Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "No dripping phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

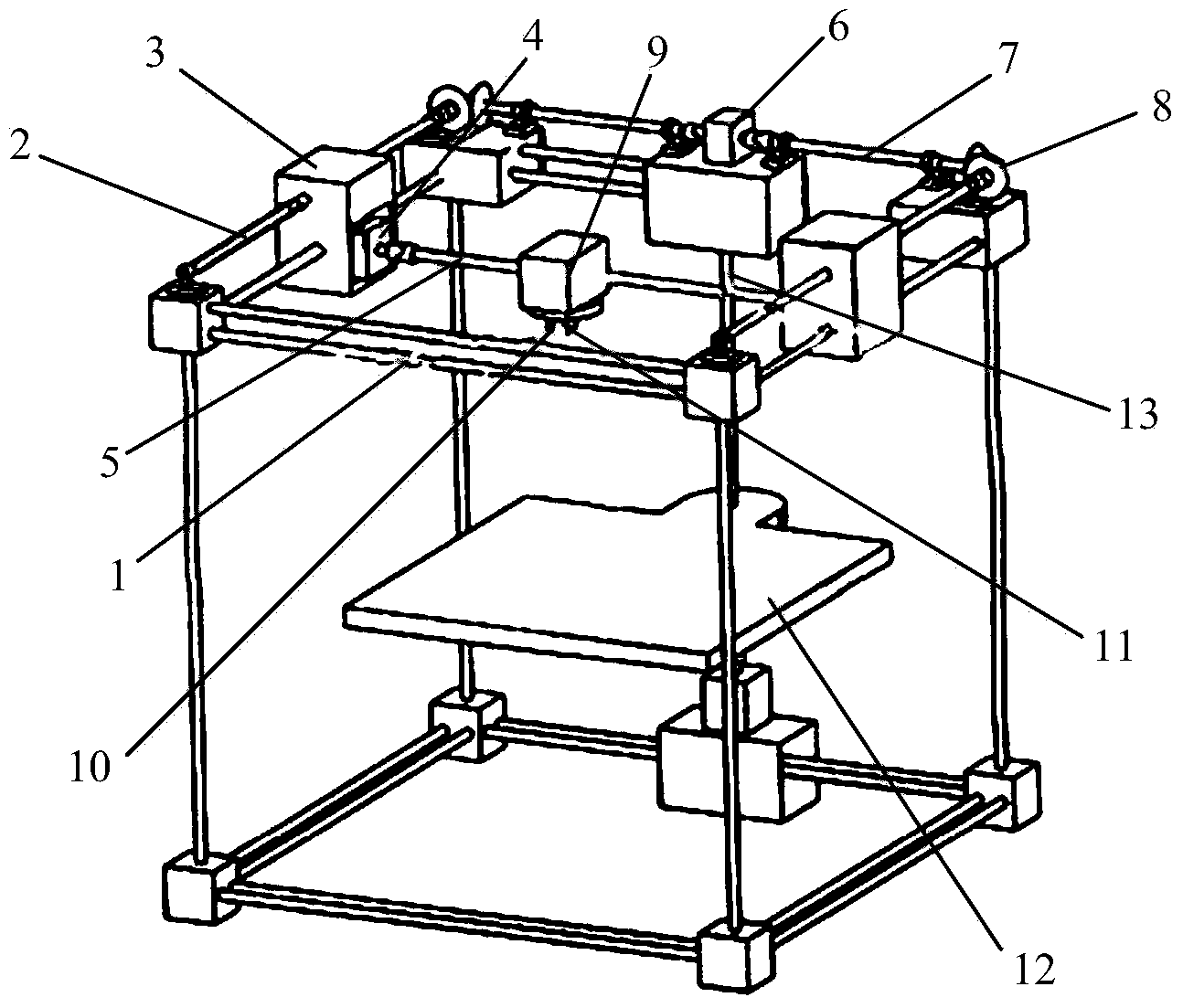

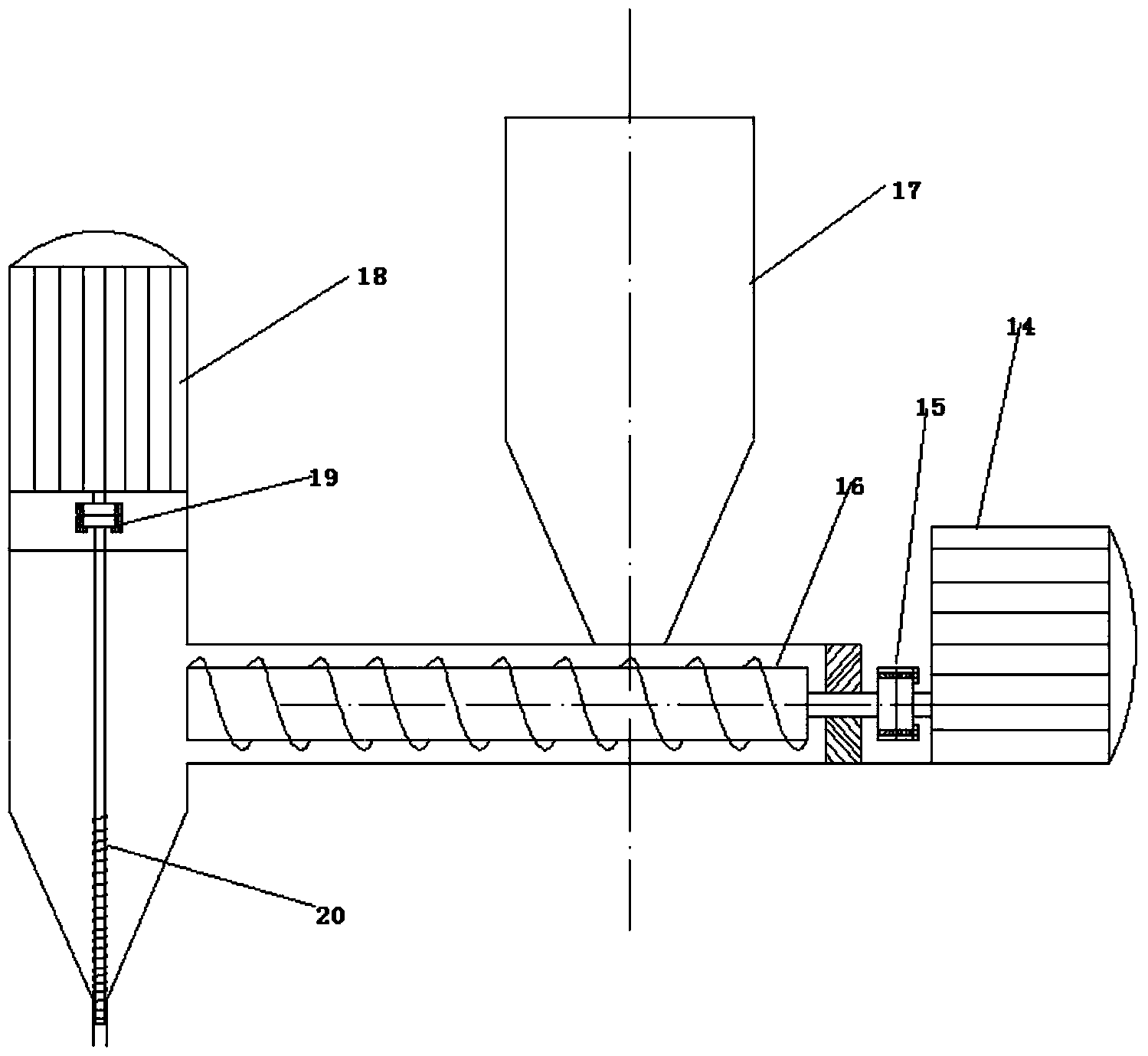

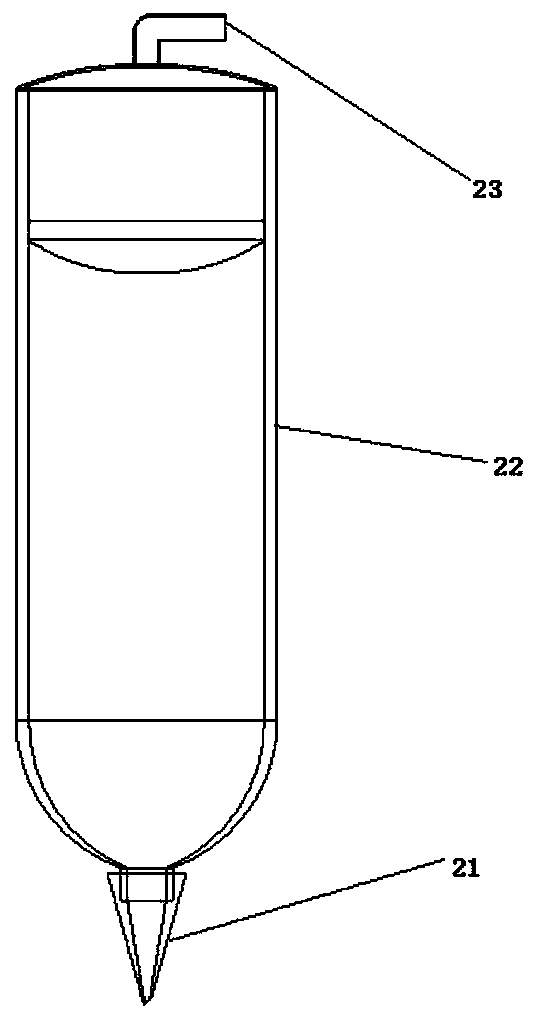

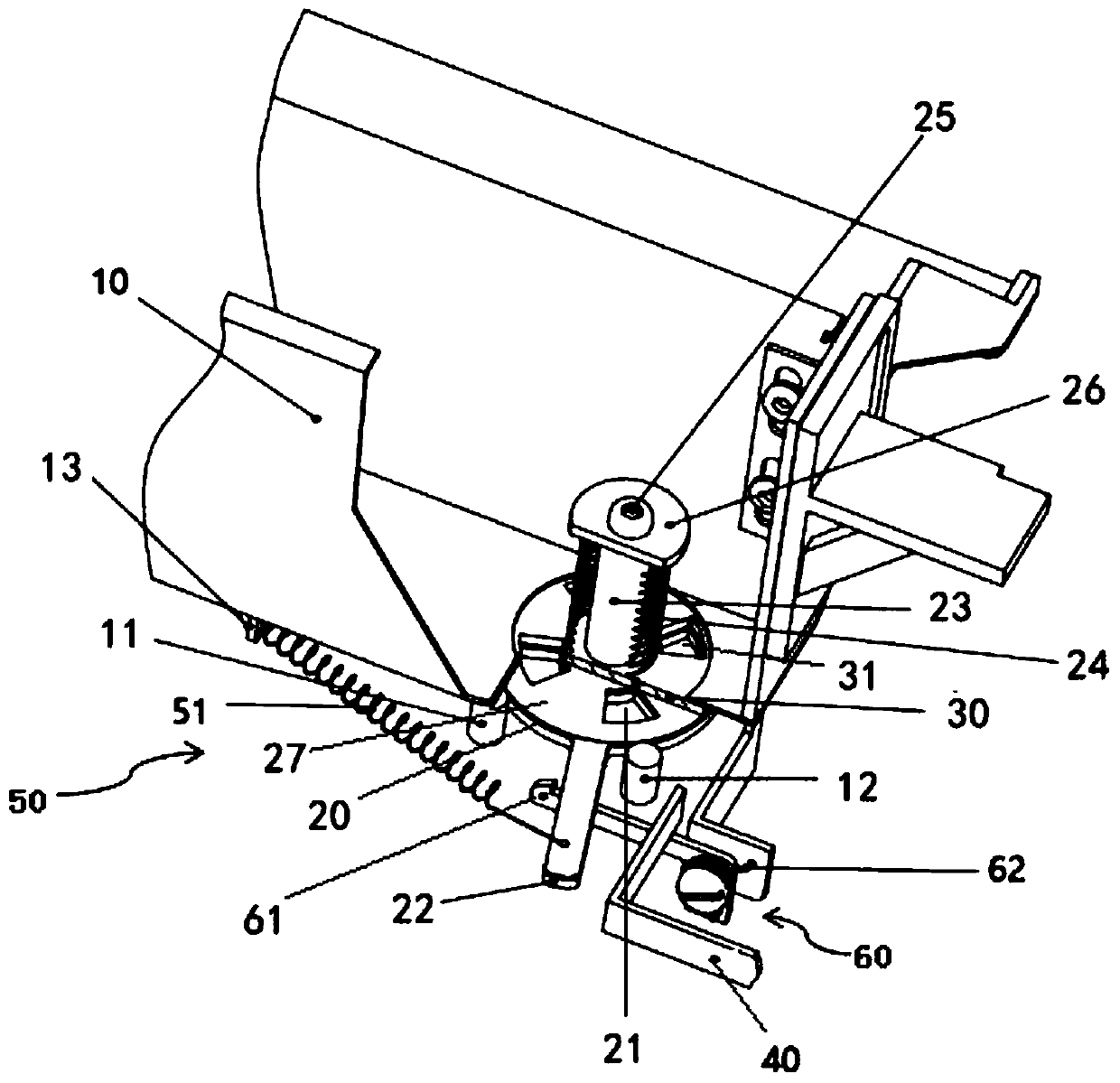

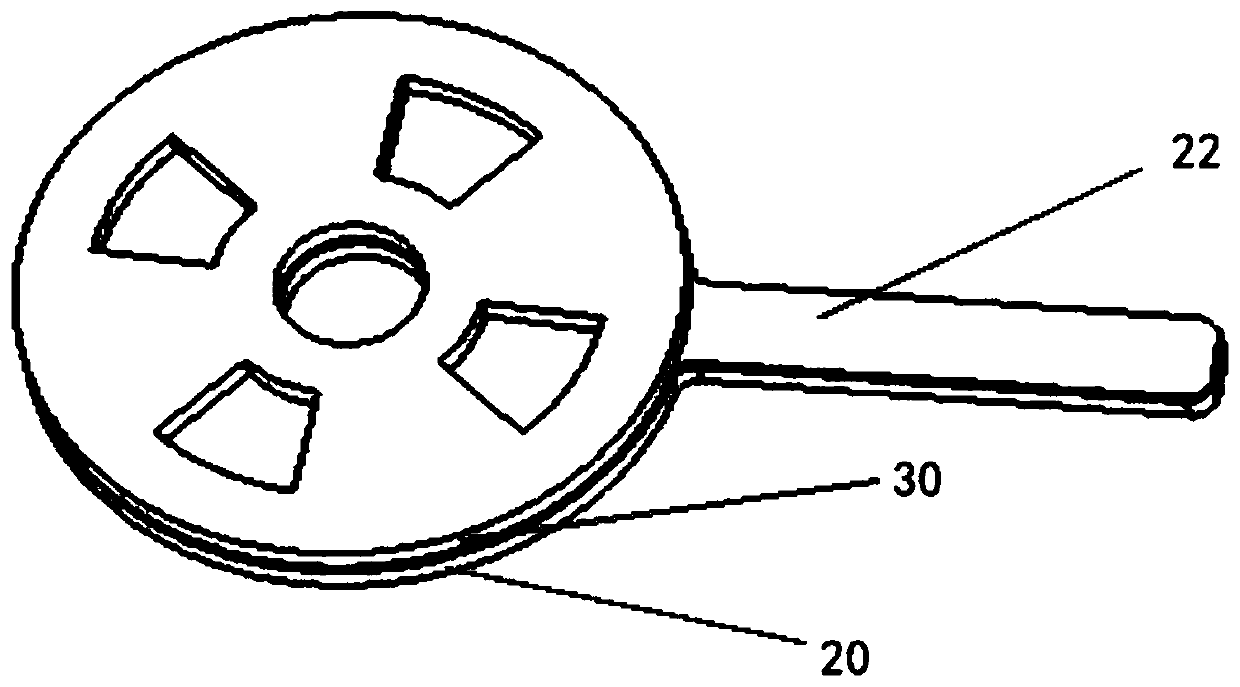

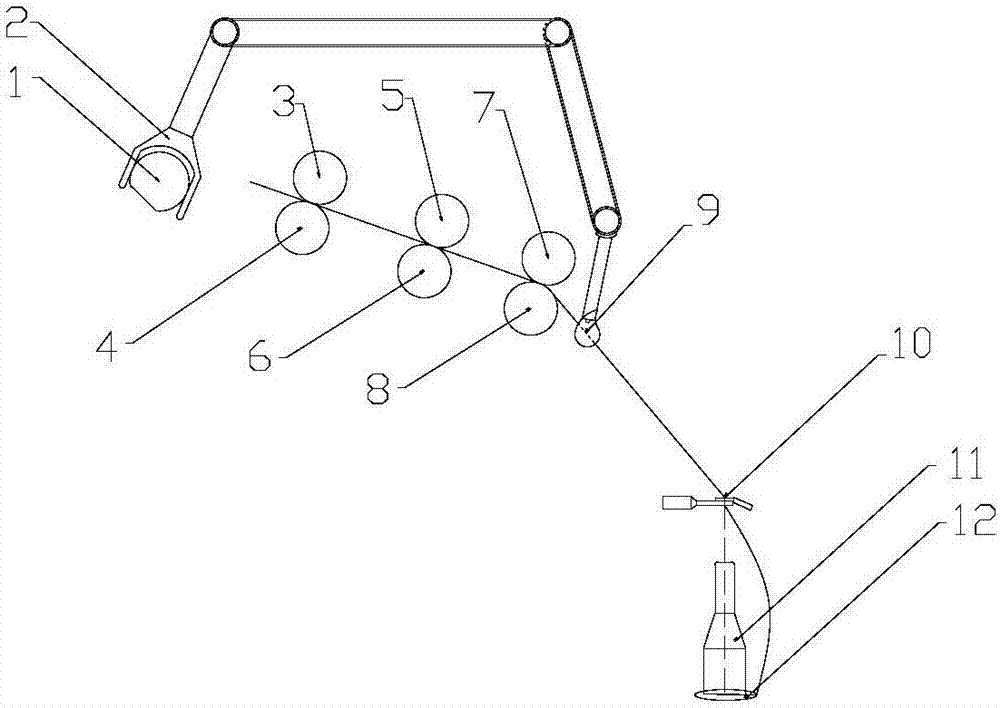

Controllable powder spray food 3D (three-dimensional) printing equipment and method

ActiveCN103932367AImprove efficiencyImprove printing efficiencyFood shapingSpray nozzleBonding problems

The invention discloses controllable powder spray food 3D (three-dimensional) printing equipment and printing method. A powder feeding device is used for pushing powdery food to an outlet through a horizontally-placed screw rod, and the powder feeding speed at the outlet is controlled by using a vertically placed spiral screw rod. Various powdery foods can be effectively bonded together, and a liquid feeding nozzle can rotate around a powdery food nozzle, so that the liquid feeding nozzle can be always kept behind a powder spout when the powdery food spout moves towards any direction, thereby ensuring the maximum bonding rate of powdery foods. By adopting the printing method, the food printing efficiency and bonding firmness can be increased greatly, the bonding problem of powdery foods in the 3D printing industry is solved effectively, and the application field of 3D printed foods is expanded.

Owner:XI AN JIAOTONG UNIV +1

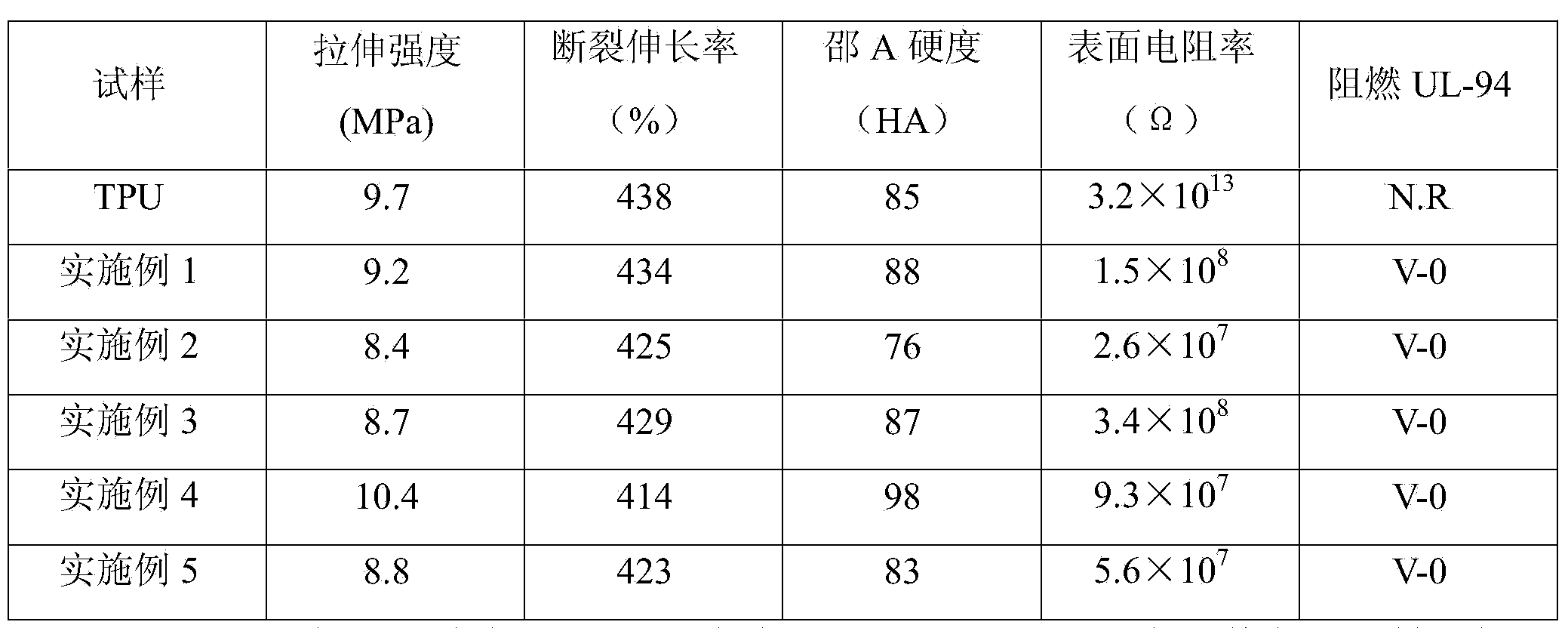

Halogen-free flame-retardant antistatic TPU (thermoplastic polyurethane) material and preparation method thereof

The invention the invention discloses a halogen-free flame-retardant antistatic TPU (thermoplastic polyurethane) material which is composed of 60-90 parts of thermoplastic polyurethane elastomer, 5-40 parts of flame retardant, 1-5 parts of antistatic agent, 0.1-0.5 part of antioxidant and 0.2-1 part of lubricant. The Shore hardness A of the TPU elastomer is 70-95HA, and the flame retardant is composed of one or more of alkyl hypophosphorous acid metal salts or hypophosphorous acid metal salts. The method comprises the following steps: proportionally selecting raw materials, uniformly mixing the selected raw materials, melting, compounding, and granulating by extrusion. The halogen-free flame-retardant antistatic TPU material has obviously lower surface resistivity and obviously higher flame-retardant grade under the condition of not influencing the tensile strength, fracture strength and Shore hardness A of the TPU substrate, is free of halogens, and has excellent flame-retardant and antistatic functions.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

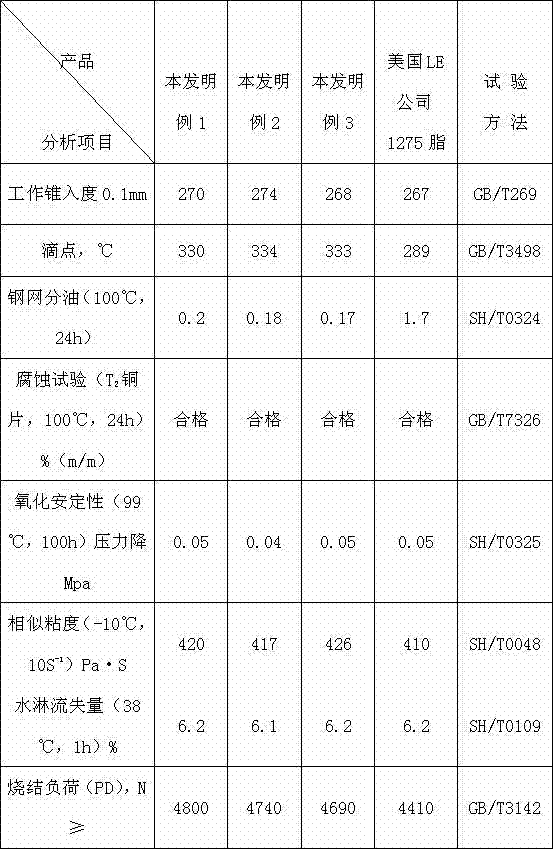

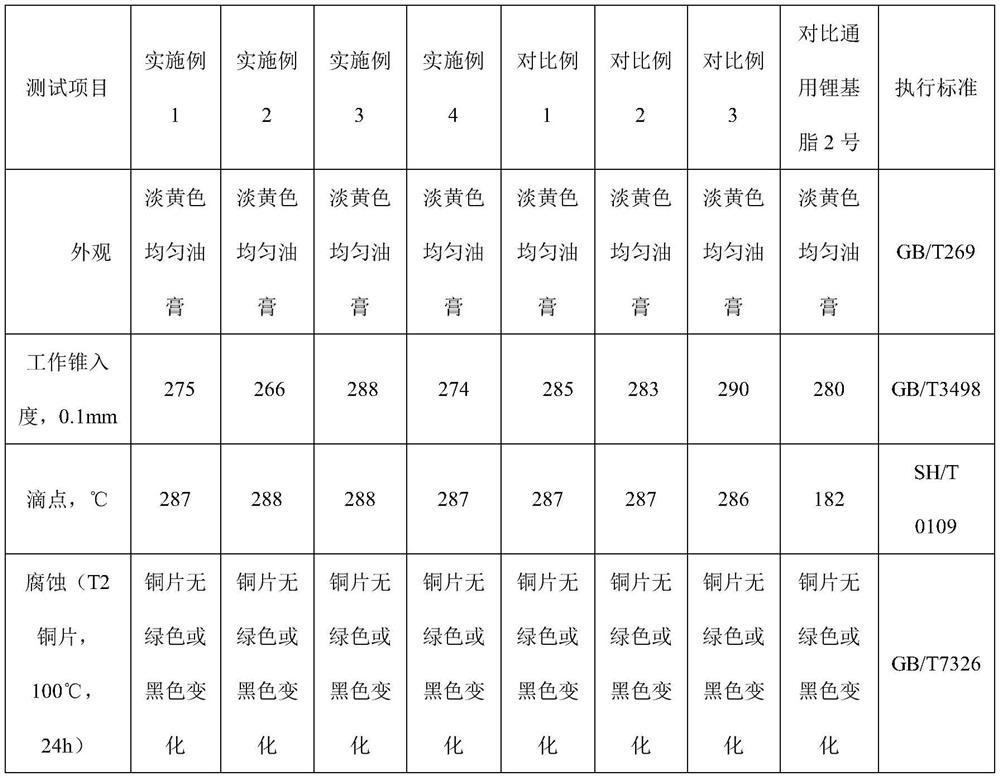

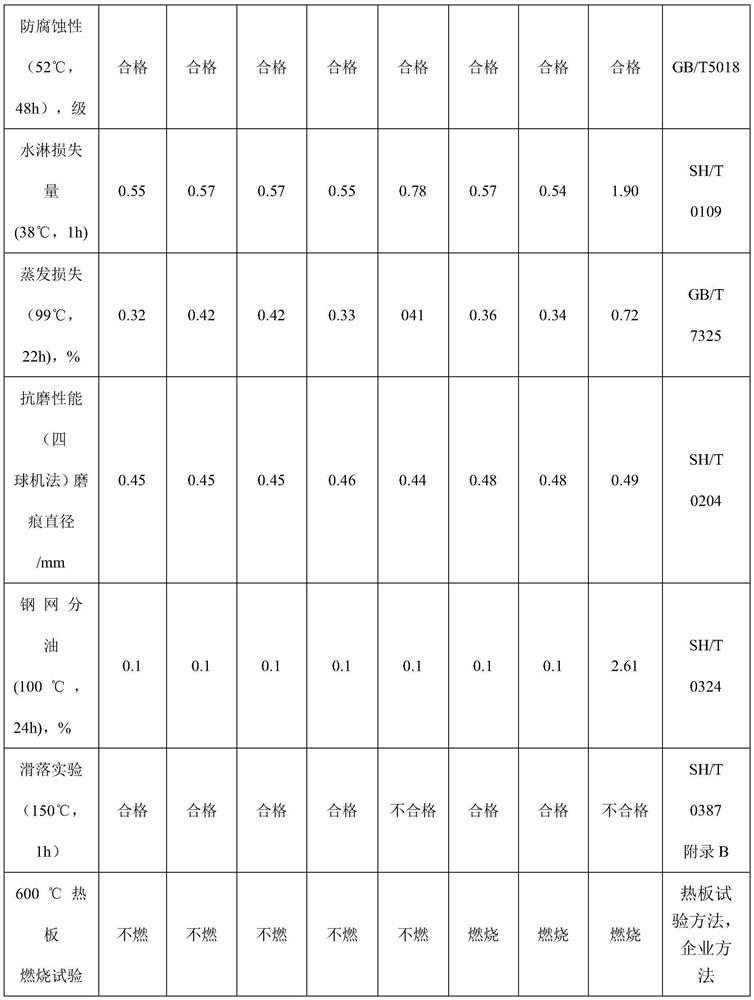

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

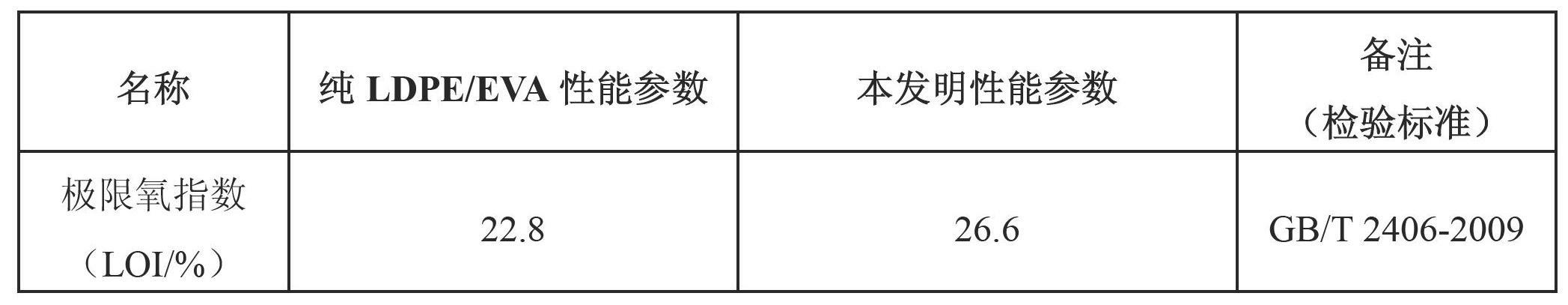

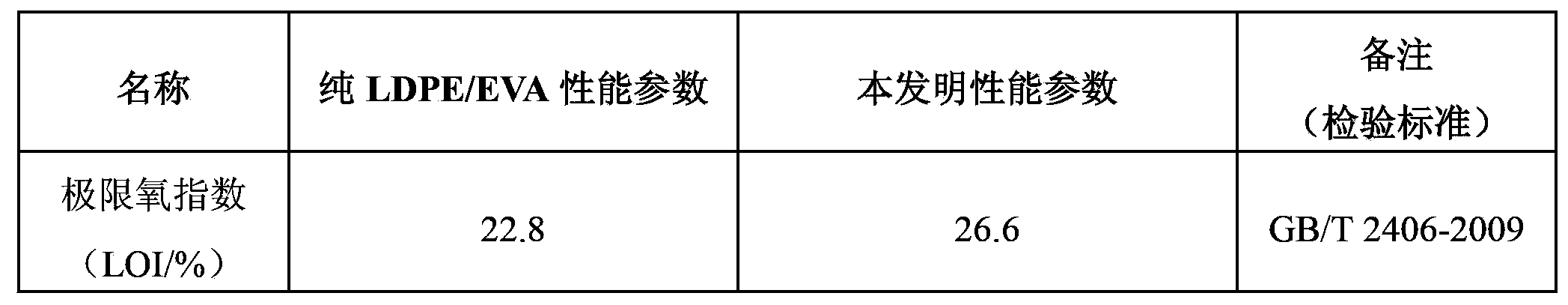

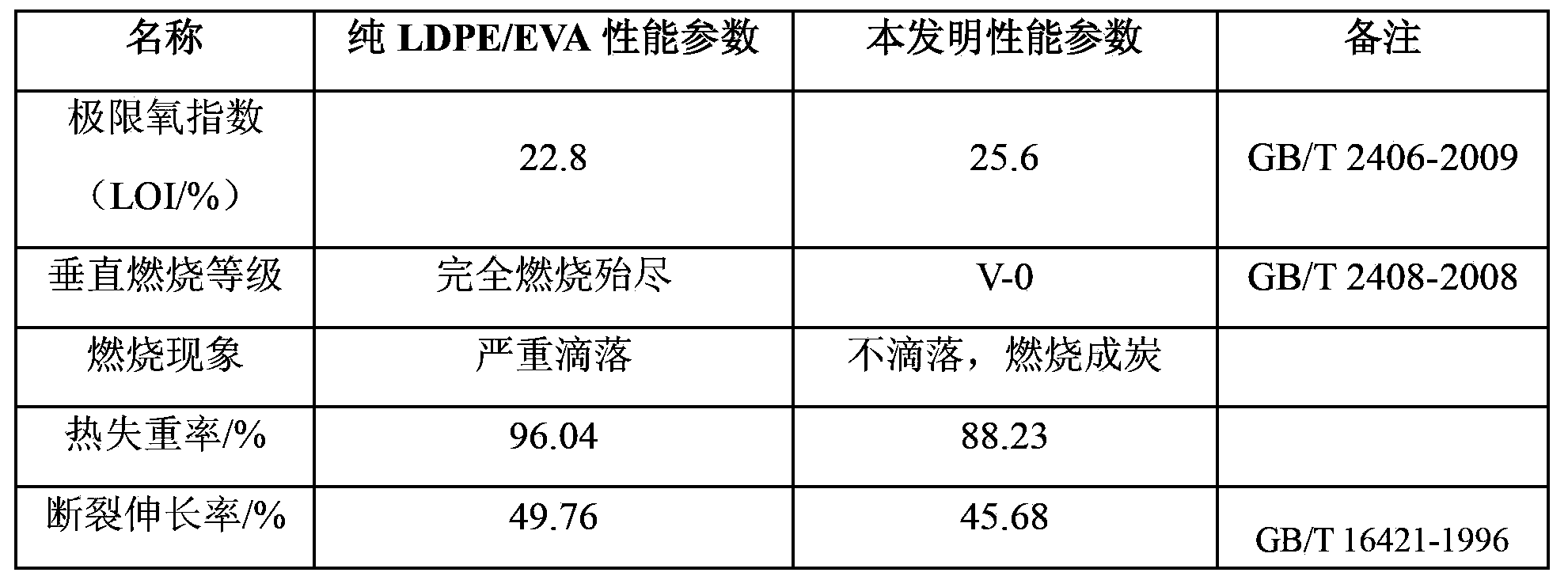

LDPE (Low-Density Polyethylene)/EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material and preparation method thereof

ActiveCN102643469ARaw materials are easy to getAbundant resourcesLow-density polyethyleneZinc borate

The invention relates to an LDPE (Low-Density Polyethylene) / EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material. The LDPE / EVA anti-flaming material comprises the following raw material compositions by weight parts: A is base resin and includes 100 parts of LDPE and EVA; B is bromine containing flame retardant and includes 10-20 parts of decabromodiphenyl ethane or decabromodiphenyl ether, C is inorganic flame retardant and includes 3-6 parts of modified antimonous oxide M-Sb2O3, 3-6 parts of talcum powder TP, 2-8 parts of zinc borate (ZB) and 2-8 parts of hydrotalcite (LDHs). The preparation method of the LDPE / EVA anti-flaming material is as follows: drying raw materials, mixing the raw materials uniformly, processing, extruding, and conducting injection molding on the raw materials to obtain the extruded anti-flaming composite material. According to the anti-flaming material and the preparation method, the advantages of the organic flame retardant, the bromine containing flame retardant and the inorganic flame retardant are combined, the using amount of the inorganic flame retardant is decreased, the limit oxygen index of the anti-flaming composite material is increased, the materials are burned into carbon directly when being burned, the dropping phenomenon can not occur, and the toxic and harmful gas can not be generated.

Owner:广西华锑科技有限公司

Multi-effect water-retaining spraying mask

InactiveCN108210357ALiquidityThere is no problem of difficult levelingCosmetic preparationsToilet preparationsGellan gumSphingomonas elodea

The invention belongs to the field of commodities for daily use, and particularly relates to a spraying mask containing gellan gum. The spraying mask provided by the invention also contains monovalentcation salt and divalent cation salt; the spraying mask formed by compounding the gellan gum, monovalent cations and divalent cations can form a gel mask with moderate hardness, so that the defect that the produced gel mask is too hard when the divalent cations are compounded with the gellan gum is overcome. In addition, the spraying provided by the invention also contains a plurality of humectants and anti-allergy agents; the formed spraying mask has the effects of resisting inflammation, resisting allergy and preserving moisture, and meanwhile, has a good skin feeling.

Owner:GUANGZHOU SOYAWA BIO TECH CO LTD

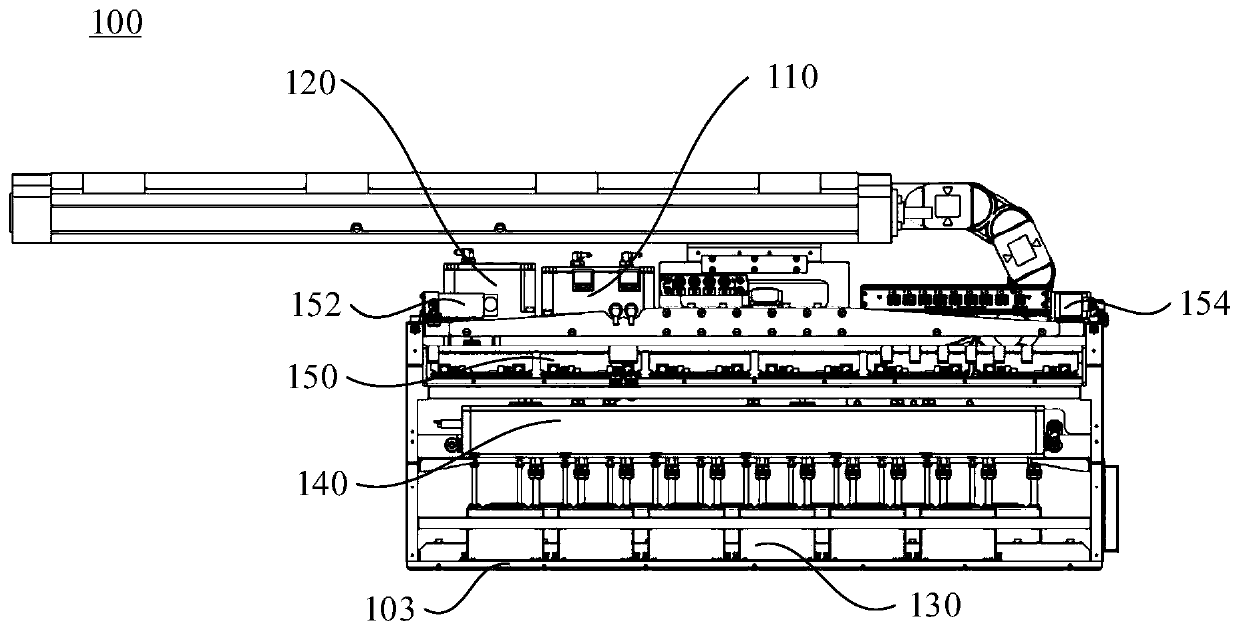

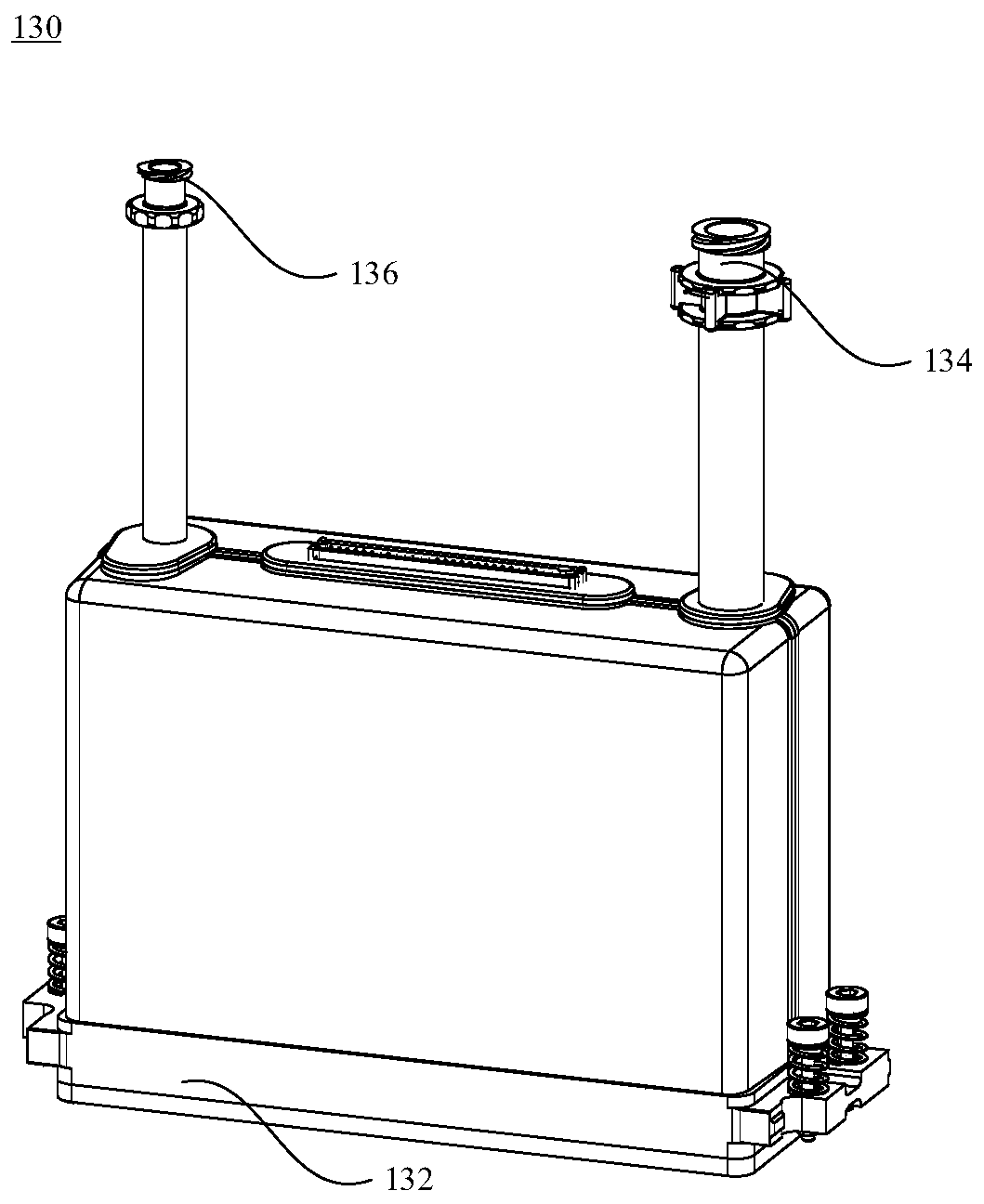

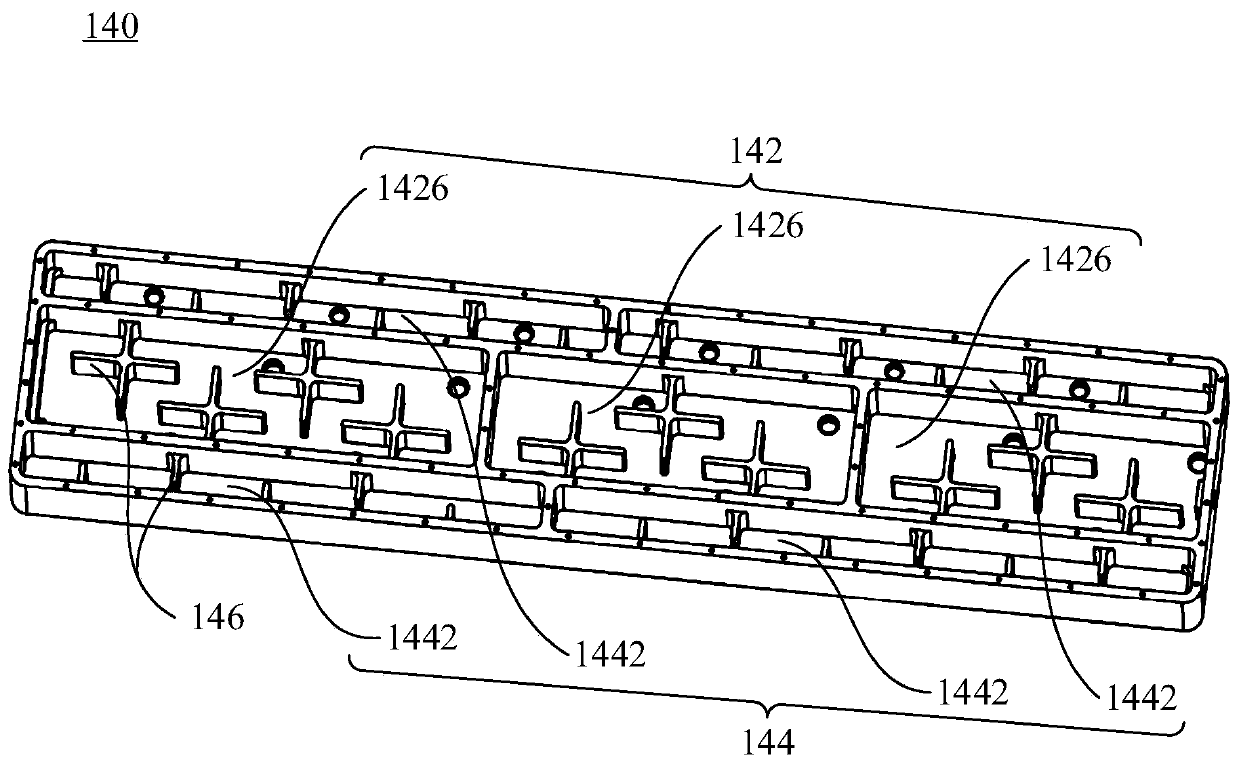

Ink-jet device and 3D printing device

PendingCN110280716AImprove stabilityReduce precipitationAdditive manufacturing apparatusFoundry mouldsSpray nozzleEngineering

The invention discloses an ink-jet device and a 3D printing device and relates to the technical field of 3D printing. A controller, a negative pressure box assembly, an ink storing box, a bottom plate and a plurality of spray head assemblies uniformly distributed on the bottom plate are included; each spray head assembly communicates with an ink supplying ink box assembly; each spray head assembly comprises a spray nozzle, an ink inlet and an ink returning port communicating with one another; the ink supplying ink box assembly comprises an ink supplying cavity and an in returning cavity; each ink inlet communicates with the ink supplying cavity, and each ink returning port communicates with the ink returning cavity; the negative pressure box assembly comprises a first cavity and a second cavity; the first cavity and the second cavity communicate with a negative pressure source so that the gas pressure in the first cavity can be larger than that in the second cavity; the first cavity communicates with the ink supplying cavity; the second cavity communicates with the ink returning cavity; and the ink supplying cavity and the ink returning cavity communicate with the ink storing box so that an ink circulating passageway of the ink storing box, the ink supplying cavity, the ink inlets, the ink returning ports and the ink returning cavity can be formed. The uniformity and the consistency of ink supplying can be improved, the ink jetting quality is improved, and then the printing effect is improved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

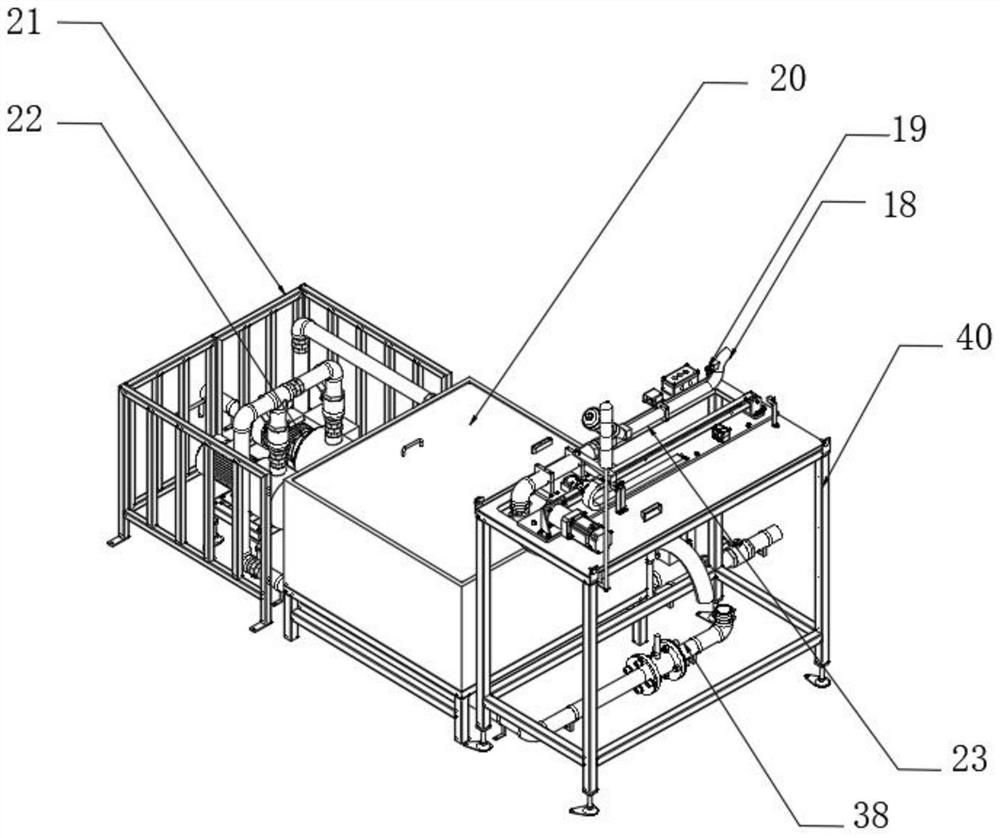

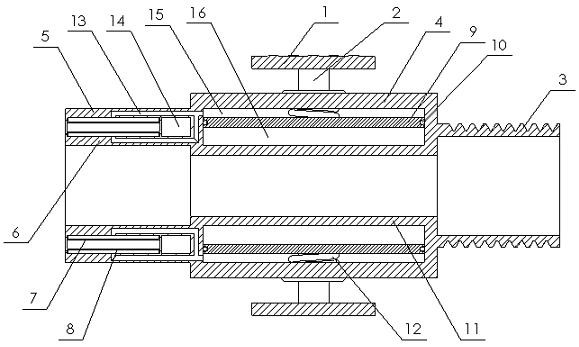

Near-dry cutting supersonic jet apparatus and control method thereof

InactiveCN103551915AReduce the temperatureNo refluxServomotor componentsMetal working apparatusSolenoid valveSpray nozzle

The invention provides a near-dry cutting supersonic jet apparatus and a control method thereof. The near-dry cutting supersonic jet apparatus comprises a control circuit board, a supersonic jet injector, a nozzle, a cutting fluid delivery pipe, a compressed air delivery pipe and an adjusting block. The supersonic jet injector is mounted on the nozzle, the adjusting block comprises a pneumatic cutting fluid one-way stop valve, a cutting fluid adjusting valve and a compressed air adjusting valve, the cutting fluid delivery pipe is connected with a cutting fluid storage tank and the supersonic jet injector, the pneumatic cutting fluid one-way stop valve and the cutting fluid adjusting valve are sequentially arranged on the cutting fluid delivery pipe from the cutting fluid storage tank to the supersonic jet injector, the compressed air delivery pipe is connected with a compressed air source and the supersonic jet injector, a control solenoid valve and the compressed air adjusting valve are sequentially arranged on the compressed air delivery pipe from the compressed air source to the supersonic jet injector, and the control solenoid valve is connected with the pneumatic cutting fluid one-way stop valve through a connecting pipe.

Owner:陈建军 +1

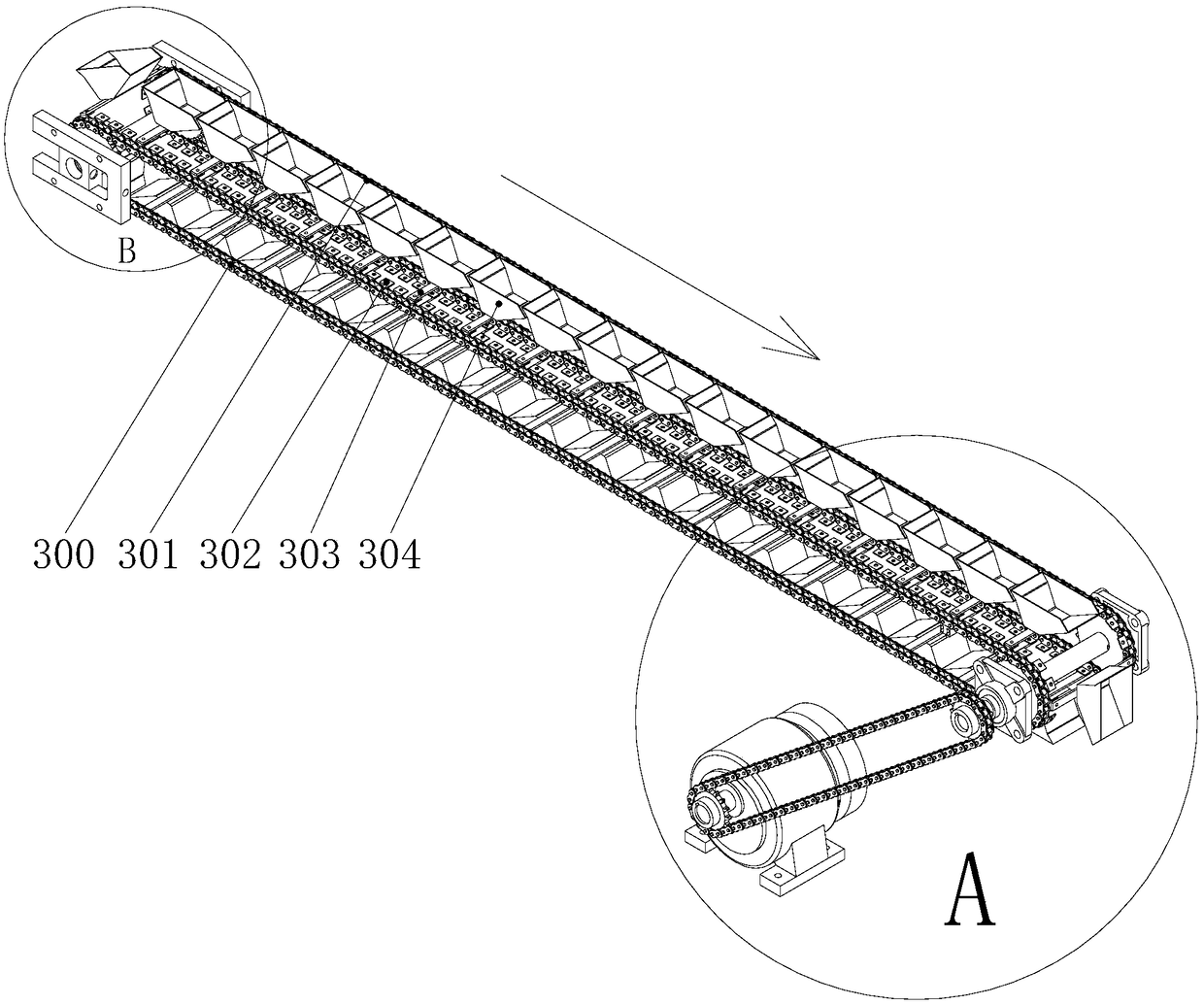

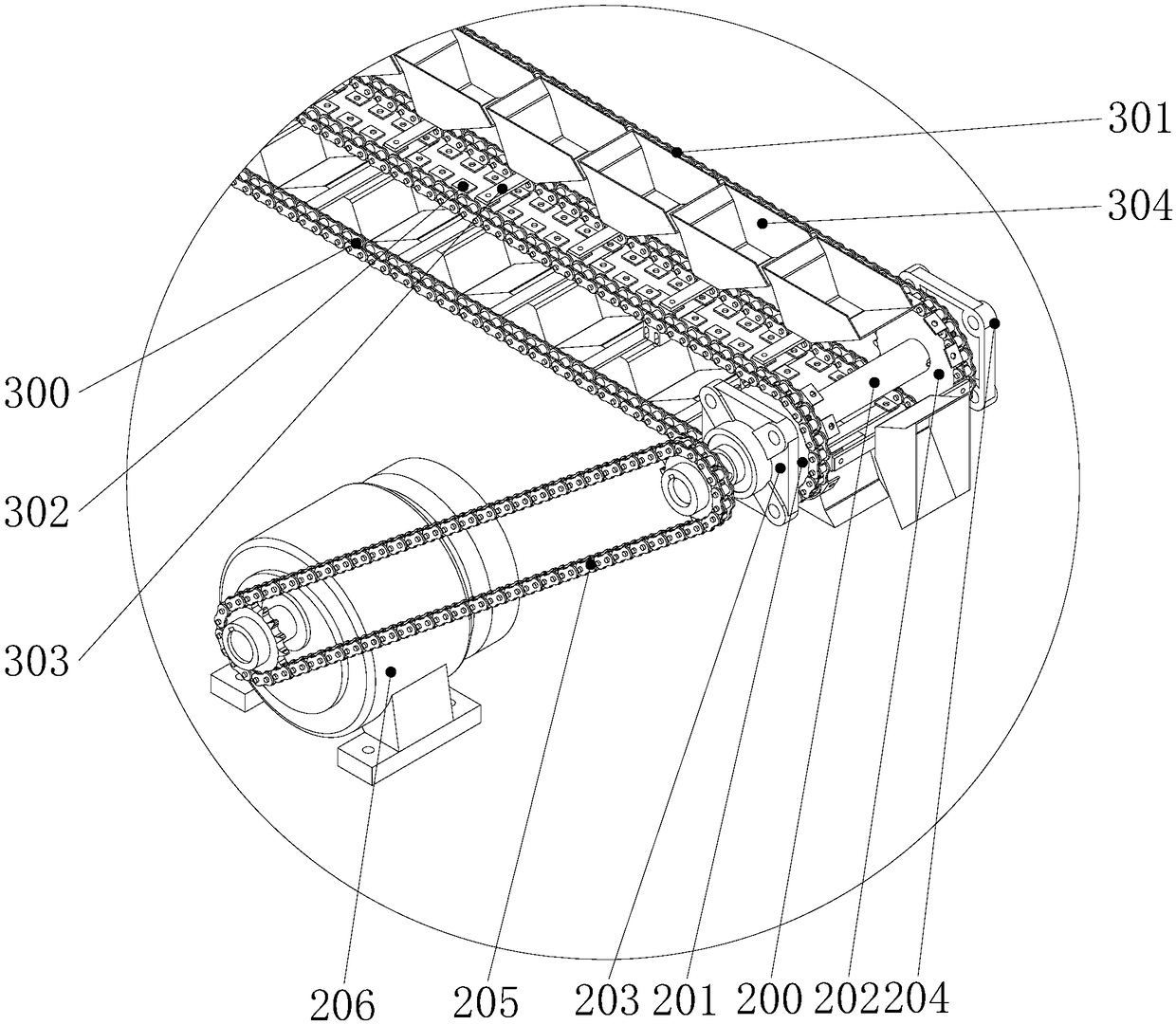

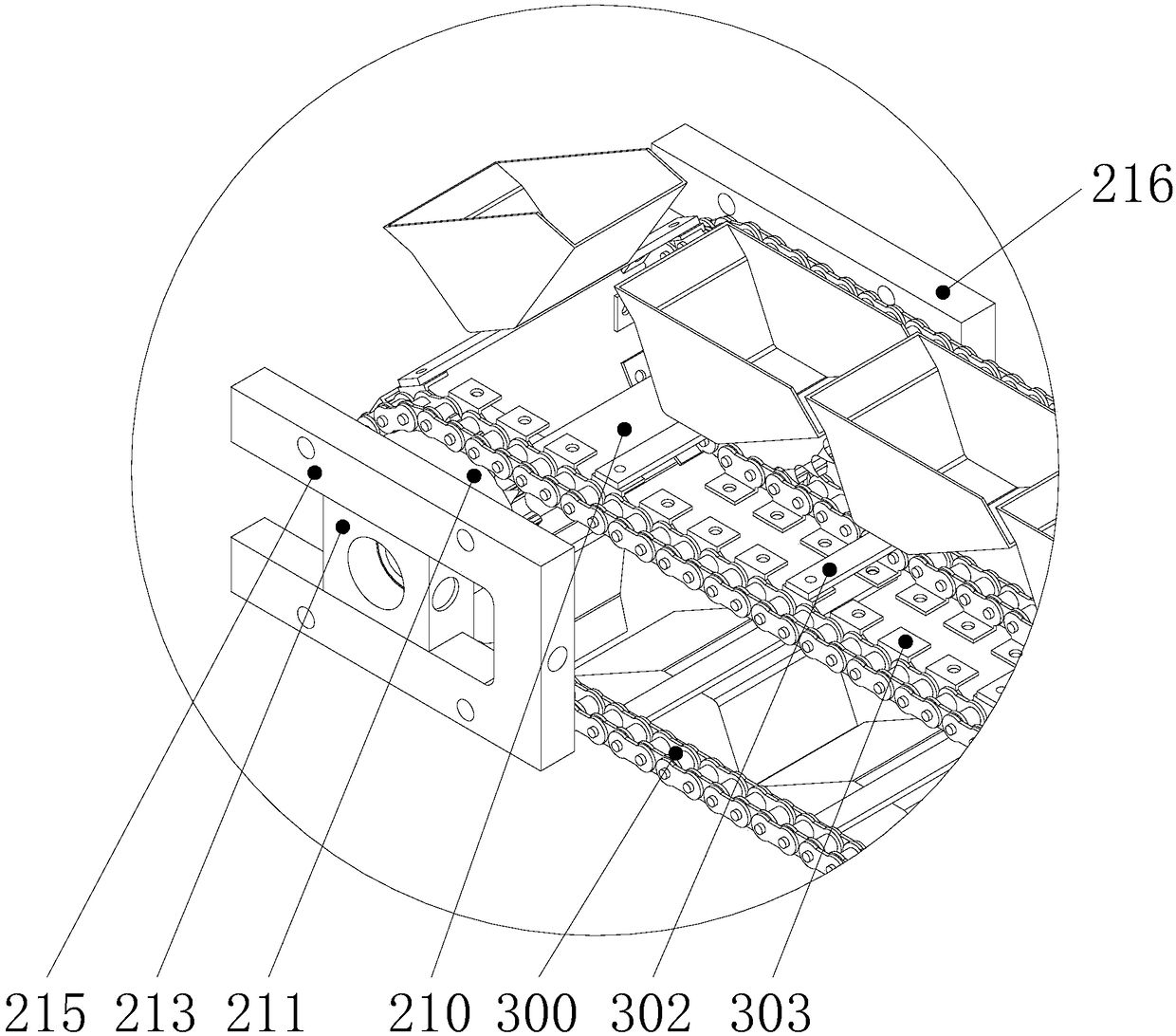

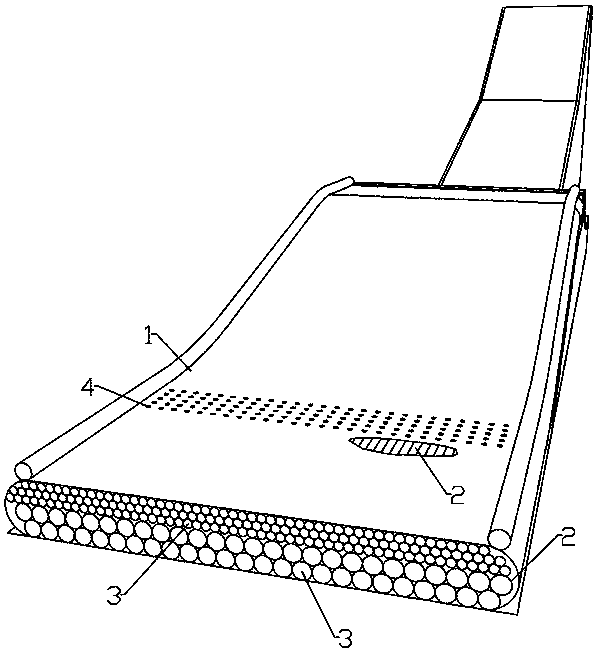

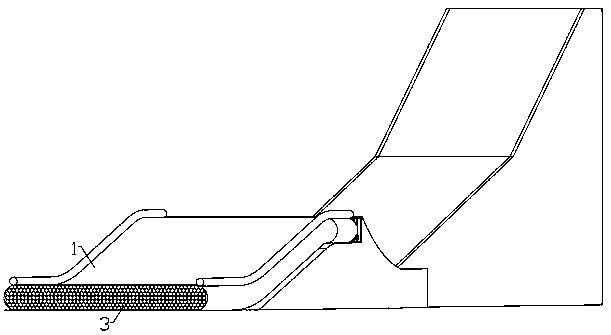

Hopper conveying machine

The invention relates to a hopper conveying machine which comprises outer U-shaped steel and inner U-shaped steel. The outer U-shaped steel and the inner U-shaped steel are arranged on a conveying machine platform; a driving shaft is arranged at the front end of the outer U-shaped steel; an outer driving gear and an inner driving gear are arranged on the driving shaft; a driven shaft is arranged at the rear end of the outer U-shaped steel; an outer driven gear and an inner driven gear are arranged on the driven shaft; an outer conveying chain sleeves on the outer driving gear and the outer driven gear; an inner conveying chain sleeves on the inner driving gear and the inner driven gear; supports are arranged on chain joints of the inner and outer conveying chains; hopper support plates arearranged on the supports; conveying hoppers are arranged on the hopper support plates and are used for conveying materials along with the movement of the conveying chains; and a driving motor is arranged on the conveying machine platform and is used for driving power onto the driving shaft through a driving chain. The hopper conveying machine provided by the invention can be used for conveying multiple particle-shaped materials (such as shrimp meat and corn kernels) and irregular materials (such as dried vegetable) in packaging production of a packaging machine.

Owner:SHANGHAI KOMATSU PACKAGING MACHINERY

Nanofiber membrane with whitening and tightening effects and preparation method of nanofiber membrane

ActiveCN111743785AOvercome the technical problem of difficult dissolutionPromote absorptionCosmetic preparationsMonocomponent protein artificial filamentHydroxyprolineSpinning

The invention relates to a nanofiber membrane with whitening and tightening effects and a preparation method of the nanofiber membrane. The nano-fiber membrane is characterized by simultaneously containing pterostilbene, dipalmitoyl hydroxyproline and prinsepia utilis royle oil which serve as oil-soluble whitening and tightening active components and fructose diphosphate trisodium, asiaticoside, hydrolyzed elastin and gynostemma pentaphylla leaf extract which serve as water-soluble whitening and tightening active components, the oil-soluble whitening and firming active component and the water-soluble whitening and firming active component are wrapped by hydrogenated lecithin to prepare a whitening and firming nano-composition, and then the whitening and firming nano-composition is mixed with succinyl glycan, rhizobium gum and deionized water to prepare the nano-fiber membrane through an electrostatic spinning process. The product has the advantages of being good in skin friendliness, good in stability, fast in absorption, convenient to use and the like, meanwhile, the oil-soluble whitening and firming active matter and the water-soluble whitening and firming active matter are loaded, the technical defect that only one of the oil-soluble whitening and firming active matter and the water-soluble whitening and firming active matter can be loaded in the prior art is overcome, and the whitening and firming effect is better.

Owner:PROYA COSMETICS

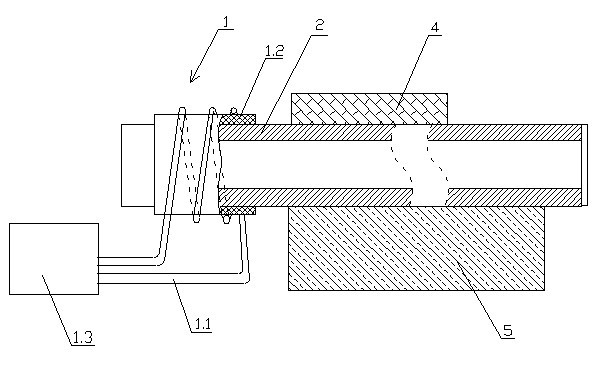

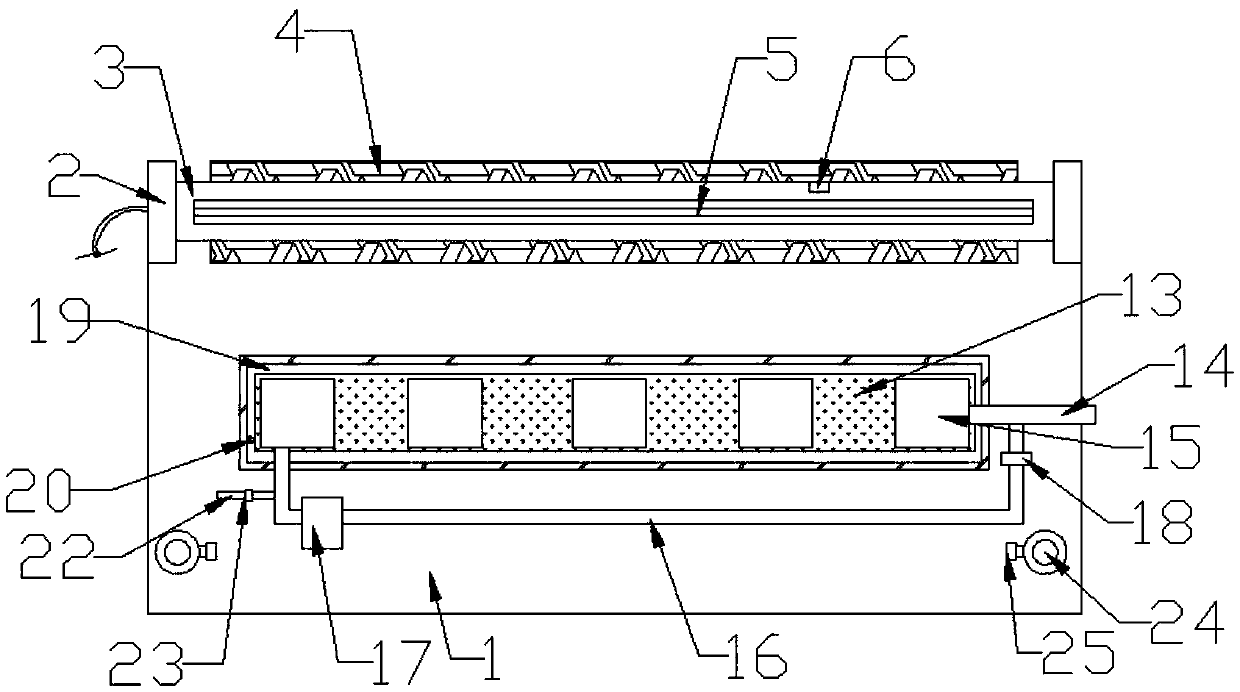

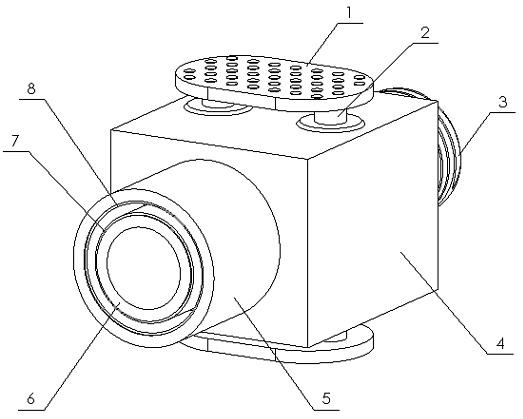

Electromagnetic heating superconducting heating system

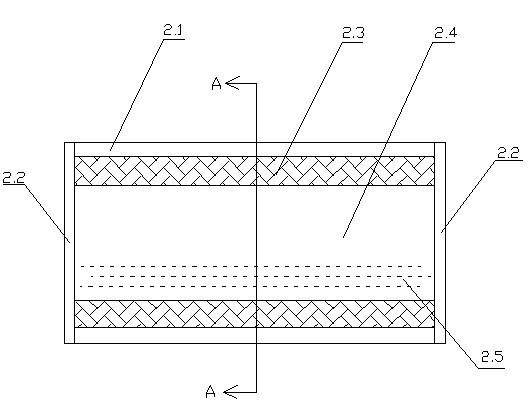

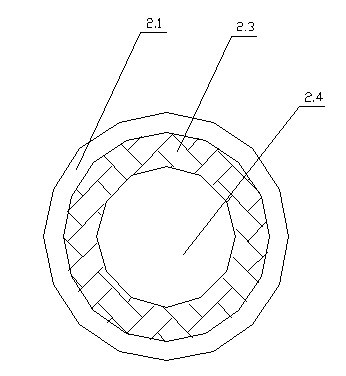

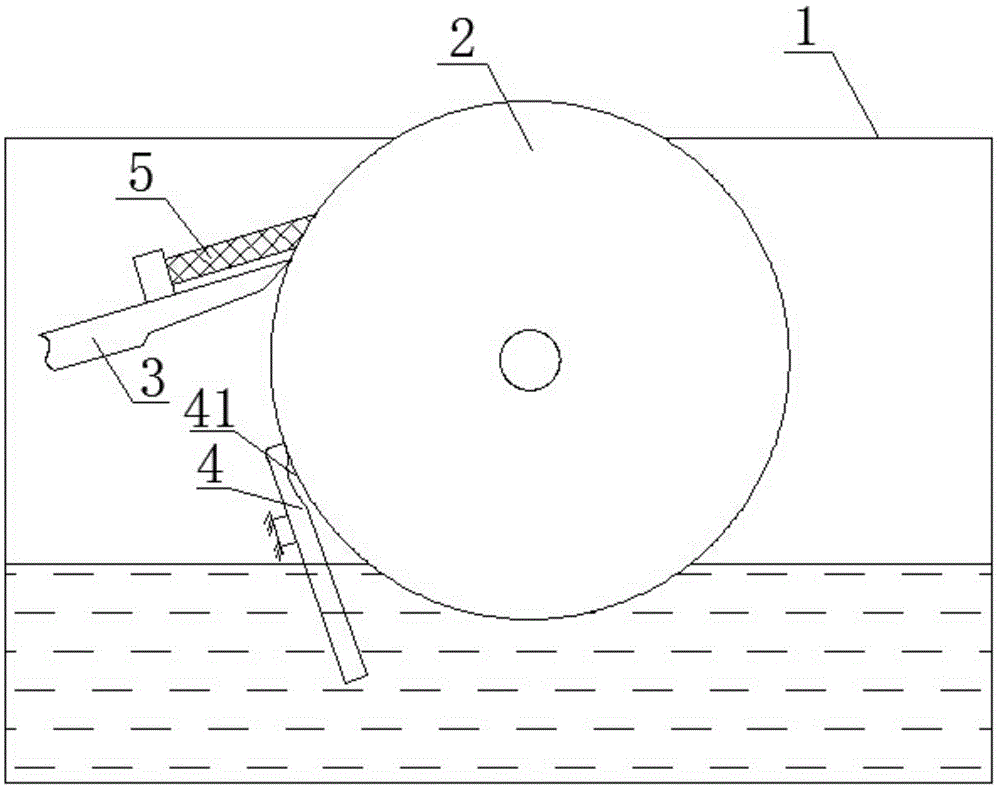

InactiveCN102022772ANo dripping phenomenonExtended service lifeLighting and heating apparatusElectric heating systemEngineeringElectromagnetic heating

The invention relates to an electromagnetic heating superconducting heating system. The electromagnetic heating superconducting heating system comprises an electromagnetic heating device (1), a superconducting tube heat transfer device (2) and a floor (4), wherein the superconducting tube heat transfer device (2) comprises a superconducting tube (2.1); the superconducting tube (2.1) and plug sealing caps (2.2) at the two ends of the superconducting tube (2.1) form a sealed cavity (2.4); a fluid suction tube core (2.3) is adhered to the inner wall of the superconducting tube (2.1); superconducting fluid (2.5) is injected into the cavity (2.4); the electromagnetic heating device (1) comprises an electromagnetic heating line (1.1), a heat preservation layer (1.2) and an electromagnetic heating controller (1.3); the heat preservation layer (1.2) covers an outer tube wall at any end of the superconducting tube (2.1); the electromagnetic heating line (1.1) is wound on the heat preservation layer (1.2); and the two ends of the electromagnetic heating line (1.1) are connected with the electromagnetic heating controller (1.3). The electromagnetic heating superconducting heating system has the advantages of long service life, high heating efficiency and low cost.

Owner:李东升 +2

Ink scraping structure of oil printing equipment

InactiveCN104608488ALiquid level stabilityInk completelyPrinting press partsPulp and paper industryFace matching

The invention provides an ink scraping structure of oil printing equipment. The ink scraping structure aims to solve the problem that when an existing ink scraping structure of the oil printing equipment is used, ink brought to a main scraping knife by a roller is large in amount and prone to accumulating and dripping, so that the completeness of ink staining of the roller is affected. The ink scraping structure comprises an ink disc, a roller and a main scraping knife, wherein the ink disc is used for containing ink, part of the roller is soaked into the ink disc, and the main scraping knife is matched with the roller. The ink scraping structure is further provided with a lower scraping knife, the middle of the lower scraping knife is fixedly connected to the inner wall of the ink disc, the upper end of the lower scraping knife is attached to the roller, and the lower end of the lower scraping knife is soaked in the ink inside the ink disc. The ink scraping angle of the lower scraping knife ranges from zero to ten degrees. The upper end of the lower scraping knife is attached to the roller and provided with an arc-shaped groove deviating from the roller. The end of the main scraping knife is connected with an auxiliary scraping knife made of rubber, and the head of the auxiliary scraping knife is provided with an arc-shaped face matched with the roller, and attached to the roller in a pressed mode. The ink scraping structure has the advantages that ink dripping is avoided, the liquid level of the ink is stable, ink staining of the roller is complete, and printed characters or patterns are complete and clear.

Owner:长兴艾飞特科技股份有限公司

Covering yarn spun with flame retardant viscose and aramid blended coated cotton fiber and manufacturing technology thereof

Disclosed is a covering yarn spun with flame retardant viscose and aramid blended coated cotton fiber and relates to the technical field of textile production. Roving is spun from, by weight, 65% of white flame retardant viscose fiber and 35% of gold aramid F14 fiber, cotton fiber 6620D filament is coated in the spinning process to produce flame retardant viscose and aramid blended coated cotton fiber 66 filament, and the number of yarns is 34 covering yarns. The manufacturing technology includes the steps of picking, carding, drawing, roving, spinning and spooling; a yarn guiding wheel is arranged on a ring spinning table, the filament is on the left-hand side of a drafting floating area, long-fine auxiliary points are added in the spooling process, removal of core leakage yarns and bubble yarns is ensured, and the relative humidity of the manufacturing environment in each process is 53-59% / yarn. The yarn has good moisture absorption and air permeability, good flame retardant performance, comfortable hand feeling and no droplet melting phenomenon.

Owner:JIHUA 3542 TEXTILE CO LTD

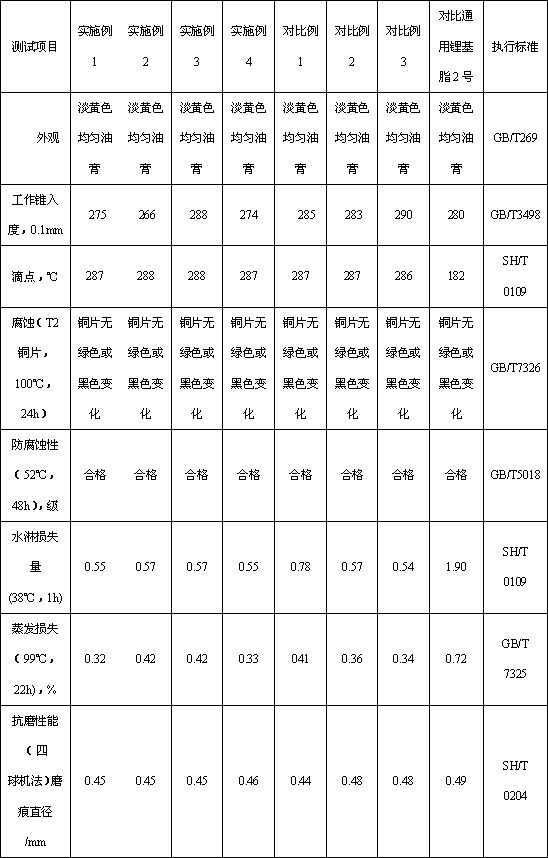

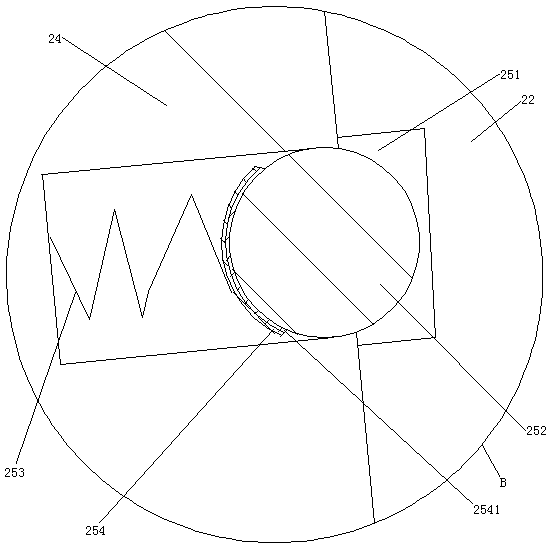

High-dropping-point flame-retardant steel wire rope lubricating grease composition, preparation method and application thereof

InactiveCN112358908AGood high temperature performanceIn-degree change is smallLubricant compositionPolymer scienceAntioxidant

The invention relates to a high-dropping-point flame-retardant steel wire rope lubricating grease composition, which is characterized by comprising the following components by weight: 70-90 parts of polyurea lubricating grease; 1-5 parts by weight of an adhesive; 1-5 parts by weight of a flame retardant; 0.1-1 part by weight of an anti-wear agent; 0.3-1.0 part by weight of an antioxidant; and 0.1-0.5 part by weight of an antirust agent, wherein the sum of the components is 100 wt%, the flame retardant is one or more of alkyl phosphate, such as tributyl phosphate, tris(2-ethylhexyl) phosphate,tris(2-chloroethyl) phosphate and tris(2,3-dichloropropyl) phosphate. The steel wire rope lubricating grease with high dropping point and flame retardancy is high in dropping point, low in high-temperature oil separation and capable of self-extinguishing lubricating grease, and even if the lubricating grease is on fire, fire propagation can be prevented within a few seconds, so that a steel wire rope is effectively lubricated, and the effect of prolonging the service life is achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

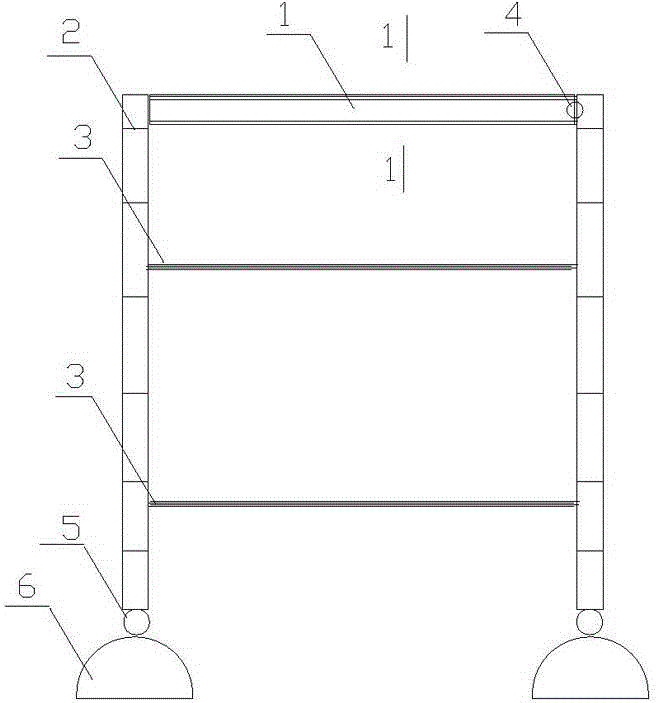

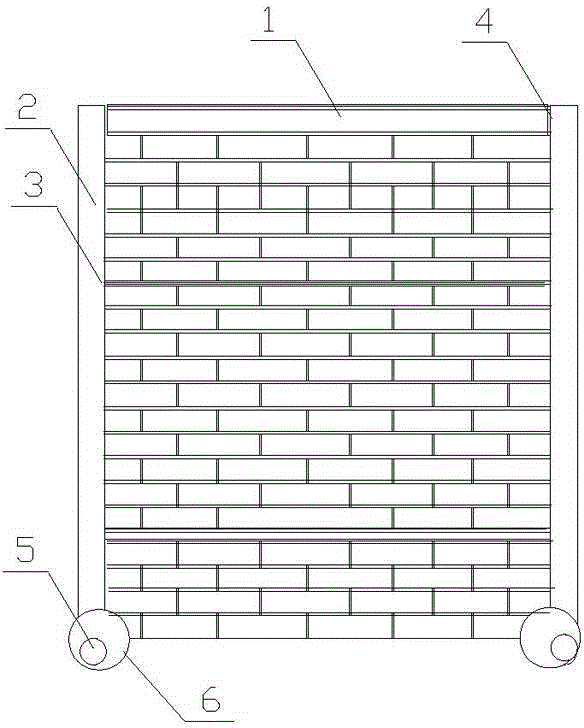

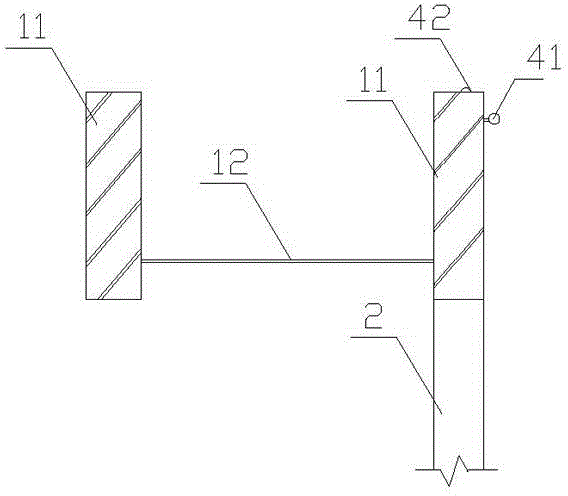

Brick wall masonry device and using method thereof

InactiveCN104806029ANo dripping phenomenonImprove economyBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a brick wall masonry device, which is designed for improving the brick wall masonry quality, and a using method thereof, and belongs to the building construction field. The brick wall masonry device comprises a masonry slot (1), stand columns (2), cross bars (3), a leveling device (4), hinges (5) and vacuum suckers (6); during ground masonry construction, the vacuum suckers (6) are firmly placed on the ground; when the masonry is carried out above the ground, the vacuum suckers (6) are firmly sucked on the wall. The using method comprises the following steps of during masonry, paving mortar in the masonry slot (1), so that a mortar surface is kept flush with the top surface of a adjustable drawbar (12) of the masonry slot; bricking and extruding mortar, so that a vertical mortar joint is full of mortar; lightly knocking a brick face with a cleaver, so that the brick top surface is kept flush with the top surface of a masonry slot plate (11). The brick wall masonry device has the beneficial effects that a mortar leakage phenomenon is not generated, the masonry quality is greatly improved, the mortar leakage is avoided, and the environment is greatly improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

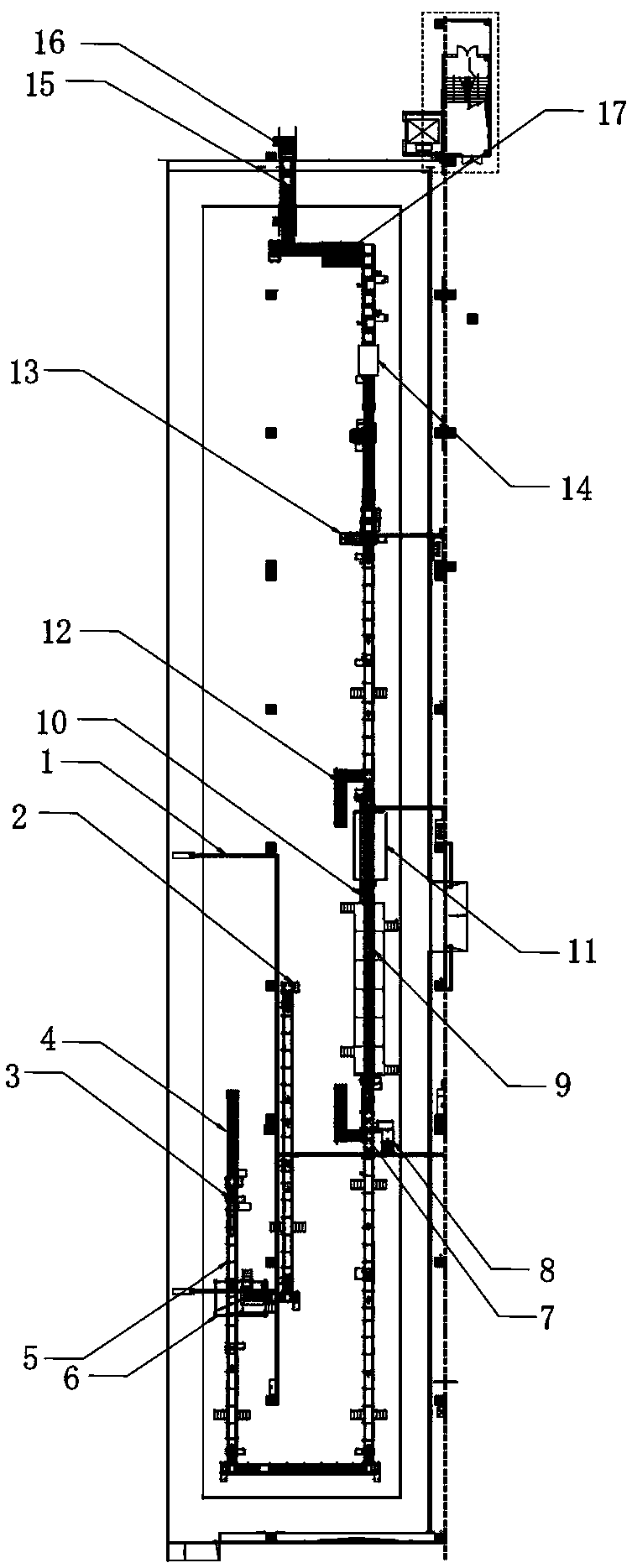

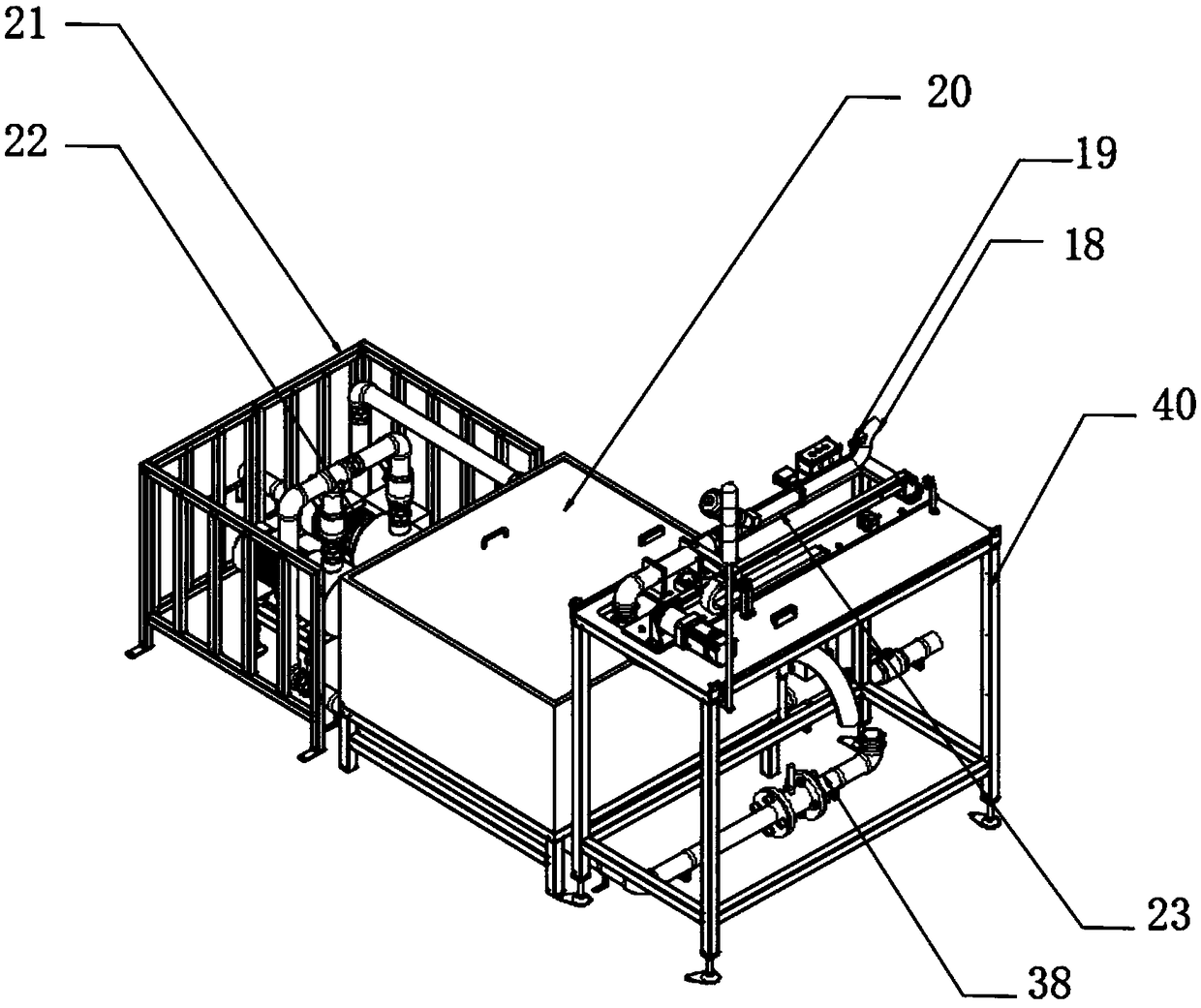

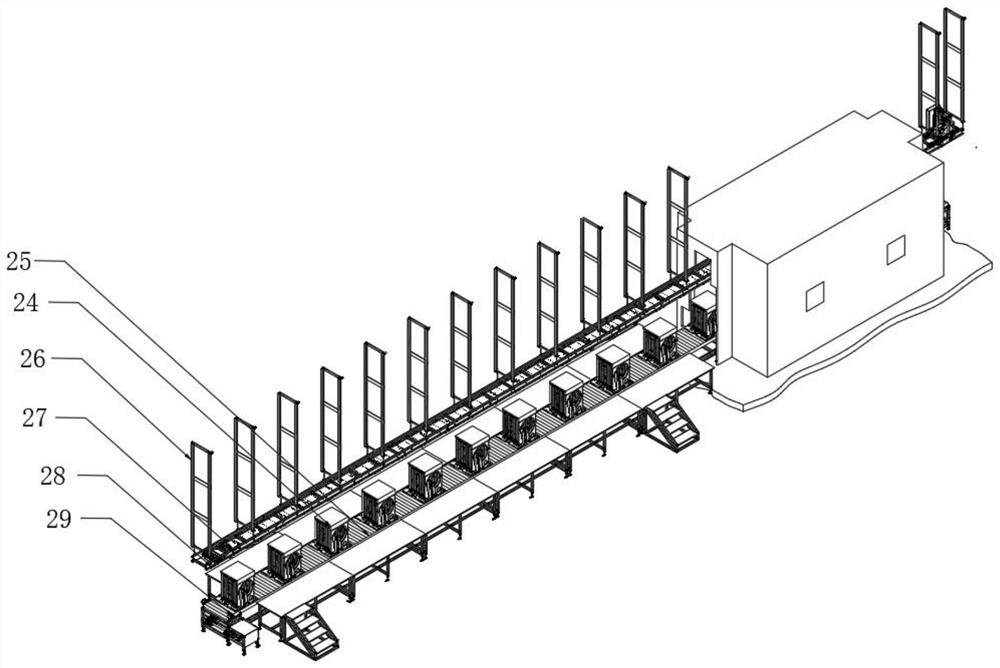

Production line for drum-type washing machines

ActiveCN109183346AFast and stable shutdownSensitive and stableStructural/machines measurementWashing machine with receptaclesCombined testProduction line

The invention discloses a production line for drum-type washing machines, which comprises an air display billboard, a lifting board return machine, a barcode printer, a chain board line, a speed chainconveying line, a power bucket device, an automatic code scanner, a water injector, a performance detection mechanism, an integrated test device, a mute room, a repaired drum conveying line, an automatic base installation foam machine, a sealing machine, a high-altitude drum conveying line, continuous lifters and a drum conveying line. The air display billboard, the lifting board return machine,the barcode printer, the chain board line, the speed chain conveying line, the power bucket device, the automatic code scanner, the water injector, the performance detection mechanism, the integratedtest device, the mute room, the repaired drum conveying line, the automatic base installation foam machine and the sealing machine are connected in turn. According to the production line for drum-typewashing machines, a water injection pump is used as a power source for water injection, the flow rate of each water injection is stable, foam bases can be quickly placed on a single line, and cost and space are saved.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

Halogen-free flame retardant conductive TPU material and preparation technique thereof

InactiveCN106543690AImprove surface activityIncrease the amount addedHeat resistanceThermoplastic polyurethane

The invention discloses a halogen-free flame retardant conductive TPU material and a preparation technique thereof. The TPU material is prepared from, by weight, 50-100 parts of thermoplastic polyurethane elastomer, 0.05-4 parts of heat stabilizer, 0-20 parts of assistant conductive agent, 3-50 parts of fire retardant, 0.1-25 parts of alkali metal salt, 0.05-3 parts of lubricant, and 0.05-4 parts of antioxygen. The preparation technique includes steps of weighing thermoplastic polyurethane elastomer, heat stabilizer, assistant conductive agent, fire retardant, alkali metal salt, lubricant, and antioxygen by weight, putting components in a high-speed mixer and mixing for 2-10 minutes; discharging, and then extruding and prilling the mixture by a dual-screw extruder and obtaining the TPU material, wherein the processing temperature of the dual-screw extruder is 140-190 DEG C, and the rotate number of the screw is 20-40 Hz. The prepared TPU material is low-smoke and toxic-free, low in addition, and high in flame retarding efficiency; besides, the TPU material is good in conducting effect, shallow in color, low in cost, good in heat resistance and others; the raw material is low in cost, and the TPU material is convenient to process and can facilitate industrial production.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

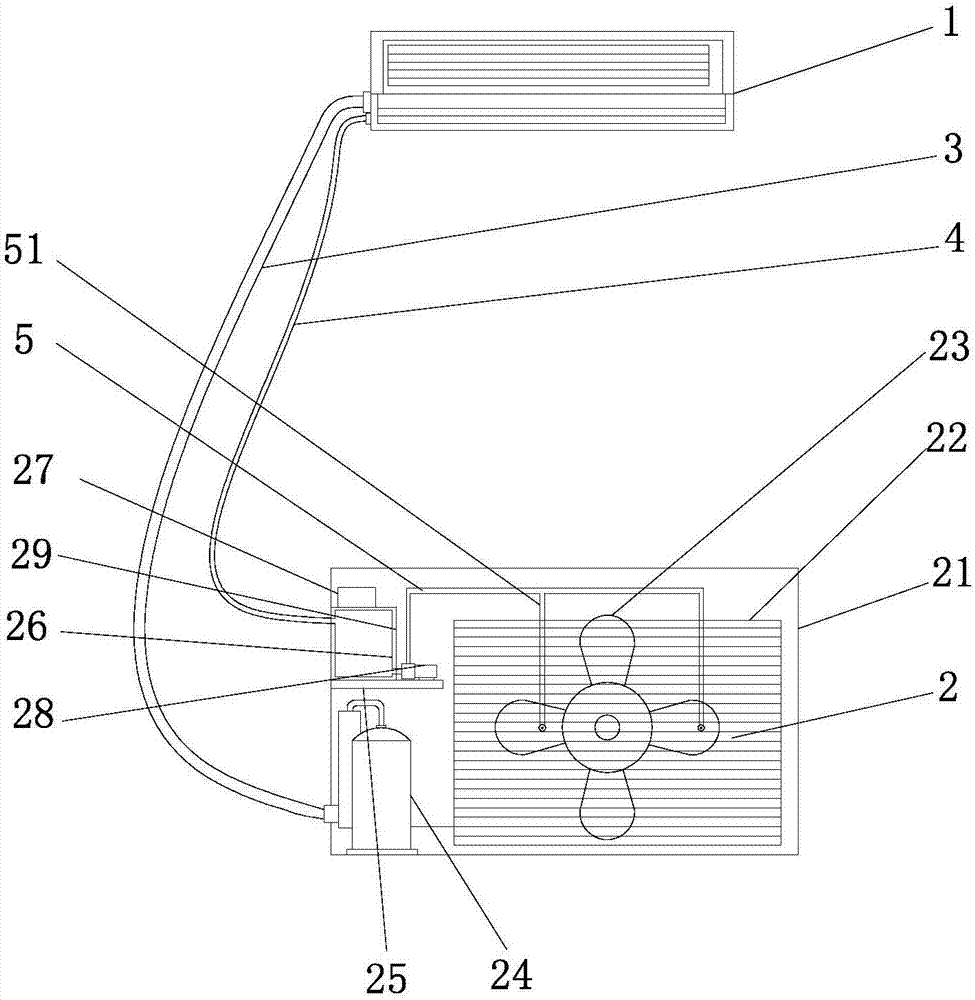

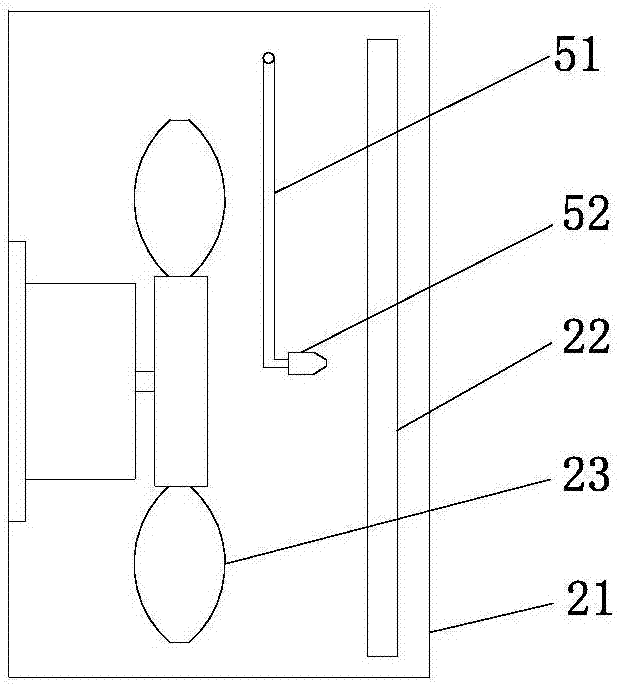

Energy-saving and environment-friendly air conditioner

InactiveCN107883453AImprove cooling effectNo dripping phenomenonMechanical apparatusCondensate preventionLiquid stateEngineering

The invention discloses an energy-saving and environment-friendly air conditioner. The energy-saving and environment-friendly air conditioner comprises a wall-mounted unit, a main unit and a refrigerant pipeline, wherein the wall-mounted unit is arranged indoors, the main unit is arranged outdoors, and the refrigerant pipeline communicates with the wall-mounted unit and the main unit and is used for allowing a refrigerant to flow; the main unit comprises a shell, a condenser, a cooling fan and a compressor, wherein the condenser is arranged in the shell and is used for converting the refrigerant from a gaseous state to a liquid state, the cooling fan is arranged in the shell and is opposite to the condenser, and the compressor is arranged on one side of the condenser; a supporting frame isarranged above the compressor; a water collecting box is arranged on the supporting frame; a condensate pipe is connected to one side of the upper part of the water collecting box; a water level controller is arranged at the top of the water collecting box; a water pump is arranged on one side of the bottom of the water collecting box; and a mist spraying assembly is connected to a water outlet of the water pump. The energy-saving and environment-friendly air conditioner has the advantages that the structure is reasonable, the refrigerating capacity of the air conditioner can be improved, condensate water is not generated in the using process, and the shell is resistant to corrosion.

Owner:夏放军

Spray pipe

PendingCN111409205ANo dripping phenomenonIncrease productivitySpray nozzlesFine working devicesRotary valveEngineering

The invention provides a spray pipe which comprises a pipe body and a rotary valve plate. Through holes are formed in the bottom of the pipe body, or installation holes are formed in the bottom of thepipe body, fixed valve plates are arranged in the installation holes, the fixed valve plates are connected with the installation holes in a circumferential sealing mode, and second valve holes are formed in the fixed valve plates, wherein the through holes are consistent with the second valve holes in shape, size and number; and the rotary valve plate is arranged on the outer side of the pipe body and is rotationally connected with the bottom of the pipe body in a sealed mode, the rotary valve plate is provided with first valve holes corresponding to the through holes and a wrench protrudingout of the outer edge of the rotary valve plate, and when the rotary valve plate rotates relative to the bottom of the pipe body, the through holes and the first valve holes are overlapped and form anopen hole for circulating liquid, or the through holes and the first valve holes are staggered and sealed. According to the spray pipe in the embodiment, the liquid discharge flow cross-sectional area can be increased during liquid discharge of a photovoltaic slicer, and the liquid discharge time can be shortened.

Owner:阳光硅谷电子科技有限公司

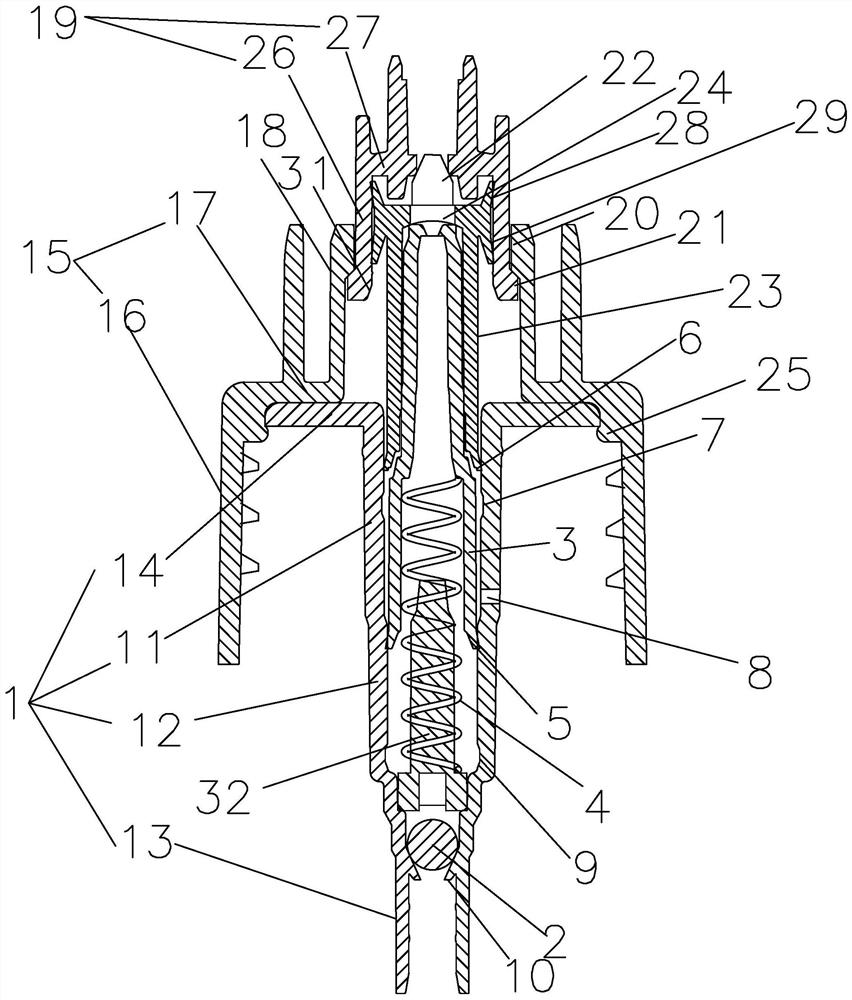

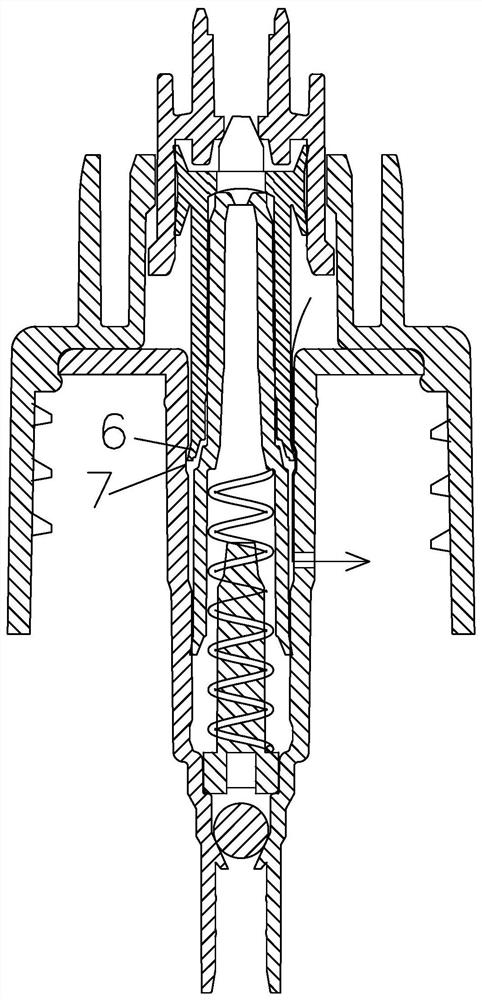

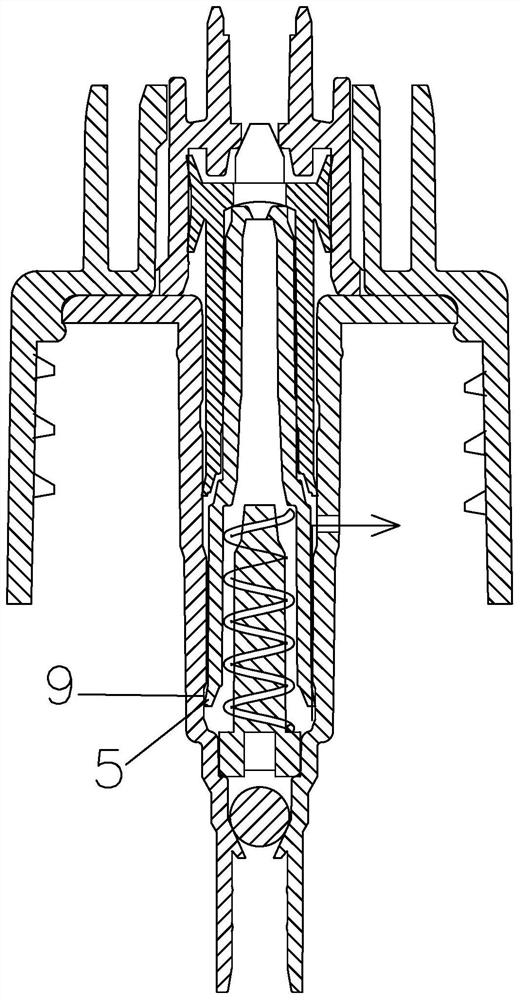

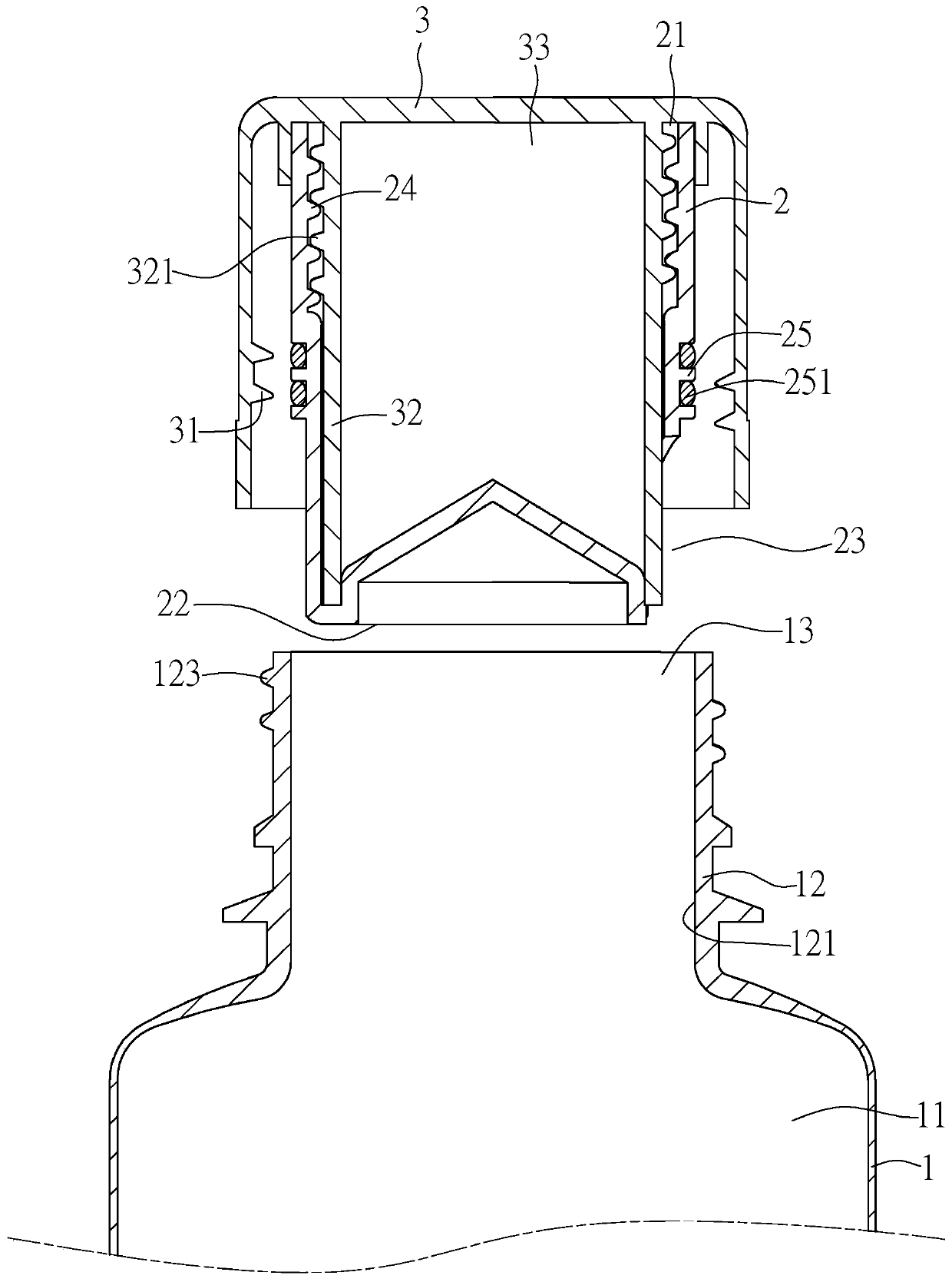

Hand pressing type atomizing pump

PendingCN113135353ANo dripping phenomenonModerate spray powerClosuresSingle-unit apparatusEngineeringMechanical engineering

The invention discloses a hand pressing type atomizing pump, and relates to the technical field of atomizing parts. The hand pressing type atomizing pump comprises a pump body, a sealing ring located at the bottom end of the pump body and a sealing ball located at the bottom end of the pump body. The sealing ball is located on the upper side of the sealing ring. The hand pressing type atomizing pump further comprises a lower piston inserted to the upper end of the pump body, an upper piston sleeving the upper end of the lower piston and a spring located in the pump and used for driving the lower piston to move to the direction away from the pump body. A via hole is formed in the upper end of the upper piston, the lower end of the lower piston is a lower sealing part attached to the inner wall of the pump body, the lower end of the upper piston is an upper sealing part attached to the inner wall of the pump body, an annular ventilation groove is formed in the position, between the upper sealing part and the lower sealing part, of the inner wall of the pump body, a hole is formed in the position, between the ventilation groove and the lower sealing part, of the pump body, and an annular liquid-permeable groove is formed in the position, between the lower sealing part and the sealing ball, of the pump body. The hand pressing type atomizing pump is free of water dripping and moderate in spraying force.

Owner:施云鹏

Surface treater for electronic yarn drawing equipment

The invention discloses a surface treater for electronic yarn drawing equipment. The surface treater comprises a workbench, a mounting base, a rotating roller, rubber sleeves, a servo motor, an oil box and an arc oil cover, wherein a bearing roller is mounted at the edge of the workbench through the mounting base, the bearing roller is sleeved with a water absorption sleeve, the rotating roller isalso mounted at the middle part of the workbench through the mounting base, the rotating roller is sleeved with a plurality of rubber sleeves, the oil box is mounted below the rotating roller, a plurality of oil ports are arranged on the oil box, the bottom end of each rubber sleeve is tightly fitted with one oil port. According to the surface treater, the rubber sleeves dip-dye an impregnating compound through the oil ports, so that a yarn bundle can be evenly coated with the impregnating compound, the coating effect is good, and the coating is even; the bearing roller with the water absorption sleeve is arranged, so that the moisture in the yarn bundle is absorbed through the water absorption sleeve, then rubber of the rubber sleeves does not drip water; the distance between the arc oilcover and the workbench is reduced, so that the effects of keeping out a water spray and shielding wind of the arc oil cover are further improved.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

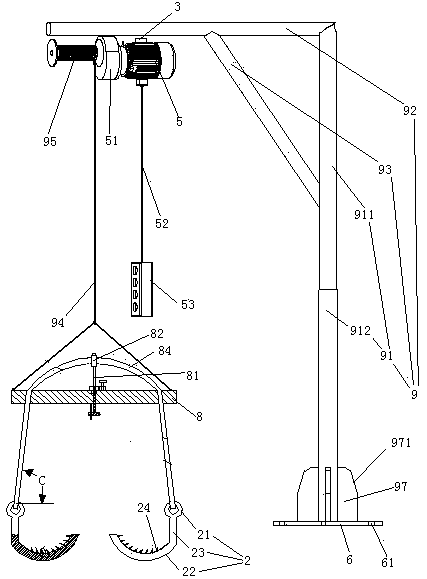

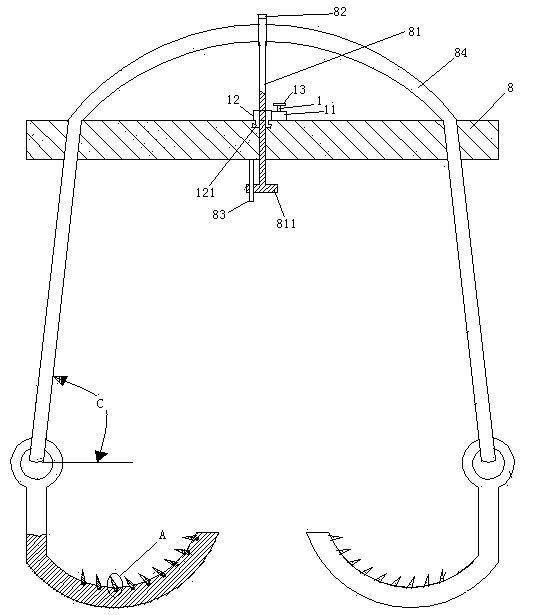

Fixed crane with adjustable rope length

The invention relates to a lifting appliance. A rope-length-adjustable fixed crane comprises a lifting bracket, a hook assembly, a wire reel and an elevating motor driving the wire reel to rotate. The lifting bracket comprises a vertical rod and a horizontal rod. A mounting plate is arranged at the lower end of the vertical rod and provided with bolt through holes. One end of the horizontal rod are connected to the upper end of the vertical rod, and the elevating motor and the wire reel are fixed to the other end of the horizontal rod. The hook assembly is connected with the wire reel together through a lifting cable. The rope-length-adjustable fixed crane can adjust the rope length to change bearing force of a connecting rope, and the problem that an existing hook assembly is liable to fracture when lifting an object with the large length due to the fact that the rope length cannot be adjusted is solved.

Owner:芜湖启博知识产权运营有限公司

High-dropping-point flame-retardant steel wire rope lubricating grease composition as well as preparation method and application thereof

ActiveCN113512461AImprove high temperature performanceIn-degree change is smallLubricant compositionPolymer scienceAdhesive

The invention relates to a high-dropping-point flame-retardant steel wire rope lubricating grease composition which is characterized by comprising the following components in parts by weight: 70-90 parts of polyurea lubricating grease; 1-5 parts by weight of an adhesive; 1-5 parts by weight of a flame retardant; 0.1-1 part by weight of an anti-wear agent; 0.3-1.0 part by weight of an antioxidant; and 0.1-0.5 part by weight of an antirust agent, wherein the sum of all the components is 100 wt%. The flame retardant is one or more of alkyl phosphate esters such as tributyl phosphate, tris (2-ethylhexyl) phosphate, tris (2-chloroethyl) phosphate and tris (2, 3-dichloropropyl) phosphate. The high-dropping-point flame-retardant steel wire rope lubricating grease is high in dropping point, small in high-temperature oil separation and capable of self-extinguishing; and even if the lubricating grease is on fire, the lubricating grease can stop spreading of fire within several seconds; and the steel wire rope can be effectively lubricated, and the service life of the steel wire rope is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Cooling method for post keen arthroplasty

InactiveCN106038044AIce effect is goodNo dripping phenomenonTherapeutic coolingTherapeutic heatingLiquid waterKnee Joint

The invention relates to a method for cooling after knee joint replacement, comprising the following steps: (1) fully absorbing liquid water with a flexible and massive water-absorbing material; (2) putting the water-absorbing material into Freeze in the refrigerator; (3) When the water-absorbent material is frozen for a period of time and squeezed without dripping and is easy to shape, take out the frozen water-absorbent material and apply it to the knee, and make the water-absorbent material stick to the front and both sides of the knee; ( 4) Apply the water-absorbing material on the knee, so that the temperature of the knee can drop to the required range. The beneficial effect of the present invention is: use flexible and block-shaped water-absorbing material to absorb water and freeze it, and then take the water-absorbing material to apply ice to the knee joint, because the water-absorbing material can be well shaped, and then can be tightly attached to the front of the knee And both sides, to achieve a better ice compress effect; in addition, as the ice compress proceeds, the ice cubes melt and are absorbed by the water-absorbing material, without dripping water, and without wetting the surrounding environment.

Owner:蒋丁贵

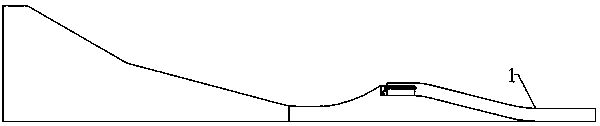

Tubular ski air bag

The invention relates to the field of ski devices, in particular to a ski soaring practice special tubular ski air bag with small rebound force, light weight, and capable of draining and discharging ponding, which comprises an outer layer of an air bag.The inner part of the outer layer of the air bag is provided with two or more layers of aerated layers, each of the aerated layerscomprises a plurality of mutually independent aerated bodies, and the aerated bodies are distributed in the length direction of the outer layer of the air bag. The independent aerated bodies can ensure constant aeration, stability of the gas pressure of an aeration layer is ensured, the absorption of external force of the ski air bag composed of multiple aerated bodies only forms three directions: downward, leftward, and rightward, so no upward rebound forceexists when a skier lands in an air bag training, and safety of the skier is ensured.

Owner:尖锋

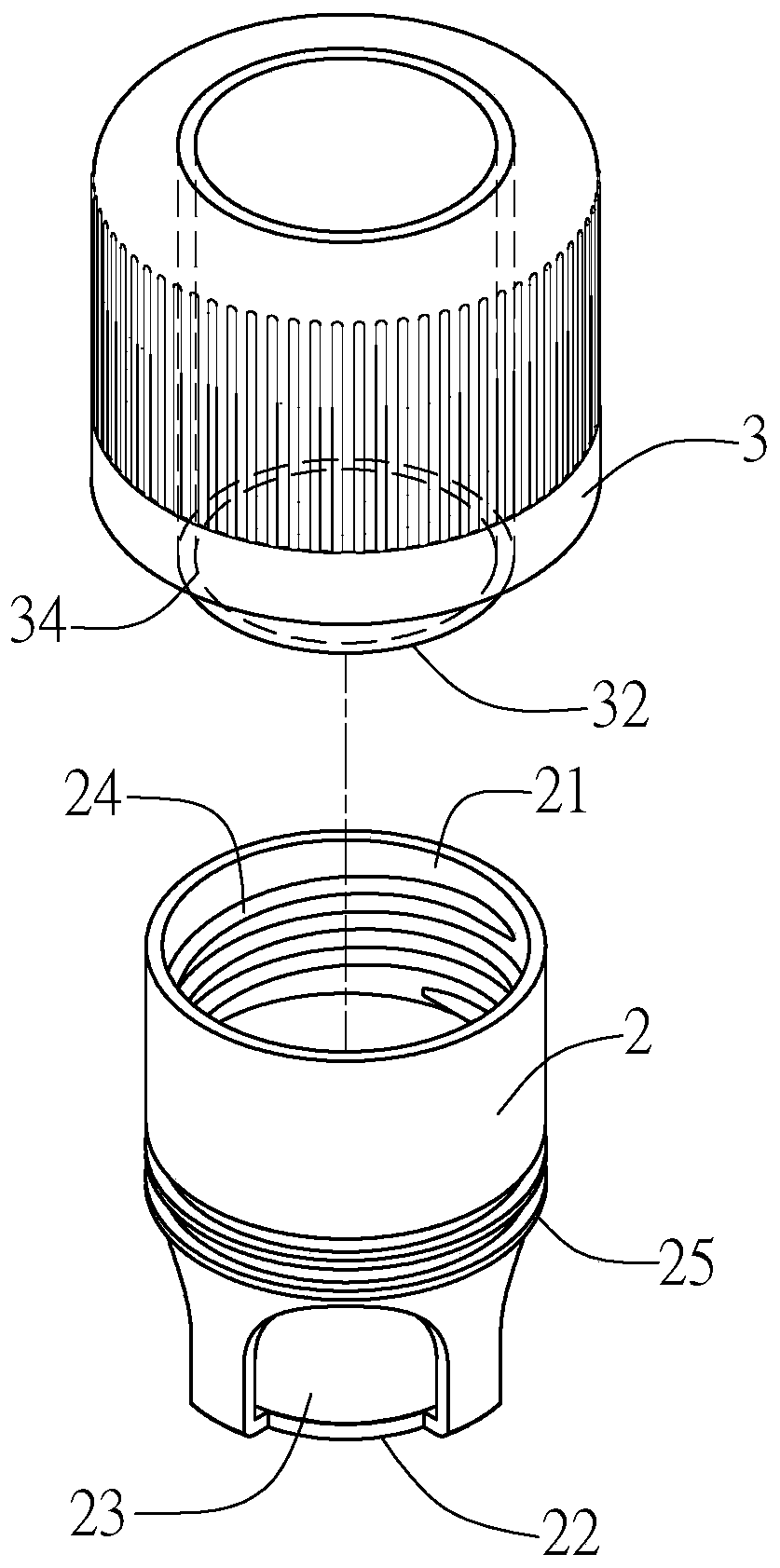

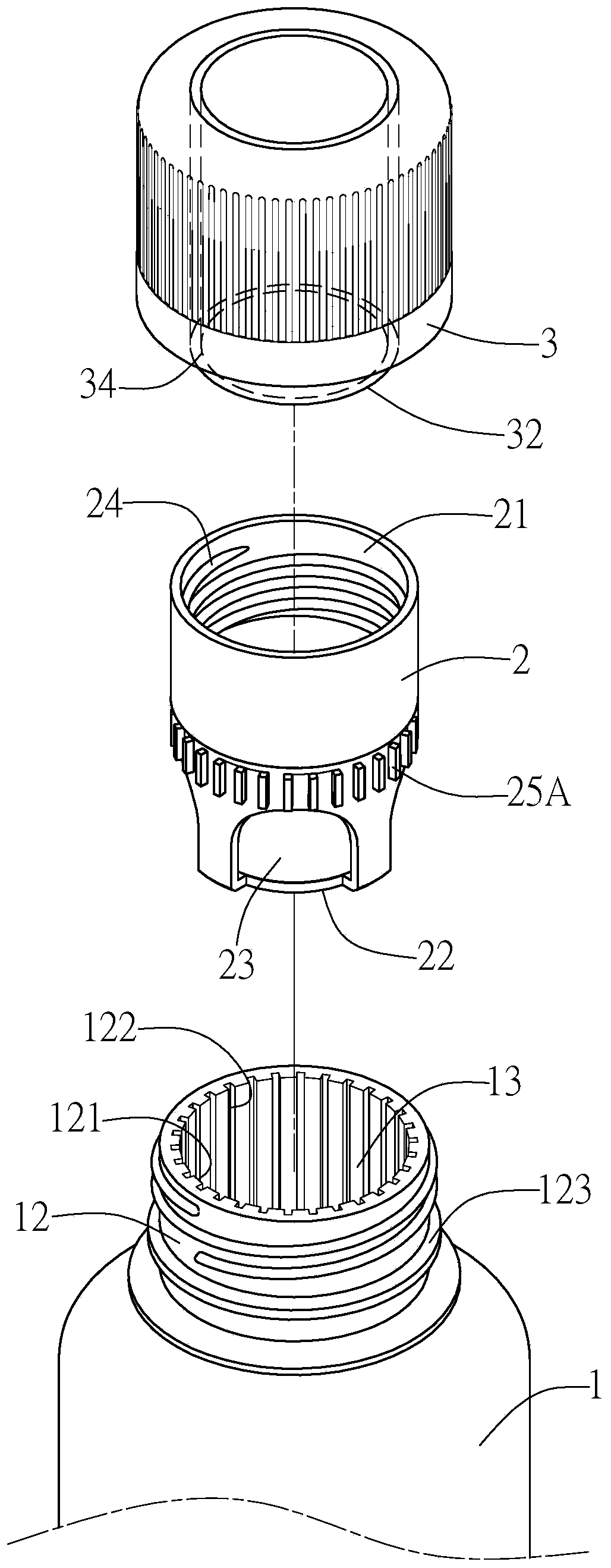

Closures and containers with such closures

ActiveCN108725988BReduce movementNo dripping phenomenonClosure with auxillary devicesContainers with multiple articlesStructural engineeringOpen hole

The invention discloses a sealing cover and a container with the same. The sealing cover is formed by assembling an inner cover and a cover body, and capable of being installed at a nozzle part of a container body. The screwing direction of an internal thread part of the inner cover and an external thread part of an extension pipe of the cover body is opposite to the screwing direction of the cover body and the nozzle part, so that when the cover body is screwed into the nozzle part, a resistance part of the inner cover is abutted against the interior of an opening of the nozzle part, the inner cover moves towards the interior of an accommodating chamber of the container body along with the rotation of the cover body, and further moves towards the interior of the opening relative to the extension pipe due to the opposite screwing direction until an open hole of the extension pipe and a release hole of the inner cover are opened and communicated; due to the action of screwing the coverbody, additives are capable of falling off from the release hole, that is, the additives are capable of being mixed into the filled liquid by swinging the container, and the operation is simple and clear; and moreover, when the cover body is unscrewed from the nozzle part, the release hole can be sealed again, so that the occurrence of the phenomenon that the remainder additives in the cover bodydrip outside is prevented.

Owner:杨芳林

Liquid film spinning method

ActiveCN107151840AModerate hardnessDoes not affect internal and external transferTextiles and paperYarnFiber

The invention relates to a spinning method, in particular to a liquid film spinning method, and belongs to the technical field of spinning. According to the liquid film spinning method, in the process of ring spinning, a water dripping device is added and installed between a guide wire and a front jaw formed by a front roller and a front skin stick of a ring spinning frame, and the yarn is fed through the water dripping device between the front jaw and the guide wire. The yarn penetrates through water droplets attached to the end of the water dripping device, hairiness fibers stretching out of backbones of the yarn hang out a liquid film wrapping the yarn from the water droplets, the hairiness fibers on the surface of the yarn attach to the backbones of the yarns through the contraction effect of the liquid film surface tension and involve in a twisting process of backbone fibers, the hairiness fibers on the surface of the yarns have the opportunity to be rolled into the backbones of the yarns to achieve the effect of reducing yarn hairiness. The liquid film spinning method has the advantages of no energy consumption, no noise and easy maintenance of the device.

Owner:安徽迪惠新材料科技有限公司

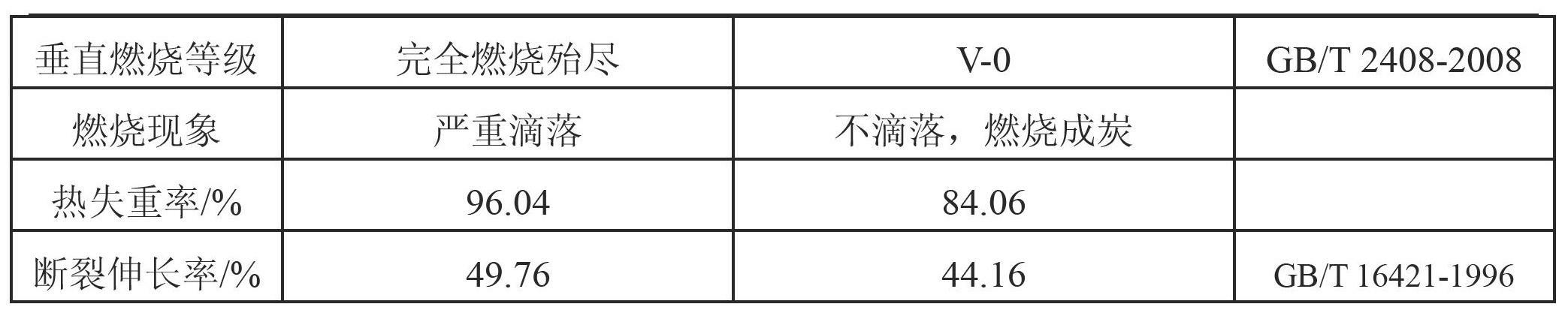

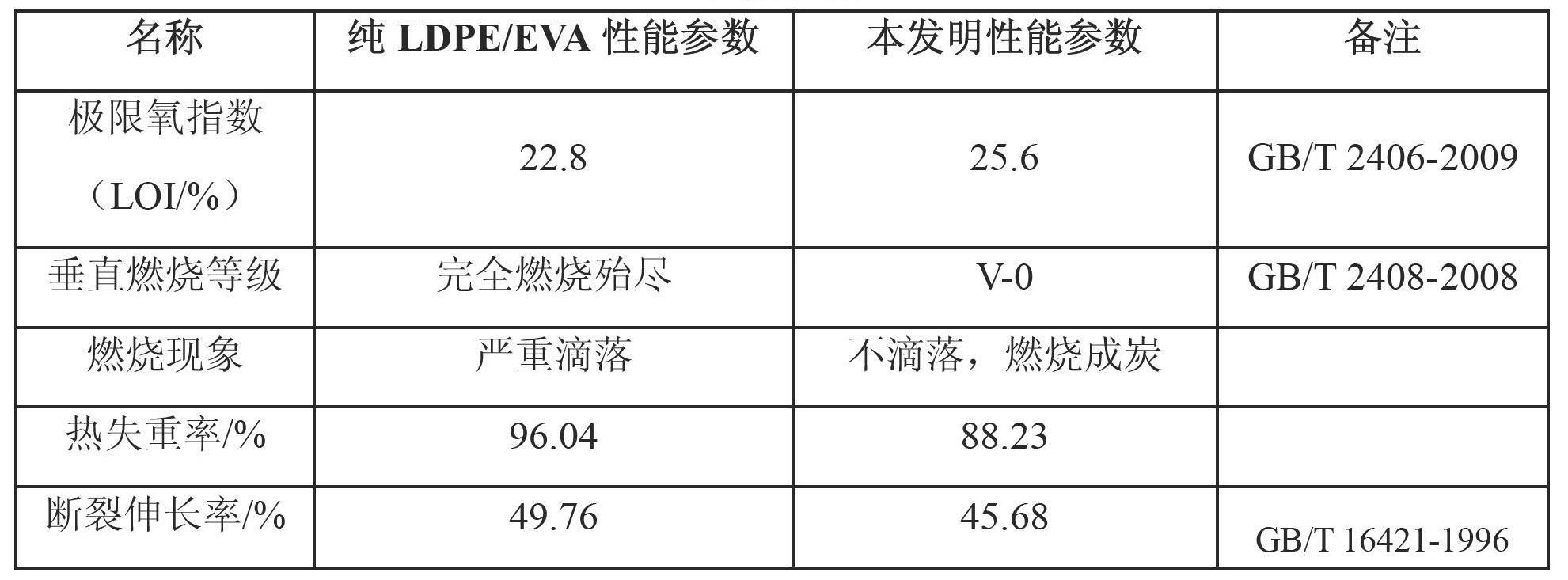

LDPE (Low-Density Polyethylene)/EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material and preparation method thereof

ActiveCN102643469BRaw materials are easy to getAbundant resourcesLow-density polyethyleneZinc borate

The invention relates to an LDPE (Low-Density Polyethylene) / EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material. The LDPE / EVA anti-flaming material comprises the following raw material compositions by weight parts: A is base resin and includes 100 parts of LDPE and EVA; B is bromine containing flame retardant and includes 10-20 parts of decabromodiphenyl ethane or decabromodiphenyl ether, C is inorganic flame retardant and includes 3-6 parts of modified antimonous oxide M-Sb2O3, 3-6 parts of talcum powder TP, 2-8 parts of zinc borate (ZB) and 2-8 parts of hydrotalcite (LDHs). The preparation method of the LDPE / EVA anti-flaming material is as follows: drying raw materials, mixing the raw materials uniformly, processing, extruding, and conducting injection molding on the raw materials to obtain the extruded anti-flaming composite material. According to the anti-flaming material and the preparation method, the advantages of the organic flame retardant, the bromine containing flame retardant and the inorganic flame retardant are combined, the using amount of the inorganic flame retardant is decreased, the limit oxygen index of the anti-flaming composite material is increased, the materials are burned into carbon directly when being burned, the dropping phenomenon can not occur, and the toxic and harmful gas can not be generated.

Owner:广西华锑科技有限公司

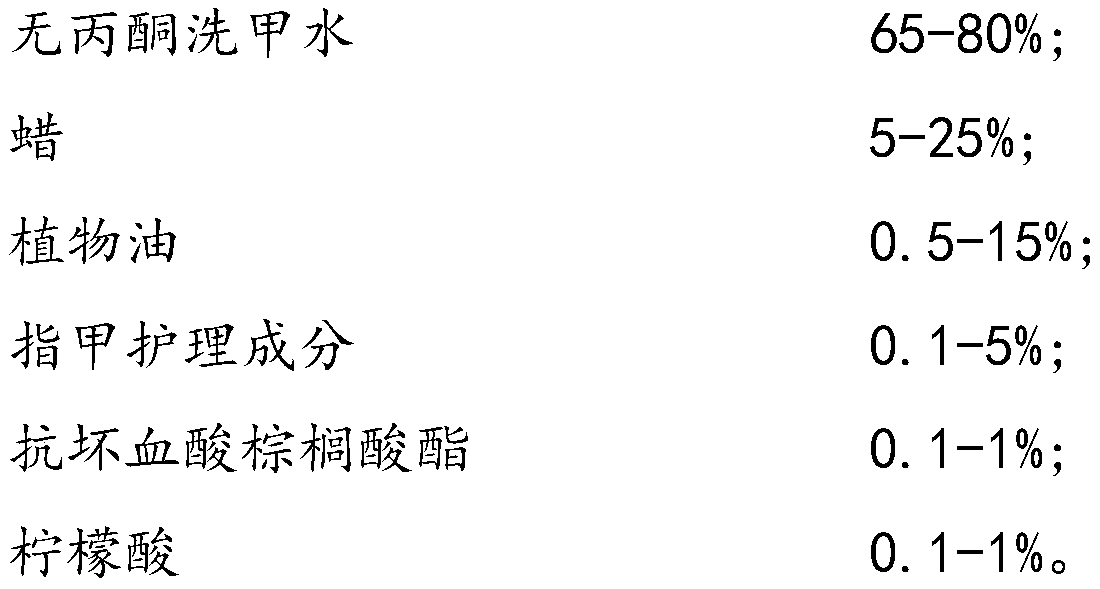

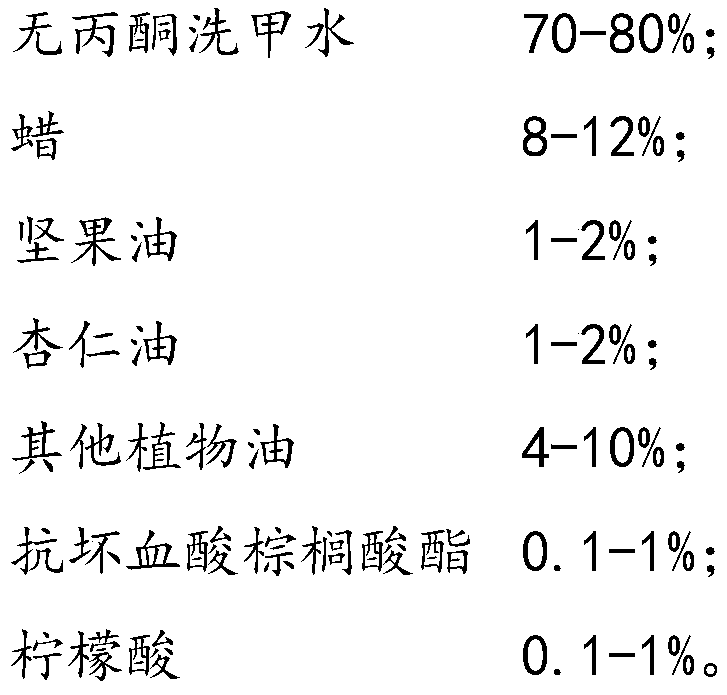

Nail polish removing cream

PendingCN111529415AStay moisturizedNo dripping phenomenonCosmetic preparationsToilet preparationsCitric acidNail polish removers

The invention provides nail polish removing cream characterized by being prepared from the substances containing the following components: 65-80% of an acetone-free nail polish remover, 5-25% of wax,0.5-15% of vegetable oil, 0.1-5% of a nail care component, 0.1-1% of palmitate and 0.1-1% of citric acid. The product is a cream-like nail polish removing product which has good removing effects and contains no acetone.

Owner:上海妮诺化妆品有限公司

A production line for drum washing machines

ActiveCN109183346BFast and stable shutdownSensitive and stableStructural/machines measurementWashing machine with receptaclesProduction lineCombined test

The invention discloses a production line of a drum washing machine, which includes a display board in the air, a lifting and returning machine, a barcode printer, a chain plate line, a double-speed chain conveyor line, a power-assisted hanging bucket device, an automatic code scanner, a water injection machine, a performance detection mechanism, a comprehensive Test equipment, quiet room, rework roller conveyor line, automatic bottom foam machine, sealing machine, high-altitude roller conveyor line, continuous elevator and roller conveyor line, and aerial display Kanban, lifting and returning board machine, barcode printer, chain plate line, Double-speed chain conveyor line, power-assisted hanging bucket equipment, automatic code scanner, water injection machine, performance testing mechanism, comprehensive testing equipment, quiet room, rework roller conveyor line, automatic bottom-filling foam machine and box sealing machine are connected in sequence. The production line of the drum washing machine uses a water injection pump as the power source for water injection. The flow rate of each water injection is stable, and the foam bottom bracket can be quickly placed on a single line body, saving cost and space.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

Connecting joint for spray connecting pipe of electric sprayer

Owner:徐州蔬客达农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com