Assembly type infilled wall in track neck type connection, frame system and construction method thereof

A prefabricated, infill wall technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve the problems of low construction efficiency, poor thermal insulation performance, poor seismic performance, etc., to improve construction efficiency and integrity. Good, improve the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

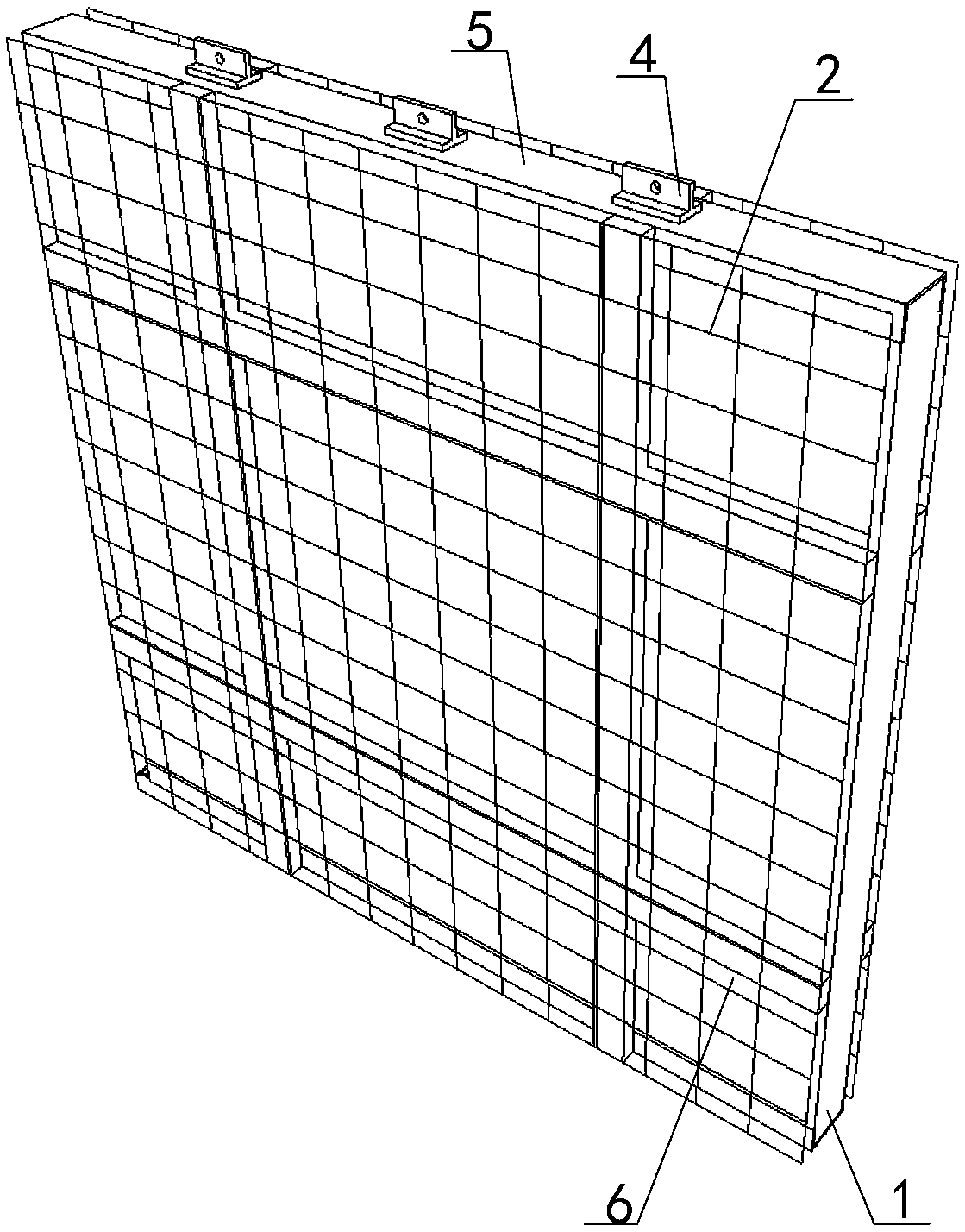

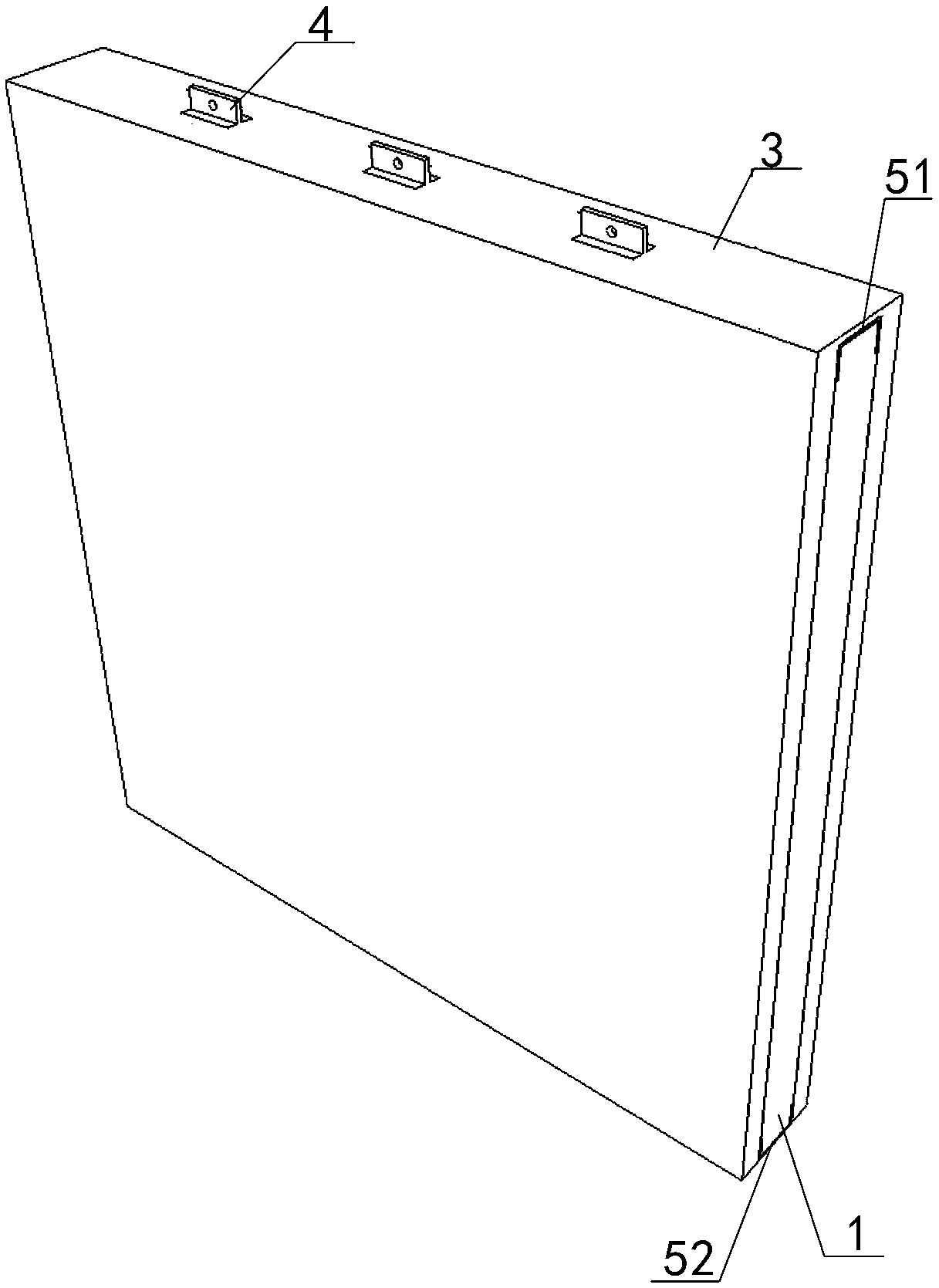

[0054] Examples see Figure 1-7 As shown, a prefabricated infill wall with track slot type connection includes a rectangular wall and wall connectors. The rectangular wall includes a steel skeleton, an insulation layer 1, a steel mesh 2 and a concrete layer 3. The wall connector includes a T-shaped steel connection block 4 .

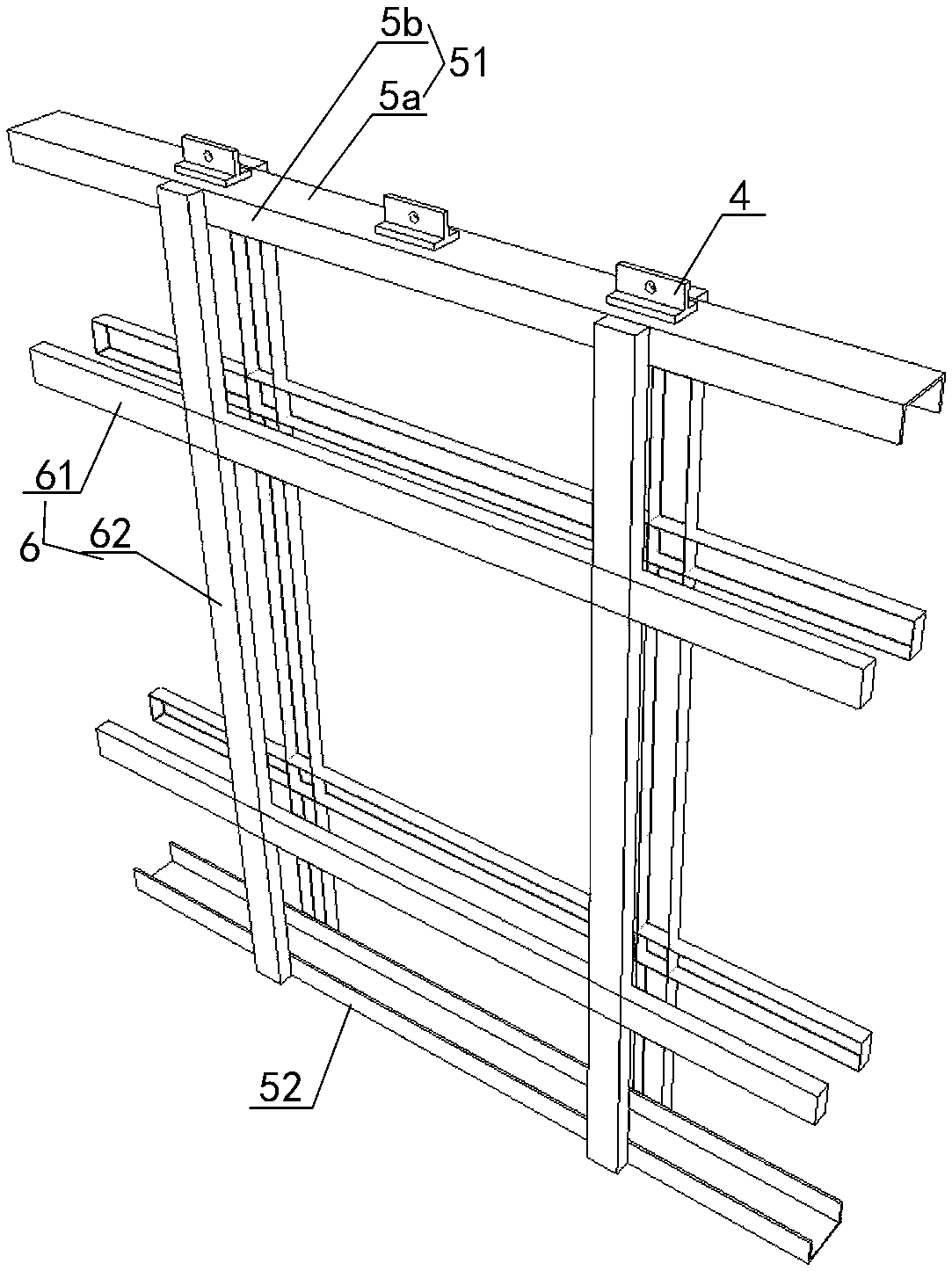

[0055] see figure 1 As shown, the steel frame includes a steel frame 5 and a light steel keel 6. There are two steel frames, including a top frame 51 and a bottom frame 52 that are respectively located at the upper and lower ends of the rectangular wall and are arranged oppositely. There are two layers of steel keels, which are arranged on both sides of the steel frame. The upper end surface of the light steel keel is flush with the upper end surface of the top frame, and the lower end surface of the light steel keel is flush with the lower end surface of the bottom frame. The light steel keel on each side The upper end and the lower end are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com