Flame-retardant toughened polydicyclopentadiene composite material and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene, which is applied in the field of preparation of the composite material, can solve the problems of degraded material and product performance, reduced catalytic activity, limited application range, etc., and achieves improved impact strength and limiting oxygen index. The effect of improving and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

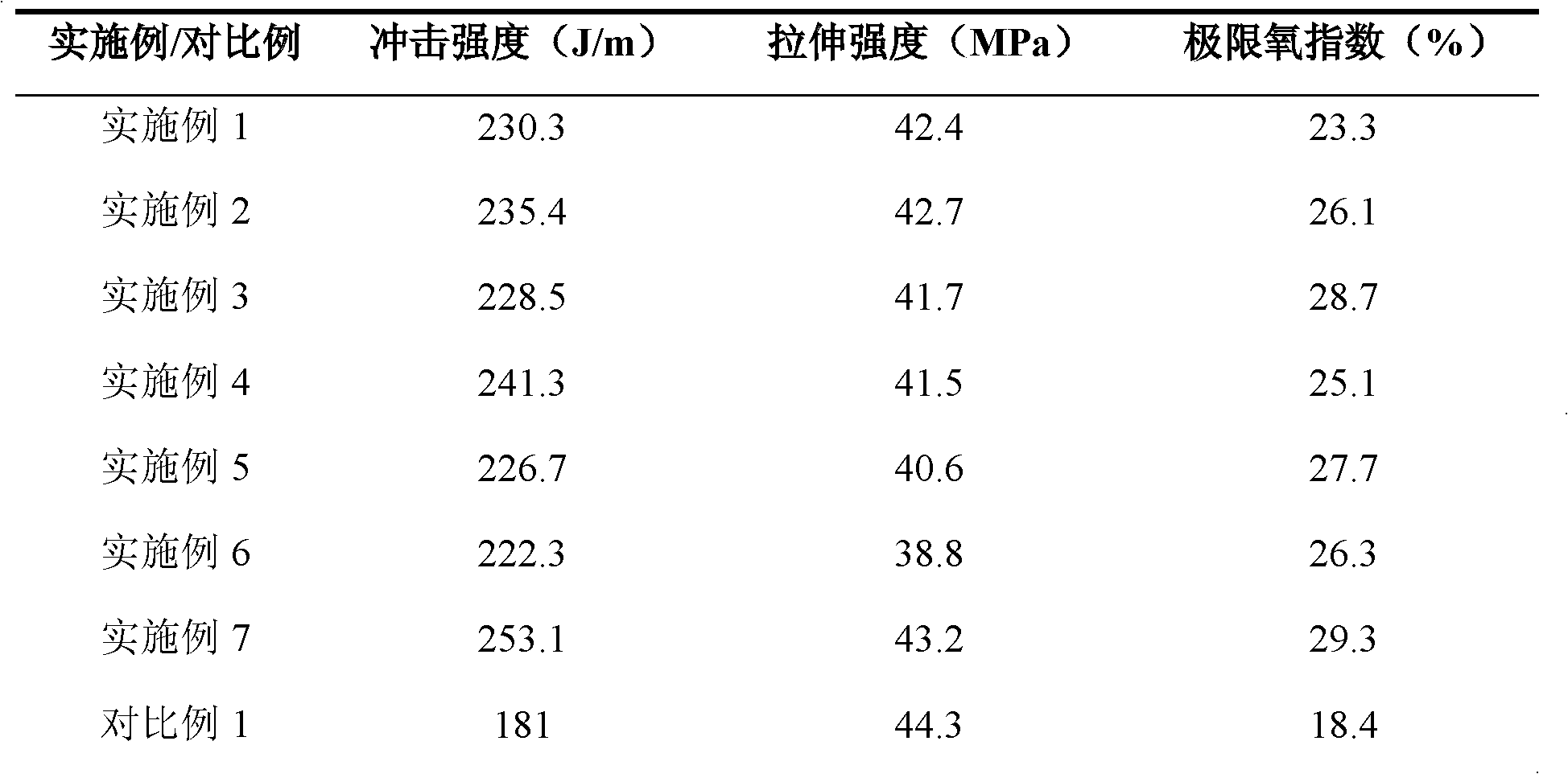

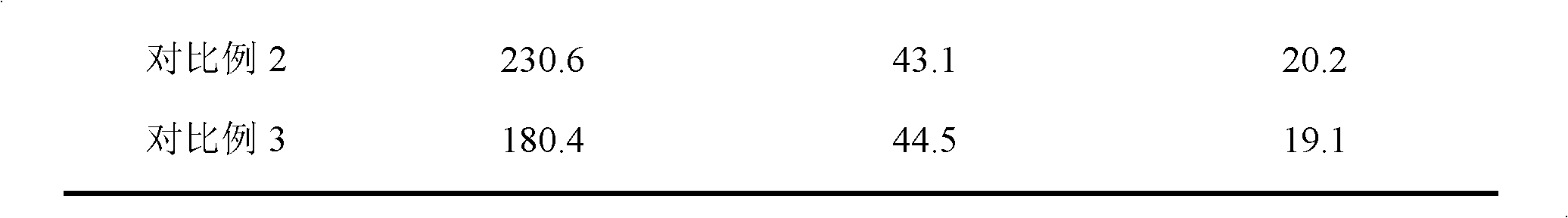

Examples

Embodiment 1

[0020] The flame-retardant and toughened polydicyclopentadiene composite material of this embodiment is obtained by blending and polymerizing the following main raw materials in the following weight percentages: 100 parts of dicyclopentadiene, number average molecular weight of 200,000, chlorine content 2 parts of 50wt% chlorinated polypropylene and 2 parts of antimony trioxide powder with an average particle size of 20 microns.

[0021] The flame-retardant and toughened polydicyclopentadiene composite material of this embodiment is prepared by the following method:

[0022] Under nitrogen protection, add 2 parts of chlorinated polypropylene with a molecular weight of 100,000 and 50% chlorine to 100 parts of dicyclopentadiene at 70°C, stir and dissolve, and then add 2 parts of dioxytrioxide with an average particle size of 20 microns. Antimony powder, after mixing evenly, is divided into two parts A and B and added to the storage tanks of RIM machine A and B respectively; in A...

Embodiment 2

[0024] The flame-retardant and toughened polydicyclopentadiene composite material of this embodiment is obtained by blending and polymerizing the following main raw materials in the following weight percentages: 100 parts of dicyclopentadiene, a number-average molecular weight of 150,000, and a bromine content. 3 parts of 60wt% brominated polypropylene and 0.5 part of antimony trioxide powder with an average particle size of 20 microns.

[0025] The flame-retardant and toughened polydicyclopentadiene composite material of this embodiment is prepared by the following method:

[0026] Under nitrogen protection, add 3 parts of brominated polypropylene with a molecular weight of 150,000 and 60% bromine to 100 parts of dicyclopentadiene at 75°C, stir and dissolve, and then add 0.5 part of dioxytrioxide with an average particle size of 20 microns. Antimony powder, after mixing evenly, is divided into two parts A and B, respectively, and added to the storage tanks of RIM machine A an...

Embodiment 3

[0028] The flame retardant and toughened polydicyclopentadiene composite material of this embodiment is obtained by blending and polymerizing the following main raw materials in the following weight percentages: 100 parts of dicyclopentadiene, a number average molecular weight of 150,000, a chlorine content 5 parts of 40wt% chlorinated polyethylene and 3 parts of antimony trioxide powder with an average particle size of 10 microns.

[0029] The flame-retardant and toughened polydicyclopentadiene composite material of this embodiment is prepared by the following method:

[0030] Under nitrogen protection, add 5 parts of chlorinated polyethylene with a molecular weight of 150,000 and 40% chlorine to 100 parts of dicyclopentadiene at 80°C, stir and dissolve, and then add 3 parts of dioxytrioxide with an average particle size of 10 microns. Antimony powder, after mixing evenly, is divided into two parts A and B, respectively, and added to the storage tanks of A and B of the RIM ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com