Low-yield-point steel plate shear wall with two connected edges

A steel plate shear wall, low yield point technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of side column damage, affecting the mechanical performance of the frame, etc., to achieve energy consumption, excellent hysteresis performance stability, hysteresis Full back curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

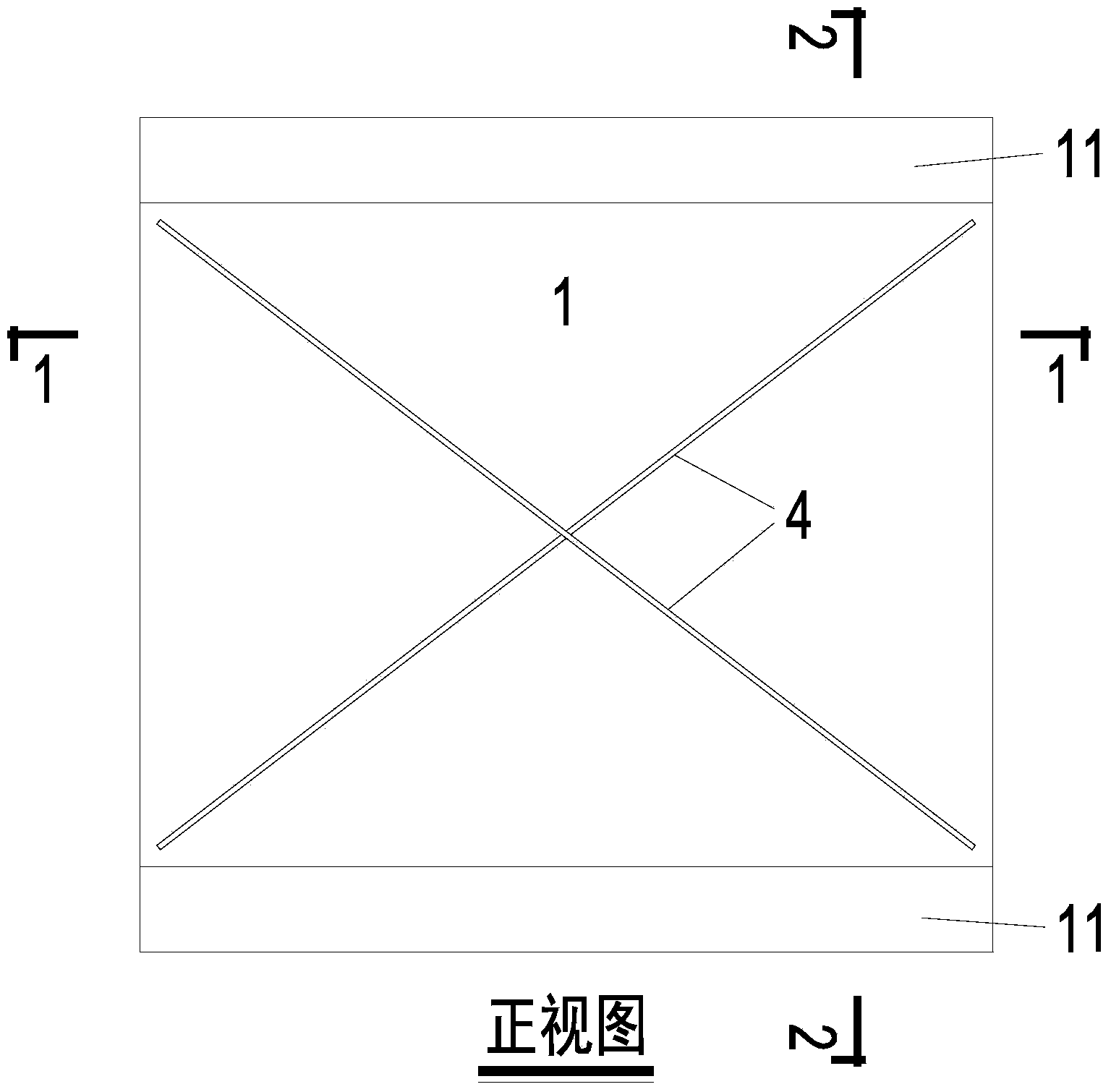

[0038] Figure 7 It is a structural schematic diagram of the bolted connection between the low yield point steel plate shear wall and the steel frame connected on both sides.

[0039] When the low-yield-point steel plate shear wall and the steel frame connected by bolts are connected on both sides, the double plywood 2 of the shear wall is connected to the steel frame beam 5 through high-strength bolts 9, and the edge member 3 of the shear wall is separated from the steel frame column 7. Open, forming a low yield point steel plate shear wall with only upper and lower edges connected.

Embodiment 2

[0041] Figure 8 It is a structural schematic diagram of the connection between the low yield point steel plate shear wall and the concrete frame using shear connectors connected on both sides.

[0042] When the steel plate shear wall with low yield point connected on both sides is connected to the concrete frame with shear connectors, the double plywood 2 of the shear wall is connected to the concrete frame beam 6 through the shear connector 10, and the edge member 3 of the shear wall is connected to the concrete frame beam. The concrete frame columns 8 are disengaged to form a low yield point steel plate shear wall with only upper and lower edges connected.

[0043] In actual manufacture, first process the main part of the low yield point steel plate shear wall connected on both sides according to the design parameters (height, width, thickness of the low yield point inner steel plate wall, the form of the upper and lower double plywood and the edge members on both sides), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com