Method for preparing polyimide fiber

A polyimide fiber and polyimide technology, applied in the field of polyimide fiber preparation, can solve the problems of inaccurate temperature control, unfavorable operation, etc., to overcome inaccurate temperature control, high limit oxygen index, Ease of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

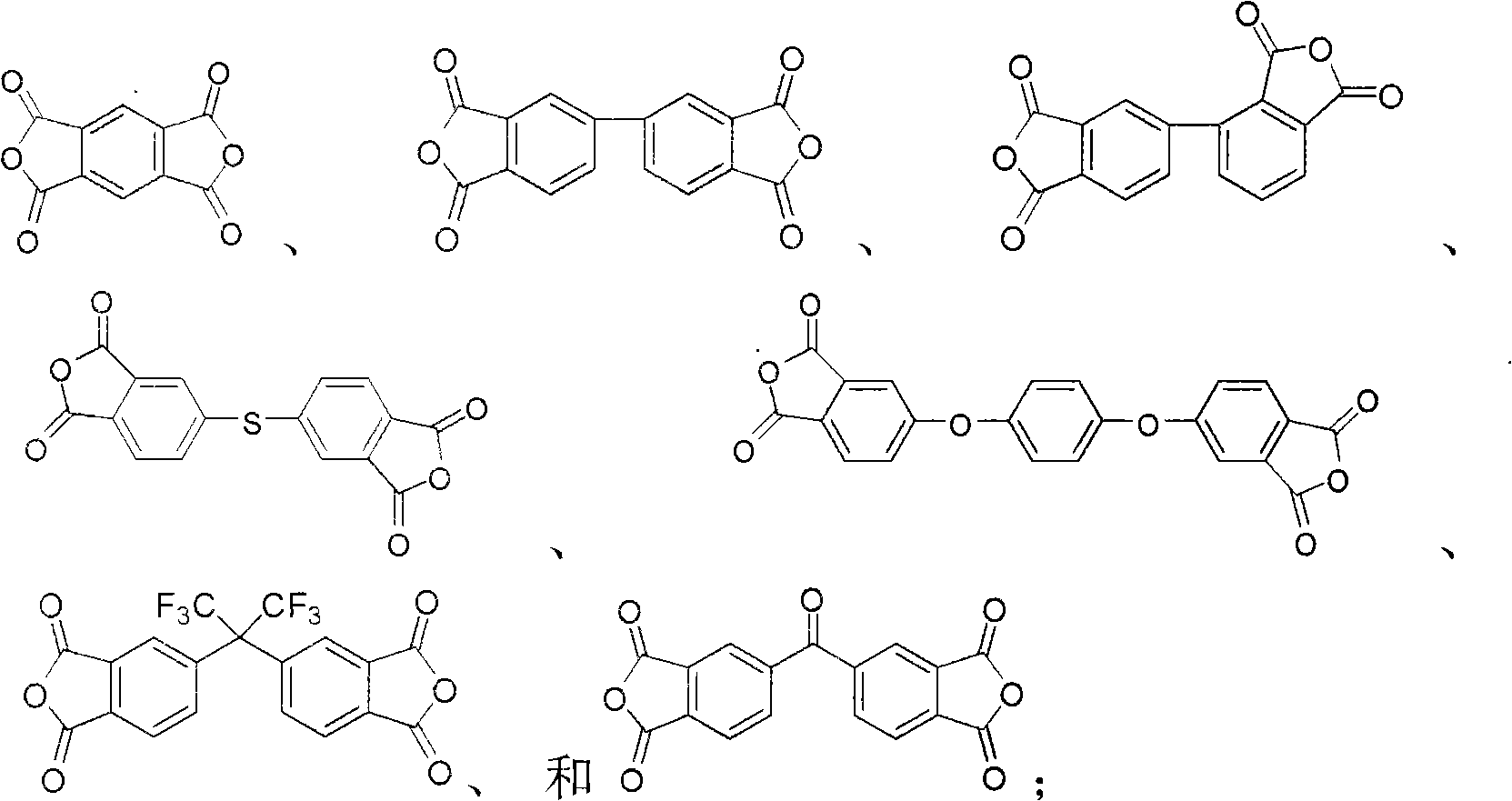

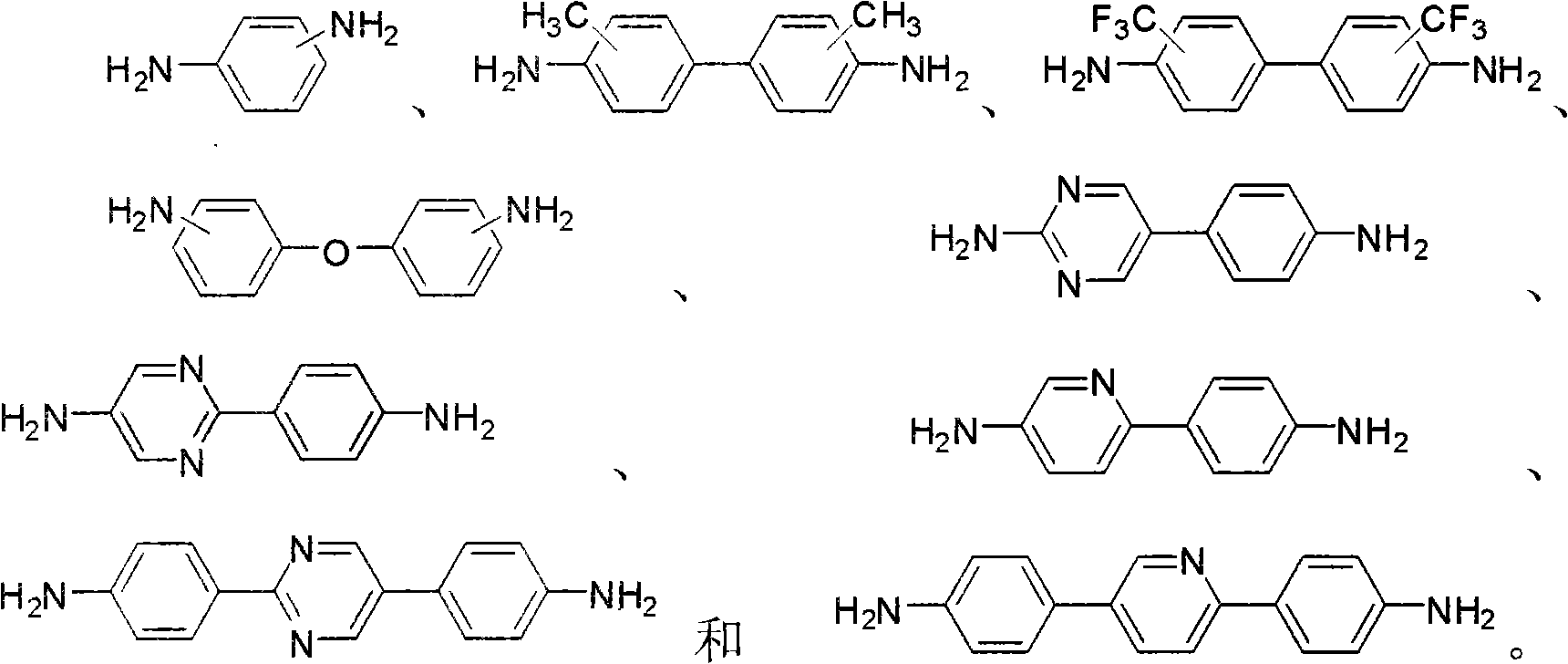

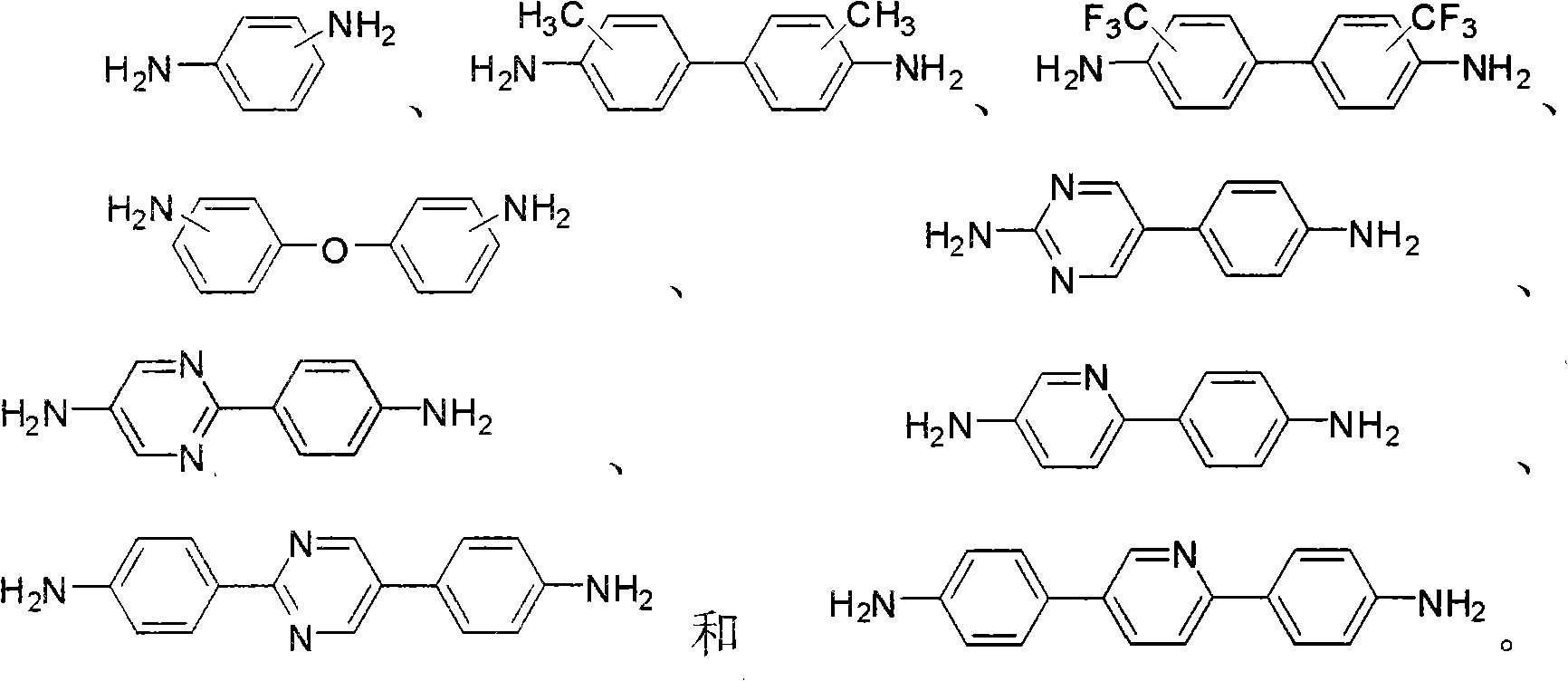

Method used

Image

Examples

Embodiment 1

[0016] Example 1: 35.14g (0.325mol) p-phenylenediamine and 352.32g (1.100mol) 2,2'-bis(trifluoromethyl)4,4'-biphenylenediamine were dissolved in 4470ml N,N- In the dimethylacetamide, 327.18 g (1.500 mol) pyromellitic dianhydride was added under stirring state, and reacted at room temperature for 10 hours to obtain a pale yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0017] The above-mentioned polyamic acid slurry is spun and formed by the dry-jet wet spinning method, and the spinning slurry at room temperature is accurately metered by a metering pump, and then extruded from the spinneret and enters the N,N-dimethyl In a coagulation bath of acetamide and water (1:1 volume ratio). The spinneret has 100 holes, the hole diameter is Φ0.08mm, the spray ratio is 3.0 times, the spinneret speed is 60m / min, and the air layer height is 30mm. The nascent polyamic acid fiber is treated in a gradient temperature-raisin...

Embodiment 2

[0018] Example 2: Dissolve 300.36g (1.500mol) of 4,4'-diaminodiphenyl ether in 3707ml of N,N-dimethylformamide, and add 218.12g (1.000mol) of pyromellitic dianhydride under stirring React with 147.11 g (0.500 mol) of 3,4'-biphenyldianhydride at -5°C for 10 hours to obtain a light yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0019] The above-mentioned polyamic acid slurry is used for spinning and forming in the wet process technology route. After the spinning slurry at room temperature is accurately metered with a metering pump, it is extruded from the spinneret and enters ethanol and water (1:2 volume ratio) through the air layer. ) in the coagulation bath. The spinneret has 150 holes, the hole diameter is Φ0.10mm, the spinning speed is 100m / min, the spray ratio is 7.0 times, and the air layer height is 50mm. The nascent polyamic acid fiber is treated in a gradient temperature-raising heat treatment furn...

Embodiment 3

[0020] Example 3: 315.38g (1.575mol) of 3,4'-diaminodiphenyl ether was dissolved in 1264ml of N-methylpyrrolidone, and 218.12g (1.000mol) of pyromellitic dianhydride and 147.11g of pyromellitic dianhydride were added under stirring (0.500mol) 3,4'-biphenyldianhydride, reacted at -10°C for 10 hours to obtain a light yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0021] The above-mentioned polyamic acid slurry is spun and formed by dry-jet wet spinning method, and the spinning slurry at room temperature is accurately metered by a metering pump, extruded from the spinneret, and then enters N-methylpyrrolidone and ethanol through the air layer. and water (1:1:6 volume ratio) coagulation bath. The spinneret has 30 holes, the hole diameter is Φ0.20mm, the spray ratio is 1 times, the spinneret speed is 30m / min, and the air layer height is 70mm. The nascent polyamic acid fiber is treated in a gradient temperature-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com