Silicon slice fixing part

A technology for fixing components and silicon wafers, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of no structure, description, etc., improve manufacturability, speed up unloading time, and reduce deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Through the following description of an embodiment of the silicon wafer fixing component of the present invention in conjunction with the accompanying drawings, the purpose, specific structural features and advantages of the present invention can be further understood.

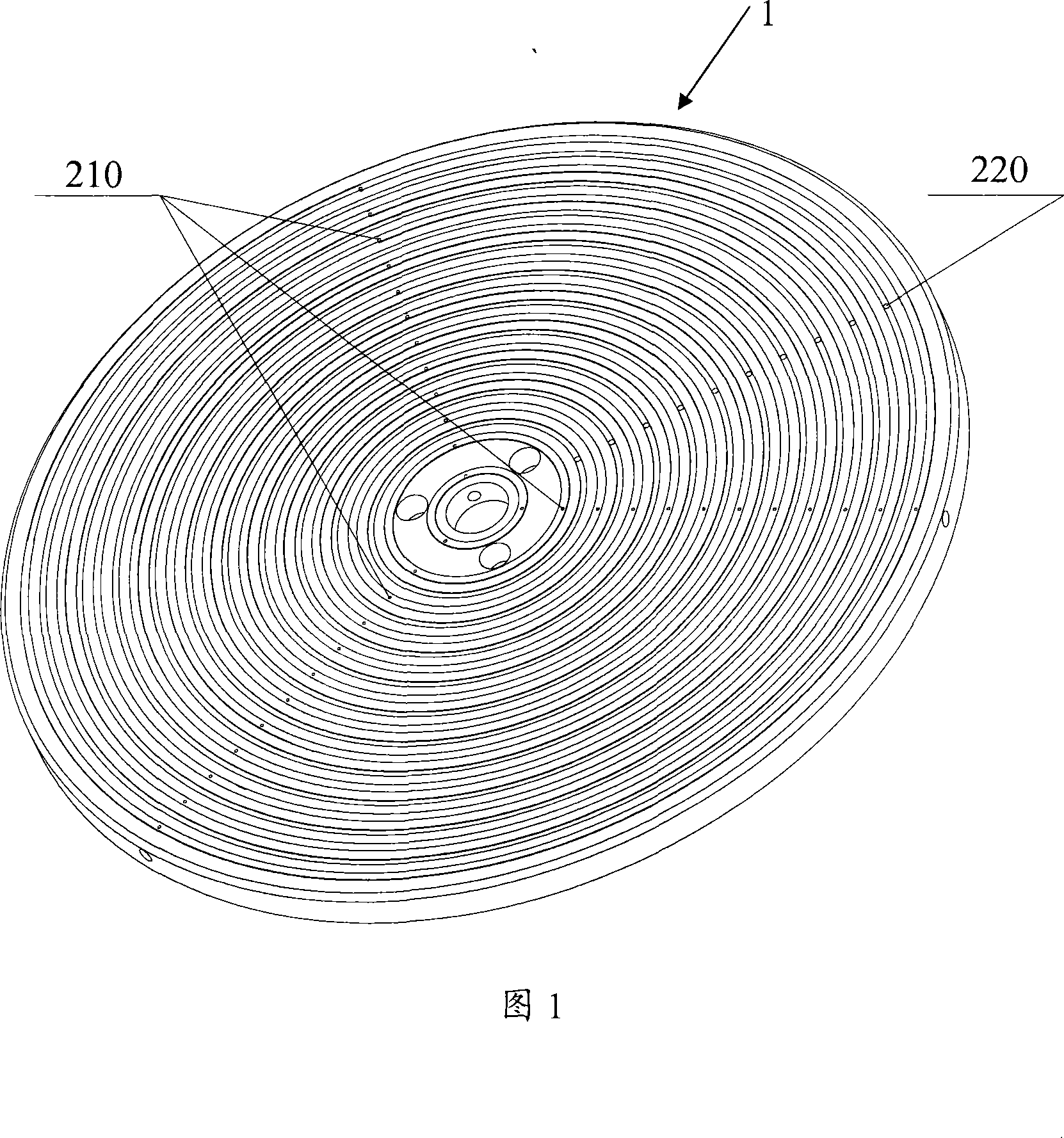

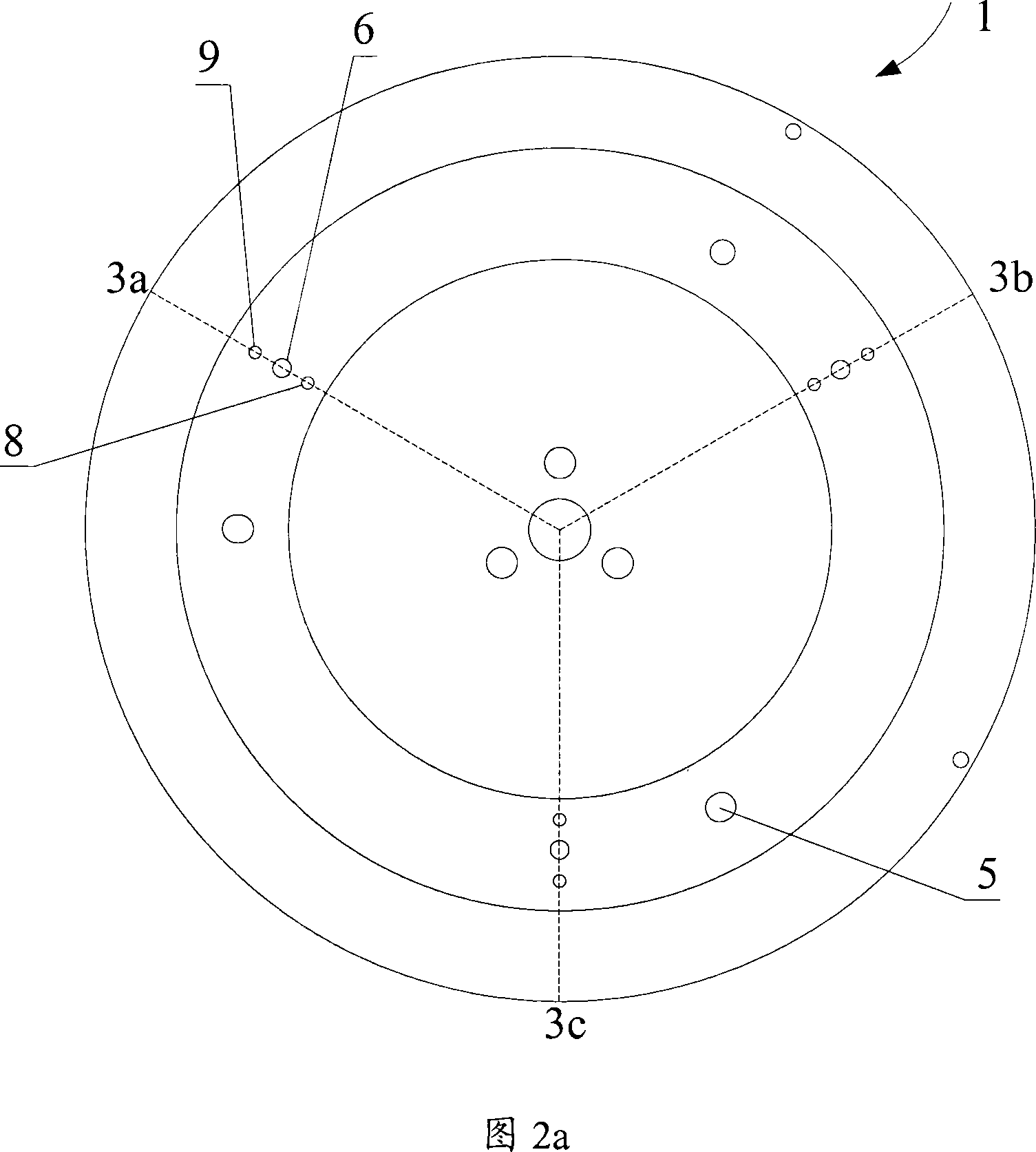

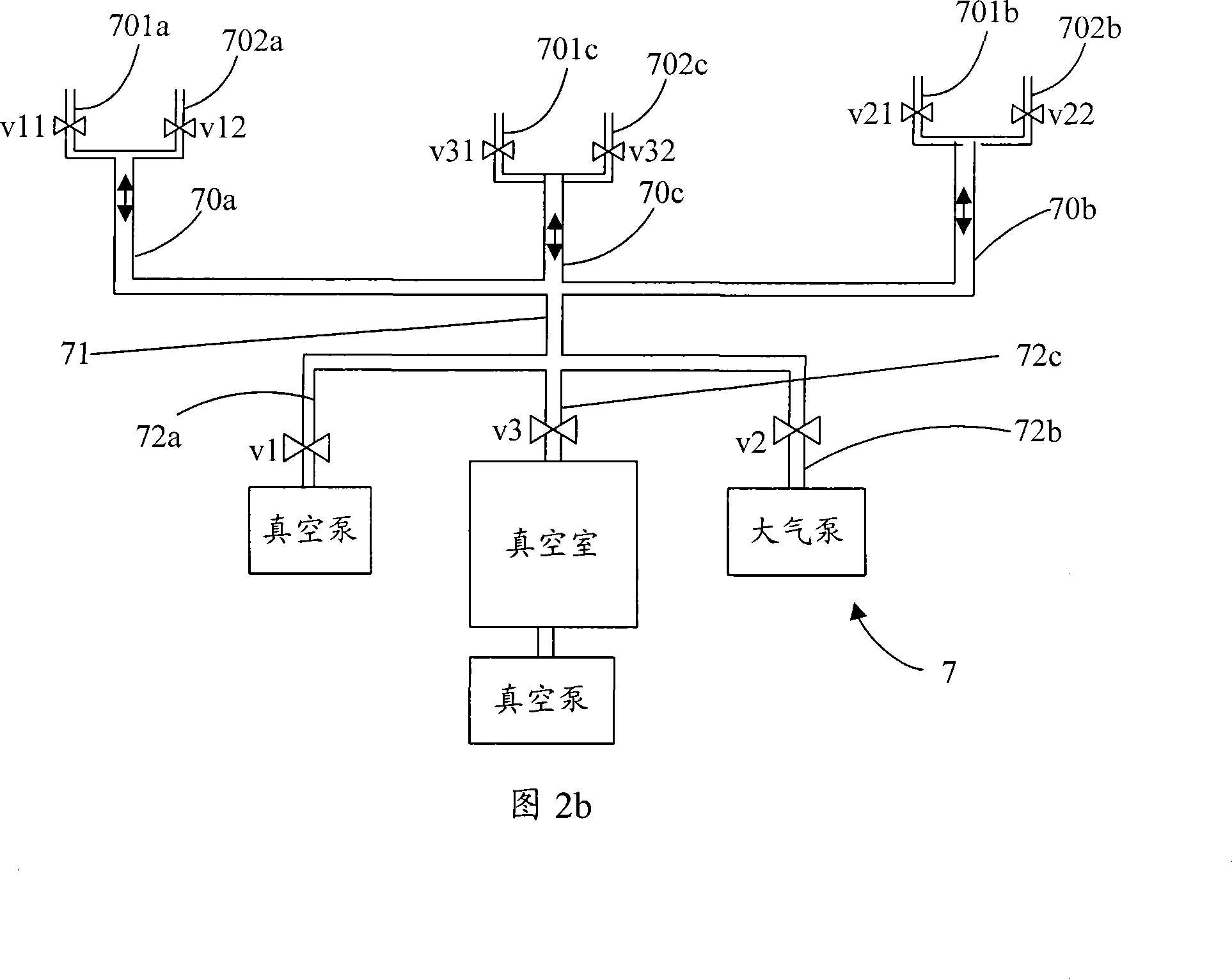

[0020] FIG. 1 is a perspective view of a silicon wafer fixing component 1 provided by the present invention. Please refer to FIG. 1 and in conjunction with FIGS. 3 to 4 , the surface (defined as the adsorption surface) 10 of the silicon wafer fixing component 1 for absorbing silicon wafers is provided with several concentric annular grooves 2 evenly distributed. The depths of the annular grooves 2 are the same, and the cross-sections are designed to be trapezoidal. In this embodiment, an isosceles trapezoid with a base angle of about 45° is adopted. This concave-convex structure reduces the deformation of the silicon wafer fixing part 1 itself, and facilitates processing. By setting the cross section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com