Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298 results about "Infill wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The infill wall is the supported wall that closes the perimeter of a building constructed with a three-dimensional framework structure (generally made of steel or reinforced concrete). Therefore, the structural frame ensures the bearing function, whereas the infill wall serves to separate inner and outer space, filling up the boxes of the outer frames. The infill wall has the unique static function to bear its own weight. The infill wall is an external vertical opaque type of closure. With respect to other categories of wall, the infill wall differs from the partition that serves to separate two interior spaces, yet also non-load bearing, and from the load bearing wall. The latter performs the same functions of the infill wall, hygro-thermically and acoustically, but performs static functions too.

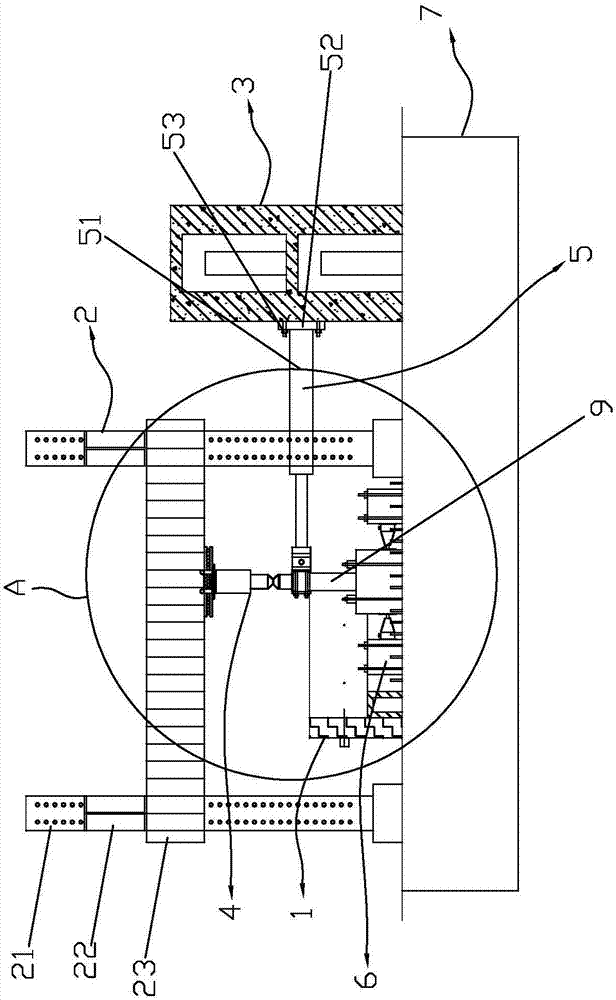

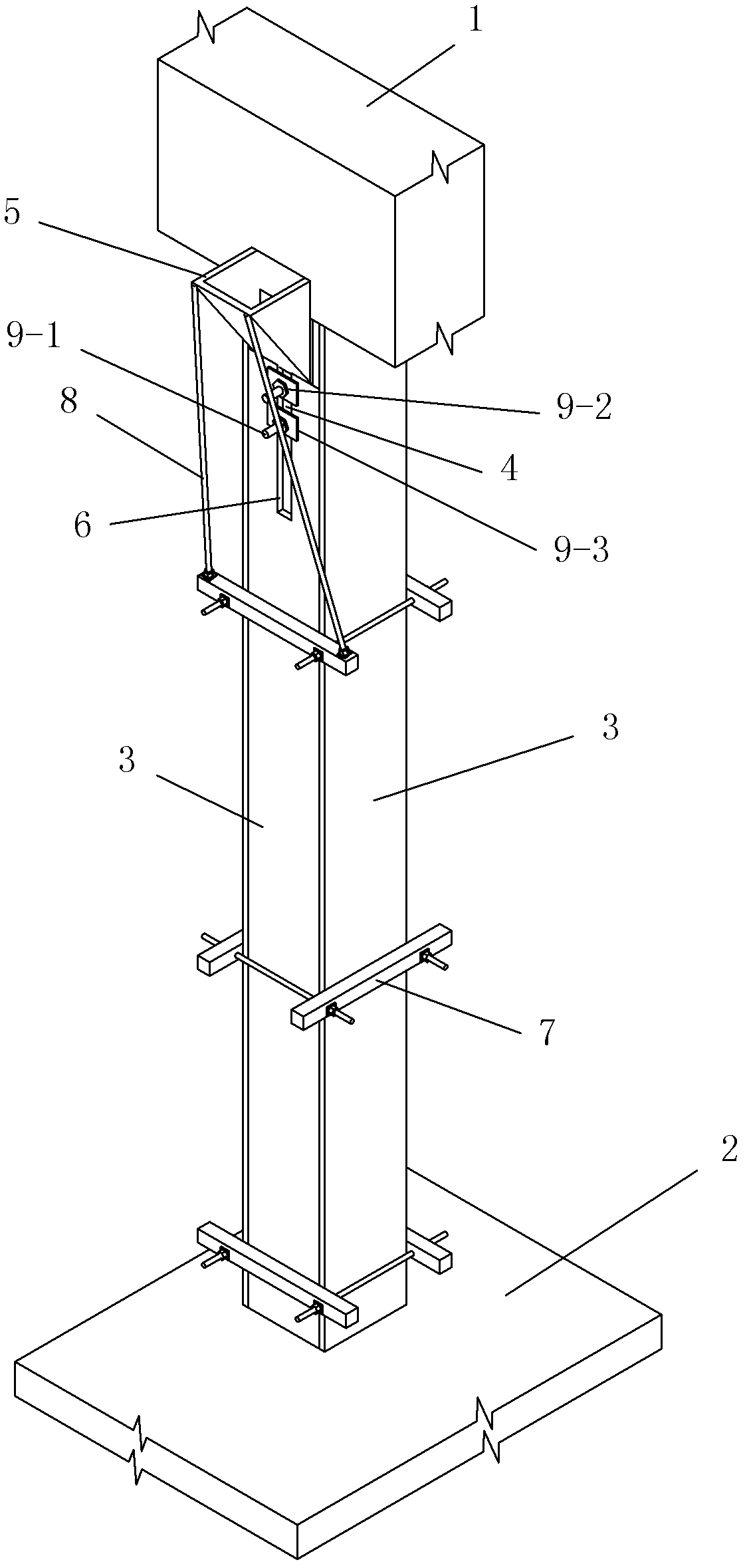

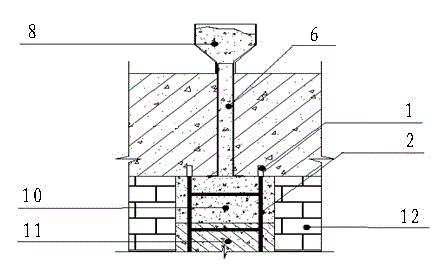

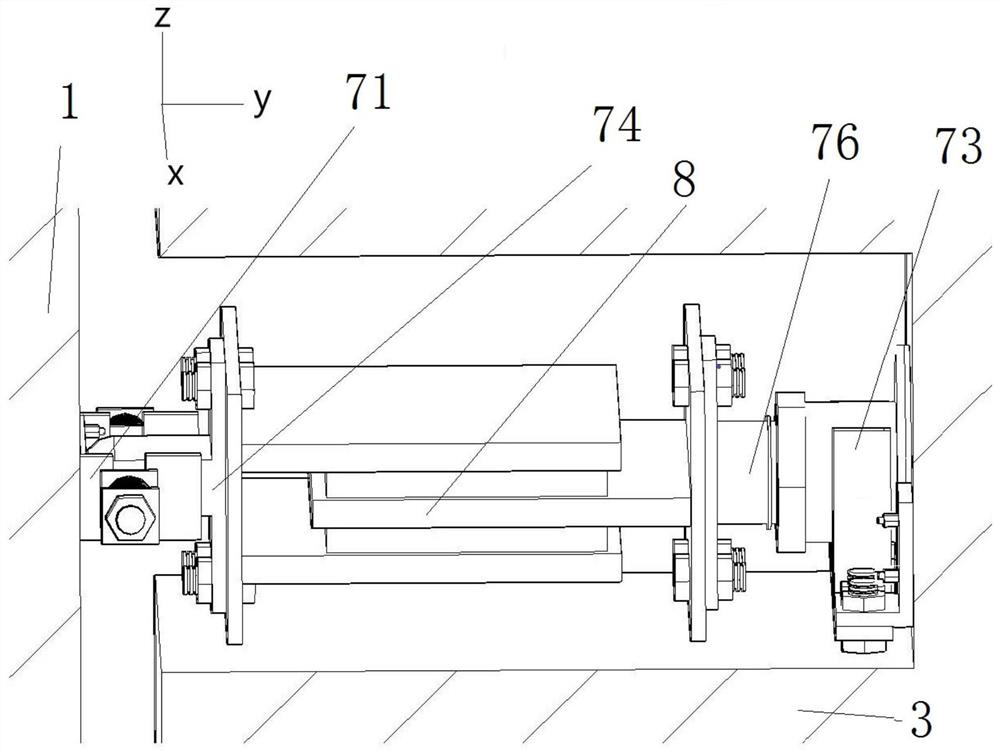

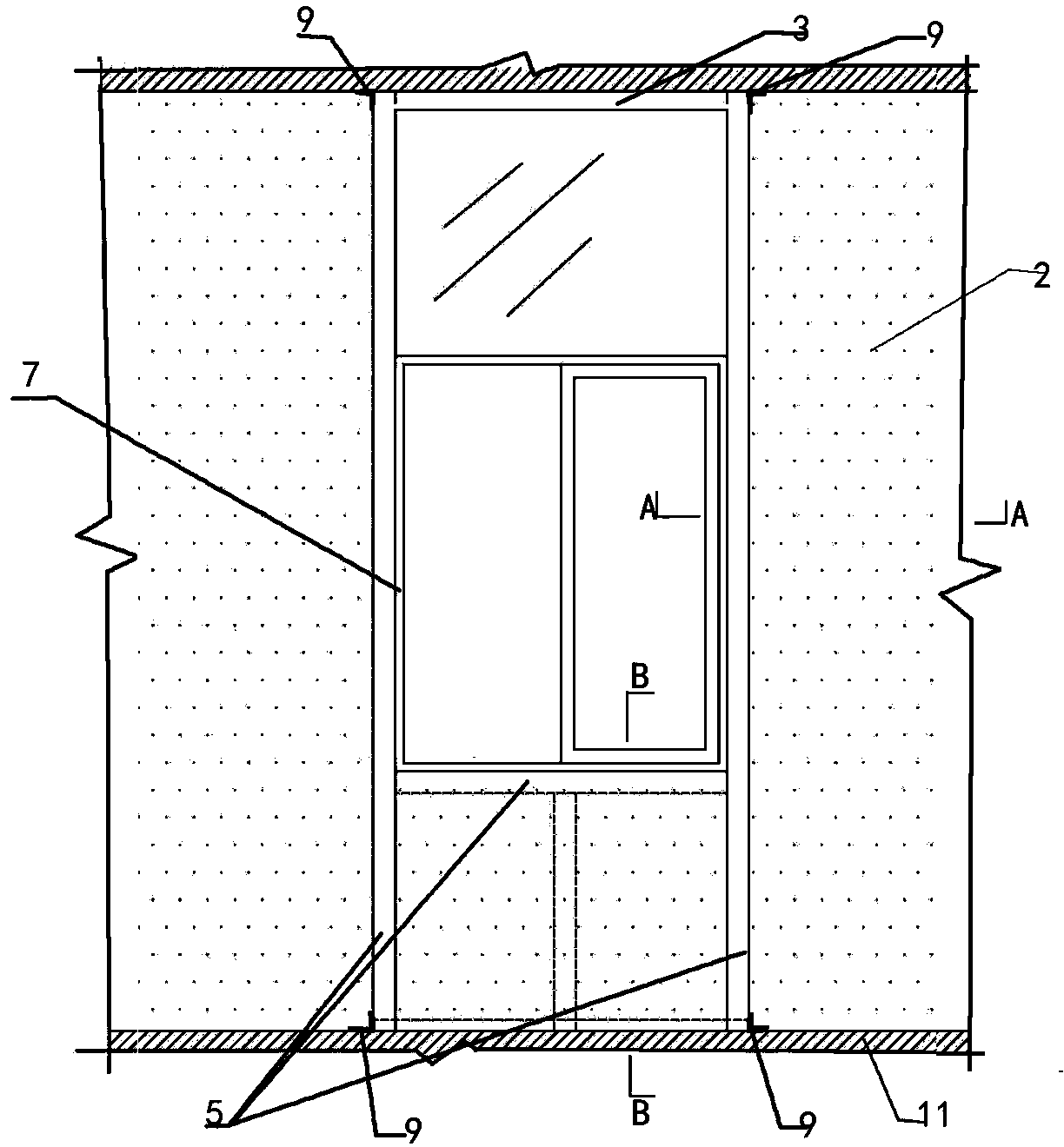

Pseudo-static testing device for concrete columns after non-peripheral fire exposure and implementation method thereof

ActiveCN107167368AThe test data is accurate and reliableRealize automatic controlVibration testingStrength propertiesFire testArchitectural engineering

The invention provides a pseudo-static testing device for concrete columns after non-peripheral fire exposure and an implementation method thereof. According to the fire exposure of a concrete column, two movable stove walls plus a temporary filling wall built in the middle opening are combined to form a fourth stove wall of a stove of the testing device. The stove is arranged in the body of a reaction frame, and a vertical load application unit is mounted on the bottom of a middle horizontal steel beam to apply vertical load on the concrete column; and a horizontal tension-compression servo loading unit is mounted on a horizontal reaction wall, and can apply pushover load and low-cycle horizontal reversed load on the concrete column specimen. The testing device first carries out a fire test under non-peripheral fire exposure on a loaded concrete column, and then carries out a pseudo-static test after fire extinguishment and cooling, and a data acquisition system is used for acquiring air pressure, temperature, displacement and load at each measuring point. The invention is applicable to the experimental study on the fire resistance and post-fire anti-seismic performance of concrete columns under non-peripheral (such as three-side, two-neighboring-sides and single-side) fire exposure.

Owner:HUAQIAO UNIVERSITY

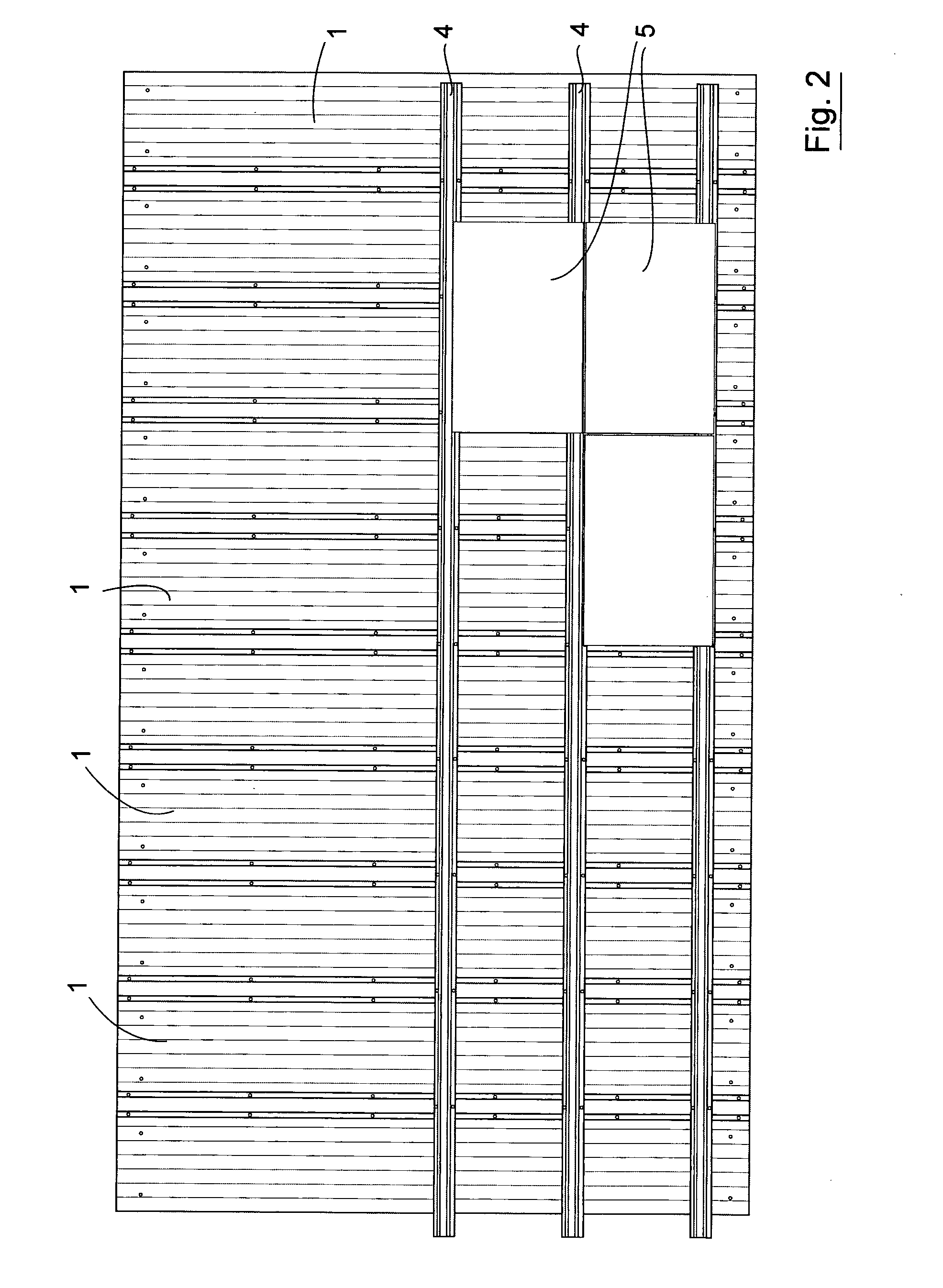

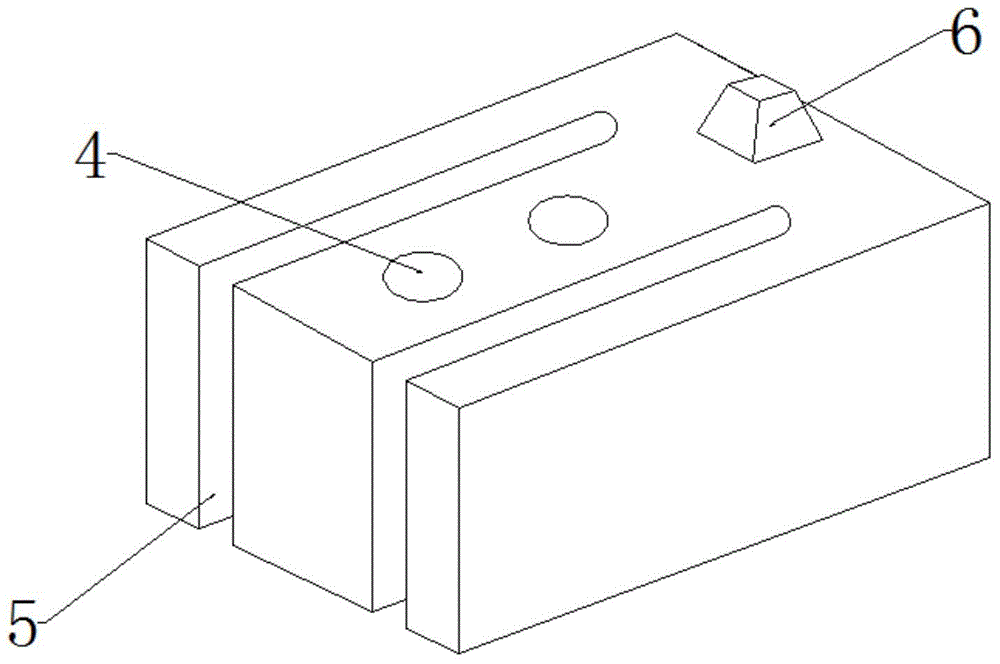

Construction method and pouring device for framework masonry infill wall structure

ActiveCN102003069AForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel barInfill wall

The invention relates to a construction method and a pouring device for a framework masonry infill wall structure. The construction method comprises the following steps of: 1, performing lofting of construction; 2, planting ribs on the end part; 3, spreading and attaching flexible materials on the end part; 4, binding steel bars; 5, constructing the wall; 6, arranging the pouring device; 7, pouring concrete; 8, removing the pouring device; and 9, curing. The technical scheme has the advantages of shortening the construction period, saving manpower and effectively ensuring construction quality.

Owner:温州城建集团股份有限公司

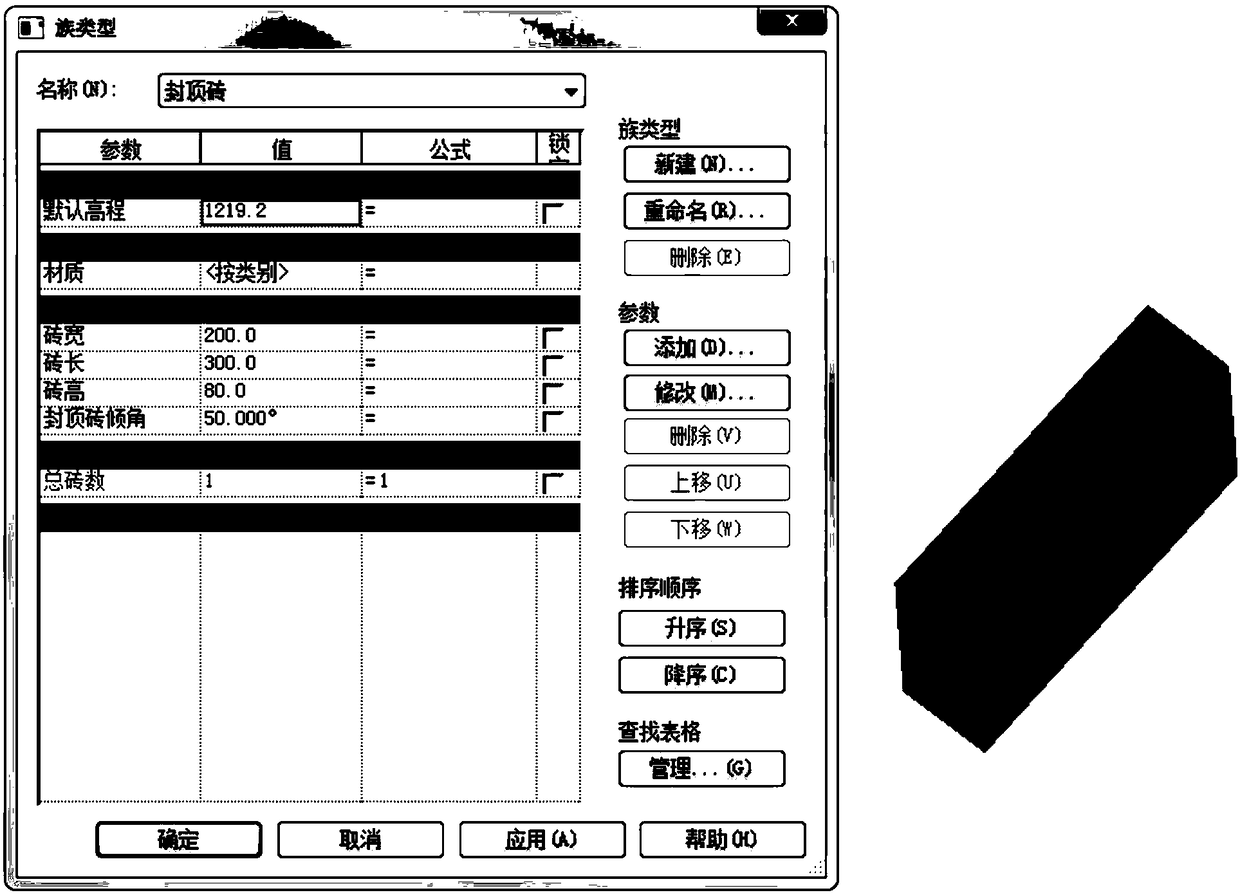

Revit-based modeling method of masonry infill wall model with computable quantities

ActiveCN109033671ASolve the problem that the engineering quantity cannot be calculatedEasy way to createGeometric CADData processing applicationsBrickWorkload

The invention discloses a modeling method of a masonry infill wall model based on Revit, which can calculate the engineering quantity. The masonry infill wall model can be created only by using Revitsoftware and its built-in dynamo integration tool. The masonry infill wall model is generated automatically by using a dynamo linear modeling method program with the common block family and the cappedblock family as basic graphical elements; the masonry infill wall model automatically calculates the masonry engineering quantity through the detailed list function of the Revit software. The invention provides a convenient creation mode for the masonry infill wall model in the Revit software, solves the problems that the masonry infill wall model with the tooth crotch, the masonry ash joint andthe capping brick in the process of being created by the Revit software is heavy in workload, low in work efficiency and the completed wall model cannot calculate the engineering quantity.

Owner:广西建工第一建筑工程集团有限公司

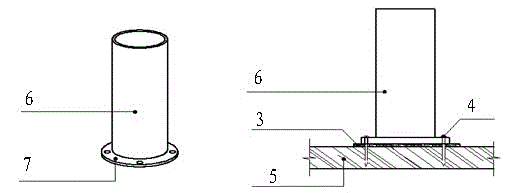

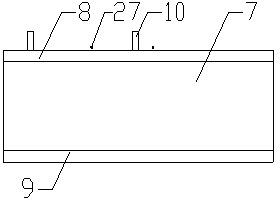

Casting molding template and casting molding process for constructional columns of infilled walls

InactiveCN102561681ASimple structureReasonable designForms/shuttering/falseworksBuilding material handlingMaterials scienceBuilding construction

The invention discloses a casting molding template and a casting molding process for constructional columns of infilled walls. The molding template comprises a lining template and a principal template, wherein the upper end part of the principal template is provided with a lining template installing slot for installing the lining template, the lining template and the principal template are assembled so as to form a constructional column template; and the lining template installing slot is provided with a horn-type feeding device, the lining template is a movable template which can carry out up-and-down motions or left-and-right motions on the inner wall of the principal template, and a template moving component is arranged on the outside surface of the lining template; and the molding process comprises the steps of 1, carrying out survey layout; 2, installing a reinforcement cage; 3, erecting the template; 4, installing the horn-type feeding device; 5, moving the lining template outwards; 6, carrying out casting construction; 7, moving back the lining template and removing the horn-type feeding device; and 8, removing the template. The casting molding template disclosed by the invention is reasonable in structure, simple in operation, economic, practical, time-saving, labor-saving and good in application effect, and can effectively solve various actual problems existing in the current construction on constructional columns of infilled walls.

Owner:陕西建工集团有限公司

Infilled wall constructional column construction method

InactiveCN103938864AImprove compactnessImprove seismic performanceBuilding material handlingArchitectural engineeringRebar

The invention relates to a construction method, in particular to an infilled wall constructional column construction method, and belongs to the building field. The infilled wall constructional column construction method comprises the steps of construction preparation, measurement and positioning layout, reinforced connecting sleeve model selection and installation, pouring vibration hole pre-buried steel pipe manufacturing and installation, root rebar pre-burying and fixation, rebar connection and binding, template manufacturing and installation, concrete pouring and construction joint retention, and secondary pouring of expansive concrete. Constructional column longitudinal carrying bars are connected with a main structure, and due to the adoption of the rebar mechanical splicing technology, working efficiency is improved by five times and construction cost is reduced by 30 percent. A constructional column template is fixed through a split bolt, a fixing point is arranged inside a constructional column, reservation of holes in a wall is avoided, and damage to an infilled wall during template fixation is reduced.

Owner:宿迁明远建设有限公司

Shock-proof prefabricated steel tube shear wall mixed structural building

ActiveCN103388357ABolt-and-solder connections for easy connectionHigh compressive strengthWallsShock proofingFloor slabSteel columns

The invention relates to a shock-proof prefabricated steel tube shear wall mixed structural building which belongs to the field of buildings. The building is provided with a foundation, wherein the foundation is respectively connected with the lower ends of shear walls and steel columns; the upper ends of the shear walls and the steel columns are connected with steel beams; the shear walls and the steel beams are connected with composite floor slabs; single shear walls on a plane are combined and connected together to form a shear wall barrel body; a vertical upper section of shear walls is connected with a vertical lower section of shear walls; stair treads are connected with supporting beams; and self-bearing masoning filler walls and main body structural components are connected together. The integrity and vibration strength of the connected structural components are reliable, so that the building is safe, economic and durable; steel structural components and steel concrete combined components have good connecting performances, so that the working environment of the operating personnel is improved to the maximum extent, the construction period is shortened, and the construction cost is lowered; and moreover, the structural components of the building are made by steel materials with higher strength, so that a large span is realized, and the building is easy to reconstruct and update after a plurality of years and has high durability.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

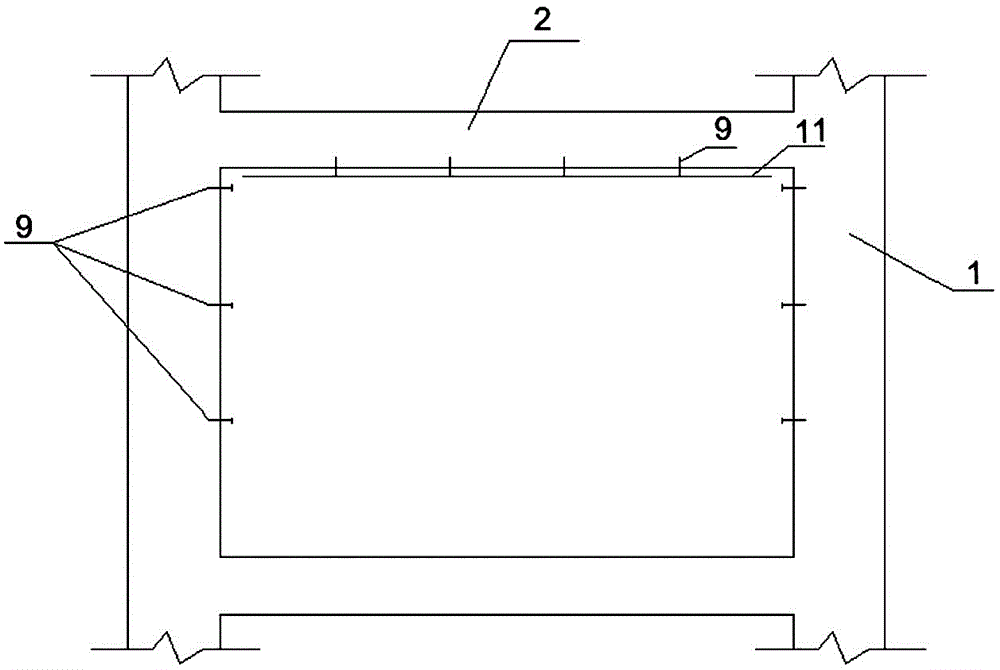

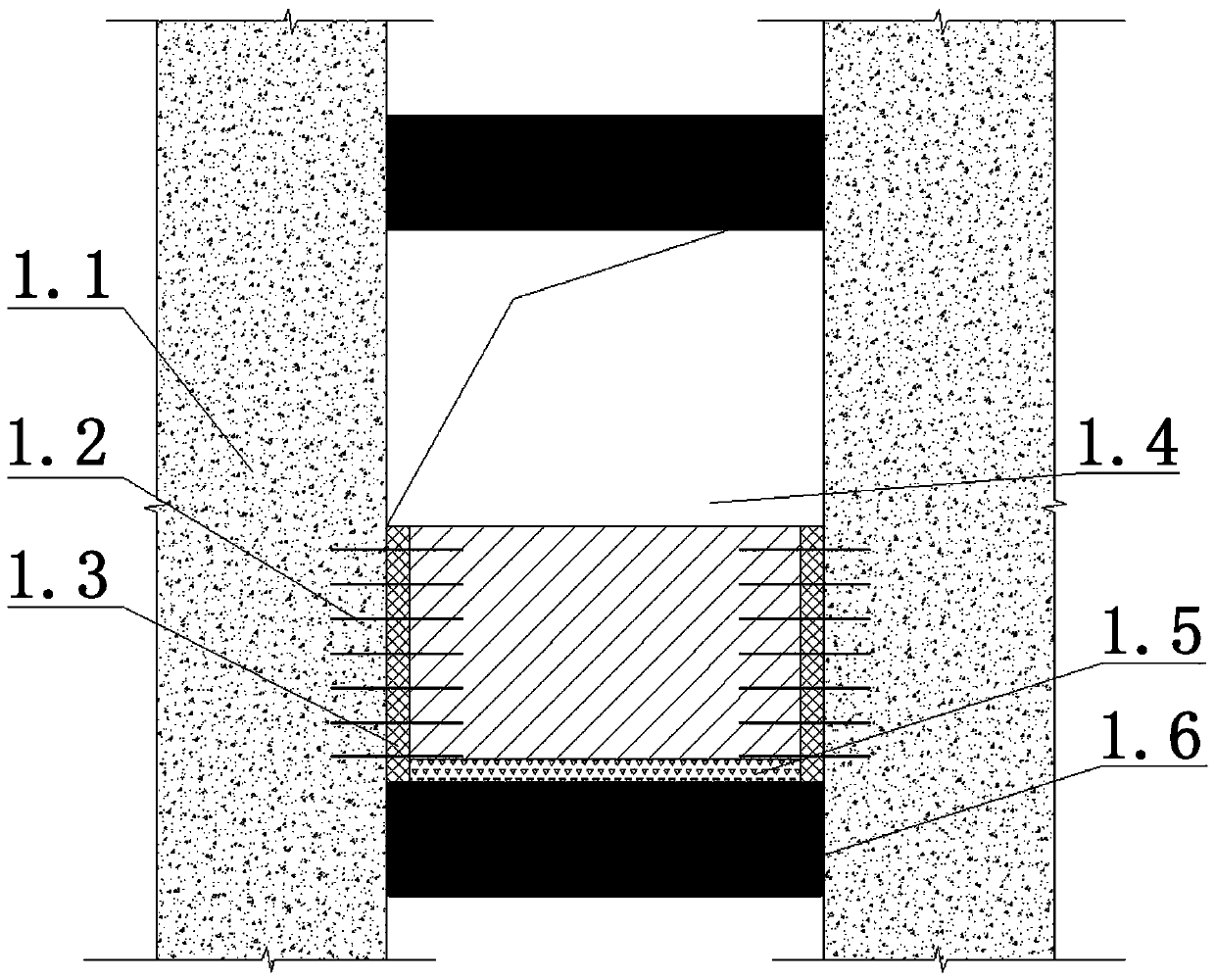

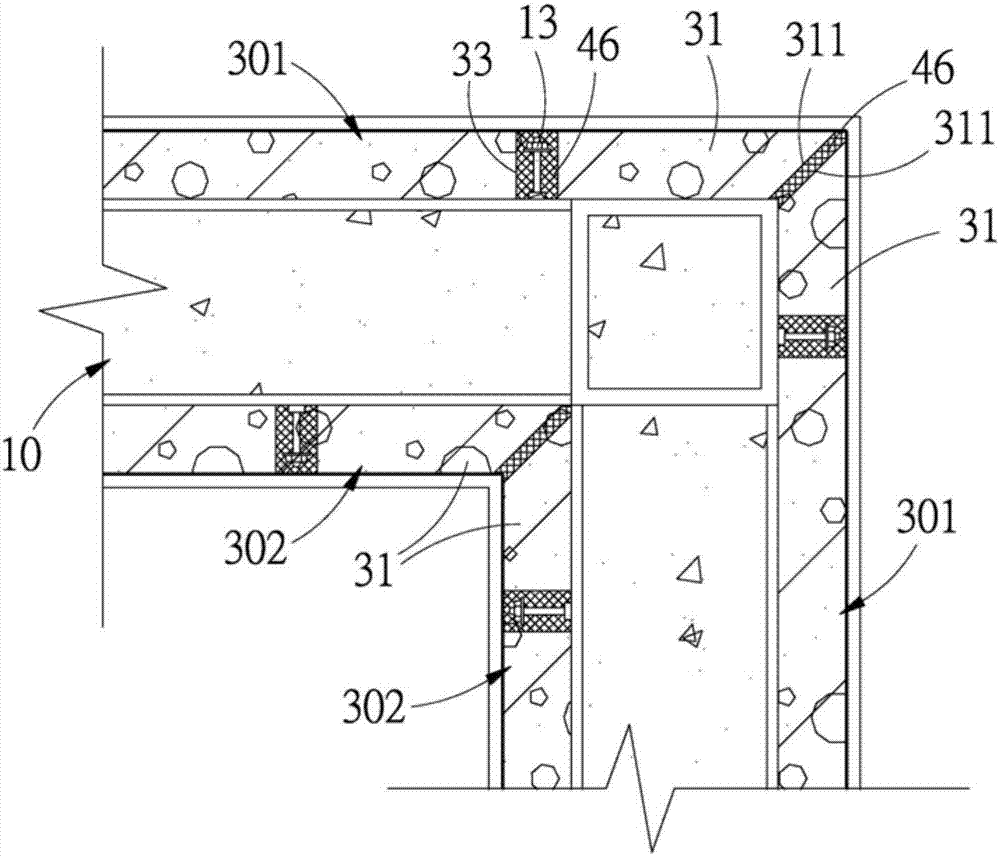

Prefabricated concrete frame infill wall system and construction method thereof

ActiveCN105937278AReduce investmentImprove construction efficiencyWallsUltimate tensile strengthInfill wall

The invention provides a prefabricated concrete frame infill wall system and a construction method thereof. The system comprises a rectangular concrete frame which is formed by concrete frame columns and concrete frame beams in an enclosing mode and an infill wall infilling the frame, anchoring ribs are implanted into the left frame columns in a uniformly spaced mode, the right frame columns and the upper frame beam on a frame inner ring, and the tail end of the anchoring rib on the upper frame beam is horizontally connected with a horizontal through long rib. According to the prefabricated concrete frame infill wall system and the construction method thereof, early cracking and corner damage of the frame infill wall are controlled by changing the structural form of the infill wall to improve the ductility of the wall and the overall anti-seismic property of the frame structure, and the anti-seismic property of the system is guaranteed by serving as the first anti-seismic defense line; in addition, the construction efficiency is high, the anti-dumping capacity is good, and the labor intensity is low. The construction method can be widely applied to concrete frame infill wall construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

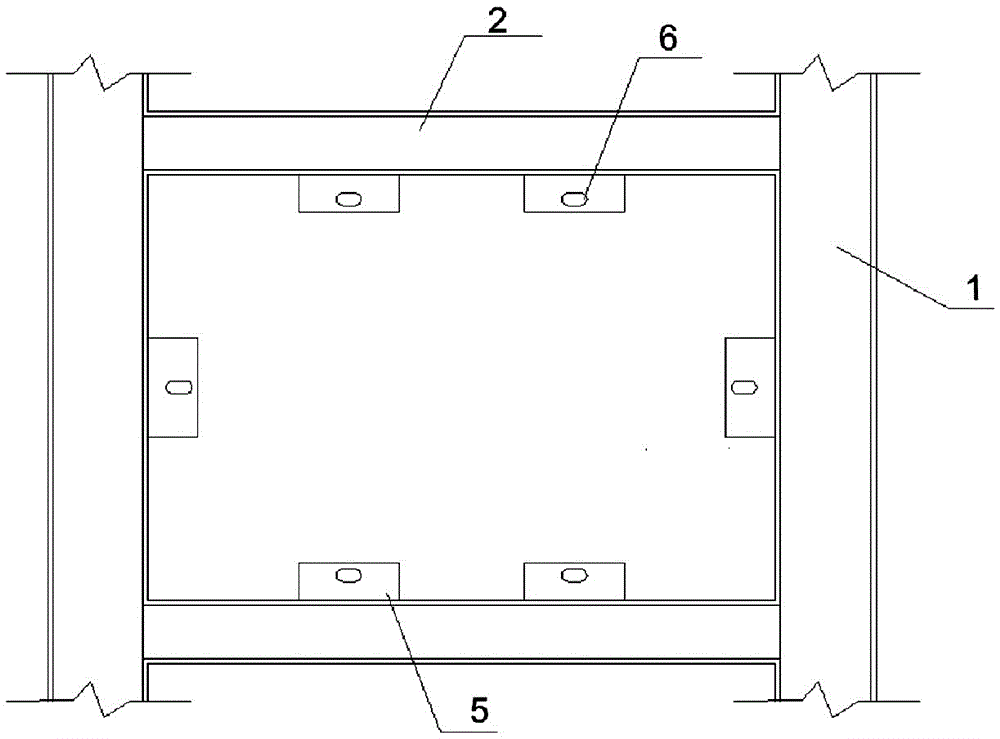

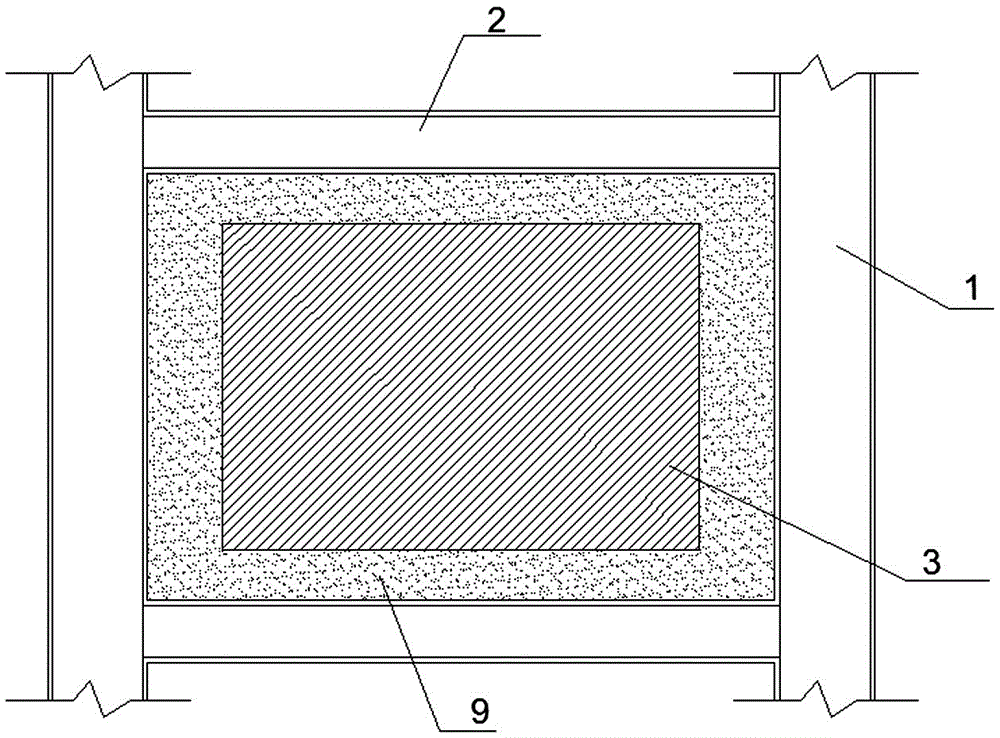

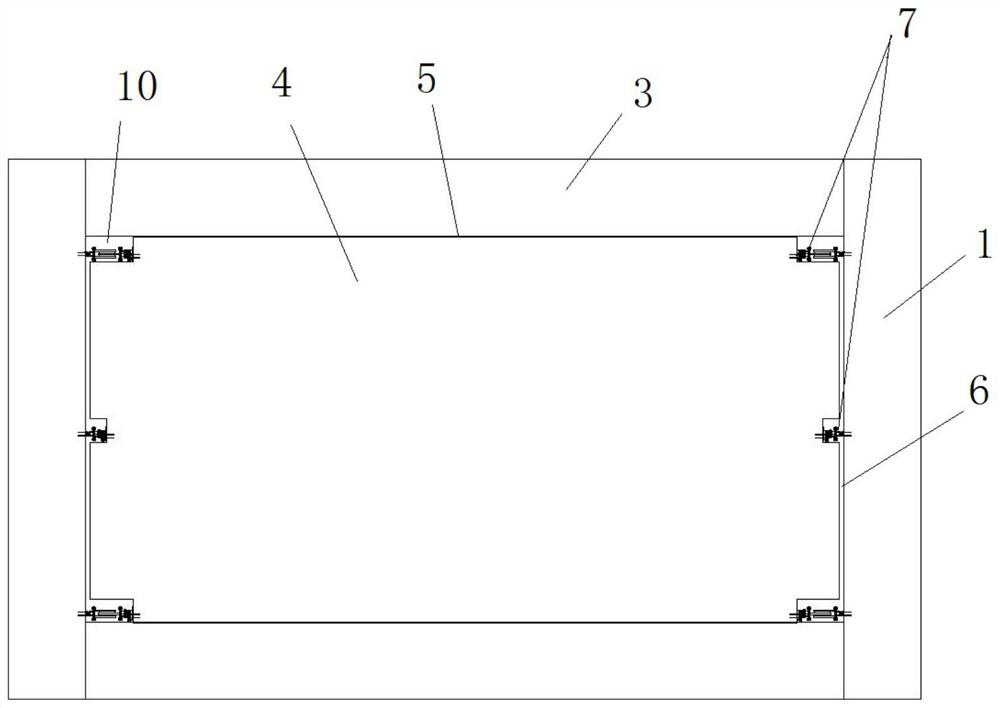

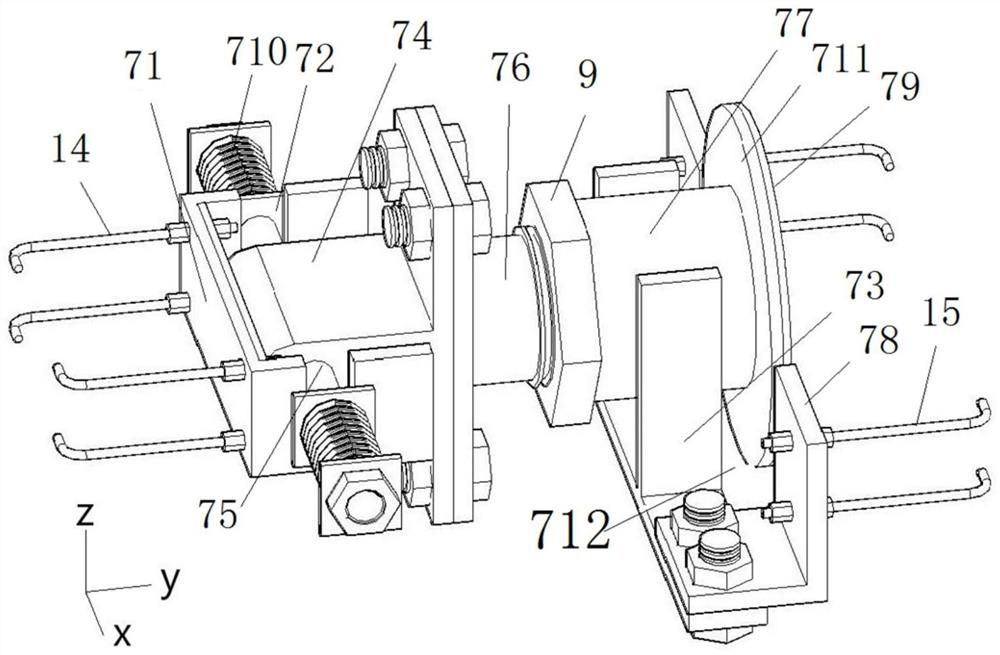

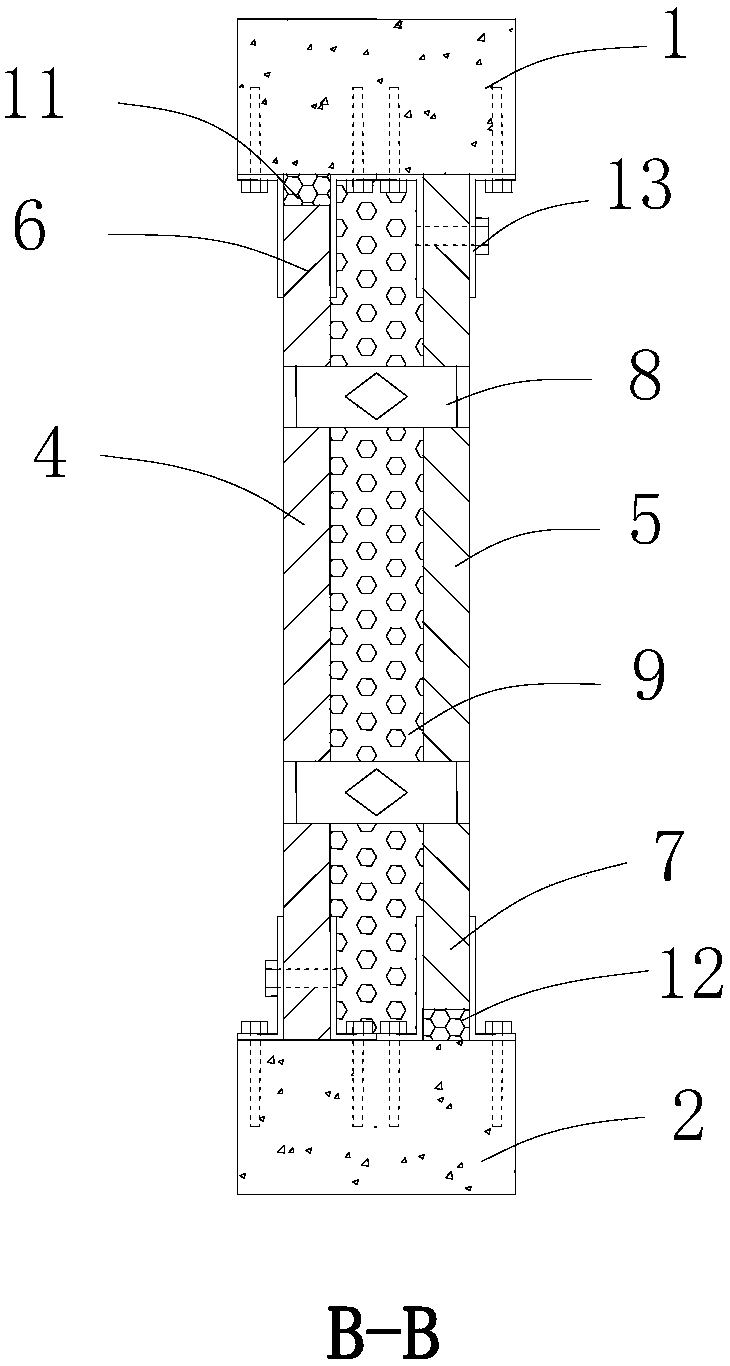

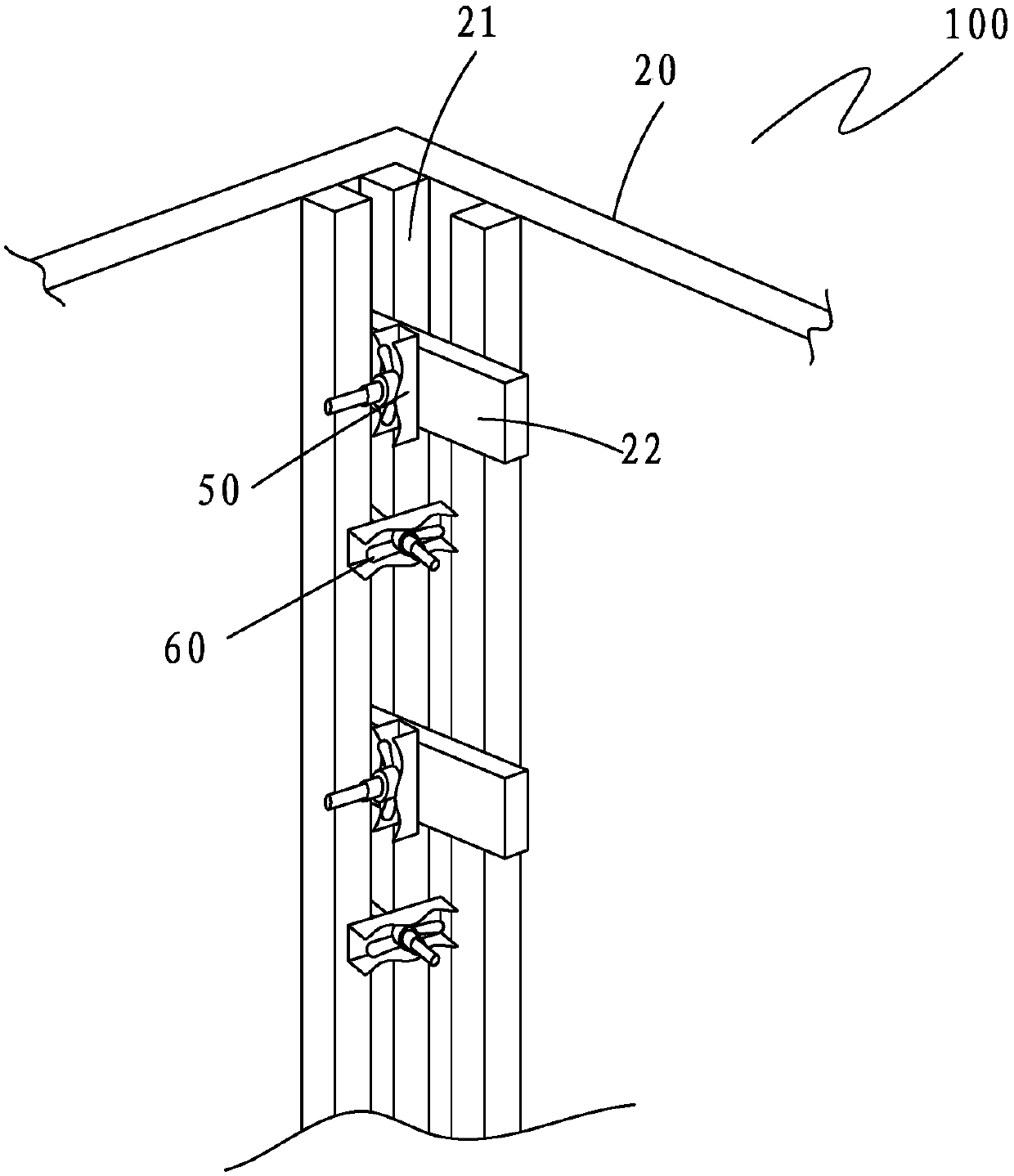

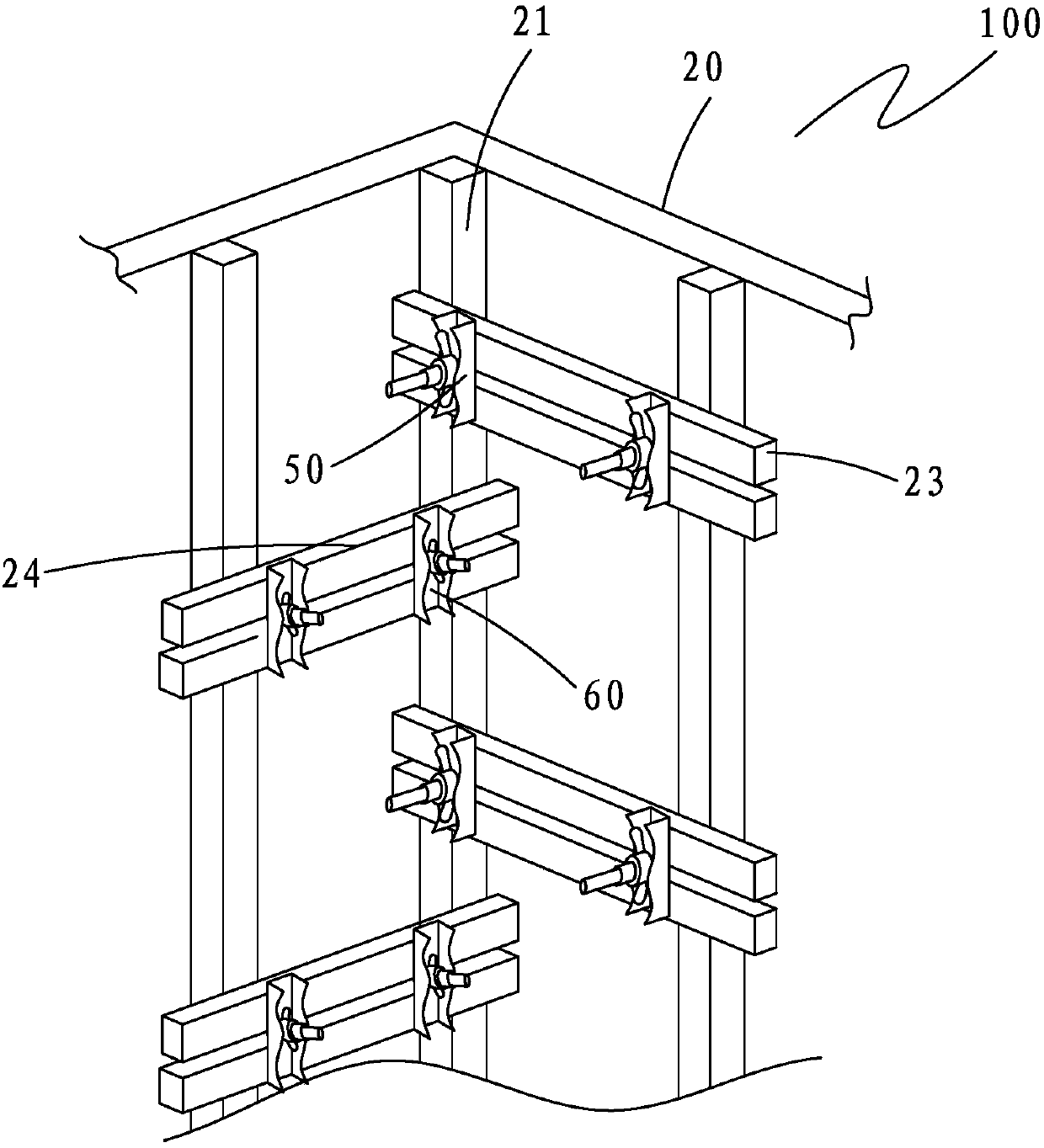

Infill wall connecting assembly in fabricated steel structure system

The invention provides an infill wall connecting assembly in a fabricated steel structure system. The infill wall connecting assembly comprises bent steel bars, steel sleeves and friction energy dissipation layers. According to the infill wall connecting assembly in the fabricated steel structure system, an infill wall is fixed through connecting pieces of steel pipe columns and the infill wall, and the friction energy dissipation layers, wherein gaps between the infill wall and the steel pipe columns, between the infill wall and cross beams as well as between the infill wall and floors are filled with the friction energy dissipation layers; the problems of difficult positioning and flashover of the infill wall can be effectively solved; the construction time of mounting and dismounting ofa support can further be saved, and the infill wall connecting assembly can be widely applied to a steel structure building; and according to the infill wall connecting assembly, the structure is simple, manufacturing and mounting are convenient, the size is easy to adjust, concealment is high, the construction cost is relatively low, and certain universality is achieved.

Owner:河北水利电力学院

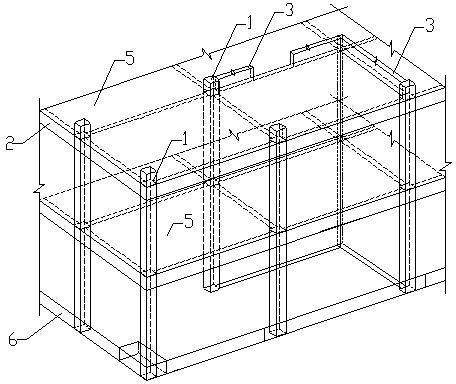

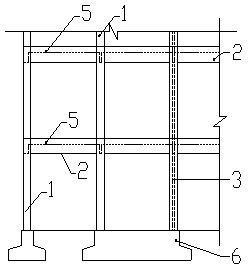

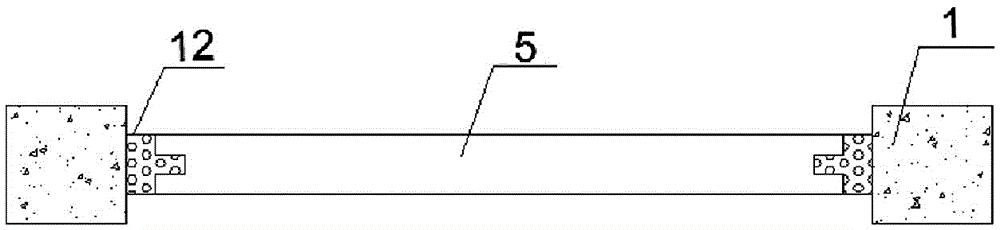

Prefabricated steel frame infill wall system and construction method thereof

ActiveCN105937263AReduce investmentImprove construction efficiencyWallsRelative displacementSteel frame

The invention provides a prefabricated steel frame infill wall system and a construction method thereof. The system comprises a rectangular steel frame which is formed by steel frame columns and steel frame beams in an enclosing mode and an infill wall infilling the steel frame; steel frame joint plates are connected to the steel frame columns and the steel frame beams on a steel frame inner ring in a uniformly spaced mode, and long circular horizontal connecting holes are formed in the steel frame joint plates. According to the prefabricated steel frame infill wall system and the construction method thereof, through design of the long circular connecting holes, relative displacement can be generated between the steel frame and the infill wall, the phenomenon that cracks are generated on the infill wall under the seismic action is effectively avoided, and the anti-seismic property of the system is guaranteed by serving as the first anti-seismic defense line; meanwhile, by adopting a complete prefabricated wallboard, the whole performance is good, construction is convenient and rapid, and the labor intensity is low. The construction method can be widely applied to steel frame infill wall construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Energy dissipation and shock absorption assembly type infilled wallboard structure

PendingCN111749371ALimit collapseImprove energy consumptionWallsProtective buildings/sheltersEngineeringMechanical engineering

The invention discloses an energy dissipation and shock absorption assembly type infilled wallboard structure. The energy dissipation and shock absorption assembly type infilled wallboard structure comprises a wallboard, the wallboard is a rectangular wallboard, the wallboard comprises two L-shaped sub-wallboards with the same size and shape; the horizontal contact interfaces of the two L-shaped sub-wallboards are filled with damping layers and are connected with each other through a bending deformation energy dissipation device in the plane of a steel plate; and the vertical contact interfaces of the two L-shaped sub-wallboards are located in the middle of the wallboard, impact buffer layers are fixedly arranged on the vertical contact interfaces correspondingly, and the space between theimpact buffer layers is filled with flexible filler. The energy dissipation and shock absorption assembly type infilled wallboard structure is provided with different levels of energy dissipation structures, the wallboard structure has the shock absorption and energy dissipation effects under the action of small earthquakes, medium earthquakes and large earthquakes; the wallboard structure has good deformation ability, the wallboard can be effectively prevented from being damaged under the conditions of small earthquakes and medium earthquakes; and the wallboard structure can play a supporting role under the condition of large earthquakes to prevent a wall body from collapsing.

Owner:HUNAN UNIV

Energy-saving insulation structure of lighting window and construction method thereof

The invention discloses an energy-saving insulation structure of a lighting window and a construction method thereof. A reinforcing keel is arranged in a filler wall around the window, waterproof cloth is arranged on the joint, the filler wall is connected outside a frame column to form a one-piece palisade structure encircling a frame column system, the frame column is partially embedded in the filler wall, the filler wall is a cast-in-situ sandwich wall, and a lightgage steel keel anchored with floor slabs at the two sides is arranged in a light porous inorganic core material. According to the energy-saving insulation structure of the lighting window and the construction method thereof, the functions of the keels, also as the wall keels, and an external window subframe are reinforced, the material is saved, and the phenomenon of 'thermal bridge' is avoided. The waterproof cloth is arranged additionally, so the air tightness and waterproof permeability of the palisade structure are improved, the heat preservation performance is improved by 2-5%, and the air tightness is improved by 5-10%. The palisade structure outside the building and the exterior wall insulation are integrated, industrial wastes are recycled as raw materials to form a non-flammable inorganic foam insulation material of which internal abundant porous structures have excellent heat preservation and sound insulation effects, the construction is simple, form stripping does not needed, the construction efficiency of the building is increased by 30%, and the cost is lowered by more than 10%.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Low-yield-point steel plate shear wall with two connected edges

InactiveCN103967166ASimple structureEasy to manufacture and installWallsShock proofingSheet steelShock resistance

The invention discloses a low-yield-point steel plate shear wall with two connected edges. The shear wall comprises a steel plate infill wall, two clamping plates and edge components. The steel plate infill wall is made of low-yield-point steel, the two clamping plates and the edge components are made of common steel, the upper edge and the lower edge of the steel plate infill wall are welded to the two clamping plates respectively, and the edges of the two sides of the steel plate infill wall are welded to the edge components. According to actual engineering requirements, obliquely crossed or crossed stiffening ribs can be arranged on the surface of the steel plate infill wall, and the stiffening ribs are made of common steel. The low-yield-point steel plate shear wall with the two connected edges is simple in structure, convenient to manufacture and install, stable and excellent in ductility and hysteretic behavior, capable of meeting the shockproof design concept of strong column and weak beam and multi-channel shockproof systems, good in shock resistance and capable of being widely applied to frame structure systems, and the size is easy to adjust.

Owner:SOUTHEAST UNIV

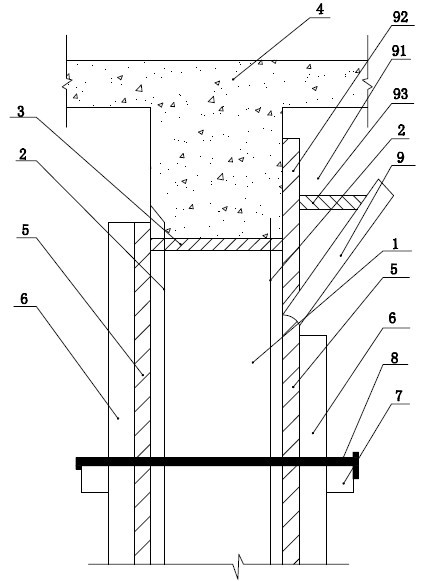

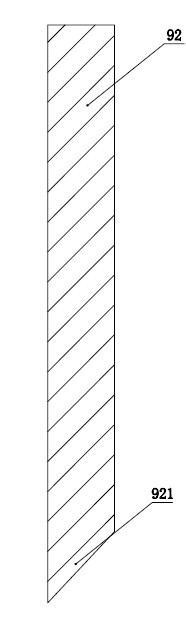

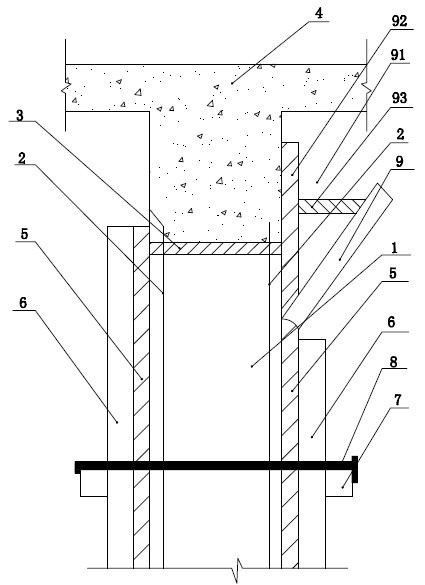

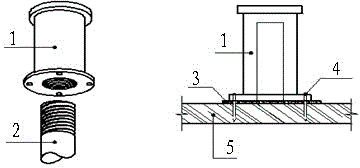

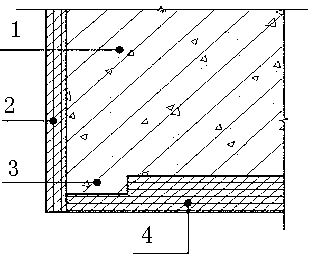

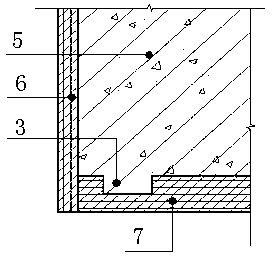

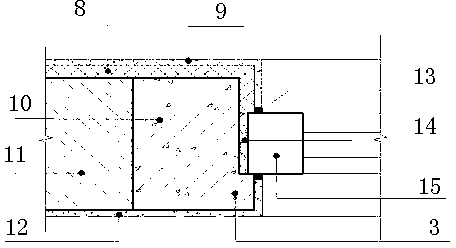

Method and structure for fixedly sealing seam between infill wall and beam or board

InactiveCN104631631AConstrained Displacement DeformationImprove sound insulationBuilding constructionsEngineeringInfill wall

The invention discloses a method for fixedly sealing a seam between an infill wall and a beam or a board. The method is characterized by including the following steps that firstly, a jacking piece is inserted in the seam between the top of the infill wall and the beam or the board in advance, the position between the infill wall and the beam or the board is jacked and fixed, and the displacement of the infill wall is restrained; secondly, filler is inserted in the middle of the span of the seam and grooves are reserved in the two sides of the seam; thirdly, the grooves in the two sides of the seam are filled with mortar compactly. The invention further discloses a structure for fixedly sealing the seam between the infill wall and the beam or the board to implement the method. By the adoption of the method and structure, the middle portion of the span of the seam between the top of the infill wall and the beam or the board is filled with the jacking piece and compressible solid, namely the filler, the sound insulation performance of a partition is improved, displacement and deformation of the infill wall are effectively restrained, construction can be conducted so as to squeeze and compact mortar in the seam conveniently, and the problem that the mortar of the seam cracks due to the fact that the mortar is not squeezed compactly is solved.

Owner:DONGGUAN CAILI BUILDING MAINTAIN TECH

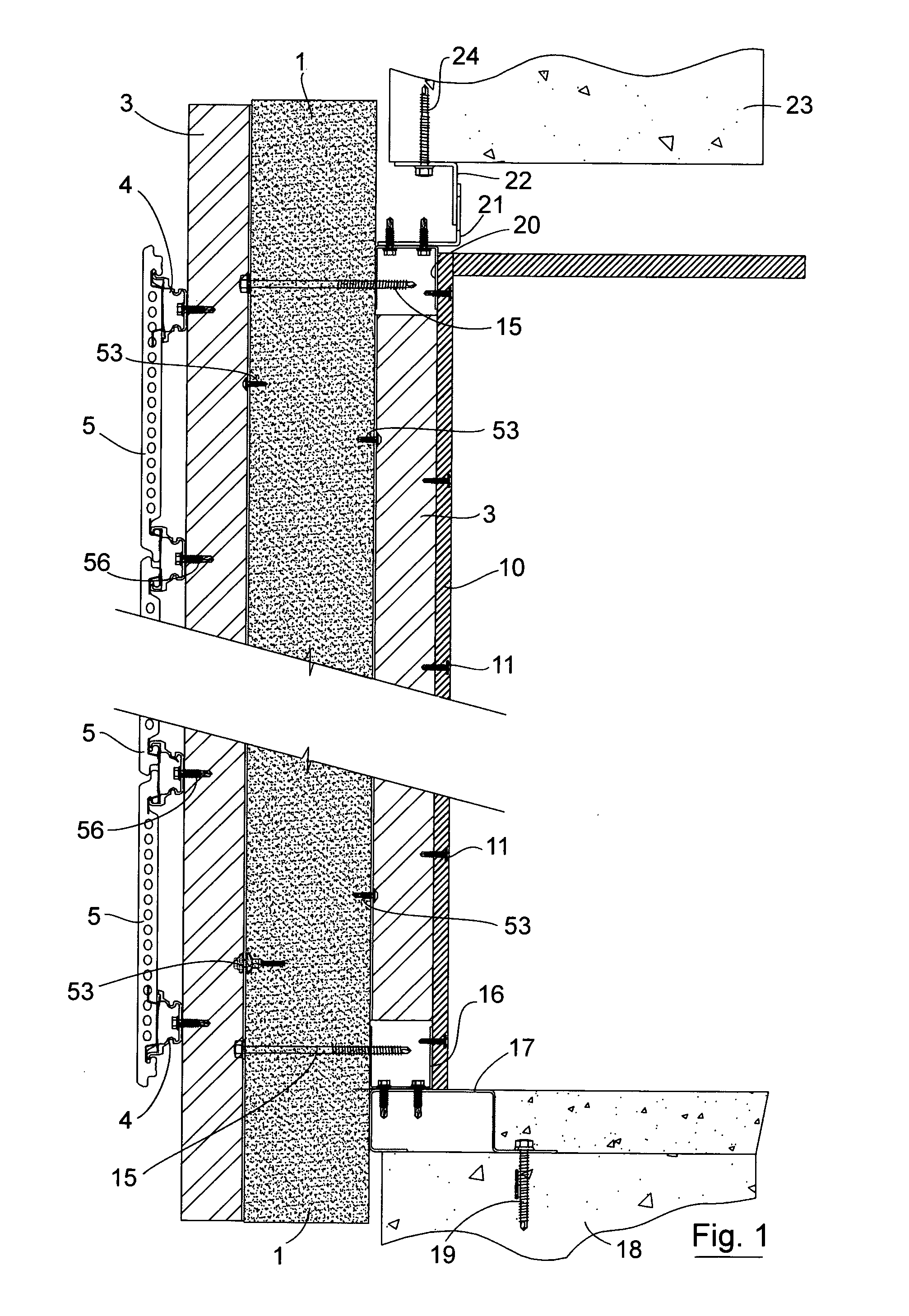

Structural infill wall panel module

A facade / wall system comprises a number of modules. Each module comprises a plurality of insulating panels which have connection means on opposite sides thereof for interengaging the panels together at joints between the panels. Reinforcing elements in the form of top hat sections bridge the joints between adjacent panels. The top hat reinforcement elements used to interconnect adjacent panels in a module ensure that the composite panels act together as monolithic structure that creates a diaphragm while providing a surface to which cladding can be fixed and also providing a cavity between the panels and the cladding attached to the modules. They stiffen the panels and thereby enhance resistance to deflection. The system is cost effective and relatively easy and quick to install.

Owner:KINGSPAN HLDG (IRL) LTD

Structural infill wall panel module

A facade / wall system comprises a number of modules. Each module comprises a plurality of insulating panels which have connection means on opposite sides thereof for interengaging the panels together at joints between the panels. Reinforcing elements in the form of top hat sections bridge the joints between adjacent panels. The top hat reinforcement elements used to interconnect adjacent panels in a module ensure that the composite panels act together as monolithic structure that creates a diaphragm whilst providing a surface to which cladding can be fixed and also providing a cavity between the panels and the cladding attached to the modules. They stiffen the panels and thereby enhance resistance to deflection. The system is cost effective and relatively easy and quick to install.

Owner:KINGSPAN HLDG (IRL) LTD

Construction method of constructional column constructed simultaneously with framework structure infill wall

ActiveCN105113660AReduce construction proceduresShorten the construction periodWallsBuilding material handlingEngineeringInfill wall

Owner:朱占元

Steamed wood fiber aerated concrete block and preparation method thereof

The invention relates to a preparation method of a steamed wood fiber aerated concrete block. According to the preparation method, a process for manufacturing a steamed aerated block is adopted, and wood fiber is adopted to replace a part of a coal ash material of the components, so that a novel filled wall building body material is prepared. By adopting the steamed wood fiber aerated concrete block, both the materials such as the coal ash can be saved, and waste materials such as waste newspaper, books and waste mold plates with high wood fiber content can be utilized. Due to addition of the wood fiber in the building body material, the weight of a building block is further reduced, the building block can be well bonded with special mortar in construction, and moreover relatively good heat-preservation property is achieved.

Owner:CHINA MCC17 GRP

Construction method of filling gaps on top of filler wall

InactiveCN106812219ASimple construction methodEasy to operateBuilding constructionsPre stressConcrete beams

Owner:CHINA MCC17 GRP

Tie system and method for connecting a cementitious backup wall made in a penetrable form and a veneer wall

ActiveUS20080098681A1Prevent movementIncrease surface areaFloorsBuilding reinforcementsEngineeringStructural engineering

A tie system is provided for use with a wall form for a cementitious backup wall and for use with a wall tie to connect between the cementitious backup wall and a veneer. The tie system includes a backup wall connector and a form connector. The form connector is connectable to the form and secures the backup wall connector in position as the wall form is filled.

Owner:HATZINIKOLAS MICHAEL

Assembly energy dissipation and vibration reduction filling wall board structure

PendingCN107700705APromote absorptionGood ability to dissipate seismic energyWallsProtective buildings/sheltersInsulation layerEngineering

The invention provides an assembly energy dissipation and vibration reduction filling wall board structure. The wall board structure is located in a space defined by an upper frame beam, a lower framebeam and frame columns, and comprises a concrete board and a plurality of energy dissipation anchoring parts. The concrete board comprises a first vertical board body and a second vertical board body, the fixed end of the first vertical board is fixedly connected with the lower frame beam, and the free end of the first vertical board body is slidably connected with the upper frame beam. The fixedend of the second vertical board body is fixedly connected with the upper frame beam, and the free end of the second vertical board body is slidably connected with the lower frame beam. A waterproofheat preservation layer is arranged between the first vertical plate body and the second vertical plate body. The multiple energy dissipation anchoring parts penetrate through the waterproof heat preservation layer, and the two ends of each energy dissipation anchoring part are connected with the first vertical board body and the second vertical board body correspondingly. The assembly energy dissipation and vibration reduction filling wall board structure is simple in structure, convenient to assemble, and improves the construction efficiency. When the upper frame beam and the lower frame beam generate relative displacement, the energy dissipation anchoring parts which are fixedly connected with the first vertical board body and the second vertical board body can generate plastic deformation, then the earthquake energy is absorbed and dissipated, and accordingly the energy dissipation and vibration reduction effects are good.

Owner:GUANGZHOU UNIVERSITY

Cast-in-place hollow reinforced concrete filled wall and its construction technology

The invention discloses a cast-in-place hollow reinforced concrete filled wall and its construction technology. The cast-in-place hollow reinforced concrete filled wall includes a single-piece thin wall, deformation partition plates, non-dismantling light filling material layers, a connection wall and a fixing hook; the deformation partition plates are arranged between the filled wall and a forced structure; two layers of single-piece thin walls opposite to each other are arranged between the deformation partition plates, horizontal reinforced bars and longitudinal reinforced bars are embedded in the single-piece thin walls, the horizontal reinforced bars pass through the deformation partition plates and are anchored in the forced structure, the longitudinal reinforced bars are anchored in a beam body, the non-dismantling light filling material layers are arranged between the single-piece thin walls, and a connection wall is arranged between the every two adjacent non-dismantling light filling material layers. According to the wall and its construction technology, the forced structure of a main body is integrally formed with the filled wall so that the outer wall can be fully coated with concrete, at the same time, the forced structure of the main body is integrally formed with the filled wall so that the materials of the forced structure and the filled wall can be same in property, the permeation prevention and cracking prevention of the wall body is facilitated, the construction process is simplified, the construction period is largely shortened, and an effective premise is provided for alternate construction.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Construction method of novel structural column for frame-structured T-shaped filled walls

InactiveCN105155725ALow costGuarantee the construction qualityWallsBuilding material handlingArchitectural engineeringQuoin

A construction method of a novel structural column for frame-structured T-shaped filled walls is characterized in that vertical bars are fixed in embedding holes of embedded parts by means of extending into embedding hollows and by means of welding, so that effective connection of the structural column with top and bottom structures is guaranteed; in order to guarantee connective integration of the T-shaped prefabricated segment structural column with walls on two sides and to facilitate building and tie bar construction, by centering on building of the above prefabricated segment structural column, connective parts of the filled walls on two sides with the structural column are built synchronously with blocks of the prefabricated segment structural column, the building of the walls is gradually spread to the far side, and thus the requirements of building specifications of the filled walls are met; each prefabricated segment is composed of two prefabricated segment blocks; the thickness of each prefabricated segment block plus a mortar joint is equal to the thickness of two bricks plus a mortar joint.

Owner:李彦斌

Anti-cracking structure for joint of full-concrete outer wall under-window filling wall and shear wall and construction method thereof

InactiveCN111335490AReduce wasteReduce the risk of water leakageWallsForms/shuttering/falseworksWater leakageFloor slab

The invention belongs to the technical field of concrete outer wall construction, and provides an anti-cracking structure for a joint of a full-concrete outer wall under-window filling wall and a shear wall and a construction method thereof in order to prevent the problem that cracks are generated at the positions such as the under-window wall due to concrete shrinkage. Anti-cracking steel bars and joint pulling plates are arranged in a concrete pouring layer at intervals, wherein the joint pulling plates comprise horizontal structure joint pulling plates and vertical structure joint pulling plates; the horizontal structure joint pulling plates are arranged between floors or beams of all layers and the under-window filling wall; and the vertical structure joint pulling plates are arrangedbetween the shear wall and the under-window filling wall; transverse anti-cracking steel bars are arranged at the joint of the shear wall and the under-window filling wall, and the transverse anti-cracking steel bars penetrate through the vertical structure joint pulling plates to be bound and overlapped with wall body steel bars of the shear wall and the under-window filling wall on the two sides. The anti-cracking structure is convenient to assemble and disassemble, construction joints are avoided, the hidden danger of water leakage of the structure is reduced, and the applicability is improved. The operation is convenient, the construction quality and effect are good, the change of the overall rigidity is avoided, the construction period is shortened, and the structural safety is guaranteed.

Owner:CHINA SHANXI SIJIAN GRP

Self-waterproof system of building external wall structure and construction method of self-waterproof system

InactiveCN103233520AImprove waterproof performanceSolve common quality problemsBuilding material handlingBuilding insulationsTemplate designArchitectural engineering

The invention provides a self-waterproof system of a building external wall structure and a construction method of the self-waterproof system. The construction method comprises the technological processes of preparation works before construction, design, preparation and installation of a template, removal of the template, building of an infilled wall and antiseep processing, plugging of holes of a concrete wall, pillars and the infilled wall and acceptance of related departments. By means of the self-waterproof system and the construction method, the sale-waterproof capacity of the external wall structure is improved, and common quality problems of the external wall surface leakage caused by waterproof failure of an external wall decorative surface layer are effectively solved.

Owner:宿迁明远建设有限公司

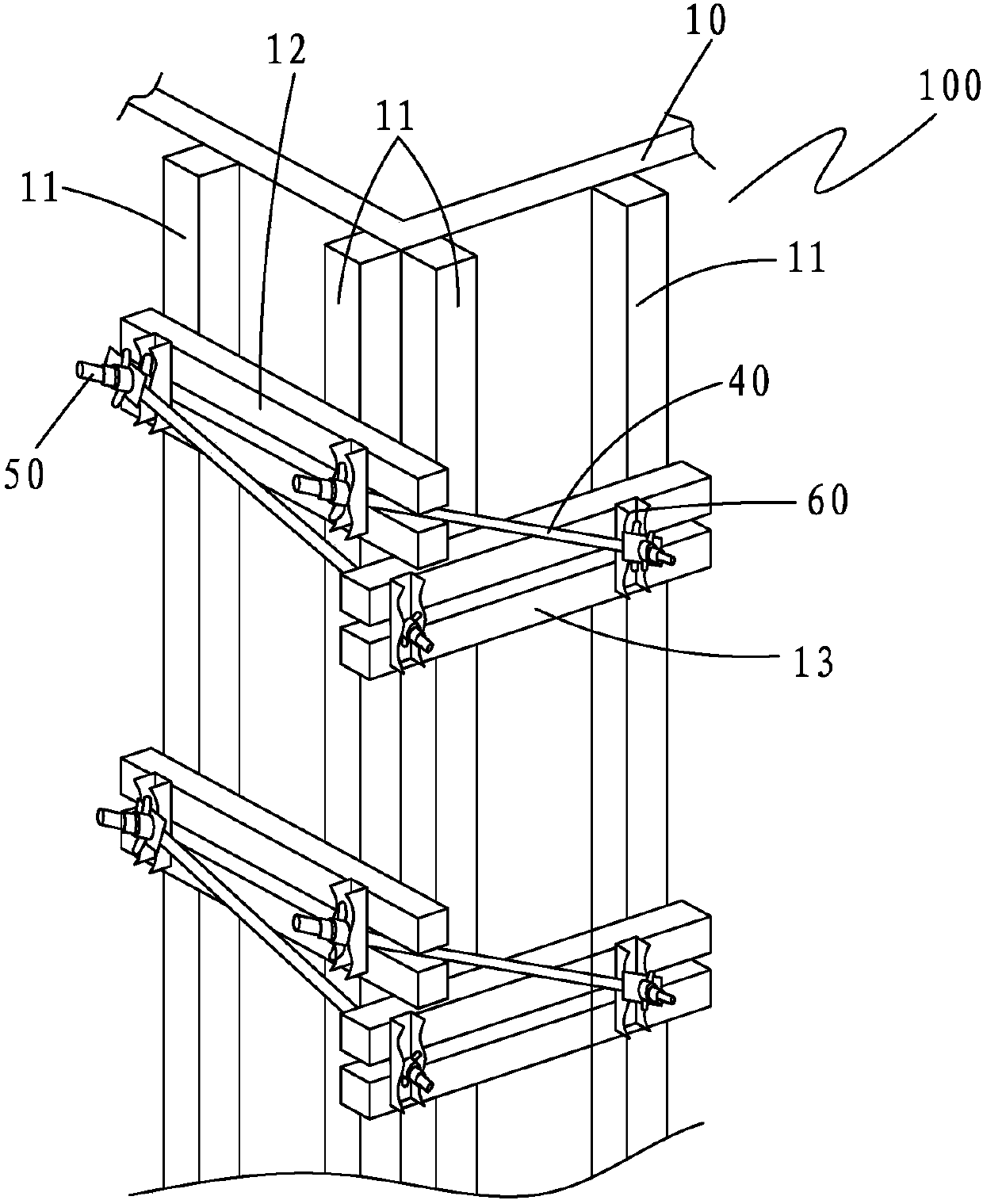

Strengthening system of L-shaped infilled wall structural column formwork and construction method

PendingCN107700836APrevent twistingReasonable forceForms/shuttering/falseworksKeelArchitectural engineering

The invention provides a strengthening system of an L-shaped infilled wall structural column formwork and further provides a construction method of the strengthening system of the L-shaped infilled wall structural column formwork. The strengthening system comprises a structural column external corner formwork and a structural column internal corner formwork. External corner vertical secondary keels are fixed to the outer side face of the structural column external corner formwork, the two external corner vertical secondary keels of the structural column external corner formwork are arranged atthe external corner, and the external corner vertical secondary keels of the two sides of the structural column external corner formwork are connected with a first transverse main keel and a second transverse main keel in a lapping mode. An internal corner vertical secondary keel is fixed to the inner side face of the structural column internal corner formwork, the internal corner vertical secondary keel of the structural column internal corner formwork is arranged at the internal corner, and a square timber is connected to the internal corner vertical secondary keel of one side of the structural column internal corner formwork in a lapping mode. The first transverse main keel and the second transverse main keel are fixed through external corner formwork strengthening combining bolts, andthe internal corner vertical secondary keel and the external corner vertical secondary keels are fixed through first opposite-pull screws and second opposite-pull screws. Finalization and repeated utilization are achieved, the cost is saved, and the structural column concrete forming appearance quality is improved.

Owner:福建建工集团有限责任公司 +1

Structure of connecting joint of infilled wall and column of autoclaved aerated concrete slab and construction method of structure

ActiveCN107119826AAchieving Elastic ConnectionsAvoid crackingWallsClimate change adaptationArchitectural engineeringAutoclaved aerated concrete

The invention provides a structure of a connecting joint of an infilled wall and a column of an autoclaved aerated concrete slab and a construction method of the structure. The structure includes a corner structure with the L-shaped cross section, ALC insulation boards, an ALC wallboard and elastic filling materials; the corner structure is provided with two installation parts by forming, a corner portion of the corner structure is formed on the connection portion of the two installation parts, and a tail end portion of the corner structure is formed on the end portions of the two installation parts, and the ALC insulation boards are arranged on vertical faces on the two sides, opposite to each other, of the installation parts of the corner structure and are elastically connected with the corner structure; the ALC wallboard is connected with the tail end portion of the corner structure and the end portions of the ALC insulation boards, and meanwhile gaps are formed between the ALC wallboard and the tail end portion of the corner structure and between the ALC wallboard and end portions of the ALC insulation boards; the gaps are filled with the elastic filling materials so as to connect the ALC wallboard with the corner structure and the ALC insulation boards. The structure and the construction method of the structure solve the technical problem that horizontal deformation of the corner structure causes the damage of a enclosure system.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

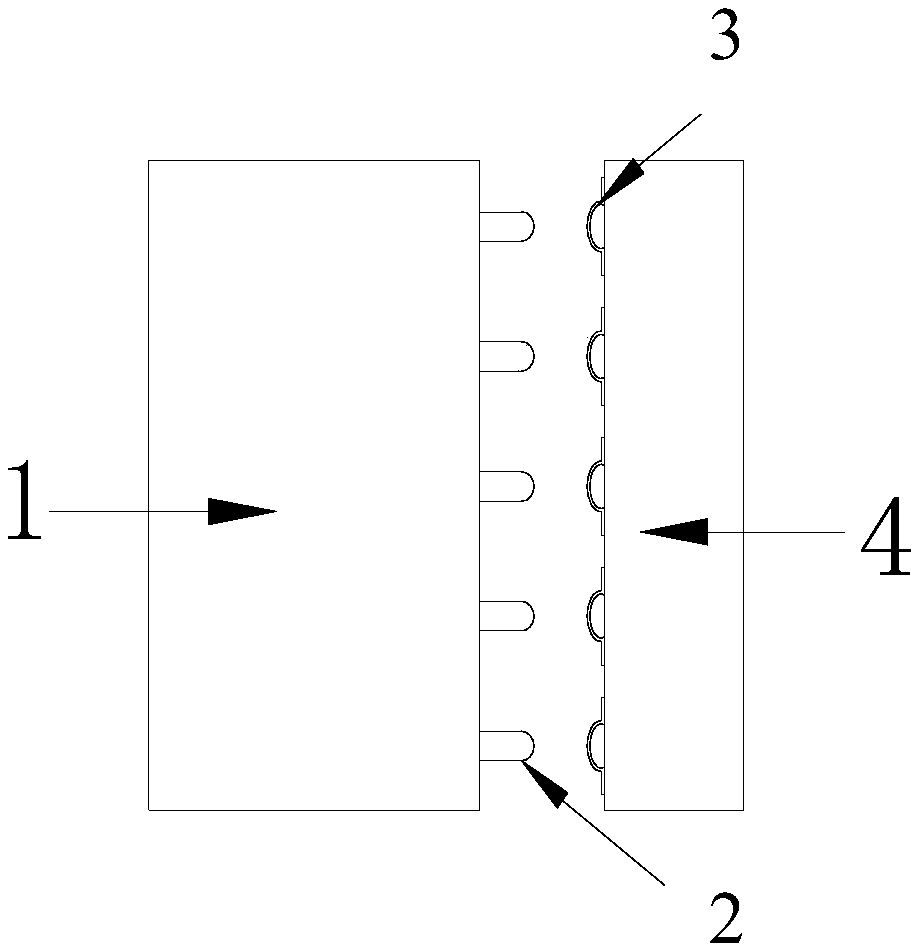

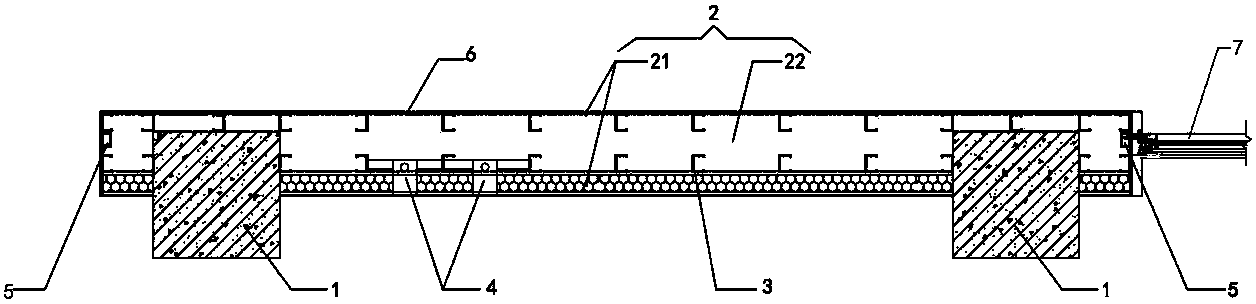

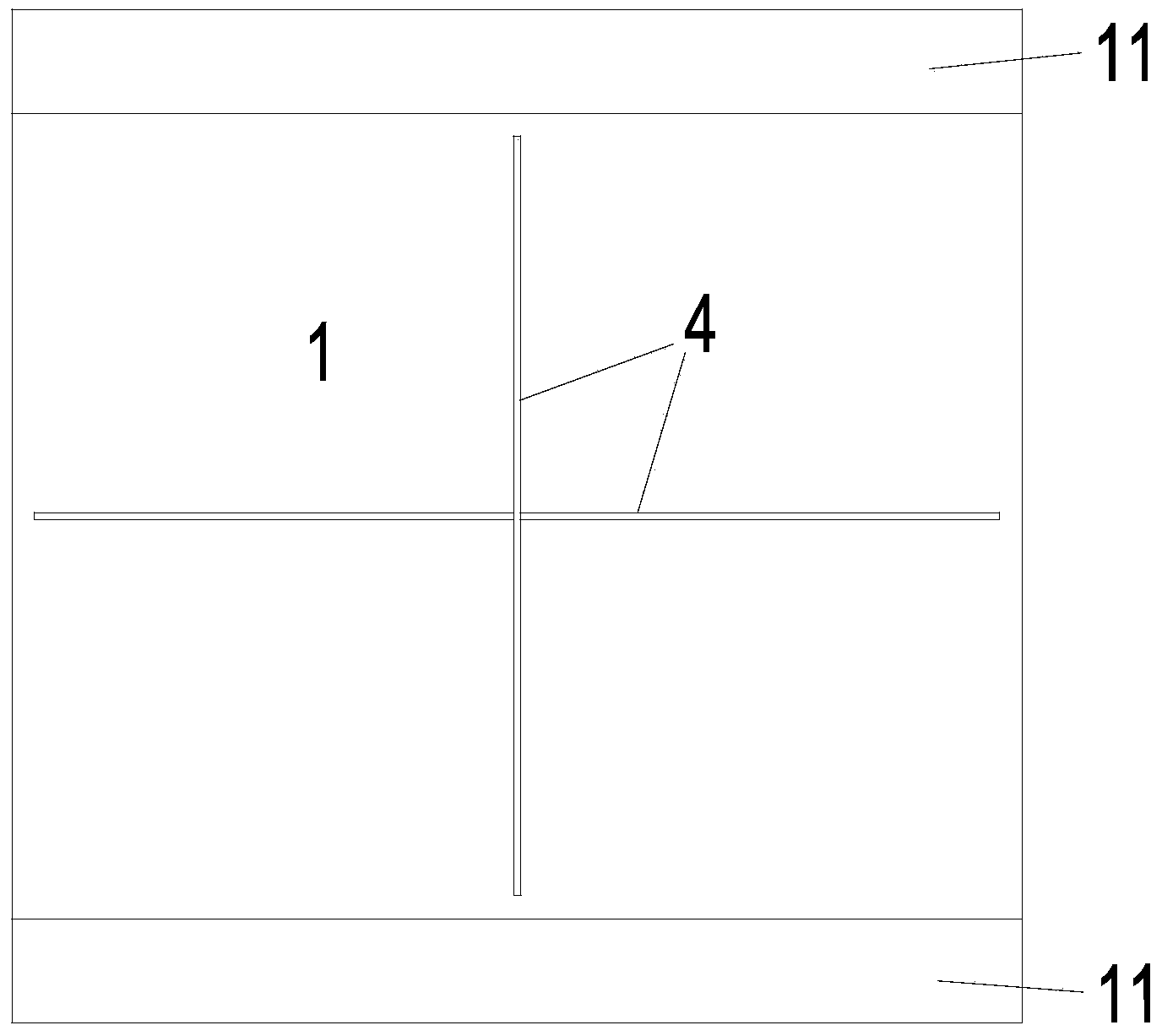

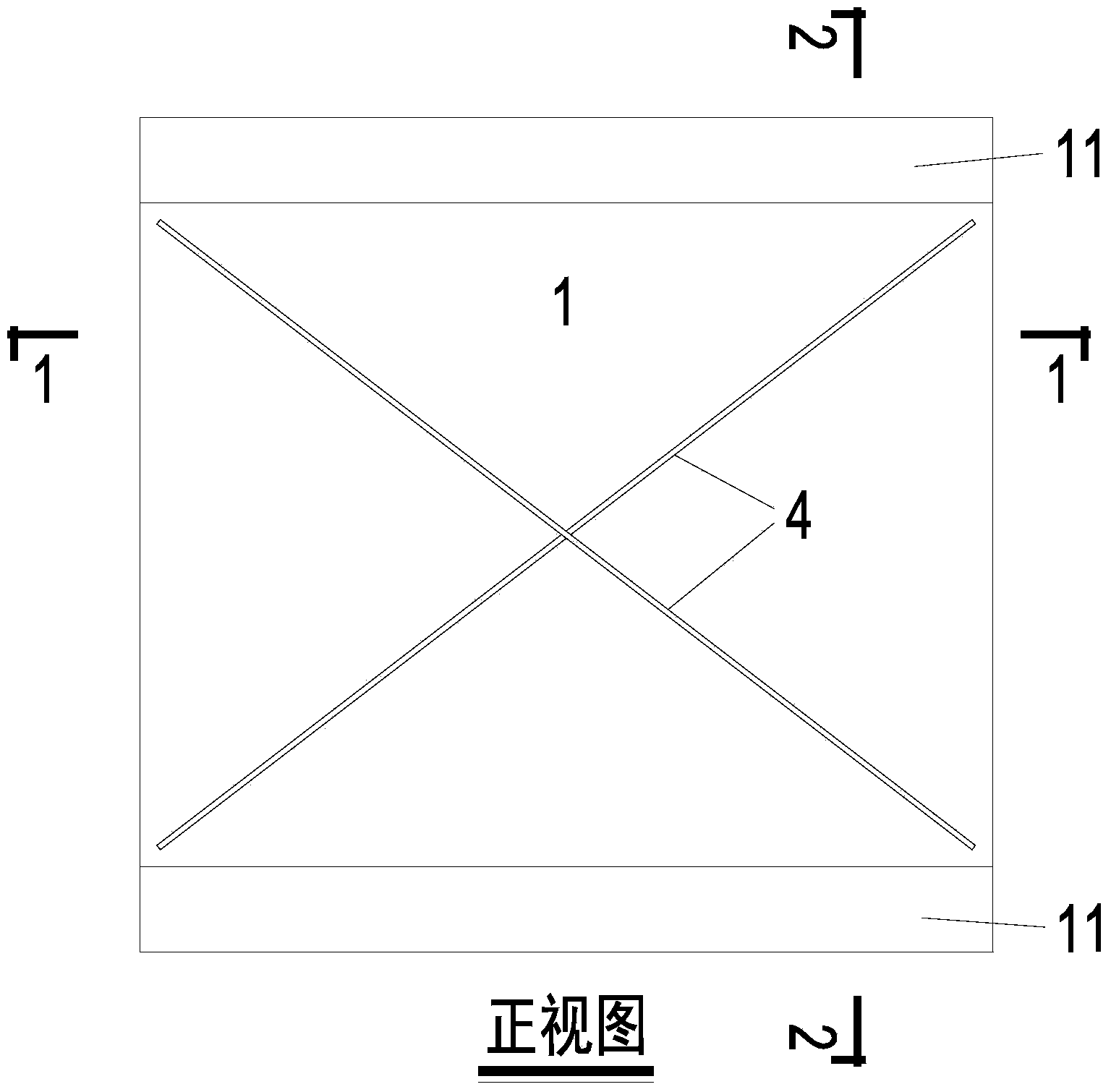

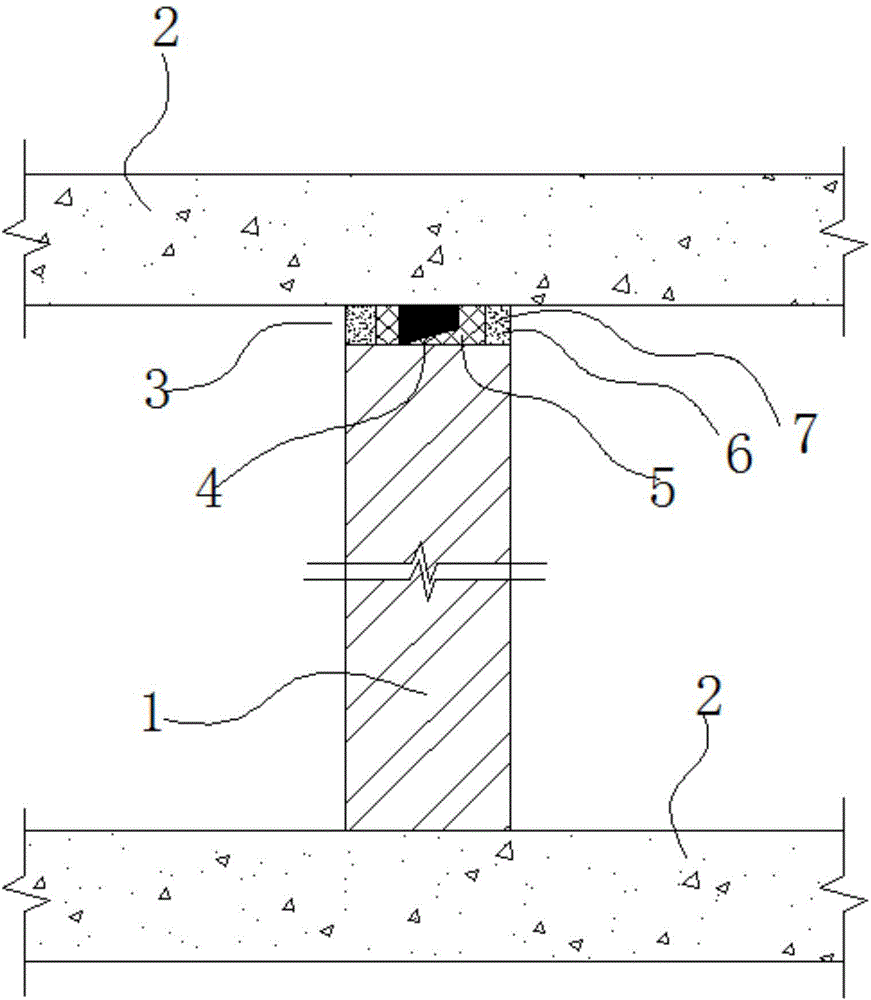

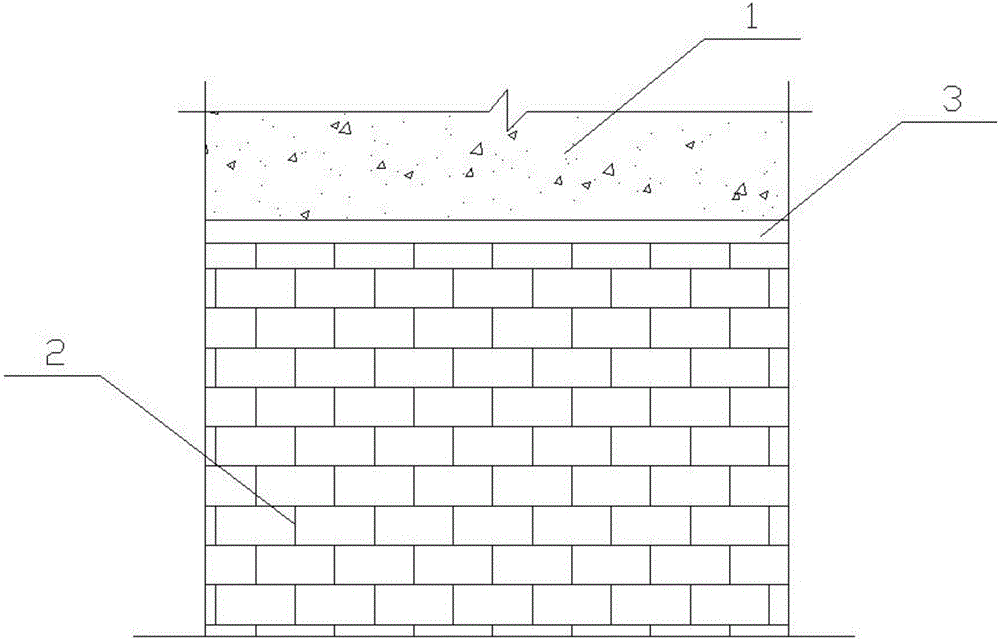

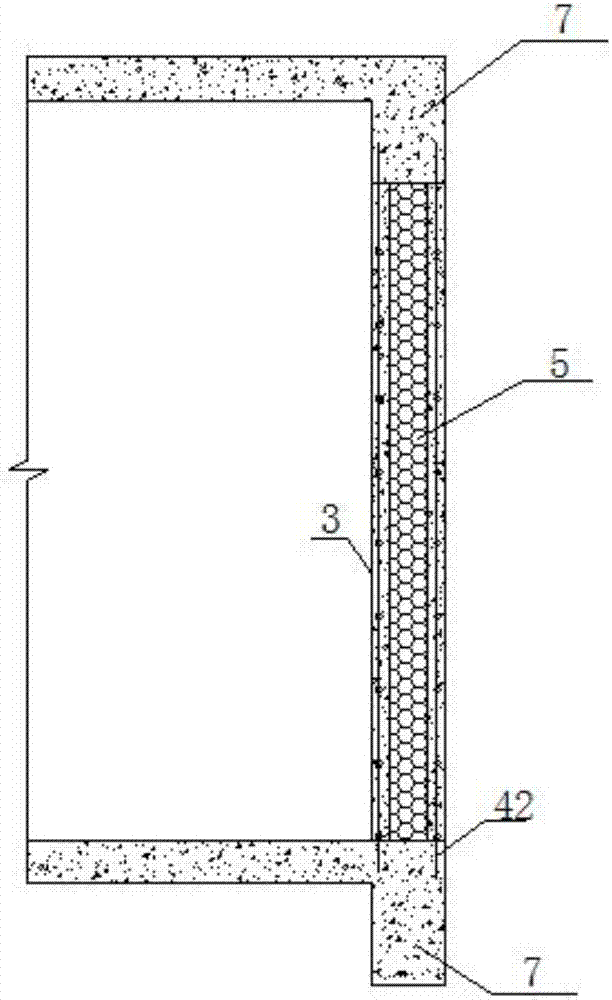

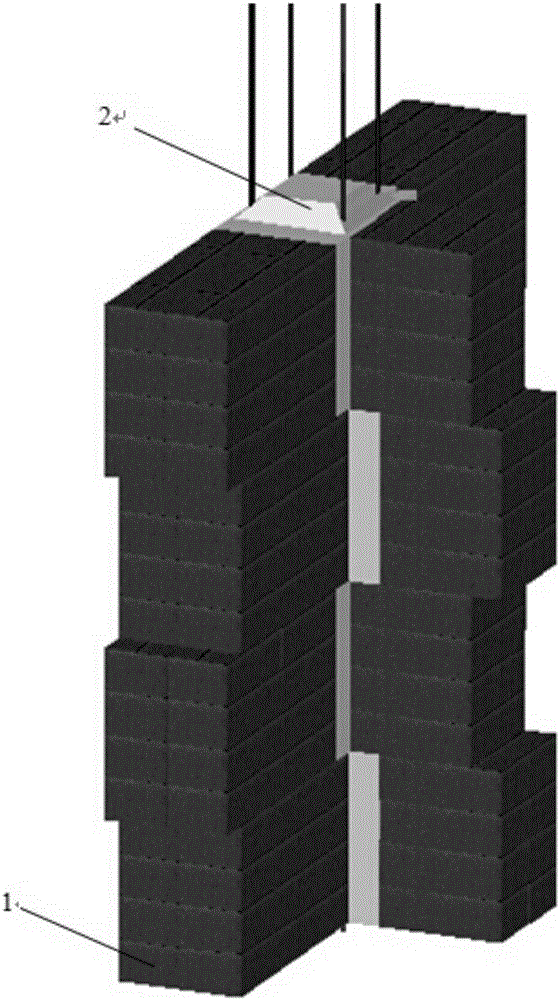

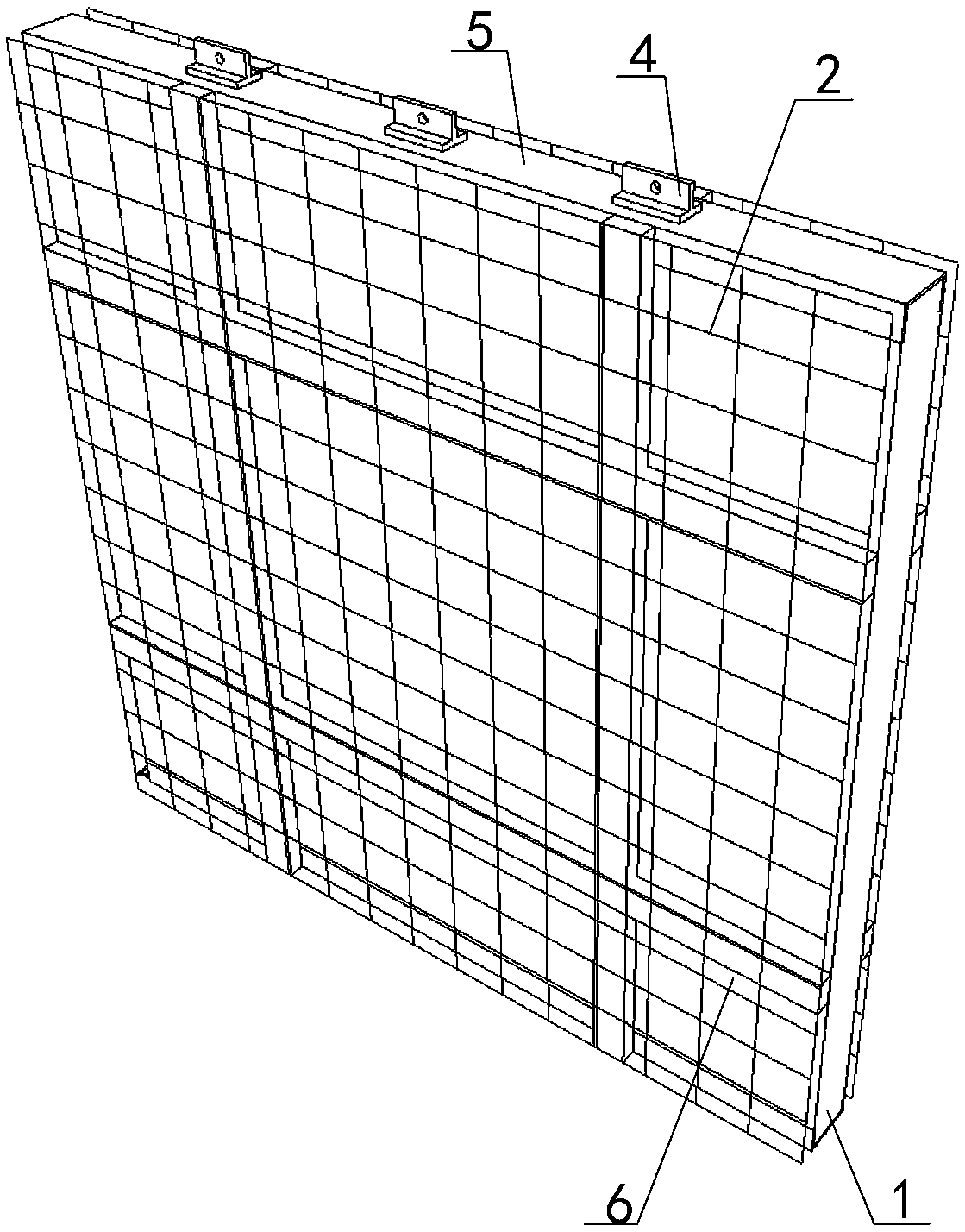

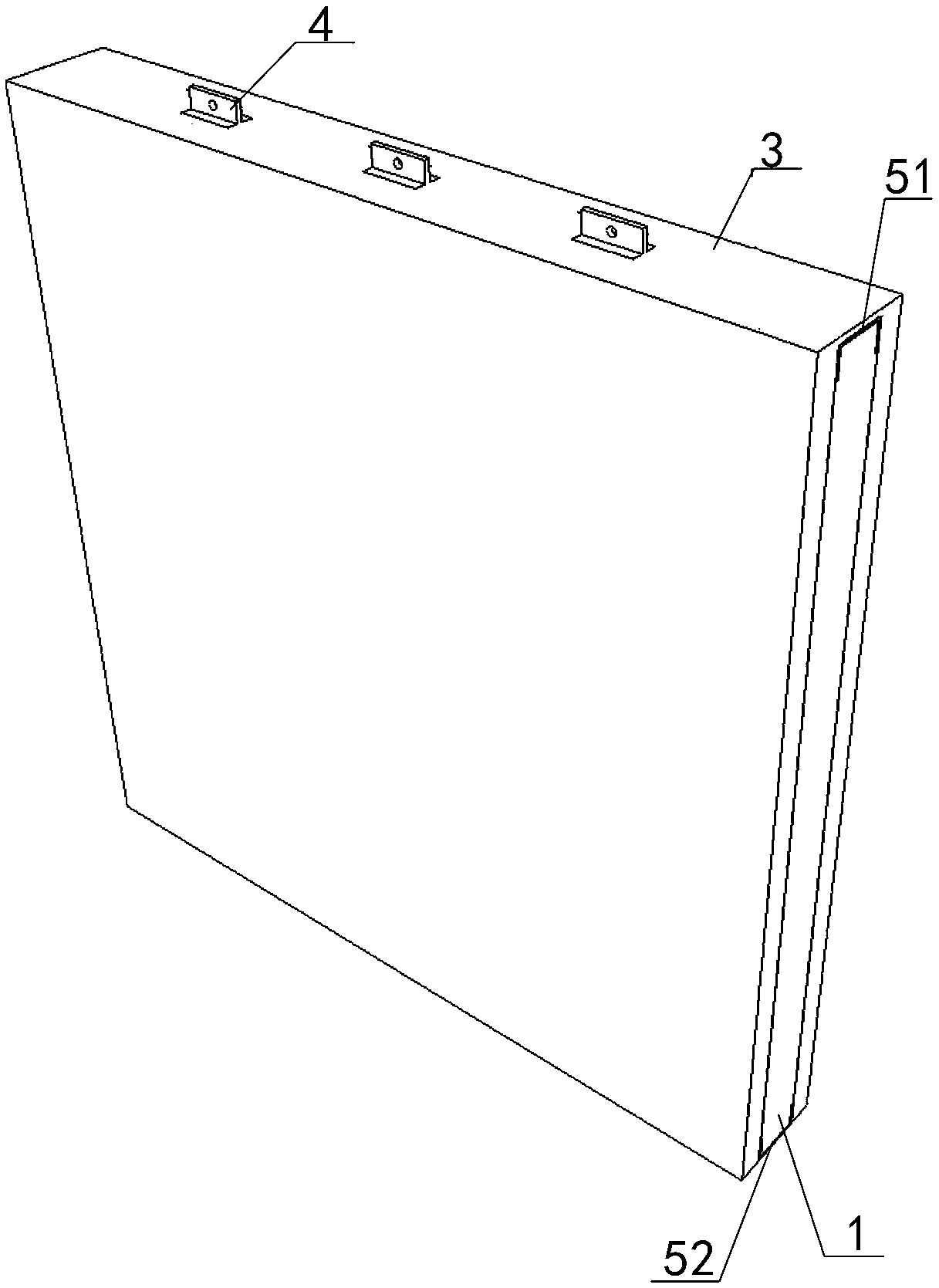

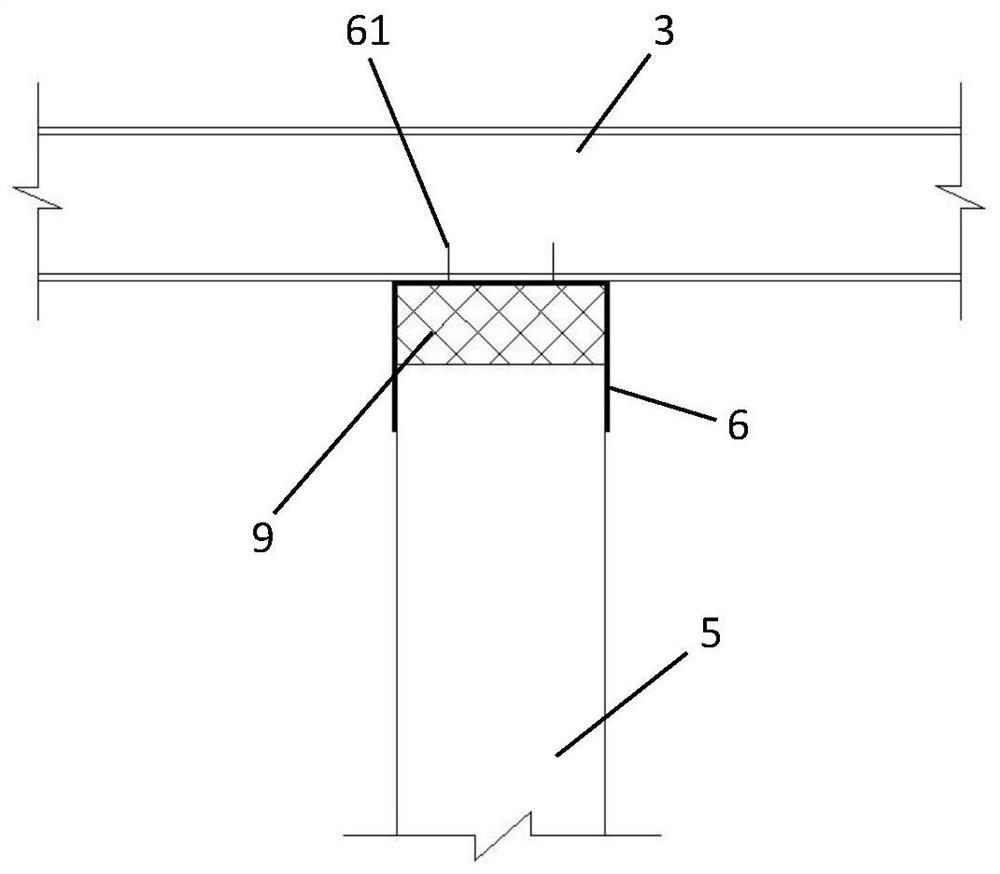

Prefabricated framework infilled wall

InactiveCN102776965AImprove sound insulationImprove insulation performanceWallsArchitectural engineeringStructural engineering

The invention provides a prefabricated framework infilled wall, which comprises prefabricated frameworks (1), wherein the prefabricated frameworks (1) are transversely arranged along the horizontal direction, and gaps (3) are arranged between adjacent prefabricated frameworks (1). Vertical ribs (4) are arranged in the gaps (3), and face layers (2) are arranged on two outer layers of the prefabricated frameworks (1). The prefabricated framework infilled wall is superior to the existing aerated concrete building block infilled walls and hollow internal model metal net cement internal parting walls in terms of comprehensive economic indicators and construction period. The prefabricated framework infilled wall has the advantages of being high in industrialized production degree and simple in site operation technology, thereby overcoming the shortcomings of the existing technology.

Owner:贵州皆盈科技开发有限公司

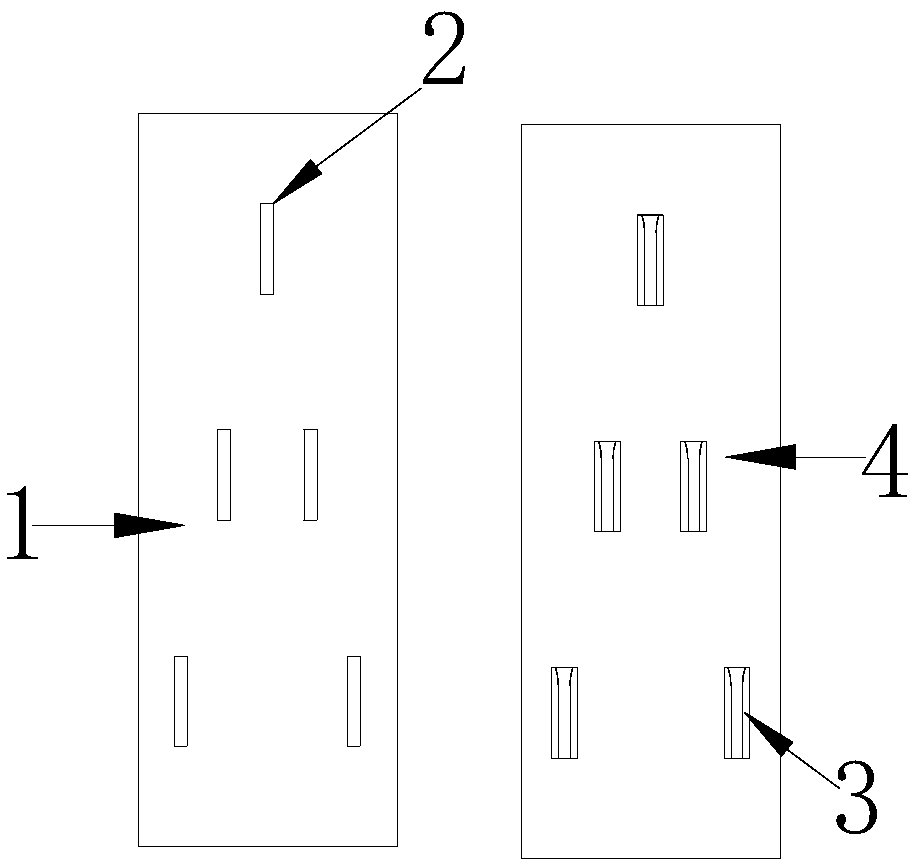

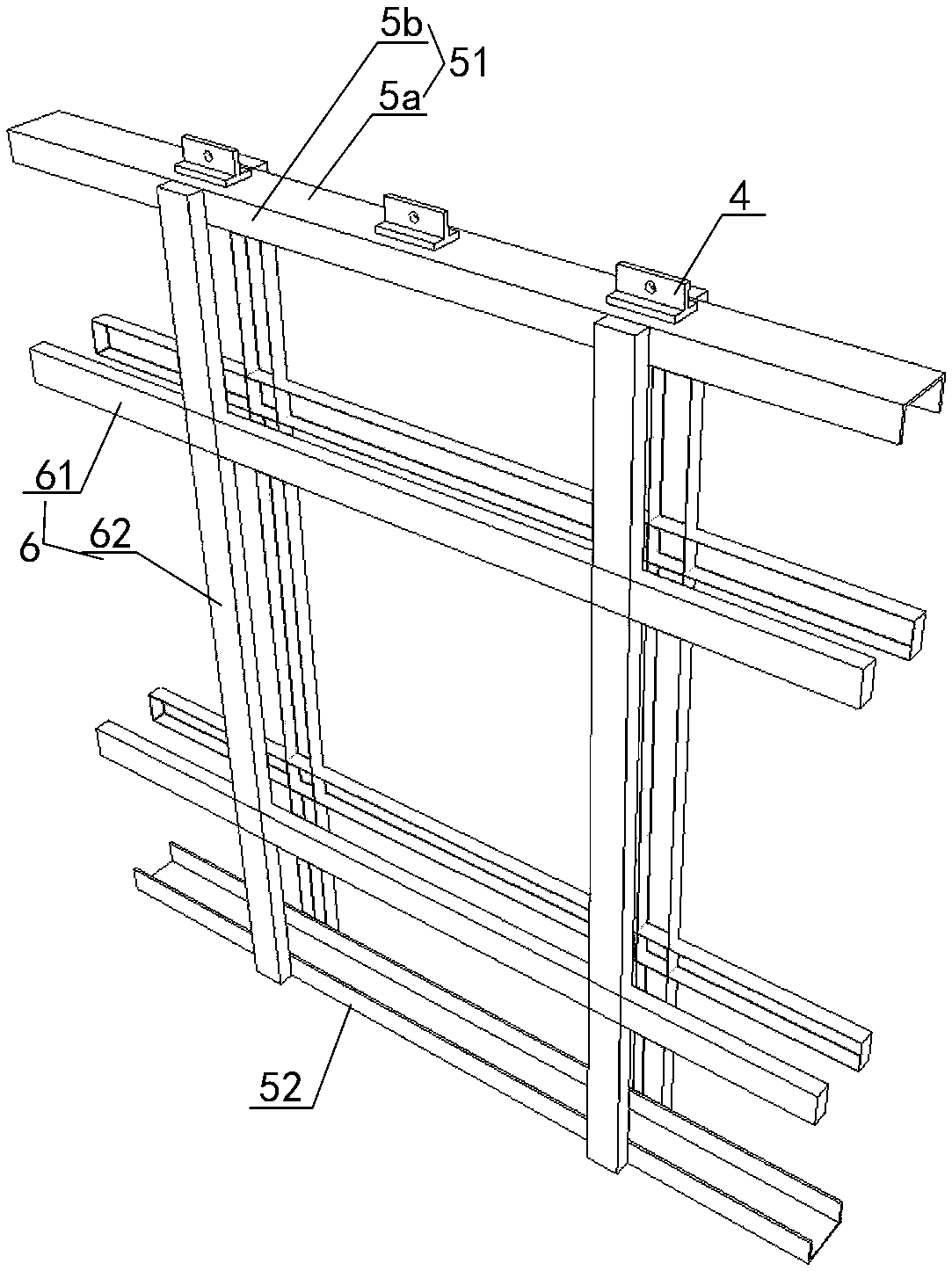

Assembly type infilled wall in track neck type connection, frame system and construction method thereof

The invention discloses an assembly type infilled wall in track neck type connection, a frame system and a construction method thereof. The assembly type filled wall comprises a rectangular wall bodyand a wall body connector; the rectangular wall body comprises a steel skeleton, an insulation layer, reinforcing meshes and a concrete layer; the wall body connector comprises T-shaped steel connecting blocks and embedding necks; the steel skeleton comprises a steel frame and lightgage steel joists, the insulation layer is embedded between the steel frame and the front lightgage steel joist, thereinforcing meshes are fixedly connected to the outside surface of the lightgage steel joist; the concrete layer respectively wrap and cast the lightgage steel joist and the reinforcing mesh on each side; the T-shaped steel connecting blocks are lined, aligned and arranged at intervals at the center of the upper side surface of the top frame, the T-shaped steel connecting blocks are embedded intothe embedding necks to relatively slide left and right in a length direction of the steel frame. By changing a connection way of the infilled wall system, the infilled wall can perform relative sliding under the effect of the seismic, so that the prefabricated infilled wall cannot be affected by the seismic force when the seismic comes, and the anti-seismic capacity of the assembly type infilled wall system is effectively improved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Filler wall with built-in crossed ladder reinforcing steel bars and manufacture method of filler wall

InactiveCN103912072AImprove performanceReduced chance of collapseWallsShock proofingIndustrial wasteSteel bar

The invention relates to a filler wall with built-in crossed ladder reinforcing steel bars and a manufacture method of the filler wall. The filler wall is located in a framework structure and consists of energy dissipation strips, concrete blocks, a concrete framework, reserved rachel tendons, and a ladder reinforcing steel mesh inclined strut. During manufacture, according to the design and normal frameworks, the concrete framework and the inclined strut are manufactured, and simultaneously, the reserved rachel tendons are shaped through manufacture. The energy dissipation strips and the concrete blocks are used for construction, the reserved rachel tendons are completely arranged at the positions of reserved reinforcing steel bars of the concrete framework, by means of the vertical energy dissipation strips, the filler wall is prevented from destroying the framework structure in an earthquake and consuming earthquake energy, the filler wall can be closely contacted with framework columns, and construction processes are saved; by means of the crossed ladder reinforcing steel mesh inclined strut, shear capacity of a wall body is improved, integrality of the wall body is enhanced, and energy-dissipating capacity is improved; according to the filler wall with built-in crossed ladder reinforcing steel bars, energy consumption capacity of an inclined strut portion and a masonry structure are fully utilized, light materials can be manufactured from industrial waste, and a function of eco-environment protection is achieved.

Owner:BEIJING UNIV OF TECH

Prefabricated assembly type self-resetting frame integral structure

PendingCN111962659AImprove horizontal bearing capacityRealize energy consumptionProtective buildings/sheltersShock proofingFloor slabArchitectural engineering

The invention discloses a prefabricated assembly type self-resetting frame integral structure which comprises foundations, steel columns, cross beams, floor slabs, prefabricated filling wallboards andU-shaped clamps. The steel columns and the foundations form self-resetting column base structures; the steel columns and the cross beams connected with two sides thereof form self-resetting joint structures; when an earthquake comes, the self-resetting joint structures located at the beam-column joints dissipate earthquake energy firstly, and the horizontal bearing capacity of the structure is improved; secondly, the floor slabs and the prefabricated filling wallboards are not in direct contact with the steel columns; certain distances are reserved between the prefabricated filling wallboardsand the bottoms of the U-shaped clamps on the upper portion and the two sides, when the overall structure has the tendency of lateral overturning, the floor slabs and the prefabricated filling wallboards keep a normal stable state, it is guaranteed that the gravity center of the overall structure does not deviate substantially along with the earthquake action, and the overall structure has the self-resetting capacity after an earthquake. And finally, the self-resetting joint structures and the self-resetting column base structures play a role to jointly ensure that joints and column bases arenot greatly damaged, so that the energy consumption and the self-resetting function of the structure are realized.

Owner:HAINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com