Building method of flame path wall of roaster

A flue wall and masonry technology, which is applied in the field of roasting furnaces, can solve the problems of high labor intensity of workers, long time of masonry, and affecting the safety of builders, so as to achieve good quality of wall masonry, low labor intensity of workers, and shorten the construction time. The effect of repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

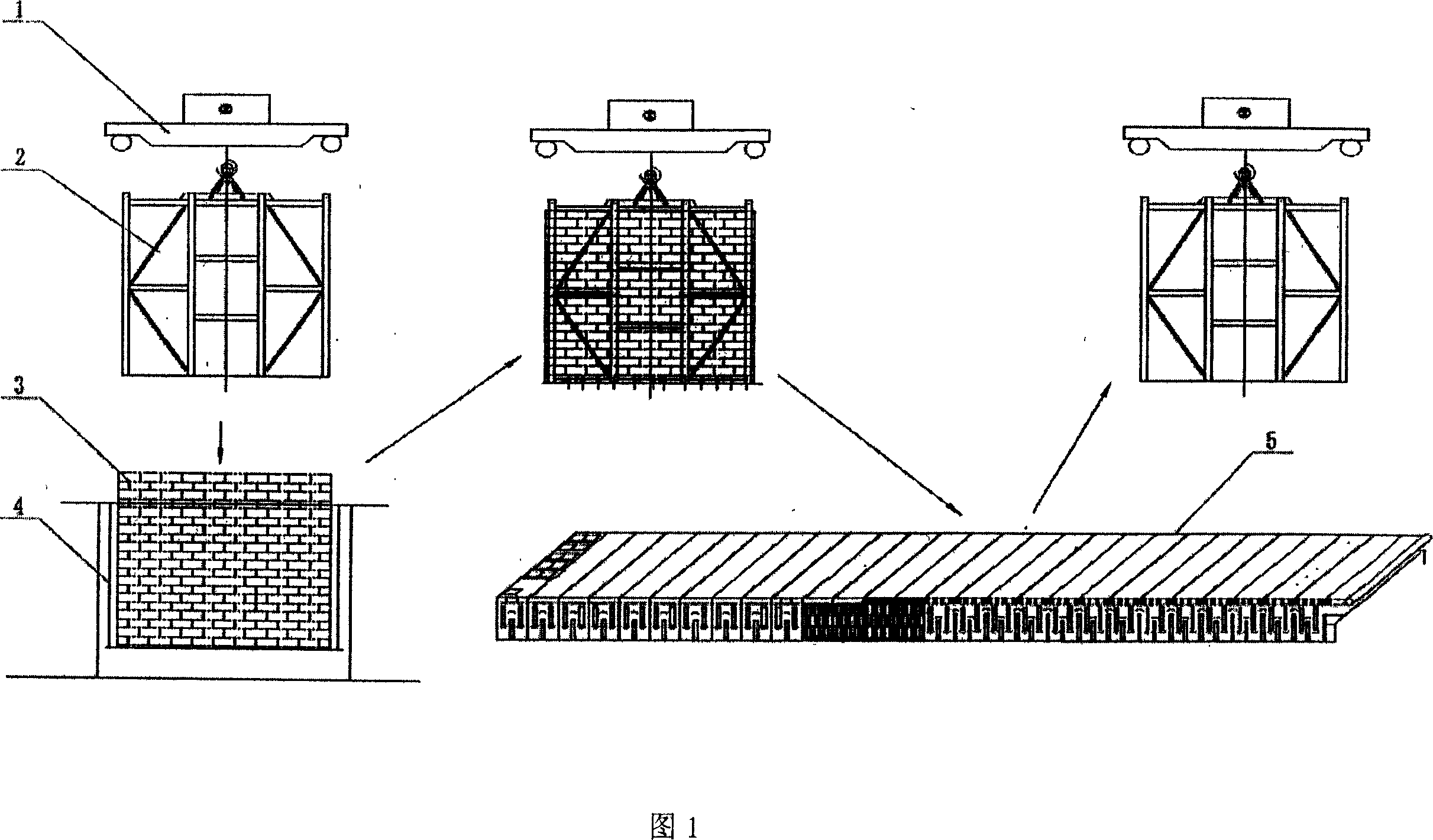

Embodiment 1

[0019] Embodiment 1: Flame wall specifications (length × width × height): 5398 mm × 530 mm × 5248 mm, weighing about 18 tons, the lifting equipment adopts the multi-functional unit of the roasting workshop, and a 25-ton electric motor is added to the unit. The hoist is specially used for hoisting the fire wall; the lifting platform is driven by double screws;

Embodiment 2

[0020] Embodiment 2: Fireway wall specifications (length × width × height): 5398 mm × 530 mm × 5148 mm, weighing about 18 tons, the lifting equipment adopts a special 25-ton hook bridge crane; the lifting platform adopts pulleys drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com