Construction method for concrete structure with fabricated masonry filler walls

A technology of concrete structure and construction method, applied in the direction of walls, building components, building structures, etc., can solve the problems of formwork removal difficulty, filling wall disturbance, high labor cost, etc., to ensure integrity and connection reliability, construction The process is simple and convenient, and the effect of high-quality wall masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

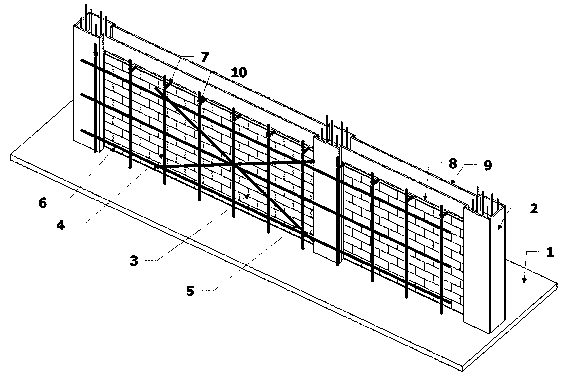

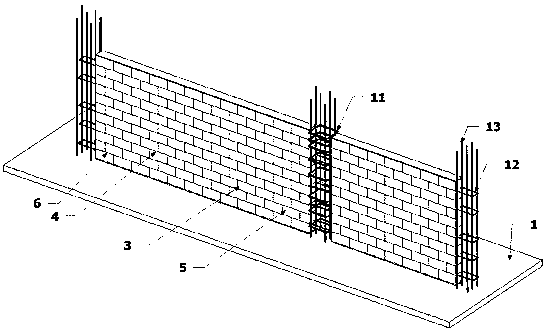

[0026] a. Confirm that the prefabricated infill wall (3) is connected and fixed with the floor (1), column or shear wall (2);

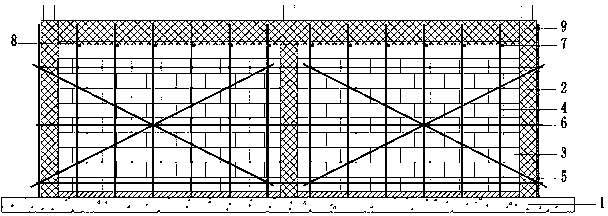

[0027] b. Upright poles (4) are supported on both sides of the prefabricated filling wall (3), and the poles (4) on the same side are fixed with oblique poles (5) and longitudinal horizontal poles (6);

[0028] c. Determine the elevation to deduct the thickness of the bottom formwork (8) of the beam formwork on the basis of the elevation of the bottom of the beam, and mark it on the pole (4);

[0029] d. Install the horizontal horizontal rod (7) at the position marked on the vertical rod, and use the connecting fastener (10) to connect and fix the horizontal horizontal rod (7) with the vertical rods on both sides of the prefabricated wall (3);

[0030] e. Install the beam formwork bottom formwork (8) and the beam formwork side formwork (9) on the horizontal bar (7), and pour the beam concrete after the beam formwork installation is completed;

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com