Strengthening system of L-shaped infilled wall structural column formwork and construction method

A formwork reinforcement and construction column technology, which is applied in formwork/formwork/work frame, building construction, and on-site preparation of building components. Simple, avoiding distortion of male corners and not straightening, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with specific examples, but the structure of the present invention is not limited to the following examples.

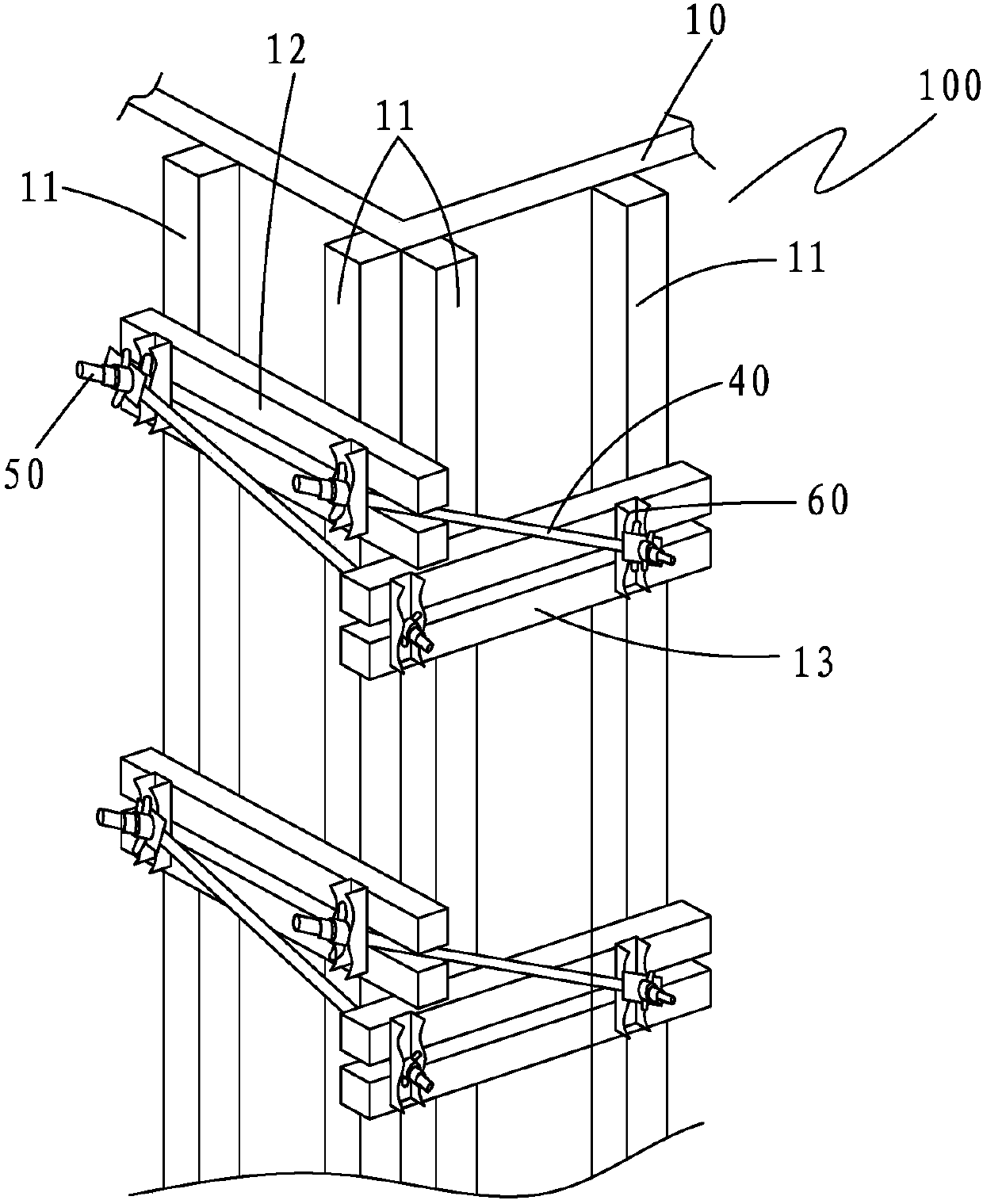

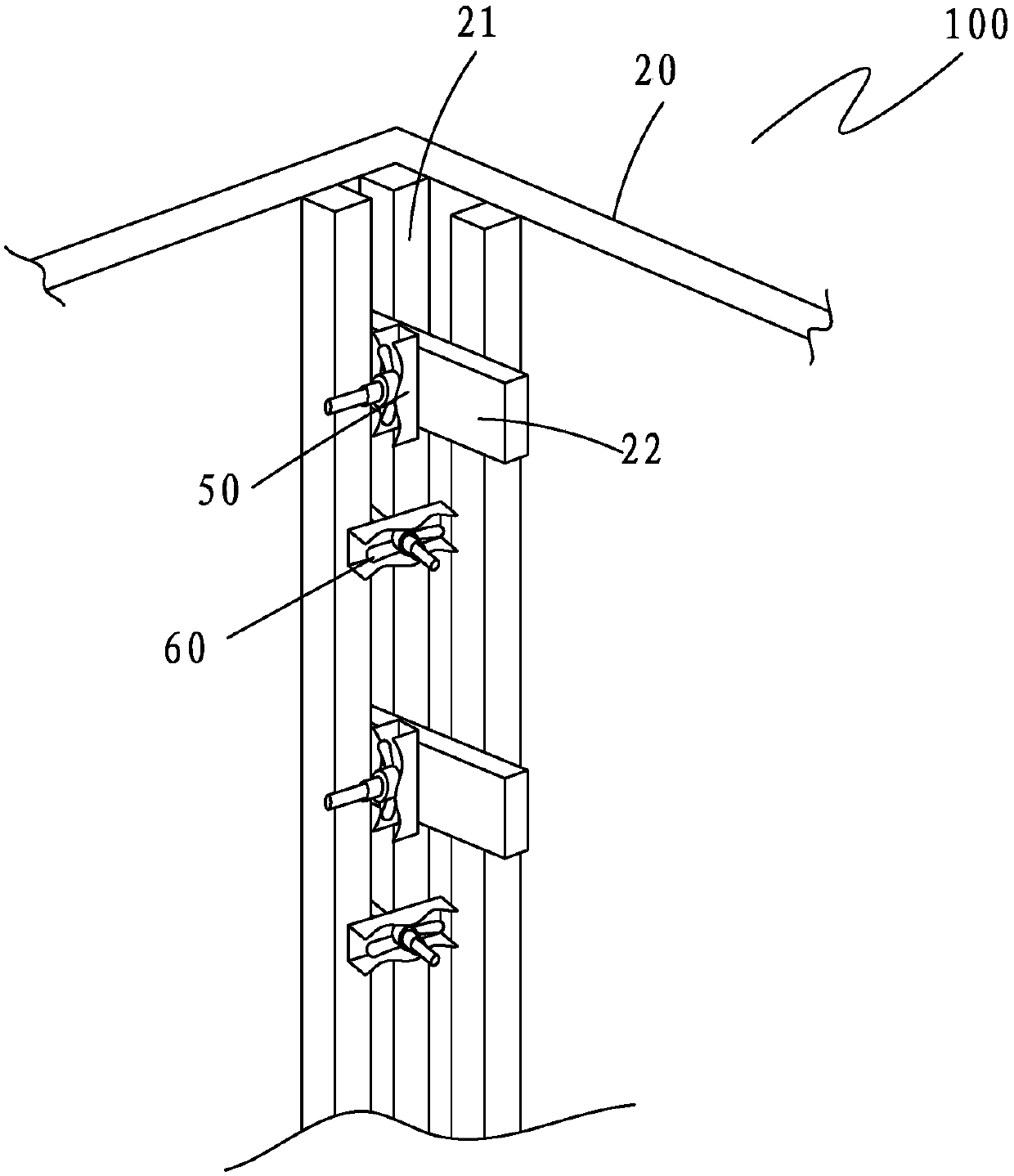

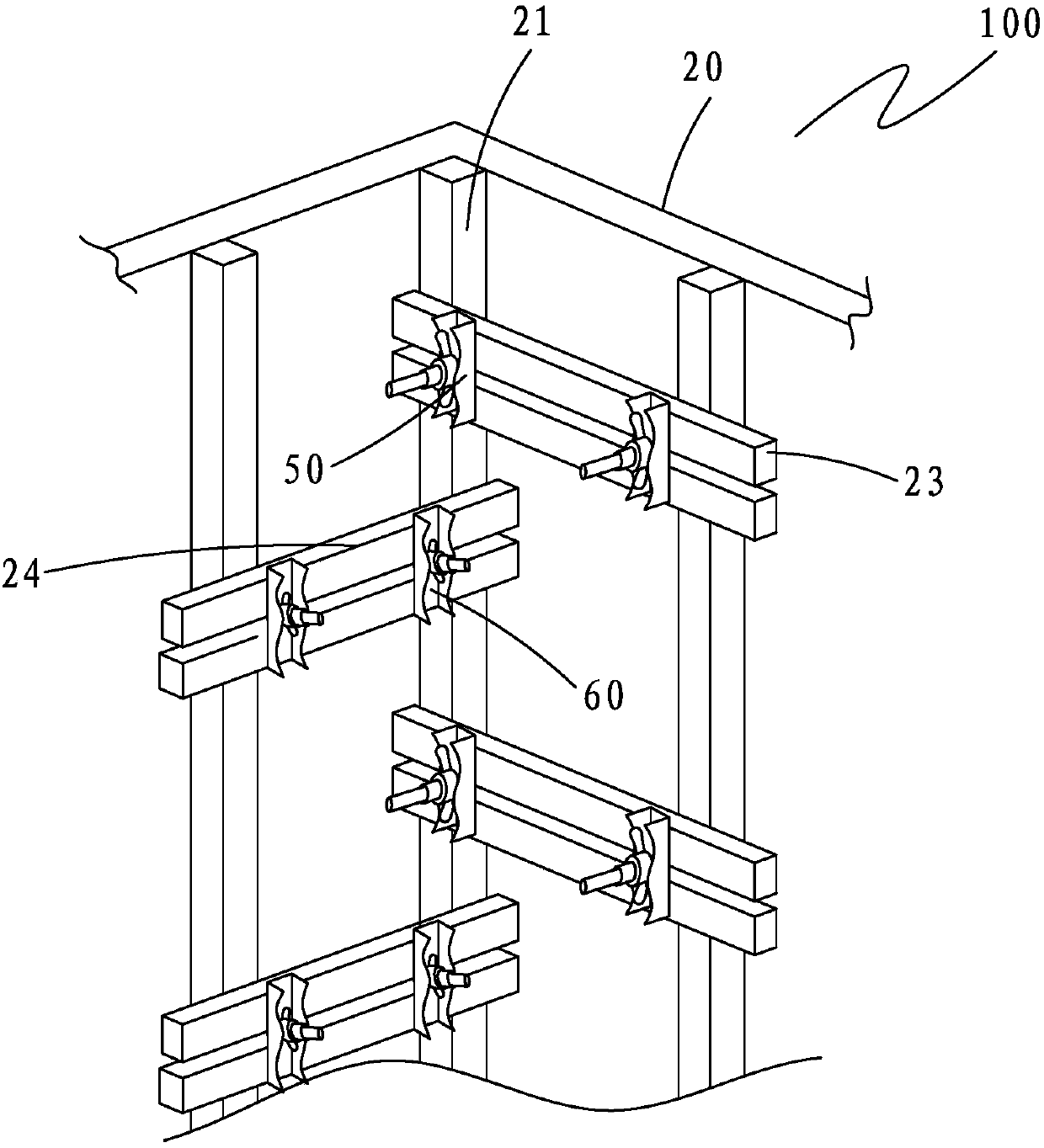

[0044] see figure 1 , figure 2 with Figure 4 As shown, a reinforcement system of a L-shaped filled wall construction column formwork of the present invention, the reinforcement system 100 includes a construction column male corner formwork 10 and a construction column internal corner formwork 20, and the construction column male corner formwork 10 and The internal corner formwork 20 of the structural column is arranged opposite to form a pouring channel 30 of an L-shaped filling wall; the outer surface of the external corner formwork 10 of the structural column is fixed with a plurality of vertical secondary keels 11 of the external corner, and two of the external corners The vertical secondary joists 11 are arranged at the male corners of the external corner formwork 10 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com