Energy-saving insulation structure of lighting window and construction method thereof

A lighting window and thermal insulation technology, which is applied in the direction of building structure, building components, and the fastening/covering of joints, can solve the problems of many construction techniques, complex construction process, low construction efficiency, etc., and achieves a high degree of construction mechanization, Simple construction process and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

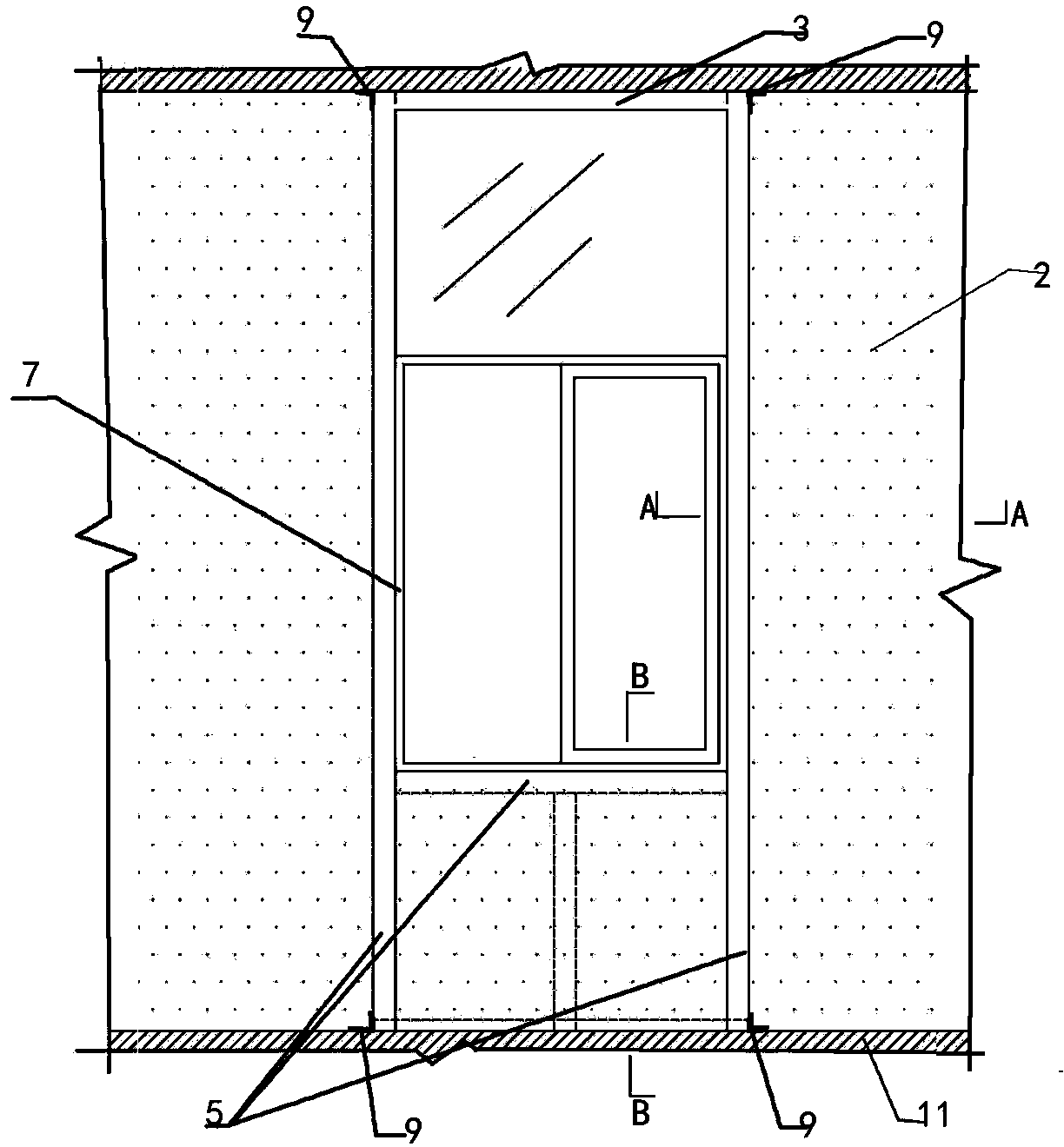

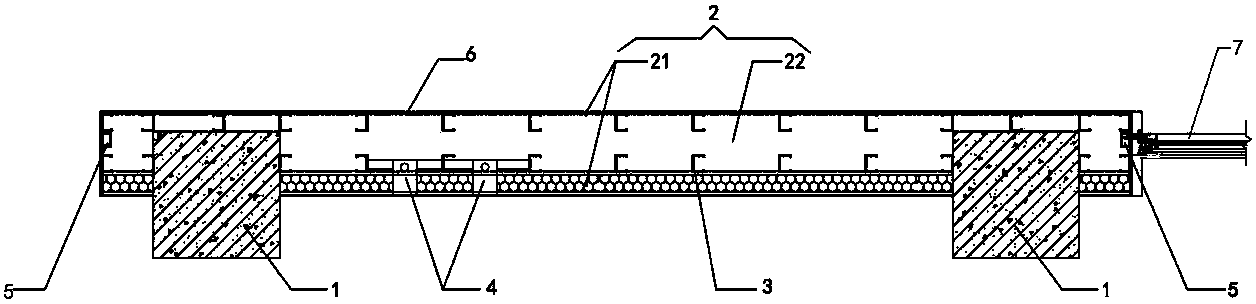

[0041] Such as Figure 1~5 As shown, an energy-saving and thermal insulation structure of a daylighting window, the window structure 7 is opened on the filling wall 2, and the filling wall 2 is arranged between the frame columns, and it is characterized in that: the edges of the filling walls around the window structure 7 are all set There is a reinforced keel 5, and the reinforced keel 5 of the outer window is installed inside the cast-in-place wall, which makes the installation of the outer window easier; the panel 21 is disconnected from the position of the reinforced keel 5, and the disconnected part is filled with thermal insulation foam 10 to make the outer window After installation, it is not easy to produce "cold bridge". The window frame 71 is bonded and anchored with the reinforcing keel 5 at the bottom. Firmly fixed, the connection between the window structure 7 and the filling wall is provided with a waterproof cloth 8, and the waterproof cloth 8 is laid at a right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com