Four rollers automatic reeling mechanism in product line of manufacturing ternary cleaner for tail gas of cars

A technology for automobile exhaust and purifier, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inoperable continuous operation, low work efficiency, complex structure, etc., so as to reduce labor intensity, improve production efficiency, bend bending good roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

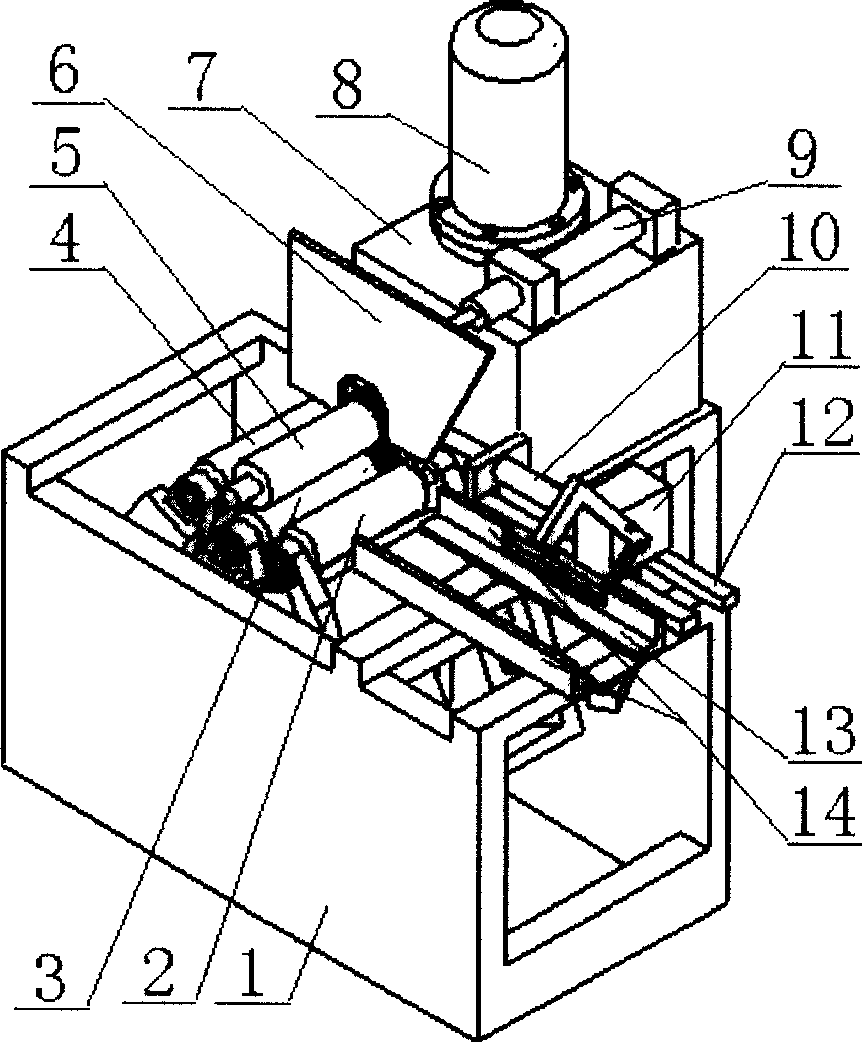

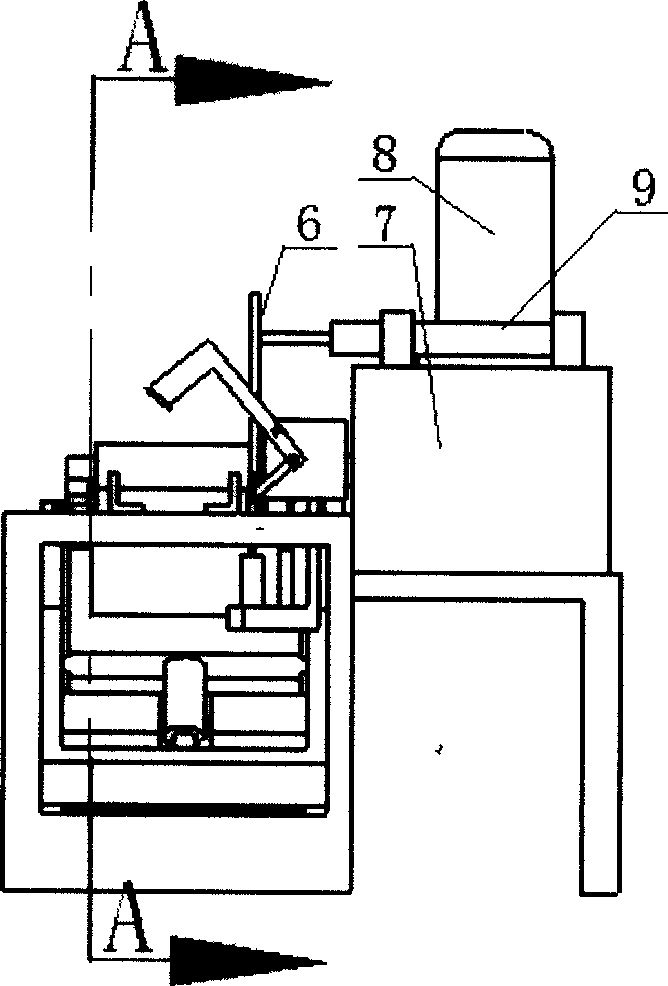

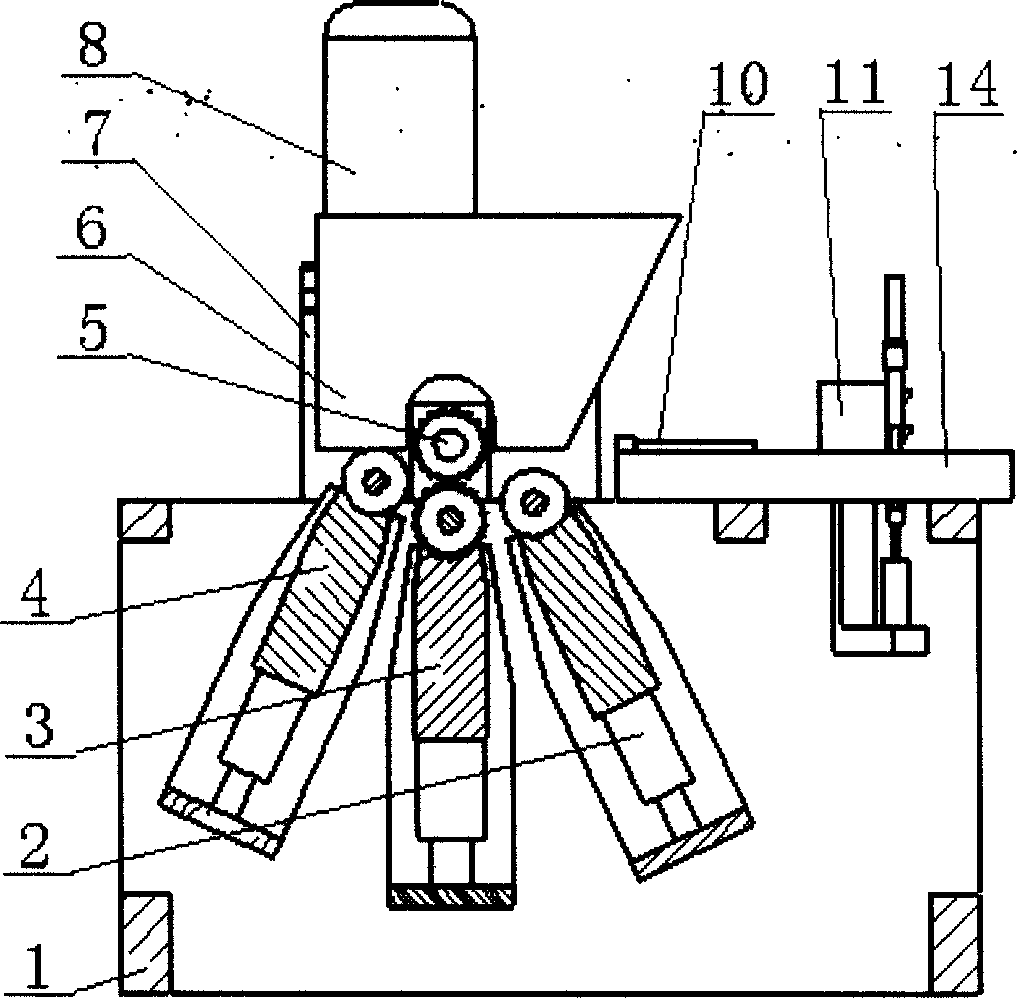

[0020] Such as Figure 1 to Figure 7 As shown, the present invention includes: frame 1, rear roller integration 2, lower roller integration 3, front roller integration 4, upper roller 5, unloading push plate 6, reduction box 7, AC motor 8, unloading cylinder 9, feeding Manipulator mobile cylinder 10, feeding manipulator 11, feeding manipulator moving guide rail 12, feeding guide rail 13, feeding baffle plate 14, upper roller bearing 33. The connection relationship is: the feeding guide rail 13 is welded on the frame 1, and the feeding baffle 14 is located on both sides of the feeding guide rail 13 and is welded on the frame 1. The moving guide rail 12 of the feeding manipulator is welded on the frame 1, parallel to the feeding guide rail 13, the moving cylinder 10 of the feeding manipulator is welded on the frame 1, and is located at one end of the moving guide rail 12 of the feeding manipulator; The end of the push rod is supported on the moving guide rail 12 of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com