Furnace hearth of maintaining room of aluminum alloy melting furnace built by combining casting materials with precast bricks

A prefabricated brick and aluminum alloy technology, applied in furnaces, furnace components, lining repair and other directions, can solve the problems of irregular shrinkage through seams, gradual bulging, etc., and achieves a simple and fast masonry process, simple production process, and thermal expansion stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

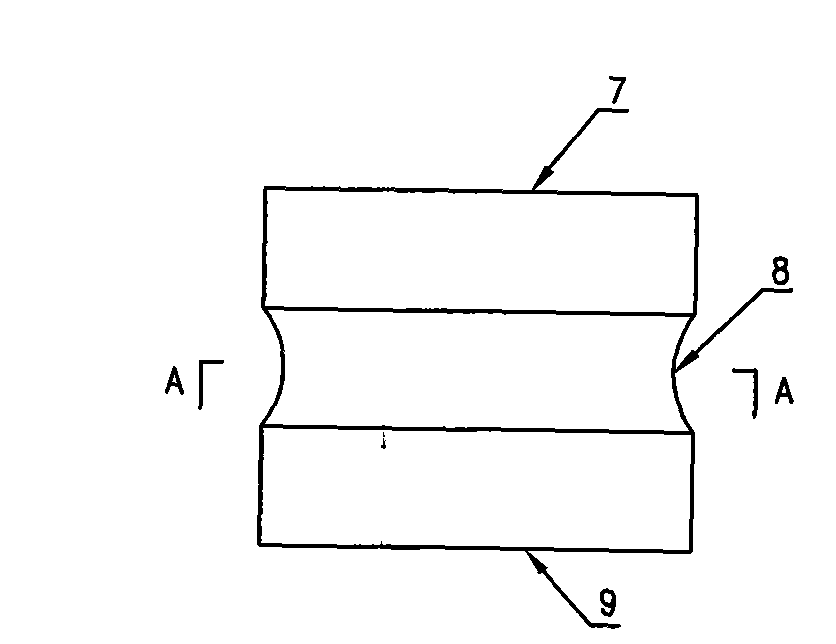

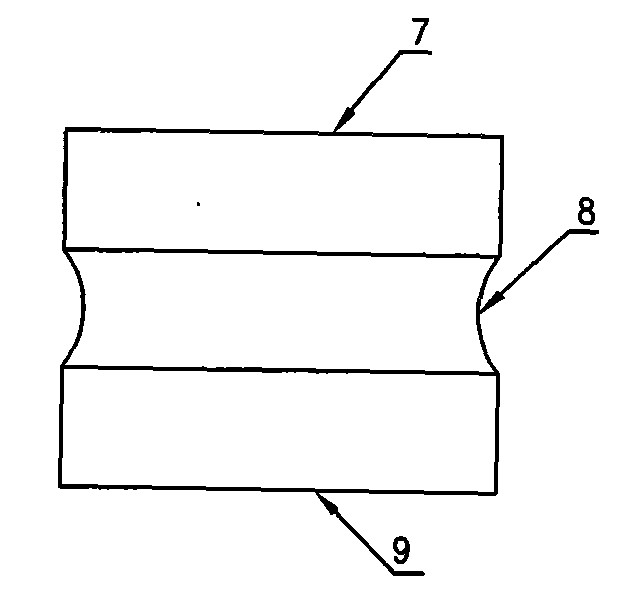

[0019] Such as Figure 5 and Image 6 As shown, the casting material of the present invention is combined with prefabricated bricks to build the aluminum alloy melting furnace holding room hearth, including a heat insulating plate layer 1, a heat insulating brick layer 2, a refractory castable layer 3 and a refractory brick layer 4, in the refractory brick layer 4 The upper part is the molten aluminum contact layer laid by high-alumina castable 5 combined with prefabricated bricks 6. The prefabricated bricks 6 have a circumferential groove 8 reserved in the middle position in the height direction, and are pounded around the prefabricated bricks 6. There is a high-alumina castable 5, and a convex-convex meshing process joint is formed between the prefabricated brick 6 and the high-alumina castable 5 in the vertical direction, and a plum blossom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com