Structure of connecting joint of infilled wall and column of autoclaved aerated concrete slab and construction method of structure

A technology of concrete slab and autoclaved aeration, which is applied to building structures, walls, building components, etc., can solve problems such as damage to the enclosure system, and achieve the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

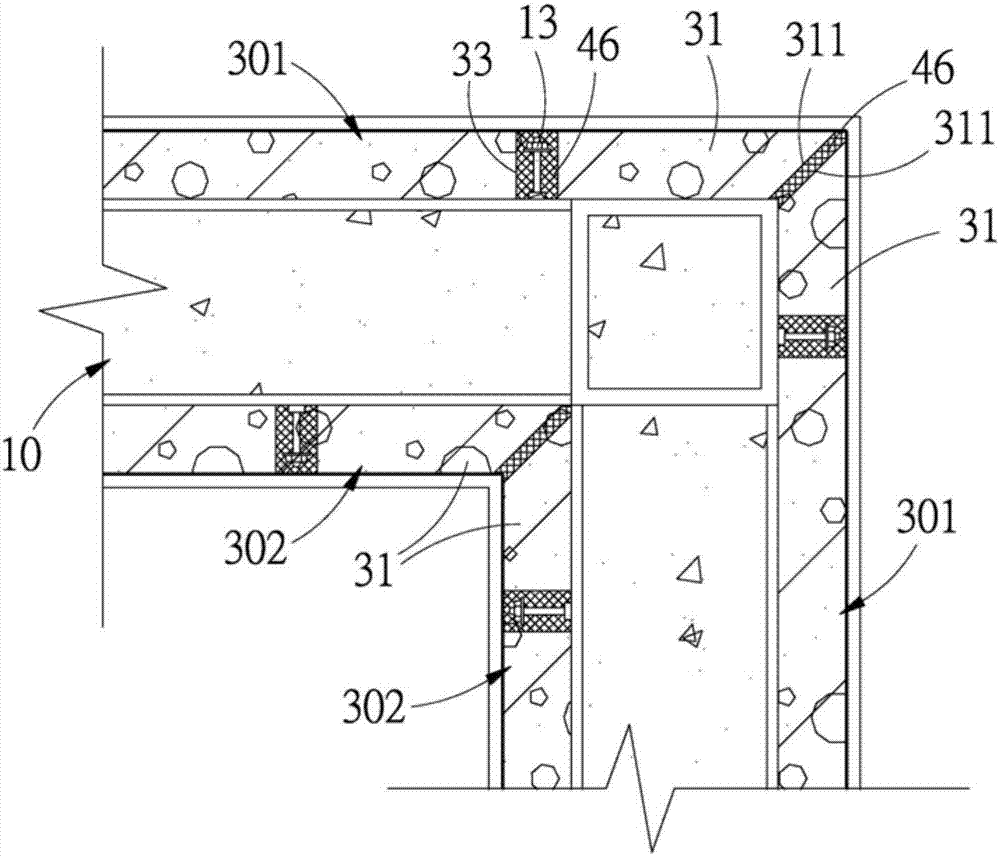

[0035] see Figure 1 to Figure 7 , the present invention provides an autoclaved aerated concrete slab filling wall and column connection node structure and its construction method, which is mainly arranged on the corner structure 10 of the main structure, specifically the ALC wall panels 20, ALC The insulation board 30 is installed on the corner structure 10 , and the ALC insulation board 30 forms an elastic connection with the corner structure 10 and the ALC wallboard 20 .

[0036] Such as figure 1 , figure 2 , image 3 As shown, the corner structure 10 includes a column body 11 and a template 12 connected to the column body 11 to form an L-shaped structure in cross section; the corner structure 10 is formed with two mounting parts, including a The first installation part 101, and the second installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com