Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

343results about How to "High limiting oxygen index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant flame-retarding textile

The invention aims to provide high-temperature resistant flame-retarding textile. The high-temperature resistant flame-retarding textile is weaved by high-temperature resistant flame-retarding yarns, and the high-temperature resistant flame-retarding yarns are blended with preoxidized fibers, high tenacity flame-retarding fibers and common flame-retarding fibers; and conducting fibers can also be used to weave the high-temperature resistant flame-retarding textile when the high-temperature resistant flame-retarding textile is prepared. The high-temperature resistant flame-retarding textile overcomes the drawback that the preoxidized fiber is difficultly spun, low in tenacity and only has single color of blackness; and the high-temperature resistant flame-retarding textile also has the advantages of high high-temperature resistance, high tenacity, good wearing comfortability, rich color, proper price and safety and reliability for the human body and is reasonable high-temperature resistant flame-retarding textile.

Owner:汕头市奥山服饰有限公司

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

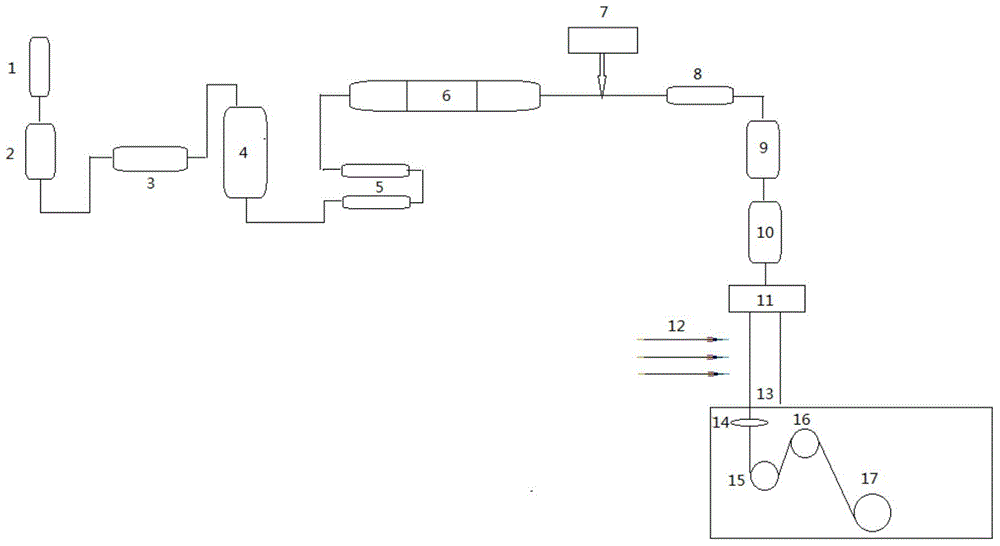

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

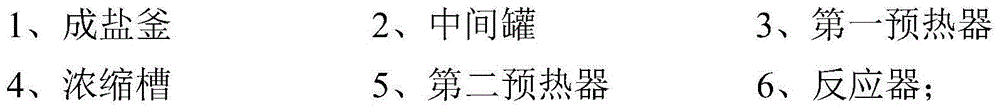

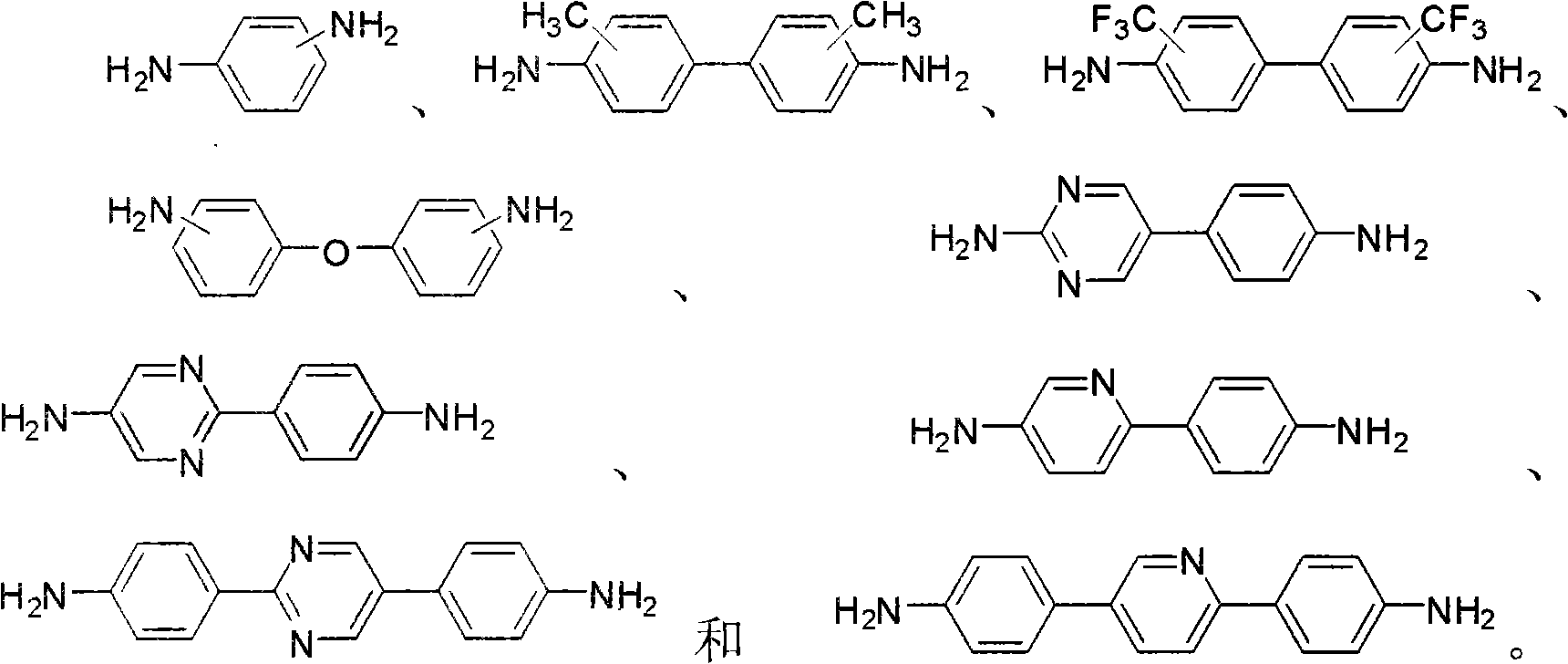

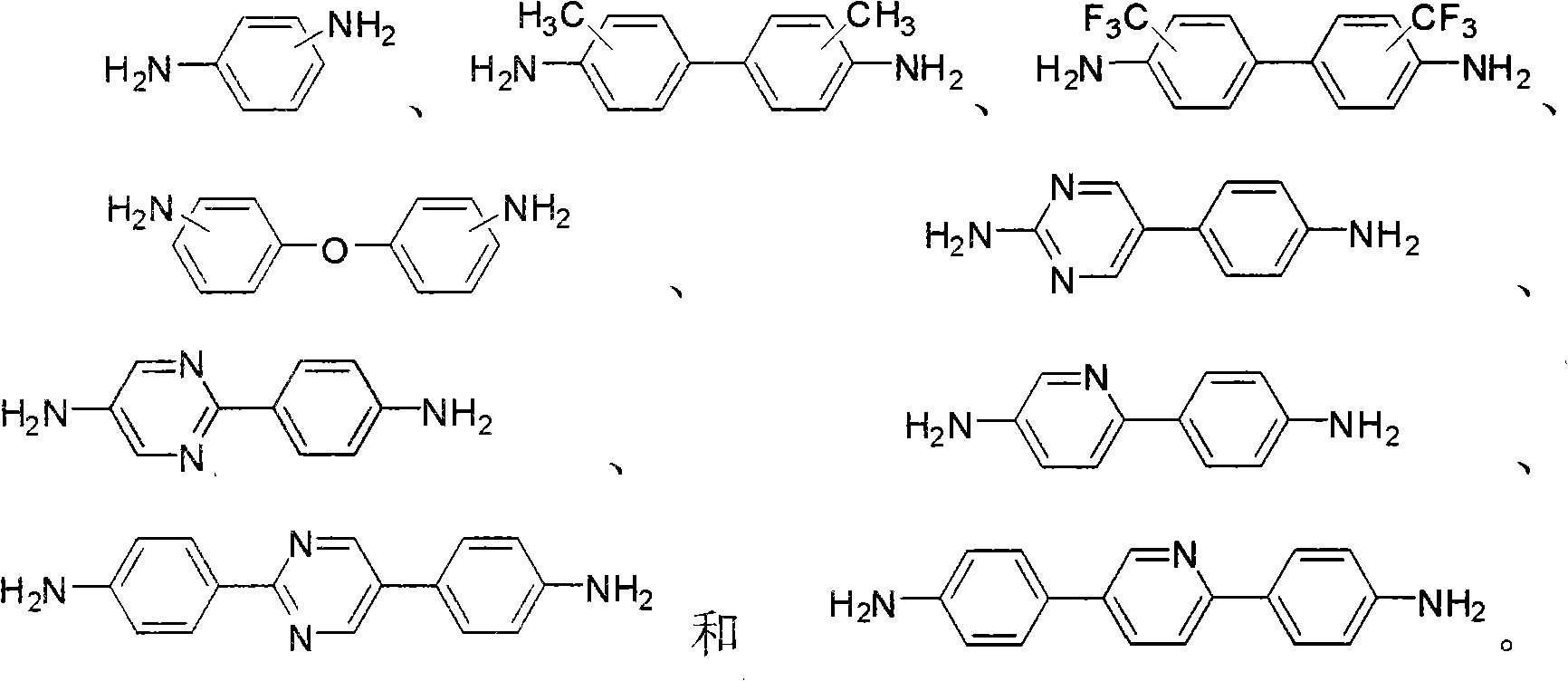

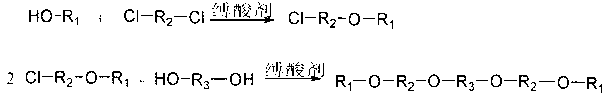

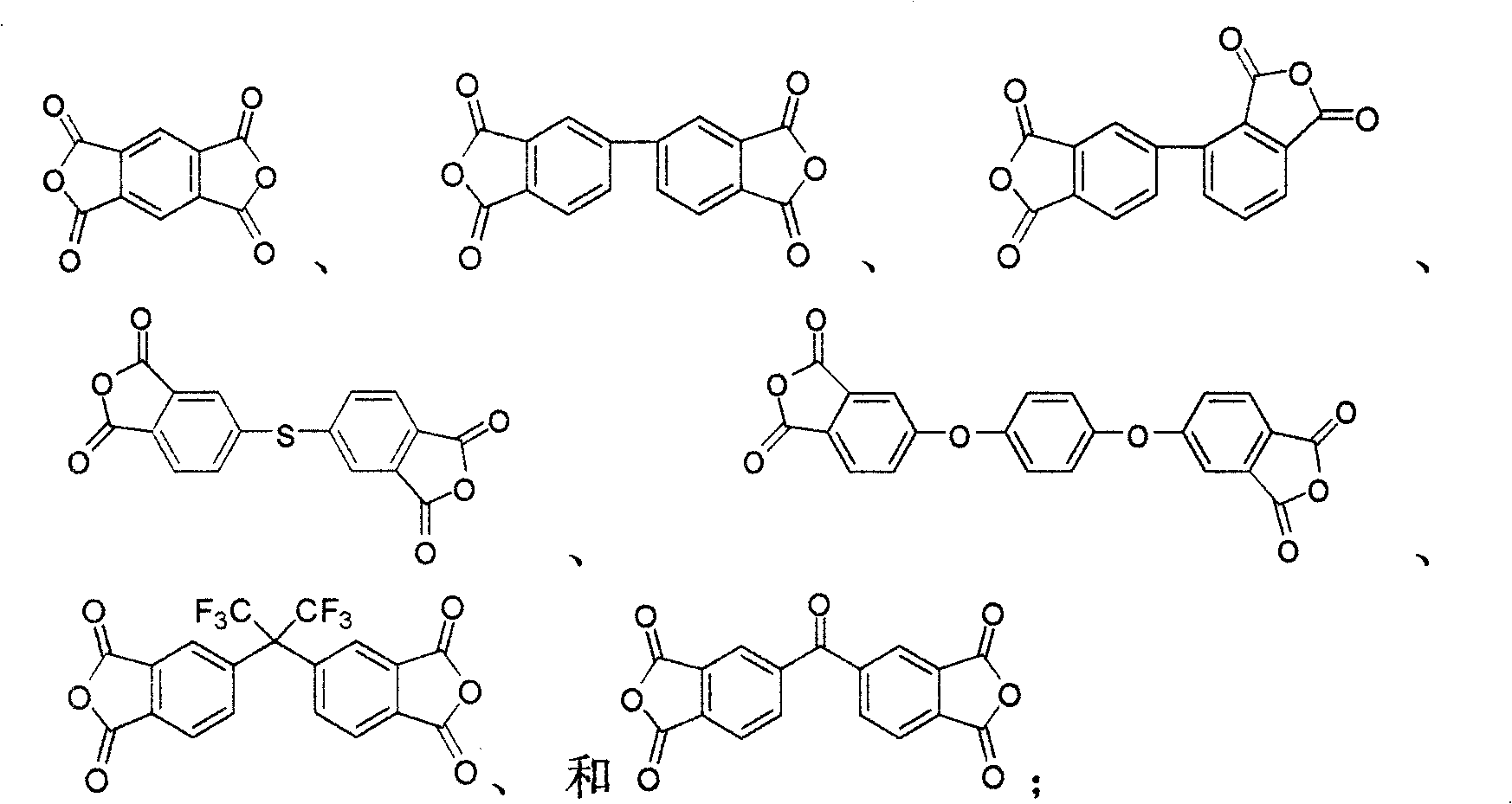

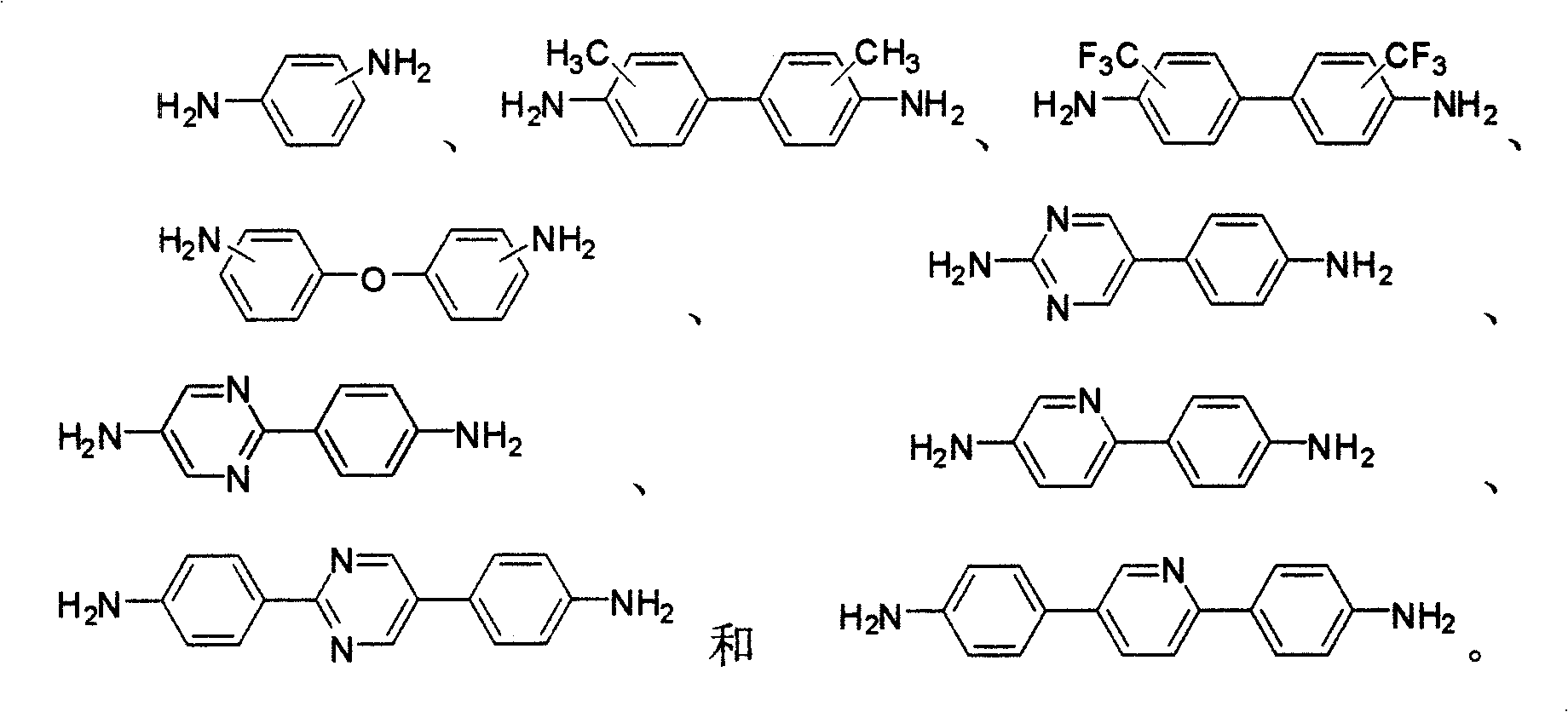

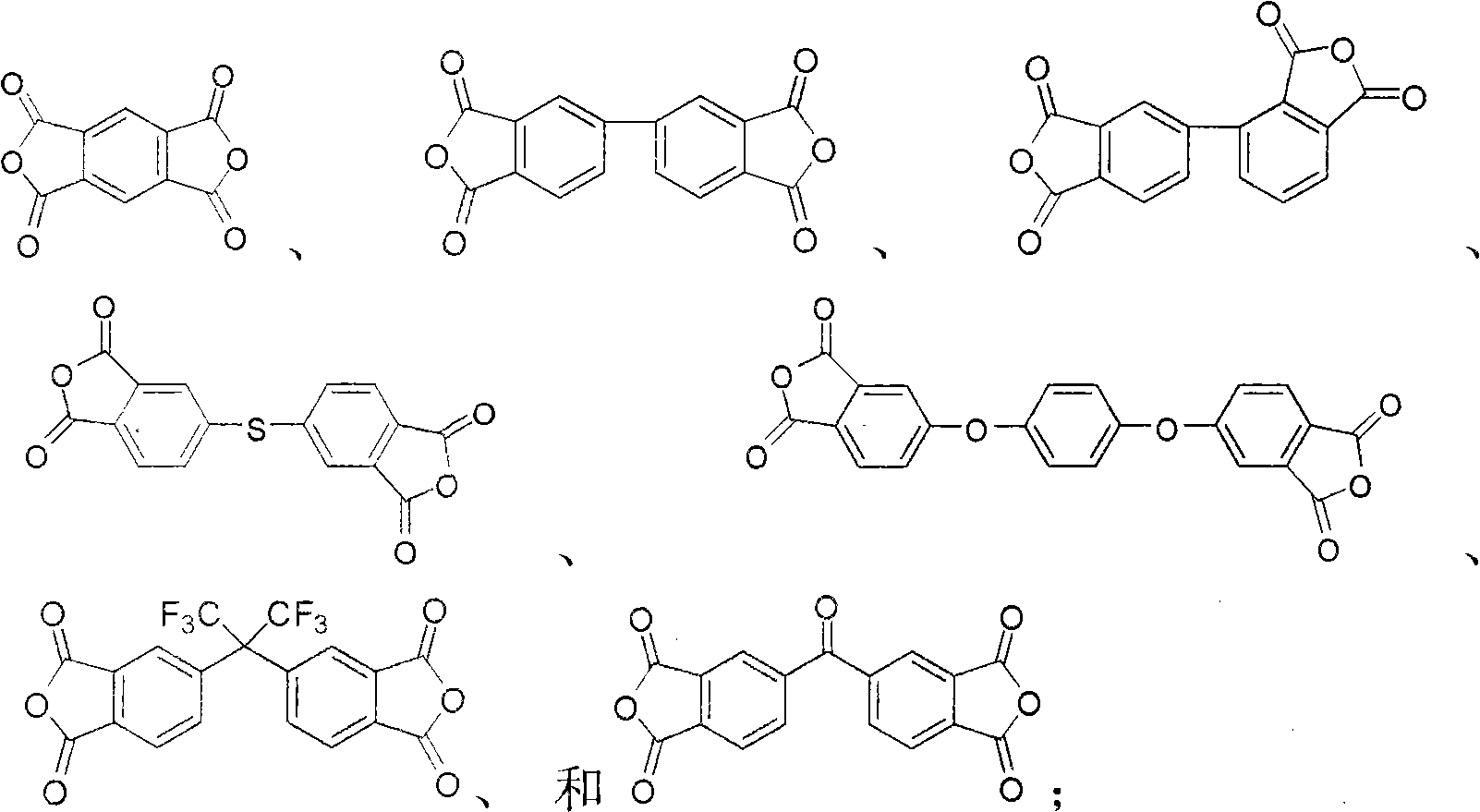

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

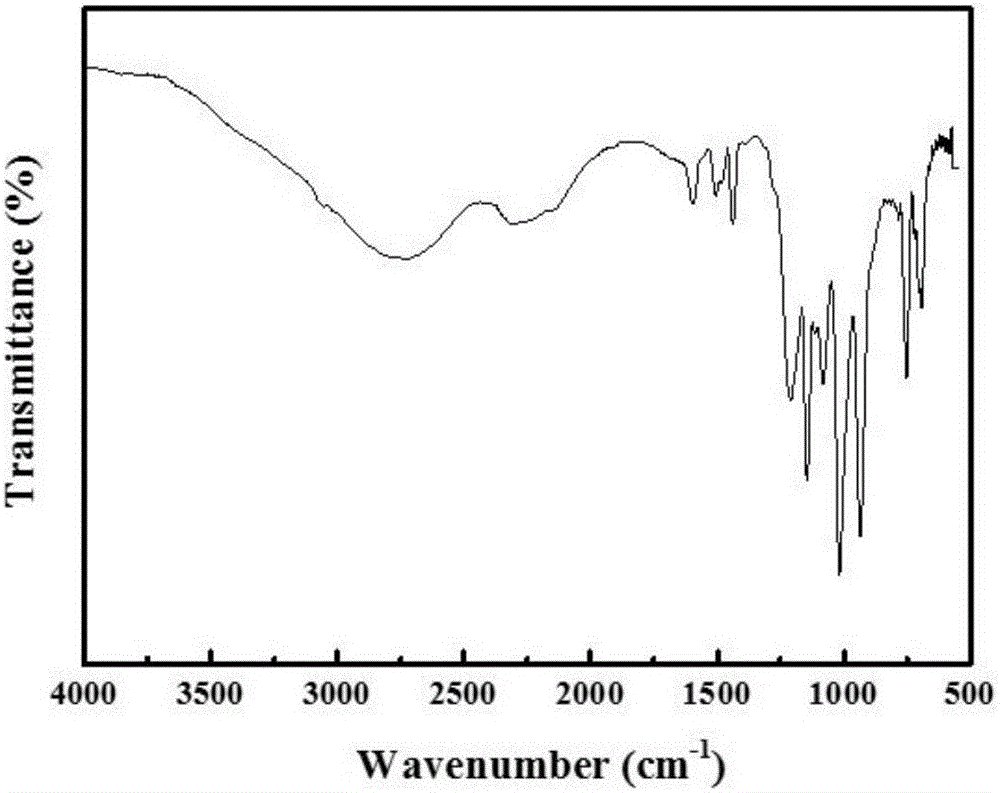

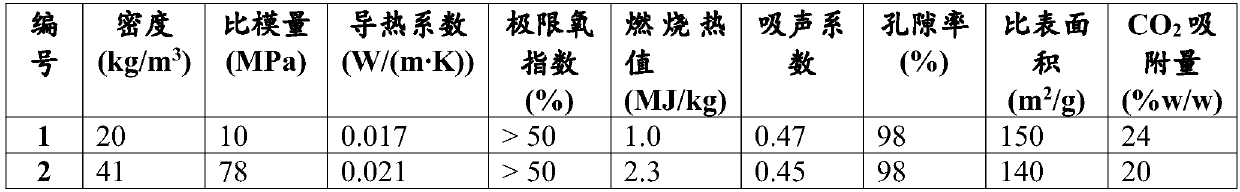

Organic amine modified ammonium polyphosphate, preparation method and applications thereof

ActiveCN103382267AThe preparation method is matureEase of control and industrial productionAmmonium polyphosphateIon

The invention discloses organic amine modified ammonium polyphosphate. Organic amine modified ammonium polyphosphate is prepared through an ionic reaction between organic amine and ammonium polyphosphate. The structure formula is shown in the description, wherein the R of the formula is a straight chain alkyl or branch chain alkyl with a carbon number between 2 and 6, and the n is not smaller than 1. The invention also discloses a preparation method and applications of organic amine modified ammonium polyphosphate. The organic amine modified ammonium polyphosphate is obtained through modifying ammonium polyphosphate by organic amine in water and alcohol solution, is capable of being used alone as the expanding flame-retardant agent, is harmless to human bodies, can obtain excellent flame-retardant effects by mixing with polypropylene, polyethylene and epoxy resin, and the preparation process is pollution free.

Owner:SICHUAN UNIV

Reactive phosphorus flame retardant containing DOPO and active double bond and preparation method and application thereof

ActiveCN103073746ASimple manufacturing methodImprove reaction conditionsGroup 5/15 element organic compoundsDouble bondPhenol

The invention discloses a reactive phosphorus flame retardant containing DOPO and an active double bond and a preparation method and application thereof. Dichloro replaces phosphate to react with polyhydric alcohols or polyhydric phenol acidifying with propylene or partial methyl propene and then with DOPO modified aryl-dihydric phenol and DOPO modified aryl-dihydric alcohol, and a reactive flame retardant monomer molecule capable of being cured and provided with active double bonds and a DOPO flame retardant group are obtained and can be used in various flame retardants of epoxyacrylates and unsaturated polyester resins and the like containing unsaturated double bond polymer resins. The flame retardant overcomes defects that the compatibility between an additive flame retardant and a matrix is poor, the additive flame retardant and the matrix are easy to lose, the water resistance is poor, and the like, and the LOI (limit oxygen index) value of resins can be improved remarkably and the flame-resistant effect is good when the flame retardant is used for flame retarding in the epoxyacrylates and the unsaturated polyester resins.

Owner:苏州安鸿泰新材料有限公司

Prepn process of polyimide fiber

InactiveCN1932091AHigh strengthHigh modulusWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The preparation process of polyimide fiber includes the following steps: 1. preparing polyamic acid solution as the spinning precursor through polycondensing maleic anhydride monomer and diamine monomer; 2. dry spinning to prepare polyamic acid fiber; 3. imidating polyamic acid fiber to form polyimide fiber; and 4. hot stretching polyimide fiber at 350-470 deg.c for 3-8 times. Thus prepared polyimide fiber has high strength, high modulus, high heat resistance, high chemical corrosion resistance and relatively high limiting oxygen index, and may be used widely as reinforcing material of composite material and cable, rope for vehicle and ship, filter material, etc.

Owner:DONGHUA UNIV

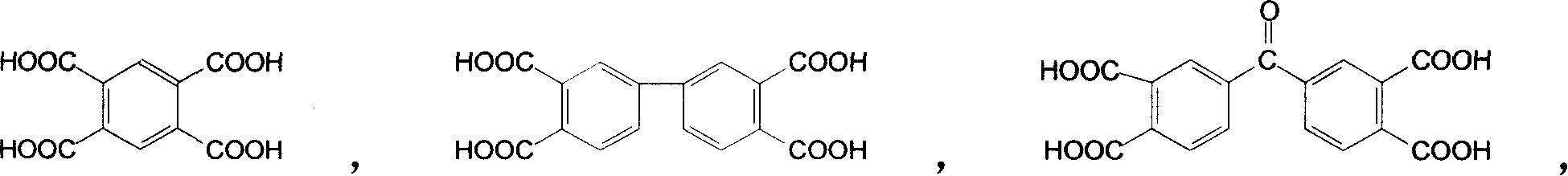

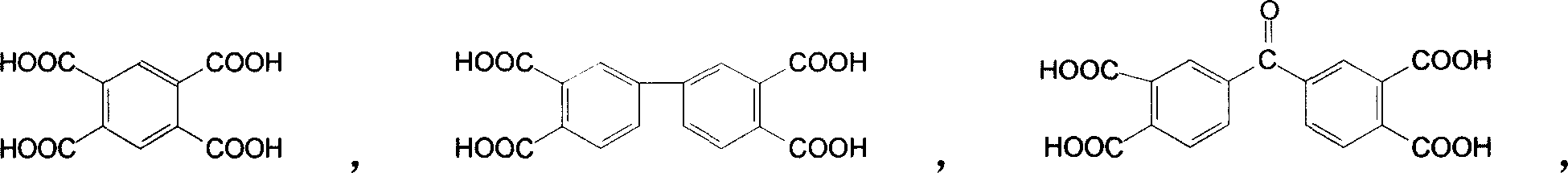

Transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyester and preparation method thereof

The invention discloses transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyester and a preparation method thereof. The transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyester consists of the following components in part by mass: 58.5 to 69.85 parts of unsaturated polyester prepolymer containing phosphorus, boron and silicon elements, 30 to 40 parts of crosslinking monomer, 0.05 to 0.5 part of hydroquinone, and 0.1 to 1 part of initiator. The transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyesteris prepared by the following steps of: adding the crosslinking monomer when the temperature of the unsaturated polyester prepolymer containing the phosphorus, boron and silicon elements is reduced to100 to 120 DEG C, further reducing the temperature to 35 to 50 DEG C, and adding the hydroquinone and the initiator. The flame retardance of the transparent reaction type phosphorus-boron-silicon flame-retardant unsaturated polyester is high, the limiting oxygen index of a curing product can be increased from 19 percent to 30 percent, and the vertical burning tested by using a 3.2mm spline reaches class UL94V-0; and the three flame-retardant elements, namely phosphorus, silicon and boron are directly introduced to an unsaturated polyester molecular chain, so the thermal-state bonding strengthof the curing product is high.

Owner:SOUTH CHINA UNIV OF TECH

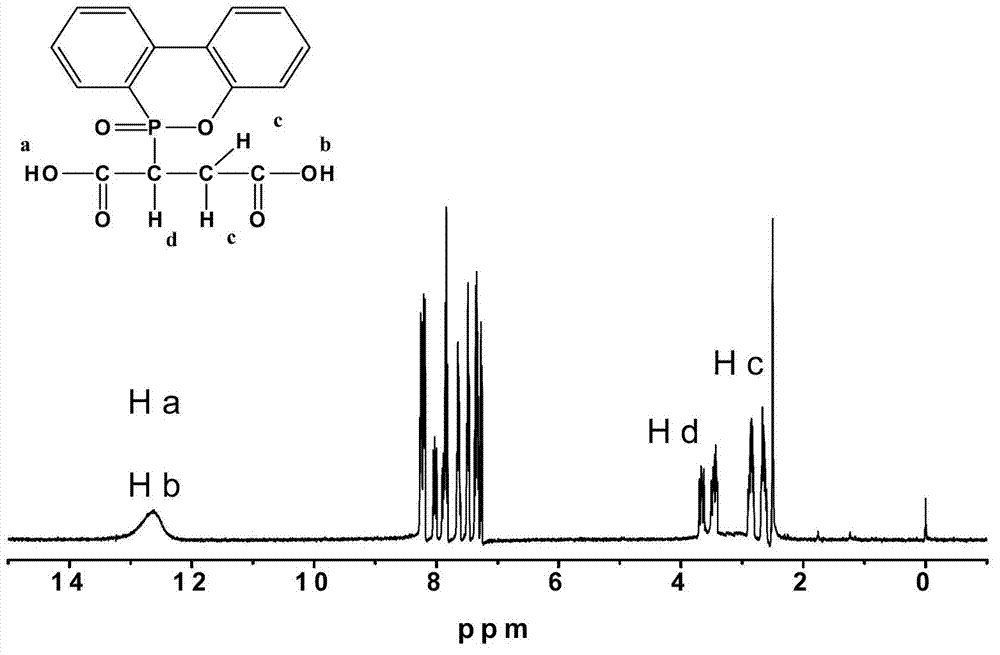

Phosphaphenanthrene polyamide flame retardant and preparation and application thereof

ActiveCN104419003AHigh phosphorus contentEasy to useGroup 5/15 element organic compoundsThermoplasticPolymer science

The invention relates to a phosphaphenanthrene polyamide flame retardant and a preparation and an application thereof. The preparation method comprises the following steps: carrying out graft modification on novel unsaturated polyamide and a phosphorus-containing group; and carrying out additive reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) to prepare the polyamide flame retardant by using the reactivity of the unsaturated polyamide. The phosphaphenanthrene polyamide flame retardant has the characteristics of being halogen-free, low in smoke, low in toxicity, low in corrosion, good in fire resistance, good in processability and the like; the environmental protection index can meet the regulatory requirements of RoHS, IEC non-halogenation and Reach method of the European union; and compared with the previously known comparable DOPO derivative, the compound has a gas phase flame-retardant effect and a condensed phase flame-retardant effect, is high in efficiency, and can be applied to inflaming retarding of thermoplastic plastics and thermosetting materials.

Owner:GUANGZHOU SHINE POLYMER TECH

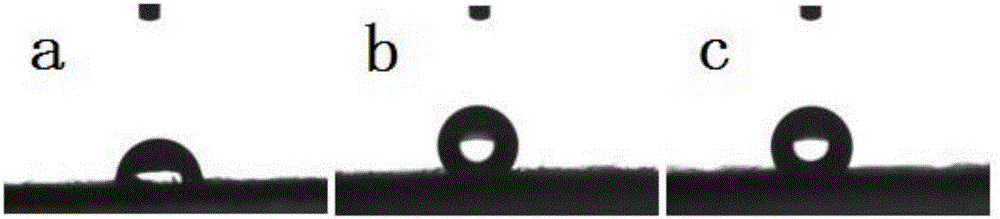

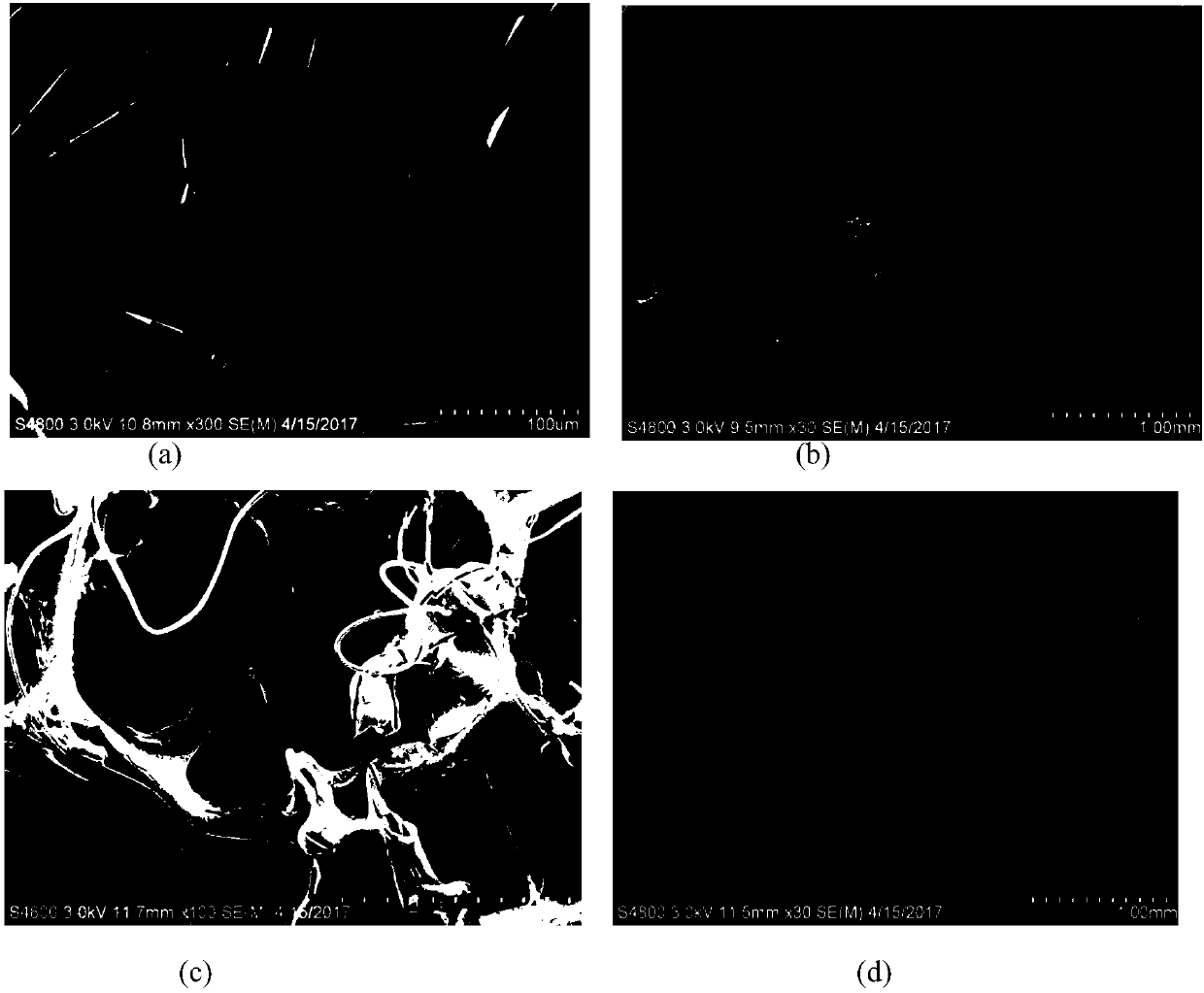

Preparation method of fabric with flame-retardant and hydrophobic functions

ActiveCN106381714AImprove the problem of non-washable flame retardantLow reaction temperatureHeat resistant fibresLiquid/gas/vapor removalOrganic solventSilanes

The invention relates to a preparation method of fabric with flame-retardant and hydrophobic functions. The preparation method comprises the following steps: performing padding finishing of fabric by use of an aqueous solution containing polybasic carboxylic acid and a catalyst, and drying to obtain pretreated fabric; uniformly mixing siloxane, a cationic surfactant and a nonionic surfactant in water; adding a flame retardant, and adjusting the pH to 2-3 for reacting to obtain sol doped with the flame retardant; adding silicate ester into the sol for reacting; after the reaction, adding long-chain alkyl silane as a hydrophobic agent for further reacting to obtain flame-retardant hydrophobic finishing liquid; impregnating the pretreated fabric in the flame-retardant hydrophobic finishing liquid;, and performing rolling baking, washing and drying to obtain the fabric with flame-retardant and hydrophobic functions. The fabric finished by the method has relatively good flame retardance and hydrophobicity as well as resistance to repeated washing; and moreover, without using an organic solvent in the preparation process, the method is conducive to environmental protection.

Owner:郑州中科纺织科技有限公司

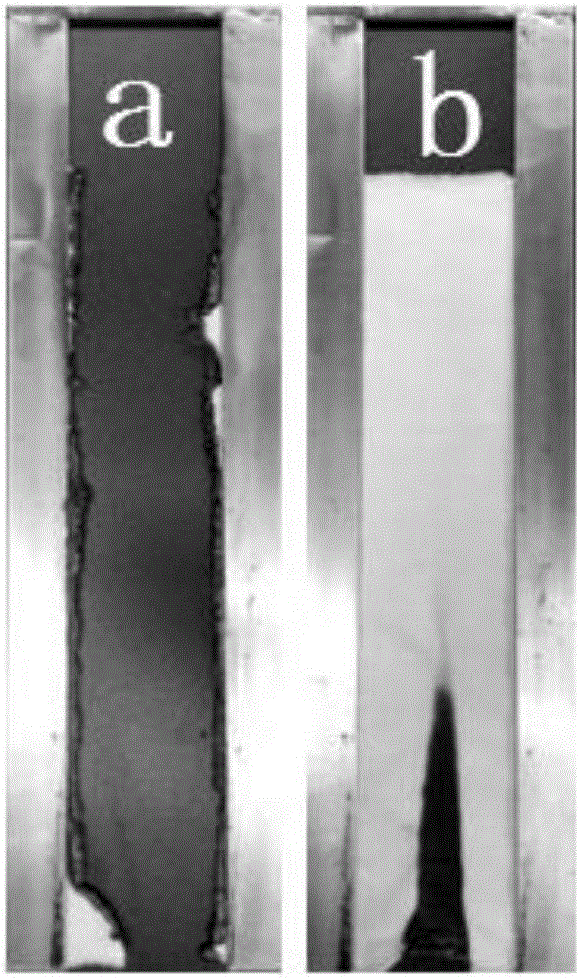

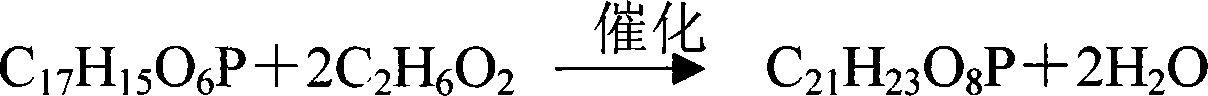

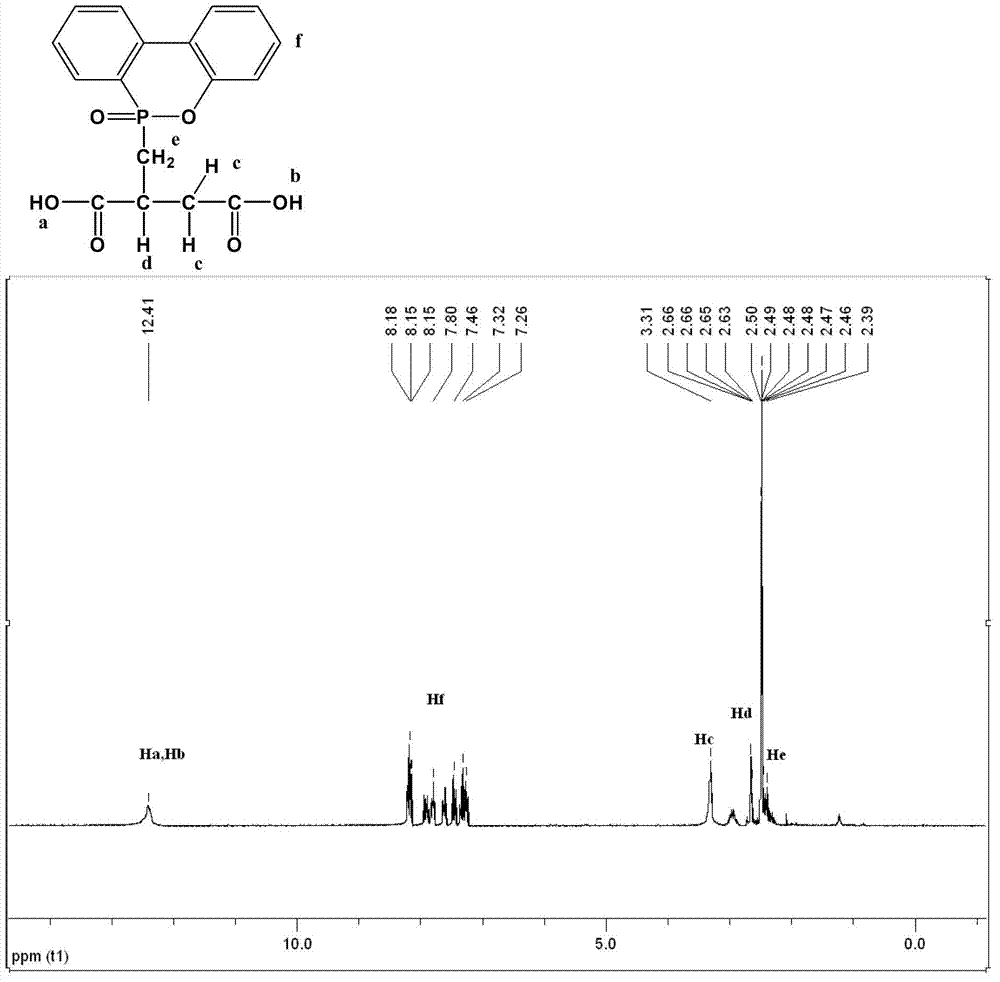

New type copolymerization type polyester in use for halogen free flame retardant

InactiveCN101092505AEasy to dyeHigh limiting oxygen indexFlame-proof filament manufactureMonocomponent polyesters artificial filamentOxideCombustion

This invention discloses a process for producing a novel halogen-free flame retardant for terylene. The flame retardant is produced by: mixing 9,10-dihydro-10 [2,3-di(hydroxycarbonyl)propyl]-10-phosphaphenanthrene-9-oxide and ethylene glycol, adding catalyst, stirring, heating, reducing pressure, and cooling. The flame retardant is yellowish liquid, and can be added into polycondensation reaction of p-terephthalic acid and ethylene glycol without any pretreatment. The flame retardant can effectively retard droplets during combustion.

Owner:郭明海

Flame-retardant modified asphalt and preparation method thereof

InactiveCN103013147AHigh limiting oxygen indexImprove the technical problem of flammabilityBuilding insulationsMolten stateAlcohol

The invention discloses flame-retardant modified asphalt and a preparation method thereof. The flame-retardant modified asphalt comprises the following components in parts by weight: 100 parts of base asphalt, 2-10 parts of vermiculite powder, 5-20 parts of aluminium hydroxide and / or magnesium hydrate, 0-5 parts of antismoke agent and 0-5 parts of coupling agent. The preparation method comprises the following steps of: mixing the vermiculite powder, the aluminium hydroxide and / or magnesium hydrate and the antismoke agent; diluting the coupling agent by using alcohol; soaking the flame-retardant mixture in a coupling agent diluent at a normal temperature and stirring; drying till the alcohol completely volatilizes, and then cooling; heating the base asphalt to a molten state, adding the flame-retardant mixture treated by the coupling agent, and uniformly stirring; and continuously heating, and shearing by a high-speed shear apparatus twice, and finally stirring and defoaming. The flame-retardant property of the road asphalt prepared by the preparation method can be increased, and the road asphalt has the pavement performance, smoke suppression performance, good stability and higher repeating utilization factor, and is non-toxic and non-corrosive; and the preparation method has the advantages of lower production cost, environment-friendly and pollution-free production, simple preparation technology, wide application and suitability for popularization.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Flame-retardant toughened polydicyclopentadiene composite material and preparation method thereof

The invention discloses a flame-retardant toughened polydicyclopentadiene composite material, which is prepared by blending and polymerizing the following main raw materials in parts by weight: 100 parts of dicyclopentadiene, 2-10 parts of halogenated polyolefin of which the halogen content is more than 40 percent by weight, 0.5-10 parts of antimonous oxide, 0-2 parts of an antioxidant and 0-2 parts of a pigment, wherein the halogenated polyolefin is chlorinated polyethylene, chlorinated polypropylene, chlorinated ethylene propylene diene monomer, chlorinated chloroprene rubber, chlorinated natural rubber, bromized polyethylene, bromized polypropylene, bromized ethylene propylene diene monomer or bromized natural rubber. In the flame-retardant toughened polydicyclopentadiene composite material disclosed by the invention, the halogenated polyolefin and the dicyclopentadiene are blended and polymerized, so that the toughness of the composite material can be improved, and the impact strength can be increased by over 25 percent; and moreover, the a halogen on the halogenated polyolefin can react with added antimonous oxide during combustion to generate SbX3 (X is a halogen) with a flame-retardant effect, so that the flame retardance of the composite material is enhanced greatly, and the limited oxygen index is increased by over 20 percent.

Owner:HENAN UNIV OF SCI & TECH

Halogen-free expanded flame retardant cable outer sheath material composition and preparation method thereof

InactiveCN103102579ALow priceLow costPlastic/resin/waxes insulatorsInsulated cablesAntioxidantMechanical property

The invention relates to a halogen-free expanded flame retardant cable outer sheath material composition and a preparation method thereof, and belongs to the technical field of cable material. The material is characterized by comprising an ethylene-vinyl acetate copolymer binder, an antioxidant, an ethylene vinyl acetate grafted maleic anhydride copolymer compatilizer, an antioxidant, an ammonium polyphosphate flame retardant, a pentaerythritol flame retardant, a release agent, and further comprising 1-3% of halloysite nanotubes and 1-2% of a silane coupling agent. The invention introduces halloysite nanotubes into the halogen-free expanded flame retardant ethylene-vinyl acetate cable sheath material to realize the purpose of flame retardant modification without affecting properties of the material, and at the same time to enhance the mechanical properties of the material. The invention has the advantages of simple process, easy operation and control, low cost of raw materials and wide range of sources; and the halogen-free expanded flame retardant cable sheath material prepared from the halogen-free expanded flame retardant cable outer sheath material composition provided by the invention has good mechanical and flame retardant properties.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC +1

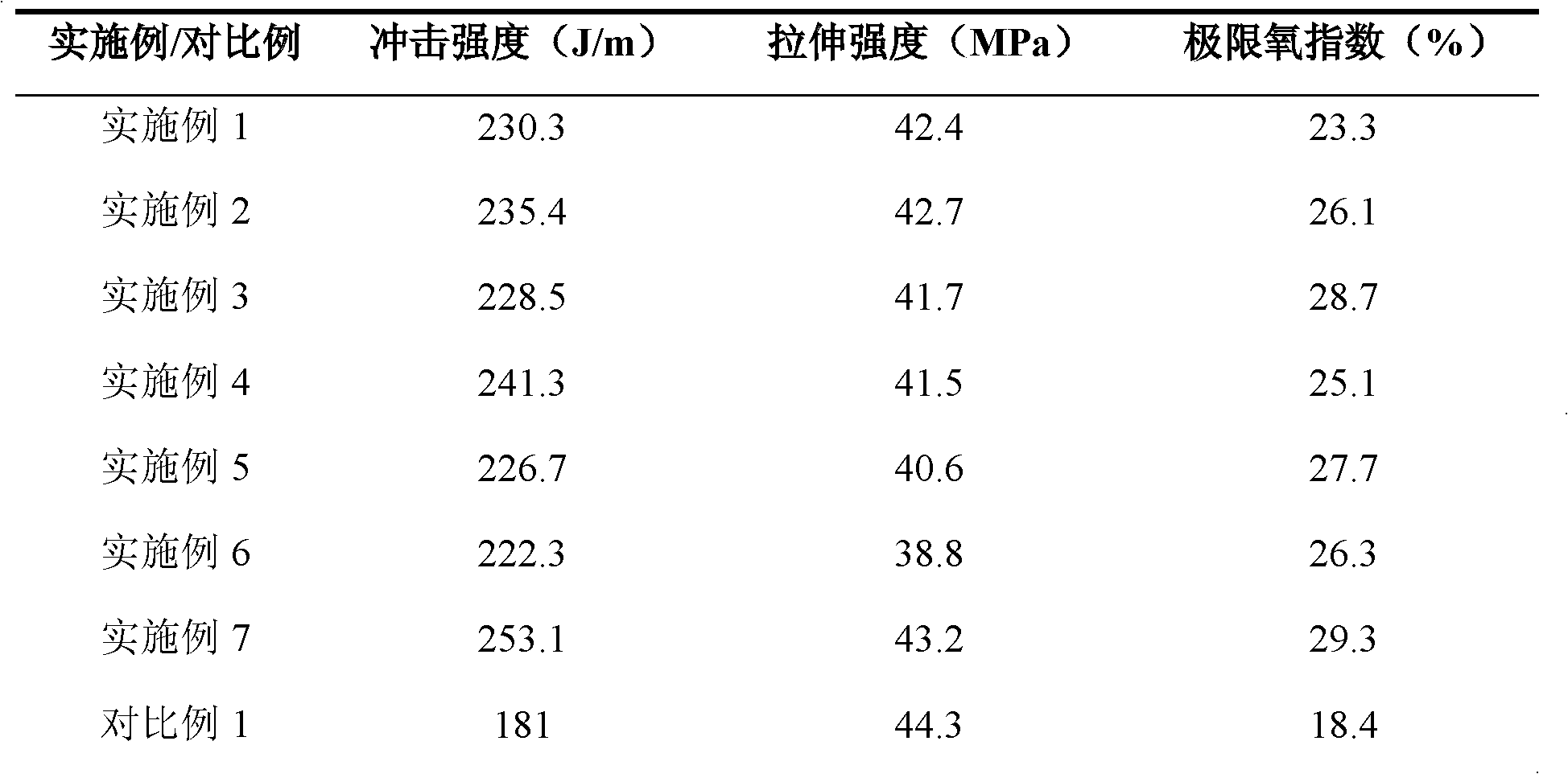

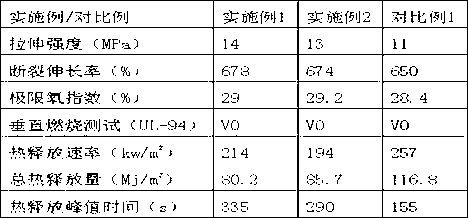

Nano-Mg-Al hydrotalcite fire-retardant EVA foaming material and preparation method thereof

InactiveCN105440420AImprove mechanical propertiesImprove flame retardant performanceCombustionFoaming agent

The present invention relates to a nano-Mg-Al hydrotalcite fire-retardant EVA foaming material comprising, by weight, 60-90 parts of an ethylene-vinyl acetate copolymer with 10-22wt% of VA, 2-10 parts of a foaming agent, 0.5-1 part of a foaming accelerator, 0.3-5 parts of a coupling agent, 0.5-1 part of a crosslinking agent, 10-50 parts of a flame retardant and 0.5-2 parts of a releasing agent, and the flame retardant is nano-Mg-Al hydrotalcite. Compared with traditional metal hydroxide flame retardants, the nano-Mg-Al hydrotalcite has great advantages in improvement of the limiting oxygen index, improvement of vertical combustion performances and reduction of heat release rate and other flame retardant aspects, and is better fire-retardant inhibitor. The present invention also provides a preparation method of the foaming material, and the method is simple to operate, the foaming process is not needed to be further modified or changed, production cost can be reduced, and energy can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

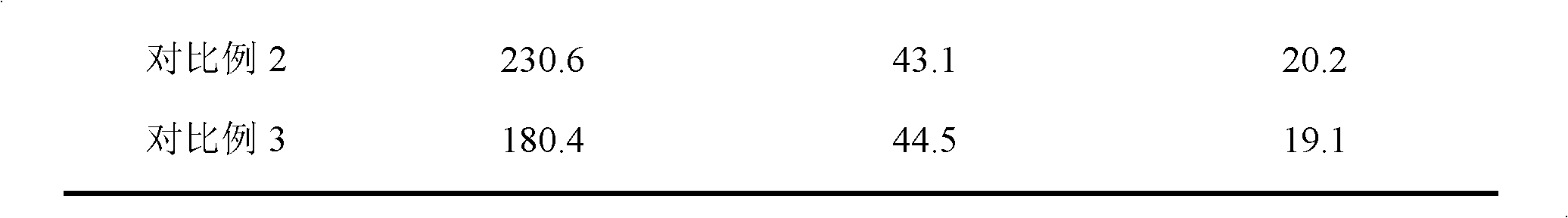

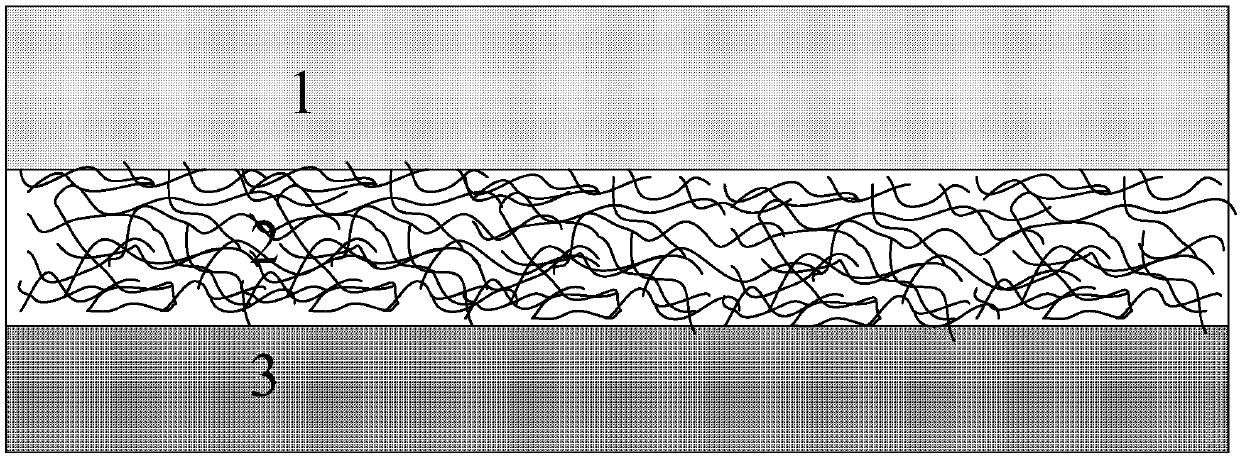

Environment-friendly anti-flaming fabric compound for motor vehicle interior and preparation method thereof

ActiveCN107553992AHigh limiting oxygen indexImprove flame retardant performanceFlame-proof filament manufactureLayered productsLow speedUltimate tensile strength

The invention discloses an environmentally friendly flame-retardant fabric compound for motor vehicle interior decoration and a preparation method thereof, comprising a motor vehicle interior environment-friendly flame-retardant fabric and a flame-retardant lining, the two are compounded by flame, flame-retardant glue or flame-retardant heat Melt-adhesive compounding achieves tight bonding. The environmentally friendly flame-retardant composite fabric for motor vehicle interiors has dry cloth surface, green environmental protection, low smoke and less toxicity, low VOC, low atomization value, no peculiar smell, soft hand feeling, excellent flame-retardant performance, high peel strength, good resilience, Good antistatic performance and other characteristics, can be widely used in seats, safety seats, ceilings, door panels, handrails, etc.

Owner:HANGZHOU XIANGJUN TEXTILE FLAME RETARDANT TECH

Preparation method for novel rubber strip for sealing of automobile doors and windows and product

The invention relates to a preparation method for a novel rubber strip for sealing of automobile doors and windows and a product. The preparation method employs ethylene propylene diene monomers as basic materials with cooperation of certain amounts of carbon black, calcium carbonate, paraffin oil, zinc oxide, stearic acid, polyvinyl alcohol, high-molecular wax, compound antioxidants, dispersants, compound accelerants, vulcanizing agents, fire retardants and the like. The above materials are subjected to mixing, open milling and vulcanization technologies to obtain the rubber strip. The preparation method has advantages of simple formula, simple production technology, short vulcanizing time, high production efficiency, relatively low production cost, easy industrialization enforcement and the like. The rubber product for sealing is advantaged by good sealing performance, uniform structure, resistance to corrosion, resistance to high and low temperature, flame resistance, environment protection and comfort.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

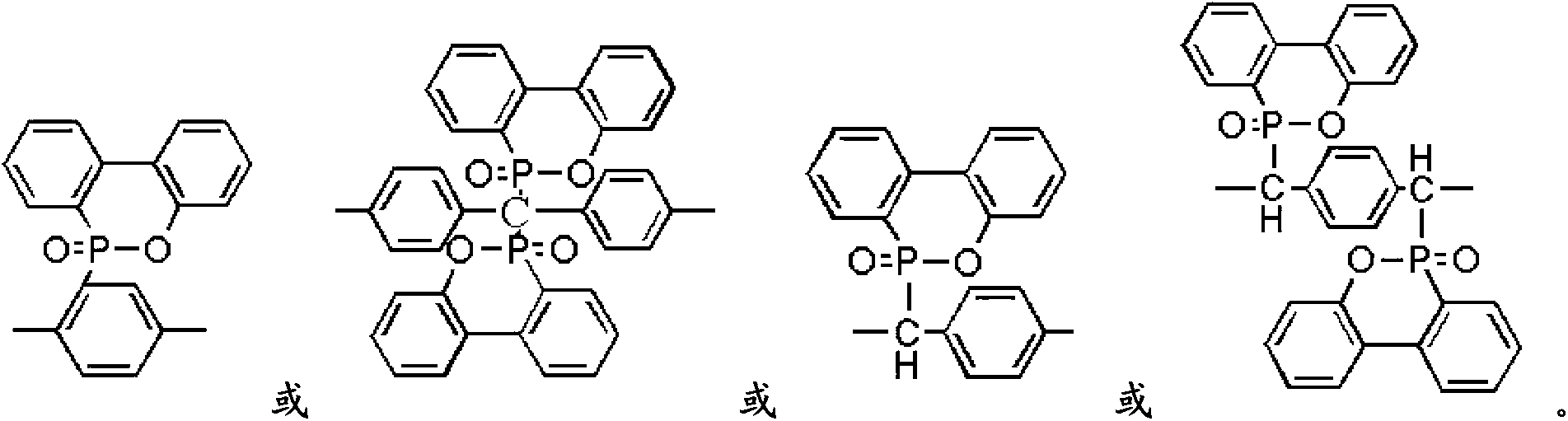

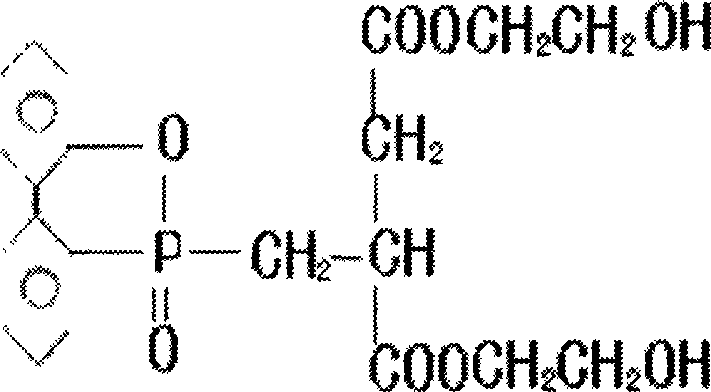

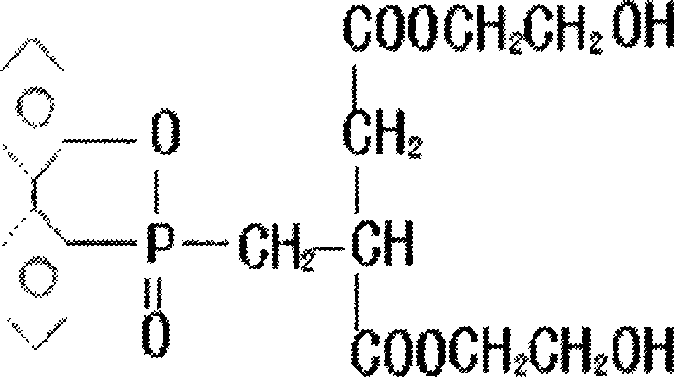

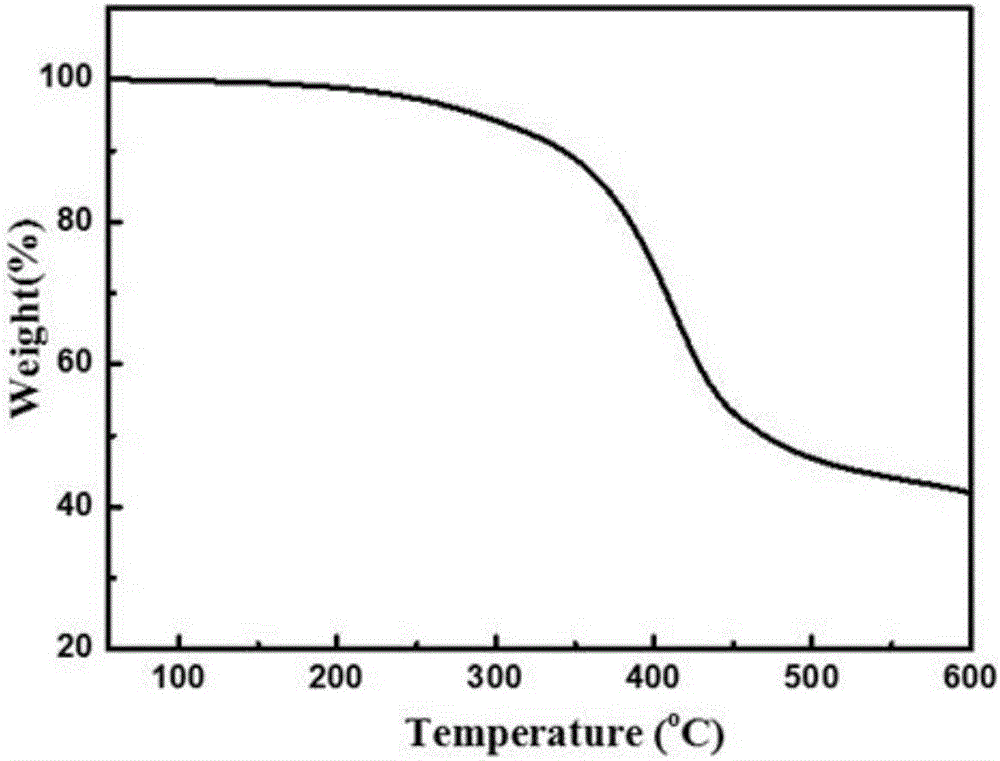

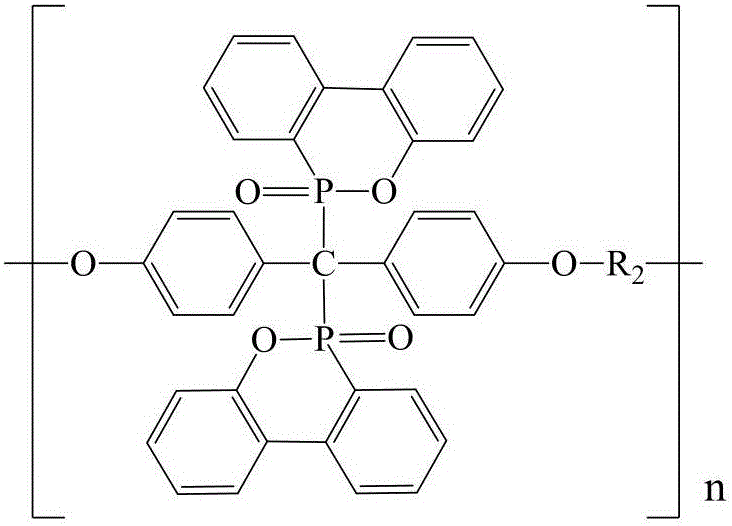

Preparation method for polyphosphoester fire retardant with dual-DOPO as branch chain

The invention belongs to the technical field of a phosphorus-containing fire retardant and specifically relates to a preparation method for a polyphosphoester fire retardant with dual-DOPO as a branch chain. The method comprises the following steps: under the protection of inert gases, reacting 4,4'-dyhydroxyl benzophenone with phenyldichlorophosphate, phenyl dichlorophosphate or pentaerythritol diphosphate diphosphoryl chloride in an anhydrous acetonitrile solvent till no halogen hydride gas is emitted, thereby acquiring a polymerized fire retardant midbody; performing heating for reaction on the midbody, initiator and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide at the temperature of 130-160 DEG C; and performing melt grafting reaction, reducing the reaction temperature to 50-70 DEG C, adding ethyl alcohol, stirring and flowing back, performing suction filtration and drying, thereby acquiring the fire retardant. According to the invention, the difficulty of the traditional process that a highly polymerized fire retardant cannot be acquired under the effect of larger steric hindrance in the process of polymerizing after compounding micro-molecule midbody can be overcome; the compounded fire retardant has higher molecular weight and narrower molecular weight distribution; and the compounded fire retardant has excellent compatibility with substance, is difficult to migrate and has excellent durability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

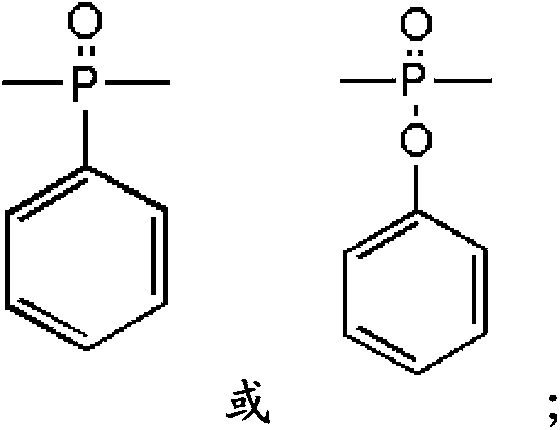

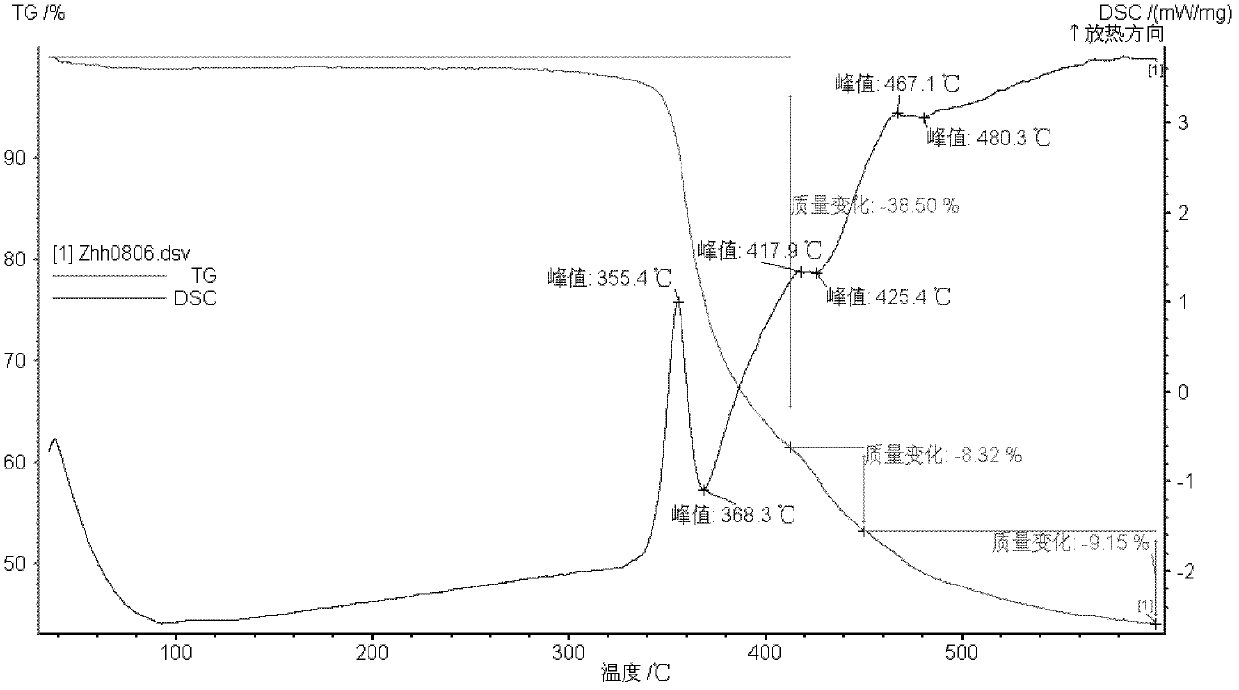

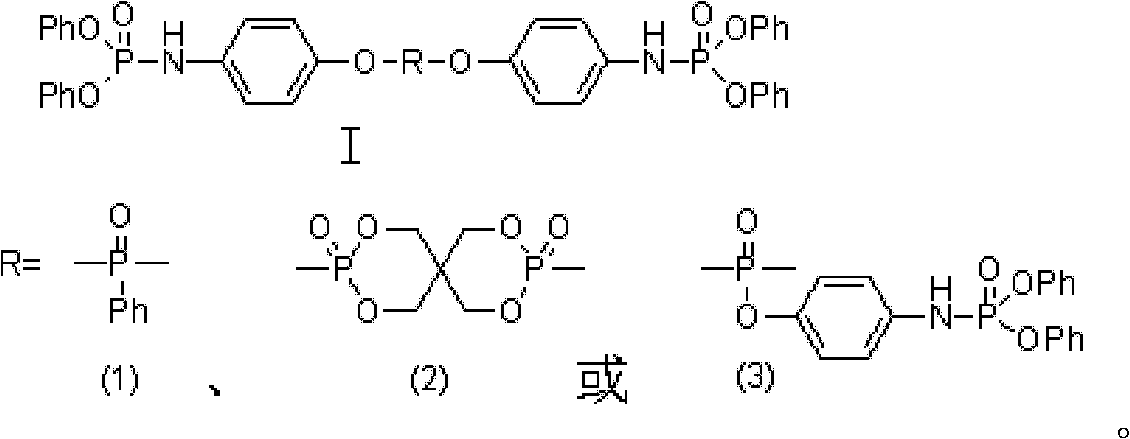

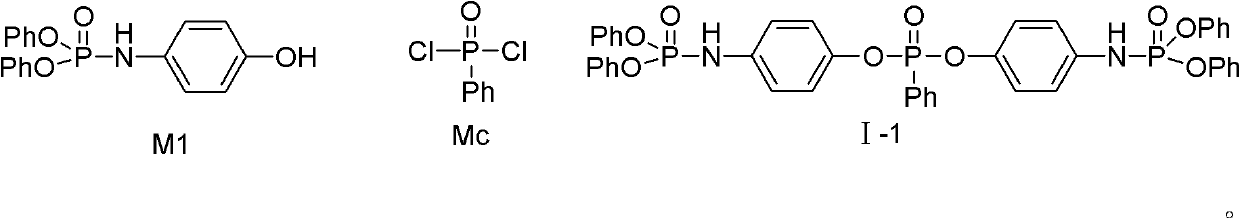

Phosphamide compound with flame retardance and preparation method and application thereof to epoxy resin

ActiveCN102503979AFew stepsSimple and fast operationGroup 5/15 element organic compoundsEpoxyBULK ACTIVE INGREDIENT

The invention discloses a phosphamide compound with flame retardance and a preparation method and application thereof to epoxy resin. The phosphamide compound is the O, O'-diphenyl phosphamide ester derivative which has the general formula I, contains two flame retardant elements which are phosphorus and nitrogen and can generate the intramolecular synergistic flame retardance effect. The phosphamide compound can be used as the active ingredients of the flame retardant, can be added into epoxy resin as the flame retardant to produce the flame-retardant epoxy resin material and can be also compounded with melamine (MA) so as to be applied to the epoxy resin material. The phosphamide compound can significantly improve the flame retarding function of the epoxy resin material.

Owner:HUAZHONG NORMAL UNIV

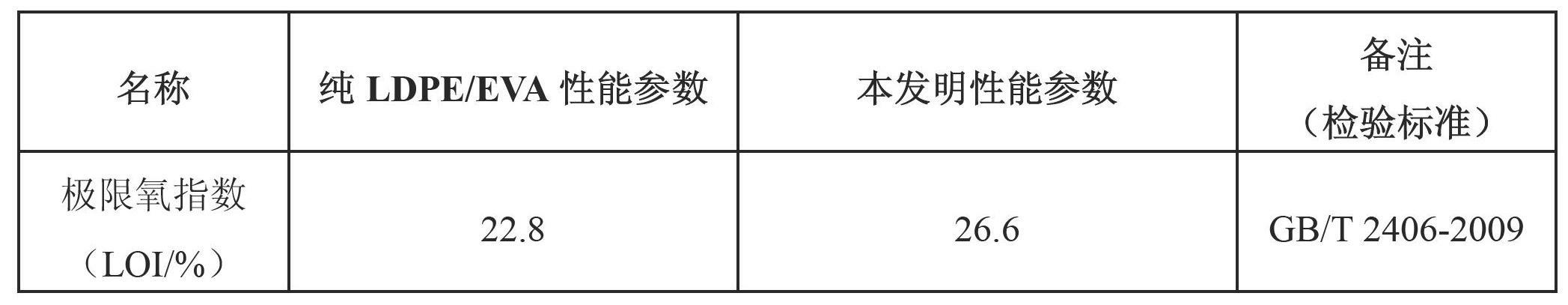

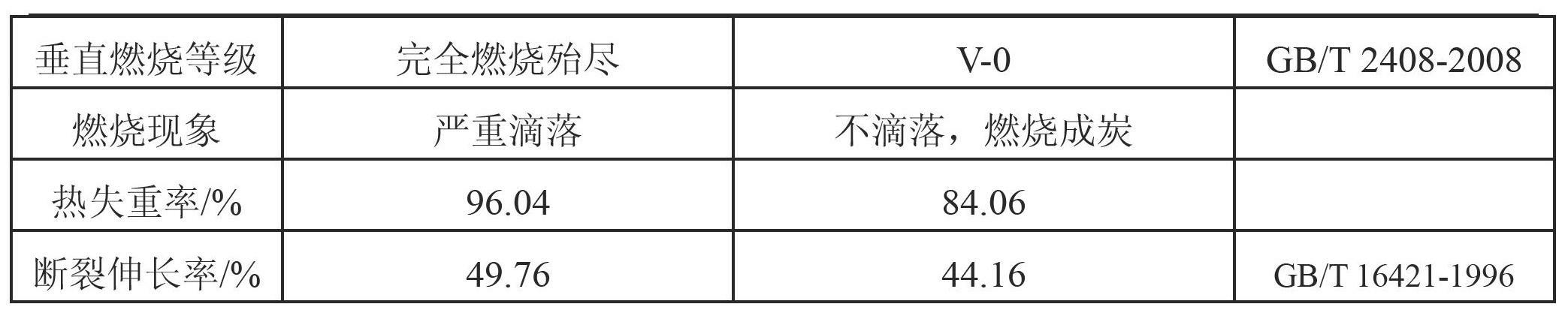

LDPE (Low-Density Polyethylene)/EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material and preparation method thereof

ActiveCN102643469ARaw materials are easy to getAbundant resourcesLow-density polyethyleneZinc borate

The invention relates to an LDPE (Low-Density Polyethylene) / EVA (Ethylene Vinyl Acetate Copolymer) anti-flaming material. The LDPE / EVA anti-flaming material comprises the following raw material compositions by weight parts: A is base resin and includes 100 parts of LDPE and EVA; B is bromine containing flame retardant and includes 10-20 parts of decabromodiphenyl ethane or decabromodiphenyl ether, C is inorganic flame retardant and includes 3-6 parts of modified antimonous oxide M-Sb2O3, 3-6 parts of talcum powder TP, 2-8 parts of zinc borate (ZB) and 2-8 parts of hydrotalcite (LDHs). The preparation method of the LDPE / EVA anti-flaming material is as follows: drying raw materials, mixing the raw materials uniformly, processing, extruding, and conducting injection molding on the raw materials to obtain the extruded anti-flaming composite material. According to the anti-flaming material and the preparation method, the advantages of the organic flame retardant, the bromine containing flame retardant and the inorganic flame retardant are combined, the using amount of the inorganic flame retardant is decreased, the limit oxygen index of the anti-flaming composite material is increased, the materials are burned into carbon directly when being burned, the dropping phenomenon can not occur, and the toxic and harmful gas can not be generated.

Owner:广西华锑科技有限公司

Method for preparing polyimide fiber

ActiveCN101338462BHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberImide

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, themooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of nylon/montmorillonoid fire retarding composite material

This invention provides a preparation of a nylon / montmorillonite flame retardant composite. First silicone oil is added in solvent and stirred to be uniformity, then montmorillonite is used for reshaping, then the silicone oil is used for the reshaping of organic and montmorillonite nylon, at last, the mixture of flame retardant is putted into Co-Rotating Twin Screw Extruder for extruding and palletizing. Nylon, organic montmorillonite, silicone oil and flame retardant can also be pre-mixed directly, and then the mixture is putted into Co-Rotating Twin Screw Extruder for extruding and palletizing. The emargination impact strength of this composite is improved, and the limit oxygen index is improved by great extent.

Owner:SICHUAN UNIV

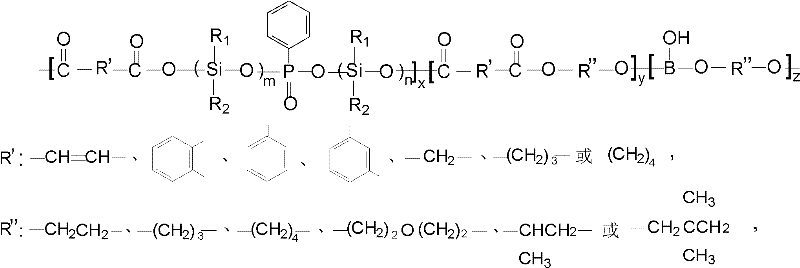

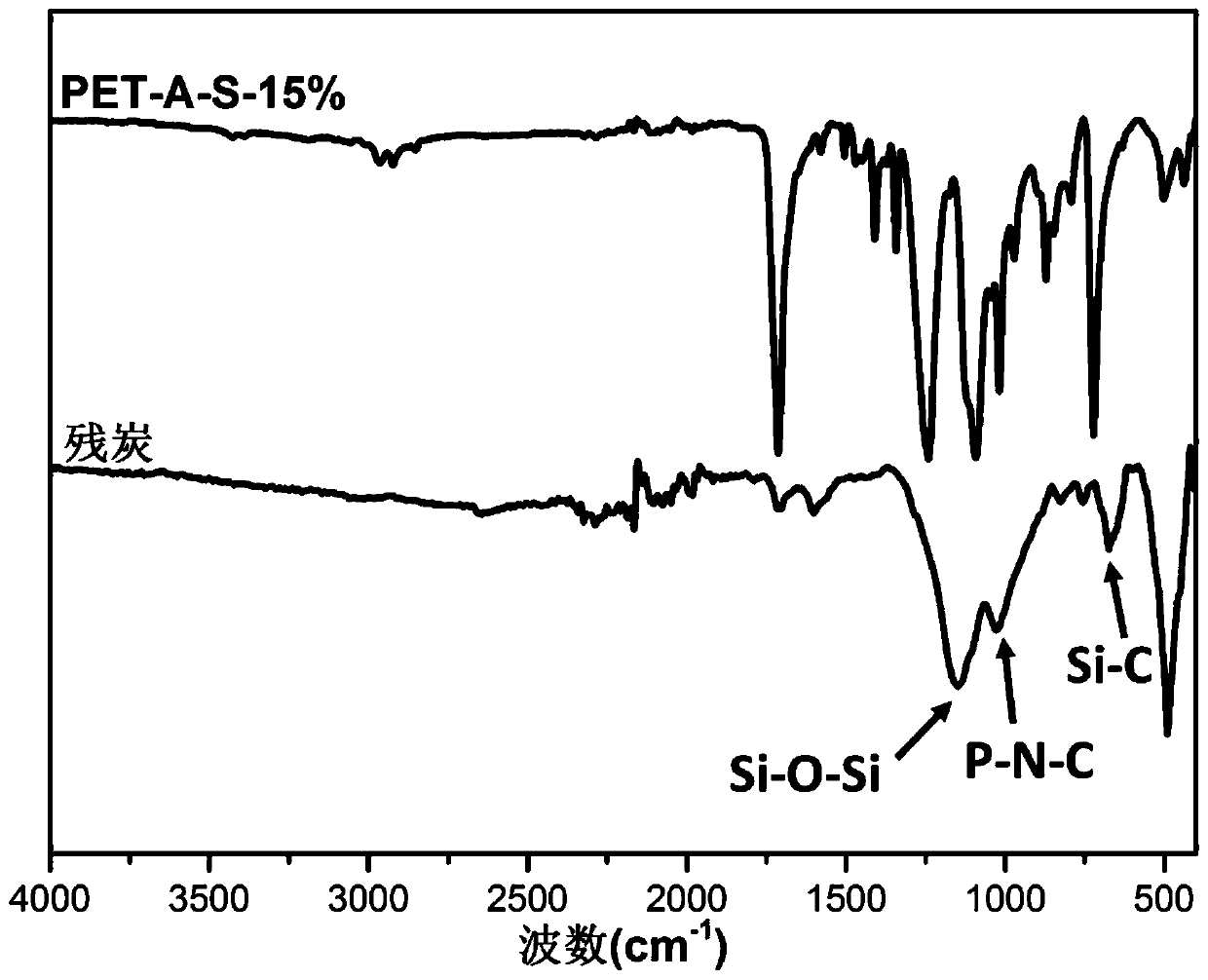

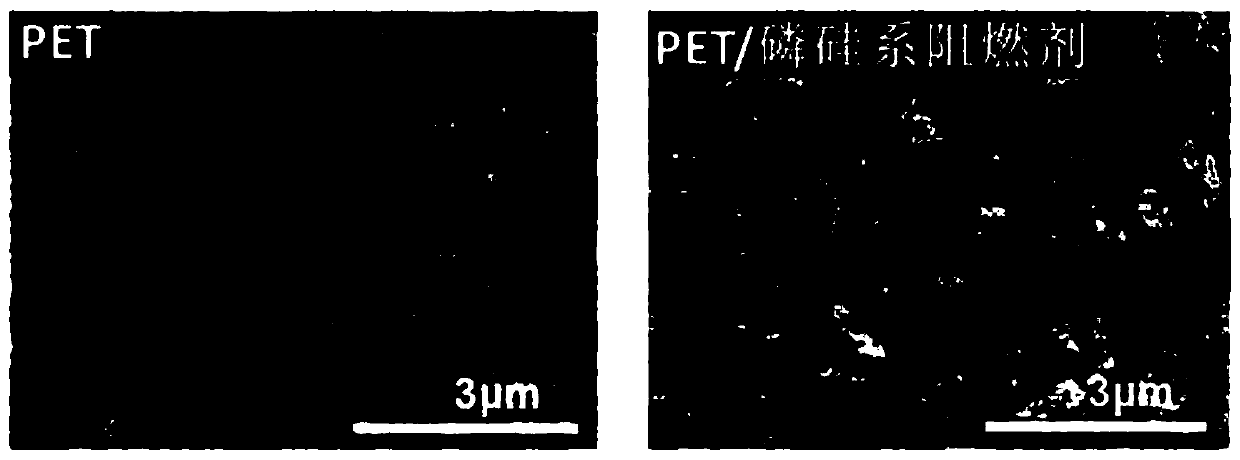

Preparation method for flame-retardant anti-dripping polyester fiber

InactiveCN110592709AImprove thermal stabilityImprove charcoal abilityFlame-proof filament manufactureMelt spinning methodsPolyesterFiber

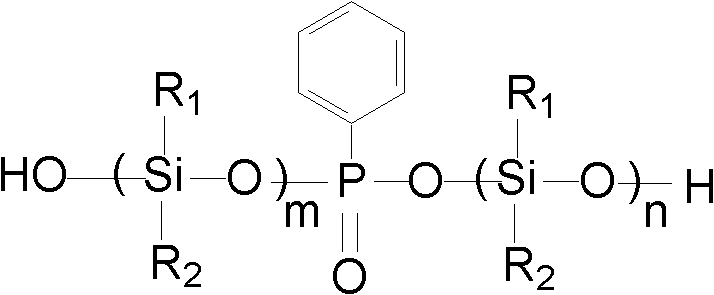

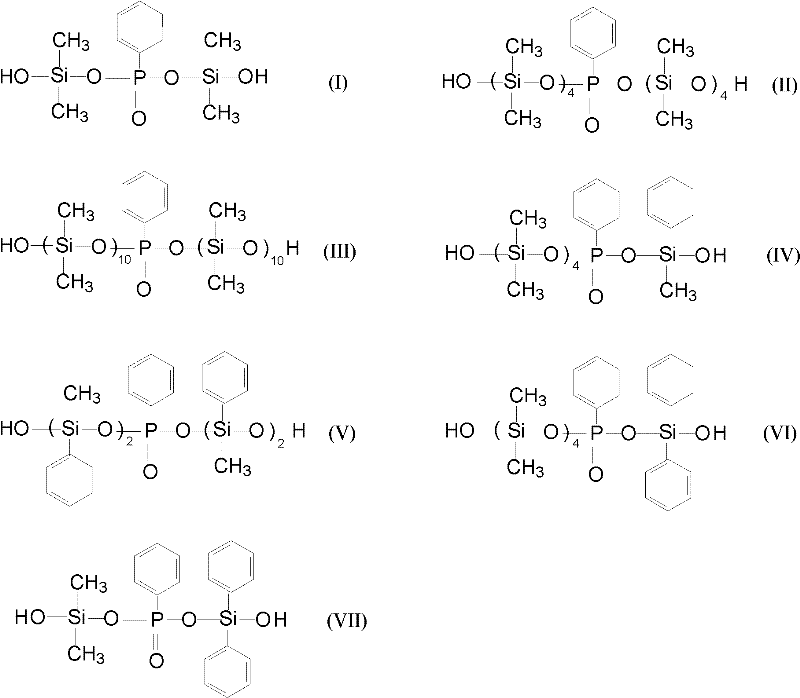

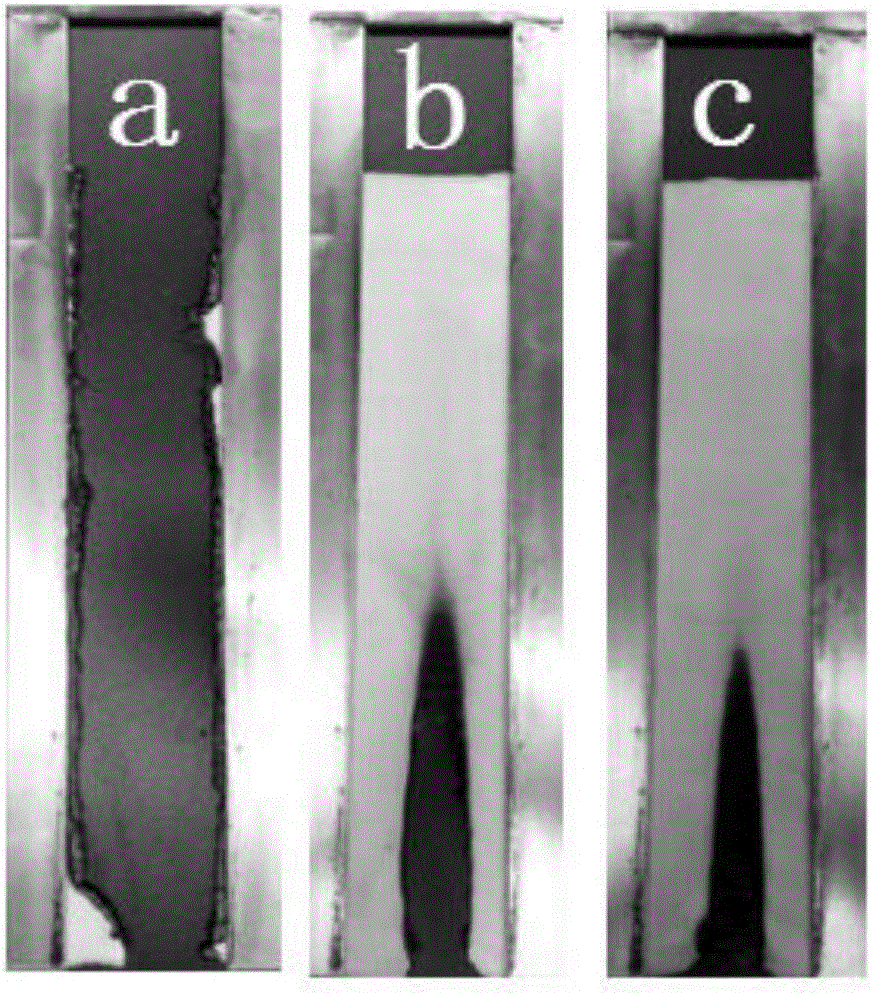

The invention discloses a preparation method for a flame-retardant anti-dripping polyester fiber. The preparation method is characterized in that polyester chips are dried until the water content is lower than 100 ppm, a phosphorus and silicon-based flame retardant is added to the polyester chips, the mixture of the phosphorus and silicon-based flame retardant and the polyester chips is fed into adouble-screw extruder for melt blending, an extruded melt is granulated by using a granulator, and phosphorus and silicon-based flame retardant modified flame-retardant anti-dripping polyester masterbatch is obtained; the masterbatch is evenly mixed with the polyester chips, the mixture of the masterbatch and the polyester chips is dried until the water content is lower than 100 ppm, and then subjected to melt blending through the double-screw extruder, the melt enters a spinning box, is jetted through spinneret orifices and then enters a spinning channel, and after air cooling, bundling, oiling, drafting, hot setting and winding, the flame-retardant anti-dripping polyester fiber is prepared. The flame-retardant anti-dripping polyester fiber prepared by using the preparation method has excellent flame resistance, the LOI value can reach 34.1%, there is no melt dripping phenomenon during burning, and compared with a pure polyester fiber, the heat release rate and the total heat releaseare greatly reduced.

Owner:DONGHUA UNIV

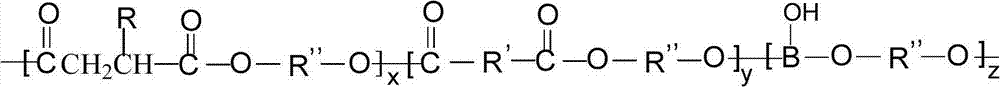

Ultraviolet-cured transparent halogen-free flame-retardant unsaturated polyester and preparation method thereof

The invention discloses an ultraviolet-cured transparent halogen-free flame-retardant unsaturated polyester and preparation method thereof. A raw material formula comprises the following raw materials in percentage by mass: 49.5-65 percent of a phosphorus-boron flame-retardant unsaturated polyester prepolymer, 50-30 percent of an active diluent, 0.4-4.5 percent of a photoinitiator and 0.1-0.5 percent of a polymerization inhibitor, wherein the phosphorus-boron flame-retardant unsaturated polyester prepolymer is prepared by reacting dibasic alcohol, unsaturated dibasic anhydride and / or unsaturated dicarboxylic acid, a phosphaphenanthrene anhydride derivative and boric acid at the temperature of 150-205 DEG C. The volatilization loss rate in the curing process of unsaturated polyester is less than 1 percent, the appearance is transparent before curing and after curing, and vertical combustion passes through a grade UL94 V-0; and the ultraviolet-cured transparent halogen-free flame-retardant unsaturated polyester has the advantages of low volatilization loss, freeness from halogen, flame retardance, transparence and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of polyester for highlight flame-retardant polyester thin film

The invention discloses a preparation method of polyester for a highlight flame-retardant polyester thin film, and the highlight flame-retardant polyester thin film prepared by using polyester. Polyester for the highlight flame-retardant polyester thin film is prepared by selecting and adding appropriate flame retardants and additives in the polymerization process of synthesizing polyester by virtue of direct esterification of PTA (purified terephthalic acid). Polyester can be added as a master batch, or can be directly used for preparing thin films without adding other anti-binding agents; compared with a conventional similar polyester thin film, the thin film prepared from polyester disclosed by the invention has relatively low haze and relatively good flame retardant properties and anti-binding properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

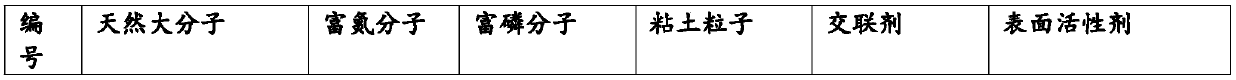

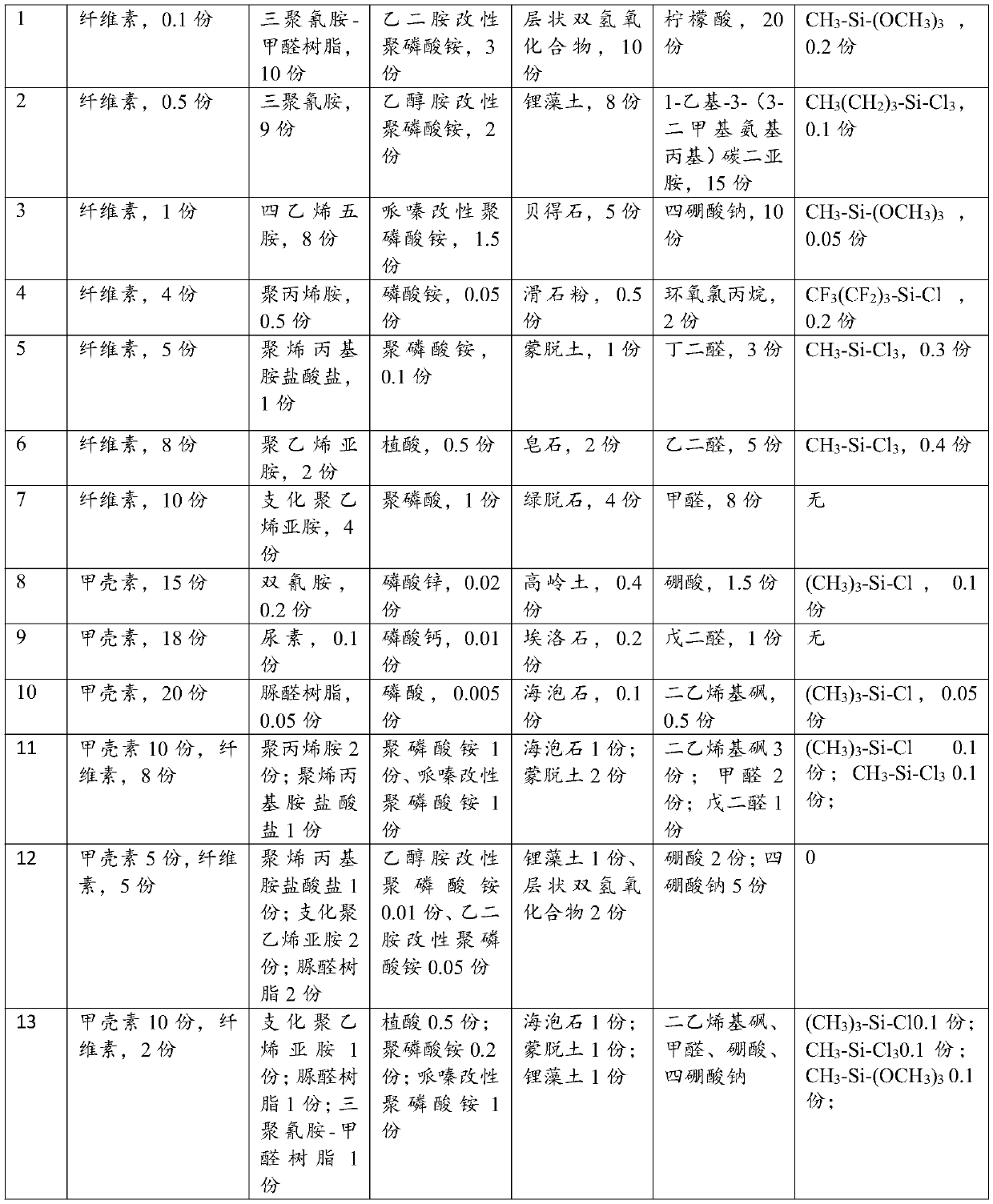

Nonflammable aerogel and preparation method and application thereof

InactiveCN109553799AImprove flame retardant performanceLow thermal conductivityCoatingsNitrogenLow density

The invention provides nonflammable aerogel and a preparation method and application thereof. The aerogel comprises the following raw materials: in parts by mass, 0.1-20 parts of natural macromolecules, 0.05-10 parts of nitrogen-rich molecules, 0.005-5 parts of phosphorus-rich molecules, 0.1-10 parts of clay particles, 0.5-20 parts of a crosslinking agent and 0-0.4 part of a surface modifier. Thenonflammable aerogel prepared by using the method has the advantages of high flame retardancy, low thermal conductivity, low density, high strength and the like, and can be applied to the fields of building insulation, sound absorption and carbon dioxide capture.

Owner:XIHUA UNIV

Graphene hybrid particle flame-retardant agent and preparation method and application thereof

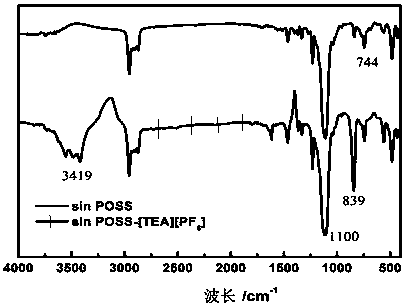

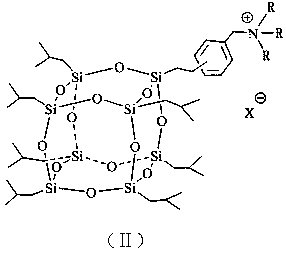

The invention discloses a graphene hybrid particle flame-retardant agent and a preparation method and application thereof. The preparation method comprises the following steps of enabling active POSS(polyhedral oligomeric silsesquioxane) and N-alkylamine to react, so as to realize ionizing; performing ion exchange reaction, so as to prepare a POSS-based quaternary ammonium salt ion liquid; enabling the POSS-based quaternary ammonium salt ion liquid to mutually react with phi-phi and phi-cations of graphene, so as to obtain the graphene hybrid particle flame-retardant agent. The prepared graphene hybrid particle flame-retardant agent is a halogen-free environment-friendly flame-retardant agent, and has the advantages that POSS, the ion liquid and graphene have different flame-retardant elements and mechanisms, and can generate the synergistic action; by adding 5% of synthesized flame-retardant agent, the limit oxygen index of PS (polystyrene) is increased to 26.5%; by adding 5% of synthesized flame-retardant agent, the limit oxygen index of PP (polypropylene) is increased to 25.9%; the effect is obviously better than the effect of organosilicone flame-retardant agent on market; thegraphene hybrid particle flame-retardant agent can be used as an additive to be applied into a polyolefin type polymer flame-retardant agent, the operation is simple and convenient, and the control is easy.

Owner:TAIZHOU UNIV

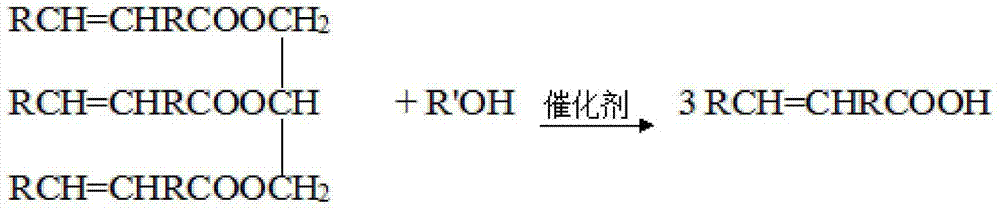

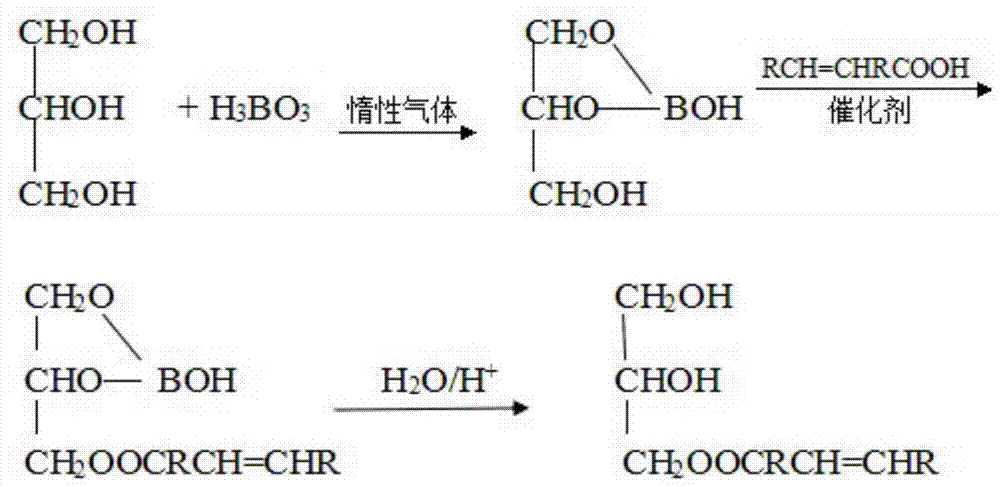

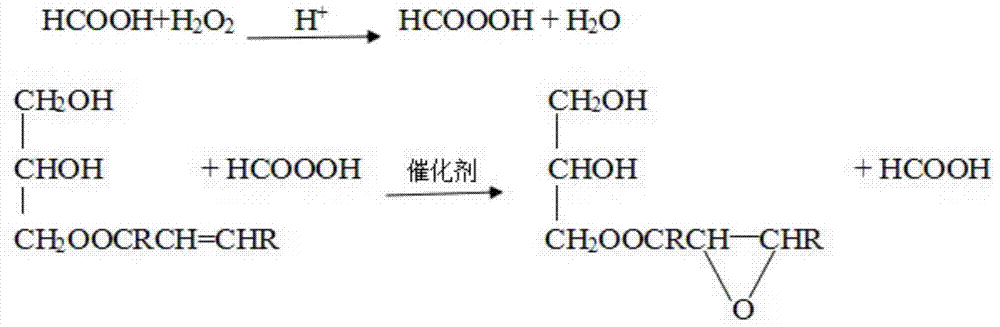

Inflaming retarding bio-based polyhydric alcohol and preparation method thereof

ActiveCN104231199AGood compatibilityImprove adhesionGroup 4/14 element organic compoundsOrganic compound preparationChemical synthesisEpoxy

The invention belongs to the field of chemical synthesis and particularly relates to a preparation method of inflaming retarding bio-based polyhydric alcohol. The preparation method includes the following steps: enabling tung oil to have saponification reaction in a solvent to generate eleostearic acid, conducting esterification on glycerin and boric acid to generate boric acid diglyceride, then enabling the boric acid diglyceride and the eleostearic acid to have esterification reaction to generate tung oil acid boric acid glyceride, then hydrolyzing the tung oil acid boric acid glyceride to generate eleostearic acid monoglyceride, then adding an epoxidizing agent into the eleostearic acid monoglyceride to conduct epoxidation reaction to generate epoxy tung oil acid ester, meanwhile utilizing a silane coupling agent to modify expansible graphite, and finally enabling the epoxy eleostearic acid ester to react with a ring opening agent. The bio-based polyhydric alcohol obtained through the method can replace petrochemical polyether polyhydric alcohol to prepare polyurethane foaming plastic, and dependence on petrochemical products is reduced.

Owner:PANZHIHUA UNIV

Graphene and nylon flame-retardant fibers and preparation method thereof

InactiveCN108149337ALow viscosityImprove liquidityFlame-proof filament manufactureMonocomponent polyesters artificial filamentMelt spinningLimiting oxygen index

The invention provides graphene and nylon flame-retardant fibers. The graphene content of the fibers is 3.5-4.5% and the limiting oxygen index is 35.5-36%. The invention also provides a preparation method of the graphene and nylon flame-retardant fibers. The preparation method comprises the following steps: preparing a silicon dioxide-graphene compound porous material, preparing a graphene dispersed suspension, preparing flame-retardant functional master batch, and performing melt spinning, cooling, forming, drawing, coiling and thermoforming. The preparation method overcomes the influence ofthe added graphene on the viscosity and liquidity of the nylon master batch, reduces the viscosity of the molten nylon master batch and improves the liquidity of the molten nylon master batch. The graphene and nylon fibers prepared the preparation method is characterized in that the graphene content is 3.5-4.5%, the dry breaking strength is 60-65N / tex, the breaking elongation is 18-24%, the Youngmodulus is 2.3-2.8Gpa, and the limiting oxygen index is as high as 35.5-36%.

Owner:余姚帕吉索新材料科技有限公司

Method for manufacturing phosphorus flame-retardant polyester

InactiveCN101671434ALess flame retardant addedHigh limiting oxygen indexMonocomponent copolyesters artificial filamentPolyesterFire retardant

The invention relates to a method for manufacturing a phosphorus flame-retardant polyester slice, which mainly comprises the following three steps: (1) reacting hydroxymethyl phenyl hypophosphorous acid (HMPPA) with ethylene glycol (EG) to generate HMPPA esterified liquid; (2) pre-esterifying phthalic acid (PTA) and EG; and (3) adding the HMPPA esterified liquid manufactured in the first step intothe esterified liquid manufactured in the second step, adding a catalyst into the mixed esterified liquid, and carrying out a conventional condensation polymerization process to form the flame-retardant polyester slice. Fibers and textiles made of the flame-retardant polyester slice manufactured by the method have good flame-retardant stability, the adding amount of the flame retardant is little,the content of phosphorus is low, and the limiting oxygen index (LOI) is high.

Owner:王忠卫

Environment-friendly type flame-proof asphalt mastic stone mixture for tunnel

The invention discloses an environment friendly type tunnel flame-proof pitch water chestnut ether broken stone mixed material, which comprises the following steps: counting with the total weight proportion of the pitch mixed material as 0. 3%-0. 5% mineral fiber, 1. 0%-1. 2% organic fire retardant, 5. 5%-6. 0% pitch, 92. 3-93. 2% broken stone; choosing the mineral fiber with the density not less than 2. 5g / cm3 and strength for extension as 3500MPa; choosing the elastic modulus of the mineral fiber as 85GPa, percentage of breaking elongation as 2. 5%, the highest working temperature at 500 deg. c and the length more than 6mm; choosing the organic fire retardant with the density at 1. 2-2. 0g / cm3 and the effective content not less than 70%; setting the fusion temperature of the organic fire retardant not less than 120 deg. c, the moisture percentage less than 5% and the fire point not less than 260 deg. c. This mixed material can prevent burning of tunnel pitch water chestnut ether broken stone mixed material (SMA) pavement effectively, which possesses environmental protection function.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com