LDPE (Low-Density Polyethylene)/EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material and preparation method thereof

A technology of flame-retardant composite materials and brominated flame retardants, which is applied in the field of composite materials, can solve problems such as dripping and high toxicity, and achieve the effects of low exudation, small negative effects, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

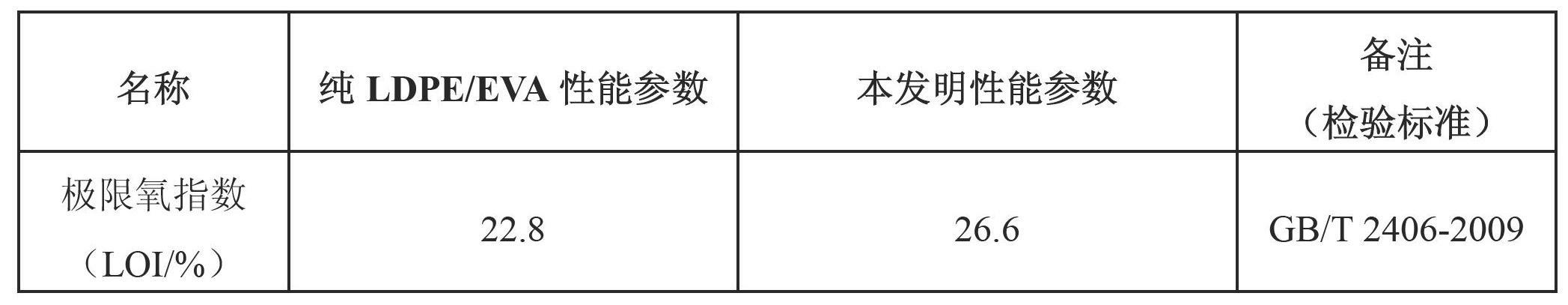

Examples

Embodiment 1

[0036] (1) Preparation of modified antimony trioxide

[0037] Place antimony trioxide in a drying oven at 80-90°C for 60 minutes, then transfer it to a mixer, and add titanate to couple at a ratio of 100:2 by weight of antimony trioxide and coupling agent. agent, at a temperature of 100-110°C and a rotation speed of 1000rpm / min, stirring and modifying for 40 minutes to obtain modified antimony trioxide M-Sb 2 o 3 .

[0038] (2) Raw material formula: (both parts by weight)

[0039] Raw material composition

Number of copies / phr

Low-density polyethylene (LDPE)

75

Ethylene-vinyl acetate copolymer (EVA)

25

Decabromodiphenylethane (DBDPE)

15

5

Modified antimony trioxide (M-Sb 2 o 3 )

5

Zinc borate (ZB)

2

Hydrotalcites (LDHs)

8

[0040] (2) Preparation method:

[0041] a. Drying of raw materials: Weigh the raw materials according to the above ratio, th...

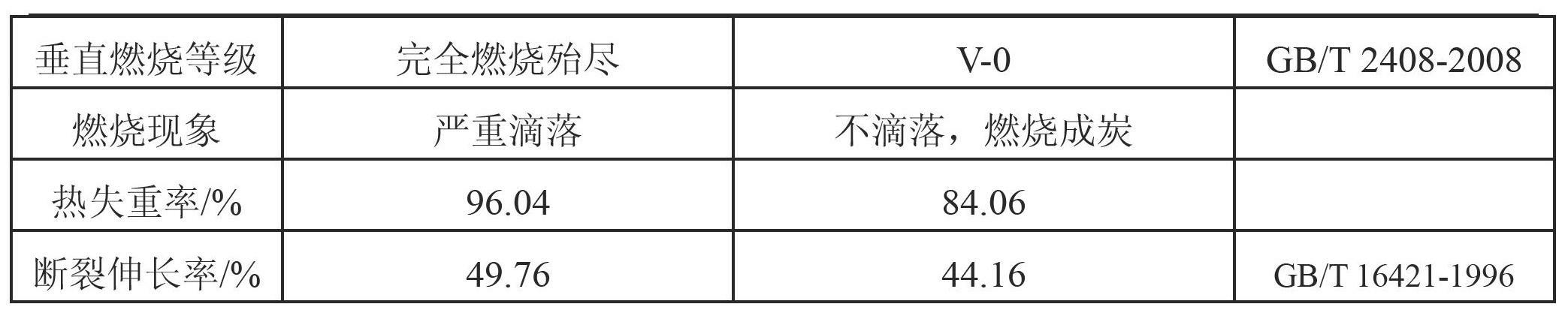

Embodiment 2

[0051] (1) Preparation of modified antimony trioxide

[0052] Place antimony trioxide in a drying oven at 90-100°C for 80 minutes, then transfer it to a mixer, and add lead ester coupling at a weight ratio of antimony trioxide to coupling agent of 100:3. agent, at a temperature of 110~120°C and a rotation speed of 2000rpm / min, stirring and modifying for 60 minutes to obtain a modified antimony trioxide M-Sb 2 o 3 .

[0053] (2) Raw material formula: (both parts by weight)

[0054] Raw material composition

Number of copies / phr

Low-density polyethylene (LDPE)

50

Ethylene-vinyl acetate copolymer (EVA)

50

Decabromodiphenylethane (DBDPE)

10

6

Modified antimony trioxide (M-Sb 2 o 3 )

2

Zinc borate (ZB)

4

Hydrotalcites (LDHs)

4

[0055] (3) Preparation method:

[0056] a. Raw material drying: Weigh the raw material according to the above ratio, then ...

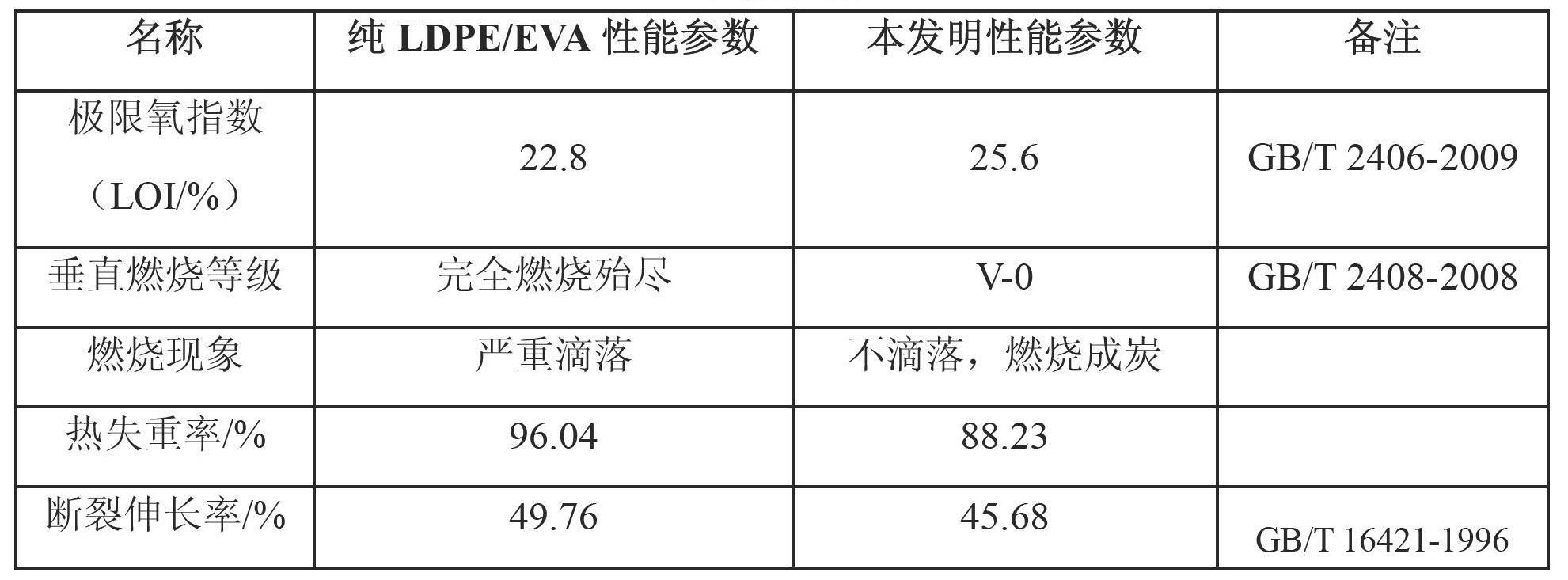

Embodiment 3

[0064] (1) Preparation of modified antimony trioxide

[0065] Place antimony trioxide in a drying oven at 85~95°C for 40 minutes, then transfer it to a blender, and add lead ester coupling at a weight ratio of antimony trioxide to coupling agent of 100:3. agent, at a temperature of 105~115°C and a rotation speed of 1500rpm / min, stirring and modifying for 30 minutes to obtain modified antimony trioxide M-Sb 2 o 3 .

[0066] (2) Raw material formula: (both parts by weight)

[0067] Raw material composition

Number of copies / phr

Low-density polyethylene (LDPE)

65

Ethylene-vinyl acetate copolymer (EVA)

35

Decabromodiphenylethane (DBDPE)

20

Talc powder (TP)

3

Modified antimony trioxide (M-Sb 2 o 3 )

4

Zinc borate (ZB)

8

Hydrotalcites (LDHs)

2

[0068] (3) Preparation method:

[0069] a. Raw material drying: Weigh the raw material according to the above ratio, then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com