Prefabricated concrete frame infill wall system and construction method thereof

A technology for filling walls and concrete, applied in the direction of walls, building components, buildings, etc., can solve the problems of low construction efficiency and poor seismic performance, and achieve the effect of improving construction efficiency, good anti-overturning ability, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

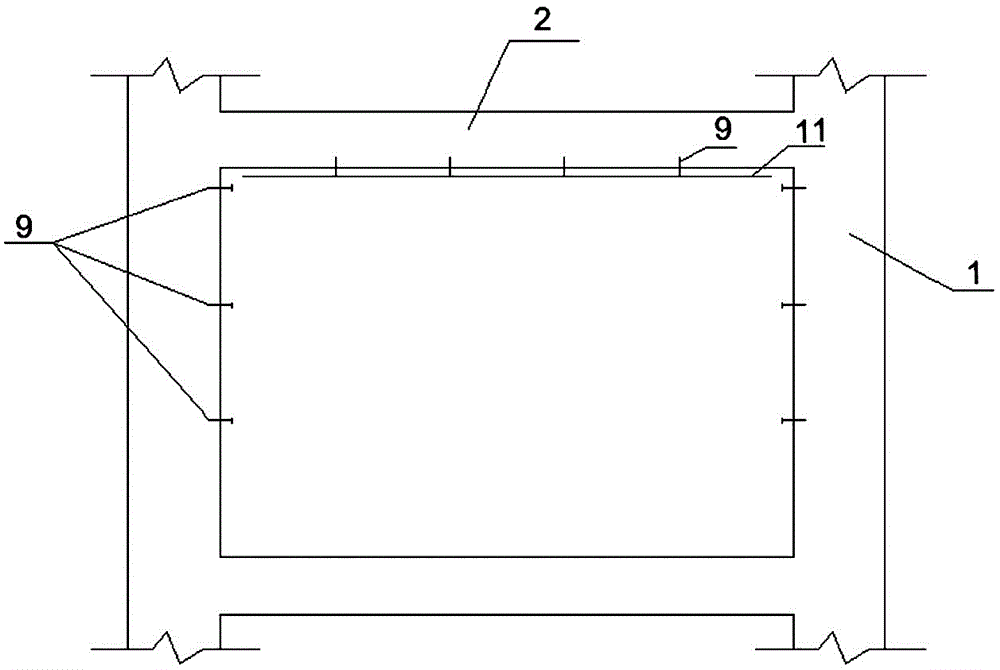

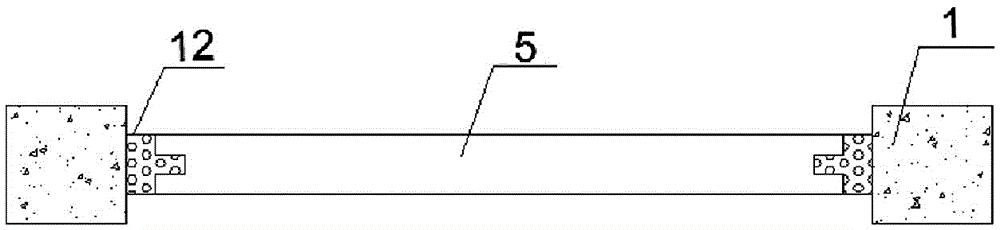

[0047] Examples see figure 2 As shown, this prefabricated concrete frame infill wall system includes frame columns 1, frame beams 2, prefabricated upper infill wall panels 3, prefabricated middle infill wall panels 4, prefabricated lower infill wall panels 5, masonry mortar 7, flame retardant Flexible filling material 12, internal tie bars 8, upper tie bars 10, anchor bars 9 and horizontal long bars 11; the prefabricated upper filling wallboard 3, the prefabricated middle filling wallboard 4 and the prefabricated lower filling wallboard 5 are Made of lightweight materials such as foam concrete, pumice concrete, etc.

[0048] The front and back sides of the prefabricated upper infill wallboard 3 , the prefabricated middle infill wallboard 4 and the prefabricated lower infill wallboard 5 are all planes, and the three are arranged in sequence in the vertical direction to form a rectangular infill wall. Mortise and tenon connection is adopted. In this example, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com