Prefabricated steel frame infill wall system and construction method thereof

A steel frame and infill wall technology, which is applied to walls, building components, buildings, etc., can solve the problem that the infill wall and the steel frame cannot be deformed synergistically, so as to save masonry time and manpower input, enhance seismic performance, and reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

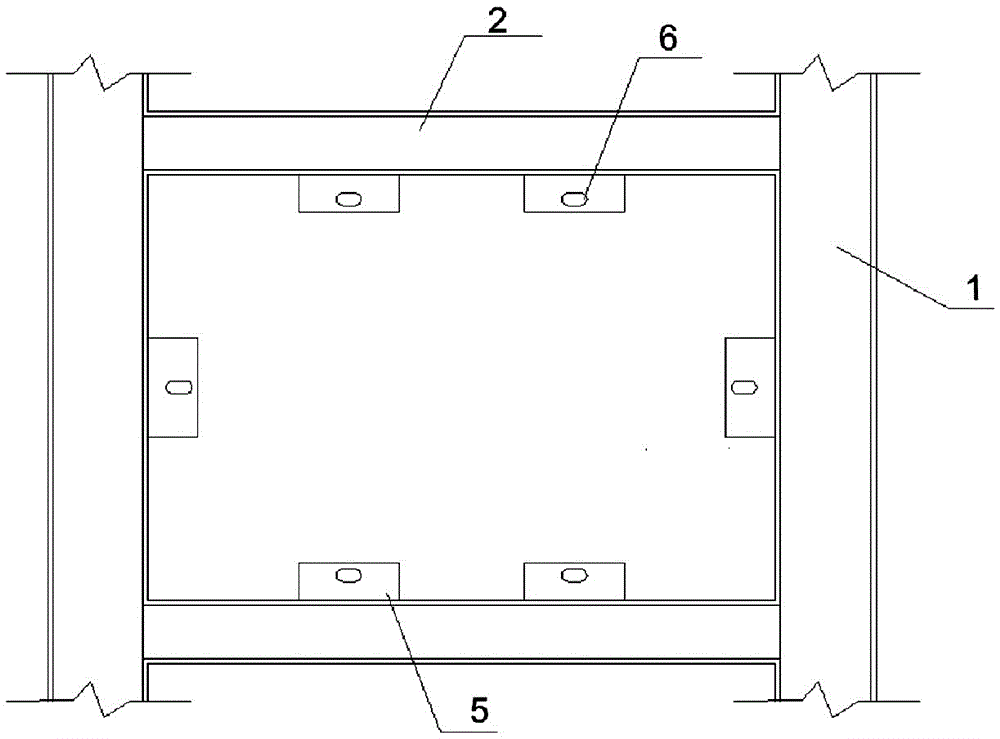

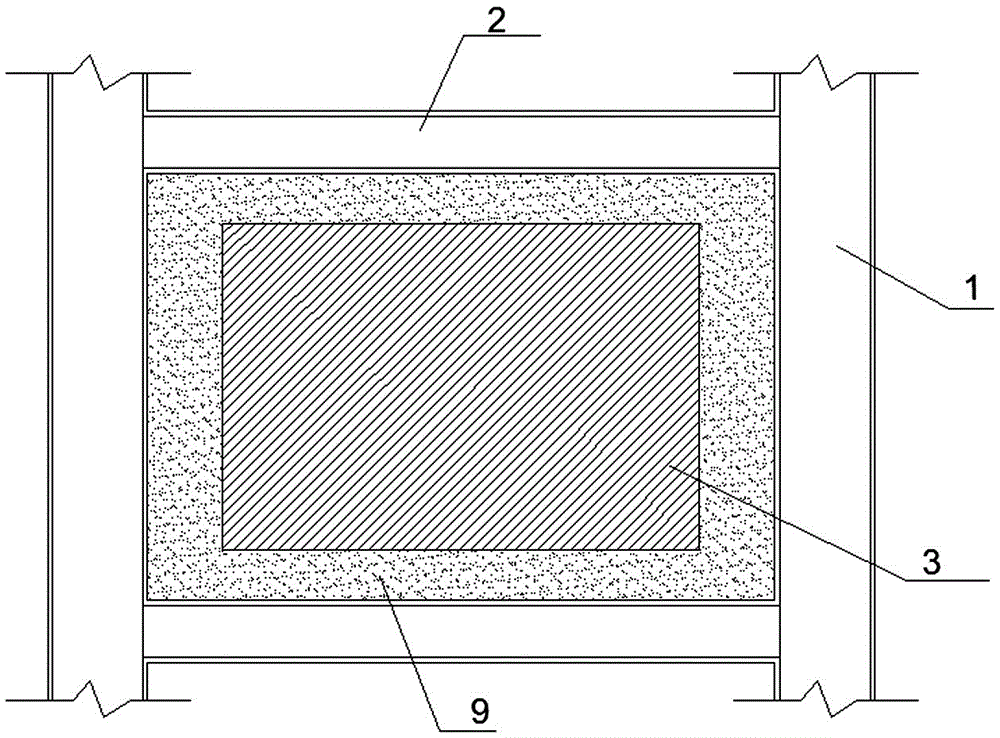

[0037] see example Figure 1 to Figure 4 As shown, this prefabricated steel frame infill wall system includes steel frame columns 1, steel frame beams 2, prefabricated infill wall panels 3, steel frame gusset panels 5, infill wall gusset panels 4 and fasteners 7, flame retardant flexible Filling material 8, waterproof mortar layer 9, etc.

[0038] The steel frame gusset plate 5 is connected to the inner side of the steel frame column 1 and the steel frame beam 2 at regular intervals by means of rigid connection, see figure 1 As shown, the steel frame gusset plate 5 is located on the inner circle of the rectangular steel frame enclosed by the steel frame column 1 and the steel frame beam 2, and the distance between the adjacent steel frame gusset plates 5 is 800mm-1200mm.

[0039] On the periphery of the prefabricated infill wall panel 3, the position corresponding to the steel frame gusset plate 5 is connected with the infill wall gusset plate 4, and the infill wall gusset pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com