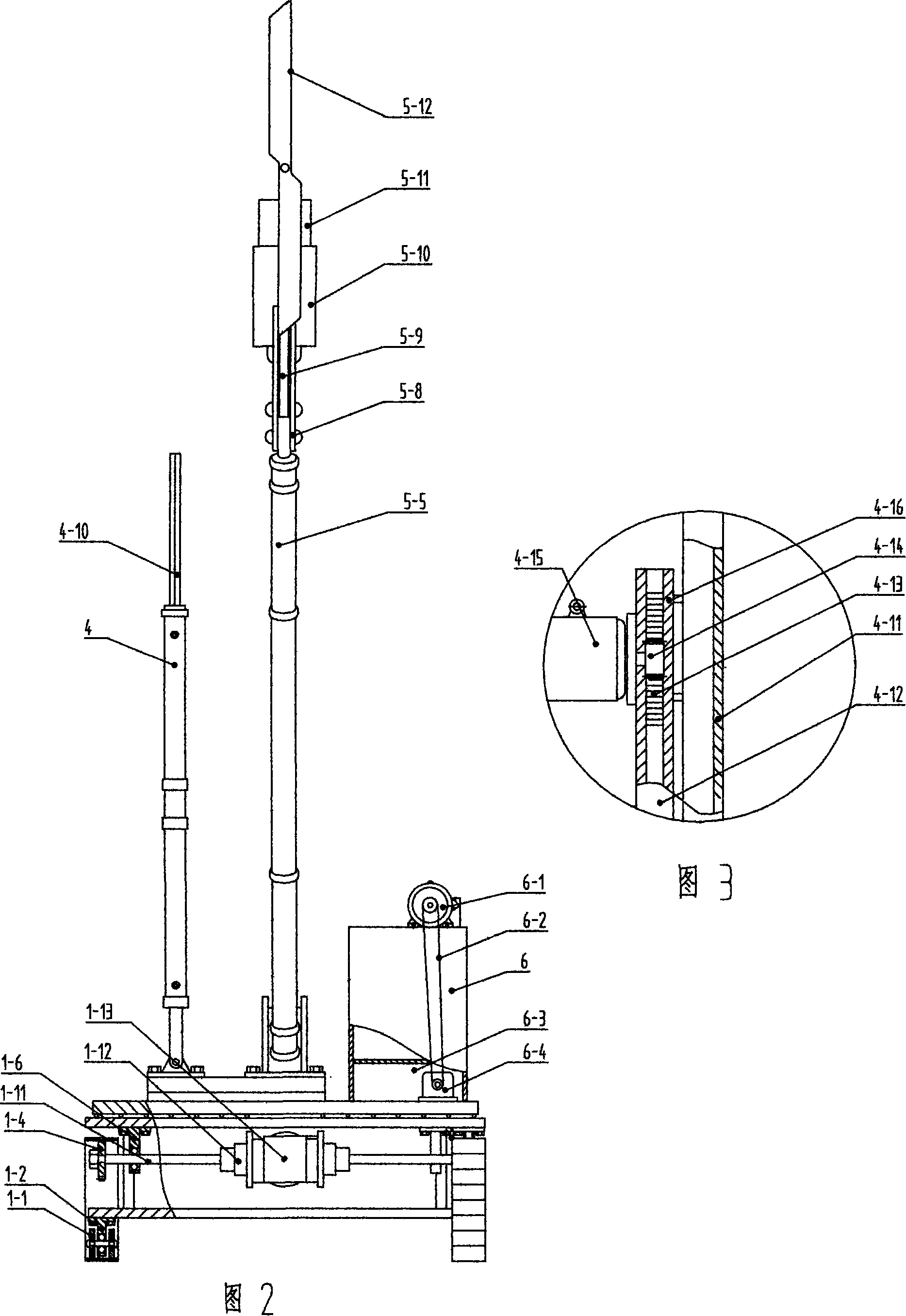

Wall rendering robot

InactiveCN101144324AStraightness is easy to guaranteeQuality improvementBuilding constructionsElectromagnetic clutchDrivetrain

The invention relates to an improved equipment on the basis of an original patent wall side plastering machine (the patent number: ZL01218090.4), and the invention is that two groups of mutually independent plane plastering devices and reentrant and outside corners plastering devices are arranged on the revolution support of a crawler belt chassis. Improvement is done to a power driving system of the crawler belt chassis, and a half axis and an electromagnetic clutch are added. The revolution support adopts a gear worm to drive. The weight of a complete machine is reduced, in order to ensure that the whole mechanization is realized for the work of the complete machine such as the plastering, the roughening, the treatment of the reentrant and outside corners during the construction, the labor strength is greatly reduced, the production efficiency is improved, and the maintenance expense is reduced, as well as the service life is prolonged.

Owner:赵呈为 +1

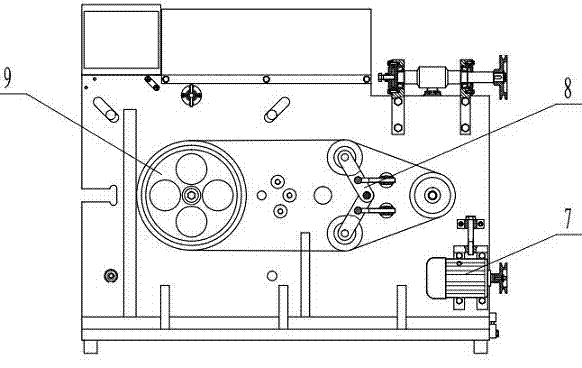

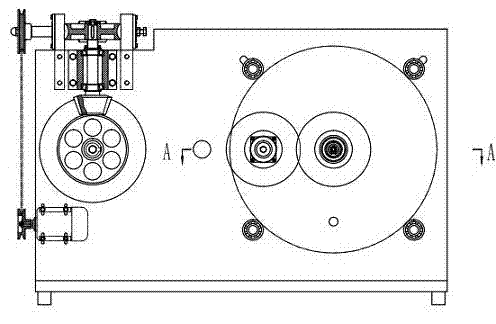

Rotary disc type cargo classifying device

ActiveCN106144496AImprove delivery efficiencyReduce manual handlingControl devices for conveyorsSortingGear wheelDrive motor

The invention discloses a rotary disc type cargo classifying device which comprises a code scanning device. The code scanning device is fixedly installed on the top of an initial conveying mechanism. The initial conveying device is connected with a sorting mechanism through a transition plate. The sorting mechanism comprises a front support. The top of the front support is provided with a rotary disc drive motor. The rotary disc drive motor is engaged with a second gear through worm and gear transmission. The second gear and a first gear are fixedly installed on the same main shaft. The first gear is engaged with a third gear at the bottom of a rotary disc to drive the rotary disc to rotate. A rear support is arranged at the bottom of the rotary disc. Multiple sliding groove devices are arranged at the positions, along the periphery of the rotary disc, of the top of the rear support. A rotating push rod mechanism is installed at the center of the rotary disc. The rotary disc type cargo classifying device is simple in structure and obvious in effect, compared with a traditional classifying mechanism, the space occupied by a cargo classifying mechanism is greatly saved, space is saved, and accurate classification of cargoes are achieved.

Owner:CHINA THREE GORGES UNIV

Open body box form interbody fusion cage

An interbody fusion cage having a generally symmetric, annular cage body surrounding a central void extending from a lower surface to an upper surface in which to retain graft material in contact with adjacent vertebra. A lateral channel extending into each half from the cage perimeter contains a worm drive screw. One or more longitudinal channels extending from the upper surface to the lower surface intersect each lateral channel and house a pin which is provided with a series of helically cut worm gear teeth on its external surface for engaging the worm drive screw. The pins are simultaneously externally threaded and engaged to the cooperatively threaded internal surface of the longitudinal channel such that rotation of the drive screw by the surgeon after implantation causes the pins to rotate with the longitudinal channel and advance into the adjacent bone.

Owner:KAMRAN AFLATOON +1

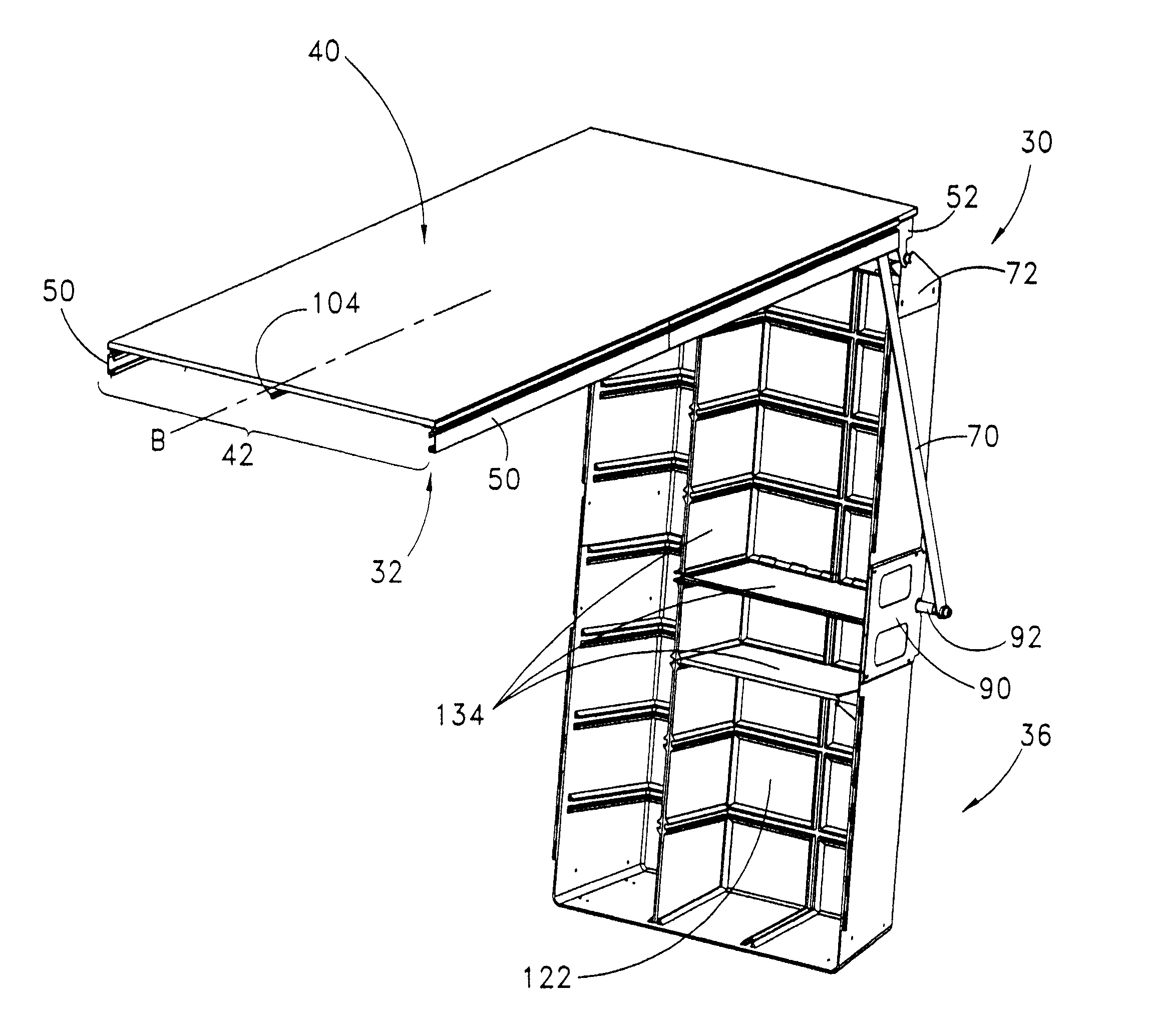

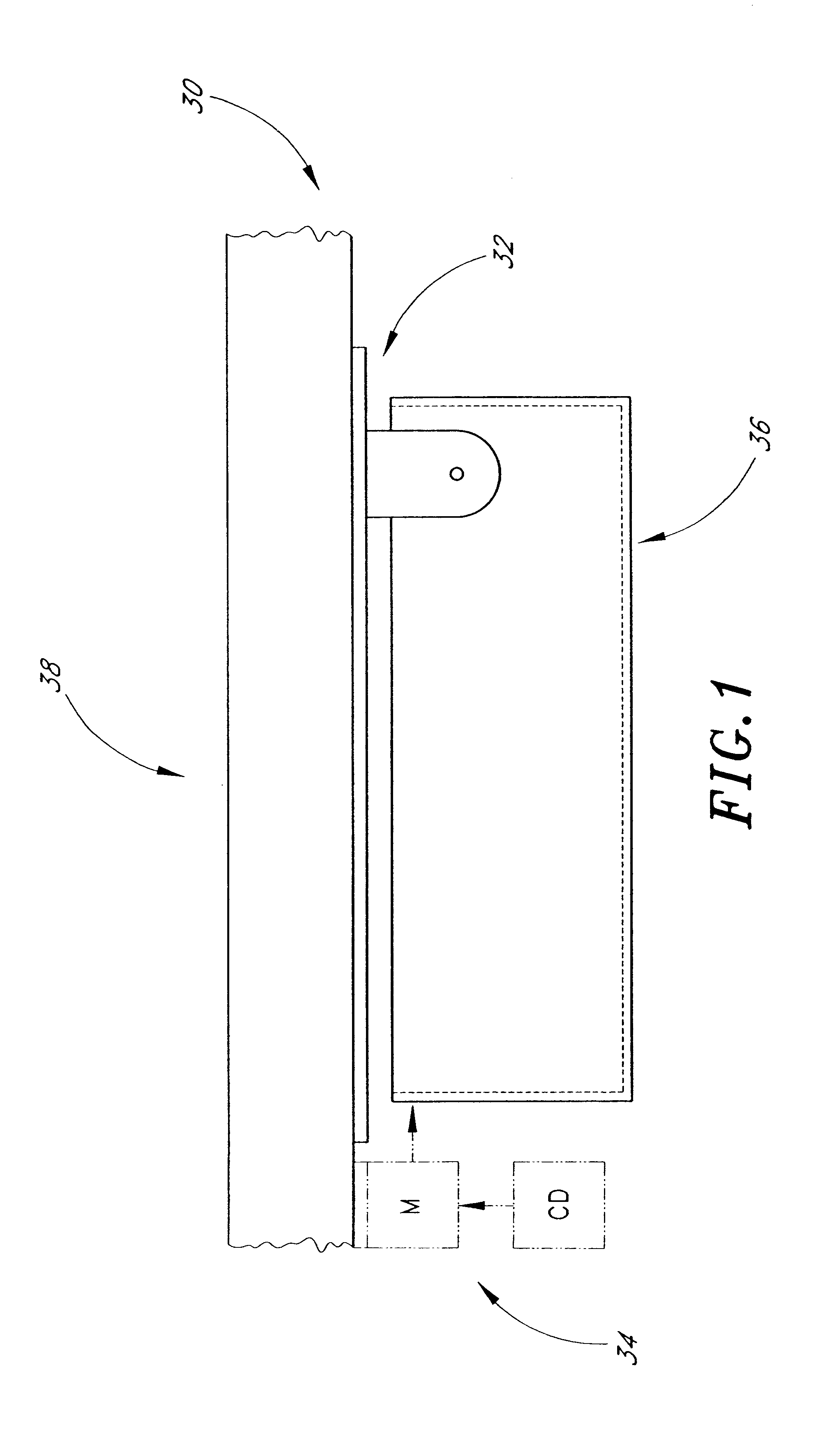

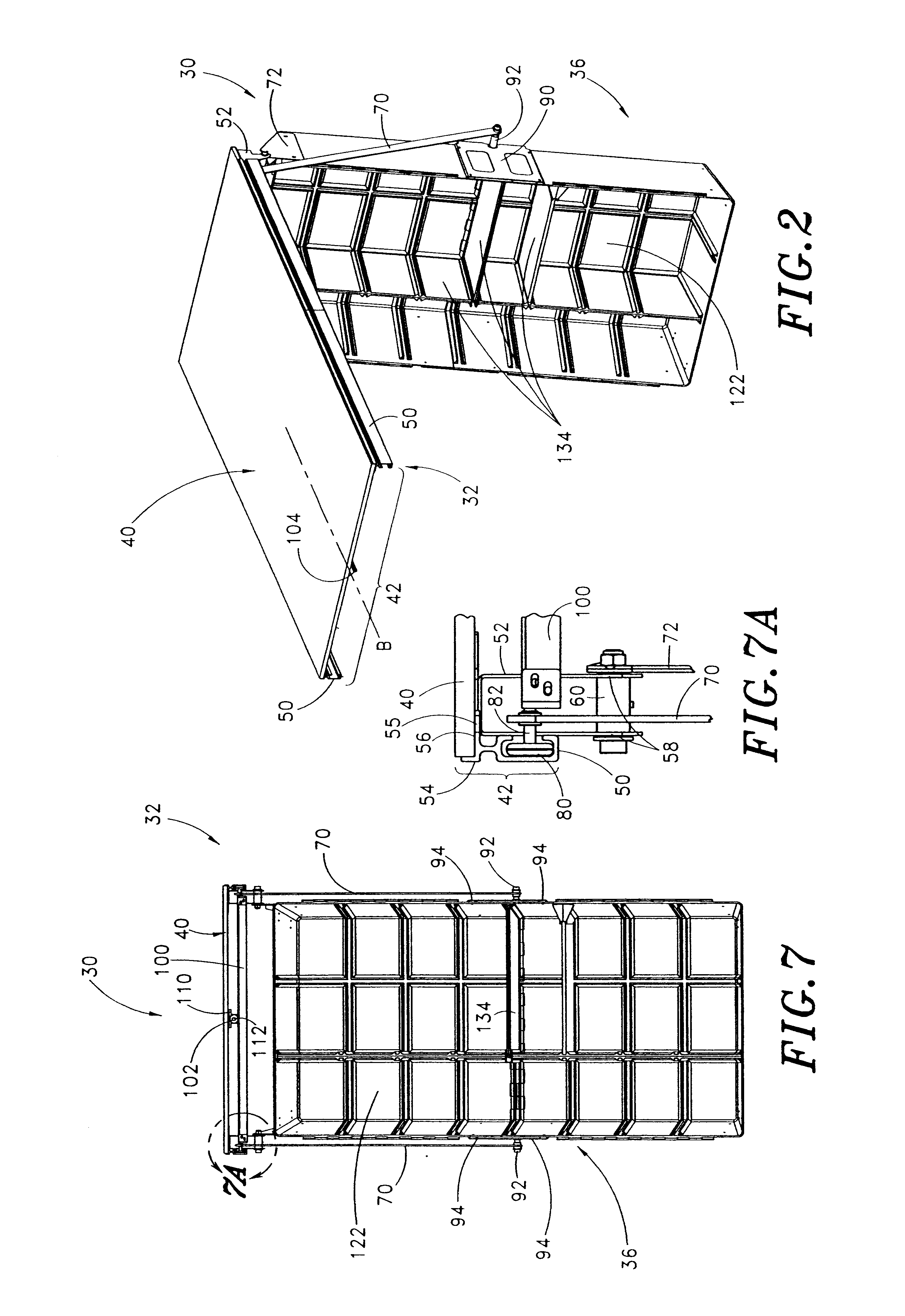

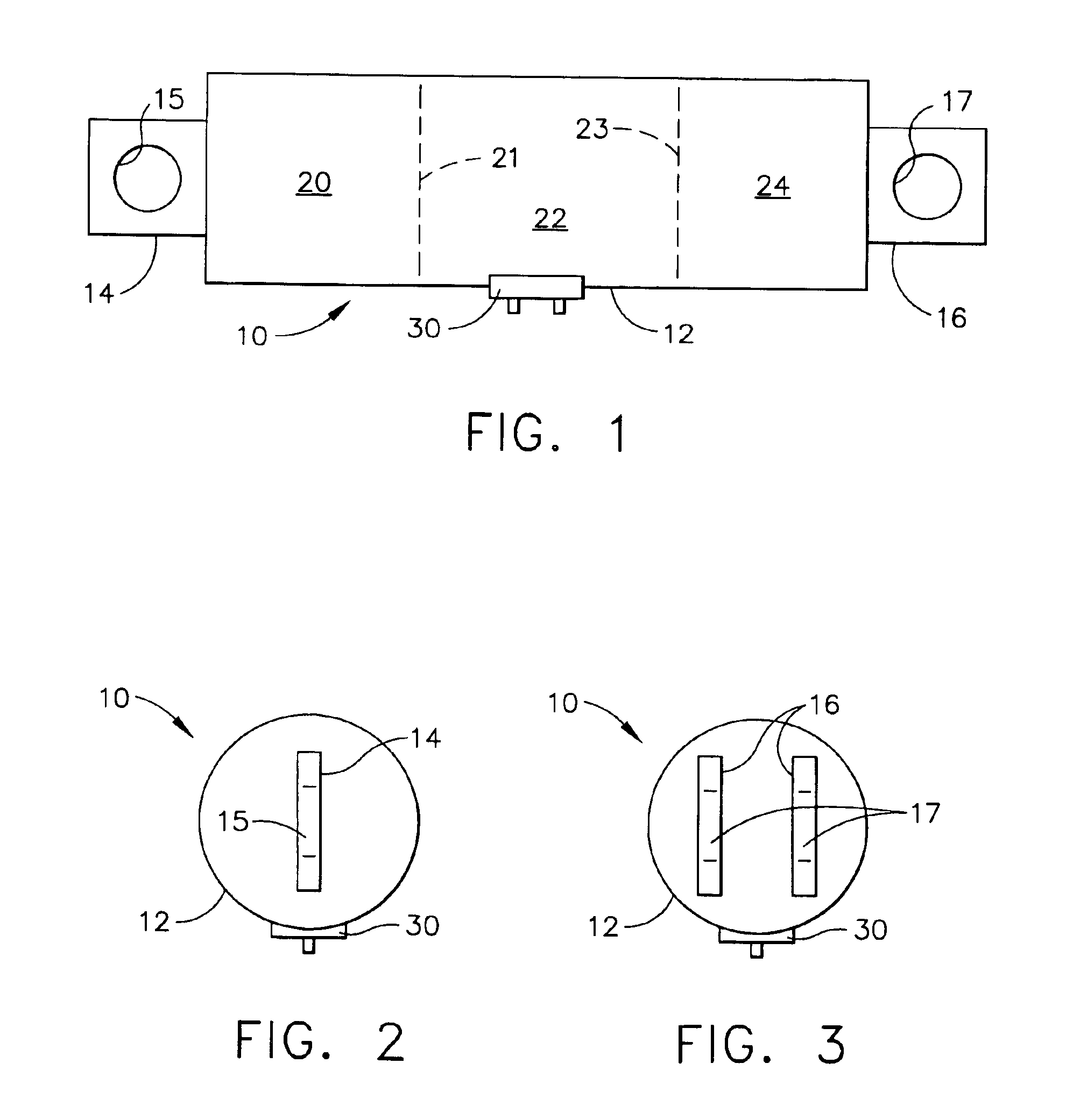

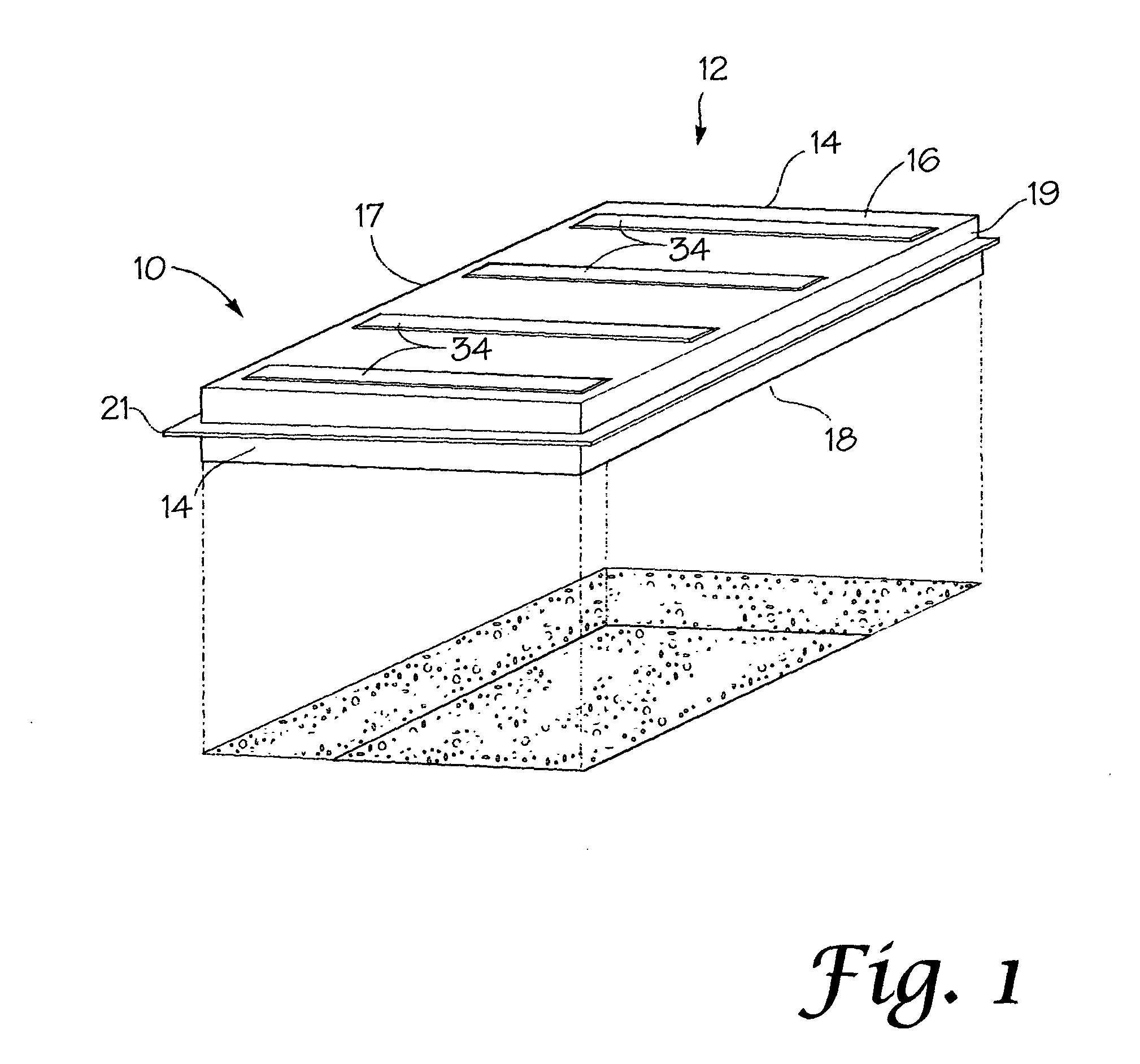

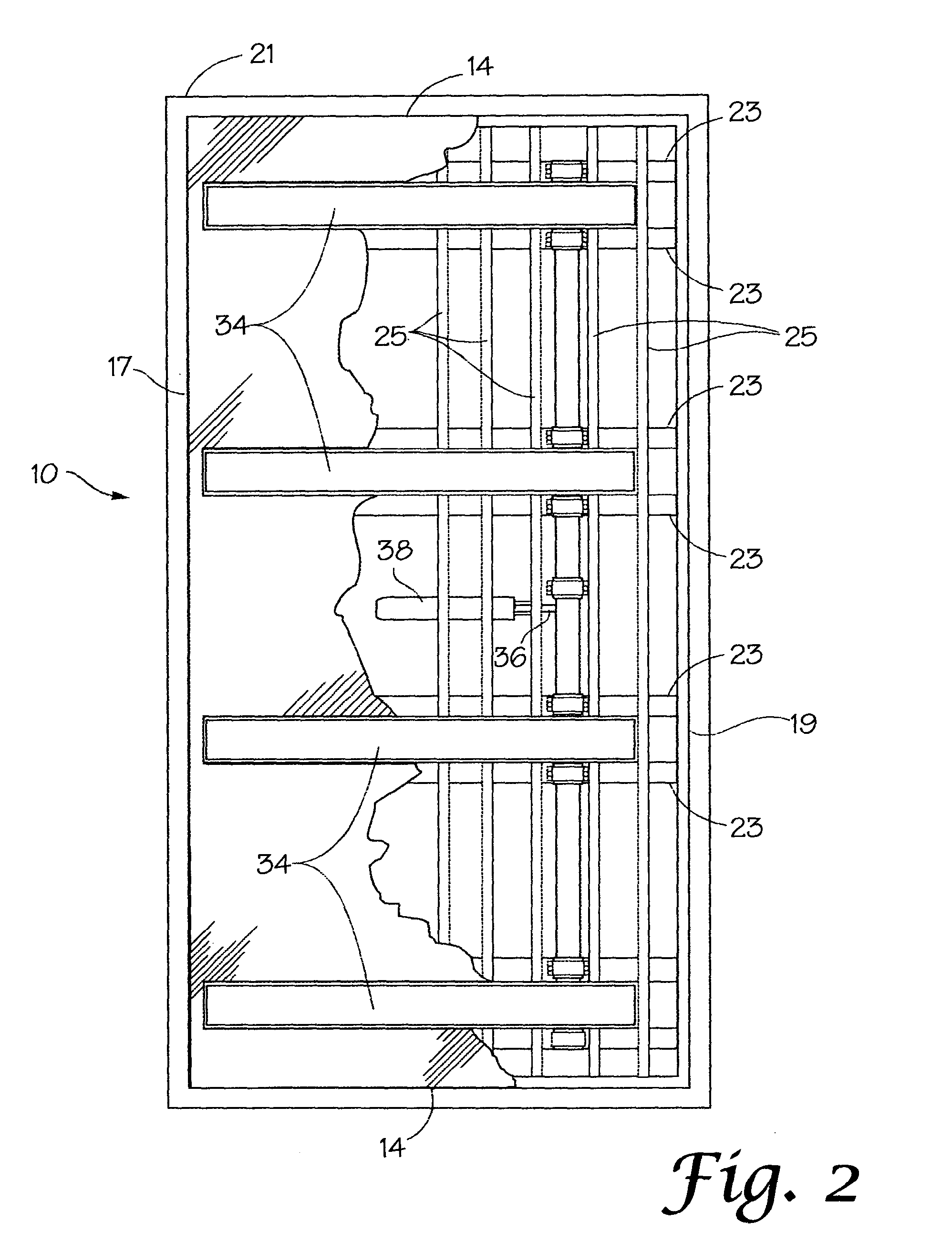

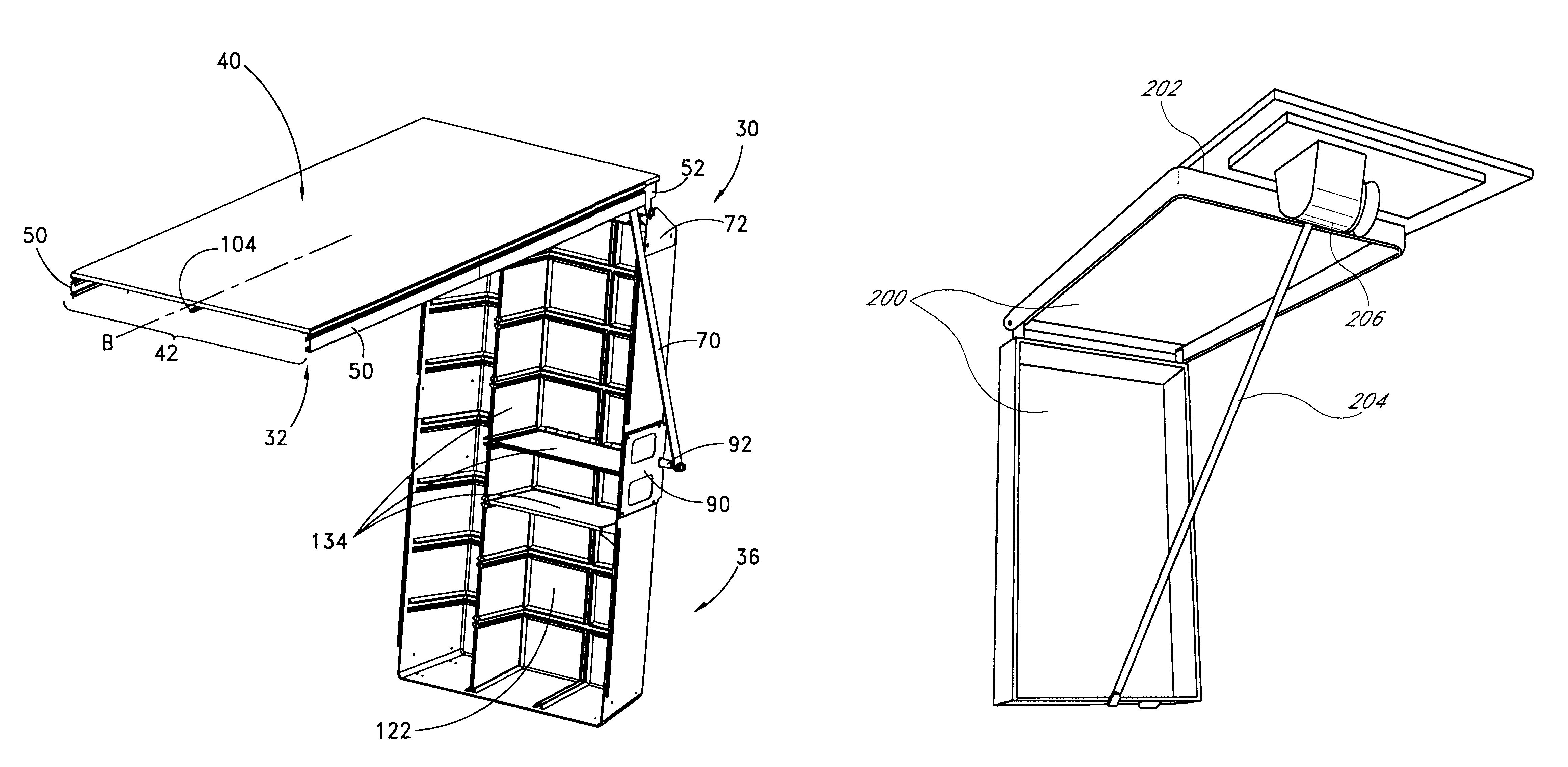

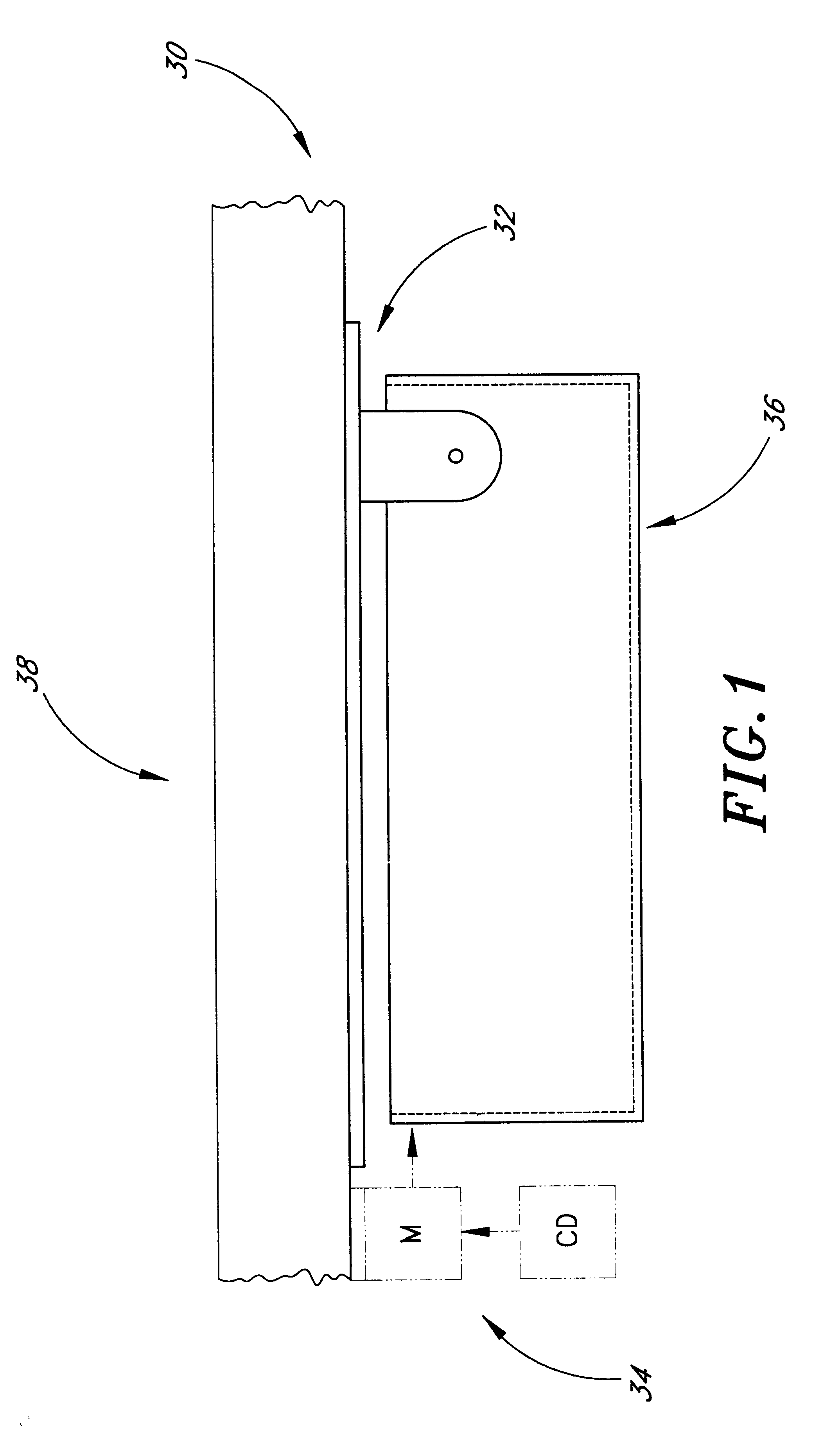

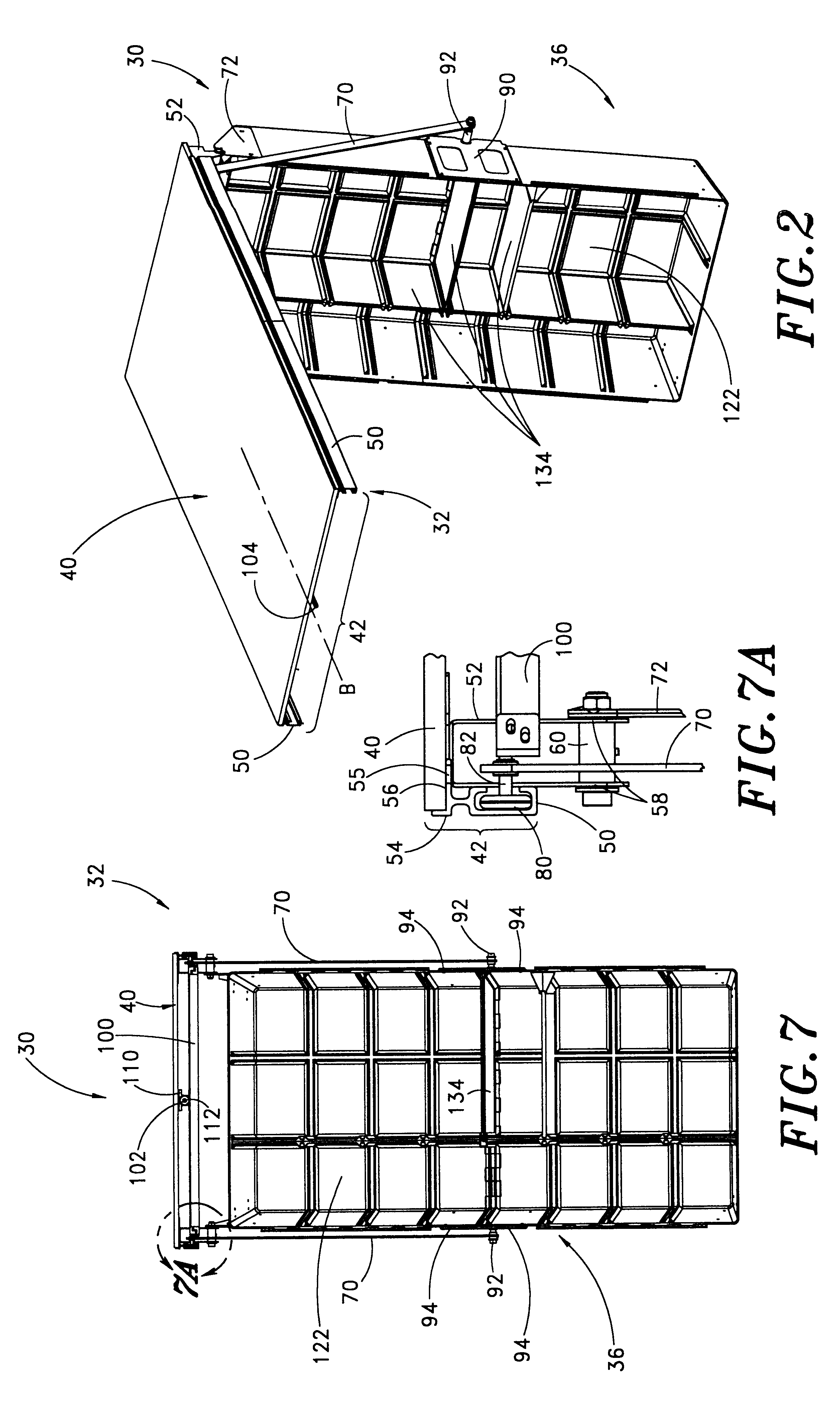

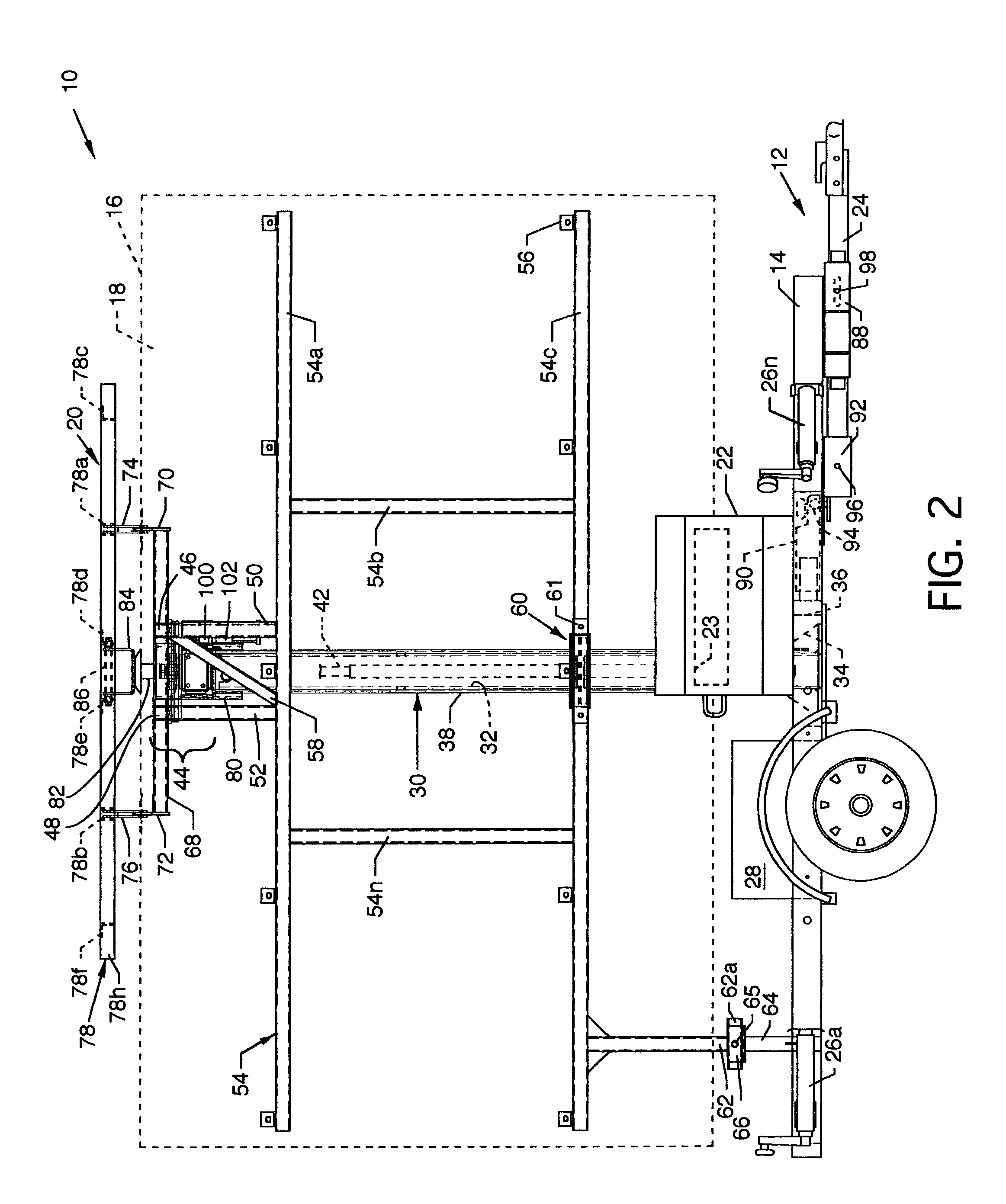

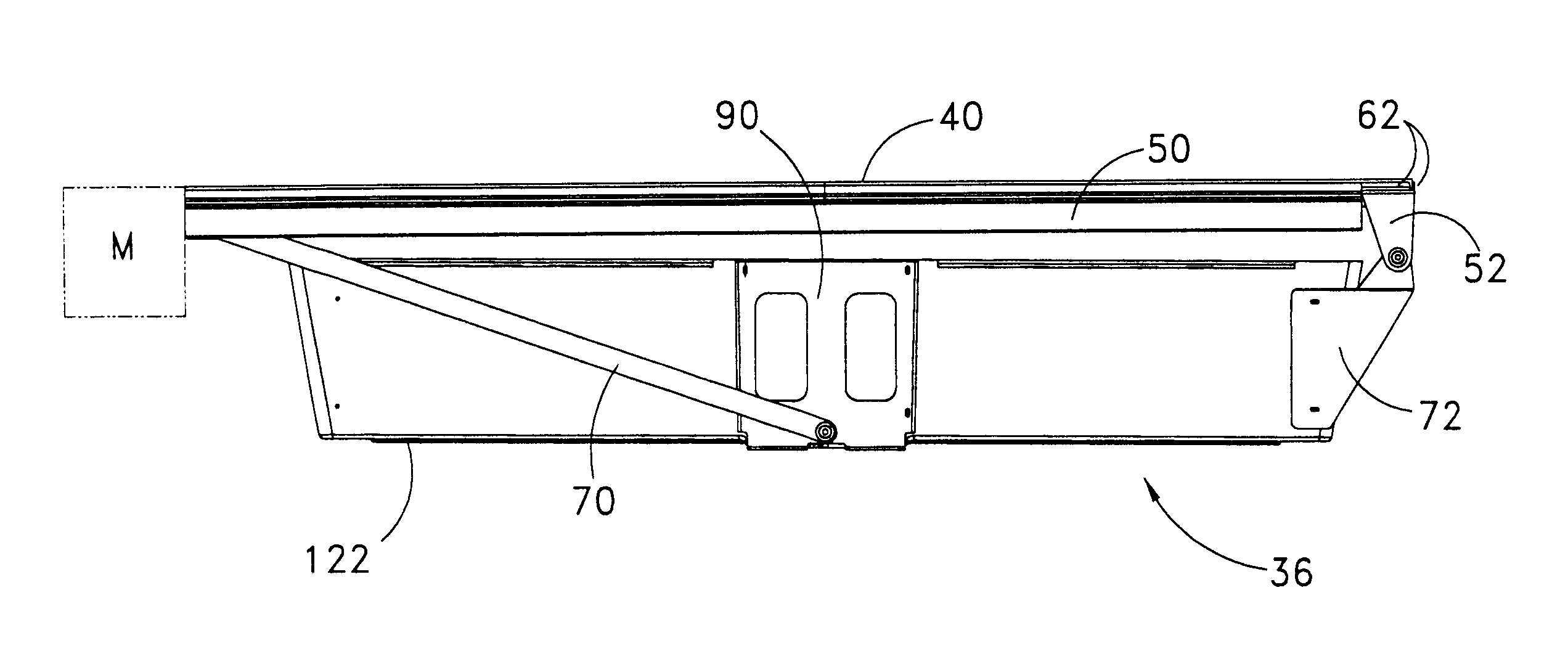

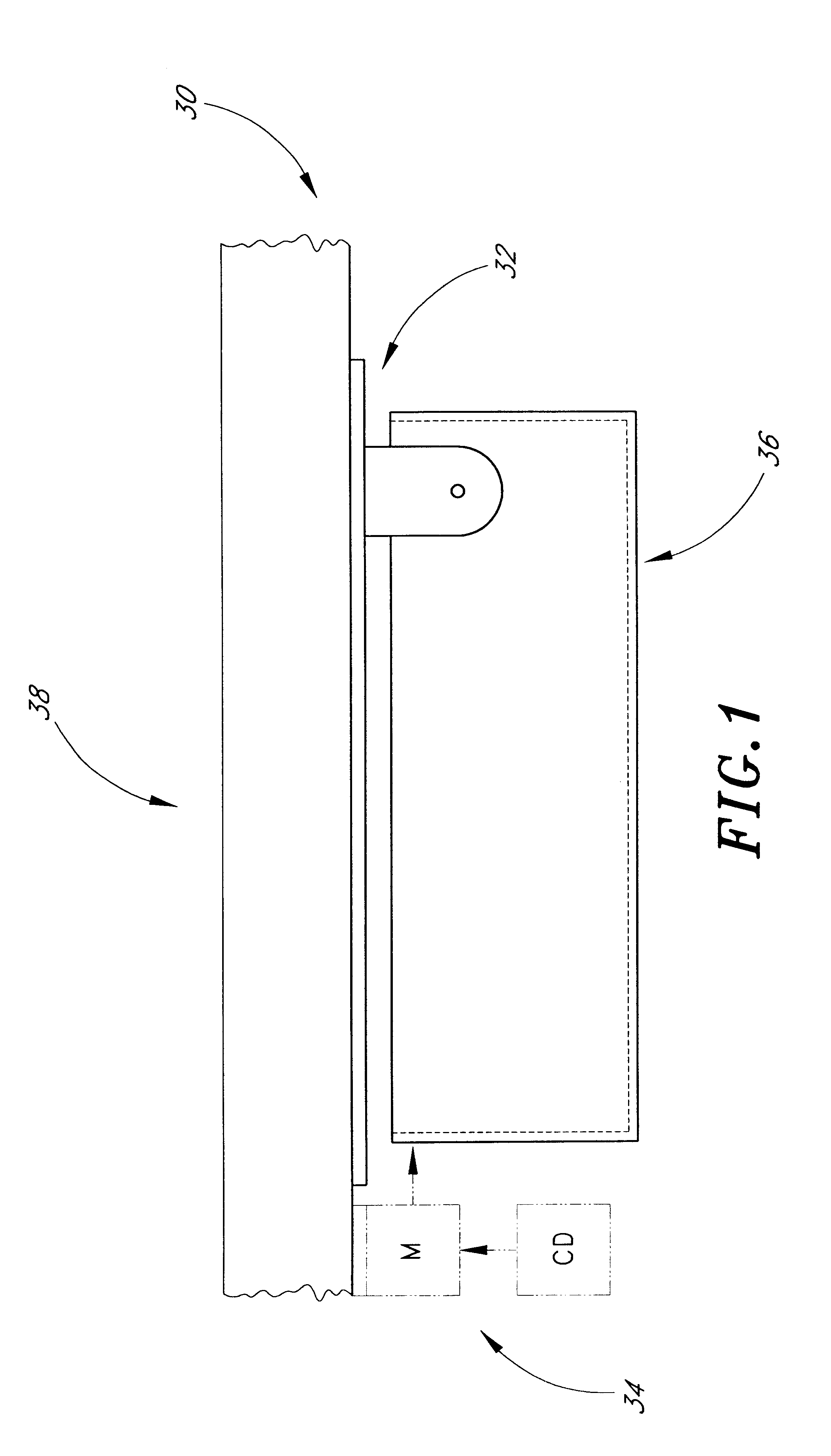

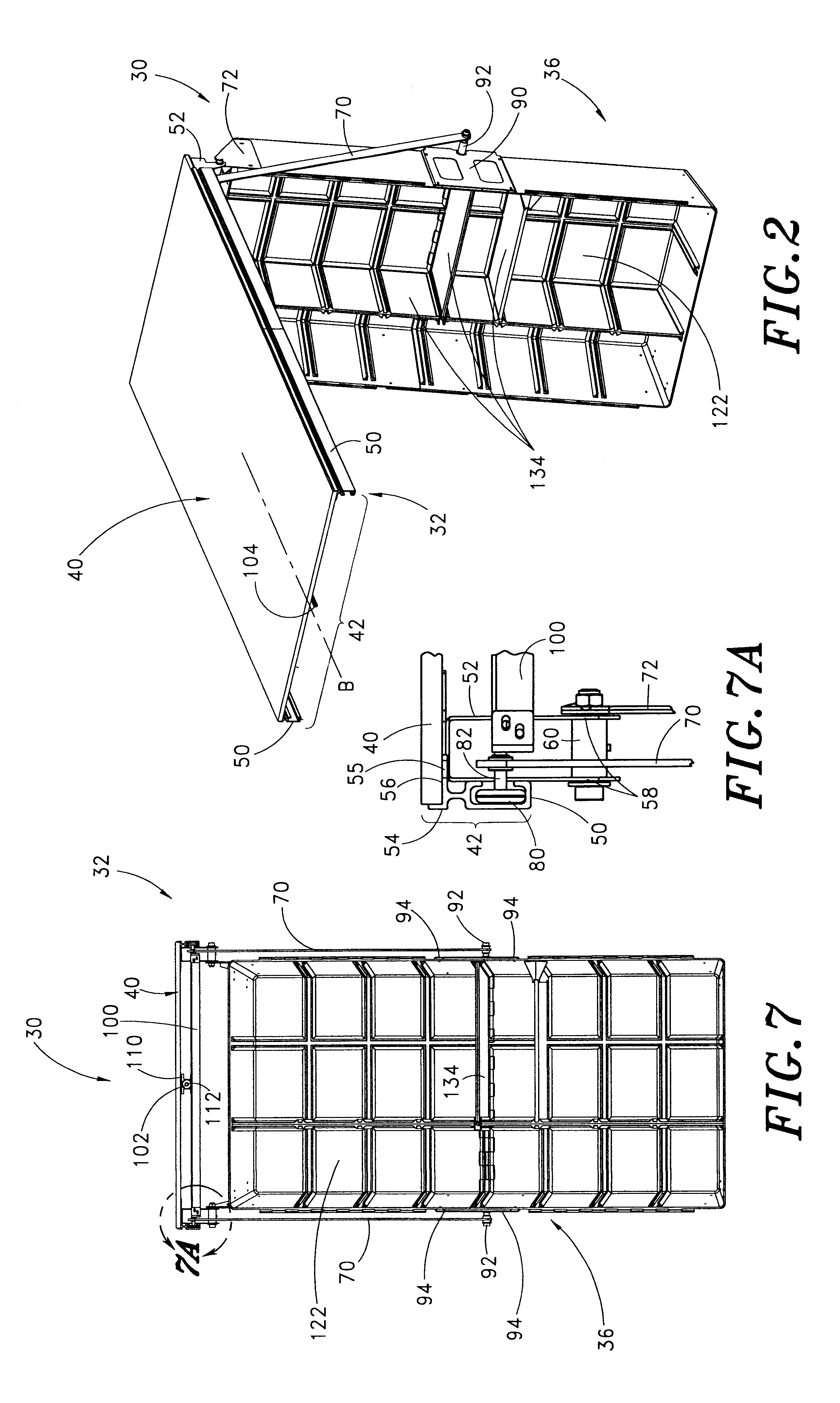

Overhead storage device

An overhead storage device includes a storage container that is pivotably or rotatably mounted to an overhead surface, such as a ceiling or a plurality of rafters. The storage container is generally moved by a motorized actuator assembly. The motorized actuator assembly can comprise a worm drive and follower nut arrangement or a flexible transmitter and spool assembly. The storage container is supported by a frame assembly and is secured to the frame assembly generally at an end of the storage container. The overhead storage device is sized to allow a motor vehicle to fit below a raised storage container in an average height garage. The storage container is assembled from two generally identical halves that are nestable for shipping and storage.

Owner:NOTT BRUCE E

Remotely releasable support strut

Methods and apparatus are provided for locking and releasing ends of a support strut coupled between a mounting platform and a load. In a preferred embodiment, the strut comprises a damping section coupled between the ends and having a gap therein when the strut is unlocked, a locking section coupled between the ends for closing the gap by applying stress to a portion of the damper section through a force transmitting member, and a releasing section coupled in parallel with part of the force transmitting member, the releasing section including a Shape Memory Alloy (SMA) and heater therefore. Heating the SMA relieves the stress and opens the gap. Release from the locked condition occurs gradually and without fracture or sudden shock and the heater can be actuated remotely. In a preferred embodiment, a worm drive turnbuckle arrangement is used to apply force to lock the strut.

Owner:HONEYWELL INT INC

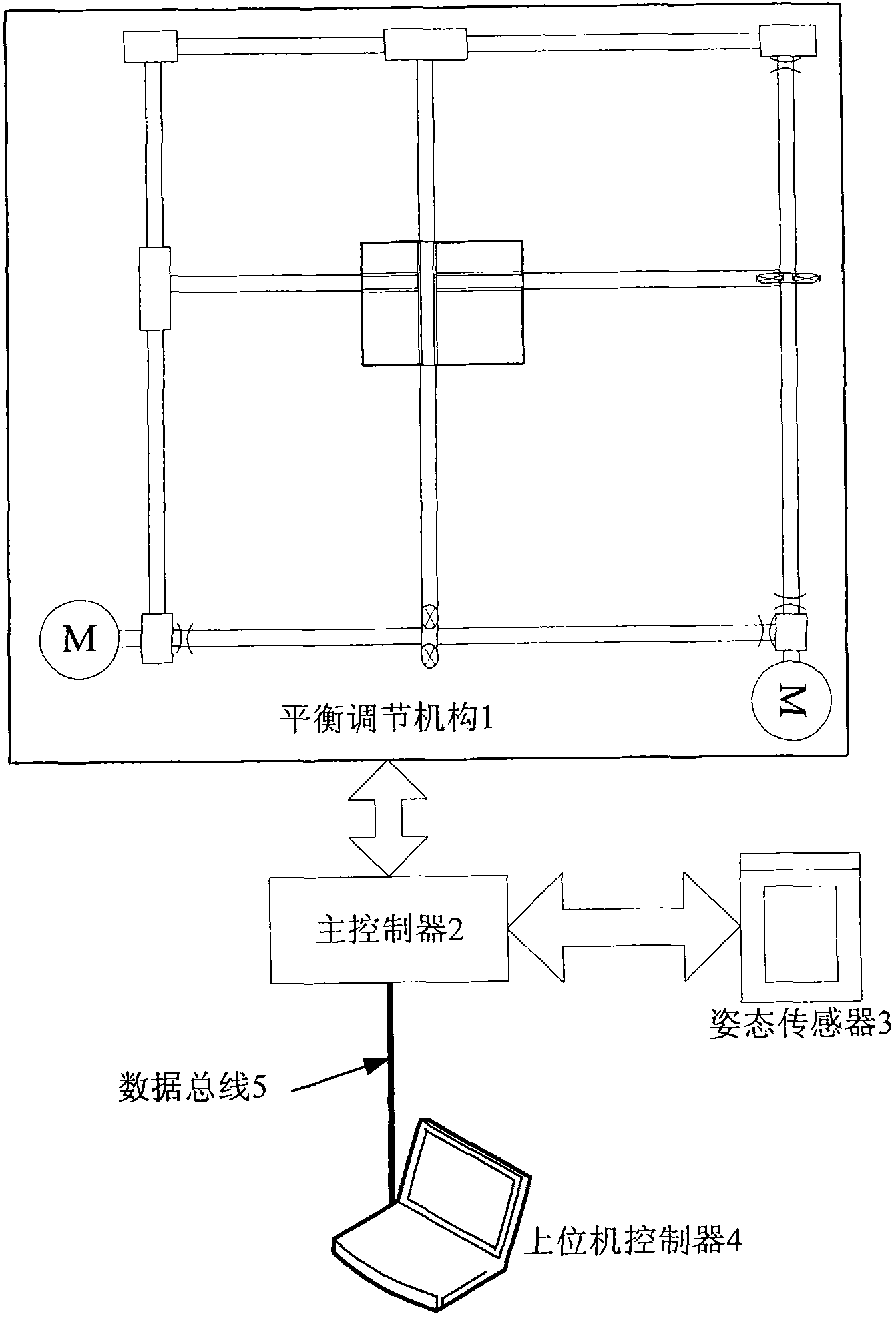

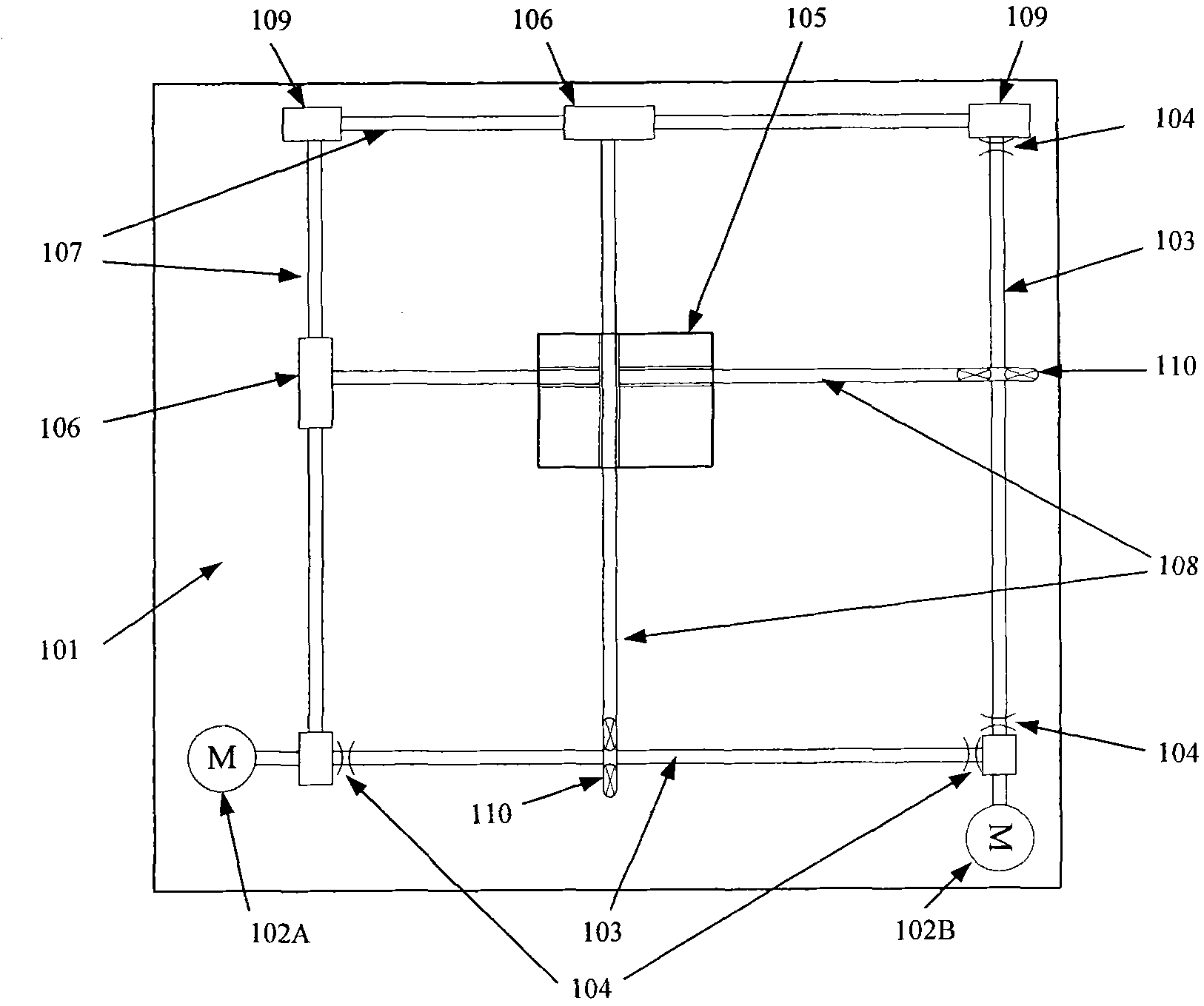

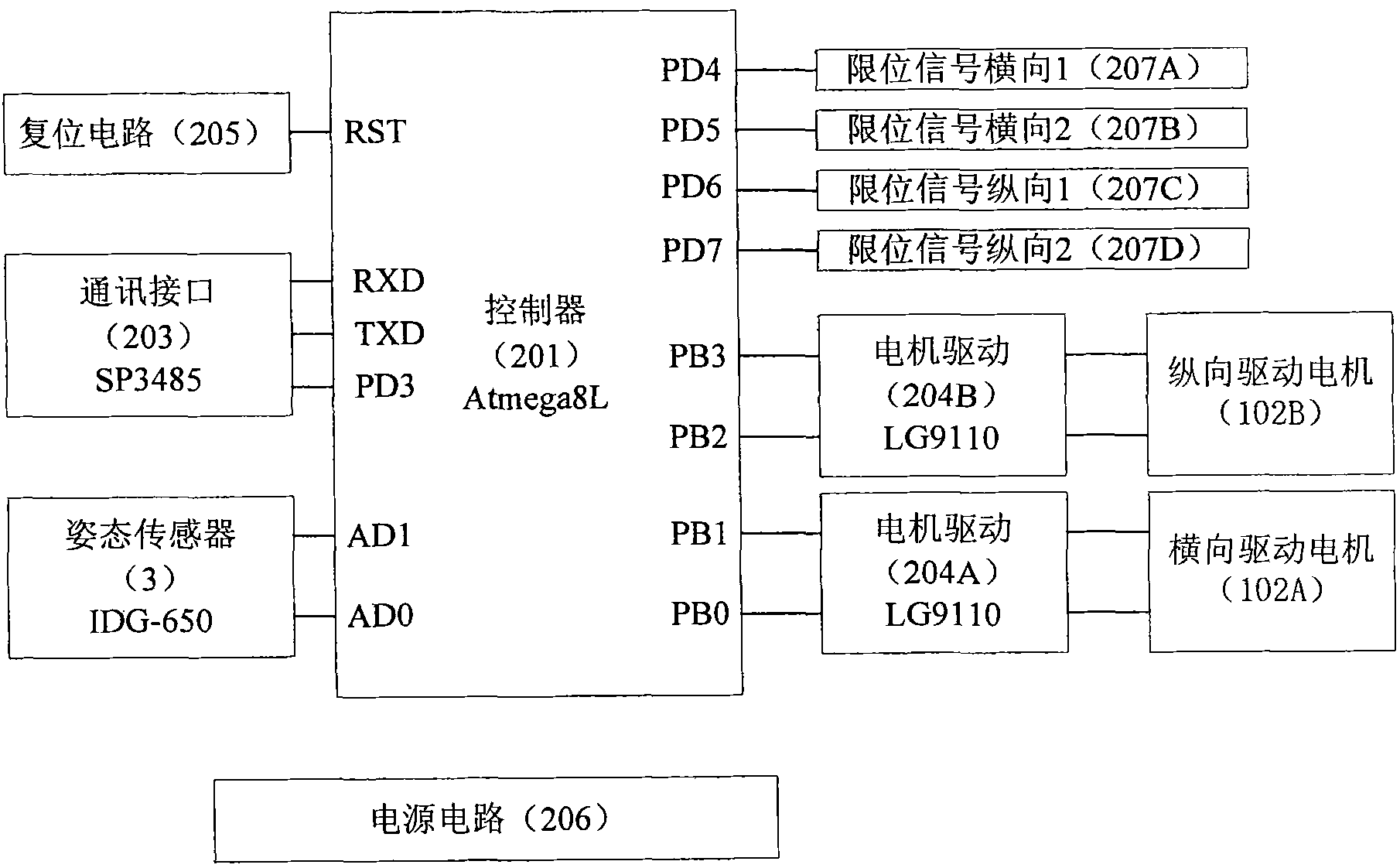

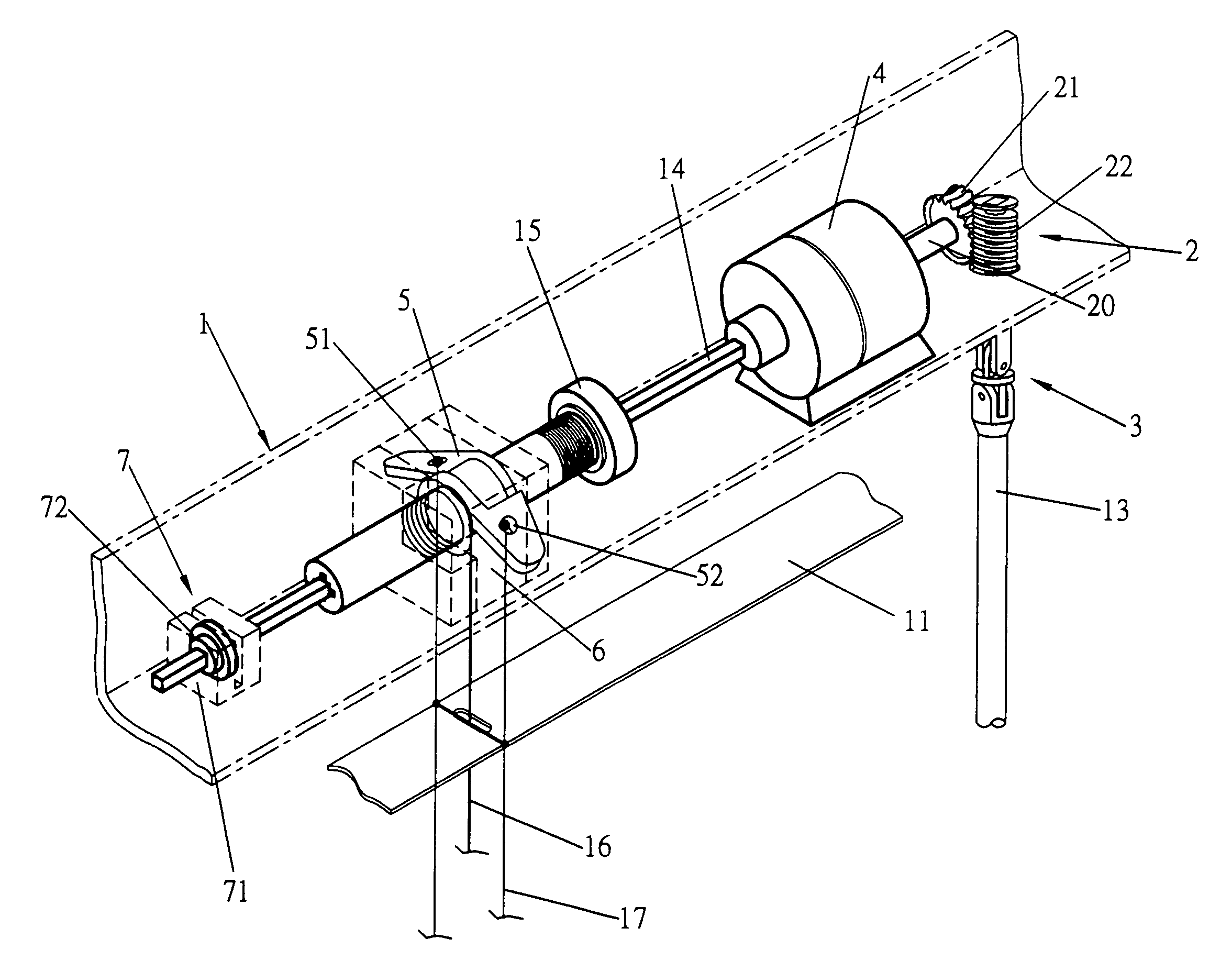

Inner system for controlling gestures of underwater robot

InactiveCN102012704AControl postureAttitude control is widely applicableAttitude controlUnderwater equipmentControl systemEngineering

The invention discloses an inner system for controlling the gestures of an underwater robot, comprising a main controller connected with an adjustment mechanism, a gesture sensor, and an upper computer controller, wherein the adjustment mechanism is a balance adjustment mechanism arranged inside the underwater robot, and comprises a gravity slider, a double-shaft drive motor, a worm, a guiderail, a slide bar, a limit switch and a mechanism platform; the double-shaft drive motor is connected with the worm to drive the worm to rotate bidirectionally; the worm drives the slide bar to perform planar movement through the transmission of a lead screw; one end of the slide bar is connected with the lead screw of the worm and penetrates the gravity slider, while the other end thereof is connected with the guiderail by a slider and drives the gravity slider to move in a plane so as to realize the gravity adjustment of the underwater robot and control the transverse swing and longitudinal incline gestures of the underwater robot. The control system for gestures can be widely applied to the gesture control of the underwater robot.

Owner:SHANGHAI UNIV

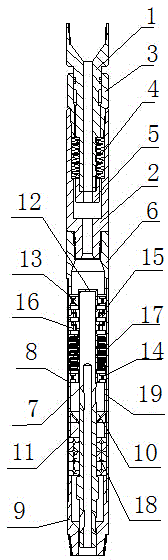

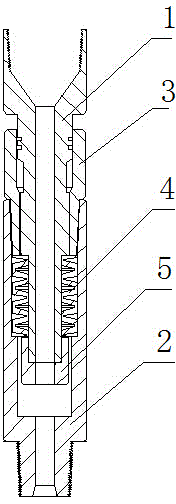

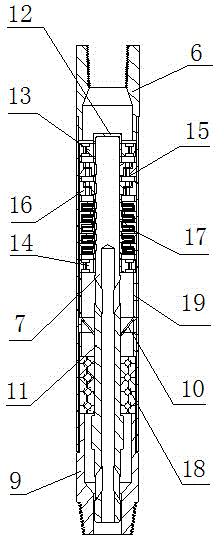

Worm-driven double-valve hydraulic oscillator

InactiveCN104895517AHold amplitudeIncrease amplitudeVibration devicesVibration drillingScrew threadEnergy consumption

The invention relates to a worm-driven double-valve hydraulic oscillator, belonging to the technical field of petroleum, natural gas extraction and drilling tools. The oscillator is composed of a vibration short-circuit assembly and a power short-circuit assembly; the vibration short-circuit assembly and the power short-circuit assembly are connected mutually through a screw thread; the power short-circuit assembly is composed of a compression sleeve, a worm shaft, a main engine shell, a lower joint, a shunting ring and a shunting sleeve; the compression sleeve is arranged at the upper end of the main engine shell through a screw thread; the lower joint is arranged at the lower end of the main engine shell through a screw thread; the worm shaft is arranged in the main engine shell; an end cover is arranged at the end head of the upper end of the worm shaft through a screw thread; an upper alignment bearing and a lower alignment bearing are arranged at the circumference of the worm shaft which is below the end cover; the shunting ring is arranged at the circumference of the worm shaft which is below the lower alignment bearing through the shunting sleeve. According to the worm-driven double-valve hydraulic oscillator, the drilling efficiency is improved, in comparison with the traditional technology, the energy consumption is reduced, and the service life is prolonged, and the worm-driven double-valve hydraulic oscillator is particularly suitable for construction need of petroleum, natural gas extraction and drilling.

Owner:YANGTZE UNIVERSITY

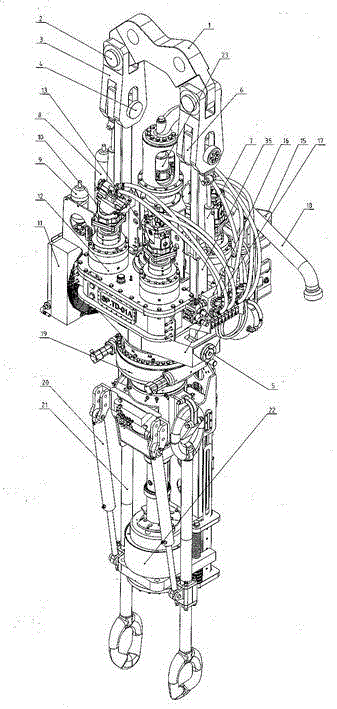

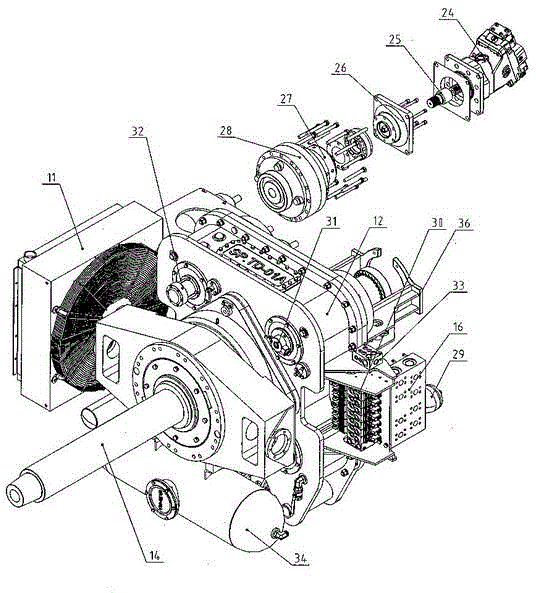

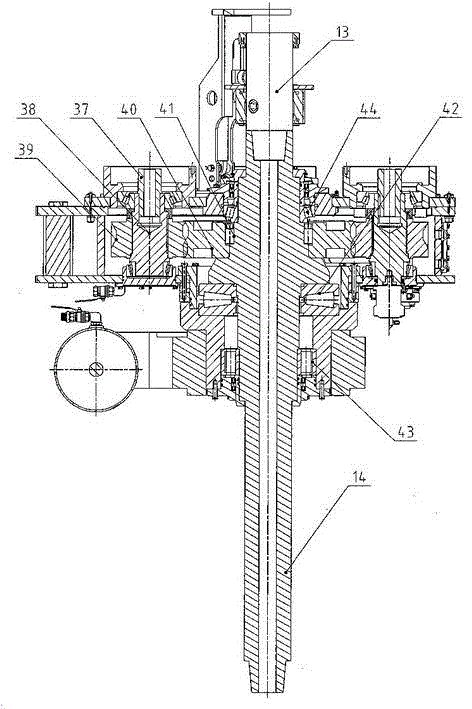

High-speed large-torque full-hydraulic top drive well-drilling device

InactiveCN104389514AComplete electro-hydraulic control systemComplete coolingDrilling rodsConstructionsLow speedTop drive

The invention discloses a high-speed large-torque full-hydraulic top drive well-drilling device which is driven by a group of high-speed small-torque hydraulic motors. Each hydraulic motor is equipped with an independent multi-piece disk brake and a planetary speed reducer; a main shaft can rotate at high speed and large torque; a disk brake is not required to be arranged. The structure of the high-speed large-torque full-hydraulic top drive well-drilling device comprises a lifting device, a main transmission box, a rotation head assembly, a hydraulic chuck and an opening-closing sliding trolley which are arranged from top to bottom, wherein the upper part of the lifting device is directly connected with a traveling trolley by virtue of a lifting cross beam; the lower part of the lifting device is connected with a lifting seat of the main transmission box; the rotation head takes a rotation driver driven by a worm as a main working part; the accurate angle location is implemented by electric-hydraulic proportional closed-loop control; the rotation head has self-locking property and can be used for simultaneously driving a drilling column to rotate with the main shaft; the low-speed torque increasing operation can be implemented. The hydraulic top driver is small in size and light in weight; electric-hydraulic proportional volumetric speed control in a high rotation speed range is implemented by a hydraulic system through a mechanical and electrical integration technology, thereby meeting the requirements of a plurality of deep well drilling processes and drilling disciplines, especially core drilling during continental scientific drilling of deep wells.

Owner:JILIN UNIV

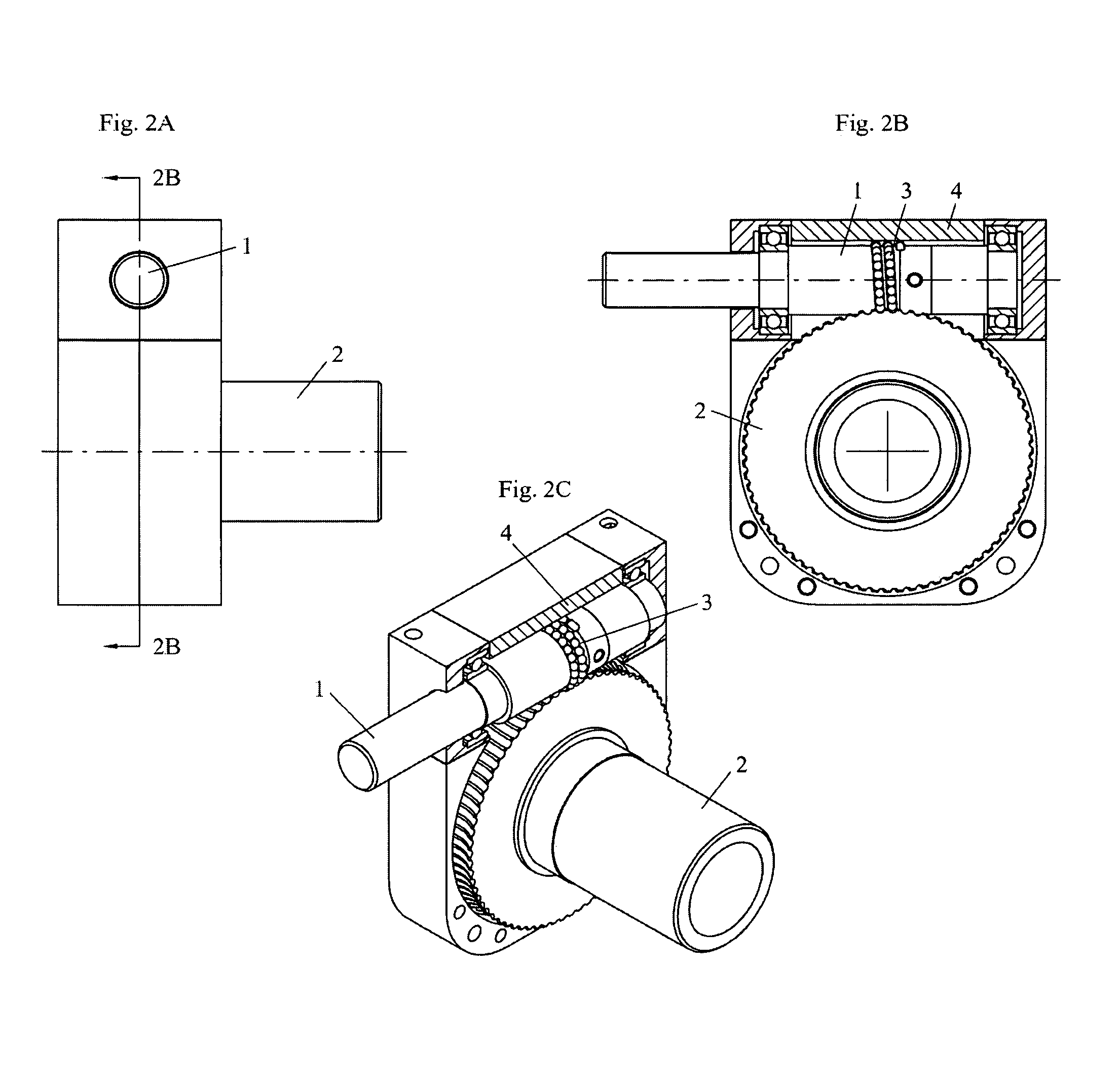

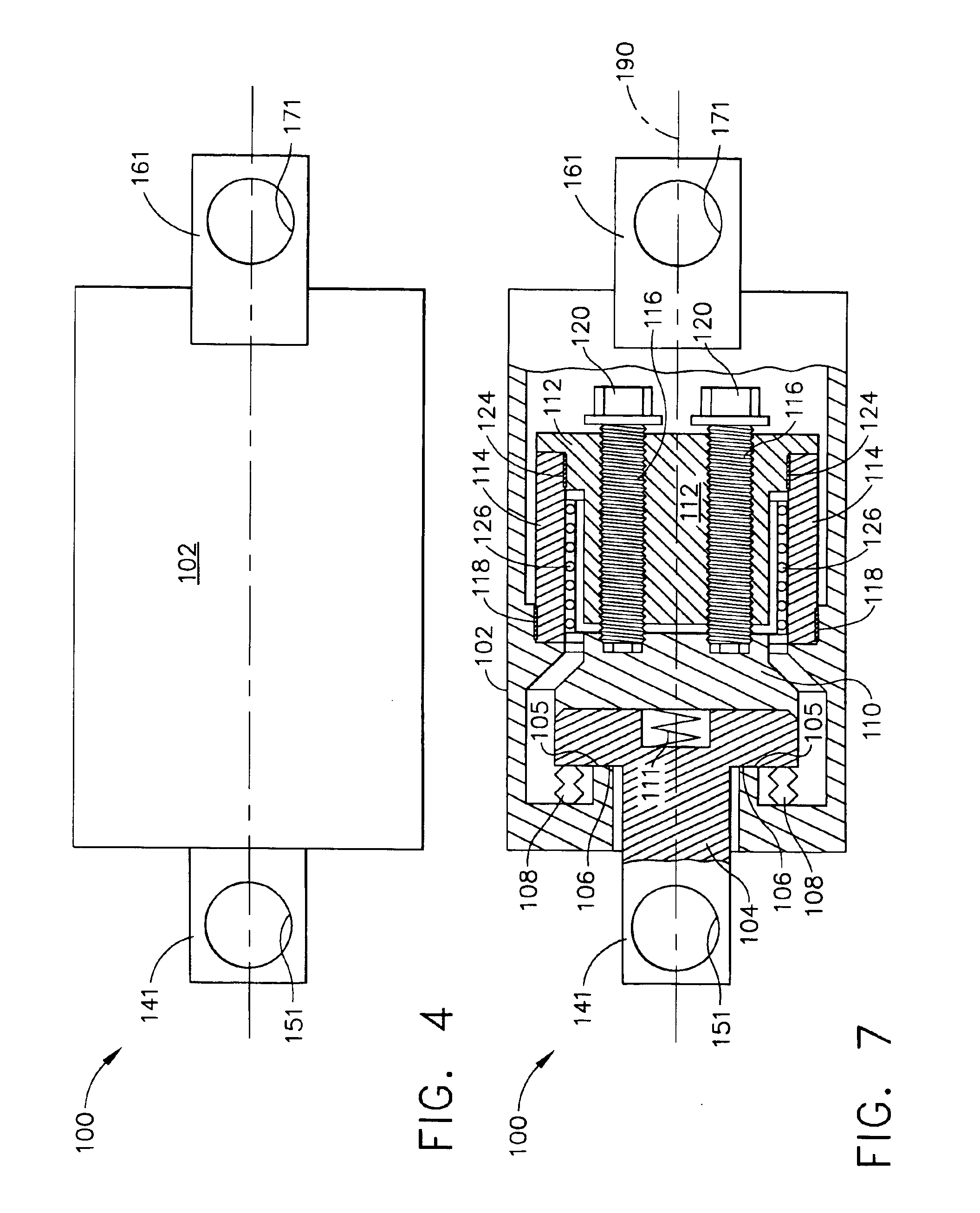

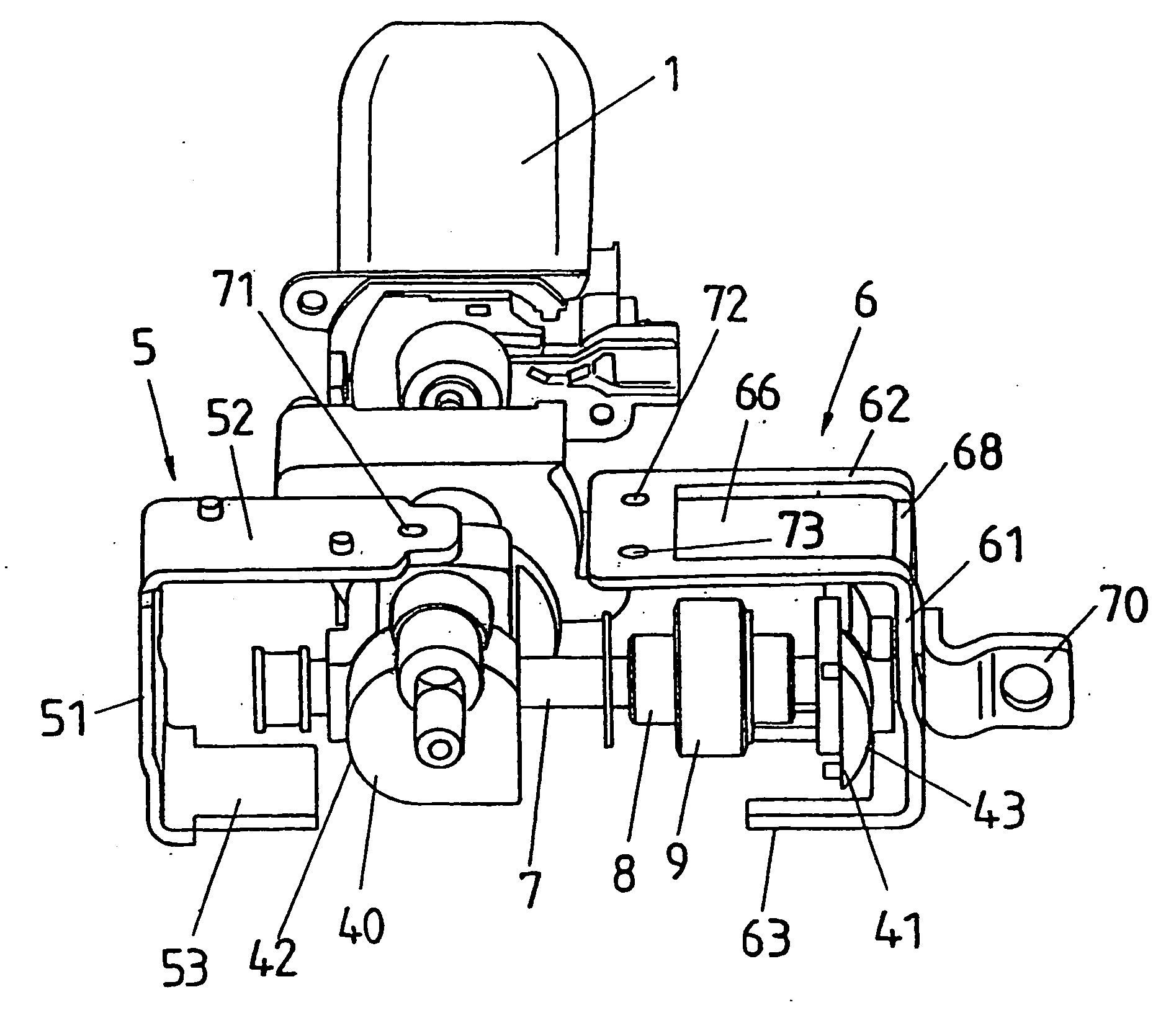

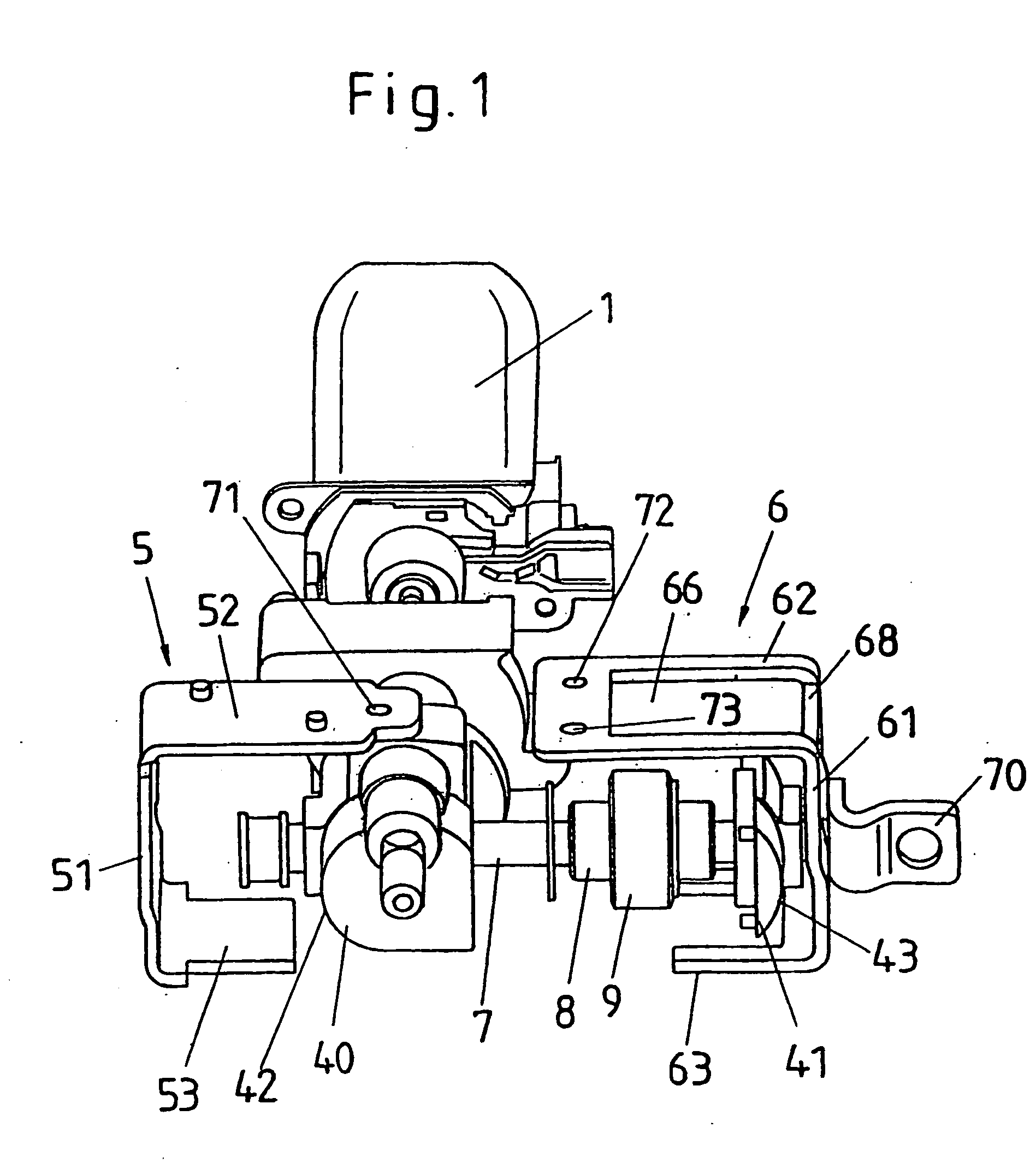

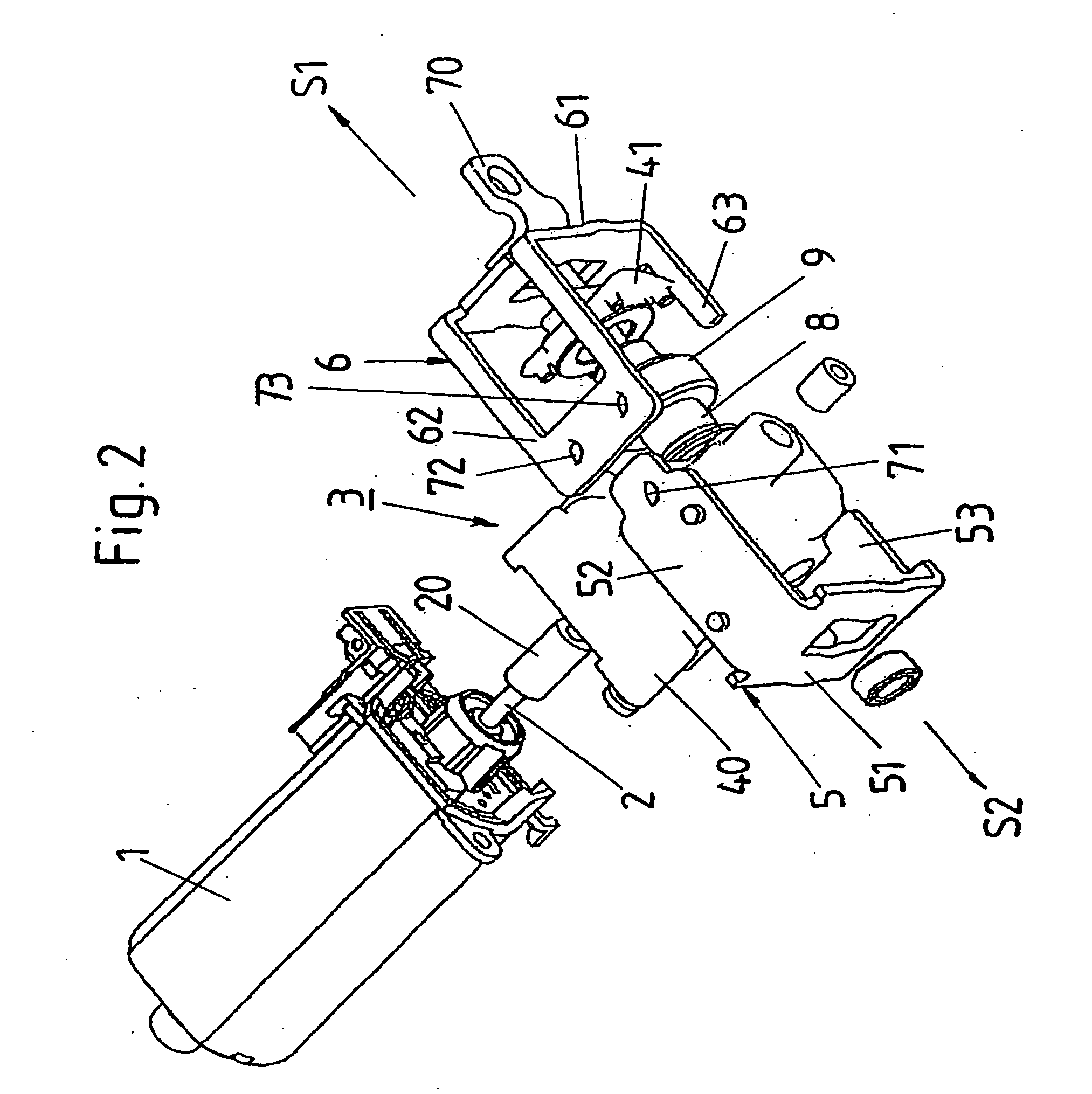

Spindle or worm drive for adjustment devices in motor vehicles

ActiveUS20050126333A1Ensure supportEasy to manufactureGearboxesToothed gearingsGear wheelEngineering

A spindle or worm drive for adjustment devices in motor vehicles. The device is secured with a fixed spindle or a fixed toothed rack to the first of two parts which can be adjusted in relation to each other, and is provided with a gear mechanism which is connected to the second of the two parts which can be adjusted in relation to each other. The gear housing is free from backlash and is enclosed by at least one bearing shell such that it is pivotable about at least one axis. The bearing shell consisting of two bearing plates which fit into one another and which can be joined to each other after enclosure of the gear housing. The gear housing is made of plastic and is provided with a concave or convex housing part which is surrounded by a convex or concave bearing shell section made of a material which is suitable for receiving crash forces, especially a metal material.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG

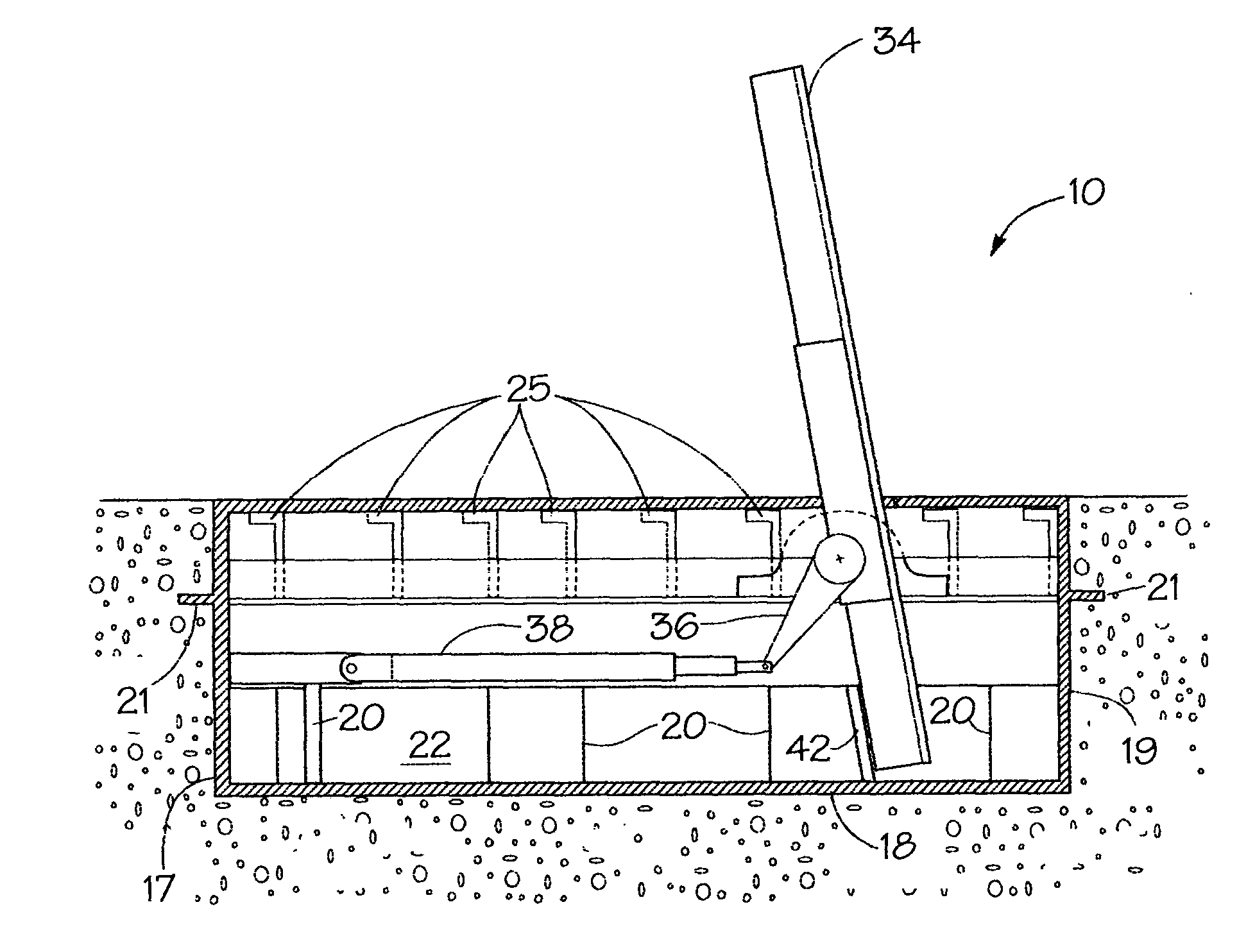

Automatic self contained collapsible traffic barrier bollard system and method of installation

A collapsible traffic barrier system is disclosed which includes a steel vault having a top, a bottom, two ends, an approach side and a shoulder side. The top may be treated with anti-skid material. A rod is rotatably mounted to support members inside the vault, wherein the rod extends across the vault from end to end. A plurality of bollards are coupled to the rod substantially near the first end thereof, whereby rotation of the rod rotates the bollards so as to extend the second ends of the bollards above the vault in a vertical direction, or raised position. An actuator having a first end anchored within the vault and a second end is coupled to the rod by means of an arm. The actuator is a worm-drive mechanism disposed for rotating the rod. A stop is anchored to the bottom of the vault for engaging the first ends of the bollards when the bollards are in the raised position.

Owner:TURPIN ROBERT R +1

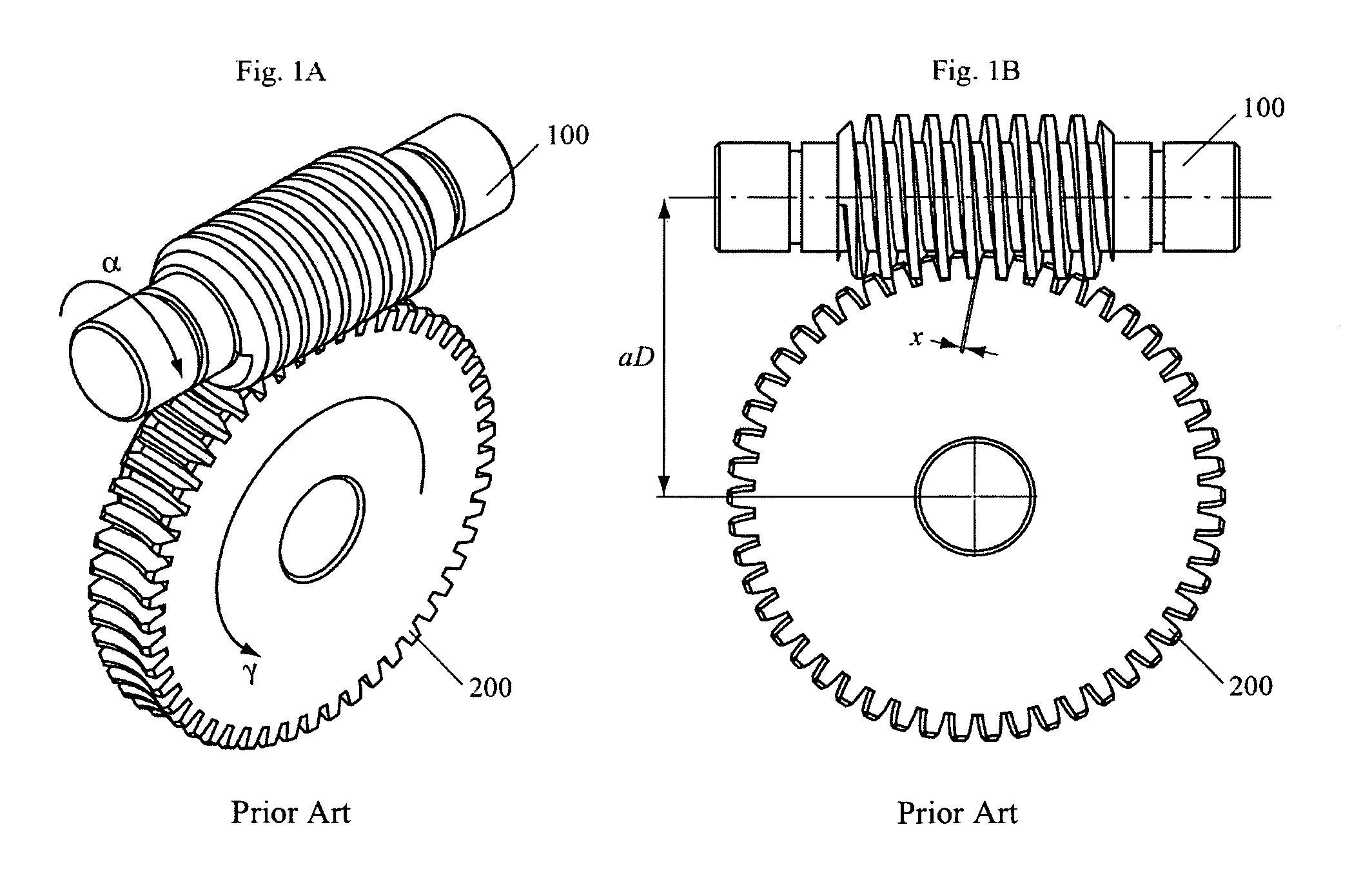

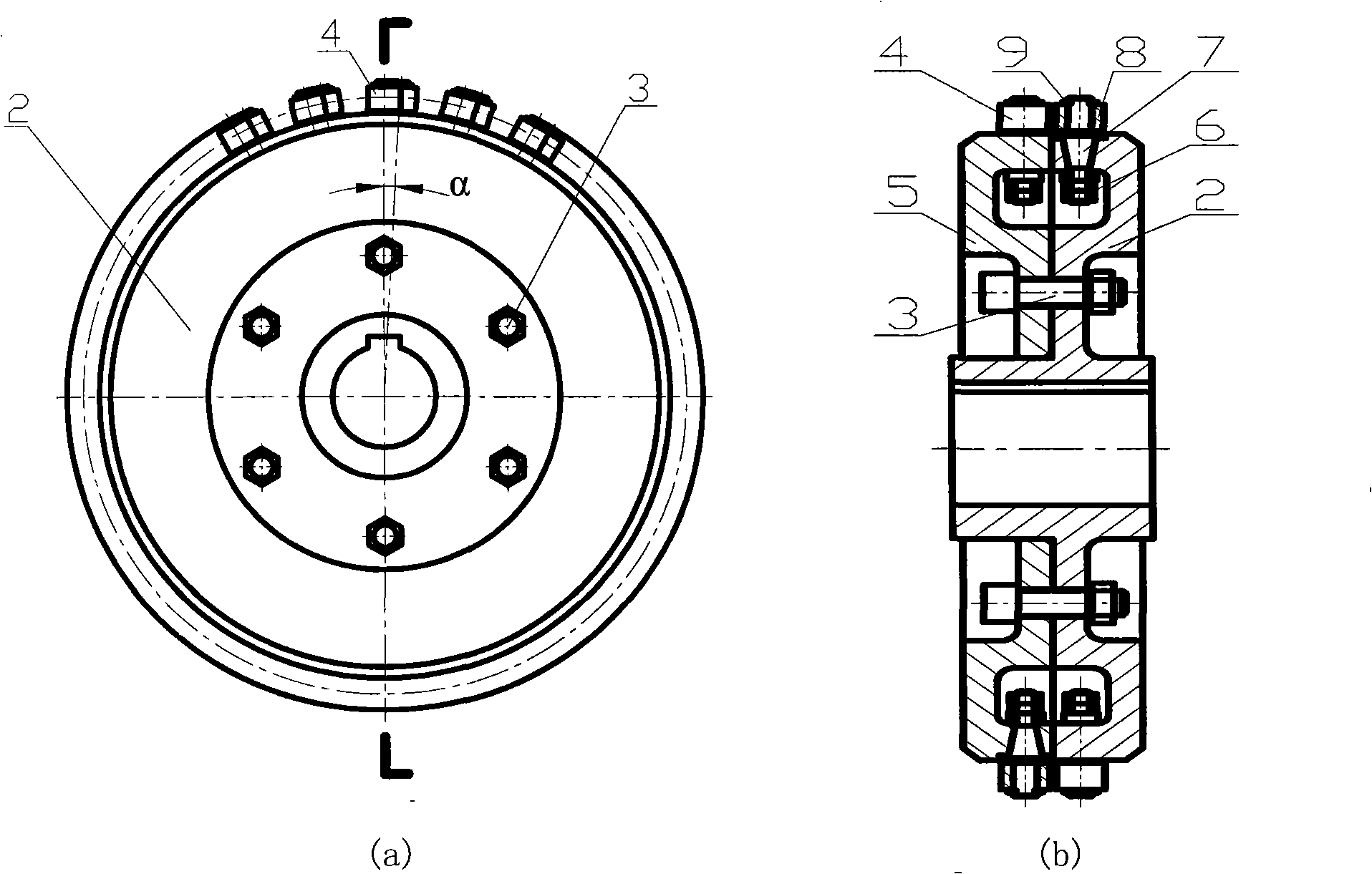

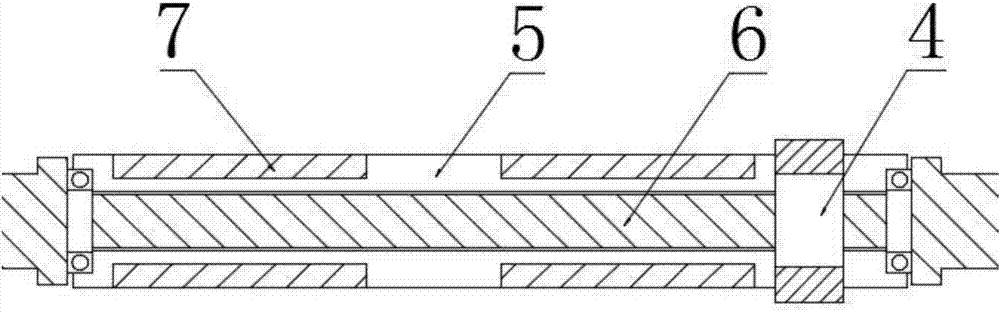

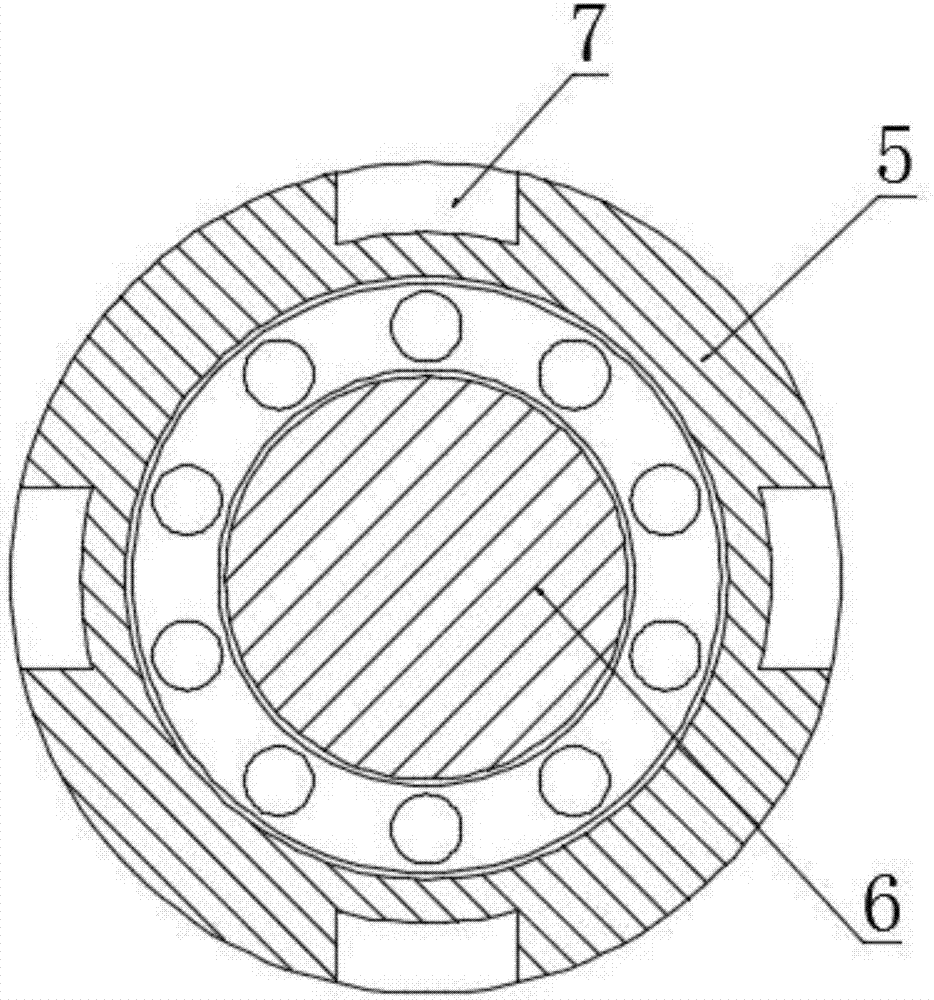

Lateral clearance-free double roller enveloped worm transmission device

InactiveCN101290042AEase of precision manufacturingImprove carrying capacityToothed gearingsPortable liftingRight flankWorm drive

The invention discloses a backlash-free double rollers enveloping worm gear, a worm wheel of the transmission mechanism comprises two half worm wheels, the rollers are uniformly distributed in circumferential direction of each half worm wheel, the rollers rotate on the rotation axes; the two rows of rollers are arranged alternatively, wherein, one row of the rollers are engaged with left flank of the worm, the other row of rollers contact the right flank of the worm; the left and right flanks of the worm are respectively enveloped by rollers which are arranged at appropriate positions on the top and bottom of the main plane; through the adjustment of the mounting positions of the two half worm wheels, the rollers can always be in contact with the flank of the worm ,so as to achieve no backlash transmission. The transmission mechanism eliminates the return error of the transmission, makes the transmission smooth and improves the accuracy of transmission. The invention has the advantages of simple structure, easy manufacture, low cost and good economy, is a novel worm transmission device combining precision transmission and power transmission, is capable of being used for precision indexing, precision transmission and precision power transmission.

Owner:XIHUA UNIV

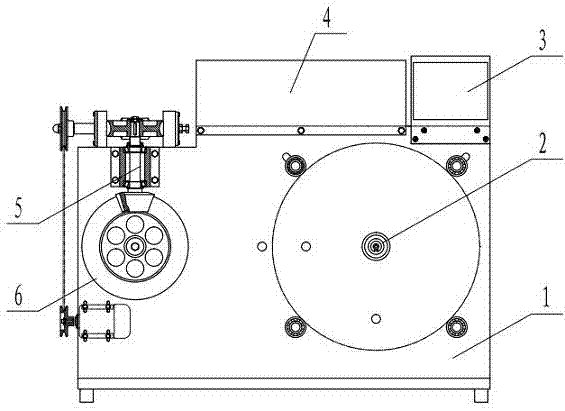

Automatic pipeline cleaner and application method thereof

InactiveCN103042010ASolve the disadvantage of only cleaning one sideAvoid the disadvantages of cleaning only one sideHollow article cleaningElectric machineryProcess engineering

The invention discloses an automatic pipeline cleaner and an application method thereof. The automatic pipeline cleaner comprises clamp mechanisms, a telescoping mechanism and a cleaning mechanism. The upper clamp mechanism and the lower clamp mechanism are mounted at two ends of the telescoping mechanism. The cleaning mechanism is mounted on the clamp mechanisms. The automatic pipeline cleaner specifically comprises a left claw, a right claw, a fixed support, a connecting rod, a drive rod, a clamp motor, a telescoping motor, a first telescoping rod, a second telescoping rod, a screw rod, a pushing plate, a worm gear, a worm, a transmission shaft, a cleaning nozzle and a rubber tube. The clamp mechanism and the telescoping mechanism can climb along a rod while the cleaning mechanism continuously sprays detergent for cleaning. The automatic pipeline cleaner is simple to use, low in technical requirements for workers, high in production efficiency, simple to machine, low in cost, suitable for cleaning of infrastructures such as street lamps, telegraph poles, advertizing board supports and petroleum pipelines, and capable of completing climbing and cleaning.

Owner:ZHEJIANG UNIV

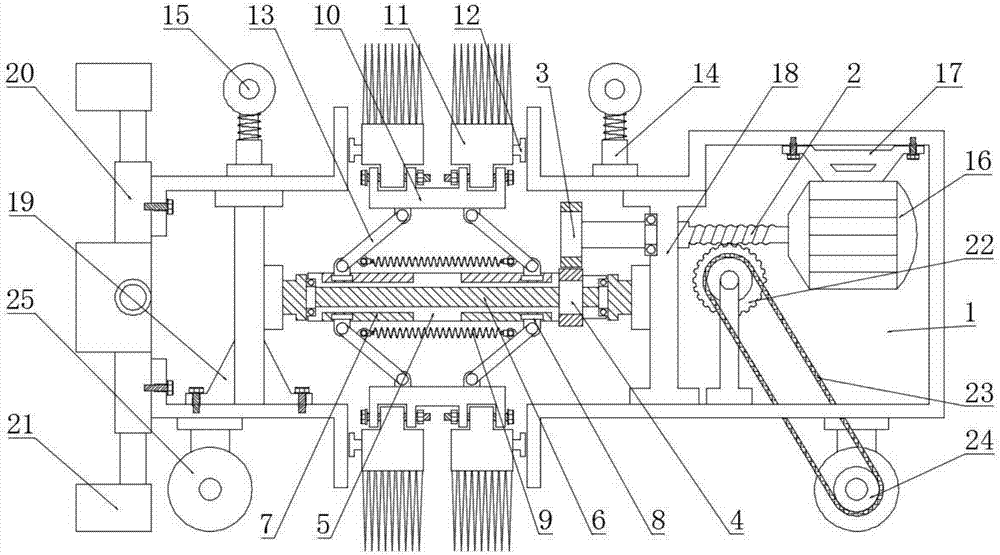

Combined quick-changing type transmission mechanism teaching aid

InactiveCN103247218ALearn more about how it worksQuick installationEducational modelsElectric machineEngineering

The invention discloses a combined quick-changing type transmission mechanism teaching aid, and belongs to the field of education teaching instruments or demonstration tools. The teaching aid comprises a motive power platform and a transmission mechanism, wherein the motive power platform comprises a vertically arranged fixed panel; a motor, a worm and gear component, a bevel gear component, a chain wheel and an output shaft are arranged on the fixed panel; the worm and gear component is positioned right above the motor and is connected with a motor belt; the worm and gear component is in shaft connection with the bevel gear component; the chain wheel and the bevel gear component are arranged relative to the fixed panel and are in shaft connection with each other through the bevel gear; the chain wheel is connected with the output shaft through a chain; and the output shaft is connected with the transmission mechanism. Tape transmission, worm and gear transmission, bevel gear wheel transmission and chain transmission are performed on the motive power platform. Through the adoption of the various combinations, the teaching aid has the advantages that various experimental demonstrations such as gear train, crank connecting rod and sliding block and gear show processing can be realized; the experimental devices can be demounted and mounted quickly; and the mechanical transmission experiment teaching is facilitated.

Owner:廊坊职业技术学院

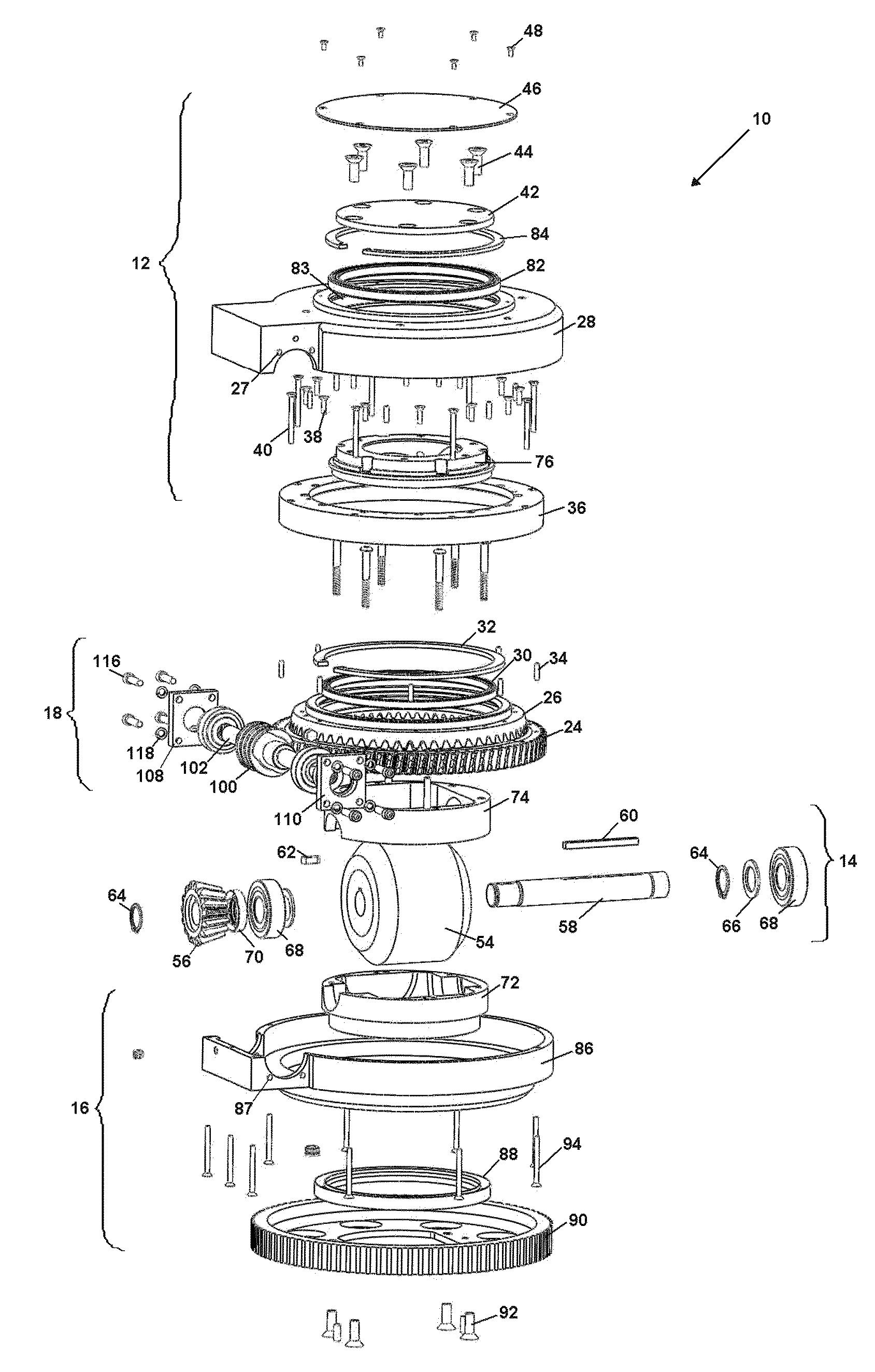

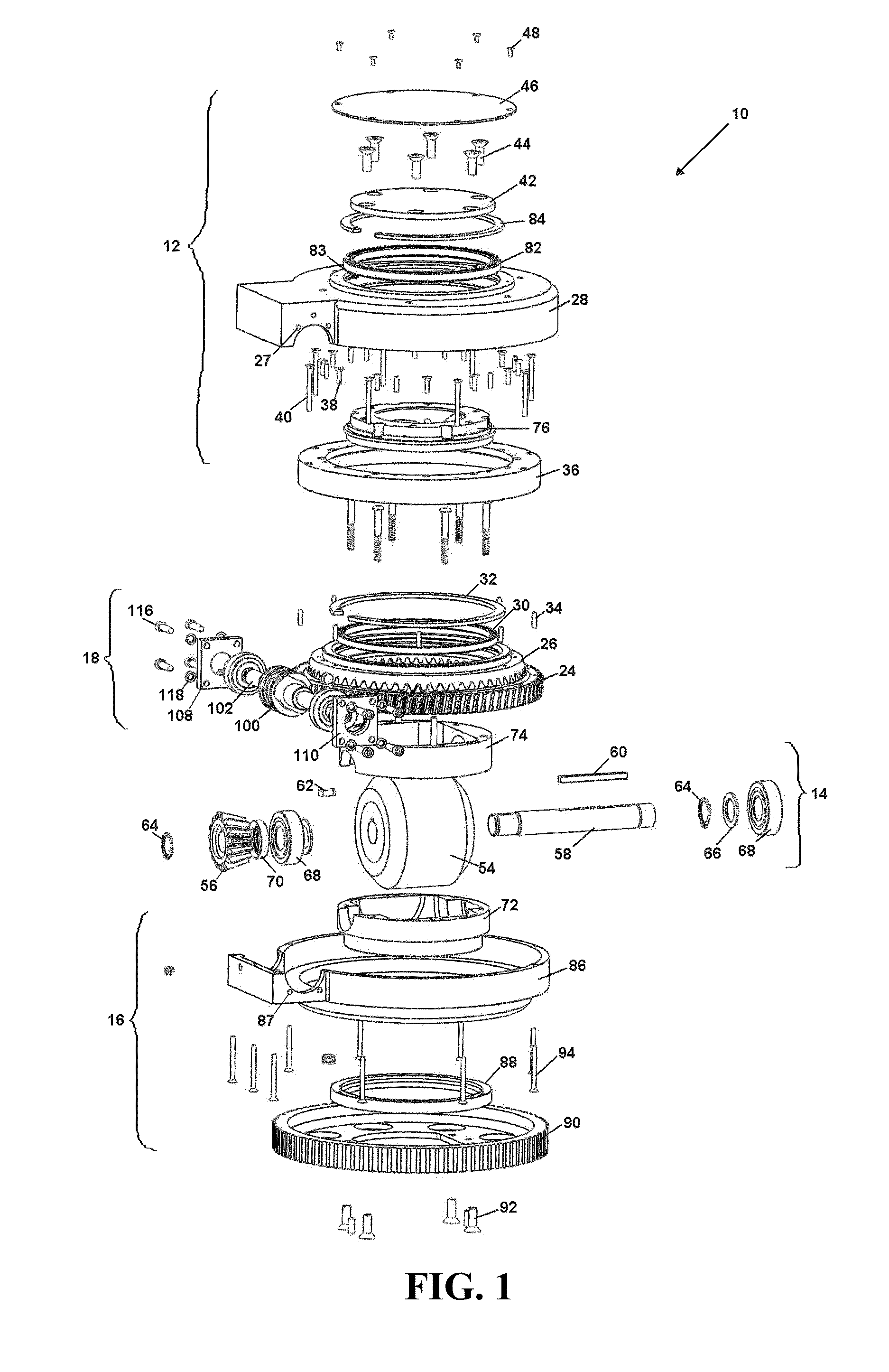

Omnidirectional drive and steering unit

ActiveUS20100181136A1Increase load capacityImprove mobilitySteering linkagesVehicle position/course/altitude controlDrive wheelGear wheel

A compact, low profile omnidirectional drive and steering unit that, in one embodiment, utilizes a single, centrally located wheel, mounted on a drive shaft, upon which is also mounted a tapered pinion gear. The pinion gear on the drive shaft meshes with a ring shaped beveled worm gear contained within the outer housing of the gear unit that surrounds the centrally located wheel. At one side of the outer housing is a worm drive that meshes with the ring shaped and beveled worm gear. Rotation of the worm drive causes rotation of the ring shaped worm gear, which causes the drive shaft mounted pinion gear to turn, which turns the drive wheel to provide driving power for whatever vehicle or system of which the unit is a part. A steering and timing gear is mounted on the lower surface of the unit to provide steering capability.

Owner:BOOMERANG SYST INC

Overhead storage device

An overhead storage device includes a storage container that is pivotably or rotatably mounted to an overhead surface, such as a ceiling or a plurality of rafters. The storage container is generally moved by a motorized actuator assembly. The motorized actuator assembly includes a worm drive and follower nut arrangement. The storage container is supported by a frame assembly and is secured to the frame assembly generally at an end of the storage container. The frame assembly also includes a plurality of arms that secure the storage container to the frame assembly. The overhead storage device is sized to allow a motor vehicle to fit below a raised storage container in an average height garage. The storage container is assembled from two generally identical halves that are nestable for shipping and storage.

Owner:NOTT BRUCE E

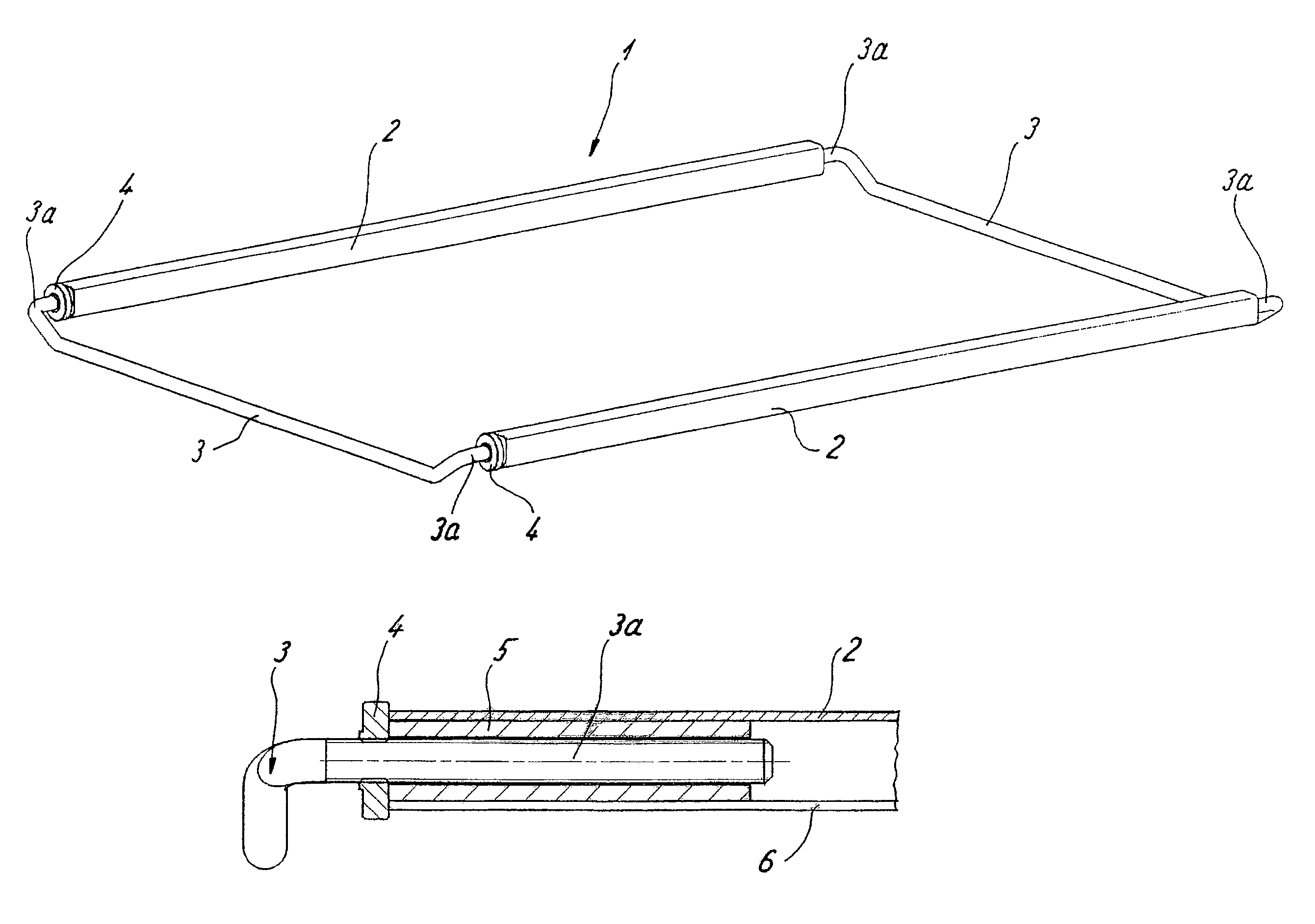

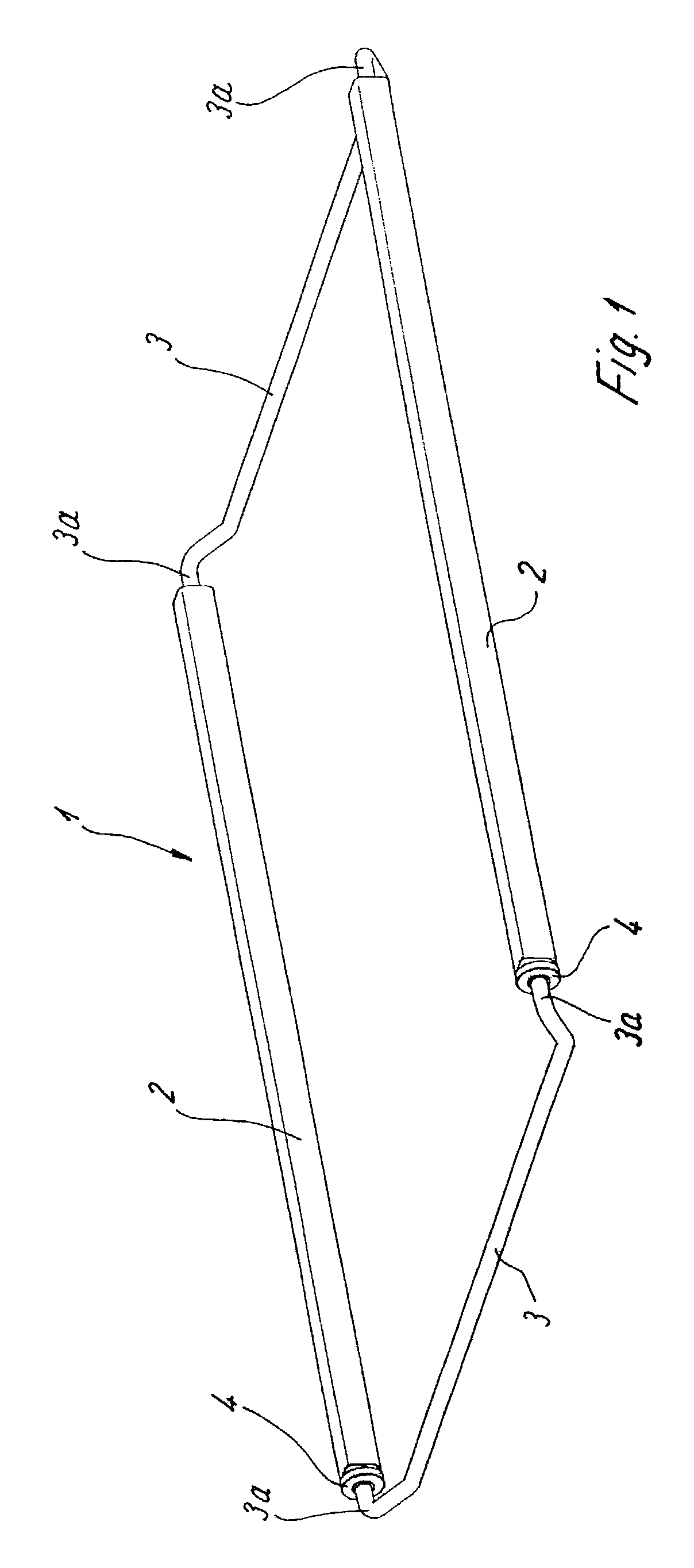

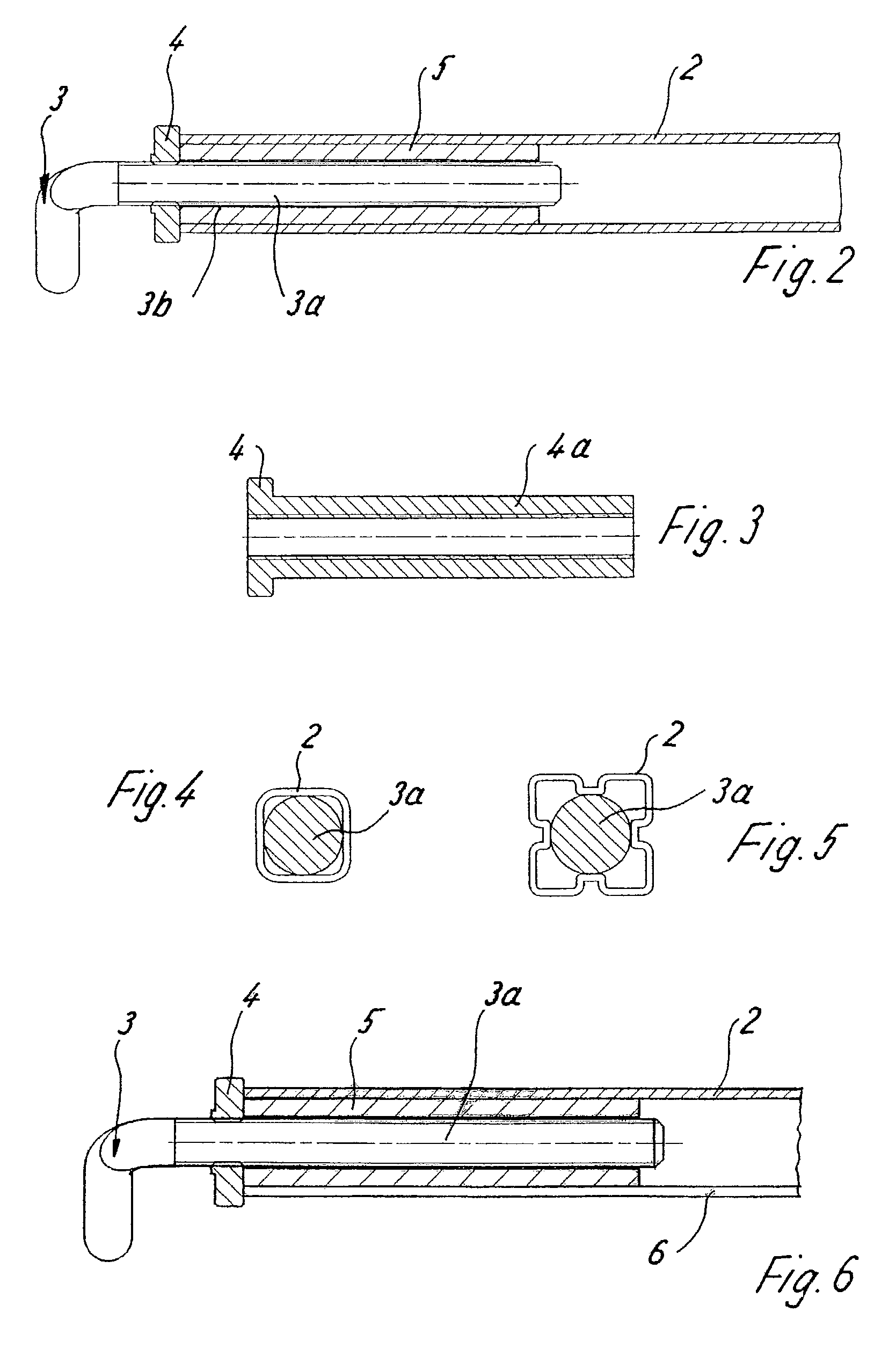

Width-adjustable carrier frame usable in household appliances, particularly in cooking and baking ovens

InactiveUS6976597B2Domestic stoves or rangesStoves/ranges shelves or racksCooking & bakingEngineering

A width-adjustable carrier frame for receiving and supporting a grilling rack, a tray, a dish, a cooking or baking sheet, or the like of an oven. The carrier frame consist of at least two cross members with tube-type front-side end areas and two approximately U-shaped carrying bows. At least one carrying bow is continuously adjustable relative to the cross member by a worm drive.

Owner:PAUL HETTICH

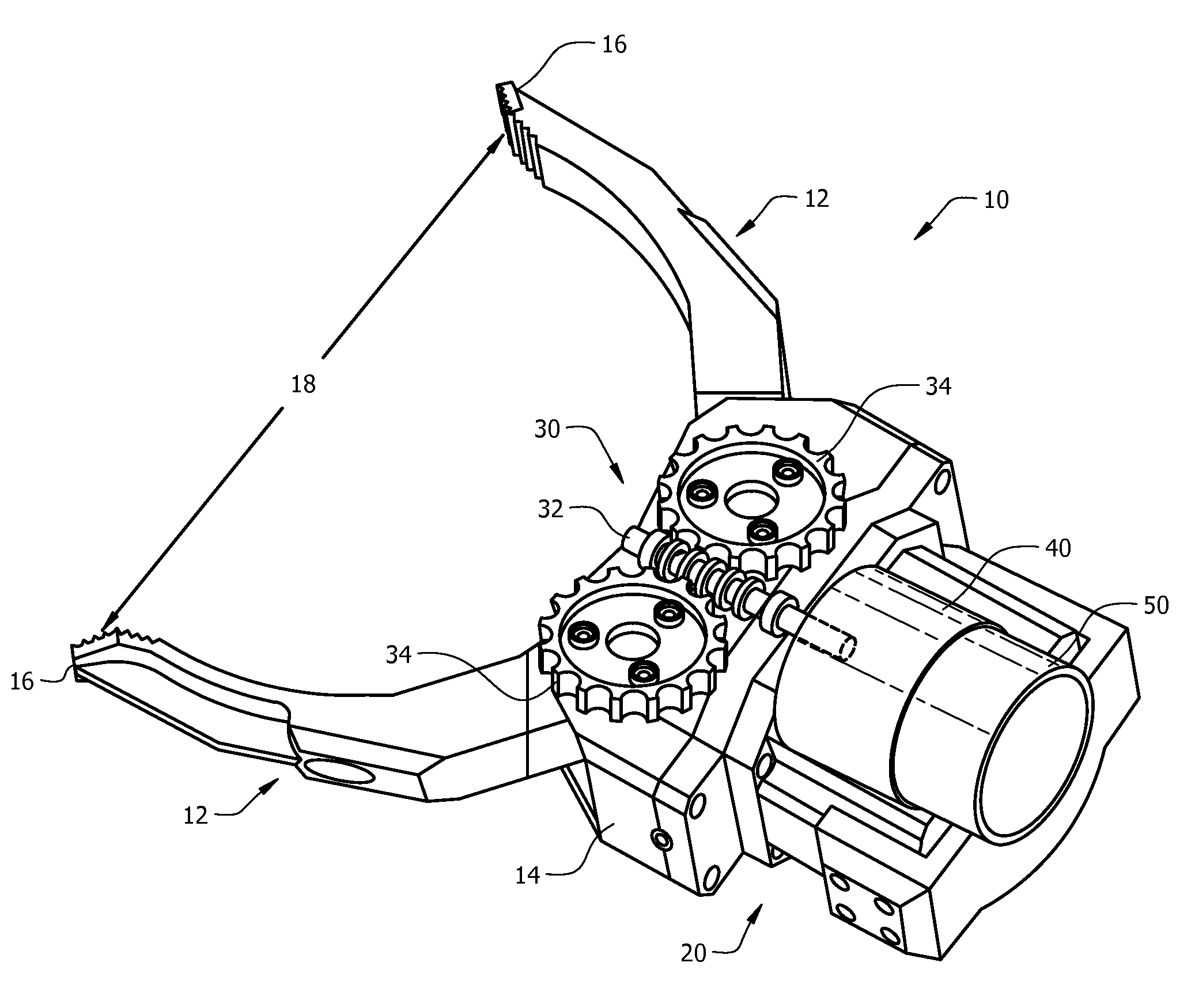

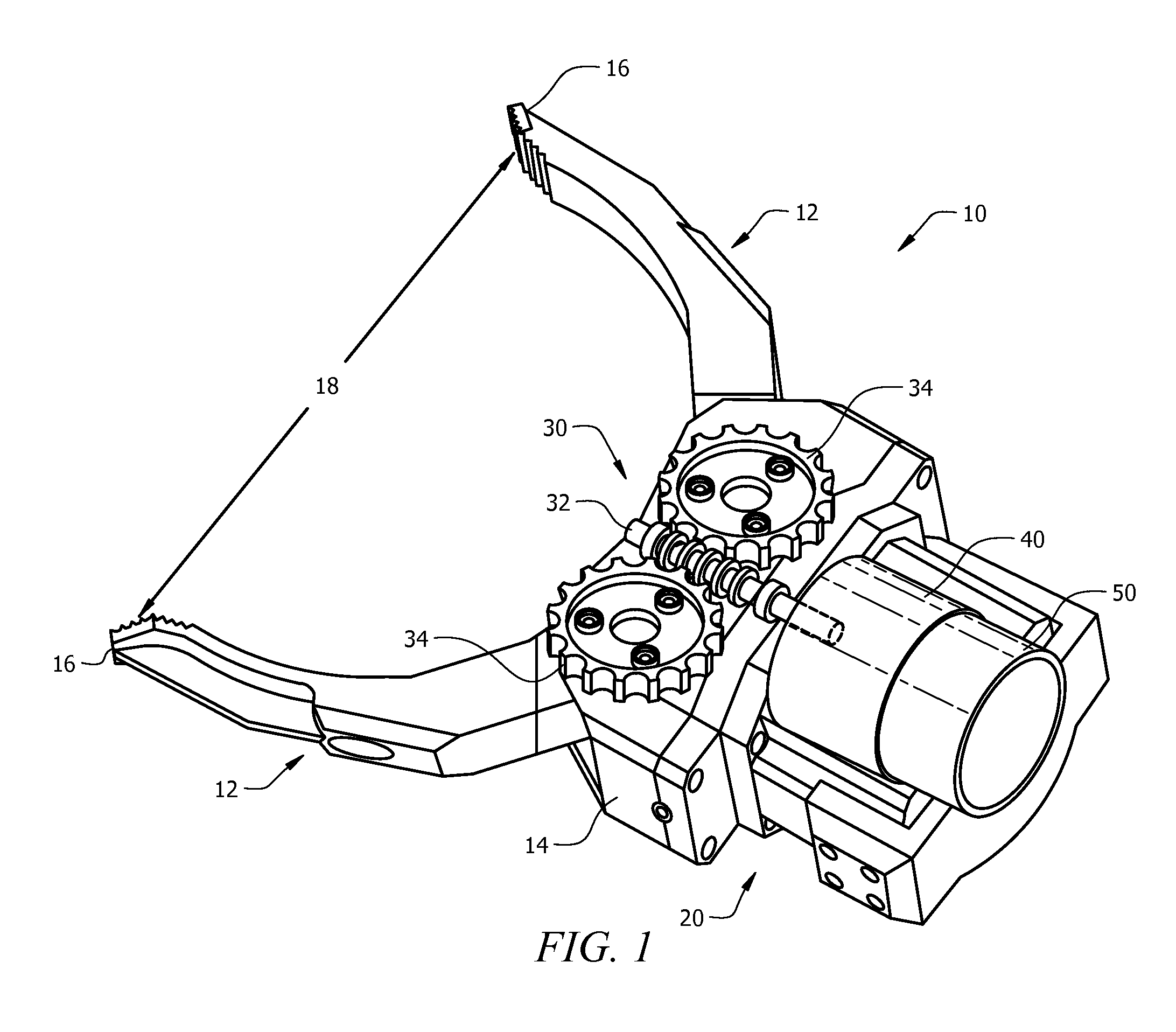

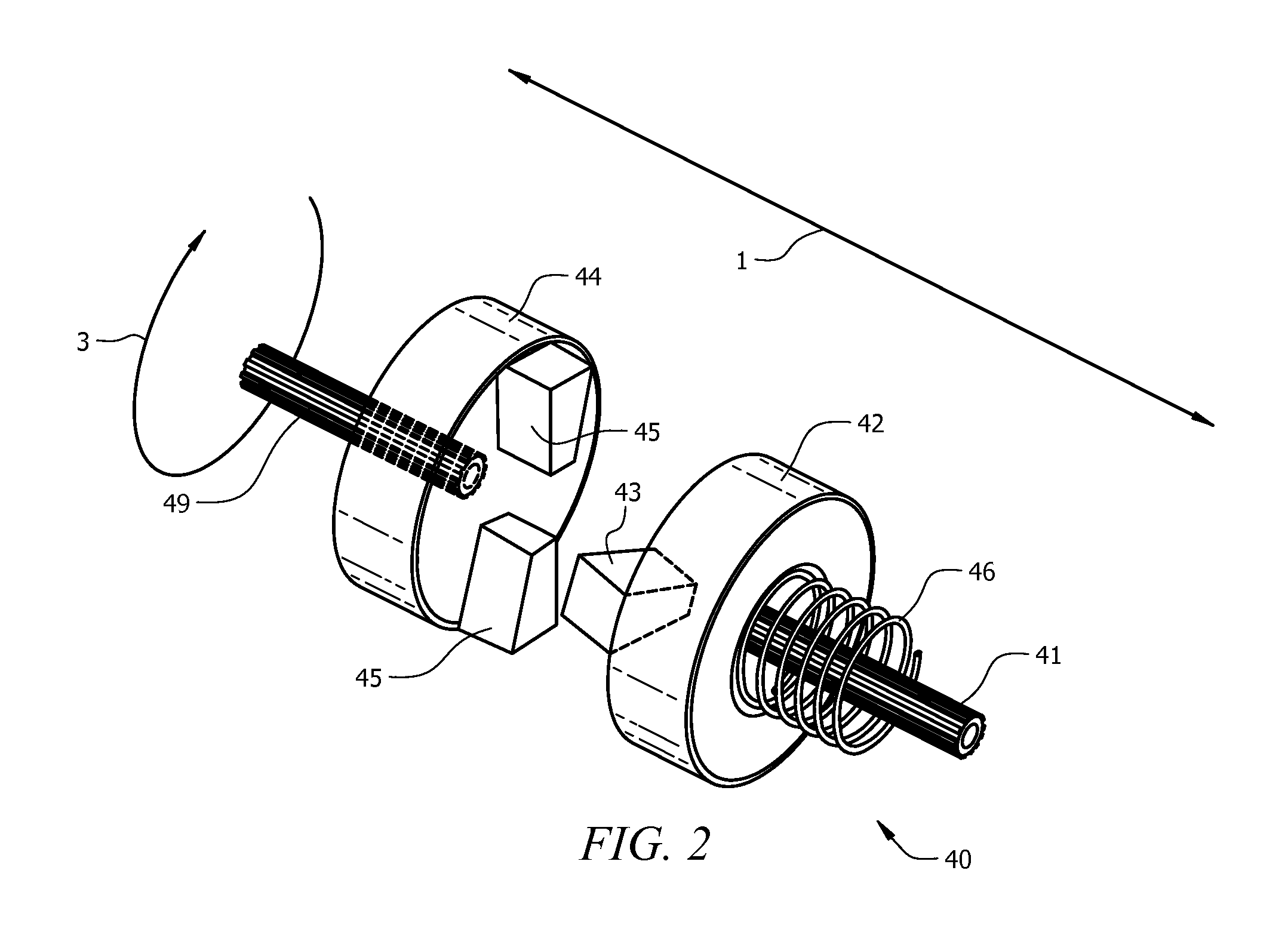

High-force robotic gripper

A robotic gripper (10) has fingers (12) that are configured to grasp an object, and an actuator (20) for driving the fingers. The actuator has a drive train (30) connected to the fingers for driving the fingers, an impact mechanism (40) mechanically connected to the drive train for driving the drive train, and a motor (50) connected to the impact mechanism for driving the impact mechanism. The impact mechanism generates a series of impacts that are delivered to the drive train when the impact mechanism is loaded beyond a threshold torque. The drive train is a back-drive inhibited drive train provided by a worm drive (32, 34) that is mechanically coupled to the impact mechanism.

Owner:HARRIS CORP

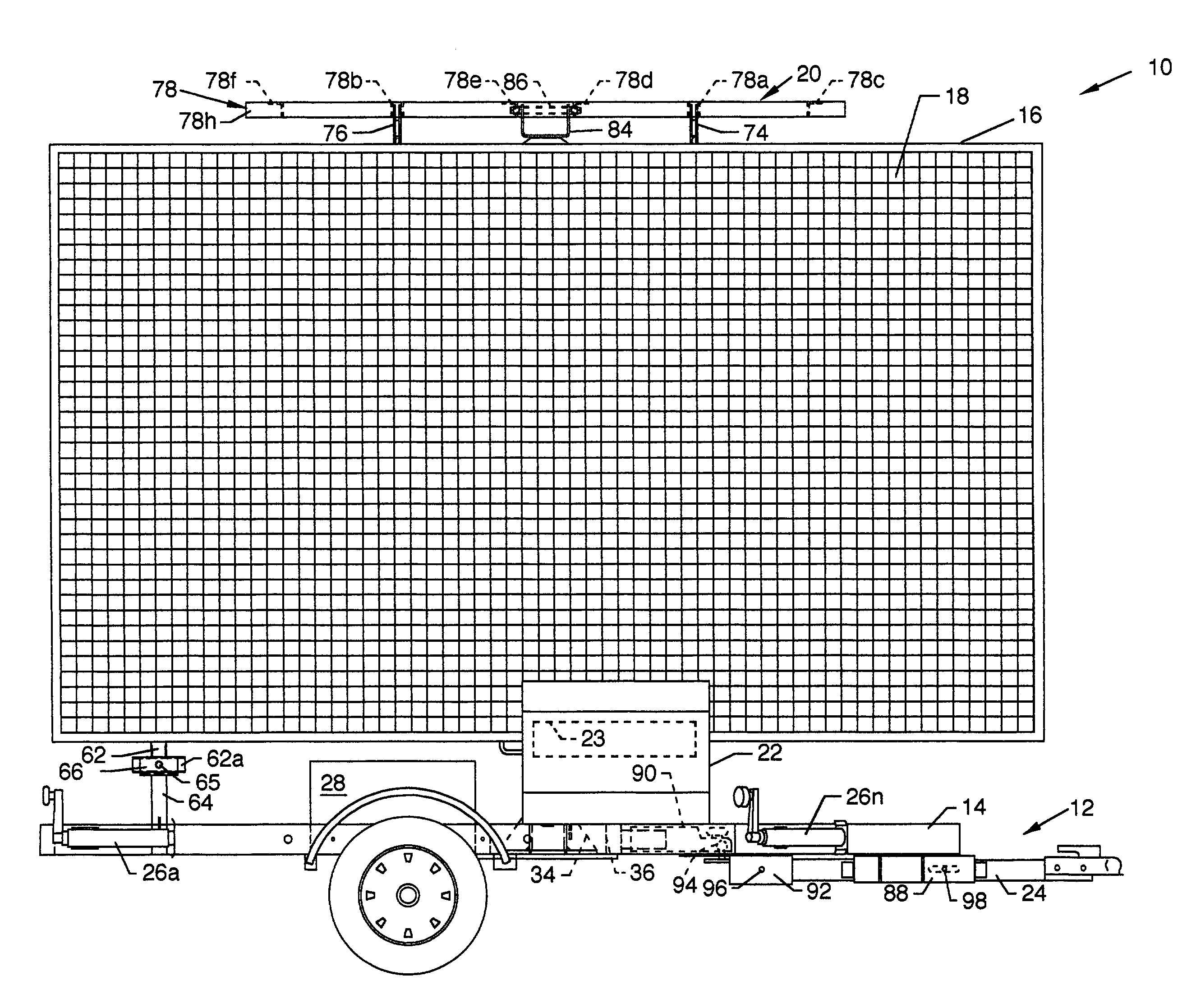

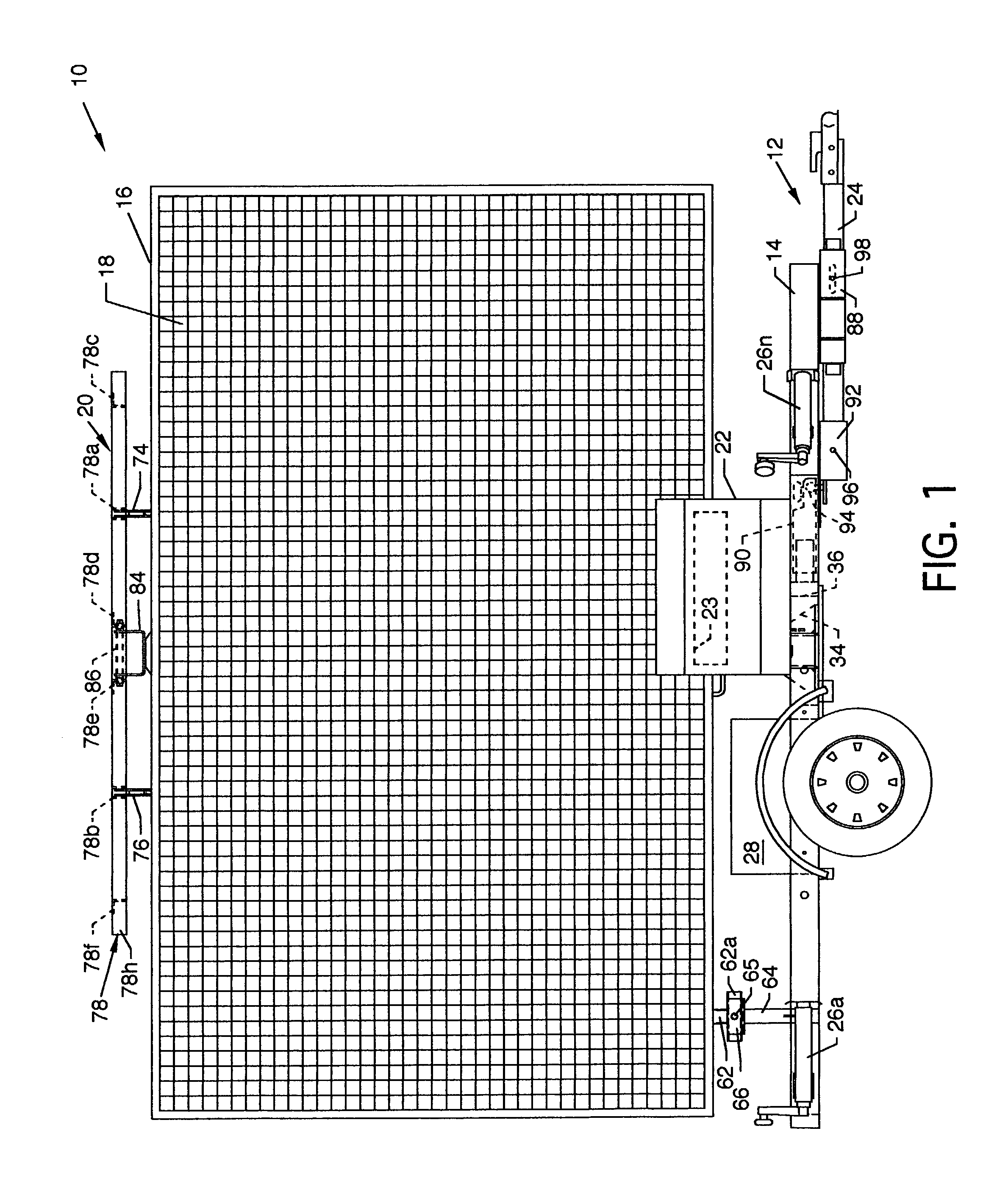

Portable sign system

InactiveUS6972689B1Avoid accidental rotationProvide stabilityRoad vehicles traffic controlElectric/electromagnetic visible signallingGear driveRemote control

A portable sign system being self-contained and having a digital display panel which can be hydraulically raised to a suitable height and subsequently be rotated by a worm gear which is manually driven or electrically driven by a motor. A broad based upper assembly having an UHMW plastic stabilizing plate and rotation plates and attached worm gear drive serves as a rotatable and stabile mount for a digital or other display panel and an attached solar array. The digital display panel is automatically locked in azimuthal position by the worm gear drive without a conscious operator effort. Azimuth orientation of the digital display panel can be effected by a hand crank, manually by an electrical switch, automatically by an onboard computer control or by remote control.

Owner:DAKTRONICS

Overhead storage device

An overhead storage device includes a storage container that is pivotably or rotatably mounted to an overhead surface, such as a ceiling or a plurality of rafters. The storage container is generally moved by a motorized actuator assembly. The motorized actuator assembly can comprise a worm drive and follower nut arrangement or a flexible transmitter and spool assembly. The storage container is supported by a frame assembly and is secured to the frame assembly generally at an end of the storage container. The overhead storage device is sized to allow a motor vehicle to fit below a raised storage container in an average height garage. The storage container is assembled from two generally identical halves that are nestable for shipping and storage.

Owner:NOTT BRUCE E

Municipal administration pipe cleaning device

InactiveCN107470286AImprove cleaning efficiencyReasonable structural designHollow article cleaningGear wheelEngineering

The invention discloses a municipal pipeline cleaning device. A driving motor is arranged on the upper part of the right end of the device body. The left end of the driving motor rotates and connects to a worm. The left end of the worm is fixedly connected to a driving gear. Rod; the inner sleeve of the sleeve rod is connected to the connecting shaft, and the outer ring of the bearing is fixedly connected to the sleeve rod; the surface of the sleeve rod is fixedly connected to the bar-shaped guide groove, and the bar-shaped guide groove is slidably connected to the sliding block, and the sliding block is hinged to the end of the connecting rod, and the middle part of the connecting rod is hinged The limit spring, the bolt at the upper end of the movable base is fixedly connected with the cleaning brush, the left end of the device body is fixedly connected with the spring telescopic rod, and the end of the spring telescopic rod is fixedly connected with the spatula. The device drives the cleaning brush outwards to clean the inner wall of the pipeline through the worm, and the left end of the device body is also provided with a retractable spatula to clean the garbage on the inner wall of the pipeline. The structural design of the device is reasonable and applicable, which greatly improves the cleaning efficiency of municipal pipelines, and has a high degree of automation.

Owner:六安市金安区一元通包装设计中心(普通合伙)

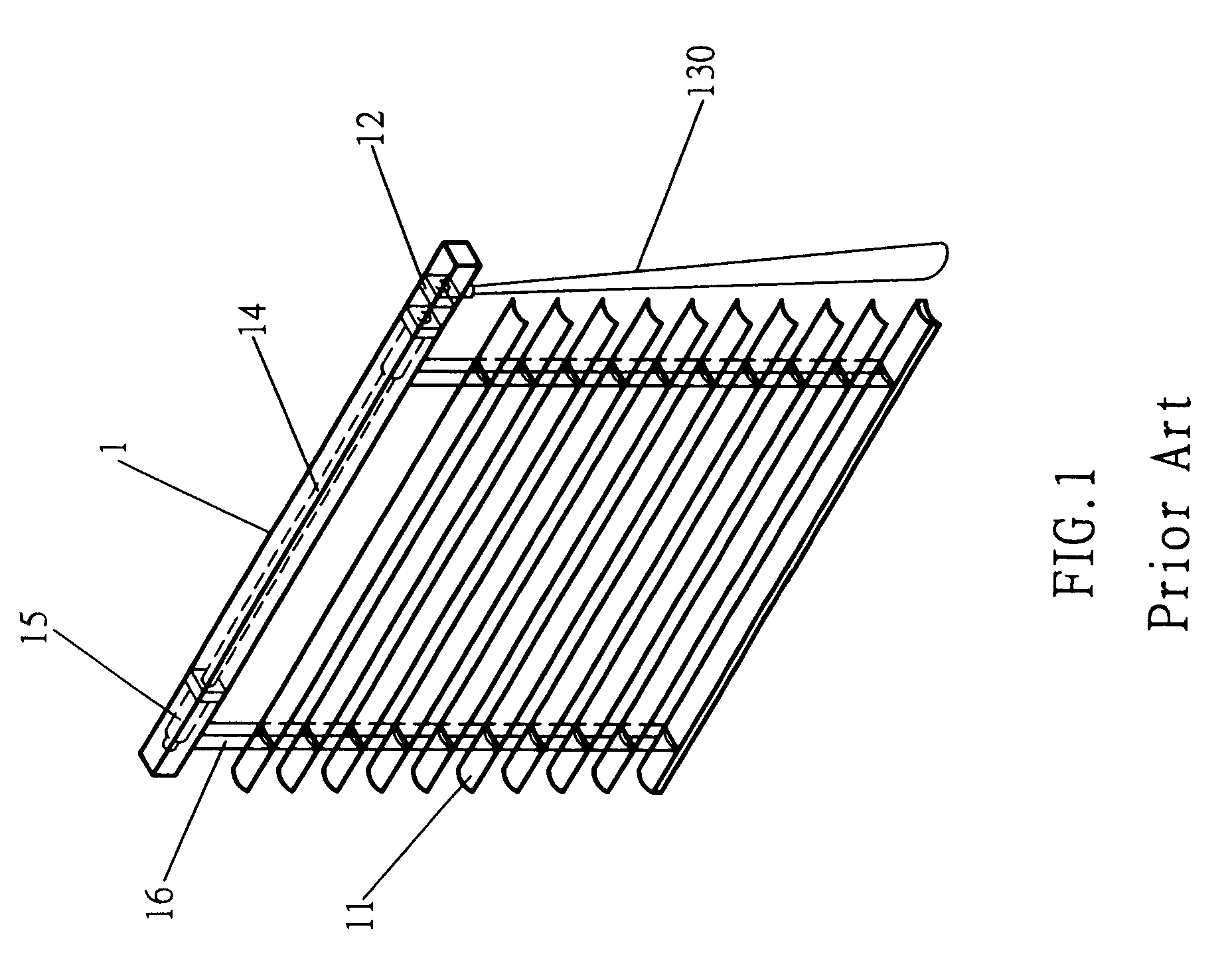

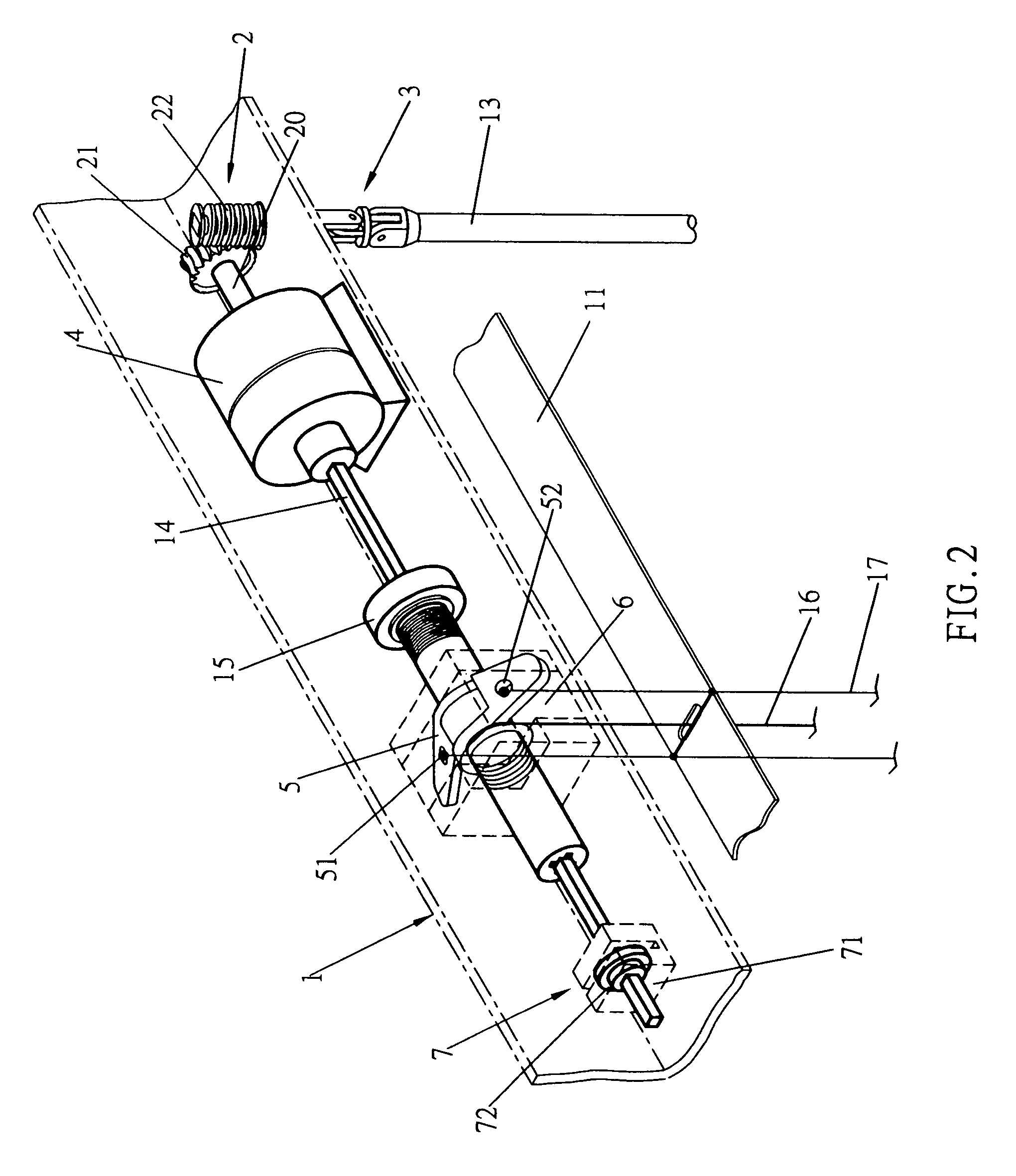

Curtain blind take-up drive mechanism with non-slip effect

InactiveUS6910516B2Avoid dangerSimple and easy and facilitating changeLight protection screensCouplingDrive shaft

A curtain blind take-up drive mechanism with non-slip effect having a freehand turn operation. The non-slip effect is configured to prevent slats of the blind from slipping down, and further includes coupling a power end of a drive shaft to a reel. The drive shaft connects to a worm gear via a transmission amplifier. The worm gear is actuated through reciprocally engaging with a worm driven via a flexible shaft coupling and through operation of a slat tilt rod. Reciprocal teeth meshing and teeth surface pressure between the worm gear and the worm achieves a high slip-rate, and thereby inhibits reverse transmission, thus accomplishing a reverse direction stoppage effect, and further producing a large frictional force and forming a surface-pressure slip effect thereof. The transmission amplifier allows the drive shaft to achieve a high rotational speed, thereby facilitating freehand operation for taking-up and letting-down of the slats.

Owner:HUANG SHIEN TE

Symmetrically adjustable corrosion-resistant battery cable connector

InactiveUS20050106952A1Easy to installEasy to removeSnap fastenersClothes buttonsElectricityElectrical conductor

An electromechanical connector for use between a power source such as a battery and a device requiring the power such as an automotive electrical system. In some embodiments, the connector includes a radius electrical contact constituting a primary electrical current path, and a band clamp with a slotted band constituting a secondary current path, and a worm drive adjustment assembly for symmetrically tighten the connector to the battery post. A kit is described having an electrical-contact conductor with a concave surface conforming to a battery post, and a band clamp to symmetrically compress the conductor against the post. Some embodiments provide a conductor that conforms to an outer portion of the post, and includes a band clamp mechanism with a band fixed at a non-moving end to the conductor, and at an opposite slotted end interfacing to a worm screw held against the conductor.

Owner:MECHANICAL ANSWERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com