Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Improve masonry quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

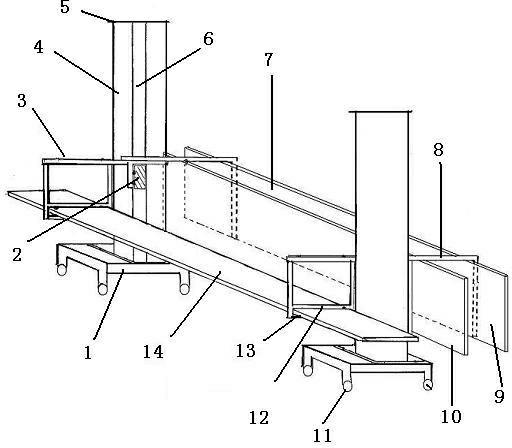

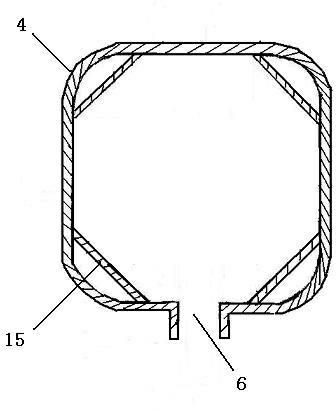

Wall building and painting device

InactiveCN102359282AImprove masonry qualityReduce line adjustmentBuilding material handlingFalseworkArchitectural engineering

A wall building and painting device comprises columns, an operating platform, a building trough, bases, lifting mechanisms and power mechanisms, wherein the cross section of each column is in the shape of a hollow square cavity with arc edges at four corners, a slide way integrally connected with an inner cavity of each column is arranged on one face of the column from bottom to top, an actuating arm integrally connected with the operating platform and a support frame of the building trough is mounted in the inner cavity of each column, one actuating arm forms optional one of the lifting mechanisms with a chain, a screw or a hydraulic lifter, the support is fixed on portions of the actuating arms of the lifting mechanisms extending out of the columns through bolts. The wall building and painting device comprises two sets of lifting mechanisms using columns for support and the support frame, the operating platform is mounted on the lower portion of a frame of the support frame on the same side of the two columns, and the building trough perpendicular to the horizontal plane is fixed on the other side of the two columns. The wall building and painting is applicable to building a wall between an upper-floor room and a lower-floor room, work amount of line adjustment, leveling and erection of a scaffold during construction can be reduced, painting is performed during building, and work efficiency and building quality are improved.

Owner:陈永兴

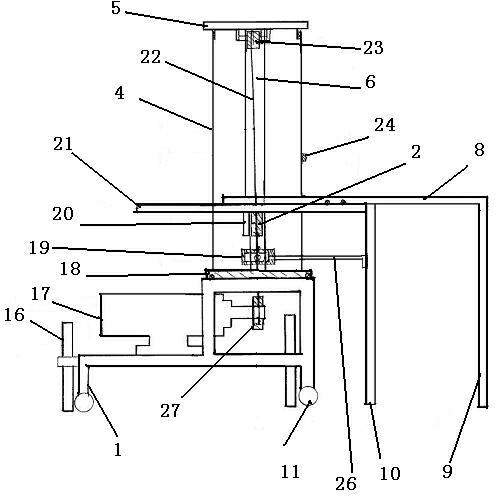

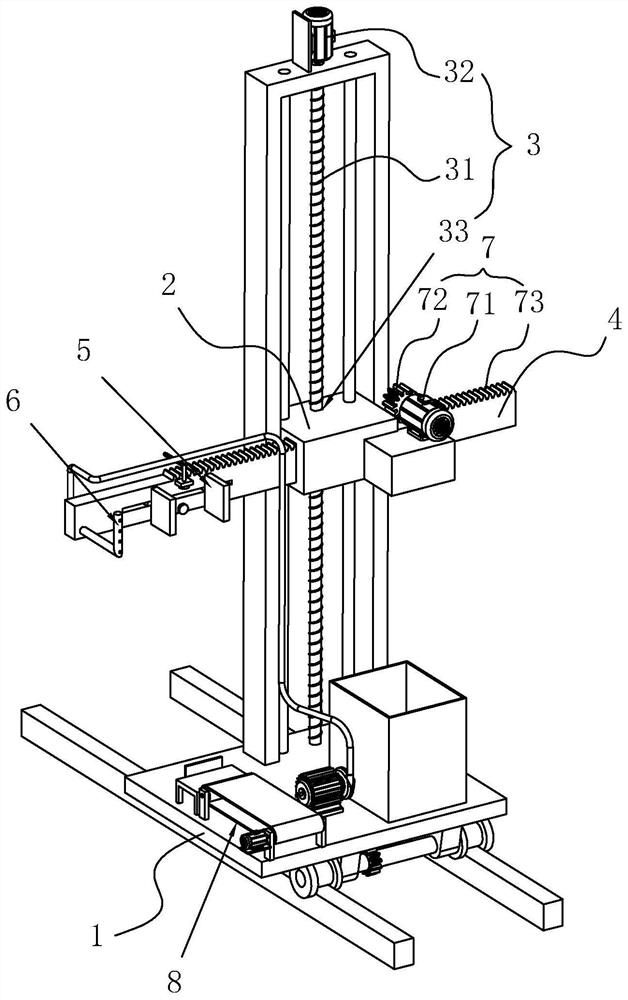

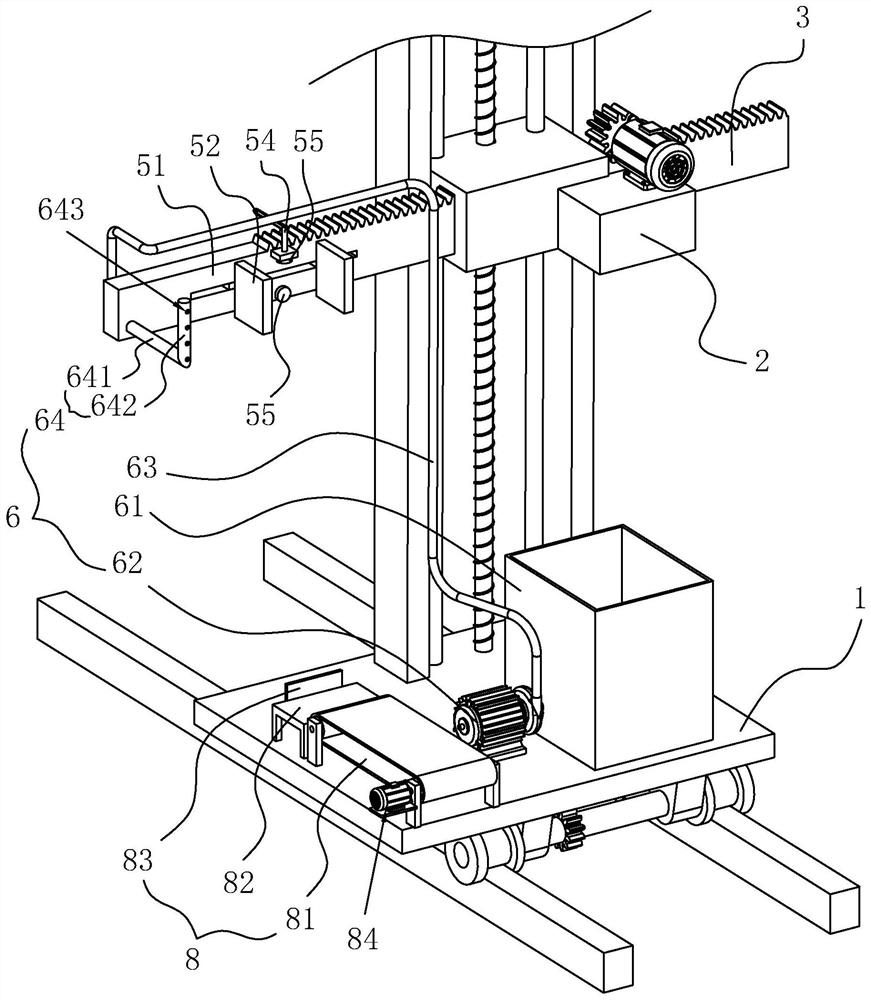

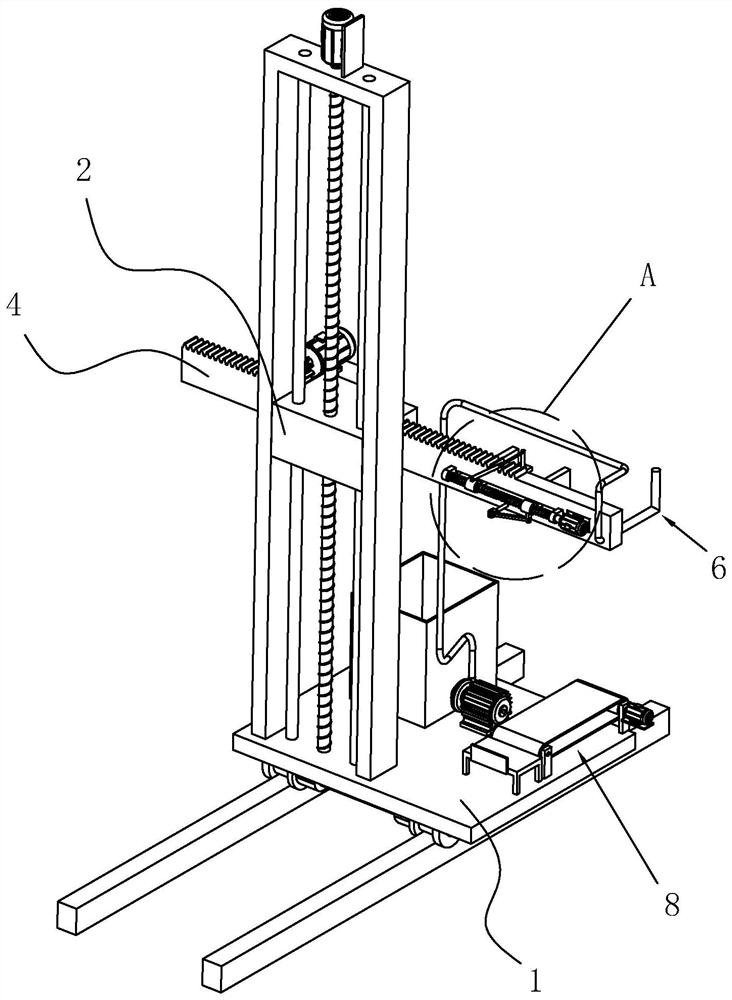

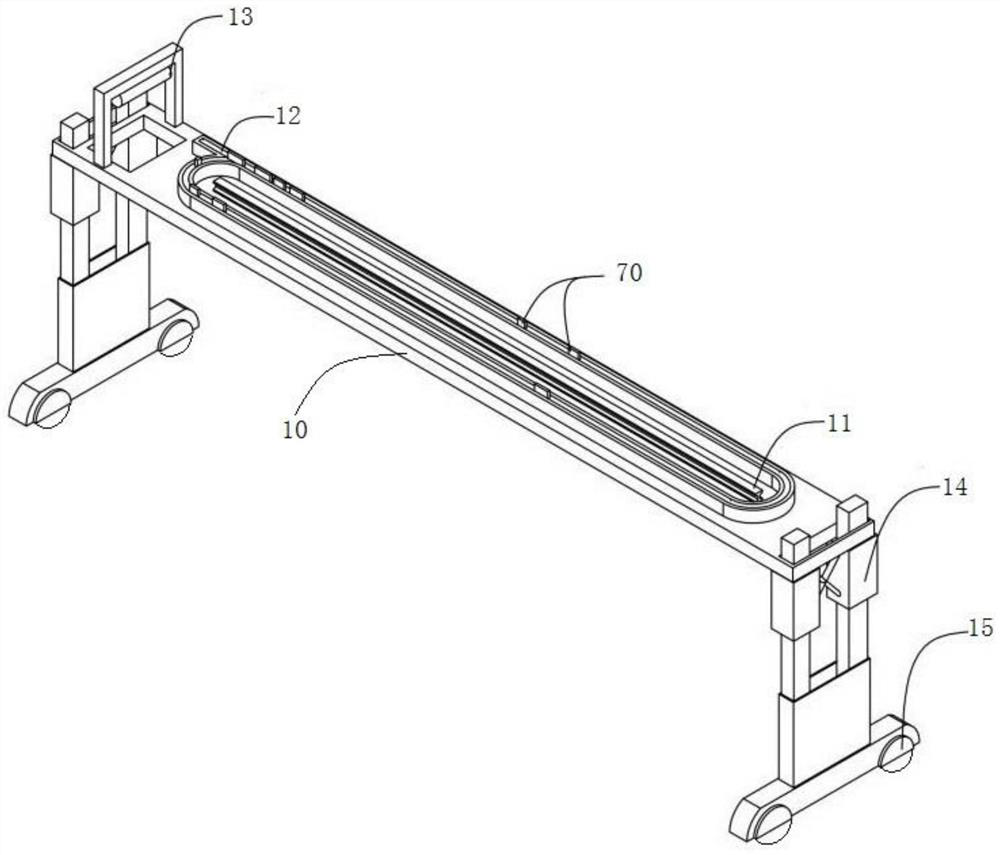

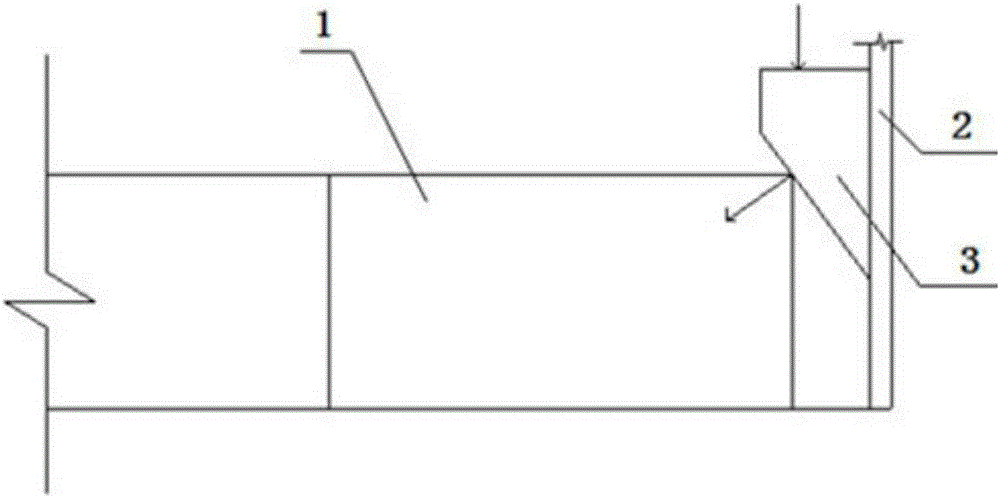

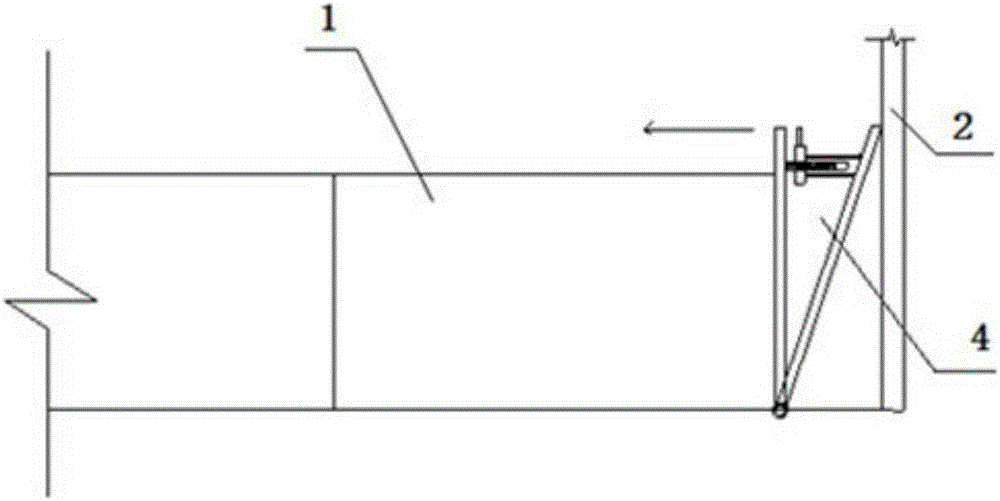

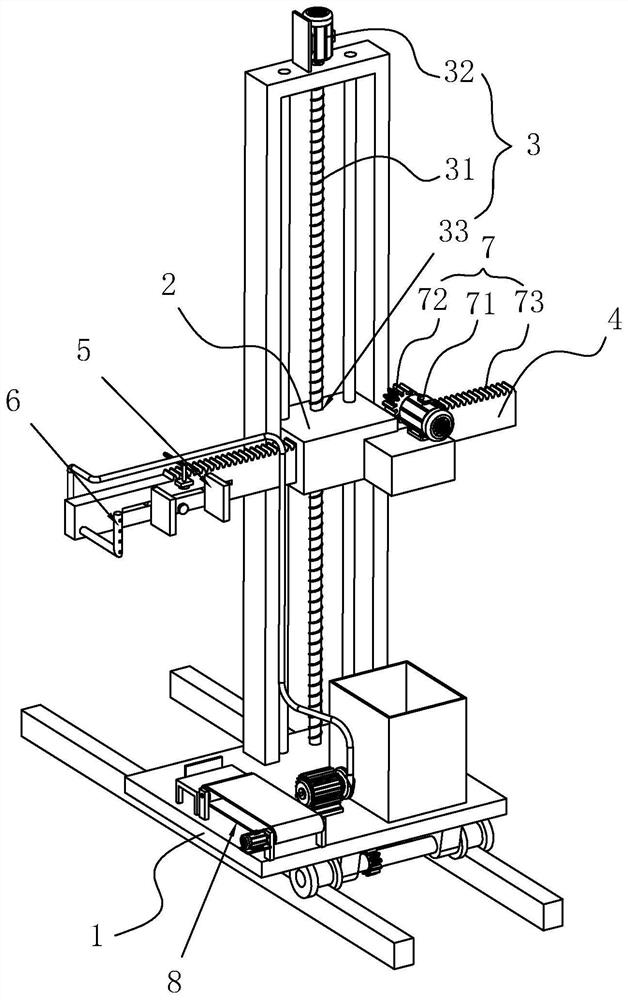

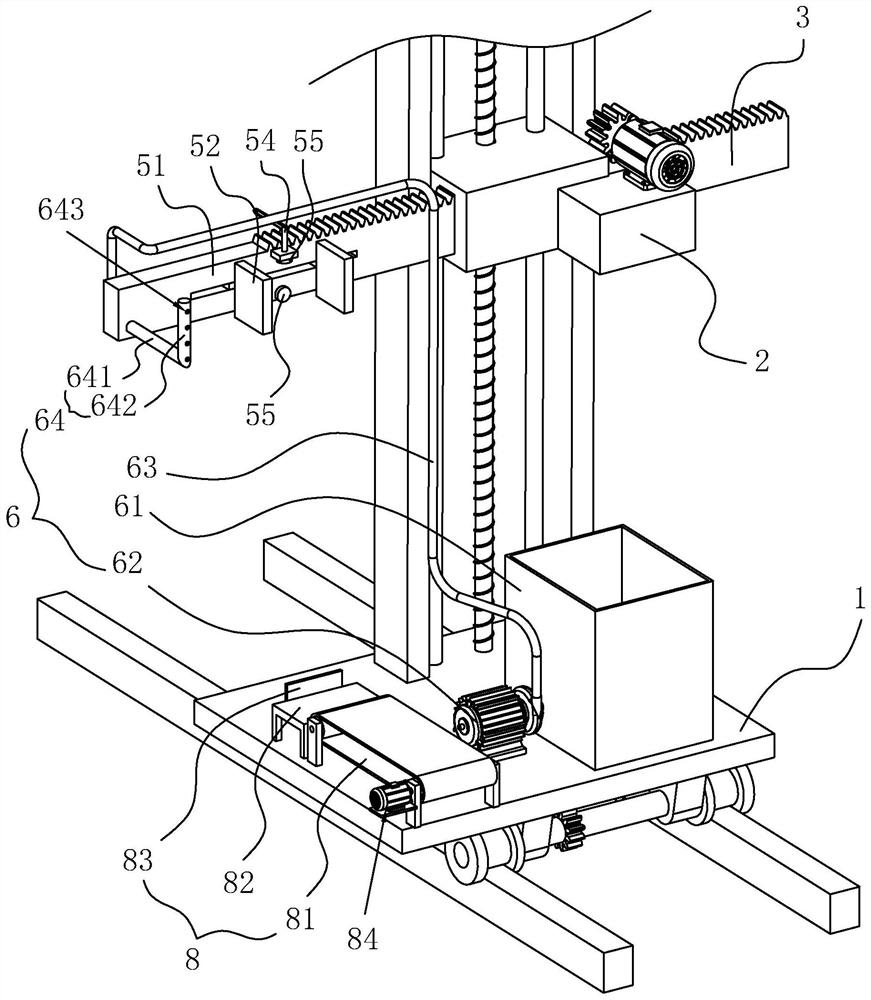

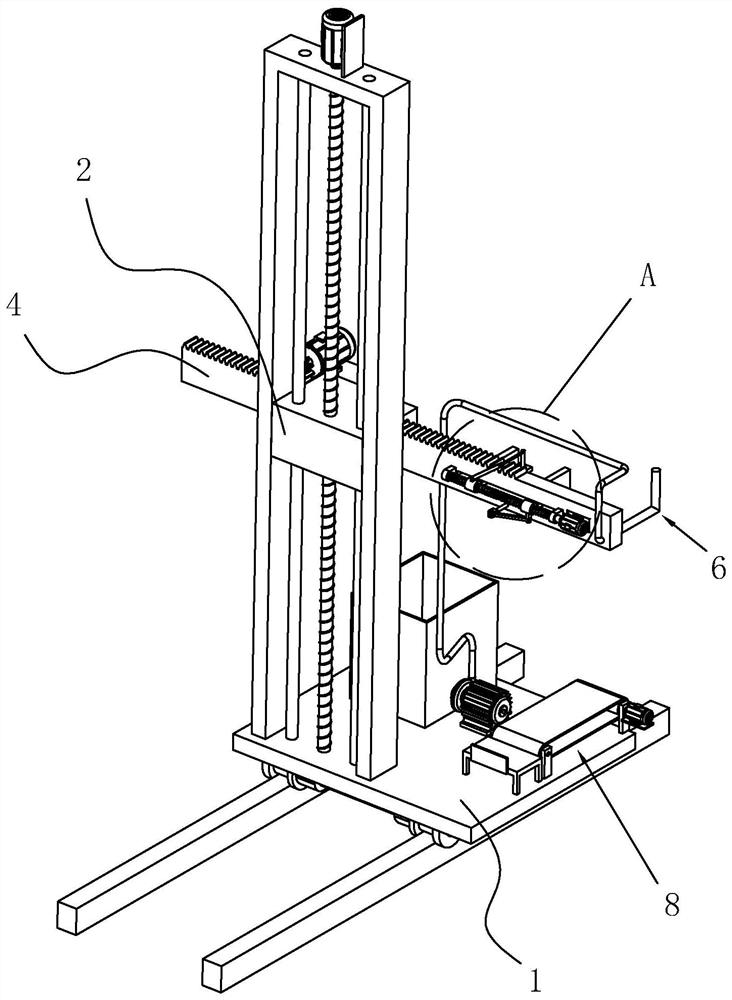

Masonry engineering construction device and construction process

ActiveCN112227749AImprove masonry qualityReduce workloadBuilding material handlingBricklayerArchitectural engineering

The invention relates to a masonry engineering construction device and a construction process. The masonry engineering construction device comprises a base which linearly and intermittently moves on the ground, a lifting seat is arranged on the base in the mode of ascending and descending in the vertical direction, a first driving device used for driving the lifting seat to ascend and descend is arranged on the base, and a supporting rod is arranged on the lifting seat in the mode of sliding in the horizontal direction; a clamping device and a guniting device are sequentially arranged on the side, on the lifting seat, of the supporting rod in the direction away from the lifting seat, a second driving device used for driving the supporting rod to slide is arranged on the lifting seat, and abrick conveying device is arranged on the position, below the clamping device, on the base; and when the construction device is used for bricklaying work, the base is moved to a to-be-bricked position, firstly, building blocks are clamped, then the lifting seat is driven to the to-be-bricked height, the supporting rod is driven to move towards a to-be-bricked wall, and mortar spraying on the walland building block placing on the wall are conducted successively in the moving process. The masonry engineering construction device and the construction process have the effects of reducing the workload of a worker and improving the masonry quality.

Owner:飞帆集团有限公司

Silica fire-resistant slurry powder

The present invention relates to the fireproof material technology field, in particular to a silicon fireproof slurry powder, which is developed to overcome the shortcoming in the prior silicon slurry powder that the material qualities between the raw material for preparing the fireproof slurry powder and the silicon brick for preparing the brick stove body are not similar so as to lead to non-adhesive in the high temperature. The present invention consists of 46-48 percent of silica, 46-48 percent of residue silica brick, 5-7 percent of fireproof clay as well as 0.03-0.05 percent of yellow starch gum. The material qualities between the residue silicon brick and the fireproof slurry powder for the brick stove body are similar; each physical and chemical index of the silicon fireproof slurry powder in the present invention is better than the national standard; by using of the silica and the residue silicon brick with the similar material quality to the silicon brick used for the stove body of the fireproof slurry powder as the main material, the present invention not only realizes the maximum utilization for the waste material, but also the present invention can overcome the shortcomings that the slurry powder and the silicon brick are adhesive in the low temperature but non adhesive in the high temperature. By contraries, the adhesion effect is much greater under the function of yellow starch gum. The present invention can enhance the brick quality for the stove body effectively and prolong the life time for the stove body; the present invention is adaptable to be used in the high temperature stove body for building the heat-air stove, coke stove or glass stove.

Owner:山西盂县西小坪耐火材料有限公司

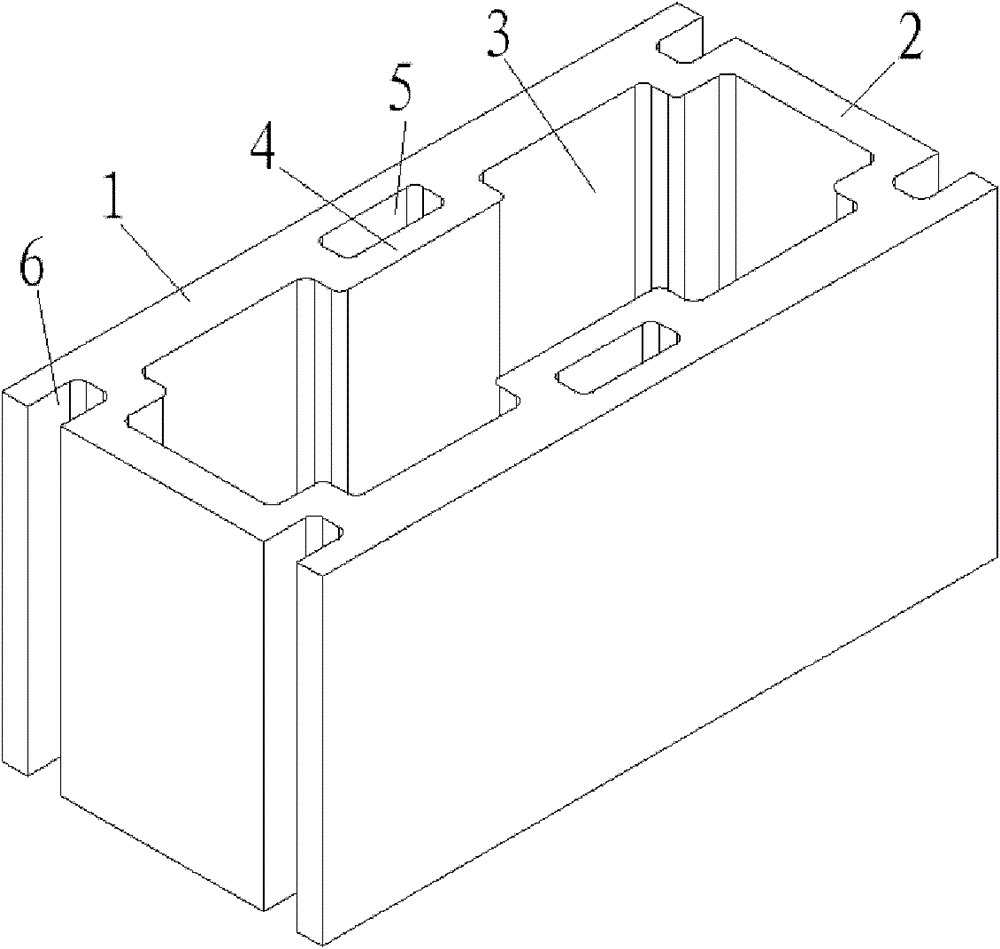

Multifunction decorative building block

InactiveCN101413318AImprove anti-seepage performanceImprove connection strengthBuilding componentsThermal insulationLoad-bearing wall

The invention discloses a multi-functional decorative block. One side of a main body of the block is provided with a dovetail groove, the main body of the block is provided with holes, the holes are isolated by partition entities, two opposite sides of the main body of the block are provided with one to two pin key grooves which are vertical and symmetrically arranged respectively, pin keys used for connecting upper-layer blocks and lower-layer blocks are inserted into pin key holes, and pin keys used for connecting adjacent blocks are inserted into the pin key grooves. By using the dovetail groove at one side, the invention can realize the compounding of thermal insulation and blocks, strengthen the structural integrity, improve building quality and construction speed, assure the realization of air cavities of sandwich wall bodies, and improve the anti-seepage performance of the wall bodies and the quality of indoor environments of buildings. By using the pin keys and the pin key grooves, the invention can strengthen the connection degree between the blocks, partially or fully substitute masonry mortar, and improve construction speed. The block can be taken as materials of load bearing wall bodies, and can also be taken as materials of self load bearing partitions or exterior decoration wall bodies.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD +1

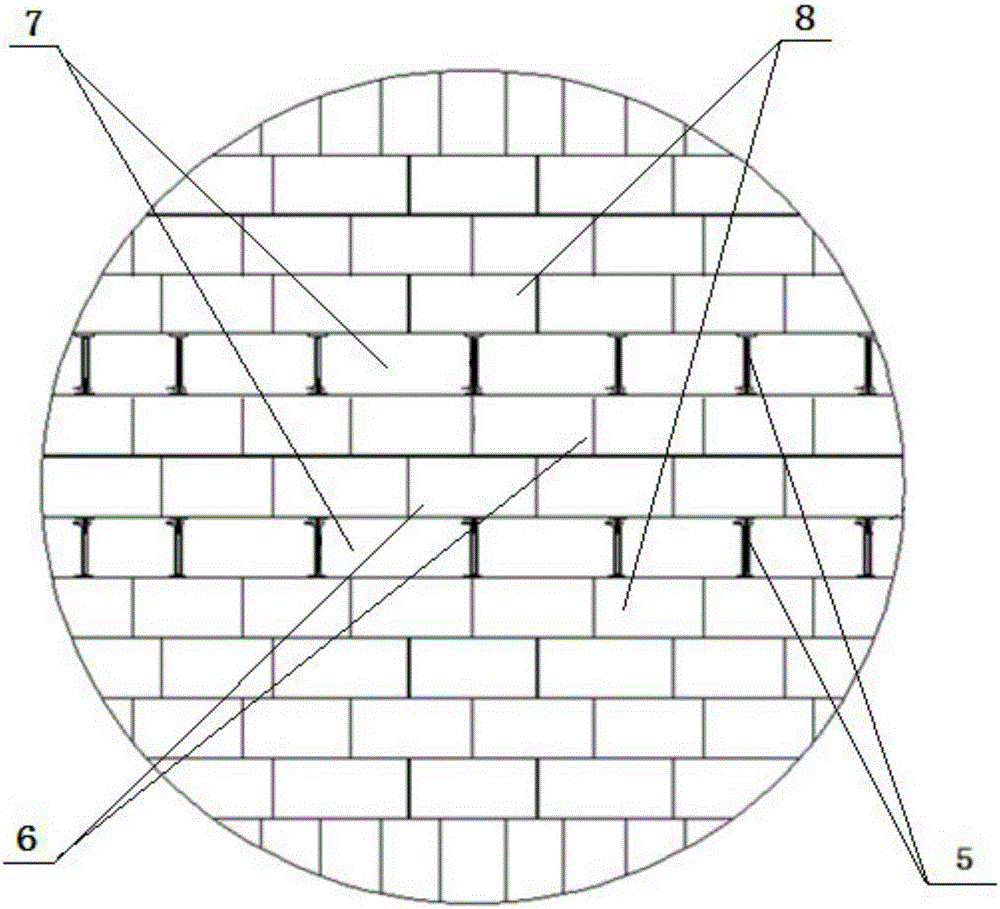

Three-dimensional control masonry method based on oven body masonry construction of coke oven

InactiveCN105778934AControl GeometryReduce labor intensityCoke oven brickworkCoke ovenProcess control

The invention discloses a three-dimensional control masonry method based on oven body masonry construction of a coke oven. The problems of low construction efficiency, long construction period, high cost and poor masonry quality of a construction method for coke oven masonry in the prior art are solved. The three-dimensional control masonry method implements whole process control on oven body masonry construction through a three-dimensional control method of erecting a marker post, transversely arranging a target and arranging a row line, so that the geometric dimension of the oven body can be effectively controlled, the construction efficiency is improved, the labor intensity of a worker is reduced, and the construction period is greatly shortened; and meanwhile, a relatively great regulating space is brought for construction of the later-stage mechanical and electrical installation project, and therefore, the three-dimensional control masonry method is beneficial for efficiently and orderly carrying out integral coke oven project construction.

Owner:CHINA MCC5 GROUP CORP

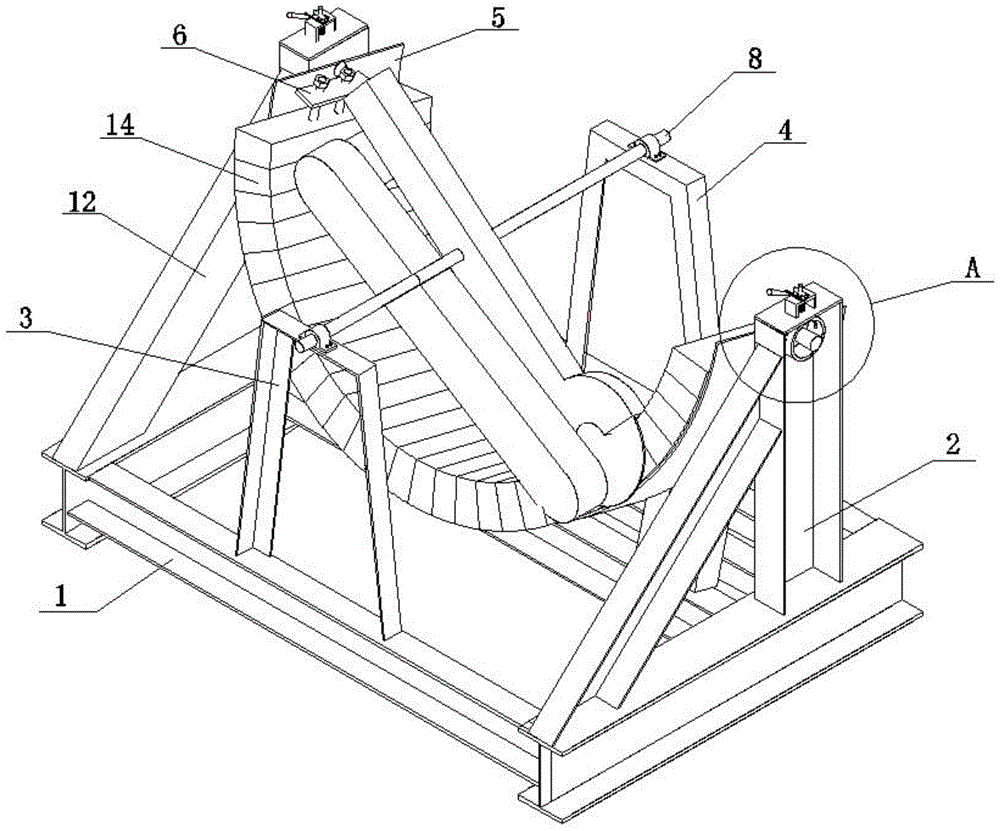

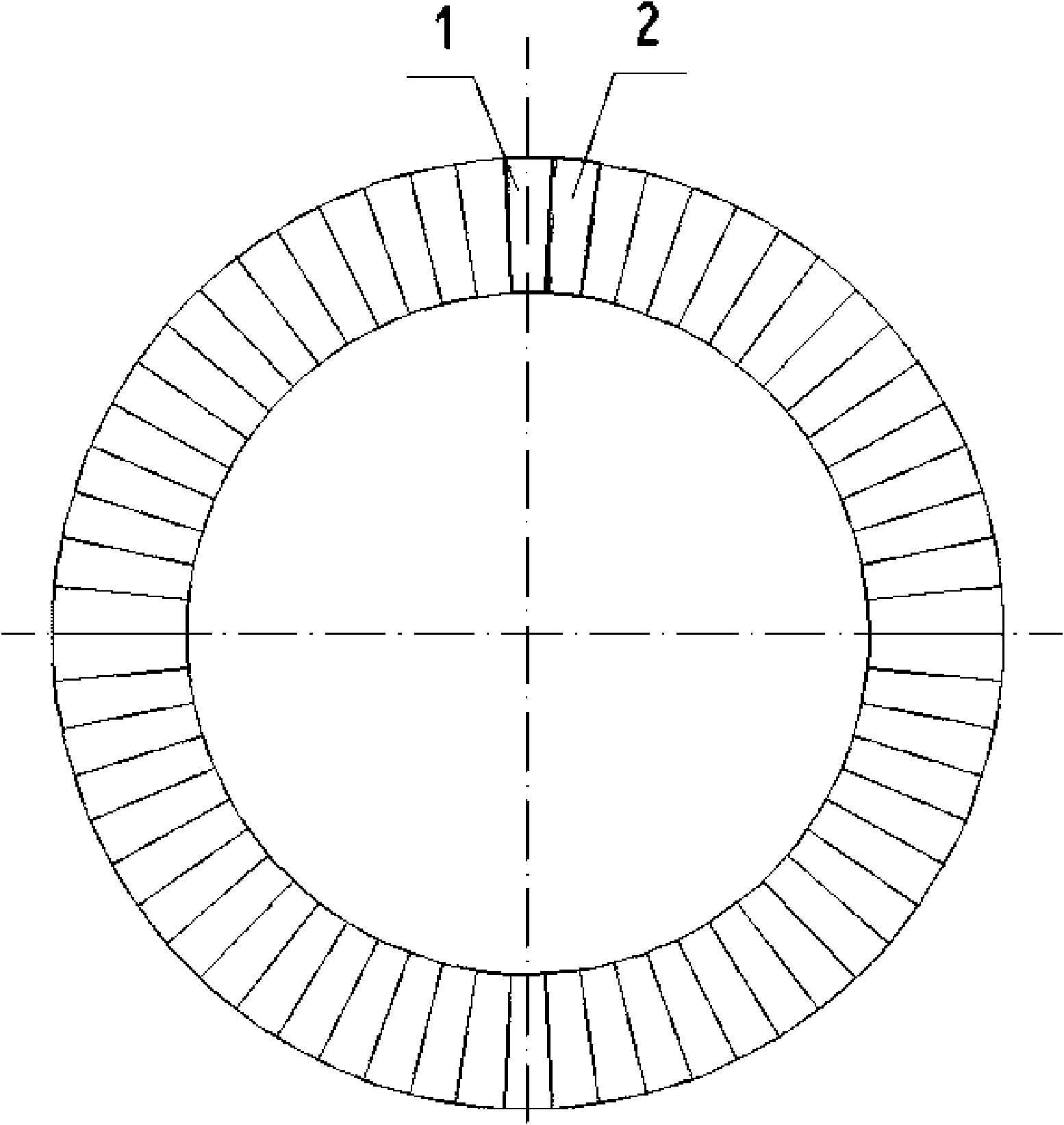

Multiple-angle rotary brick cutter

ActiveCN104827589AGuaranteed stabilityImprove masonry qualityWorking accessoriesStone-like material working toolsBatch processingDrive shaft

The invention discloses a multiple-angle rotary brick cutter which comprises a rack and an arc-shaped plate. A small rotary shaft is respectively arranged at two ends of the arc-shaped plate and is connected with the rack and drives the arc-shaped plate to rotate. A cutting device is arranged above the arc-shaped plate and comprises a motor and a rotary shaft with two ends connected to the rack, the rotary shaft vertically penetrates through a rotating arm, a cutting piece is arranged at the lower end of the rotating arm, and a drive shaft of the cutting piece is connected with the driving end of the motor through a belt. The axis of the rotary shaft and the axis of the arc-shaped plate are located on the same straight line, and the rotating arm rotates around the rotary shaft. The multiple-angle rotary brick cutter is supported by the arc-shaped plate and can be used for batch processing of wholly-semicircular refractory bricks for building of arched brickworks, a cutting angle can be changed by turning the arc-shaped plate, and wholly non-semicircular refractory bricks can be processed to meet the building requirement of brickworks. The stability of the arc-shaped plate in the cutting process is ensured by adopting a locking device, and cutting accuracy is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

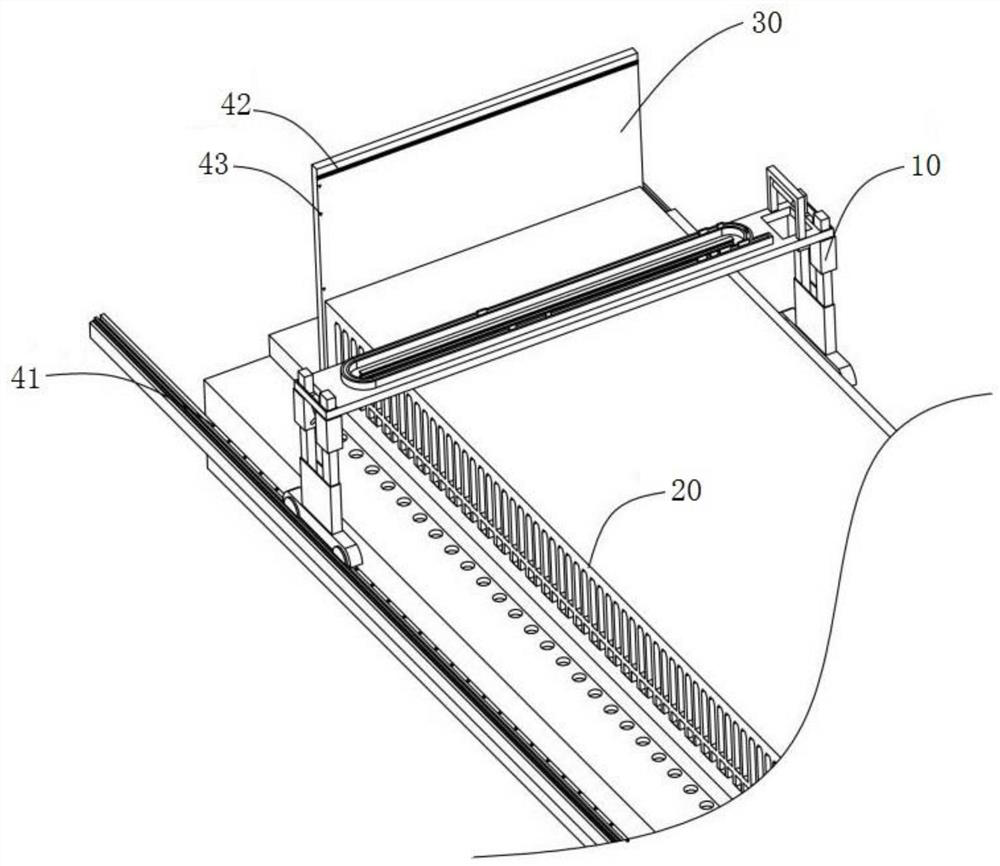

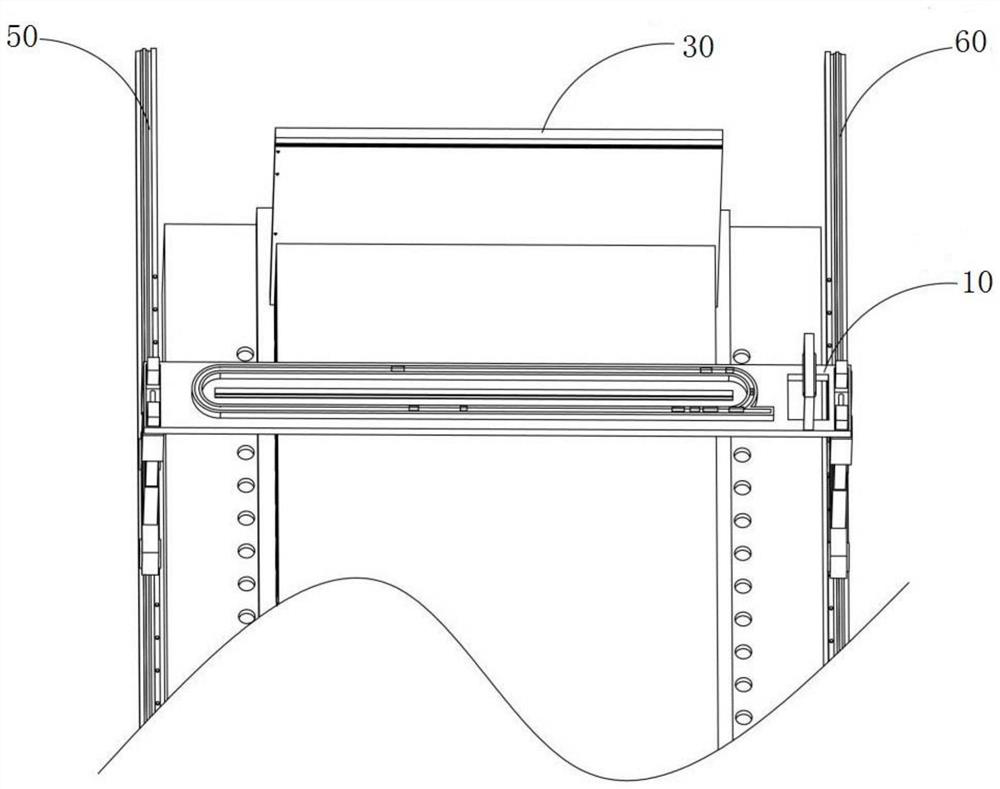

Process method and system for building coke oven by machine

PendingCN113150797ASave human effortImprove masonry qualityCoke oven brickworkMachine buildingProcess engineering

The invention relates to a process method and system for building a coke oven by a machine. The process method comprises the following steps of 1) early-stage preparation, 2) adjusting a beacon, 3) conveying the refractory material, and (4) building. The system comprises a building platform, an elevator, an annular conveying belt, a walking track, a building machine / building robot, a lifting mechanism and a walking mechanism. Starting from solving the problems of machine walking and raw material conveying, the machine building of the coke oven is realized, the building efficiency and the building quality can be greatly improved, and the human input and the coke oven construction cost are reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

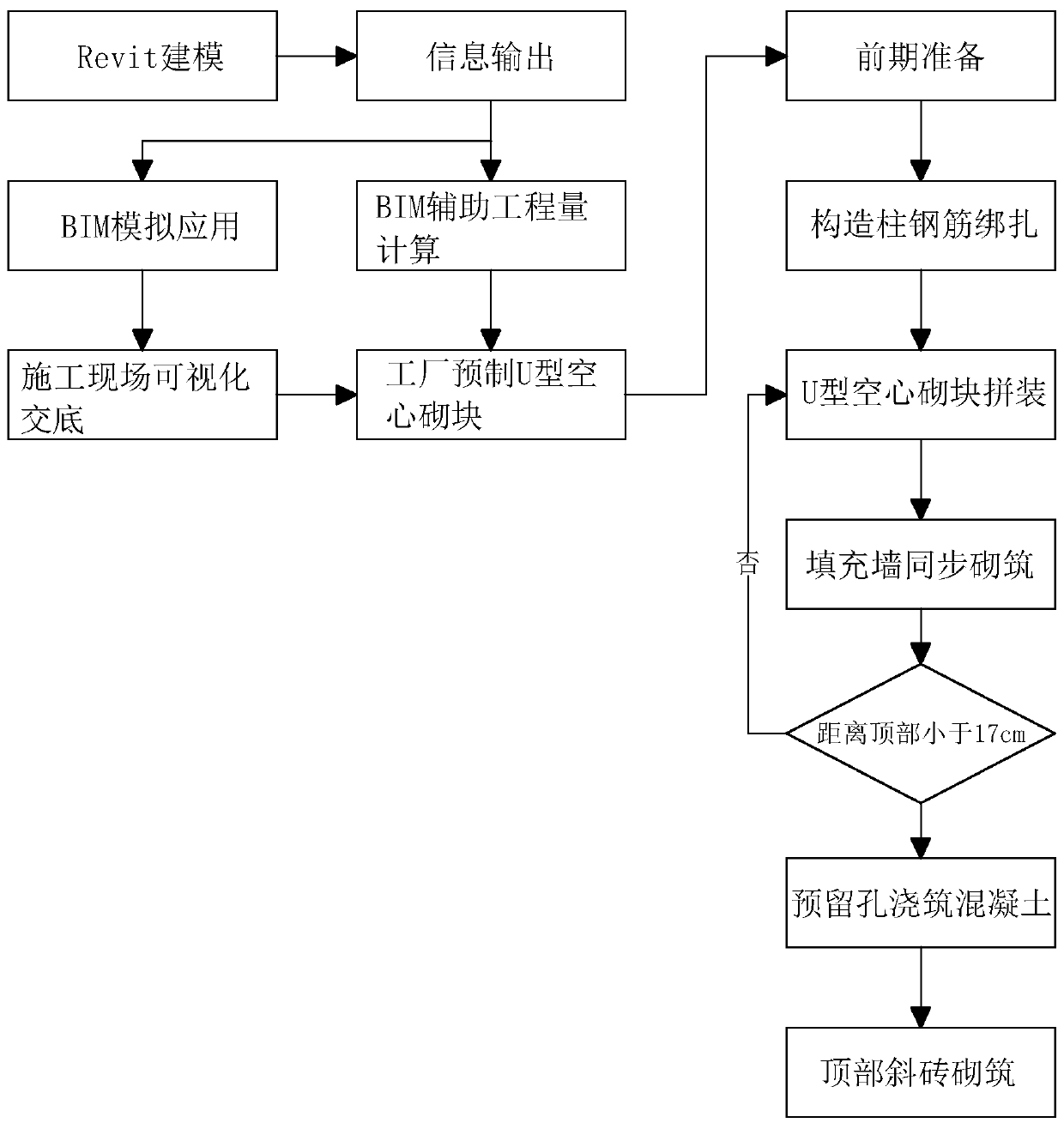

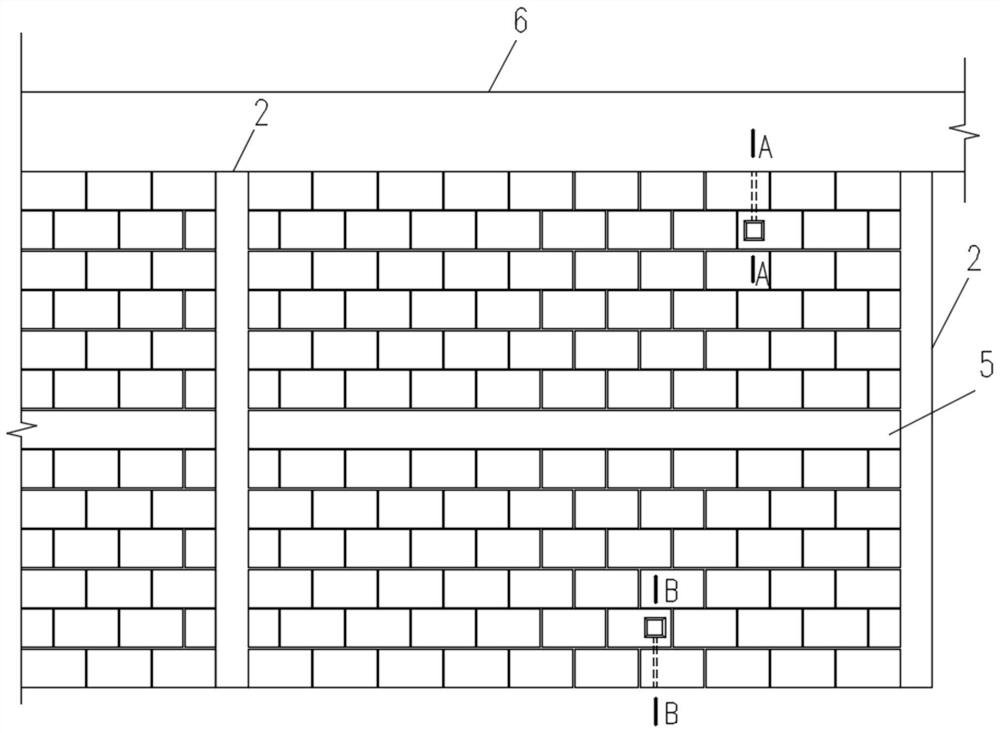

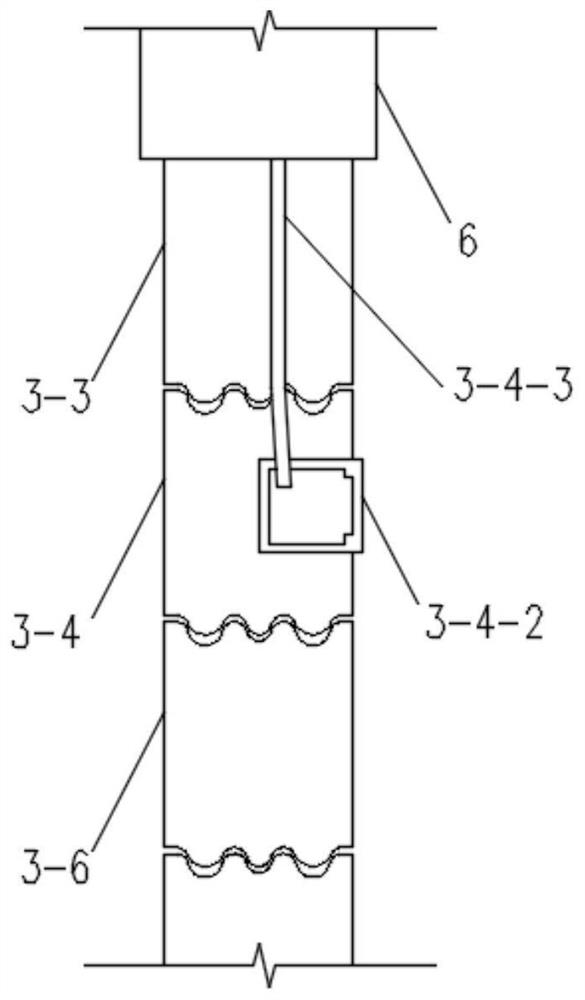

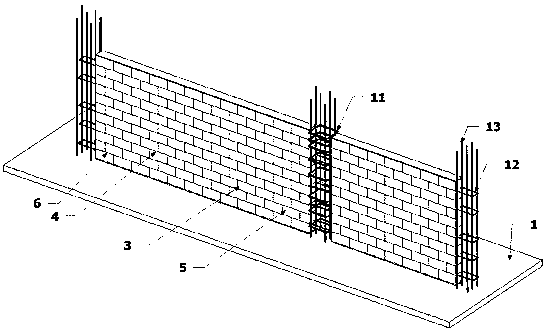

Hollow block formwork-free constructional column synchronous infilled wall construction method based on BIM technology

PendingCN110929324AGuarantee smooth constructionImprove masonry qualityGeometric CADOffice automationHollow coreRebar

The invention discloses a hollow block formwork-free constructional column synchronous infilled wall construction method based on the BIM technology. The method comprises the following steps that S1,REVIT modeling is conducted; S2, outputting information; S3, performing BIM simulation application; S4, calculating the BIM auxiliary engineering quantity; S5, performing visual disclosure on a construction site; S6, the U-shaped hollow building blocks are prefabricated in a factory; S7, early-stage preparation; S8, constructional column steel bars are bound; S9, assembling the U-shaped hollow building blocks; S10, the filler walls are built synchronously; S11, concrete is poured into the preformed holes; and S12, top inclined bricks are built. U-shaped hollow building blocks are prefabricatedthrough the BIM technology to serve as an outer mold of the constructional column to replace a traditional formwork, concrete is poured at the rear top to form the constructional column, formwork erecting is not needed in the whole construction process, and formwork-erecting-free construction of the constructional column is achieved.

Owner:浙江百厦建设有限公司

Plastering-free and concealed pipe grooving-free secondary structure wall and construction method thereof

PendingCN112780009ASave time and costRealize the effect of no plasteringWallsBuilding material handlingPipeJoint (building)

The invention discloses a plastering-free and concealed pipe grooving-free secondary structure wall and a construction method thereof. The plastering-free and concealed pipe grooving-free secondary structure wall comprises a first steel component pre-buried in a floor, wherein a constructional column is welded to the upper portion of the first steel component; at least one side face of the constructional column is connected with a wall body formed by riveting a plurality of building blocks; mortar joints exist between the building blocks; a ring beam is arranged at the supporting joint of the wall body; the ring beam is welded to the contact position of the constructional column through a second steel component pre-buried in the end of the ring beam; and the top of the constructional column is fixedly connected with a structural beam. The common quality problem that secondary structure concrete is rough in quality is solved, the masonry quality of a filler wall is remarkably improved, and the plastering-free effect of the wall is achieved; and the technological measures of special pipe distribution building block wrapping and laying and pre-buried wire box matched building block assembling are adopted, the wall concealed wiring pipe grooving-free effect is achieved, energy saving and environment friendliness are promoted, and a good effect is achieved.

Owner:中铁十六局集团城市建设发展有限公司

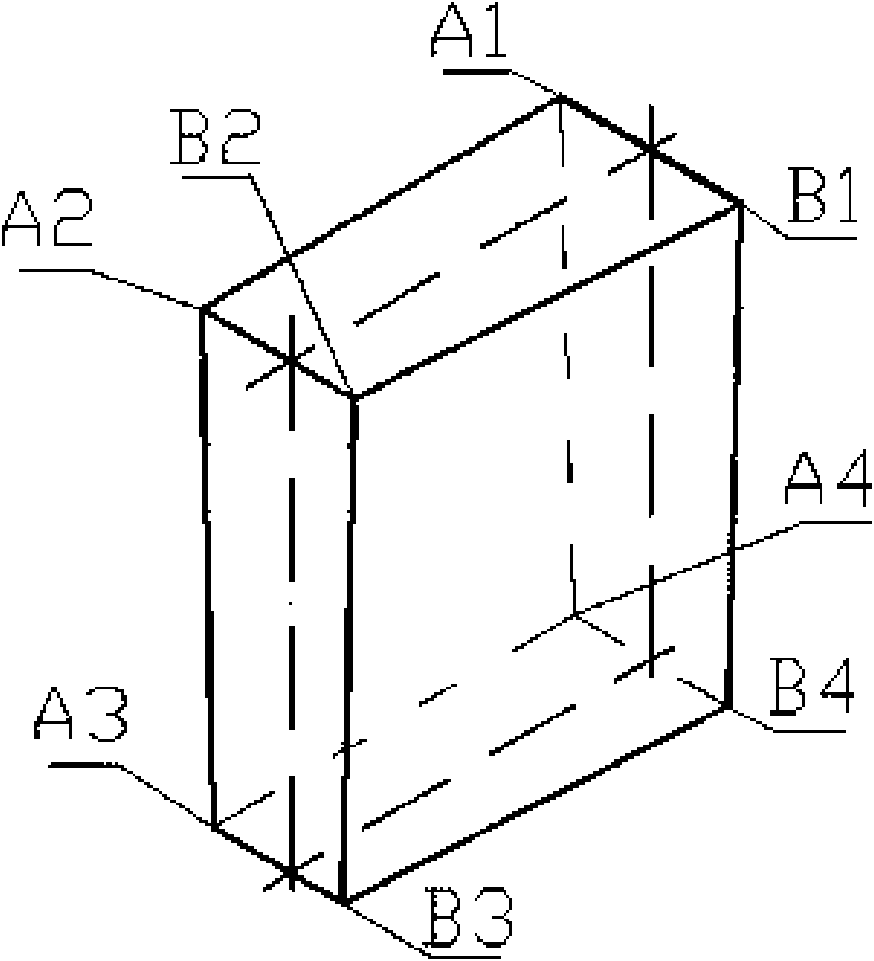

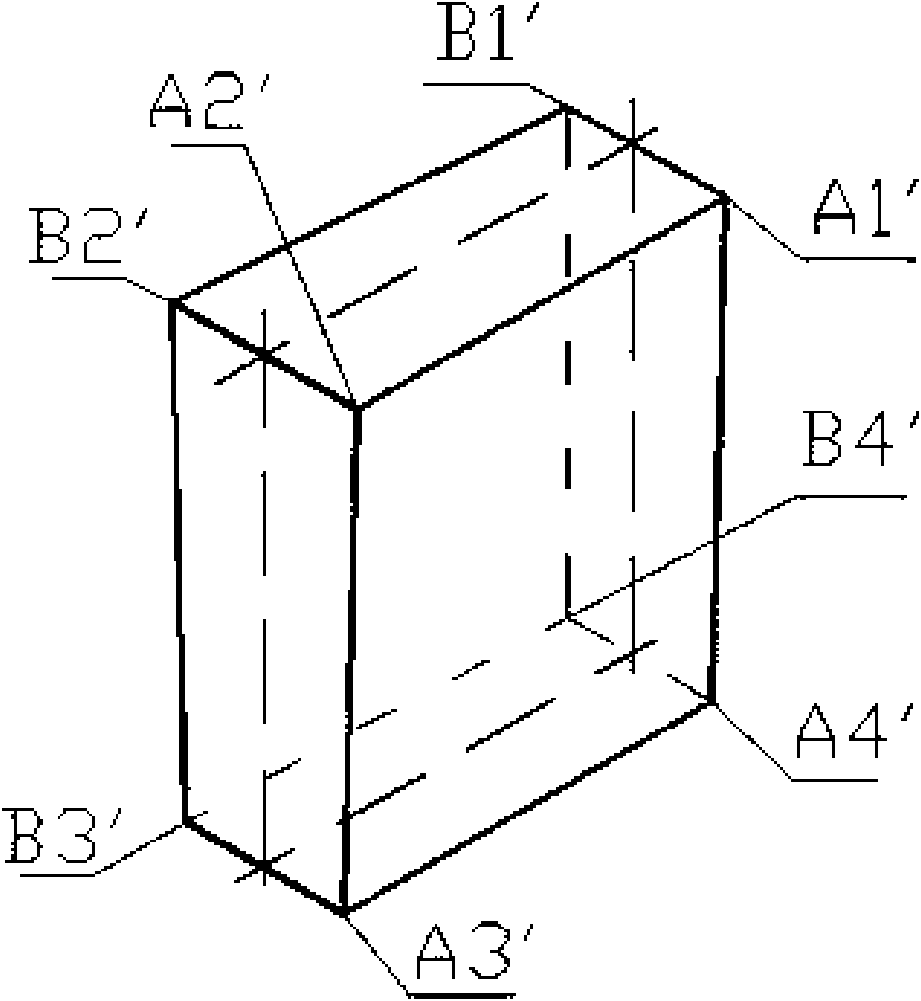

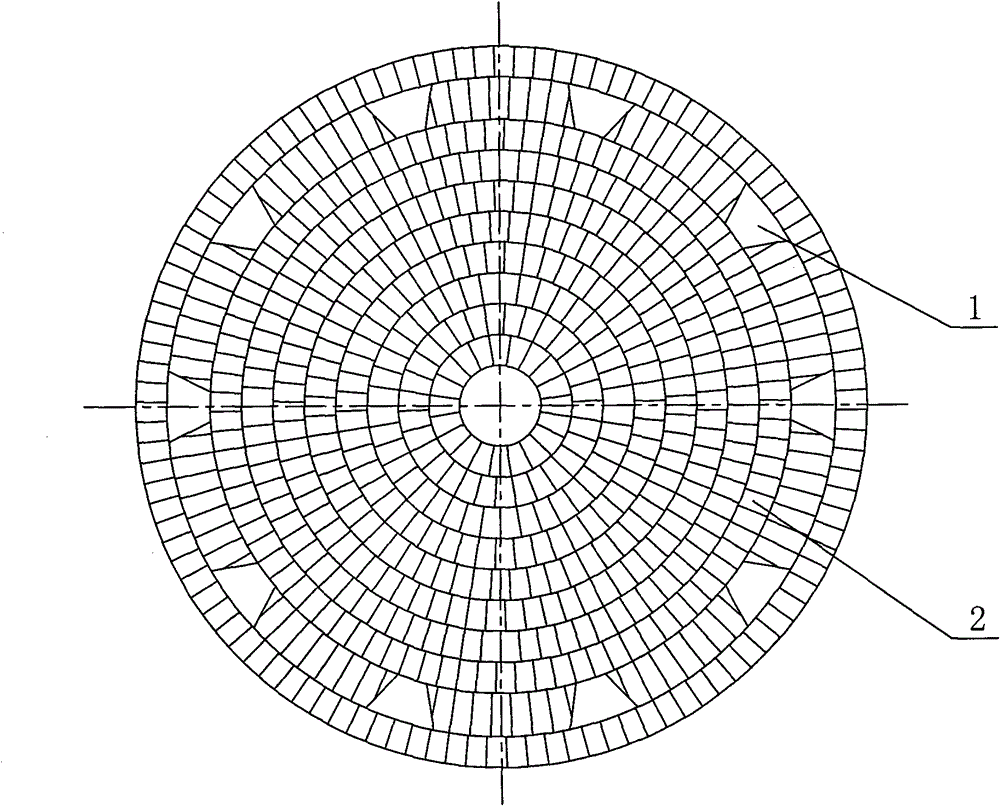

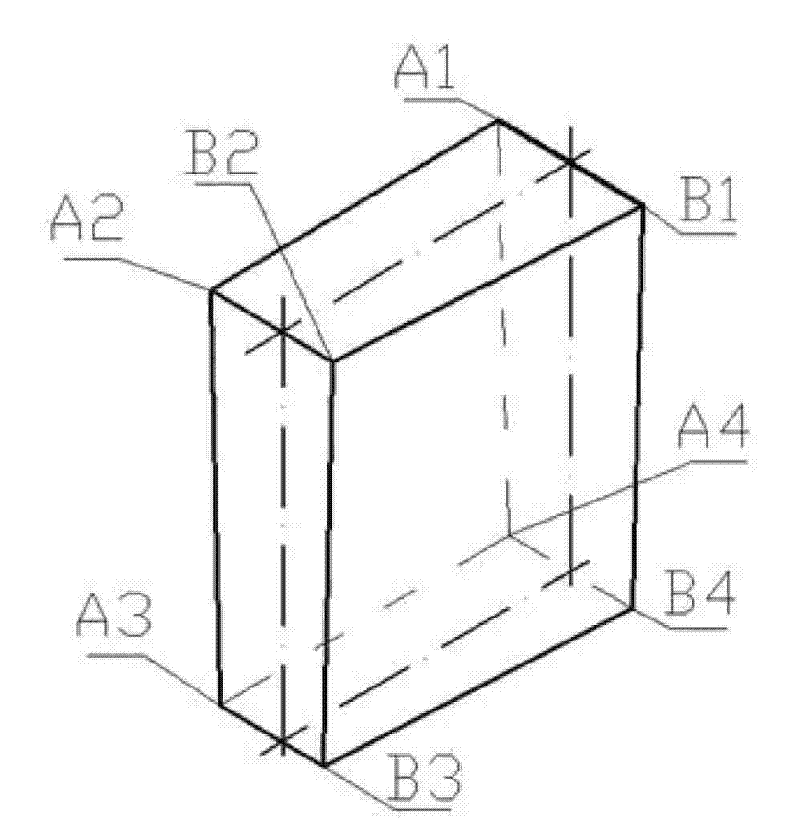

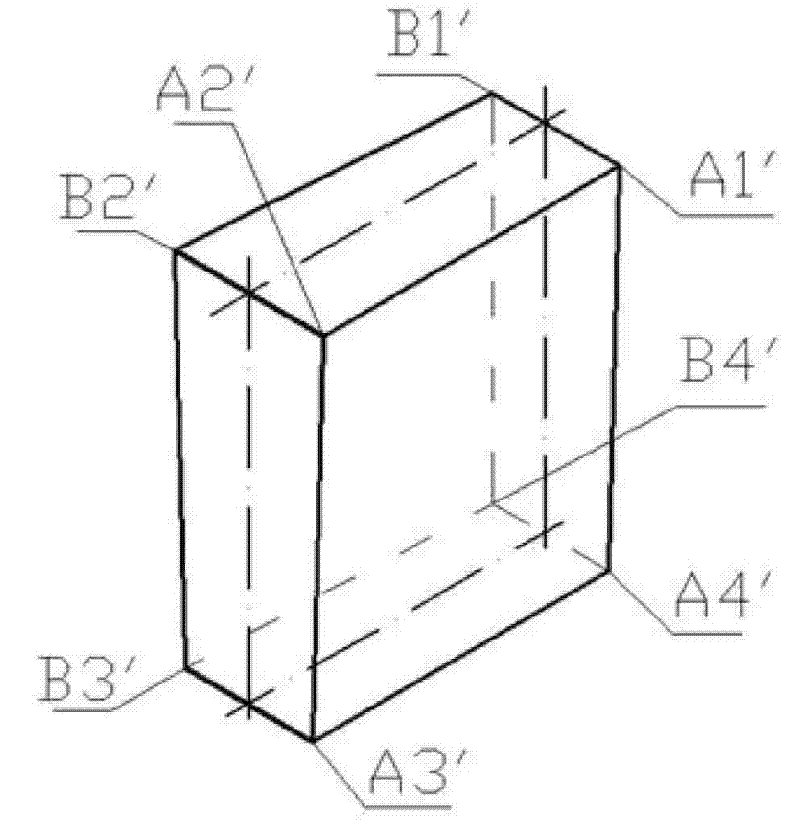

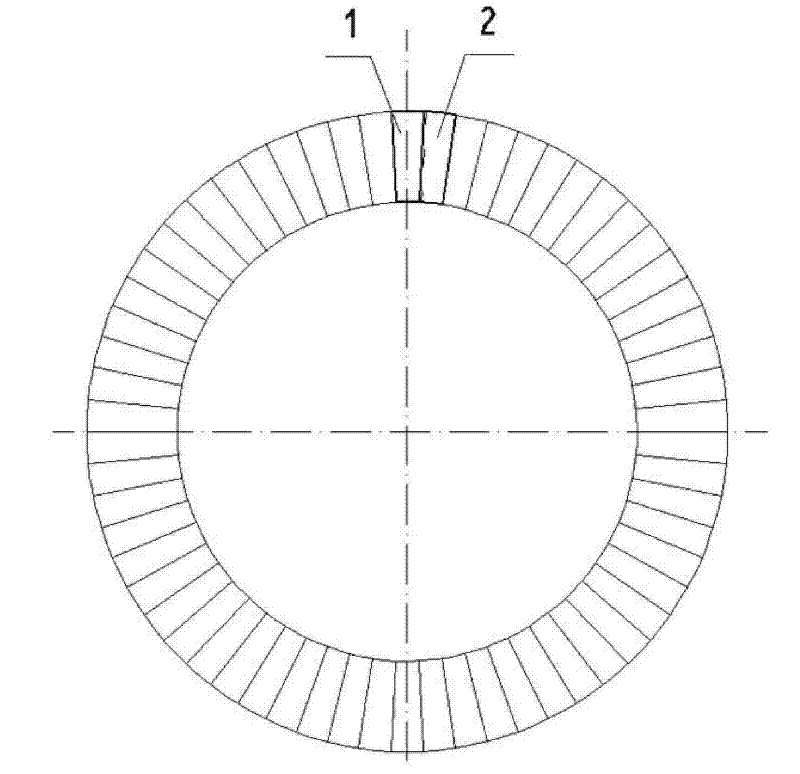

Radiation type building brick combination door neck brick and building method thereof

ActiveCN101634519AReduce labor intensityImprove construction efficiencyLinings repairRadiationMaterials science

The invention relates to the field of heat engineering kiln firebrick building and discloses a radiation type building brick combination door neck brick comprising a first brick and a second brick, wherein the first brick and the second brick can be mutually bonded; the first brick comprises a surface A and a surface B; when the surface B and the first brick are built, an angle between radiation lines of an annular building surface is smaller than a self-lock frictional angle of the first brick; the second brick comprises a surface C and a surface D; when the surface C and the first brick are built, an angle between the radiation lines of the annular building surface is smaller than a self-lock frictional angle of the second brick; the surface B of the first brick is mutually bonded with the surface C of the second brick; and the surface A of the first brick and the surface D of the second brick are respectively bonded with the adjacent bricks. The invention also provides a building method of the combination door neck brick, and the combination door neck brick is adopted to combine each ring, By changing the shape of the combination door neck brick and the building construction method, the locking strength of the brick rings and the integral structural performance of a kiln lining are increased; when bricks of both sides are not destroyed, a combination door is locked by neck bricks, and the quality of the brick and the integral building construction is ensured.

Owner:WUGANG REFRACTORY CO LTD

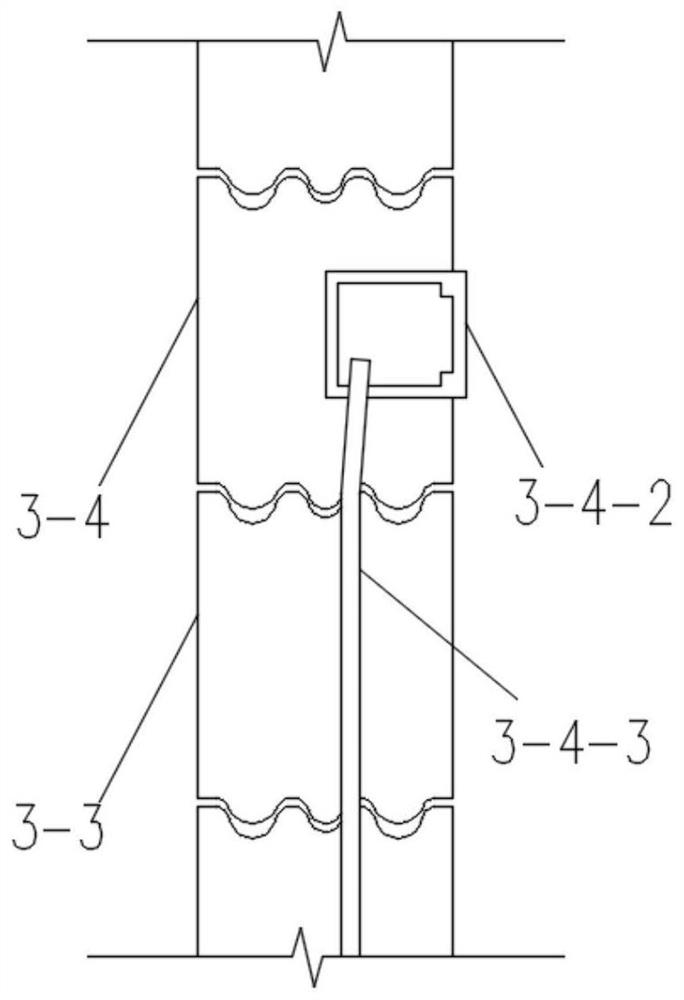

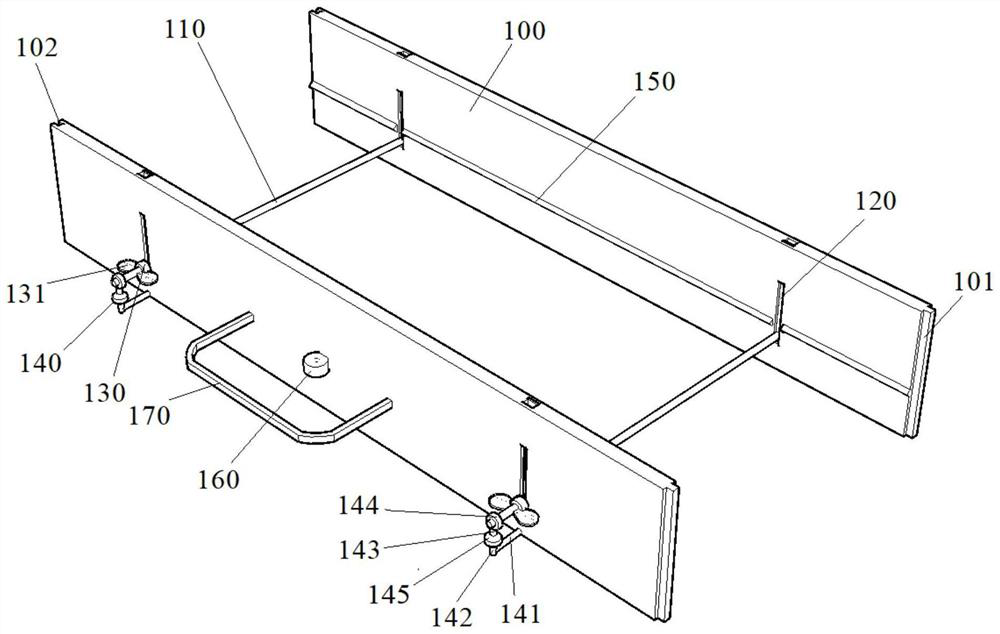

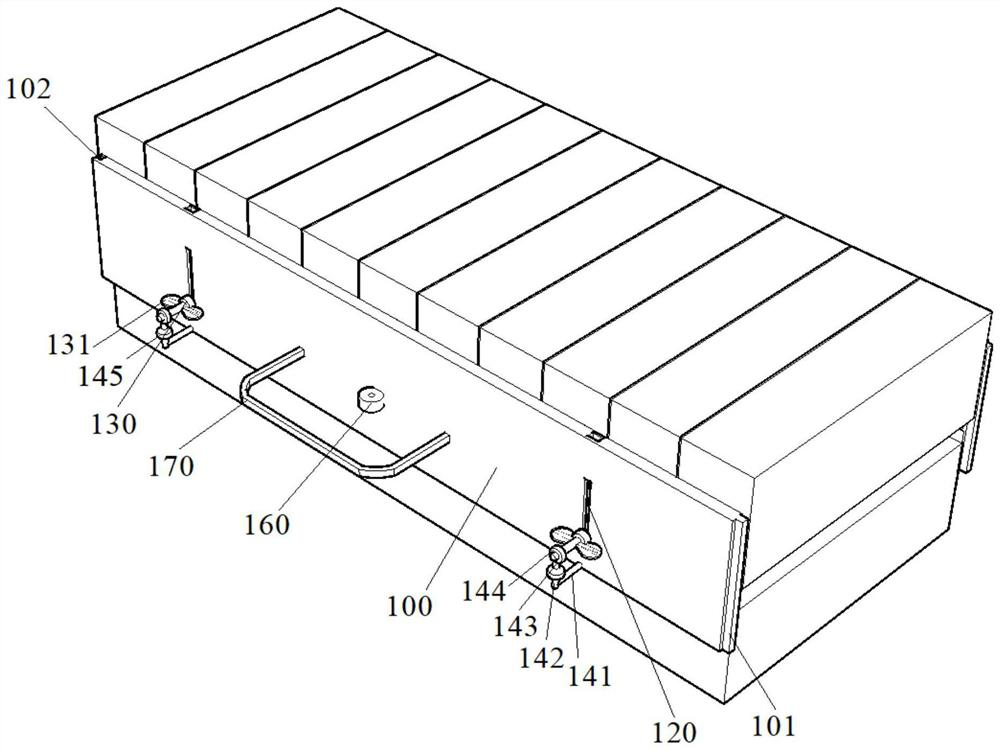

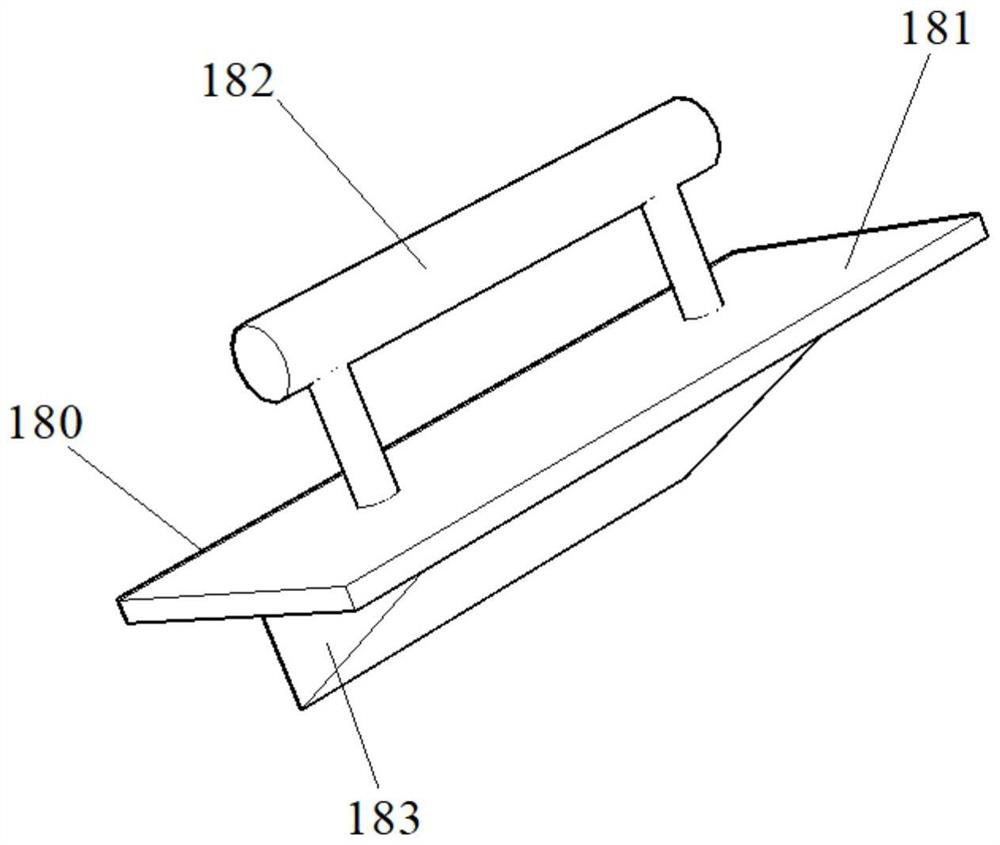

Device for improving wall masonry quality

InactiveCN111779294AImprove verticalityImprove masonry qualityBuilding material handlingScreedArchitectural engineering

The invention provides a device for improving wall masonry quality, and relates to the field of building equipment. The device for improving the wall masonry quality comprises two clamping plates andat least two pull rods arranged opposite to each other; the two clamping plates are respectively provided with strip holes in one-to-one correspondence with the pull rods; the strip holes extend alongthe width direction of the corresponding clamping plate; each pull rod orderly passes through the corresponding strip holes on the two clamping plates; at least two fastening bolts capable of movingalong each pull rod are respectively arranged on each pull rod in a sleeving mode; each fastening bolt is connected with at least one stopper; each clamping plate is respectively connected with an adjustable screw component connected to the pull rods in a one-to-one correspondence mode; and the adjustable screw component is configured to extend and contract along the width directions of the clamping plates. The device for improving the wall masonry quality provided by the invention can improve the perpendicularity of a masonry wall while ensuring the saturation of a masonry mortar layer.

Owner:CHINA FIRST METALLURGICAL GROUP

Silica fire-resistant slurry powder

Owner:山西盂县西小坪耐火材料有限公司

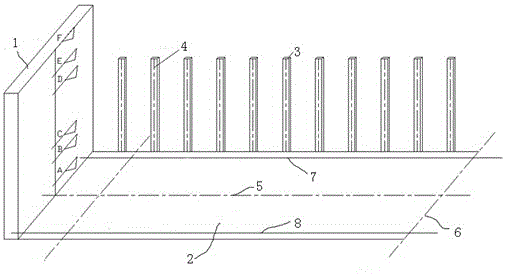

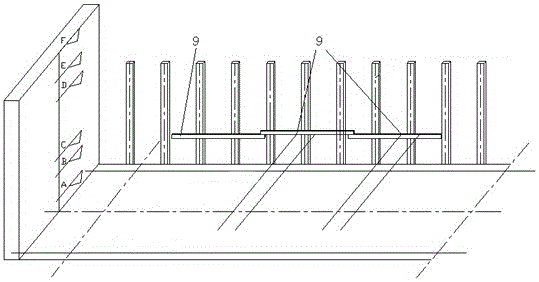

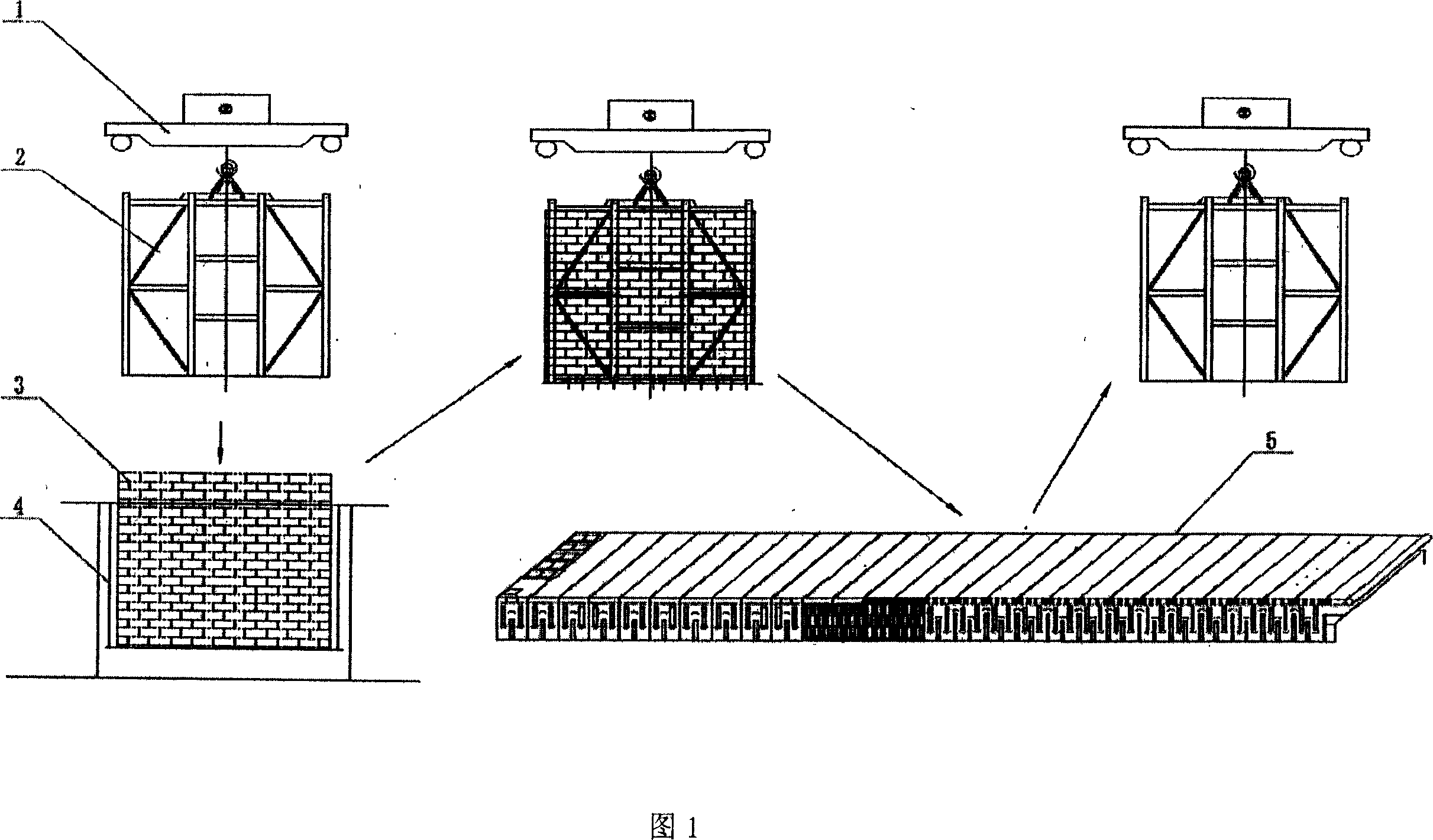

Building method of flame path wall of roaster

InactiveCN101149155AImprove masonry qualityReduce labor intensityLinings repairFirebridgesEngineeringLifting equipment

This invention is a carbon roaster flame path wall building method. It includes procedurals such as wall building, integral swing and spot assembly. There is lifting platform outside of the roaster. The flame path wall swing frame is arranged on the platform. The flame path wall body is built in the frame. The frame and flame path wall are swung together to the corresponding position of roaster by lifting equipment. After falling on the ground, the frame board is unloaded and plastered with fire-proof ash to fix the flame path wall. This invention not only improves constructing environment, but also reduce the working intensity of workers. This invention greatly shortens the troubleshooting time of roaster and increases the manufacturing efficiency.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

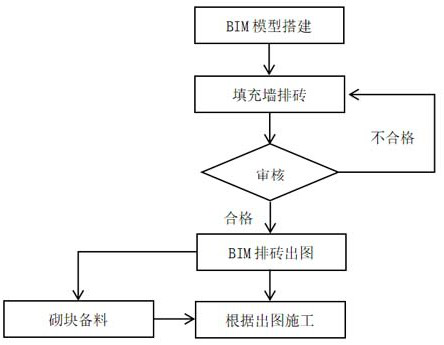

Arc-shaped infilled wall construction method based on BIM technology

InactiveCN113513179AUniform arcBeautiful arrangementGeometric CADBuilding material handlingMaterials preparationBrick

The invention relates to an arc-shaped filler wall construction method based on a BIM technology. The method comprises the steps that 1, a BIM model is built; 2, bricks are arranged on a filler wall; 3, auditing is conducted; 4, building blocks are prepared, specifically, the building blocks are prepared in a masonry material storage yard according to a brick arrangement drawing and a material table by field constructors, numbering is conducted according to the brick arrangement drawing, and materials of one wall are arranged together and prepared to be conveyed to a designated place; and 5, construction is conducted according to the drawing, specifically, the brick arrangement drawing is pasted to the wall edge before masonry is started, and masonry workers conduct masonry according to the brick arrangement drawing and the numbers of the bricks. According to the building block quantity statistical table generated based on the BIM technology, material preparation is carried out in advance, building is directly carried out according to the brick arrangement drawing number after the materials are in place, and the construction efficiency is improved.

Owner:SHANGHAI BAOYE GRP CORP

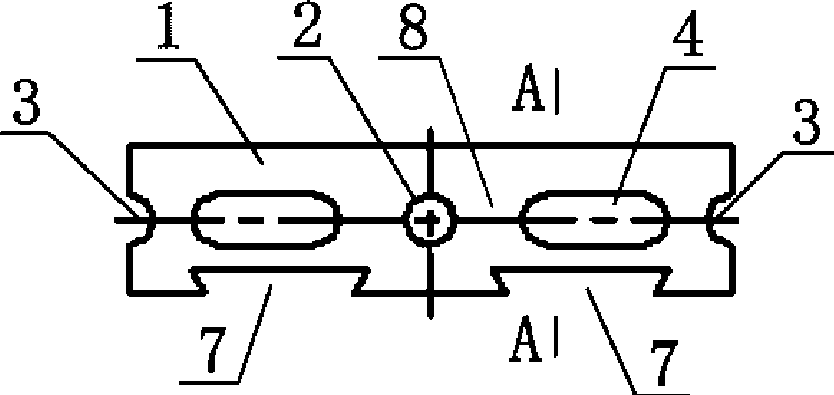

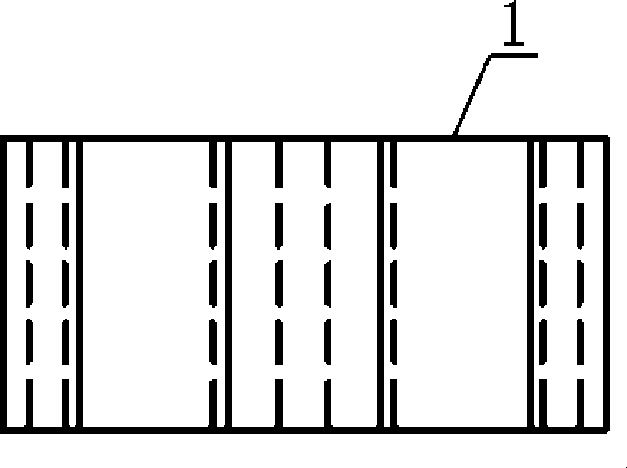

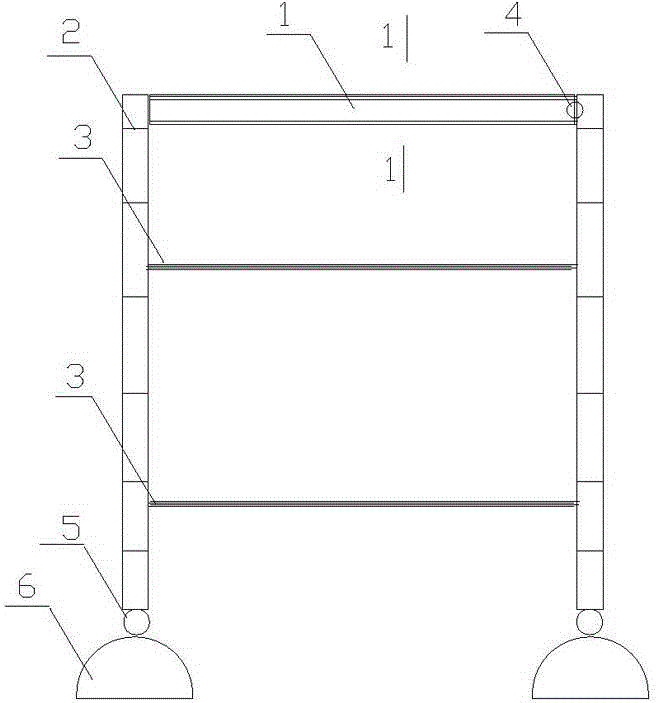

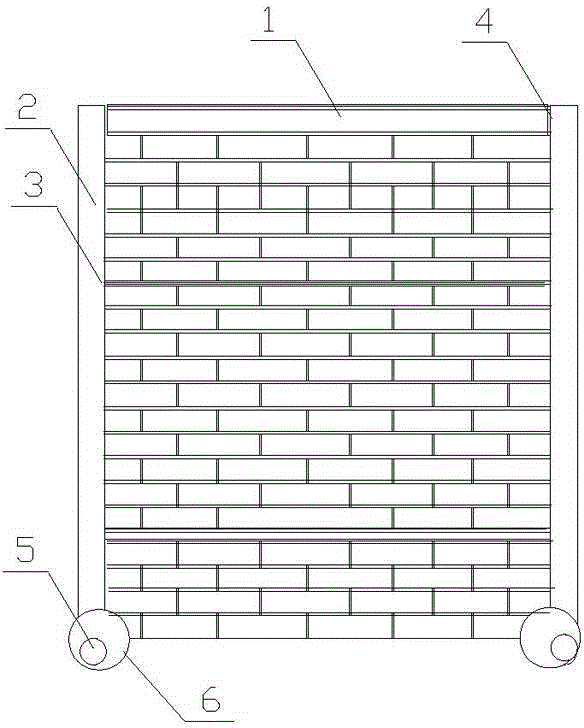

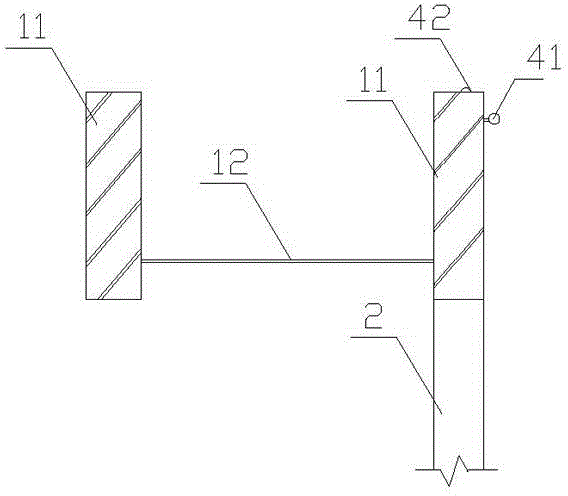

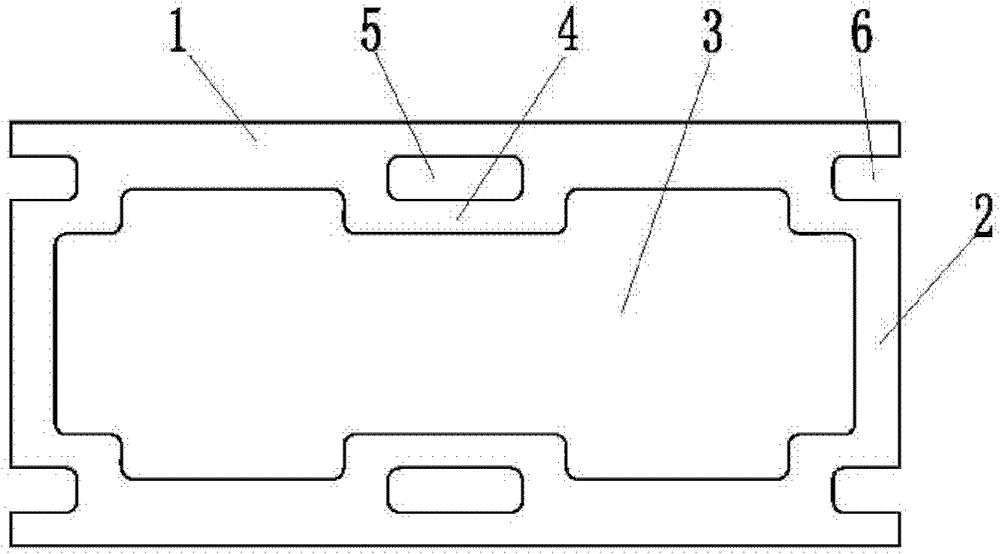

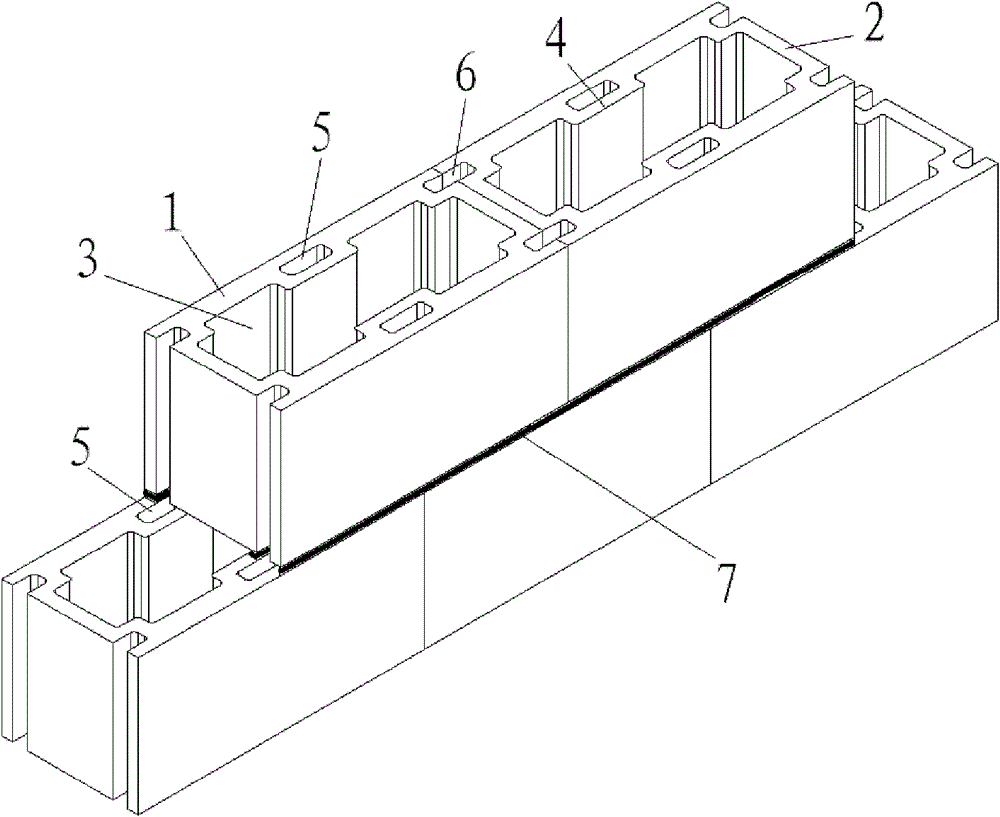

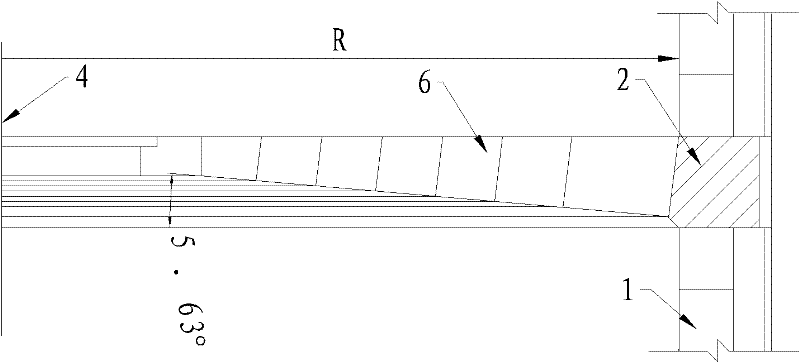

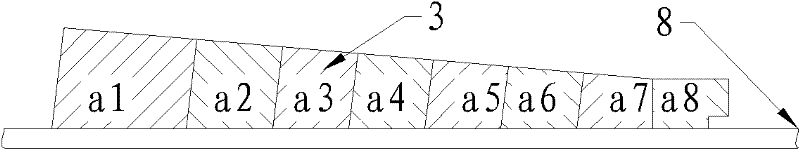

Brick wall masonry device and using method thereof

InactiveCN104806029ANo dripping phenomenonImprove economyBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a brick wall masonry device, which is designed for improving the brick wall masonry quality, and a using method thereof, and belongs to the building construction field. The brick wall masonry device comprises a masonry slot (1), stand columns (2), cross bars (3), a leveling device (4), hinges (5) and vacuum suckers (6); during ground masonry construction, the vacuum suckers (6) are firmly placed on the ground; when the masonry is carried out above the ground, the vacuum suckers (6) are firmly sucked on the wall. The using method comprises the following steps of during masonry, paving mortar in the masonry slot (1), so that a mortar surface is kept flush with the top surface of a adjustable drawbar (12) of the masonry slot; bricking and extruding mortar, so that a vertical mortar joint is full of mortar; lightly knocking a brick face with a cleaver, so that the brick top surface is kept flush with the top surface of a masonry slot plate (11). The brick wall masonry device has the beneficial effects that a mortar leakage phenomenon is not generated, the masonry quality is greatly improved, the mortar leakage is avoided, and the environment is greatly improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

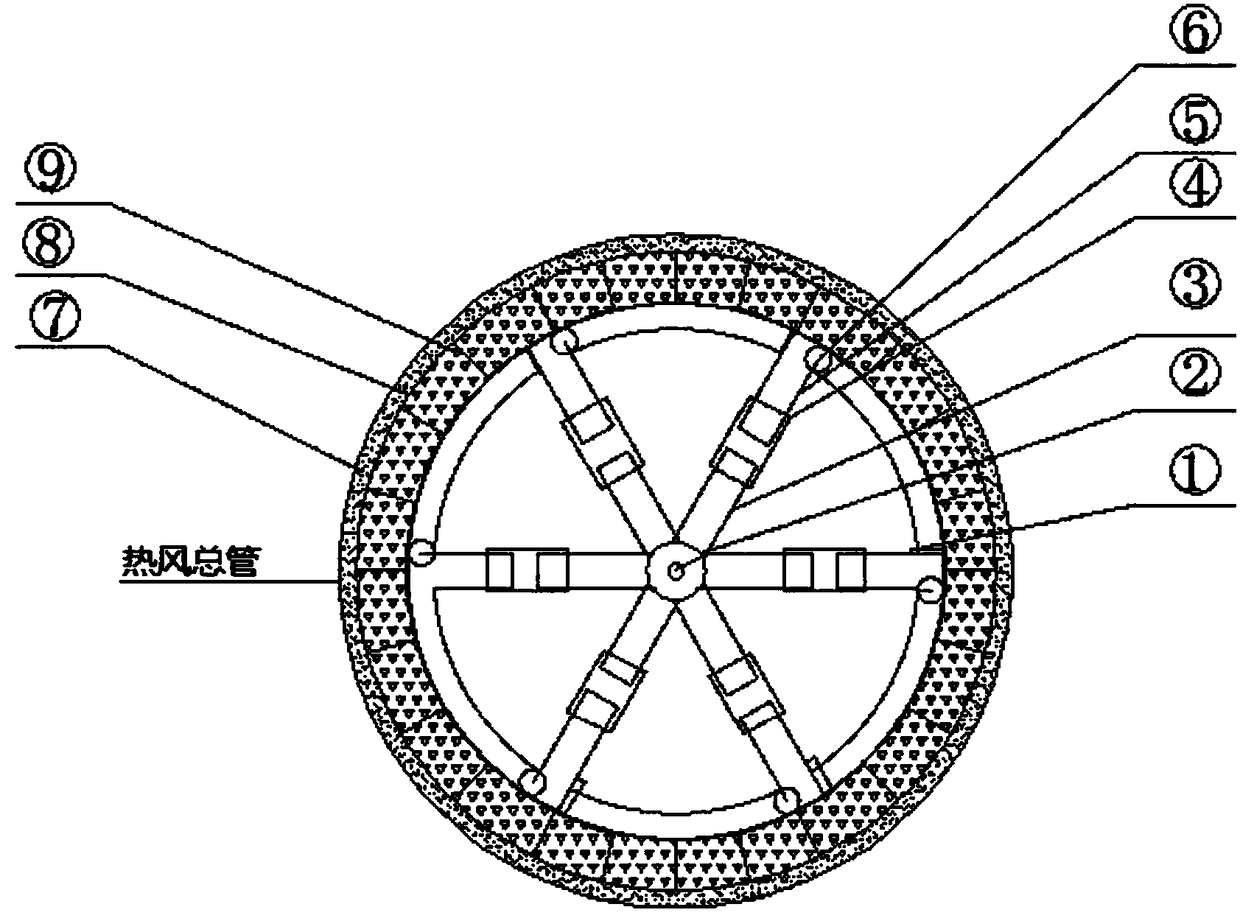

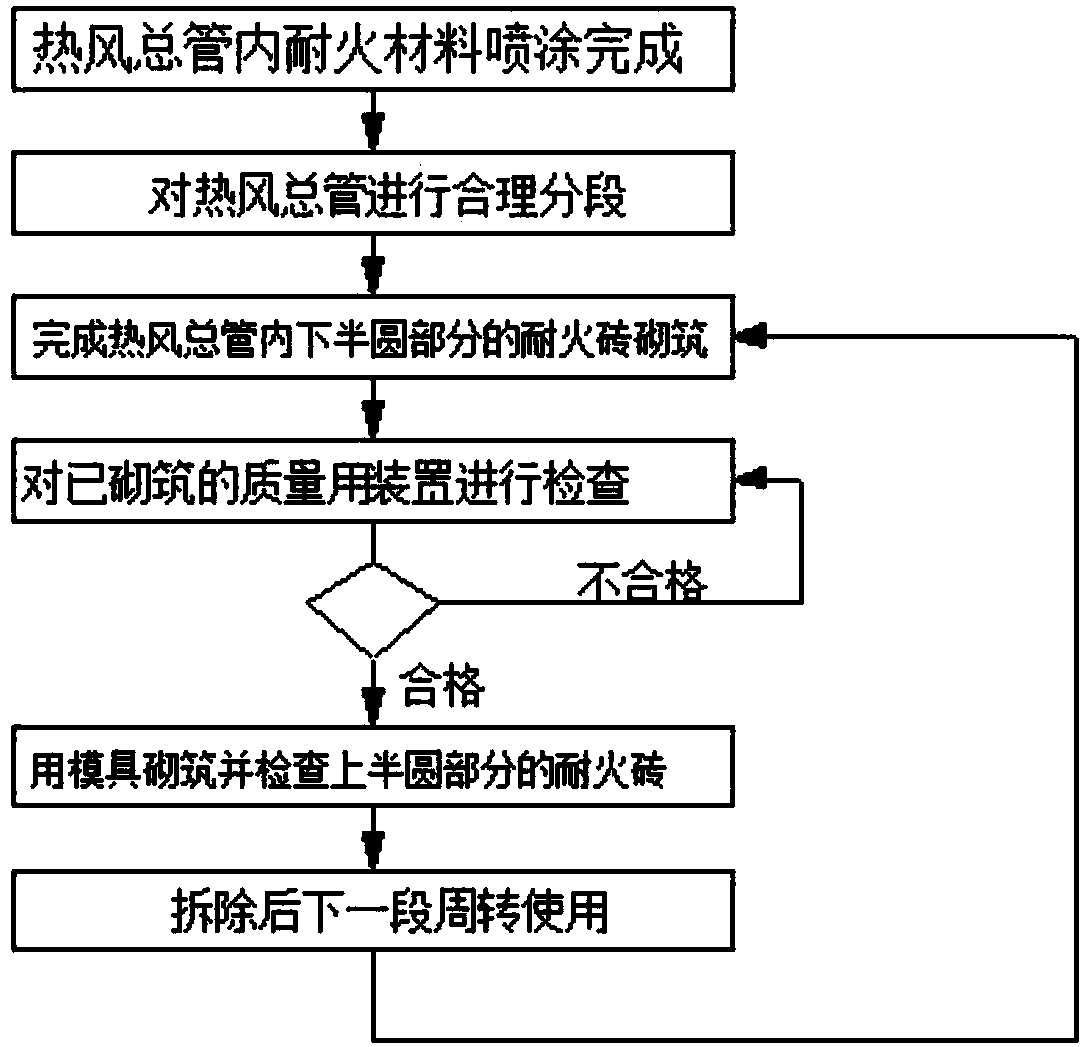

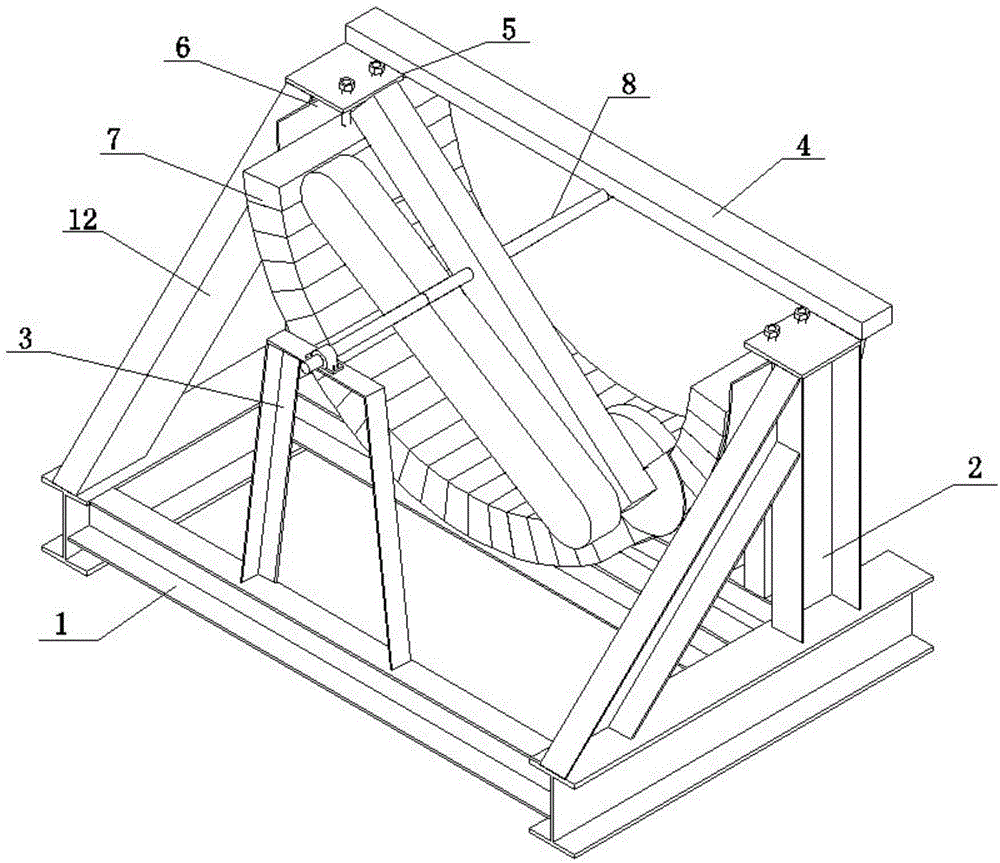

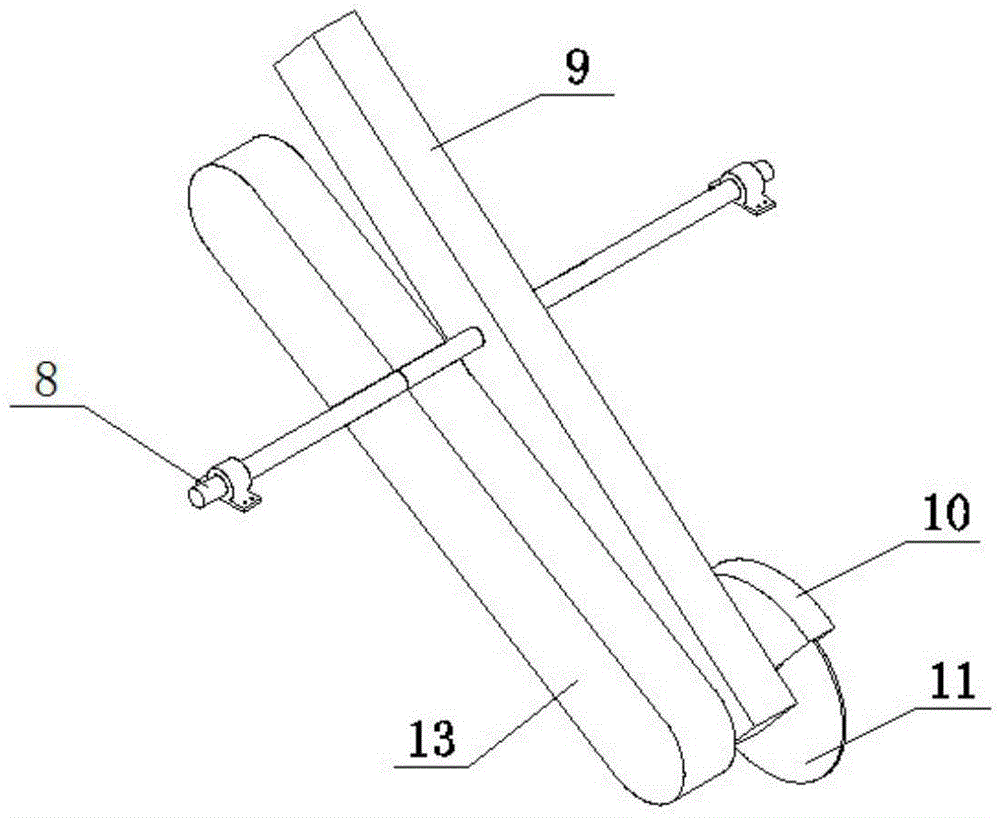

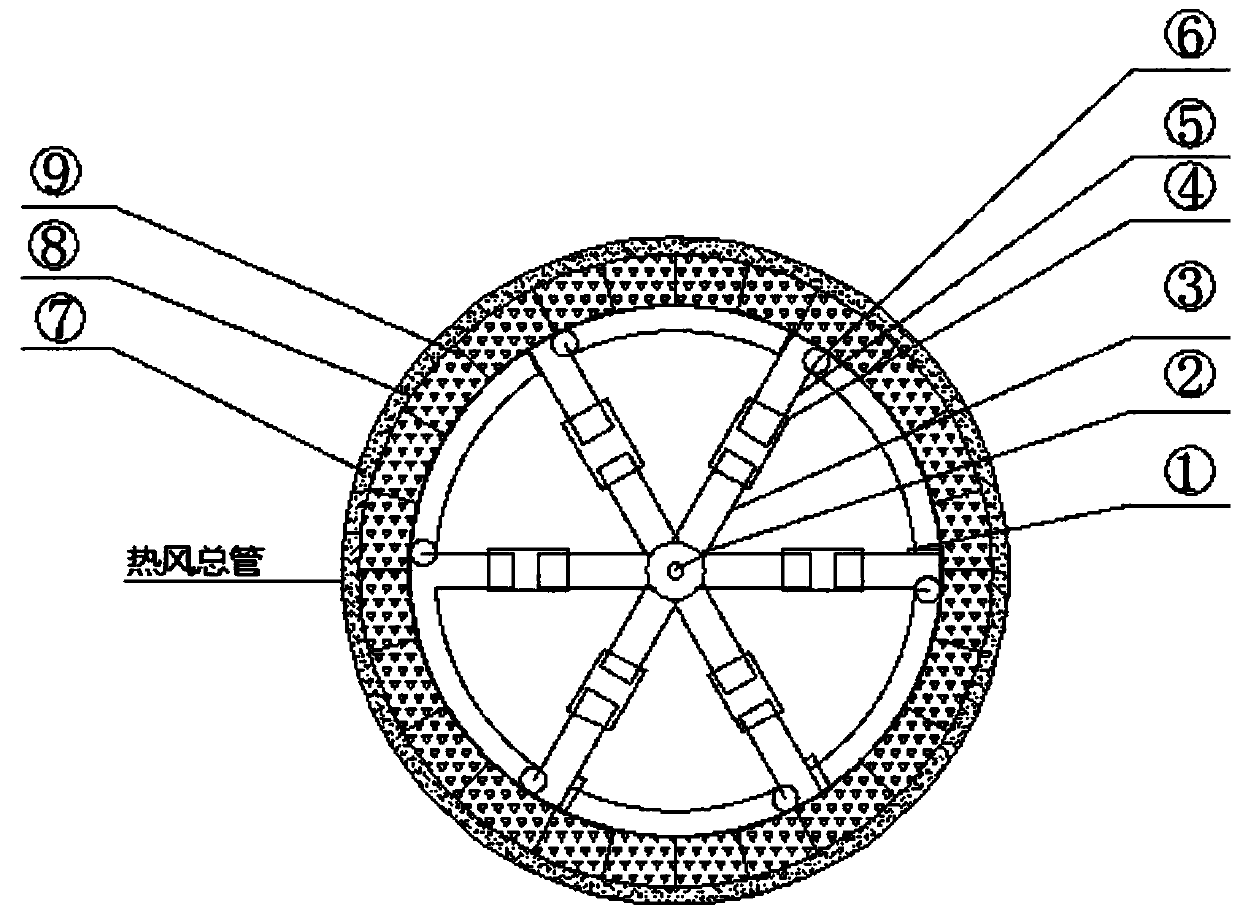

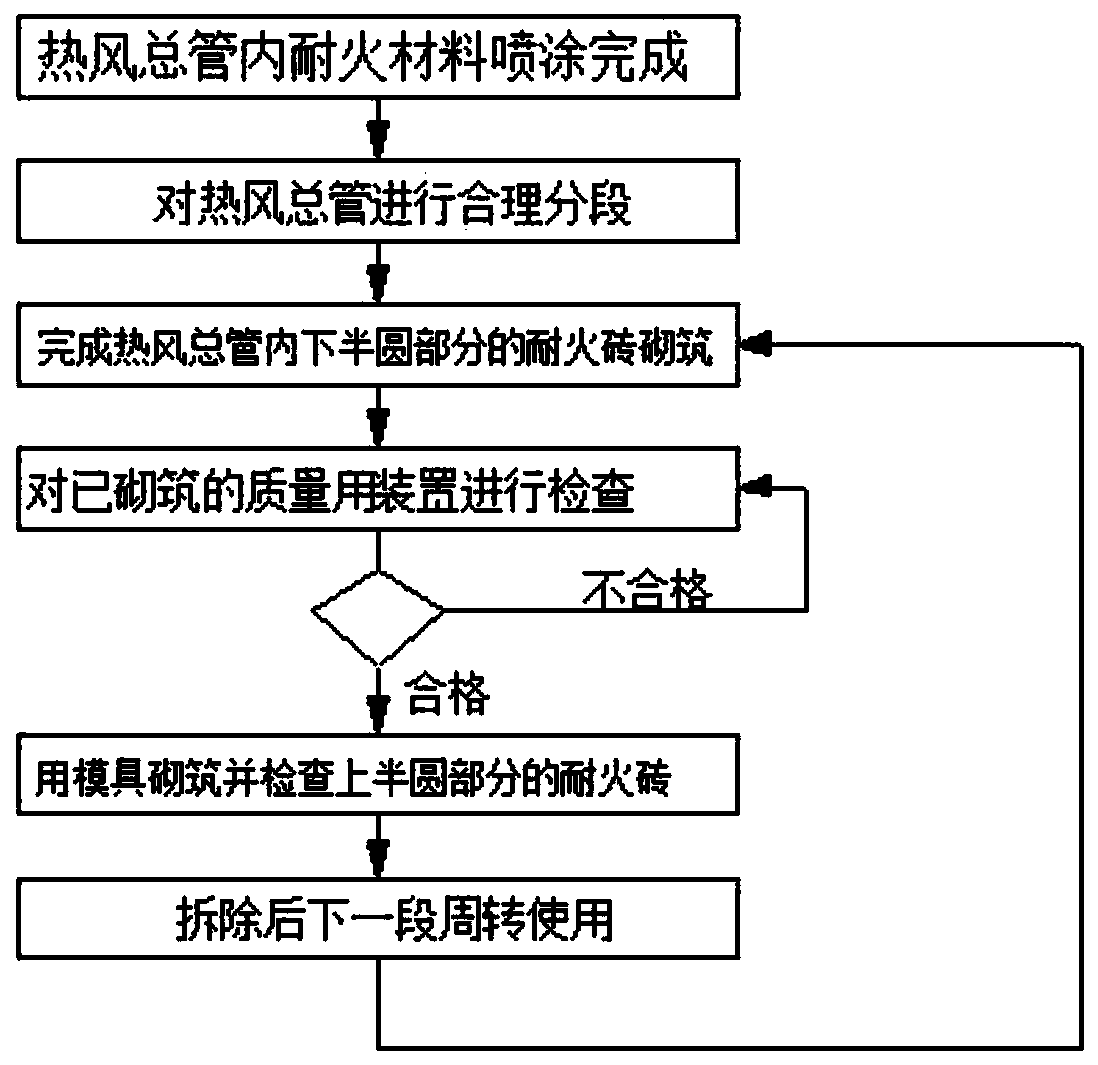

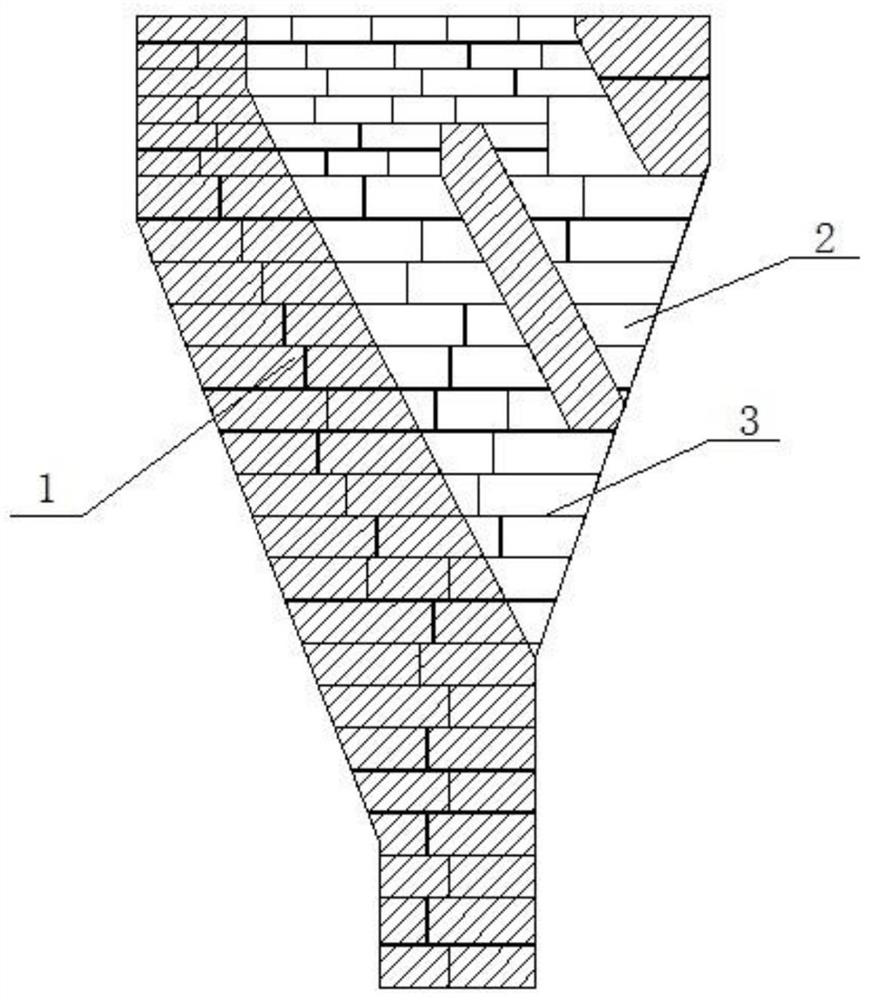

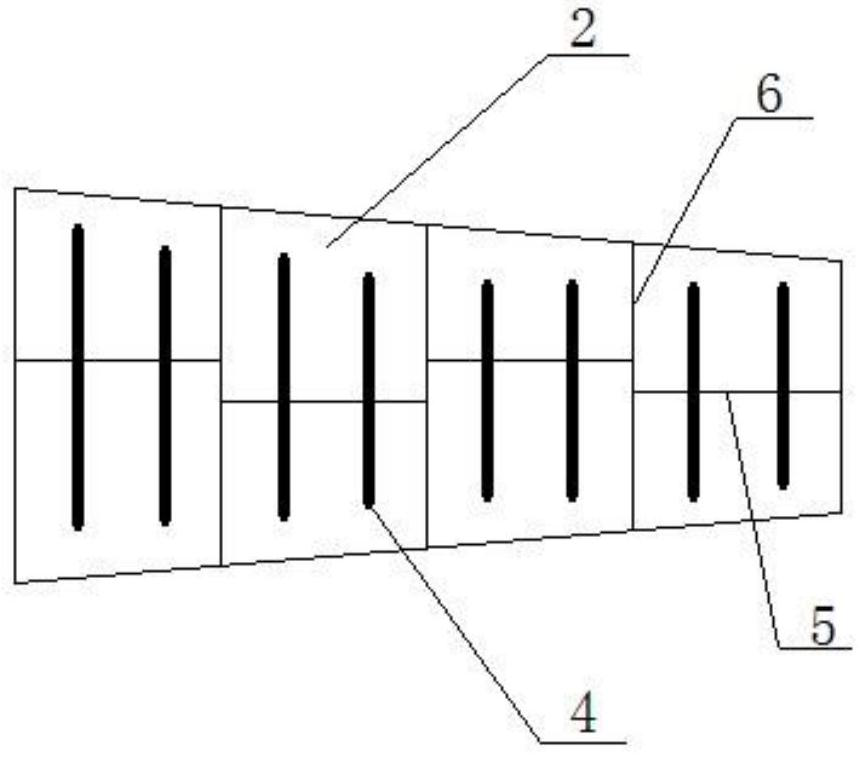

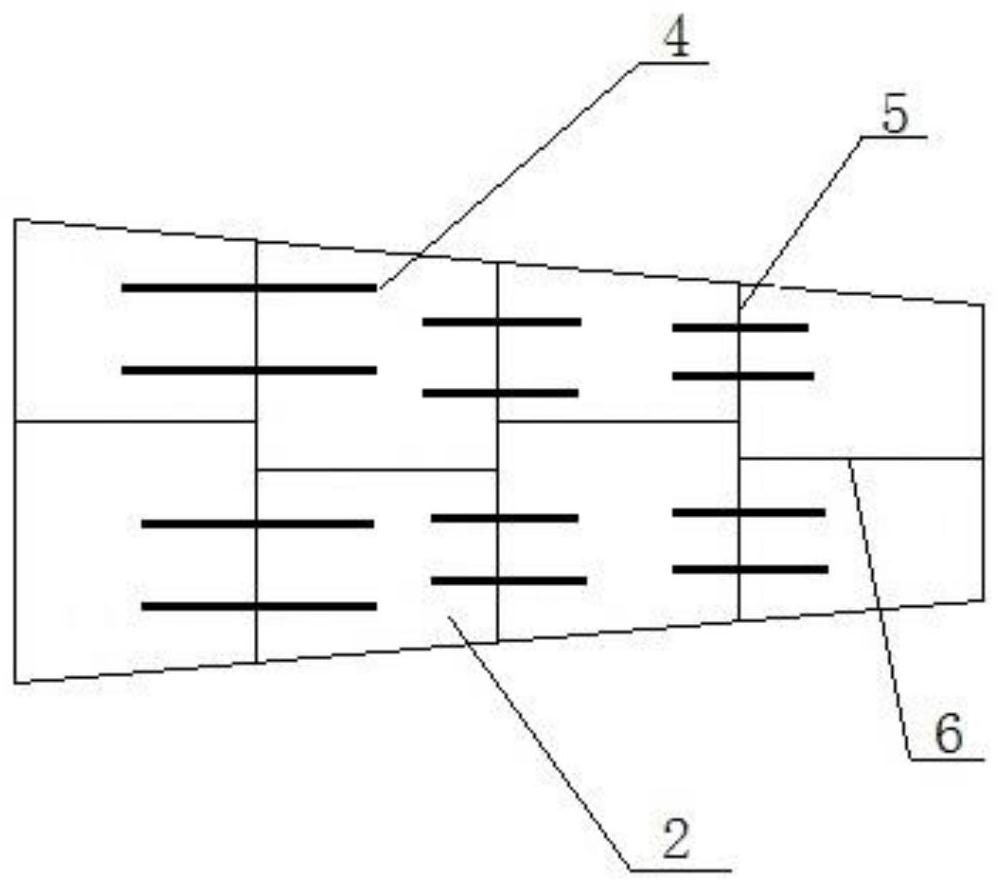

Hot blast main refractory material building die and construction method thereof

ActiveCN108396090AEasy to operateEasy to disassembleBlast furnace detailsHeating stovesBrickButt joint

The invention relates to a hot blast main refractory material building die and a construction method thereof. The die comprises a center shaft and three supporting rods with the middle portions rotationally arranged on the center shaft. The supporting rods can stretch and contract on the two sides of the center shaft. Arc arms are hinged to the two ends of each supporting rod, one ends are provided with butt-joint clamping grooves, the arc arms are distributed around the center shaft in the same direction and are equal in length, the other ends of the arc arms can be connected with the butt-joint clamping grooves in the next supporting rods in a matched manner, and the refractory brick inner circle meeting the design requirement can be defined after the arc arms and the butt-joint clampinggrooves are connected in a matched manner. According to the die, construction is conducted in a rotation pushing manner, the number of pipe interior supports is reduced on the premise that the quality testing and die dismounting time is saved, the quality is guaranteed on the premise that space is saved, the construction quality problem can be rapidly found, repeated usage can be achieved in thenarrow space of a hot blast main, and collisions are avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

Underwater stone block building technology

InactiveCN1372045ASave workImprove construction progressArtificial islandsUnderwater structuresUnderwaterConstruction design

The present invention relates to an underwater blockstone masonry process in building engineering blockstone masonry field, and is characterized by that according to the construction design requirements for blockstone preparing blockstones, at the same time mixing cemkent and grit, stirring them and making them into dried cement grit mixture outside of foundation pit; arranging a layer of blockstones in the water of foundatino pit; respectively spreading and filling dry cement grit mixture material on the blockstone layer and into the gaps between blockstones; after the dry cement grit mixture material is mixed with water, the above-mentioned cement grid mixture material can be become into cement mortar; then laying second layer of blockstones until the construction is completed.

Owner:大庆油田路桥工程有限责任公司

Rotary brick cutting machine

ActiveCN104827590AImprove masonry qualityAvoid displacementWorking accessoriesStone-like material working toolsDrive shaftEngineering

The invention discloses a rotary brick cutting machine. The rotary brick cutting machine comprises a machine frame and an arc-shaped plate. The two ends of the arc-shaped plate are connected with the machine frame. A cutting device is arranged above the arc-shaped plate and comprises a motor and a rotating shaft with the two ends connected to the machine frame. The rotating shaft perpendicularly penetrates through a rotating arm and drives the rotating arm to rotate. A cutting disc is arranged at the lower end of the rotating arm. A transmission shaft of the cutting disc is connected with the driving end of the motor through a belt. Limiting plates are arranged at the two ends of the arc-shaped plate respectively. According to the rotary brick cutting machine, the arc-shaped plate serves as a support, and refractory bricks integrally in a semicircular shape can be processed to be used for constructing arch-shaped brickworks, wherein all the refractory bricks arranged according to the brickworks serve as wholes; as for the refractory bricks of one construction unit, the multiple refractory bricks firstly serve as a whole to be arranged on the arc-shaped plate, then the whole is cut, gaps between the refractory bricks are small, the construction quality of the brickworks is improved, and the construction intensity is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

Brick joint control tool used for fully laying carbon bricks on furnace bottom of blast furnace, and using method of brick joint control device

InactiveCN105219901AShould not be damagedLong-term turnover useBlast furnace componentsBlast furnace detailsEconomic benefitsBuilding construction

The invention provides a brick joint control tool used for fully laying carbon bricks on the furnace bottom of a blast furnace and the using method of the brick joint control device. The brick joint control tool comprises a screw wedge and a screw support, the method used for fully laying the carbon bricks on the furnace bottom of the blast furnace comprises the following steps: during brick entering and pre-laying, using the screw wedge for wedge-caulking to the two ends of each carbon brick to be built in each row, during carbon brick laying, placing the screw support on the two sides of a brick in a center row so as to tightly prop the carbon brick to be built, removing the screw wedge, and removing the screw support. The brick joint control tool provided by the invention has the advantages that the material access is easy, the manufacturing is simple, brick joint control is convenient, and brick joint quality can reach the standard easily; adjustment can be performed arbitrarily, the probability of damage is low, and repeated and long-term cycle use is facilitated. Therefore, the laying quality is improved, and the construction progress is accelerated; and timber for manufacturing wooden wedges and the cost for purchasing screw jacks in the traditional process are reduced greatly, therefore, the construction cost is lowered, and economic benefits are improved.

Owner:TIANJIN 20 CONSTR

A self-insulating anti-seismic block and its application method

InactiveCN103174252BReduce in quantityImprove carrying capacityConstruction materialWallsVertical planeThermal insulation

The invention belongs to the technical field of building materials, and relates to a building block. The building block comprises a longitudinal outer wall and a transverse outer wall which are enclosed to form a hollow thermal insulation cavity, and is characterized in that: the middle part of the longitudinal outer wall is provided with a reinforcing rib which protrudes towards the direction of the hollow thermal insulation cavity; the reinforcing rib and the longitudinal outer wall are enclosed together to form a middle grouting passage which is vertically run-through; the middle grouting passage is symmetrically arranged along a middle vertical plane of the longitudinal outer wall of the building block; and the outer end face of the transverse outer wall is provided with a vertical end face grouting groove. The building block has the characteristics of high self-thermal-insulation capacity, light deadweight, high strength and the like, and has a flat appearance, high integrity and high earthquake-proof capacity after being built; in addition, by matching with a method for building a vertical thermal insulation wall or a thermal insulation wall without mortar joints by applying the self-thermal-insulation earthquake-proof building block, the construction efficiency can be greatly increased, and easiness for standardization, high cost performance and high easiness for guaranteeing the construction quality are guaranteed. The building block can be widely applied to overall maintenance outside a building structure and a bearing structure of a low-rise building, and has extremely broad market prospect.

Owner:JIANGXI WEIYI TECH DEV

Method for building converter bottom

The invention relates to a method for building a converter bottom. The converter bottom is built in a successive building and drilling mode. The method comprises the following steps of: 1) taking solid bottom gun bricks for later use; 2) building converter bottom bricks outwards along the center of the converter bottom, and starting to lay the solid bottom gun bricks when the converter bottom bricks are built to the positions of gun holes; 3) pre-positioning the bottom gun bricks, ensuring that the bottom gun bricks are closely adjacent to the converter bottom bricks, and building the converter bottom bricks among the bottom gun bricks, wherein the movement amount of the bottom gun bricks is controlled within + / -50mm away from the central line of a bottom gun; and 4) after a converter is built, drilling at positions of the bottom gun bricks corresponding to a muzzle and performing top-bottom blowing. The method effectively reduces brick cutting amount, ensures high building quality, reduces accident rate and improves building efficiency.

Owner:ANGANG STEEL CO LTD

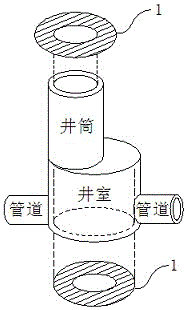

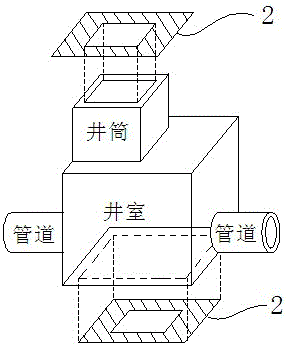

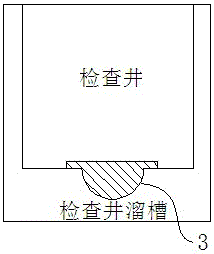

A mold for an inspection well and a method for constructing an inspection well using the mold

ActiveCN105113608BImprove masonry qualityAvoid accumulationArtificial islandsSewerage structuresBuilding constructionEnvironmental geology

The invention belongs to the field of building engineering, and particularly relates to molds for inspection wells and a method for constructing the inspection wells through the same. The molds comprise the circular well mold, the rectangular well mold and the chute plastering mold. The circular well mold is used for construction of a circular well and is of a circular plate structure with a circular hollow interior, the outer diameter of the circular well mold is equal to the inner diameter of a well chamber, and the inner diameter of the circular well mold is equal to that of a shaft. The rectangular well mold is used for construction of a rectangular well and is of a rectangular plate structure with a rectangular hollow interior, the length and width of the outer side of the rectangular well mold are equal to those of the inner wall of a well chamber, and the length and width of the inner side of the rectangular well mold are equal to those of the inner wall of a shaft. The chute plastering mold is used for well bottom chute plastering and is a semicircular mold with the diameter equal to the inner diameter of a pipeline. In the constructing process of the inspection wells, the specially-made molds for the inspection wells are used for comparison control and used based on construction conditions for rectifying a deviation in time in the construction process, and error accumulation is avoided, so that the overall construction quality of the inspection wells is improved, and the working efficiency of workers is improved.

Owner:JINAN URBAN CONSTR GRP

Device and method for controlling verticality and center distance of coke oven tube brick masonry

ActiveCN112574762BEasy to adjustPrevent fallingCoke oven safety devicesCoke oven brickworkInfraredClassical mechanics

The invention provides a device for controlling the verticality and center distance of coke oven pipe brick masonry, which includes a positioning device and a pipe brick hole cleaning device. An infrared rangefinder and a target for measuring the center distance, the positioning device includes a verticality correction device and a placement frame for placing the infrared rangefinder, the position of the positioning device can be adjusted, and the target is connected to the furnace by a screw The head is fixed. The positioning device is used to quickly measure and assist in adjusting the verticality and center distance of the pipe bricks. The infrared rangefinder and the target form a center distance measurement system. The verticality correction device is used to adjust the verticality of the pipe bricks. The invention can quickly and accurately adjust the verticality and center distance of pipe bricks, avoid the problems of upper and lower pipe bricks being misplaced and excessive center distance error resulting in re-laying, ensure the quality of masonry, and improve the efficiency of masonry.

Owner:CHINA FIRST METALLURGICAL GROUP

Multilayer roaster building method and hearth replacing method

InactiveCN101900486BImprove maintenance qualityEnsure height positionFurnace componentsBrickArchitectural engineering

The invention discloses a multilayer roaster building method and a hearth replacing method which are easy to ensure the building quality, wherein the building method comprises the following steps of: manufacturing a hearth arch vaulting; building the wall and each layer of skew bricks of a roaster; installing the hearth arch vaulting at a position at a bottommost layer, building a hearth at the bottommost layer, and sequentially upwards installing the hearth arch vaulting and building the hearth layer by layer, wherein when the hearth arch vaulting is installed, the installation height of thehearth arch vaulting is more than the designed hearth position height; and after the slurry of a hearth brick joint is initially set, dismantling the hearth arch vaulting. Hearth bricks are firstly selected, prebuilt and numbered, and a slurry test before hearth building is done. In the hearth replacing method thereof, when the hearth arch vaulting is installed, the installation height of the hearth arch vaulting is more than the designed hearth position height, and the hearth bricks are built according to prebuilt numbers. The invention can effectively overcome hearth sinking, improves the building efficiency and quality, reduces the fault rate, saves the maintenance cost and can be used for the daily maintenance in heavy repair, medium repair and periodical repair and the building of newly-established roaster linings.

Owner:PANGANG GRP ENG TECH +1

Radiation type building brick combination door neck brick and building method thereof

The invention relates to the field of heat engineering kiln firebrick building and discloses a radiation type building brick combination door neck brick comprising a first brick and a second brick, wherein the first brick and the second brick can be mutually bonded; the first brick comprises a surface A and a surface B; when the surface B and the first brick are built, an angle between radiation lines of an annular building surface is smaller than a self-lock frictional angle of the first brick; the second brick comprises a surface C and a surface D; when the surface C and the first brick arebuilt, an angle between the radiation lines of the annular building surface is smaller than a self-lock frictional angle of the second brick; the surface B of the first brick is mutually bonded with the surface C of the second brick; and the surface A of the first brick and the surface D of the second brick are respectively bonded with the adjacent bricks. The invention also provides a building method of the combination door neck brick, and the combination door neck brick is adopted to combine each ring, By changing the shape of the combination door neck brick and the building construction method, the locking strength of the brick rings and the integral structural performance of a kiln lining are increased; when bricks of both sides are not destroyed, a combination door is locked by neck bricks, and the quality of the brick and the integral building construction is ensured.

Owner:WUGANG REFRACTORY CO LTD

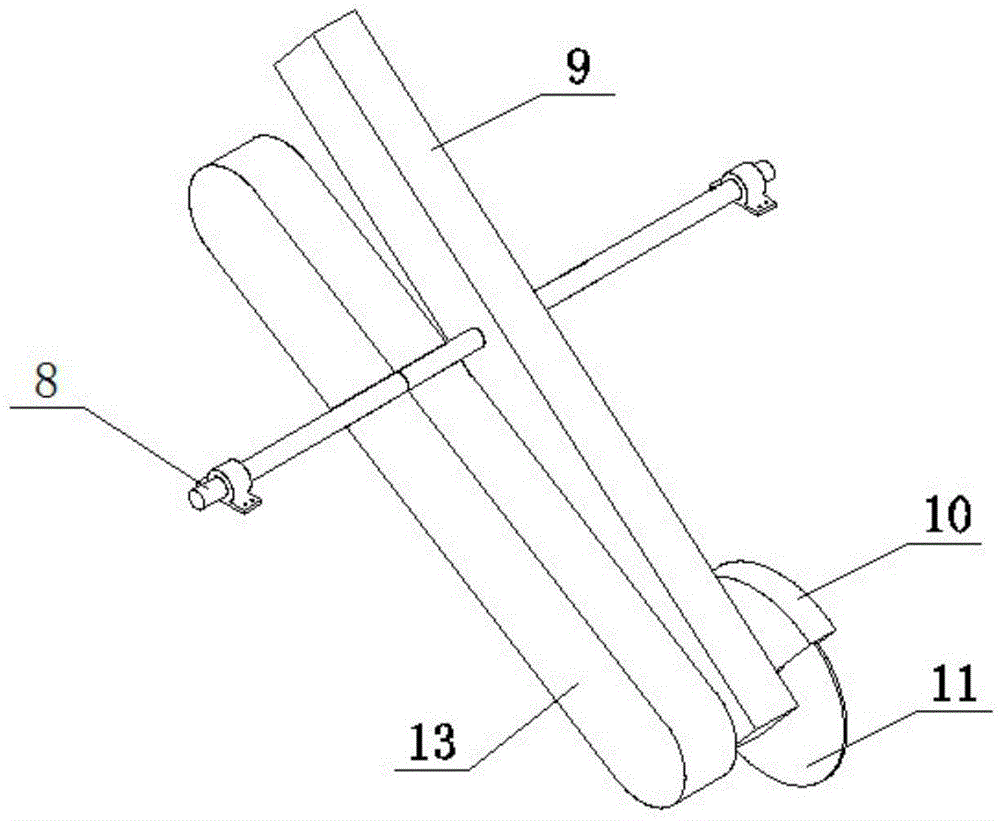

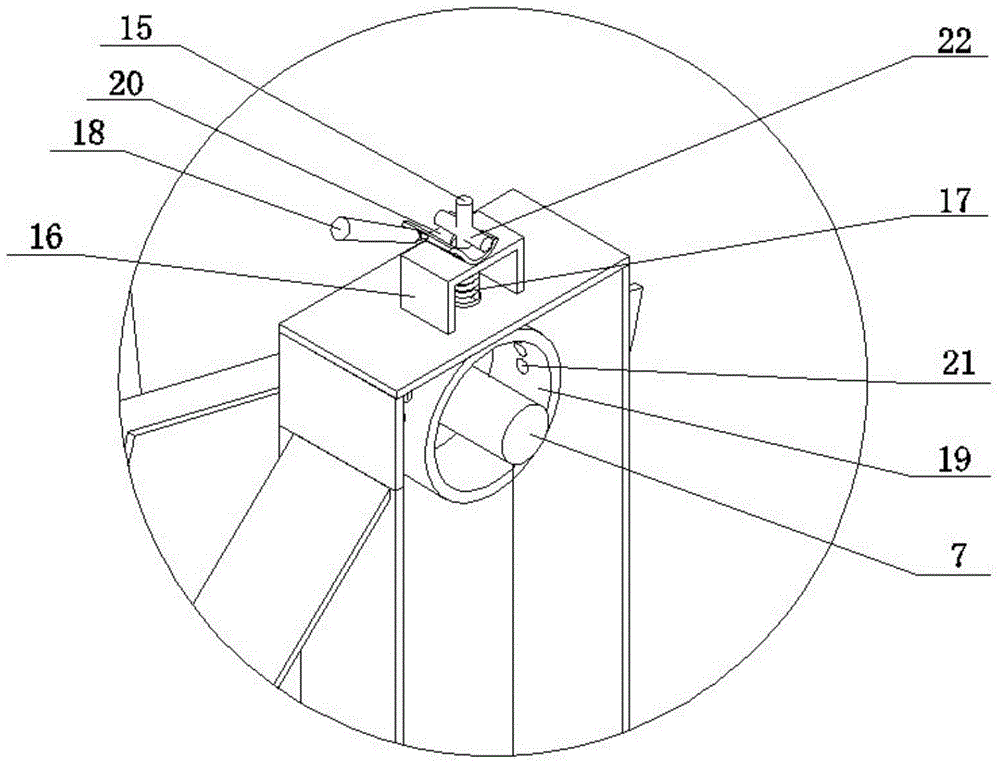

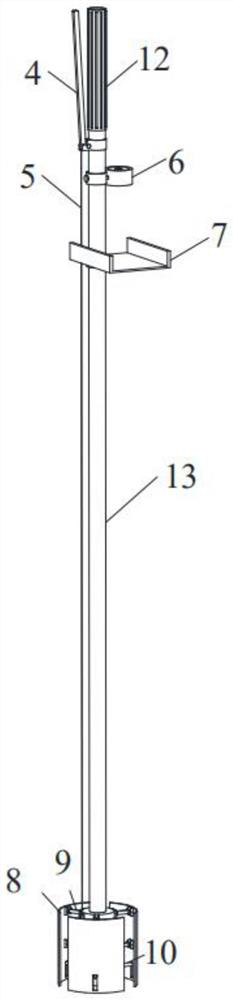

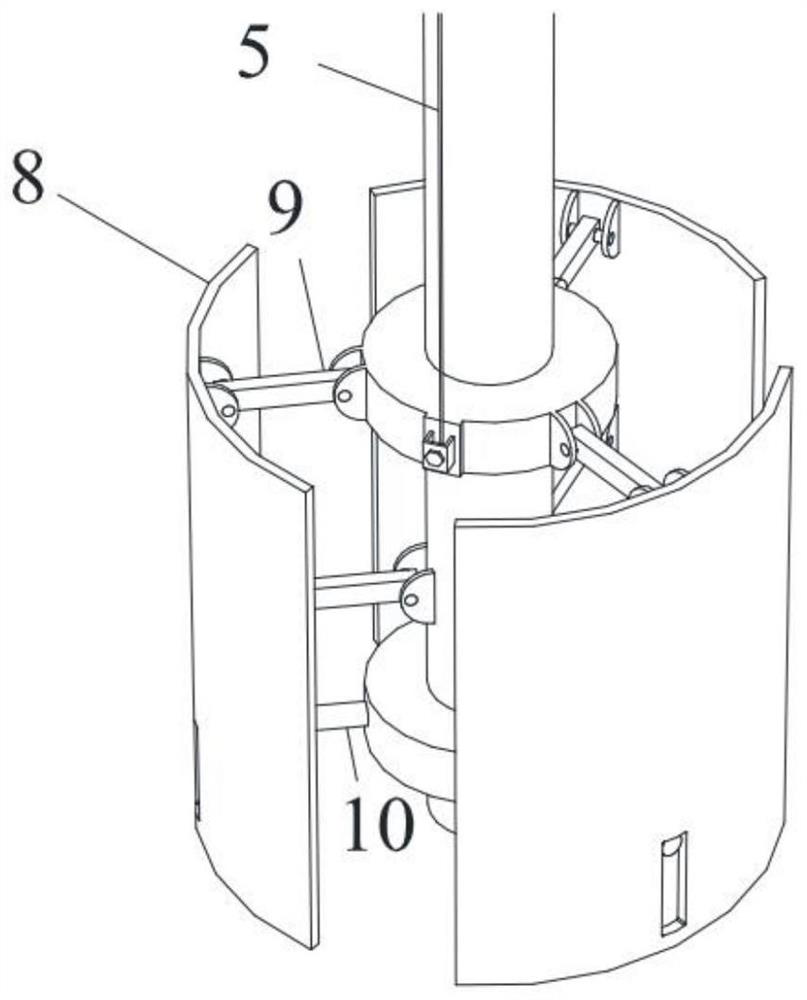

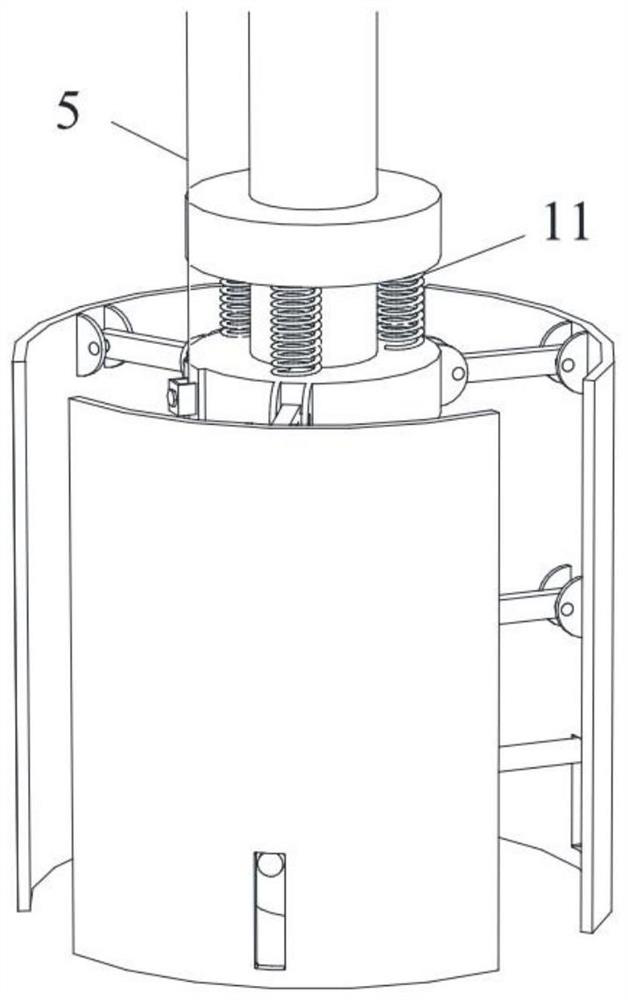

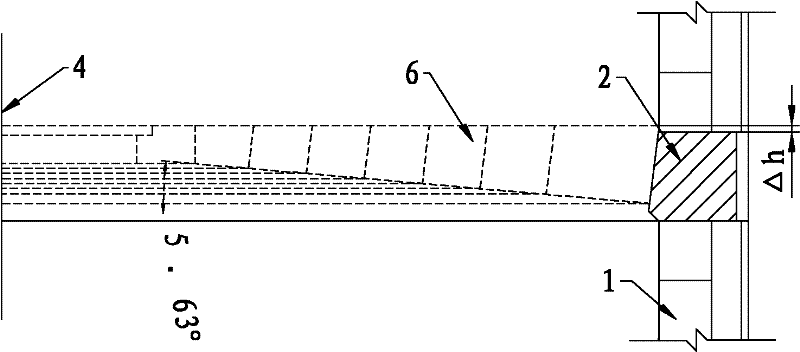

A kind of masonry engineering construction device and its construction technology

ActiveCN112227749BReduce workloadImprove masonry qualityBuilding material handlingBrickArchitectural engineering

The application relates to a masonry construction device and its construction technology, which includes a base that moves intermittently in a straight line on the ground, a lifting seat is arranged on the base to move up and down in the vertical direction, and a first mechanism for driving the lifting seat to go up and down is arranged on the base. Drive device, the lifting seat is provided with a support rod sliding along the horizontal direction, the support rod is located on the side of the lifting seat away from the lifting seat, and the clamping device and the spraying device are arranged in sequence, and the lifting seat is provided with a first for driving the support rod to slide. Two driving devices, a brick feeding device is arranged on the base below the clamping device. When using the construction device for bricklaying work, move the base to the position to be laid, first clamp the block, then drive the lifting seat to the height to be laid, drive the support rod to move to the wall to be laid, and during the moving process Among them, the mortar is sprayed on the wall and the blocks are placed on the wall successively. This application has the effect of reducing the workload of the staff and improving the quality of masonry.

Owner:飞帆集团有限公司

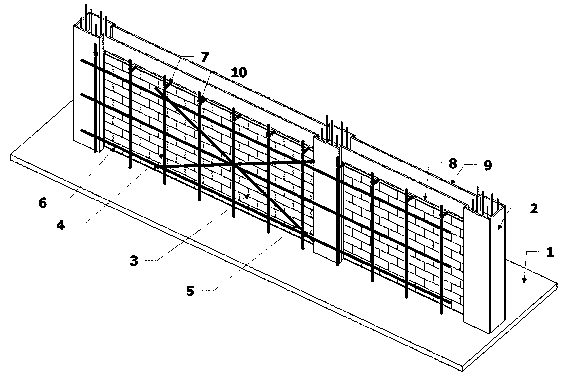

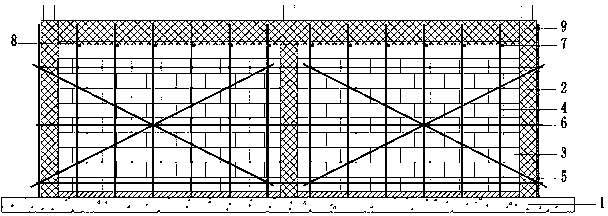

Construction method for concrete structure with fabricated masonry filler walls

InactiveCN108457402AHigh value attached to the wallHigh quality wall masonryWallsRebarReinforced concrete

The invention discloses a construction method for a concrete structure with fabricated masonry filler walls. The construction method comprises the specific processes that gaskets are placed on a floor(1) and mortar is laid on the floor (1), then the fabricated masonry filler walls (3) are lifted, and after the walls are lifted, the fabricated masonry filler walls (3) and frame columns or shear walls (2) are connected and fixed; then vertical rods (4) are erected on the two sides of the fabricated masonry filler walls (3), and the vertical rods (4) are fixedly connected with diagonal web members(5) and longitudinal horizontal rods (6) by connecting fasteners (10); transverse horizontal rods (7) are arranged at the bottoms of beam formwork bottom forms (8) above the fabricated masonry filler walls (3), and the transverse horizontal rods (7) and the vertical rods (4) are fixed by the connecting fasteners (10); and then the beam formwork bottom forms (8) and beam formwork side forms (9) are erected on the transverse horizontal rods (7), reinforced concrete beams are poured, and after concrete is maintained to the specified strength, formworks are removed according to the regulations.

Owner:黄靓 +1

Hot air main pipe refractory masonry mold and its construction method

ActiveCN108396090BPrevent slidingImprove masonry qualityBlast furnace detailsHeating stovesBrickButt joint

The invention relates to a hot blast main refractory material building die and a construction method thereof. The die comprises a center shaft and three supporting rods with the middle portions rotationally arranged on the center shaft. The supporting rods can stretch and contract on the two sides of the center shaft. Arc arms are hinged to the two ends of each supporting rod, one ends are provided with butt-joint clamping grooves, the arc arms are distributed around the center shaft in the same direction and are equal in length, the other ends of the arc arms can be connected with the butt-joint clamping grooves in the next supporting rods in a matched manner, and the refractory brick inner circle meeting the design requirement can be defined after the arc arms and the butt-joint clampinggrooves are connected in a matched manner. According to the die, construction is conducted in a rotation pushing manner, the number of pipe interior supports is reduced on the premise that the quality testing and die dismounting time is saved, the quality is guaranteed on the premise that space is saved, the construction quality problem can be rapidly found, repeated usage can be achieved in thenarrow space of a hot blast main, and collisions are avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

Bracket structure for chute area of dry quenching furnace

PendingCN113755187AImprove masonry qualityExtended service lifeCoke quenchingMortar jointStructural engineering

The invention relates to a bracket structure for a chute area of a dry quenching furnace. The bracket structure is formed by building a plurality of layers of bracket bricks; and a plurality of supporting pieces are arranged between every two adjacent layers of bracket bricks, the supporting pieces are hard supporting pieces, the thickness of the supporting pieces is the same as that of mortar joints, the top faces of the supporting pieces make direct contact with the upper layer of bracket bricks, and the bottom faces of the supporting pieces make direct contact with the lower layer of bracket bricks. The supporting pieces are placed in the refractory mortar joints between the bracket brick layers, so that the problems of sinking of the annular air duct and cracking of the chute partition wall caused by deformation of the bracket mortar joints and inaccurate bracket elevation control are effectively prevented, the masonry quality of the dry quenching furnace is improved, and the service life of the dry quenching furnace is prolonged.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com